Utv Kit Build Your Own: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for utv kit build your own

In today’s competitive landscape, sourcing the right UTV kit to build your own vehicle presents a unique challenge for international B2B buyers. With diverse market demands and varying operational environments, businesses must navigate a complex array of options to find the best solutions for their specific needs. This guide aims to simplify that process by providing a comprehensive overview of the UTV kit market, detailing types of kits available, their applications across different industries, and essential factors for supplier vetting.

From agriculture in Brazil to adventure tourism in Nigeria, understanding the specific requirements and customization options available is crucial for maximizing investment. Additionally, this guide delves into cost considerations, helping buyers identify budget-friendly yet high-quality solutions that align with their operational goals. By empowering B2B buyers with actionable insights and a clear framework for evaluating potential suppliers, this resource ensures informed purchasing decisions that can enhance operational efficiency and customer satisfaction.

Whether you’re looking to enhance your fleet with tailored UTVs or seeking innovative solutions for unique applications, this guide is designed to equip you with the knowledge and tools necessary to thrive in the global UTV kit marketplace.

Understanding utv kit build your own Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Gas UTV Kits | Gas-powered, customizable engine options | Agriculture, landscaping, utility work | Pros: Cost-effective, high performance. Cons: Limited by fuel availability in remote areas. |

| Electric UTV Kits | Battery-powered, eco-friendly options | Eco-conscious operations, urban use | Pros: Low emissions, quiet operation. Cons: Range limitations, longer recharge times. |

| Off-Road Builder Kits | Enhanced suspension, rugged tires, additional accessories | Adventure tourism, outdoor recreation | Pros: Superior durability, tailored for rough terrains. Cons: Higher initial investment, specialized maintenance. |

| Utility Vehicle Kits | Focus on cargo capacity, towing capabilities | Construction, heavy-duty transport | Pros: Versatile for various tasks, robust design. Cons: May lack speed and agility. |

| Performance UTV Kits | Upgraded engines, performance tires, and custom tuning options | Racing, competitive sports | Pros: Enhanced speed and handling. Cons: Increased wear and potential for higher costs. |

What Are the Characteristics of Custom Gas UTV Kits?

Custom gas UTV kits allow businesses to tailor their vehicles to specific operational needs. They feature various engine options, providing flexibility in power and fuel efficiency. This type is particularly suitable for industries such as agriculture and landscaping, where robust and reliable vehicles are essential. B2B buyers should consider fuel availability and maintenance costs when selecting these kits, as they may vary by region.

How Do Electric UTV Kits Differ in Functionality?

Electric UTV kits are designed with sustainability in mind, offering battery-powered alternatives that reduce emissions. These kits are ideal for urban applications and eco-conscious businesses looking to minimize their carbon footprint. However, buyers should evaluate the range and charging infrastructure available in their operational areas, as these factors can significantly impact usability and efficiency.

What Advantages Do Off-Road Builder Kits Provide?

Off-road builder kits enhance the performance of UTVs for rugged terrains, featuring upgraded suspension systems and specialized tires. They cater to industries involved in adventure tourism and outdoor recreation. While these kits offer superior durability and customization for challenging environments, potential buyers should be aware of the higher initial investment and the need for specialized maintenance.

What Should Buyers Consider About Utility Vehicle Kits?

Utility vehicle kits focus on maximizing cargo capacity and towing capabilities, making them suitable for construction and heavy-duty transport sectors. These kits provide a robust design that can handle various tasks, offering versatility for businesses. However, buyers should consider the trade-off between speed and utility, as these vehicles may not be as agile as performance-focused options.

How Do Performance UTV Kits Meet Competitive Needs?

Performance UTV kits are tailored for racing and competitive sports, featuring upgraded engines and performance tires. They are designed for businesses looking to participate in events or offer high-speed recreational activities. While these kits enhance speed and handling, buyers must be prepared for increased wear and potential higher costs associated with maintenance and repairs.

Key Industrial Applications of utv kit build your own

| Industry/Sector | Specific Application of utv kit build your own | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Custom UTVs for farm management and operations | Improved efficiency in fieldwork, tailored to specific tasks | Local terrain adaptability, availability of agricultural attachments |

| Mining | UTVs for transportation of workers and equipment | Enhanced safety and reduced downtime in rugged environments | Durability, load capacity, and compliance with safety regulations |

| Construction | UTVs for site transport and material handling | Increased productivity and reduced manual labor | Customization options for tool storage and towing capabilities |

| Tourism & Recreation | UTVs for guided tours and outdoor adventures | Differentiation in service offerings and improved customer experience | Comfort features, fuel efficiency, and terrain adaptability |

| Emergency Services | UTVs for search and rescue operations | Rapid response in challenging environments | Reliability, ease of maintenance, and emergency equipment compatibility |

How is ‘utv kit build your own’ Used in Agriculture?

In agriculture, ‘build your own’ UTV kits allow farmers to customize vehicles specifically for tasks such as crop monitoring, livestock transport, and equipment towing. By tailoring features like storage space and towing capacity, businesses can enhance operational efficiency. International buyers, particularly in regions like Brazil and Nigeria, need to consider local agricultural practices and terrain when selecting components, ensuring that the UTV can withstand environmental challenges.

What are the Benefits of Custom UTVs in Mining Operations?

Mining operations often require robust transportation solutions for both personnel and equipment. Custom UTVs can be built to handle heavy loads and navigate rough terrains, ensuring safety and efficiency. Businesses in the mining sector must prioritize durability and compliance with safety standards when sourcing UTV kits. Buyers should also evaluate the local availability of parts for maintenance and repair, especially in remote areas.

Why Choose Custom UTVs for Construction Sites?

In the construction industry, UTVs are invaluable for transporting materials and personnel around job sites. A ‘build your own’ kit enables construction firms to create vehicles optimized for specific tasks, such as carrying tools or materials. This customization can lead to significant productivity gains. Buyers should focus on features like tool storage and towing capabilities while considering local regulations and site conditions in their sourcing decisions.

How Can UTVs Enhance Tourism and Recreation Services?

For tourism and recreation businesses, custom UTVs can provide unique experiences for guided tours and outdoor adventures. By selecting comfort features and terrain-specific enhancements, companies can differentiate their services, attracting more customers. International buyers should assess the local market demand for recreational vehicles and consider factors like fuel efficiency and maintenance support when sourcing UTV kits.

What Role Do UTVs Play in Emergency Services?

Emergency services utilize UTVs for rapid response in challenging terrains, making customization essential for effective operations. ‘Build your own’ kits can be tailored to include emergency equipment and storage solutions, enhancing response capabilities. Buyers in this sector should prioritize reliability and ease of maintenance, especially in high-pressure situations, while also ensuring compatibility with existing emergency response systems.

3 Common User Pain Points for ‘utv kit build your own’ & Their Solutions

Scenario 1: Difficulty in Choosing the Right Components for Custom Builds

The Problem: B2B buyers often face a significant challenge when it comes to selecting the appropriate components for their ‘build your own’ UTV kits. With numerous options available for engines, tires, frames, and accessories, the overwhelming variety can lead to confusion and indecision. This is particularly pronounced in international markets, where local availability and compatibility with regional regulations can further complicate the decision-making process. Buyers may fear that their selections will not meet performance expectations or may lead to costly modifications later on.

The Solution: To address this issue, buyers should start by thoroughly understanding their specific requirements. Conduct a detailed needs assessment that considers the intended use of the UTV—whether for agricultural tasks, recreational activities, or rugged terrain navigation. Once needs are identified, it is critical to engage with reputable suppliers who offer comprehensive product specifications and compatibility information. Utilizing online configurators available on manufacturer websites can provide a visual representation of different builds, helping buyers make informed choices. Additionally, leveraging local dealer expertise can offer insights into the best components suited for specific environments, ensuring that the selected parts will work harmoniously together.

Scenario 2: Navigating Compliance and Regulatory Challenges in Different Regions

The Problem: For B2B buyers operating in diverse geographical regions, navigating the maze of compliance and regulatory requirements can be daunting. Different countries, especially in Africa, South America, and the Middle East, have varying laws regarding vehicle emissions, safety standards, and modifications. Buyers may be unsure if their custom UTV builds will meet local regulations, which can lead to legal troubles or increased costs for retrofitting or fines.

The Solution: To mitigate compliance risks, buyers should invest time in researching local regulations relevant to UTVs in their target markets. This includes understanding emissions standards, safety requirements, and any specific modifications that may be legally mandated. Collaborating with local legal experts or industry associations can provide clarity on the necessary compliance measures. Furthermore, sourcing UTV kits from manufacturers that prioritize regulatory compliance can streamline the process. These manufacturers often provide documentation and certifications that assure buyers of the kit’s legality in their regions, thereby reducing the likelihood of complications post-purchase.

Scenario 3: Overcoming Assembly Challenges and Skill Gaps

The Problem: Many B2B buyers may encounter obstacles during the assembly of their ‘build your own’ UTV kits, especially if they lack the technical skills or experience. In some cases, businesses may not have access to a skilled workforce capable of undertaking complex assembly tasks, which can lead to delays in project timelines and increased labor costs. This is particularly relevant in regions where specialized training for UTV assembly is scarce.

The Solution: To overcome assembly challenges, buyers should consider partnering with experienced UTV assembly professionals or firms that specialize in custom builds. This collaboration can help ensure that the assembly is performed correctly and efficiently. Additionally, manufacturers should provide comprehensive assembly guides, including detailed videos and step-by-step instructions that can aid in the process. Investing in training workshops for the existing workforce can also be beneficial; suppliers may offer training sessions or resources that equip buyers with the necessary skills to handle assembly confidently. Finally, incorporating modular designs into the kits can simplify assembly, allowing teams to work on different components simultaneously, thus speeding up the overall process.

Strategic Material Selection Guide for utv kit build your own

What Are the Key Materials for Building Your Own UTV Kit?

When selecting materials for a UTV kit build, it’s essential to consider various factors that can influence the performance, durability, and cost-effectiveness of the final product. Here, we analyze four common materials used in UTV construction, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Steel Perform in UTV Kit Builds?

Steel is a widely used material in UTV construction due to its excellent strength and durability. It typically has a high tensile strength, making it suitable for high-stress applications. Steel components can withstand high temperatures and pressures, which is critical for UTVs operating in rugged environments.

Pros: Steel is relatively inexpensive and readily available. Its durability ensures a long lifespan, making it a cost-effective choice for manufacturers. Additionally, steel can be easily welded and fabricated, allowing for complex designs.

Cons: Steel is prone to corrosion if not properly treated, which can be a significant disadvantage in humid or wet environments. It is also heavier than other materials, which can affect the vehicle’s overall weight and fuel efficiency.

Impact on Application: Steel is compatible with various media, including oils and fuels, making it suitable for UTVs used in diverse terrains.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers in regions like Africa and South America may need to consider local availability and the cost of corrosion-resistant coatings.

What Role Does Aluminum Play in UTV Construction?

Aluminum is another popular choice for UTV kits due to its lightweight nature and resistance to corrosion. It has a lower density than steel, which helps reduce the overall weight of the UTV, enhancing fuel efficiency and maneuverability.

Pros: Aluminum is highly resistant to corrosion, making it ideal for off-road vehicles that may encounter moisture and harsh conditions. Its lightweight nature contributes to better performance and handling.

Cons: The primary drawback of aluminum is its cost, which can be significantly higher than steel. Additionally, while it is strong, it may not withstand the same level of impact as steel, making it less suitable for certain high-stress applications.

Impact on Application: Aluminum is compatible with various fluids and has good thermal conductivity, which can be advantageous for engine components.

Considerations for International Buyers: Buyers should be aware of the specific grades of aluminum that comply with local standards. In regions like the Middle East, where temperatures can be extreme, selecting the right alloy is critical for performance.

Why Choose Composite Materials for UTV Kits?

Composite materials, such as fiberglass and carbon fiber, are increasingly popular in UTV construction. These materials offer a unique combination of strength and lightweight properties, making them suitable for various applications.

Pros: Composites are highly resistant to corrosion and can be molded into complex shapes, offering design flexibility. They are also lighter than metals, which can enhance performance.

Cons: The manufacturing process for composites can be complex and costly, which may increase the overall price of the UTV kit. Additionally, repair processes for damaged composite materials can be more challenging than for metals.

Impact on Application: Composites can be tailored for specific applications, such as body panels or interior components, providing excellent aesthetic qualities.

Considerations for International Buyers: Understanding the specific manufacturing standards for composite materials is essential. Buyers in Europe may need to comply with stringent regulations regarding material safety and performance.

How Does Plastic Fit into UTV Kit Builds?

Plastic materials, including high-density polyethylene (HDPE) and polypropylene, are often used for various components in UTV kits, such as body panels and storage compartments.

Pros: Plastics are lightweight, resistant to corrosion, and can be produced at a lower cost than metals. They also offer good impact resistance, making them suitable for off-road applications.

Cons: While plastics are durable, they may not withstand extreme temperatures as well as metals. Additionally, some plastics can degrade over time when exposed to UV light, which may limit their lifespan.

Impact on Application: Plastics are compatible with various substances, including fuels and oils, making them versatile for different UTV applications.

Considerations for International Buyers: Buyers should ensure that the plastics used meet local environmental regulations and standards for durability. In regions like Africa, where UV exposure can be high, selecting UV-stabilized plastics is crucial.

Summary of Material Selection for UTV Kits

| Material | Typical Use Case for UTV Kit Build Your Own | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and structural components | High strength and durability | Prone to corrosion | Low |

| Aluminum | Body panels and lightweight components | Lightweight and corrosion-resistant | Higher cost and lower impact strength | High |

| Composite | Body panels and aesthetic components | Design flexibility and low weight | Complex manufacturing process | High |

| Plastic | Storage compartments and body panels | Lightweight and cost-effective | Limited temperature resistance | Medium |

This strategic material selection guide offers insights into the various materials available for UTV kit builds, emphasizing their properties and suitability for international B2B buyers. Understanding these factors will enable buyers to make informed decisions that align with their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for utv kit build your own

What Are the Main Stages in the Manufacturing Process of UTV Build-Your-Own Kits?

The manufacturing process for UTV (Utility Task Vehicle) build-your-own kits typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is designed to ensure that the final product meets quality and performance standards.

-

Material Preparation: This stage involves sourcing high-quality raw materials, such as steel, aluminum, and plastics. Suppliers should be vetted to ensure they comply with international standards, as the integrity of the materials directly impacts the durability and performance of the UTV. In addition, the materials may undergo initial inspections to verify their quality before further processing.

-

Forming: Once the materials are prepared, they are shaped into the necessary components using various forming techniques. Common methods include stamping, bending, and welding. Advanced technologies like CNC (Computer Numerical Control) machining may also be employed for precision and efficiency. These techniques ensure that each part meets the specific design requirements and tolerances.

-

Assembly: The assembly stage is where all the components come together. Skilled technicians assemble the UTV kits, often using jigs and fixtures to maintain alignment and accuracy. Assembly lines may incorporate both manual labor and automated processes to optimize efficiency. Quality checkpoints are essential during this stage to ensure that components fit correctly and function as intended.

-

Finishing: The final stage of manufacturing involves finishing processes such as painting, powder coating, or galvanizing to protect the UTV from environmental factors and enhance its aesthetic appeal. This stage also includes final inspections to check for surface defects and ensure that all components meet established quality standards.

Which Key Techniques Are Used in UTV Kit Manufacturing?

In the manufacturing of UTV kits, several key techniques are employed to ensure precision and quality:

-

CNC Machining: This technique allows for high-precision cutting and shaping of components, ensuring uniformity and accuracy across all parts. CNC machines can produce complex geometries that manual processes may struggle to achieve.

-

Robotic Welding: Automation through robotic welding enhances the consistency and quality of welds, reducing the risk of human error. This technique also speeds up production times while maintaining high-quality standards.

-

3D Printing: For prototyping and producing small batches of custom parts, 3D printing offers flexibility and rapid development. It allows manufacturers to test designs before mass production, ensuring that the final product meets customer specifications.

-

Quality Control Automation: Advanced technologies, such as machine vision systems, can be integrated into the manufacturing process to automatically inspect parts for defects, ensuring that only high-quality components proceed to assembly.

What Are the International Quality Standards Relevant to UTV Kit Manufacturing?

Quality assurance is critical in the manufacturing of UTV kits, particularly for B2B buyers operating in diverse international markets. Several quality standards are relevant:

-

ISO 9001: This international standard focuses on quality management systems (QMS) and is applicable to organizations of all sizes. Certification to ISO 9001 demonstrates a commitment to quality assurance and continuous improvement.

-

CE Marking: For products sold in the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards. UTV manufacturers targeting the European market must ensure their products comply with relevant directives.

-

API Standards: The American Petroleum Institute (API) standards are crucial for UTVs that may be used in oil and gas operations. Compliance with API standards assures buyers of the product’s suitability for harsh environments.

How Are Quality Control Checkpoints Structured in UTV Manufacturing?

Quality control (QC) is integral to the manufacturing process, and it typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint occurs upon receiving raw materials and components. Inspections ensure that incoming items meet specified quality standards before being released for production.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC monitors processes and products at various points. This ensures that any defects are caught early, minimizing waste and rework.

-

Final Quality Control (FQC): Before the UTV kits are packaged and shipped, a final inspection assesses the overall product quality, checking for performance, safety, and compliance with specifications.

What Common Testing Methods Are Used to Ensure UTV Kit Quality?

Various testing methods are employed to ensure the quality and reliability of UTV kits:

-

Performance Testing: UTVs undergo rigorous performance testing to assess speed, handling, and durability under different conditions. This testing ensures that the vehicle can perform as expected in real-world scenarios.

-

Material Testing: Tests such as tensile strength, fatigue, and impact resistance are conducted on materials to verify their suitability for the intended application.

-

Environmental Testing: UTV kits are subjected to tests simulating extreme temperatures, humidity, and exposure to corrosive environments. These tests ensure that the vehicle can withstand harsh operating conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is essential to ensure product reliability. Here are some actionable steps:

-

Conduct Audits: Regular audits of suppliers can help assess their manufacturing processes and quality control systems. Buyers should request access to audit reports and certifications to verify compliance with international standards.

-

Request Quality Reports: Suppliers should provide detailed quality reports outlining their QC processes, inspection results, and any corrective actions taken. This transparency builds trust and confidence in the supplier’s capabilities.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. This is particularly important for international buyers who may face challenges in verifying quality remotely.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances:

-

Regulatory Compliance: Buyers must understand the regulatory landscape in their target markets, as different regions may have distinct quality standards and certification requirements.

-

Cultural Considerations: Effective communication and collaboration with suppliers from different cultural backgrounds are crucial for ensuring quality expectations are clearly understood and met.

-

Supply Chain Transparency: Building strong relationships with suppliers and fostering transparency throughout the supply chain can enhance quality assurance efforts and mitigate risks associated with sourcing materials and components.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing UTV build-your-own kits, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘utv kit build your own’

To assist B2B buyers in procuring ‘UTV kit build your own’ solutions, this guide outlines essential steps for effective sourcing. By following this checklist, you can ensure that your procurement process is efficient, thorough, and tailored to your specific needs.

Step 1: Define Your Technical Specifications

Before diving into the procurement process, clearly outline the technical specifications of the UTV kit you need. This includes the desired engine type (gas or electric), horsepower, fuel capacity, and additional features such as cargo space and safety equipment. Establishing these parameters upfront ensures that you remain focused on suitable options, avoiding potential overspending on unnecessary features.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify suppliers who specialize in UTV kits. Look for companies with a solid reputation in the industry, focusing on their experience, customer reviews, and case studies. Creating a shortlist of potential suppliers based on this research will streamline your selection process and help you connect with those who can meet your specific requirements.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Key points to investigate include:

– Product Quality: Check certifications or quality assurance processes.

– Customer Support: Assess the availability and responsiveness of their support team.

Step 4: Request Quotes and Compare Options

Once you have identified potential suppliers, request detailed quotes that outline pricing, delivery timelines, and any warranties or guarantees. Comparing these quotes will help you understand the market rate and identify any cost discrepancies. Pay attention to:

– Shipping Costs: Factor in international shipping if sourcing from overseas.

– Payment Terms: Understand the payment structure, including deposits and financing options.

Step 5: Assess Customization Options

Customization is a significant advantage of building your own UTV. Discuss with suppliers the extent to which they can accommodate custom requests, such as specific colors, accessories, or modifications. Ensure that the supplier has a flexible approach to customization, which can enhance the functionality of your UTV according to your unique operational needs.

Step 6: Verify Compliance with Local Regulations

Check that the UTV kits comply with local regulations and standards in your target market, especially in regions like Africa and South America where regulations may vary significantly. This step is vital to avoid legal issues and ensure safety during operation. Research the necessary certifications and documentation required for importing and using UTVs in your region.

Step 7: Finalize and Place Your Order

After thorough evaluation and comparison, finalize your choice of supplier and place your order. Ensure all contractual terms are clear, including delivery schedules and after-sales support. Maintain communication with the supplier throughout the process to address any concerns that may arise and ensure a smooth transaction.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing UTV kits effectively, ensuring they select the best options for their operational requirements.

Comprehensive Cost and Pricing Analysis for utv kit build your own Sourcing

What Are the Key Cost Components for UTV Kit Build Your Own?

When considering the ‘build your own’ UTV kits, understanding the cost structure is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials directly affects the overall cost. High-quality materials may increase the upfront cost but can offer better durability and performance, leading to lower maintenance costs over time. Buyers should evaluate the trade-offs between initial investment and long-term savings.

-

Labor: Labor costs can vary significantly based on location and expertise. In regions with higher labor costs, such as Europe, buyers might consider sourcing from countries with lower labor rates to reduce expenses while maintaining quality.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and equipment. Understanding a supplier’s overhead structure can provide insights into their pricing strategy and help buyers identify potential areas for negotiation.

-

Tooling: Tooling costs are often a significant upfront investment, especially for custom builds. These costs can be amortized over large production runs, so suppliers may offer better pricing for bulk orders or higher volume commitments.

-

Quality Control (QC): QC processes ensure that the UTV meets safety and performance standards. Investing in robust QC can prevent costly recalls and repairs, emphasizing the importance of selecting suppliers who prioritize quality.

-

Logistics: Shipping costs can vary widely depending on the origin and destination, particularly for international shipments. Understanding Incoterms and associated logistics costs can help buyers accurately calculate total expenses.

-

Margin: Suppliers will typically include a profit margin that can fluctuate based on competition, demand, and market conditions. Buyers should be aware of market prices to negotiate effectively.

What Influences Pricing for UTV Kits?

Several factors influence pricing in the UTV kit market, particularly for international B2B buyers:

-

Volume/MOQ: Minimum Order Quantities (MOQ) can significantly impact pricing. Ordering in larger volumes typically reduces the per-unit cost, making it essential for buyers to evaluate their needs against potential savings.

-

Specifications and Customization: Customization options can lead to increased costs. Buyers should clearly define their requirements to avoid unnecessary expenses associated with features they do not need.

-

Materials: The type of materials selected can greatly affect price. Premium materials may enhance performance but will also increase costs. Balancing quality and price is crucial.

-

Quality and Certifications: Products with higher quality standards and certifications may command higher prices. Buyers should assess whether these certifications are necessary for their market or if more cost-effective options are available.

-

Supplier Factors: Supplier reputation, reliability, and service level can influence pricing. Established suppliers may charge more but could offer better support and assurance of quality.

-

Incoterms: Understanding shipping terms can lead to cost savings. Buyers should be familiar with different Incoterms to negotiate better shipping arrangements and avoid unexpected charges.

How Can Buyers Negotiate and Optimize Costs?

B2B buyers can adopt several strategies to enhance cost-efficiency:

-

Negotiation: Engage in open discussions with suppliers about pricing, especially if placing large orders. Building long-term relationships can lead to better pricing and service.

-

Total Cost of Ownership: Consider not just the purchase price but the total cost of ownership, including maintenance, operation, and disposal costs. This perspective can reveal more cost-effective options over time.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and tariffs, as these can significantly impact the total cost of acquiring UTV kits. Strategic planning around these factors can lead to substantial savings.

-

Market Research: Conduct thorough market research to understand prevailing prices and trends. This information can empower buyers in negotiations and decision-making processes.

Disclaimer

Prices are indicative and can vary based on market conditions, supplier terms, and specific buyer requirements. It’s advisable for buyers to conduct due diligence and obtain multiple quotes to ensure they secure the best possible deal.

Alternatives Analysis: Comparing utv kit build your own With Other Solutions

When considering the best off-road vehicle solutions, the “UTV Kit Build Your Own” offers customization and cost benefits. However, it’s essential to evaluate alternative options to determine the best fit for your business needs. This analysis provides a comparative look at building your own UTV against ready-made vehicles and leasing options, which can serve similar purposes.

| Comparison Aspect | UTV Kit Build Your Own | Ready-Made UTVs | UTV Leasing |

|---|---|---|---|

| Performance | Highly customizable; tailored to specific needs | Standardized performance; may not fit all requirements | Consistent performance, but limited customization |

| Cost | Generally cost-effective, especially for bulk orders | Higher upfront cost; includes manufacturer markups | Lower initial costs; periodic payments can add up |

| Ease of Implementation | Requires technical skills; time-consuming | Quick setup; minimal assembly required | Quick access; no assembly required |

| Maintenance | Can be tailored to specific components; may require specialized knowledge | Manufacturer support; standardized parts | Maintenance often included in the lease |

| Best Use Case | Ideal for businesses needing specific configurations | Suitable for general use with standard requirements | Best for businesses seeking flexibility and lower upfront costs |

What Are the Advantages and Disadvantages of Ready-Made UTVs?

Ready-made UTVs provide a straightforward solution for businesses needing reliable off-road vehicles without the hassle of assembly. They are manufactured with standardized components, ensuring consistency in performance and maintenance. However, the lack of customization can be a drawback for businesses that require specific features or configurations. The higher upfront costs and potential for manufacturer markups may also deter budget-conscious buyers.

How Does UTV Leasing Compare to Building Your Own?

Leasing UTVs can be an attractive alternative for businesses looking to minimize initial capital expenditure. Leasing agreements often include maintenance and support, making it a hassle-free option for companies that want to avoid the complexities of ownership. However, the trade-off is limited customization, as leased vehicles typically come with pre-set configurations. Additionally, over time, lease payments can accumulate to a point where they exceed the cost of purchasing a vehicle outright.

Conclusion: Which UTV Solution is Right for Your Business Needs?

Choosing the right UTV solution depends on your business’s specific requirements, budget, and operational strategy. For companies seeking tailored vehicles that meet unique specifications, the “UTV Kit Build Your Own” option is ideal. In contrast, businesses prioritizing immediate availability and standardized performance may find ready-made UTVs more suitable. Meanwhile, leasing offers flexibility and lower upfront costs, making it a viable option for those who prefer to keep their capital free for other investments. By evaluating these alternatives against your operational needs, you can make an informed decision that aligns with your business goals.

Essential Technical Properties and Trade Terminology for utv kit build your own

What Are the Key Technical Properties for Building Your Own UTV?

Building your own Utility Task Vehicle (UTV) involves understanding several critical specifications that ensure optimal performance and durability. Here are some essential technical properties to consider:

-

Material Grade

– Definition: Refers to the quality and type of materials used in the construction of the UTV, such as steel, aluminum, or composite materials.

– Importance: Higher-grade materials enhance durability and performance, making the vehicle more suitable for rugged terrains. Selecting the right material can also affect the vehicle’s weight, fuel efficiency, and overall lifespan. -

Weight Capacity

– Definition: This indicates the maximum load a UTV can safely carry, including passengers and cargo.

– Importance: Understanding weight capacity is crucial for ensuring the vehicle can handle the intended loads without compromising safety or performance. This is especially relevant for commercial applications where heavy loads are common. -

Horsepower (HP)

– Definition: A measurement of the engine’s power output.

– Importance: Horsepower directly affects the UTV’s speed and towing capabilities. Selecting the right horsepower is essential for matching the vehicle’s performance to its intended use, whether for agricultural, recreational, or industrial applications. -

Suspension System

– Definition: The system that absorbs shocks from uneven terrain, which includes components like shocks, struts, and springs.

– Importance: A robust suspension system enhances ride comfort and vehicle control, particularly in off-road conditions. For B2B buyers, investing in quality suspension components can reduce maintenance costs and improve the vehicle’s longevity. -

Fuel Efficiency

– Definition: This measures how effectively the UTV uses fuel, typically expressed in miles per gallon (MPG).

– Importance: Fuel efficiency is a key consideration for operational cost-effectiveness, especially for businesses that rely on UTVs for daily tasks. Higher fuel efficiency translates to lower operational costs and a reduced environmental impact. -

Tire Specifications

– Definition: Refers to the size, tread type, and material of the tires.

– Importance: The right tire specifications ensure optimal traction, stability, and performance on various terrains. This can significantly influence the UTV’s functionality in agricultural, construction, or recreational settings.

What Are Common Trade Terms in the UTV Industry?

Understanding industry jargon is crucial for effective communication and decision-making. Here are some key trade terms relevant to the UTV kit market:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Relevance: In the UTV industry, OEM parts are often seen as the standard for quality and compatibility. B2B buyers should prioritize OEM parts to ensure reliability and performance in their builds. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding MOQ is vital for procurement planning. B2B buyers should negotiate MOQs that align with their project needs and budget constraints, particularly when sourcing components for UTV builds. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and availability for specific products or services.

– Relevance: Issuing RFQs allows businesses to compare prices and terms from multiple suppliers, enabling informed purchasing decisions and potential cost savings. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms is crucial for international buyers to understand shipping costs, risks, and responsibilities. This knowledge helps in negotiating terms that favor their logistics and budget. -

Aftermarket Parts

– Definition: Replacement parts not made by the OEM.

– Relevance: Aftermarket parts can provide cost-effective alternatives for UTV builds and repairs. However, buyers should assess the quality and compatibility of these parts carefully to avoid issues with performance and safety. -

Customization Options

– Definition: Refers to the various features and modifications that can be made to a UTV to meet specific needs.

– Relevance: Understanding available customization options allows businesses to tailor UTVs to their operational requirements, enhancing functionality and user satisfaction.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing components for UTV builds, ultimately enhancing their operational efficiency and product performance.

Navigating Market Dynamics and Sourcing Trends in the utv kit build your own Sector

What Are the Key Market Dynamics and Trends in the UTV Kit Build Your Own Sector?

The UTV (Utility Task Vehicle) kit build-your-own sector is witnessing significant growth driven by a combination of factors including increased demand for customization, cost-effectiveness, and rising outdoor recreational activities. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are keen on sourcing UTV kits that cater to local terrains and specific use cases, such as agriculture, tourism, and adventure sports.

Emerging trends in B2B sourcing include the integration of advanced technologies such as 3D printing and augmented reality, which facilitate the customization process. These technologies enable buyers to visualize their UTV designs before purchase, enhancing decision-making. Additionally, the shift towards online marketplaces is simplifying procurement processes, allowing international buyers to access a wider variety of UTV kits and components directly from manufacturers and suppliers worldwide.

Market dynamics are also influenced by fluctuating material costs and supply chain challenges, particularly post-pandemic. Buyers must stay informed about these fluctuations to negotiate better terms and ensure timely delivery of components. Furthermore, the growing trend of DIY (Do It Yourself) projects among consumers is driving the demand for builder kits, which empower users to create tailored vehicles that suit their specific needs.

How Is Sustainability Impacting Sourcing Decisions in the UTV Kit Build Your Own Sector?

Sustainability is becoming a crucial consideration for B2B buyers in the UTV kit sector. As environmental concerns gain prominence, buyers are increasingly seeking products that minimize ecological impact. This includes sourcing components made from recycled or sustainably sourced materials, which not only reduce waste but also appeal to environmentally conscious consumers.

The importance of ethical supply chains cannot be overstated. Buyers are now more inclined to partner with manufacturers who demonstrate a commitment to sustainable practices, such as fair labor conditions and responsible sourcing. Certifications like ISO 14001 for environmental management and FSC (Forest Stewardship Council) for wood products are becoming vital benchmarks for evaluating suppliers.

Additionally, the push for energy-efficient UTVs is influencing sourcing trends. Manufacturers are focusing on electric and hybrid models, which promise lower emissions and reduced operational costs. For international buyers, particularly in regions facing stringent environmental regulations, sourcing from suppliers who prioritize sustainability can also enhance brand reputation and open up new market opportunities.

How Has the UTV Kit Build Your Own Sector Evolved Over Time?

The evolution of the UTV kit build-your-own sector can be traced back to the increasing popularity of off-road vehicles in the late 20th century. Initially, UTVs were primarily used for agricultural and industrial purposes, but as recreational use surged, so did the demand for customization options. The rise of DIY culture in the 2000s marked a significant turning point, as manufacturers began offering builder kits that allowed consumers to personalize their vehicles according to their preferences.

Over the years, advancements in manufacturing technologies and materials have enhanced the quality and variety of UTV kits available. Today, buyers can choose from a plethora of options, including electric models and kits designed for specific terrains. This transformation has not only catered to consumer demand for personalization but has also fostered a vibrant community of enthusiasts who share their builds and experiences online, further driving interest and innovation in the sector.

In conclusion, navigating the UTV kit build-your-own sector requires an understanding of market dynamics, sustainability considerations, and the historical context that has shaped the current landscape. International B2B buyers must stay informed and proactive to leverage opportunities and mitigate challenges in this evolving market.

Frequently Asked Questions (FAQs) for B2B Buyers of utv kit build your own

-

How do I solve supply chain challenges when sourcing UTV kits internationally?

To address supply chain challenges when sourcing UTV kits, first establish strong relationships with reliable suppliers who understand your market’s needs. Conduct thorough research to identify suppliers with a proven track record in international shipping and compliance with local regulations. Utilize technology for real-time tracking and communication to mitigate delays. Additionally, consider diversifying your supplier base to avoid disruptions and ensure you have alternative options if issues arise. -

What is the best way to vet suppliers for UTV kits?

The best way to vet suppliers for UTV kits includes conducting background checks, reviewing their business history, and assessing customer feedback. Request references and case studies to understand their reliability and quality. Evaluate their production capabilities, quality assurance processes, and compliance with international standards. It’s also beneficial to visit their facilities if possible, or utilize third-party inspection services to verify their operations and product quality. -

What customization options are available for UTV kits?

Customization options for UTV kits can vary widely by supplier, but typically include choices for engine specifications, color, accessories, and performance enhancements. Suppliers may offer packages that allow you to select specific features tailored to your operational needs, such as off-road capabilities or utility functions. Ensure you discuss your customization needs upfront with suppliers to confirm they can meet your specifications and timelines. -

What are the typical minimum order quantities (MOQs) for UTV kits?

Minimum order quantities (MOQs) for UTV kits can differ based on the supplier and the specific components included in the kit. Generally, MOQs range from a few units to several dozen. Suppliers often set these limits to ensure cost-effectiveness in production and shipping. When negotiating, inquire about potential flexibility in MOQs, especially if you’re a new buyer or looking to test the market with a smaller order. -

What payment terms should I expect when sourcing UTV kits?

Payment terms for sourcing UTV kits can vary significantly by supplier. Common terms include a deposit upfront (often 30% to 50%) with the balance due upon shipment or delivery. Some suppliers may offer financing options or extended payment terms for larger orders. Always clarify payment terms before finalizing contracts and ensure they align with your cash flow capabilities. Consider using secure payment methods to protect your transactions. -

How can I ensure quality assurance for UTV kits sourced internationally?

To ensure quality assurance for UTV kits, implement a comprehensive quality control process that includes pre-production samples and regular inspections during manufacturing. Establish clear quality standards and communicate them with your supplier. Consider hiring a third-party inspection service to conduct final checks before shipment. Additionally, ensure that suppliers provide warranties or guarantees on their products to protect your investment. -

What logistics considerations should I keep in mind when importing UTV kits?

When importing UTV kits, logistics considerations include understanding shipping methods, customs regulations, and potential tariffs or duties applicable in your region. Work with experienced logistics partners who can help navigate these complexities. Plan for lead times and possible delays, especially when shipping internationally. It’s also wise to evaluate warehousing options to manage inventory effectively upon arrival. -

How do I handle after-sales support for UTV kits?

Handling after-sales support for UTV kits involves establishing a clear communication channel with your supplier for ongoing assistance. Ensure that the supplier provides detailed installation guides, technical support, and access to spare parts. Consider creating a feedback loop where you can report issues and receive timely responses. Additionally, offering local support or partnerships can enhance customer satisfaction and address any operational concerns effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Utv Kit Build Your Own Manufacturers & Suppliers List

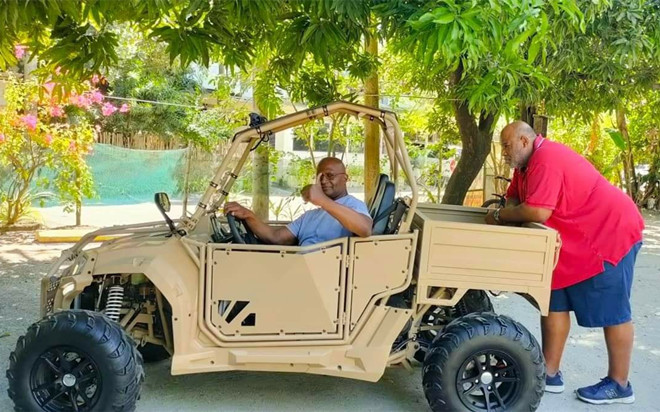

1. Landmaster – N6 & N7 Standard Cab 2025

Domain: landmaster.com

Registered: 2001 (24 years)

Introduction: [{‘model’: ‘N6 Standard Cab 2025’, ‘starting_price’: ‘$10,999’, ‘towing_capacity’: ‘1,500lbs’, ‘engine_size’: ‘570cc’, ‘torque’: ’25ft-lbs’, ‘top_speed’: ’24mph’, ‘bed_capacity’: ‘500lbs’}, {‘model’: ‘N7 Standard Cab 2025’, ‘starting_price’: ‘$13,499’, ‘towing_capacity’: ‘1,500lbs’, ‘engine_size’: ‘627cc’, ‘torque’: ’34ft-lbs’, ‘top_speed’: ’35mph’, ‘bed_capacity’: ‘500lbs’}, {‘model’: ‘N7 Crew Ca…

2. Thumper Fab – Custom Side-by-Side Kits

Domain: thumperfab.com

Registered: 2019 (6 years)

Introduction: DIY side-by-side building project; requires two engines, four tires, and various accessories; options for standard or comfortable seats; choice between all-terrain or off-road tires; accessory packages available (standard or deluxe including rearview mirror, windshield, GPS); assembly steps include frame assembly, installing wheels and axle, attaching handlebars and seat, adding final touches like…

3. UTV Source – SuperATV Polaris Steering Stop Kit

Domain: utvsource.com

Registered: 2009 (16 years)

Introduction: Builder Kits: A diverse range of builder kits designed for various off-road vehicles, tailored for outdoor enthusiasts. Key products include: 1. SuperATV Polaris Steering Stop Kit – Ensures optimal steering angles to prevent damage to suspension and tires. 2. SuperATV Polaris RZR XP 1000 Radiator Relocation Kit – Relocates the radiator to prevent clogging and ensure efficient cooling. 3. DynoJet P…

4. Custom UTV – Building Advice

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom UTV similar to a Polaris Ranger 1500; user is seeking advice on building a custom frame; has welding skills but limited automotive knowledge; considering using a salvaged Ranger with a bent frame as a project; discussions suggest that building a custom UTV may be more expensive than purchasing a mass-produced one; recommendations to start with a donor UTV and to consult with manufacturers o…

5. Can-Am – Maverick X3 MAX Roll Cage Kit

Domain: houser-racing.com

Registered: 1999 (26 years)

Introduction: [{‘name’: ‘Can-Am Maverick X3 MAX (4-Seater) RivTab DIY (Weld Yourself) Roll Cage Kit’, ‘price’: ‘$1,971.48’, ‘shipping’: ‘FREE SHIPPING’, ‘availability’: ‘Sold Out’}, {‘name’: ‘Kawasaki KRX 1000 (2-Seater) RivTab DIY (Weld Yourself) Roll Cage Kit’, ‘price’: ‘$1,350.00’, ‘shipping’: ‘FREE SHIPPING’, ‘availability’: ‘Sold Out’}, {‘name’: ‘Polaris RZR Pro R (2-Seater) RivTab DIY (Weld Yourself) Roll…

6. FX Buggy – Build Your Own Crosskart Buggy

Domain: fxbuggy.com

Registered: 2017 (8 years)

Introduction: FX Buggy offers plans and parts to build your own Crosskart Buggy, including a FREE frame plan. Key features include:

– Independent suspension with double wishbone construction

– Strong seamless tubing roll cage

– Short ratio steering rack for precise steering

– Detailed building plans for easy handling

– Suitable for chain-driven motorcycle engines with up to 180 hp and 120 Nm torque

– Soli…

Strategic Sourcing Conclusion and Outlook for utv kit build your own

In the evolving landscape of UTV kit building, strategic sourcing emerges as a critical factor for success. By selecting high-quality components and reliable suppliers, businesses can enhance their product offerings, ensuring that they meet the specific needs of their target markets in diverse regions such as Africa, South America, the Middle East, and Europe. Customization not only leads to cost savings but also allows for tailored solutions that can significantly improve customer satisfaction and loyalty.

B2B buyers should prioritize partnerships with manufacturers who provide comprehensive support, including access to builder kits and essential tools that facilitate the assembly process. This approach ensures that businesses can deliver vehicles that are not only functional but also adaptable to various terrains and climates, thereby increasing their market appeal.

Looking ahead, the demand for customizable UTV solutions will continue to rise, driven by consumer preferences for personalized experiences. International buyers are encouraged to embrace this trend by investing in strategic sourcing practices that foster innovation and efficiency. By doing so, they position themselves to capitalize on emerging opportunities in the UTV market, paving the way for sustained growth and competitive advantage.