Unlocking Value: A Strategic Analysis of the Vizio Tv Screen Replacement Parts Market

Introduction: Navigating the Global Market for vizio tv screen replacement parts

In today’s fast-paced global market, sourcing Vizio TV screen replacement parts poses significant challenges for international B2B buyers. Companies must navigate a complex landscape of suppliers, pricing variations, and product authenticity to ensure they are making informed purchasing decisions. This guide aims to simplify the process by providing a comprehensive overview of Vizio TV screen replacement parts, including the various types available, their applications, and essential criteria for vetting suppliers.

Our detailed exploration covers everything from LED backlight strips to mainboards, empowering you to understand the full spectrum of parts required for effective repairs. We also address the cost implications of sourcing these components, helping you budget effectively while maximizing value. As the demand for Vizio products continues to grow in regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Brazil—understanding the nuances of sourcing replacement parts becomes imperative.

By leveraging the insights in this guide, you will be equipped to make strategic decisions that enhance your supply chain efficiency and ensure the longevity of your Vizio products. Whether you are a repair shop owner or a distributor, this resource serves as a vital tool in navigating the global marketplace for Vizio TV screen replacement parts, ultimately leading to improved customer satisfaction and business success.

Understanding vizio tv screen replacement parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| LED Backlight Strips | Essential for screen brightness; varies by model | Repair shops, electronics retailers | Pros: Affordable, easy to install. Cons: Compatibility issues with different models. |

| Power Supply Boards | Regulates power supply to the TV; model-specific | Repair centers, electronic manufacturers | Pros: Critical for functionality. Cons: High demand can lead to stock shortages. |

| Main Boards | Central hub for TV operations; integrates various functions | Service centers, wholesalers | Pros: Vital for overall performance. Cons: Complex installation, requires skilled technicians. |

| Screen Panels | The display component; varies in size and resolution | Electronics retailers, repair services | Pros: Directly impacts viewing experience. Cons: Often the most expensive part to replace. |

| Remote Controls | Interface for user interaction; compatible with multiple models | Retailers, online marketplaces | Pros: High turnover, easy to sell. Cons: Often lost or damaged, leading to frequent replacements. |

What Are the Characteristics of LED Backlight Strips for Vizio TVs?

LED backlight strips are crucial components that enhance the brightness and color quality of Vizio TV screens. They are model-specific, meaning that the correct strips must be sourced based on the TV’s model number. B2B buyers, such as repair shops and electronics retailers, often seek these parts due to their affordability and straightforward installation process. However, buyers must be cautious of compatibility issues, as using incorrect strips can lead to subpar performance or further damage.

How Do Power Supply Boards Function in Vizio TVs?

Power supply boards are integral to the operation of Vizio TVs, as they regulate the power supplied to various components. These boards are also model-specific, which means that accurate identification of the TV model is essential when ordering replacements. B2B applications primarily include repair centers and electronic manufacturers that require reliable power components. While these boards are essential for functionality, they may be subject to high demand, leading to potential stock shortages.

Why Are Main Boards Important for TV Performance?

Main boards serve as the central hub for all operational functions in a Vizio TV, managing everything from video processing to connectivity. Their complexity requires skilled technicians for installation and troubleshooting, making them a critical component for service centers and wholesalers. While they are vital for maintaining overall TV performance, their intricate nature can pose challenges during installation, necessitating a knowledgeable workforce.

What Should Buyers Consider When Sourcing Screen Panels?

Screen panels are the most visible and significant components of Vizio TVs, directly affecting the viewing experience through their resolution and display quality. They come in various sizes and specifications, making it imperative for B2B buyers, such as electronics retailers and repair services, to ensure they select the correct panel for each model. Although screen panels significantly enhance visual appeal, they are often the most expensive replacement part, requiring careful cost-benefit analysis when sourcing.

How Do Remote Controls Fit into the Replacement Parts Market?

Remote controls are essential for user interaction with Vizio TVs, and they are compatible with multiple models, creating a broad market for B2B buyers. Retailers and online marketplaces frequently stock these items due to their high turnover rate; they are often lost or damaged. While remote controls are generally easy to sell and replace, their frequent demand can lead to challenges in maintaining adequate inventory levels.

Key Industrial Applications of vizio tv screen replacement parts

| Industry/Sector | Specific Application of vizio tv screen replacement parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Repair and refurbishment of display TVs in stores | Enhanced customer experience with functional displays | Availability of parts, quick delivery, and warranty options |

| Hospitality | Maintenance of TVs in hotels and resorts | Improved guest satisfaction and retention | Bulk purchasing options, compatibility with various models |

| Education | Upkeep of TVs in educational institutions | Facilitates learning through functional audiovisual aids | Quality assurance, cost-effectiveness, and supplier reliability |

| Broadcasting | Replacement for malfunctioning TVs in studios | Ensures uninterrupted operations during broadcasts | Timely delivery, technical support, and part compatibility |

| Home Electronics Repair Services | Servicing customer-owned Vizio TVs | Builds customer loyalty through reliable repair services | Access to a wide range of parts, competitive pricing |

How Are Vizio TV Screen Replacement Parts Utilized in Retail Settings?

In the retail sector, Vizio TV screen replacement parts are crucial for maintaining the functionality of display TVs used in stores. These TVs often serve as focal points for marketing and promotional activities, and any downtime can lead to lost sales opportunities. Retailers benefit from having a reliable supply of replacement parts to quickly address issues, ensuring that displays remain operational. Buyers in this sector should prioritize suppliers that offer a comprehensive range of parts and expedited shipping options to minimize downtime.

What Role Do Vizio TV Replacement Parts Play in the Hospitality Industry?

In hotels and resorts, Vizio TVs are commonly used in guest rooms and common areas. Replacement parts are essential for maintaining these devices, as well-functioning TVs directly influence guest satisfaction. By providing high-quality entertainment options, hospitality businesses can enhance the overall guest experience, leading to higher retention rates. When sourcing parts, hospitality buyers should consider bulk purchasing agreements and compatibility with various TV models to ensure a seamless maintenance process.

Why Are Vizio TV Parts Important for Educational Institutions?

Educational institutions utilize Vizio TVs as part of their audiovisual aids to facilitate learning. Maintaining these devices is vital, as they are integral to delivering engaging content in classrooms. Replacement parts help ensure that these resources remain operational, thereby supporting effective teaching and learning environments. Buyers in this sector should focus on sourcing high-quality parts that meet educational standards while also considering cost-effectiveness and supplier reliability.

How Do Vizio TV Replacement Parts Impact Broadcasting Companies?

Broadcasting companies rely on Vizio TVs for various operational needs, including monitoring broadcasts and displaying content. Any malfunction can disrupt operations, making the availability of replacement parts critical. Quick repairs help ensure uninterrupted service, which is essential in the fast-paced broadcasting environment. Sourcing considerations for these companies should include the speed of delivery, technical support, and compatibility with existing equipment to maintain seamless operations.

What Are the Benefits of Vizio TV Parts for Home Electronics Repair Services?

Home electronics repair services often deal with a variety of brands, including Vizio. Having access to a wide range of replacement parts allows these businesses to provide timely and effective repairs to customers. This not only enhances customer loyalty but also positions the repair service as a reliable option in a competitive market. Repair services should seek suppliers that offer competitive pricing and a diverse inventory to meet the demands of their clientele effectively.

3 Common User Pain Points for ‘vizio tv screen replacement parts’ & Their Solutions

Scenario 1: Difficulty in Sourcing Authentic Vizio TV Screen Replacement Parts

The Problem:

B2B buyers often struggle with sourcing authentic replacement parts for Vizio TVs due to a saturated market filled with counterfeit or substandard components. This is particularly challenging for businesses in regions like Africa and South America, where local suppliers may not have established relationships with reputable manufacturers. Without access to genuine parts, buyers risk purchasing inferior products that may not meet performance standards, leading to increased repair costs and dissatisfied customers.

The Solution:

To ensure the procurement of authentic Vizio TV screen replacement parts, B2B buyers should establish direct partnerships with certified distributors or authorized service centers. Conducting thorough research to identify reliable suppliers is crucial. This includes verifying the distributor’s credentials, checking for customer reviews, and ensuring they provide warranties on their products. Additionally, buyers should consider leveraging online marketplaces that specialize in electronic components, such as ShopJimmy, which often have sections dedicated to authentic parts with clear specifications and competitive pricing. By focusing on trusted sources, businesses can secure high-quality components that enhance their repair service’s reputation and reliability.

Scenario 2: Navigating Technical Specifications for Replacement Parts

The Problem:

Many B2B buyers face the challenge of navigating complex technical specifications when selecting replacement parts for Vizio TVs. Different models often require unique components, and a lack of clear documentation can lead to confusion and incorrect orders. This is especially problematic for businesses that need to maintain a diverse inventory to cater to a wide range of customer needs.

The Solution:

To effectively navigate technical specifications, B2B buyers should invest time in creating a comprehensive database of Vizio TV models and their corresponding parts. This can be accomplished by referencing manufacturer catalogs and reputable online resources that provide detailed breakdowns of parts and their compatibility with various TV models. Additionally, using inventory management software can help track which parts are frequently ordered together, streamlining the ordering process. Establishing relationships with technical support from suppliers can also provide valuable insights into specifications, ensuring that the right parts are ordered the first time, reducing return rates and improving customer satisfaction.

Scenario 3: Managing Inventory and Supply Chain Challenges

The Problem:

Managing inventory levels for Vizio TV screen replacement parts can be a significant pain point for B2B buyers, particularly in regions with fluctuating demand. Overstocking can lead to increased holding costs, while understocking can result in lost sales opportunities and customer dissatisfaction. Additionally, supply chain disruptions can exacerbate these challenges, making it difficult to maintain an adequate stock of essential components.

The Solution:

Implementing a just-in-time (JIT) inventory management system can help businesses balance their stock levels effectively. By analyzing historical sales data and trends, buyers can forecast demand more accurately and adjust their inventory accordingly. Collaborating closely with suppliers to establish flexible order quantities and lead times is essential; this allows businesses to respond quickly to changes in demand without overcommitting to stock. Additionally, utilizing technology such as inventory management software can automate reordering processes, ensuring that parts are replenished as needed without the risk of overstocking. This proactive approach not only enhances operational efficiency but also ensures that businesses can meet customer demands promptly, leading to increased satisfaction and loyalty.

Strategic Material Selection Guide for vizio tv screen replacement parts

What Are the Common Materials Used in Vizio TV Screen Replacement Parts?

When selecting materials for Vizio TV screen replacement parts, it is crucial to consider their properties, advantages, disadvantages, and the implications for international buyers. Below are analyses of four common materials used in these applications.

1. Glass

Key Properties: Glass is known for its excellent optical clarity and rigidity. It can withstand moderate temperature changes but is susceptible to shattering under high impact.

Pros & Cons: The primary advantage of glass is its superior visual quality and durability against environmental factors like UV exposure. However, it is relatively heavy and can be fragile, leading to higher shipping costs and potential breakage during transit.

Impact on Application: Glass is essential for the screen itself, ensuring high-definition display quality. However, its weight and fragility may limit its use in portable applications.

Considerations for International Buyers: Compliance with safety standards is vital, especially in regions with strict regulations on electronic components. Buyers should verify that the glass meets ASTM standards for impact resistance.

2. Plastic (Polycarbonate)

Key Properties: Polycarbonate is lightweight, impact-resistant, and can withstand temperatures up to 120°C. It is also less prone to shattering compared to glass.

Pros & Cons: The main advantage of polycarbonate is its durability and lower weight, which can reduce shipping costs. However, it may scratch easily, and its optical clarity is not as high as glass.

Impact on Application: Polycarbonate is often used in protective covers or back panels, providing a balance between protection and weight. Its compatibility with various media types makes it suitable for multiple applications.

Considerations for International Buyers: Buyers should ensure that the polycarbonate used complies with international standards like ISO for safety and environmental impact, particularly in regions with stringent regulations.

3. Metal (Aluminum)

Key Properties: Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. It can withstand high temperatures and mechanical stress.

Pros & Cons: The advantages of aluminum include its strength and durability, making it suitable for structural components. However, it can be more expensive than plastic and may require specialized manufacturing techniques.

Impact on Application: Aluminum is typically used in the frames and mounts of TVs, providing stability and support. Its lightweight nature allows for easier installation and transport.

Considerations for International Buyers: Compliance with standards such as ASTM for material properties is essential. Buyers should also consider the environmental impact of aluminum production and recycling, especially in regions focused on sustainability.

4. Silicone

Key Properties: Silicone is flexible, heat-resistant, and has excellent electrical insulation properties. It can withstand temperatures ranging from -60°C to 230°C.

Pros & Cons: The flexibility of silicone allows it to absorb shocks, making it ideal for gaskets and seals. However, it may not provide the structural support needed for heavier components.

Impact on Application: Silicone is often used in seals and protective pads, enhancing the overall durability of the TV. Its compatibility with various electronic components makes it a versatile choice.

Considerations for International Buyers: Buyers should ensure that silicone materials meet international safety standards, particularly in regions where electronic safety is closely monitored.

Summary Table of Materials for Vizio TV Screen Replacement Parts

| Material | Typical Use Case for Vizio TV Screen Replacement Parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Screen panel for high-definition display | Excellent optical clarity | Heavy and fragile | High |

| Plastic | Protective covers and back panels | Lightweight and impact-resistant | Scratches easily | Medium |

| Metal | Frames and mounts for structural support | Strong and durable | Higher manufacturing costs | High |

| Silicone | Seals and protective pads | Flexible and shock-absorbing | Limited structural support | Medium |

This guide provides a comprehensive overview of the materials commonly used in Vizio TV screen replacement parts, emphasizing their properties, applications, and considerations for international buyers. Understanding these factors is crucial for making informed purchasing decisions in the B2B marketplace.

In-depth Look: Manufacturing Processes and Quality Assurance for vizio tv screen replacement parts

What Are the Main Stages of Manufacturing Vizio TV Screen Replacement Parts?

The manufacturing process for Vizio TV screen replacement parts involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring that the final product meets quality standards and performs reliably.

Material Preparation

The first step in manufacturing replacement parts is sourcing high-quality materials. This typically includes glass, LED components, and electronic circuitry. Manufacturers often rely on suppliers who can provide materials that meet specific international standards, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals). Proper material preparation is crucial as it lays the foundation for durability and performance.

Forming

Once materials are prepared, the forming process begins. For glass panels, this involves cutting and shaping the glass to fit specific dimensions. Advanced techniques like CNC (Computer Numerical Control) machining may be used to ensure precision. For LED components, the fabrication process includes assembling chips onto printed circuit boards (PCBs) using methods like Surface Mount Technology (SMT). This stage is essential for achieving the desired functionality and performance characteristics.

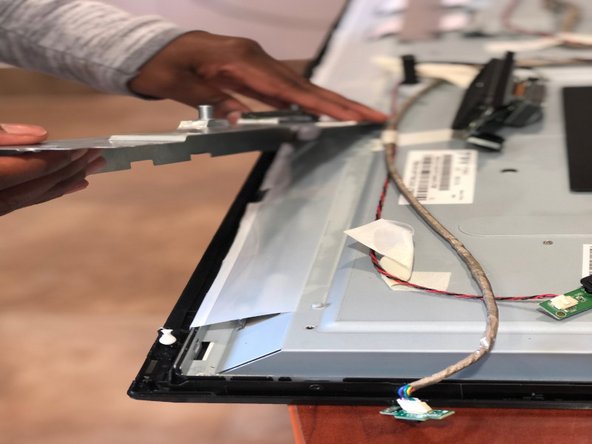

Assembly

The assembly phase involves combining various components to create the complete replacement part. This may include integrating the screen with LED backlighting, power supply units, and other electronic circuits. During this stage, manufacturers often employ automated assembly lines to enhance efficiency and reduce human error. Manual assembly may still be required for intricate tasks that necessitate a high level of precision.

Finishing

The final stage is finishing, which includes quality checks, surface treatment, and packaging. This stage ensures that the product is not only functional but also aesthetically appealing. Techniques such as polishing and coating are commonly employed to enhance the visual quality of the screens. Proper packaging is also crucial for protecting the parts during shipping and handling.

How Is Quality Assurance Implemented in Manufacturing Vizio TV Screen Replacement Parts?

Quality assurance (QA) is a critical component in the manufacturing of Vizio TV screen replacement parts. It ensures that the products meet specific standards and function reliably. International and industry-specific standards guide these QA processes.

Relevant International Standards

Manufacturers often adhere to international quality management standards such as ISO 9001, which focuses on consistent quality and customer satisfaction. Additionally, compliance with CE marking ensures that products meet European safety, health, and environmental protection requirements. In regions like Africa and South America, understanding these certifications can enhance buyer confidence and facilitate smoother trade processes.

Industry-Specific Standards

For electronic components, industry-specific standards such as IPC (Institute for Printed Circuits) guidelines are essential. These standards cover the manufacturing and assembly of electronic components, ensuring that they meet performance and safety criteria.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integral to the manufacturing process, with several checkpoints established to maintain high standards. Key QC checkpoints include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

Incoming Quality Control (IQC)

At the IQC stage, raw materials and components are inspected upon arrival. This includes verifying certifications and conducting physical inspections to check for defects or inconsistencies. Ensuring that only high-quality materials enter the production process is crucial for maintaining overall product quality.

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC involves continuous monitoring of production stages. This includes checking assembly accuracy, ensuring that components are correctly integrated, and measuring performance metrics. Advanced technologies such as automated visual inspection systems can be employed to enhance the efficiency and reliability of this stage.

Final Quality Control (FQC)

FQC occurs after assembly and before packaging. This stage involves comprehensive testing of the final product, including functional tests, stress tests, and visual inspections. Manufacturers often use standardized testing methods to ensure that the replacement parts meet the specified performance standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is paramount. Here are several strategies to ensure that suppliers maintain high standards:

Conducting Audits

Buyers should conduct regular audits of potential suppliers. This includes on-site inspections to assess manufacturing practices, quality control processes, and adherence to international standards. Audits provide valuable insights into a supplier’s operational capabilities and commitment to quality.

Reviewing Quality Reports

Requesting and reviewing quality reports from suppliers can offer additional assurance of their quality control measures. These reports should include information on defect rates, testing results, and compliance with international standards. Consistent reporting indicates a supplier’s dedication to maintaining high-quality products.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspectors can perform comprehensive evaluations during various stages of production, ensuring that the products meet the required specifications before shipment.

What Are the Specific Quality Control Nuances for International Buyers?

International B2B buyers must navigate various quality control nuances that can impact their procurement processes. Understanding these nuances is essential for successful transactions.

Cultural and Regulatory Differences

Different regions may have varying cultural attitudes toward quality and compliance. Buyers must be aware of these differences to establish effective communication with suppliers. Additionally, understanding regional regulatory requirements, such as import tariffs and safety standards, is crucial for ensuring compliance and avoiding costly delays.

Logistics and Supply Chain Considerations

Quality control does not end at the manufacturing facility. International buyers must consider logistics and supply chain practices that can affect product integrity during transport. Establishing clear agreements on packaging standards and handling procedures can help mitigate risks associated with shipping.

Building Long-Term Relationships

Finally, fostering long-term relationships with suppliers can enhance quality assurance efforts. By collaborating closely with suppliers, buyers can influence quality standards and practices, leading to improved product reliability and performance over time.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for Vizio TV screen replacement parts is crucial for B2B buyers. By focusing on these areas, buyers can make informed decisions, ensuring that they source high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vizio tv screen replacement parts’

In the competitive landscape of B2B procurement, sourcing Vizio TV screen replacement parts requires a methodical approach. This guide will help international buyers streamline their purchasing process, ensuring that they acquire quality parts at competitive prices while minimizing risks.

Step 1: Define Your Technical Specifications

Before you begin sourcing, clearly outline the specifications for the replacement parts you need. This includes identifying the model numbers, types of components (e.g., screens, backlight strips, power supplies), and any other technical requirements. Having precise specifications is crucial as it helps avoid compatibility issues and ensures that you’re sourcing the correct parts.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify potential suppliers. Look for companies that specialize in Vizio parts, such as PartStore.com and ShopJimmy, which offer a wide range of components. Ensure that these suppliers have a proven track record in the industry and positive customer reviews, as this can significantly impact the quality of parts you receive.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Consider their experience with Vizio products specifically, as familiarity with the brand can influence the quality and reliability of the parts supplied.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications and comply with international standards. This could include ISO certifications or other quality assurance marks that indicate adherence to best practices in manufacturing and sourcing. Certifications are indicators of reliability and can help mitigate risks associated with poor-quality parts.

Step 5: Assess Pricing and Payment Terms

Compare pricing across different suppliers while also considering the total cost of ownership, including shipping and potential tariffs. Be wary of prices that seem too low, as they may indicate substandard quality. Additionally, clarify payment terms—ensure they are favorable and secure, especially for international transactions.

Step 6: Request Samples or Test Parts

If possible, request samples or smaller quantities of the parts before placing a larger order. Testing these parts can help ensure they meet your quality standards and are compatible with your existing equipment. This step is vital to prevent costly returns or replacements down the line.

Step 7: Establish a Communication Plan

Once you select a supplier, set up a clear communication plan to ensure effective collaboration. Determine points of contact, preferred communication channels, and response times. Effective communication can significantly enhance the procurement process, allowing for quick resolution of any issues that may arise.

By following these steps, international B2B buyers can confidently navigate the sourcing process for Vizio TV screen replacement parts, ensuring they secure high-quality components that meet their technical needs and business objectives.

Comprehensive Cost and Pricing Analysis for vizio tv screen replacement parts Sourcing

When sourcing Vizio TV screen replacement parts, understanding the comprehensive cost structure is essential for international B2B buyers. The cost components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

What Are the Key Cost Components for Vizio TV Replacement Parts?

Materials: The primary cost driver is the materials used in manufacturing replacement parts, such as LED backlight strips, screens, and circuit boards. Prices can vary based on the quality and type of materials selected, with higher-quality components often leading to increased durability and performance.

Labor: Labor costs encompass the wages paid to workers involved in the production, assembly, and testing of the replacement parts. Regions with lower labor costs may offer competitive pricing, but it is crucial to balance this with quality and reliability.

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, which can then be passed on to buyers.

Tooling: Initial tooling costs can be significant, especially for custom parts. Buyers should consider whether they require specific tooling for their orders, as this can influence the overall cost.

Quality Control (QC): Implementing robust QC measures is vital to ensure product reliability. While it may increase initial costs, it ultimately leads to fewer returns and higher customer satisfaction, which is especially important in the B2B sector.

Logistics: Shipping and handling costs can vary widely based on the distance and mode of transport. Buyers should be aware of potential tariffs and customs duties when importing parts into their regions.

Margin: Suppliers typically include a margin to cover their expenses and profit. Understanding the margin expectations of suppliers can aid in negotiations.

How Do Price Influencers Affect Vizio TV Replacement Parts Sourcing?

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Purchasing in bulk often leads to lower per-unit costs, making it beneficial for buyers looking to stock up on replacement parts.

Specifications and Customization: Custom parts or those with specific specifications may incur additional costs. Buyers should evaluate whether the added features are necessary or if standard parts suffice.

Materials and Quality Certifications: Parts that meet specific quality certifications may command higher prices. Buyers should assess whether the certifications are necessary for their market and customer base.

Supplier Factors: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers with a track record of quality may charge more but can offer peace of mind regarding product reliability.

Incoterms: Understanding Incoterms is essential for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can impact total costs.

What Tips Can Help Buyers Negotiate Better Prices for Vizio TV Parts?

Negotiation: Engage in open dialogue with suppliers about pricing and terms. Demonstrating a willingness to build a long-term relationship can lead to better pricing and terms.

Cost Efficiency: Focus on total cost of ownership rather than just the initial purchase price. Assess factors such as durability, warranty, and after-sales support, as these can influence overall costs.

Pricing Nuances for International Buyers: Buyers in regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and economic conditions that may affect prices. Additionally, understanding local regulations regarding imports can help avoid unexpected costs.

Disclaimer on Indicative Prices

Pricing for Vizio TV screen replacement parts can fluctuate based on market conditions, supplier pricing strategies, and geopolitical factors. The prices listed by suppliers may vary significantly, and it is advisable for buyers to conduct thorough market research and supplier comparisons before making purchasing decisions.

Alternatives Analysis: Comparing vizio tv screen replacement parts With Other Solutions

Exploring Alternatives to Vizio TV Screen Replacement Parts

In the rapidly evolving market of television technology, B2B buyers must consider various solutions for screen replacements. While Vizio TV screen replacement parts offer a direct approach for repairing specific Vizio models, exploring alternative methods can provide additional value, flexibility, and cost-effectiveness. This analysis will compare Vizio TV screen replacement parts with alternative solutions, helping international buyers make informed decisions.

| Comparison Aspect | Vizio TV Screen Replacement Parts | Universal TV Screen Repair Kits | Third-Party Screen Replacement Services |

|---|---|---|---|

| Performance | High-quality, OEM parts ensure optimal functionality. | Varies by brand; may not guarantee perfect fit or performance. | Professional repairs can restore screens to original quality. |

| Cost | Moderate pricing; costs can accumulate with multiple parts. | Generally lower upfront cost, but quality may vary. | Typically higher due to labor costs; may save on future repairs. |

| Ease of Implementation | Requires technical skills for installation; may involve multiple steps. | User-friendly; often includes tools and guides for DIY repairs. | Hassle-free; professionals handle everything from assessment to repair. |

| Maintenance | OEM parts often require less frequent replacements. | Potential for higher maintenance; quality may degrade faster. | Regular maintenance and checks included in service contracts. |

| Best Use Case | Ideal for businesses needing specific Vizio model repairs. | Suitable for budget-conscious buyers looking for a quick fix. | Recommended for large enterprises with multiple screens needing repair. |

In-Depth Analysis of Alternatives

Universal TV Screen Repair Kits

Universal repair kits offer a cost-effective solution for businesses that require quick fixes without the need for specific OEM parts. These kits typically include a variety of tools and components designed to work with multiple brands and models. However, the performance can be inconsistent, as the fit may not be perfect, which can lead to further issues down the line. While they are generally more affordable, the potential for lower quality should be carefully considered.

Third-Party Screen Replacement Services

For enterprises that prioritize convenience and quality assurance, third-party screen replacement services present an attractive option. These services employ skilled technicians who can assess and repair screens effectively, often restoring them to original quality. While the initial cost is higher due to labor, this solution mitigates risks associated with DIY repairs and can save costs over time by reducing the frequency of repairs. This option is particularly beneficial for organizations managing multiple screens across various locations.

Conclusion: Choosing the Right Solution for Your Business Needs

Selecting the right solution for TV screen replacements depends on several factors, including budget, technical expertise, and the specific needs of your organization. Vizio TV screen replacement parts are ideal for businesses that prioritize OEM quality and performance for specific models. In contrast, universal repair kits may appeal to those looking for budget-friendly options, albeit with some risks regarding quality. Finally, third-party services offer a comprehensive solution, especially for larger enterprises that prefer outsourcing repairs. By carefully evaluating these alternatives, B2B buyers can make informed decisions that align with their operational goals and budgetary constraints.

Essential Technical Properties and Trade Terminology for vizio tv screen replacement parts

What Are the Essential Technical Properties for Vizio TV Screen Replacement Parts?

Understanding the technical specifications of Vizio TV screen replacement parts is crucial for B2B buyers. Here are some key properties to consider:

-

Material Grade: The quality of materials used in replacement parts can significantly affect durability and performance. Common materials include LCD panels made from tempered glass and LED backlight strips composed of durable plastics. High-grade materials ensure longevity and reduce the frequency of replacements, which is essential for maintaining customer satisfaction and reducing operational costs.

-

Screen Resolution: This specification indicates the number of pixels that make up the display. Vizio TVs typically come in resolutions such as 720p, 1080p, and 4K (2160p). For B2B buyers, understanding resolution is vital as it directly impacts viewing quality. Ensuring that replacement screens match the original specifications helps maintain the integrity of the product and meets consumer expectations.

-

Backlight Type: Replacement parts may utilize different backlighting technologies, such as LED or OLED. LED backlight strips are common in Vizio TVs and are essential for proper illumination of the screen. Buyers should ensure compatibility with specific models to guarantee optimal performance and brightness levels.

-

Dimensions and Tolerance: Precise measurements of replacement parts, including width, height, and thickness, are crucial for compatibility. Tolerance refers to the acceptable range of variation in these dimensions. A tight tolerance ensures that the replacement part fits seamlessly, which is especially important in assembly and repair processes.

-

Power Supply Specifications: The power supply board is critical for the functioning of Vizio TVs. Specifications such as voltage, amperage, and wattage should match the original components to prevent operational issues. Understanding these specifications helps buyers avoid compatibility problems and ensures reliable performance.

What Are the Common Trade Terms Related to Vizio TV Screen Replacement Parts?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B market. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts that are used in the manufacturing of a product. In the context of Vizio TVs, OEM parts are those made by the same manufacturer as the original components, ensuring quality and compatibility.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory effectively and negotiate better pricing.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing and availability for specific products. For buyers of Vizio TV screen replacement parts, issuing an RFQ can help in obtaining competitive pricing and understanding lead times.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in global trade. Familiarity with Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is vital for buyers to understand shipping costs and risks associated with international transactions.

-

Lead Time: This refers to the time taken from placing an order until the product is received. For B2B buyers, understanding lead times for Vizio TV screen replacement parts is crucial for inventory management and meeting customer demands.

-

Warranty Period: This specifies the duration during which a product is guaranteed to perform as expected. Knowing the warranty terms for replacement parts can influence purchasing decisions, as a longer warranty may indicate higher confidence in product quality.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing Vizio TV screen replacement parts, ensuring quality, compatibility, and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the vizio tv screen replacement parts Sector

What Are the Key Market Dynamics and Sourcing Trends for Vizio TV Screen Replacement Parts?

The Vizio TV screen replacement parts market is experiencing notable growth driven by the increasing demand for affordable and efficient repair solutions among consumers and businesses alike. Internationally, particularly in regions like Africa, South America, the Middle East, and Europe, there is a rising trend towards cost-effective electronics repair as opposed to purchasing new devices. This shift is largely influenced by economic factors, including inflation and supply chain disruptions, which have made new electronics less accessible.

Emerging B2B technology trends are reshaping the landscape of parts sourcing. Digital platforms that facilitate real-time inventory tracking and order processing are becoming increasingly popular among international buyers. These platforms not only streamline the procurement process but also enhance transparency in pricing and availability. Furthermore, advancements in logistics and shipping technology have improved the speed and reliability of sourcing replacement parts across borders, making it easier for businesses in regions such as Vietnam and Brazil to access quality Vizio components.

Another significant trend is the growing emphasis on customization and integration of smart technologies within replacement parts. As Vizio TVs become more advanced, replacement parts are also evolving to meet the needs of smart home integration, thus creating new opportunities for B2B suppliers to offer tailored solutions that enhance customer satisfaction and retention.

How Can Sustainability and Ethical Sourcing Impact the Vizio TV Screen Replacement Parts Market?

Sustainability is increasingly becoming a central theme in the sourcing of Vizio TV screen replacement parts. With consumers and businesses alike becoming more environmentally conscious, there is a pressing need for suppliers to adopt ethical sourcing practices. This includes utilizing recycled materials, reducing waste in manufacturing processes, and ensuring that the supply chain adheres to environmental regulations.

Ethical supply chains not only help in minimizing environmental impact but also enhance brand reputation. B2B buyers are more likely to partner with suppliers that demonstrate a commitment to sustainability. This can be achieved through certifications that highlight compliance with environmental standards, such as ISO 14001, or by sourcing parts made from eco-friendly materials.

The importance of transparency in sourcing practices cannot be overstated. International buyers are increasingly demanding detailed information about the origin of materials and the ethical practices of suppliers. As a result, companies that invest in sustainable and ethical sourcing will not only meet regulatory requirements but also gain a competitive edge in the market, positioning themselves as responsible players in the electronics repair sector.

What Is the Brief Evolution of the Vizio TV Screen Replacement Parts Market?

The evolution of the Vizio TV screen replacement parts market can be traced back to the increasing prevalence of flat-screen televisions in the early 2000s. As Vizio established itself as a significant player in the consumer electronics space, the demand for replacement parts grew in tandem with the brand’s popularity. Initially, the market was dominated by a few key players, but the landscape has shifted considerably with the advent of online marketplaces that connect B2B buyers directly with suppliers.

In recent years, the rise of DIY repair culture has further fueled demand for replacement parts, as consumers seek to extend the lifespan of their devices without incurring the costs associated with professional repairs. This trend has led to a diversification of the market, with an increasing number of suppliers offering a wider variety of components, including LED backlight strips, power supply boards, and complete repair kits. As technology continues to advance, the market is expected to evolve further, emphasizing sustainability and ethical sourcing practices as key differentiators for B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of vizio tv screen replacement parts

-

How do I solve compatibility issues with Vizio TV screen replacement parts?

To resolve compatibility issues, always verify the model number of your Vizio TV against the replacement parts. Manufacturers usually provide detailed specifications for each part, including dimensions and compatibility lists. Consider reaching out to suppliers with your model number to confirm whether a specific part will work for your TV. Additionally, reviewing customer feedback can provide insights into the compatibility of parts from different suppliers. -

What is the best way to source Vizio TV screen replacement parts internationally?

When sourcing Vizio TV replacement parts internationally, prioritize suppliers with a proven track record in your region. Look for companies that specialize in electronic parts and have experience exporting to your country. Utilize platforms like Alibaba or TradeIndia to connect with verified suppliers. Additionally, check for certifications and customer reviews to ensure product quality and reliability. -

What are the typical minimum order quantities (MOQs) for Vizio TV replacement parts?

Minimum order quantities (MOQs) can vary significantly by supplier and part type. Generally, MOQs for Vizio TV parts may range from 10 to 100 units. When negotiating with suppliers, consider your inventory needs and financial capacity. Some suppliers may offer flexibility for first-time buyers or smaller businesses, so it’s worth discussing your specific requirements upfront. -

What payment terms should I expect when purchasing Vizio TV screen replacement parts?

Payment terms can vary widely among suppliers. Common practices include advance payment, net 30, or 50% upfront with the remainder upon delivery. For international transactions, consider using secure payment methods like PayPal, Letter of Credit (LC), or escrow services to protect your investment. Discussing payment terms upfront can help avoid misunderstandings and ensure a smooth transaction process. -

How can I ensure quality assurance for Vizio TV replacement parts?

To ensure quality assurance, select suppliers who provide warranties or guarantees on their parts. Request samples before placing a large order to evaluate the part’s quality firsthand. Additionally, inquire about the supplier’s quality control processes, such as testing and certification of their products. Building relationships with reputable suppliers can also lead to better quality assurance over time. -

What logistics options are available for shipping Vizio TV replacement parts?

Logistics options for shipping Vizio TV replacement parts include air freight for faster delivery or sea freight for cost-effective solutions. Consider the urgency of your order when selecting a shipping method. Additionally, ensure that your supplier has experience with international shipping and provides tracking information. Customs clearance processes can vary, so familiarize yourself with your country’s import regulations to avoid delays. -

Can I customize Vizio TV replacement parts to fit my specific needs?

Many suppliers offer customization options for Vizio TV replacement parts, particularly for bulk orders. If you require specific features or modifications, discuss your needs with potential suppliers. Customization may involve adjustments in size, color, or functionality, which can enhance compatibility with your existing equipment. However, be aware that customization might increase lead times and costs. -

What are the best practices for vetting suppliers of Vizio TV screen replacement parts?

To effectively vet suppliers, start by researching their reputation online through customer reviews and ratings. Verify their business credentials, such as registration and certification, to ensure legitimacy. Request references from past clients and inquire about their experience with product quality and customer service. Engaging in direct communication can also provide insights into their responsiveness and reliability, helping you make an informed decision.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Vizio Tv Screen Replacement Parts Manufacturers & Suppliers List

1. Vizio – TV Screens

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: TV Screens for Vizio for sale on eBay. Related searches include Vizio Replacement Screens, Vizio Flat Screen TV, Vizio Monitor, Vizio TV with DVD Player, Vizio TV Screen LCD Repair, Vizio Smart TV, Vizio 3D TV, and 80 in Vizio TV. Categories include TV, Video & Home Audio Parts, with types such as Screen, Backlight, Inverter, Display Panel, Housing, Inverter Board, LED Strip, Main Board Module, Po…

2. P65-F1 – LCD TV Repair Considerations

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Model: P65-F1, Type: LCD TV, Condition: Screen not cracked, Parts inquiry: Need to replace LCD or screen, Cost consideration: Repair may not be cost-effective compared to buying a new TV, Suggested parts source: eBay, Potential repair cost: $300 for screen replacement.

3. Vizio – M-Series 65 Quantum TV

Domain: ifixit.com

Registered: 2001 (24 years)

Introduction: Vizio M-Series 65″ Quantum TV, Model# M658-G1, Serial# LTCWYHMV4359567

4. Vizio – V505-G9 LCD Screen Replacement

Domain: justanswer.com

Registered: 2004 (21 years)

Introduction: Vizio TV model V505-G9; input: 120V~50/60hz, 1.8A; part number: 10243013233; serial number: LIAXXVV4801523; front glass broken; TV is new (purchased 3 months ago); technician indicated that the LCD screen will cost between $400 to $500 for replacement; manufacturers typically do not have screens available for purchase in stock.

5. VIZIO – V-series 55-Inch 4K Ultra HD Smart LED TV

Domain: applianceparts.com

Registered: 1998 (27 years)

Introduction: {“model_number”:”V555G1″,”description”:”V-series 55-Inch Class 4K Ultra HD Smart LED TV”,”replacement_parts”:[{“part_number”:”389G202A15NHLD”,”description”:”VIZIO-TPV AC Power Cord 1500 For America”,”availability”:”Ships in 15 days”,”price”:”10.95″},{“part_number”:”ADTVI2815AAV”,”description”:”VIZIO-TPV Adapter (Power) Board”,”availability”:”In Stock”,”price”:”50.95″},{“part_number”:”X20T836801300…

Strategic Sourcing Conclusion and Outlook for vizio tv screen replacement parts

In the evolving landscape of Vizio TV screen replacement parts, strategic sourcing emerges as a vital component for international B2B buyers. This process not only ensures access to a wide range of high-quality components—from LED backlight strips to power supply boards—but also fosters partnerships with reliable suppliers. By leveraging the diverse offerings available from platforms like PartStore.com and ShopJimmy, businesses can enhance their operational efficiency and reduce downtime associated with repairs.

Moreover, as the demand for Vizio TVs continues to rise across regions like Africa, South America, the Middle East, and Europe, the importance of maintaining a robust supply chain cannot be overstated. Buyers should prioritize suppliers who offer swift shipping options and competitive pricing, ensuring they remain agile in responding to market needs.

Looking ahead, the potential for growth in the Vizio parts market is significant. Companies that adopt a proactive sourcing strategy will not only meet current demands but will also position themselves favorably for future opportunities. Engage with trusted suppliers today to secure a competitive edge in this dynamic market.