Unlocking Value: A Strategic Analysis of the Diesel Dirt Bike For Sale Market

Introduction: Navigating the Global Market for diesel dirt bike for sale

The global market for diesel dirt bikes presents a unique opportunity for B2B buyers seeking reliable and fuel-efficient alternatives to traditional gasoline-powered motorcycles. However, sourcing the right diesel dirt bike for sale can be challenging due to varying specifications, regional preferences, and supplier reliability. This guide aims to demystify the complexities of purchasing diesel dirt bikes by providing a comprehensive overview of the different types available, their applications across various industries, and essential criteria for vetting suppliers.

In this guide, we will explore the diverse range of diesel dirt bikes, including military-grade models and commercial variants designed for rugged terrains. Additionally, we will address critical factors such as cost considerations, maintenance requirements, and the benefits of diesel engines, such as enhanced fuel efficiency and lower operational costs. For international B2B buyers from regions like Africa, South America, the Middle East, and Europe—including countries such as Nigeria and Vietnam—this guide serves as an invaluable resource. It empowers buyers to make informed purchasing decisions, ensuring they choose the right products that meet their operational needs while navigating the complexities of global trade.

By understanding the nuances of the diesel dirt bike market, buyers can streamline their procurement process, optimize their investments, and ultimately enhance their operational capabilities.

Understanding diesel dirt bike for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Diesel Dirt Bike | Single-cylinder diesel engine, rugged construction | Agriculture, Utility Work | Pros: Excellent torque, fuel efficiency. Cons: Lower horsepower compared to gas models. |

| Military-Grade Diesel Bike | Built for military use, capable of running on multiple fuels | Defense, Security Operations | Pros: Versatile fuel options, durable. Cons: Limited availability, potentially higher costs. |

| Off-Road Adventure Diesel Bike | Enhanced suspension and off-road capabilities | Recreational, Tourism | Pros: Superior handling, designed for rugged terrain. Cons: Higher maintenance costs. |

| Utility Diesel Dirt Bike | Designed for heavy loads, equipped with cargo racks | Construction, Mining | Pros: High load capacity, built for durability. Cons: Bulkier design may affect maneuverability. |

| Custom Diesel Dirt Bike | Tailored specifications, aftermarket modifications available | Specialized Industries, Custom Projects | Pros: Fully customizable, meets specific needs. Cons: Potentially longer lead times for delivery. |

What are the Characteristics of Standard Diesel Dirt Bikes?

Standard diesel dirt bikes are characterized by their single-cylinder diesel engines, which provide excellent torque and fuel efficiency. These bikes are robustly constructed to withstand harsh environments, making them suitable for agricultural and utility work. When considering a purchase, B2B buyers should evaluate the bike’s power output, maintenance requirements, and overall performance in off-road conditions.

How Do Military-Grade Diesel Bikes Differ from Others?

Military-grade diesel bikes are designed for rigorous use in defense and security operations. They can run on various fuels, including diesel, kerosene, and jet fuel, making them highly versatile for military logistics. B2B buyers in defense sectors should consider the bike’s durability, fuel adaptability, and compliance with military standards when making a procurement decision.

What Makes Off-Road Adventure Diesel Bikes Ideal for Recreational Use?

Off-road adventure diesel bikes are built with enhanced suspension systems and features that facilitate superior handling on rugged terrains. These bikes are popular in the recreational and tourism sectors, appealing to adventure enthusiasts. B2B buyers should assess factors such as comfort, performance in various terrains, and the availability of spare parts when considering these models.

Why Are Utility Diesel Dirt Bikes Essential for Heavy Industries?

Utility diesel dirt bikes are specifically designed to handle heavy loads, often equipped with cargo racks and reinforced structures. These bikes are invaluable in construction and mining industries where durability and load capacity are critical. Buyers should focus on the bike’s load ratings, fuel efficiency, and maintenance requirements to ensure they meet operational needs.

What Are the Benefits of Custom Diesel Dirt Bikes?

Custom diesel dirt bikes offer tailored specifications and modifications to meet specific industry needs. These bikes can be designed for specialized applications, making them suitable for niche markets. B2B buyers should consider the customization options, lead times for delivery, and potential costs associated with bespoke builds when exploring this category.

Key Industrial Applications of diesel dirt bike for sale

| Industry/Sector | Specific Application of diesel dirt bike for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Military and Defense | Tactical mobility in rugged terrains | Enhanced logistics and fuel efficiency in operations | Need for robust, all-terrain capabilities and adaptability to various fuel types. |

| Agriculture | Transporting personnel and supplies on farms | Efficient movement across challenging landscapes | Durability, fuel efficiency, and ease of maintenance are crucial. |

| Construction and Mining | Site access and personnel transport | Cost-effective and agile transport solutions | Look for models with strong towing capacity and off-road performance. |

| Tourism and Recreation | Guided tours and adventure sports | Unique experiences that attract customers | Aesthetic appeal and reliability in diverse environments are important. |

| Emergency Services | Rapid response in disaster relief scenarios | Quick access to remote locations during emergencies | Reliability and ease of repair in the field are key factors. |

How Are Diesel Dirt Bikes Used in Military and Defense Applications?

In military contexts, diesel dirt bikes are utilized for tactical mobility, allowing personnel to navigate challenging terrains where traditional vehicles may falter. Their ability to run on various fuels, including diesel and jet fuel, simplifies logistics in combat zones, ensuring that troops can refuel from the same sources as other military vehicles. Buyers in this sector require bikes that are rugged, lightweight, and capable of handling rough terrain while offering low maintenance needs.

What Role Do Diesel Dirt Bikes Play in Agriculture?

In the agricultural sector, diesel dirt bikes serve as versatile transport vehicles, enabling farmers to traverse expansive and rugged landscapes. They are ideal for moving equipment, tools, and personnel efficiently across fields and uneven terrain. The fuel efficiency of diesel bikes translates into lower operational costs, which is a significant advantage for farmers in regions where fuel prices can be volatile. Buyers should focus on durability and ease of maintenance to ensure long-term utility in harsh environments.

How Are Diesel Dirt Bikes Beneficial for Construction and Mining Industries?

Construction and mining companies benefit from diesel dirt bikes as they provide agile transport solutions on job sites that are often inaccessible to larger vehicles. These bikes facilitate the movement of workers and small equipment, improving overall site efficiency. For international buyers, particularly in developing regions, sourcing bikes with high towing capacity and robust off-road capabilities is essential to meet the demanding conditions typical of construction and mining operations.

How Can Diesel Dirt Bikes Enhance Tourism and Recreation?

In the tourism and recreation industry, diesel dirt bikes are used for guided tours and adventure sports, offering unique experiences that attract thrill-seekers. Their all-terrain capabilities allow tour operators to take groups into remote and scenic locations, enhancing customer satisfaction. Buyers in this sector should prioritize aesthetics, reliability, and performance in diverse environments to ensure a memorable experience for clients while minimizing downtime.

What Are the Advantages of Diesel Dirt Bikes for Emergency Services?

For emergency services, diesel dirt bikes provide rapid response capabilities, especially in disaster relief scenarios where access to remote areas is crucial. These bikes can navigate through debris and rough terrain, enabling responders to reach those in need quickly. Buyers in this field must consider the reliability of the bikes and the ease of repair in the field, as these factors can significantly impact response times during critical situations.

3 Common User Pain Points for ‘diesel dirt bike for sale’ & Their Solutions

Scenario 1: Navigating the Complexities of Import Regulations for Diesel Dirt Bikes

The Problem: International buyers often face significant hurdles when attempting to import diesel dirt bikes due to complex and varying regulations across countries. For instance, a buyer in Nigeria may struggle with stringent import duties, environmental regulations, and compliance with local vehicle specifications. These hurdles can lead to increased costs, delays in delivery, and potential legal issues if the bikes do not meet local standards.

The Solution: To navigate these complexities, buyers should conduct thorough research on the import regulations specific to their country before making a purchase. Engaging with a local customs broker can provide invaluable insights into the necessary documentation, tariffs, and compliance requirements. Furthermore, establishing a relationship with a reputable supplier who is experienced in international sales can ensure that the diesel dirt bikes meet local specifications. Buyers should also consider sourcing from manufacturers that offer models specifically designed for their market, as this can simplify compliance and reduce the risk of legal complications.

Scenario 2: Addressing Maintenance and Spare Parts Availability for Diesel Dirt Bikes

The Problem: A common concern for B2B buyers is the availability of maintenance services and spare parts for diesel dirt bikes, especially in regions with limited access to specialized services. For example, a buyer in a remote area of South America might find it challenging to obtain the necessary parts for repairs, leading to prolonged downtime and loss of revenue.

The Solution: To mitigate this issue, buyers should prioritize sourcing diesel dirt bikes from manufacturers or dealers that offer comprehensive after-sales support and a robust supply chain for spare parts. Establishing a partnership with a local dealer or service center can ensure that spare parts are readily available, thus minimizing downtime. Additionally, buyers should consider purchasing maintenance packages that include training for local technicians on how to service diesel dirt bikes effectively. This approach not only enhances operational efficiency but also builds local expertise, ensuring quicker turnaround times for repairs.

Scenario 3: Understanding the Total Cost of Ownership for Diesel Dirt Bikes

The Problem: Many B2B buyers underestimate the total cost of ownership (TCO) associated with diesel dirt bikes, including fuel costs, maintenance, insurance, and potential downtime. For instance, a fleet manager in the Middle East might be lured by low initial purchase prices but fails to account for high fuel consumption or maintenance costs in the long run, impacting overall profitability.

The Solution: To gain a clear understanding of TCO, buyers should conduct a detailed analysis that includes all potential costs over the bike’s lifecycle. This involves not only the purchase price but also fuel efficiency, maintenance schedules, and the cost of parts. Buyers can leverage tools like TCO calculators or consult with industry experts to forecast expenses accurately. Furthermore, negotiating bulk purchase agreements can lead to discounts on both the bikes and maintenance services. By having a comprehensive view of the total cost, buyers can make more informed purchasing decisions that align with their financial objectives.

Strategic Material Selection Guide for diesel dirt bike for sale

What Materials Are Commonly Used in Diesel Dirt Bikes and Their Key Properties?

When considering the strategic material selection for diesel dirt bikes, several materials stand out due to their unique properties and performance characteristics. Understanding these materials can help B2B buyers make informed decisions that align with their operational requirements and market conditions.

How Does Aluminum Benefit Diesel Dirt Bike Construction?

Aluminum is a popular choice for various components of diesel dirt bikes, including frames and engine casings. Its key properties include a high strength-to-weight ratio, which allows for lightweight designs without compromising structural integrity. Aluminum also exhibits excellent corrosion resistance, making it suitable for off-road applications where exposure to moisture and dirt is prevalent.

Pros: The lightweight nature of aluminum enhances maneuverability and fuel efficiency, crucial for competitive riding. Additionally, aluminum is relatively easy to manufacture and can be extruded or cast into complex shapes.

Cons: While durable, aluminum can be more expensive than steel and may not withstand extreme impacts as effectively. It can also be prone to fatigue over time, particularly in high-stress applications.

Impact on Application: Aluminum’s compatibility with various engine types and its ability to dissipate heat effectively make it a prime candidate for high-performance diesel engines.

Considerations for International Buyers: Buyers in regions like Africa and South America should be aware of local recycling capabilities, as aluminum can be economically recycled. Compliance with international standards such as ASTM B221 for aluminum extrusions is also essential.

What Role Does Steel Play in Diesel Dirt Bike Manufacturing?

Steel is another fundamental material used in diesel dirt bikes, particularly for structural components like the frame and suspension systems. It boasts high tensile strength and impact resistance, making it ideal for rugged environments.

Pros: Steel is cost-effective and widely available, making it a go-to material for manufacturers. Its durability ensures longevity, reducing maintenance costs over time.

Cons: Steel is heavier than aluminum, which can affect the bike’s overall weight and performance. Additionally, it is susceptible to corrosion if not properly treated or coated.

Impact on Application: Steel’s strength makes it suitable for high-load applications, such as suspension systems that must endure significant stress during operation.

Considerations for International Buyers: Buyers should ensure that the steel used complies with local standards, such as DIN 17100 in Europe, to guarantee quality and performance.

How Does Composite Material Enhance Performance in Diesel Dirt Bikes?

Composite materials, particularly carbon fiber and fiberglass, are increasingly utilized in diesel dirt bikes for components like body panels and fairings. These materials are known for their lightweight and high-strength properties.

Pros: Composites can significantly reduce the weight of a bike, improving acceleration and handling. They also offer excellent resistance to corrosion and environmental degradation.

Cons: The manufacturing process for composites can be complex and costly, which may deter some manufacturers. Additionally, repairs can be more challenging compared to metals.

Impact on Application: Composites are particularly advantageous for components that require a high strength-to-weight ratio, making them suitable for performance-oriented applications.

Considerations for International Buyers: Buyers should consider the availability of repair facilities for composite materials in their regions, as specialized skills and equipment may be necessary for maintenance.

What About Rubber and Plastics in Diesel Dirt Bike Components?

Rubber and plastics are commonly used for seals, gaskets, and fuel tanks in diesel dirt bikes. These materials are essential for ensuring proper sealing and preventing leaks.

Pros: Rubber and plastics are cost-effective and provide excellent resistance to various chemicals, including fuels and oils. They also offer good flexibility and shock absorption properties.

Cons: Over time, rubber can degrade due to UV exposure and extreme temperatures, while plastics may not be as durable as metals or composites.

Impact on Application: The compatibility of rubber and plastics with diesel fuels is critical, as improper materials can lead to failures and safety hazards.

Considerations for International Buyers: Buyers should verify that the rubber and plastics used meet relevant standards, such as JIS K 6301 for rubber materials, to ensure safety and performance.

Summary Table of Material Selection for Diesel Dirt Bikes

| Material | Typical Use Case for diesel dirt bike for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frames, engine casings | Lightweight, corrosion-resistant | Higher cost, fatigue-prone | Medium |

| Steel | Structural components, suspension systems | High strength, cost-effective | Heavier, corrosion risk | Low |

| Composite | Body panels, fairings | Lightweight, high strength | Complex manufacturing, difficult repairs | High |

| Rubber/Plastics | Seals, gaskets, fuel tanks | Cost-effective, chemical resistance | Degradation over time | Low |

This guide provides a comprehensive overview of the materials used in diesel dirt bikes, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for diesel dirt bike for sale

What Are the Main Stages in the Manufacturing Process of Diesel Dirt Bikes?

The manufacturing process of diesel dirt bikes involves several critical stages that ensure both performance and durability. Understanding these stages is essential for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, where environmental and operational demands can vary widely.

Material Preparation: How Are Components Selected and Processed?

Material selection is crucial in the manufacturing of diesel dirt bikes. High-strength steel, aluminum alloys, and composite materials are typically chosen for their weight-to-strength ratio. The preparation stage involves cutting, bending, and machining these materials to precise specifications. Advanced technologies like CNC machining ensure high accuracy and repeatability in component fabrication, which is essential for the assembly of complex systems like the engine and frame.

Forming: What Techniques Are Used to Shape Components?

Forming techniques such as stamping, forging, and extrusion are employed to create various components of the bike. For instance, the frame may be formed using hydroforming, which allows for complex shapes that improve strength without adding excessive weight. Additionally, the engine components are often cast in molds, providing the necessary durability to withstand the rigors of off-road riding. Each forming technique is selected based on the specific requirements of the component in terms of strength, weight, and cost-effectiveness.

Assembly: How Are Different Parts Integrated?

The assembly process is where the bike comes together, integrating various components such as the engine, transmission, suspension, and braking systems. This stage often employs both automated and manual assembly techniques to ensure precision. Skilled technicians perform critical tasks, such as aligning the engine and securing the frame, while robotics may be used for repetitive tasks like welding or fastener installation. Each assembly line is designed to minimize errors and maximize efficiency.

Finishing: What Processes Enhance the Durability and Aesthetic Appeal?

Finishing processes include painting, powder coating, and surface treatments that enhance both the aesthetic and functional aspects of the dirt bike. For example, powder coating provides a robust layer that protects against corrosion and wear, which is vital for vehicles used in harsh environments. Quality checks during this stage ensure that the final product meets aesthetic standards while also adhering to functional requirements.

What Quality Assurance Measures Are Essential for Diesel Dirt Bikes?

Quality assurance is a fundamental aspect of manufacturing diesel dirt bikes, ensuring that each unit meets international standards and customer expectations. For B2B buyers, understanding these quality control measures is crucial for making informed purchasing decisions.

Which International Standards Should Buyers Be Aware Of?

Manufacturers of diesel dirt bikes often adhere to international quality standards such as ISO 9001, which focuses on quality management systems. This certification indicates a commitment to continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE (Conformité Européenne) for safety and compliance in Europe, and API (American Petroleum Institute) standards for engines, are significant for buyers concerned about safety and reliability.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integrated throughout the manufacturing process to identify and rectify issues early. These typically include:

- Incoming Quality Control (IQC): Inspection of raw materials to ensure they meet specified requirements before entering the production process.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing to catch defects in real-time, ensuring that each step adheres to established standards.

- Final Quality Control (FQC): Comprehensive testing of the completed bike, including performance and safety tests, to ensure it meets all regulatory and customer specifications.

What Testing Methods Are Commonly Used?

Testing methods for diesel dirt bikes include performance testing, where the bike is subjected to various conditions to evaluate its handling, power output, and fuel efficiency. Durability tests simulate the stresses of off-road riding, while environmental tests assess how the bike performs under different weather conditions. Vibration testing and noise level measurements are also conducted to ensure the bike operates within acceptable limits.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in international markets, verifying a supplier’s quality control practices is essential to mitigate risks associated with product reliability and safety.

What Audit Procedures Should Be Followed?

Buyers should consider conducting on-site audits of potential suppliers. This includes reviewing quality management systems, inspecting manufacturing facilities, and assessing adherence to international standards. An audit provides insight into the supplier’s capabilities and commitment to quality.

How Important Are Quality Reports and Documentation?

Requesting quality reports and documentation from suppliers is vital. This includes certificates of compliance, test results, and records of past audits. Such documentation serves as evidence of the supplier’s quality control processes and can help buyers make informed decisions.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can further enhance trust in the supplier’s quality assurance practices. These independent organizations assess the manufacturing process and verify compliance with specified standards, providing an additional layer of assurance for B2B buyers.

What Are the Quality Control Nuances for International Buyers?

International buyers must navigate various quality control nuances that can impact their purchasing decisions.

How Do Regional Standards Affect Quality Assurance?

Different regions may have varying regulations and standards that affect quality assurance practices. For instance, CE marking is essential for products sold in Europe, while other regions may have their own specific requirements. Buyers should familiarize themselves with these regional standards to ensure compliance.

What Challenges Do Buyers Face in Global Sourcing?

Global sourcing presents challenges such as language barriers, differing regulations, and varying levels of manufacturing expertise. Buyers should consider local partnerships or consult with experts familiar with the target market to navigate these complexities effectively.

In summary, understanding the manufacturing processes and quality assurance practices for diesel dirt bikes is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control measures, buyers can make informed decisions that align with their operational needs and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diesel dirt bike for sale’

In the competitive landscape of sourcing diesel dirt bikes, having a structured approach is essential for B2B buyers. This guide provides a step-by-step checklist to streamline the procurement process, ensuring you secure high-quality products that meet your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of successful sourcing. Consider factors such as engine type (single-cylinder, diesel conversion), displacement, torque, and fuel efficiency. Additionally, think about the intended use—whether for military, recreational, or commercial purposes—as this will influence the specifications you prioritize.

Step 2: Research Market Trends and Demand

Understanding the current market trends and demand for diesel dirt bikes is vital. Analyze which models are popular in your target regions, such as Africa or South America, and identify emerging markets that show potential for growth. Utilize market reports and industry publications to gather data on pricing, features, and buyer preferences.

Step 3: Evaluate Potential Suppliers

Before making any commitments, thoroughly vet potential suppliers. Request detailed company profiles, including their manufacturing capabilities, certifications, and past projects. Look for references from other buyers in your industry or region to gauge their reliability and quality of service. It’s also beneficial to assess their responsiveness and support structure.

Step 4: Request Samples and Demonstrations

Obtaining samples or arranging demonstrations can significantly inform your purchasing decision. This step allows you to evaluate the performance, build quality, and usability of the diesel dirt bikes firsthand. Pay attention to details such as ease of maintenance and the bike’s handling under various conditions, which can be crucial for end-users.

Step 5: Negotiate Pricing and Payment Terms

Once you have identified suitable suppliers and assessed the products, engage in negotiations regarding pricing and payment terms. Be transparent about your budget and expected volume to secure favorable terms. Consider options for bulk discounts, extended warranties, or financing plans that can enhance your overall procurement strategy.

Step 6: Verify Compliance with Local Regulations

Ensure that the diesel dirt bikes comply with local regulations and standards in your target market. This includes emissions standards, safety certifications, and any specific import/export regulations. Failing to meet these requirements can lead to costly delays and penalties, so thorough verification is essential.

Step 7: Establish Logistics and Delivery Plans

Finally, develop a logistics plan for the delivery of the bikes. Coordinate with suppliers to understand their shipping capabilities and timelines. Consider factors such as customs clearance, transportation costs, and local distribution networks to ensure that the bikes arrive on time and in good condition.

By following this practical sourcing guide, B2B buyers can navigate the complexities of procuring diesel dirt bikes effectively, ensuring they meet their operational needs while optimizing costs and compliance.

Comprehensive Cost and Pricing Analysis for diesel dirt bike for sale Sourcing

What Are the Key Cost Components in Sourcing Diesel Dirt Bikes?

When sourcing diesel dirt bikes, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and desired profit margin.

-

Materials: The type of materials used for constructing the bikes significantly impacts cost. High-quality steel, advanced composites, and specialized components for diesel engines will generally increase expenses. Buyers should consider the trade-off between cost and durability, especially for rugged terrains.

-

Labor: Skilled labor is essential for assembling diesel dirt bikes, especially when modifications are required for diesel engine compatibility. Labor costs can vary significantly based on the region, so buyers should factor in local wage standards when evaluating potential suppliers.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and administrative expenses related to the manufacturing process. A facility with high overhead might pass those costs onto buyers, affecting the final price.

-

Tooling: Custom tooling may be necessary for specific bike configurations or modifications, which can add to initial costs. Long-term contracts might allow for shared tooling expenses, benefiting both buyers and manufacturers.

-

Quality Control: Effective QC processes ensure that the bikes meet safety and performance standards. While robust QC can increase upfront costs, it minimizes risks related to product defects and warranty claims.

-

Logistics: Shipping and handling costs can vary widely based on the destination. Buyers should consider not only the shipping fees but also potential tariffs, taxes, and insurance costs associated with international shipments.

-

Margin: Suppliers typically include a profit margin in their pricing structure. Understanding the average margin for similar products in the market can help buyers negotiate better deals.

How Do Price Influencers Affect Diesel Dirt Bike Sourcing?

Several factors can influence the pricing of diesel dirt bikes in the B2B market:

-

Volume/MOQ: Purchasing in bulk often leads to significant discounts. Suppliers may offer lower prices for larger orders, which is beneficial for buyers planning to resell or use multiple units.

-

Specifications/Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected price increases during negotiations.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO standards) can raise prices but provide assurance of reliability and performance. Buyers should weigh the benefits against the costs.

-

Supplier Factors: The supplier’s reputation, reliability, and financial stability can influence pricing. Established suppliers may charge more but offer better support and warranties.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) can impact total costs. Buyers should clarify who bears the costs and risks at each stage of transportation.

What Are Effective Buyer Tips for Sourcing Diesel Dirt Bikes?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips to enhance cost-efficiency:

-

Negotiation: Engage in open dialogue with suppliers to negotiate terms. Leverage multiple quotes to create competitive pressure, but ensure that quality and service levels are not compromised.

-

Total Cost of Ownership (TCO): Assess the TCO, which includes not just the purchase price but also maintenance, fuel efficiency, and potential resale value. Diesel dirt bikes often provide better fuel economy, which can reduce long-term costs.

-

Pricing Nuances for International Markets: Be aware that prices may vary by region due to local demand, supply chain logistics, and regulatory costs. Conduct market research to understand pricing trends in the target market.

-

Quality Assurance: Prioritize suppliers who provide guarantees or warranties. This can save costs associated with repairs and replacements in the long run.

Disclaimer on Indicative Prices

The prices for diesel dirt bikes can fluctuate based on market conditions, supplier pricing strategies, and additional costs associated with international shipping and tariffs. Always consult multiple suppliers for the most accurate and current pricing information to ensure a fair deal.

Alternatives Analysis: Comparing diesel dirt bike for sale With Other Solutions

Exploring Alternatives to Diesel Dirt Bikes for Sale

In the search for effective transportation solutions for rugged terrains, diesel dirt bikes present a unique option. However, various alternative technologies also cater to similar needs, each with distinct advantages and disadvantages. This analysis provides a comparative overview of diesel dirt bikes against other viable options, helping B2B buyers make informed decisions.

| Comparison Aspect | Diesel Dirt Bike for Sale | Electric Dirt Bike | Gasoline Dirt Bike |

|---|---|---|---|

| Performance | Moderate torque, low horsepower (~30 HP) | High torque, instant power delivery | Higher horsepower, quick acceleration |

| Cost | Generally higher initial cost; lower fuel costs | Higher initial purchase price; lower maintenance | Moderate initial cost; fluctuating fuel prices |

| Ease of Implementation | Requires specific fuel availability; less common | Requires charging infrastructure | Widely available fuel; easy refueling |

| Maintenance | Moderate; diesel engines are durable but complex | Low; fewer moving parts, less frequent servicing | Moderate; regular maintenance needed |

| Best Use Case | Military and off-road applications | Urban commuting, recreational use | General recreation, racing |

What Are the Advantages and Disadvantages of Electric Dirt Bikes?

Electric dirt bikes are gaining traction as an alternative due to their instant torque and lower maintenance needs. They provide a smooth ride with minimal noise, making them ideal for urban commuting and recreational use in noise-sensitive areas. However, the higher initial cost and the need for charging infrastructure can be significant barriers, particularly in regions with limited access to electrical outlets. Battery life and range are also critical factors, as they may not match the endurance of diesel-powered options in rugged terrains.

How Do Gasoline Dirt Bikes Compare to Diesel Options?

Gasoline dirt bikes are widely popular for their high horsepower and quick acceleration, making them suitable for racing and recreational activities. They are generally more affordable and easier to refuel, given the widespread availability of gasoline. However, they can be less fuel-efficient and may require more frequent maintenance compared to diesel options. Additionally, their environmental impact is greater, which could be a consideration for organizations focused on sustainability.

Conclusion: Which Solution Is Best for Your Business Needs?

Choosing the right transportation solution depends on your specific operational needs, budget, and environmental considerations. Diesel dirt bikes excel in durability and fuel economy, making them suitable for military and off-road applications. Electric dirt bikes are perfect for urban settings, offering low maintenance and eco-friendliness, while gasoline dirt bikes provide performance and ease of use for general recreational purposes. Assessing these factors will help B2B buyers select the most appropriate solution tailored to their unique requirements.

Essential Technical Properties and Trade Terminology for diesel dirt bike for sale

What Are the Key Technical Properties of Diesel Dirt Bikes for Sale?

When considering a diesel dirt bike for sale, it’s essential to understand the technical specifications that define performance, reliability, and suitability for various terrains. Here are some critical specs to evaluate:

1. Engine Type and Configuration

The engine type, typically a single-cylinder design for diesel dirt bikes, is crucial. Diesel engines are known for their torque and fuel efficiency, making them ideal for off-road conditions. For example, the diesel KLR650 features a specially designed engine that can run on various fuels, including biodiesel and kerosene. Understanding the engine configuration helps buyers assess the bike’s capability to handle rugged terrains and long-distance travel.

2. Displacement

Displacement, measured in cubic centimeters (cc), refers to the total volume of all the cylinders in the engine. For instance, a diesel dirt bike might have a displacement of around 652 cc. Higher displacement typically translates to more power and torque, which is vital for off-road performance. Buyers should consider displacement in relation to their intended use, as it affects acceleration, climbing ability, and fuel consumption.

3. Fuel Economy

Fuel economy is a critical property, especially for B2B buyers looking for cost-effective options. Diesel dirt bikes are known for their superior fuel efficiency compared to gasoline counterparts, often achieving significantly higher miles per gallon. This factor is particularly important for businesses operating in remote areas where fuel availability may be limited.

4. Weight and Load Capacity

The weight of the dirt bike influences handling, speed, and maneuverability. A typical diesel dirt bike may weigh around 400 lbs (approximately 181 kg). Additionally, load capacity refers to the maximum weight the bike can carry, including the rider and any cargo. Understanding these aspects helps buyers determine whether the bike can handle the intended use, whether for transport or recreational purposes.

5. Suspension and Braking System

The suspension system’s design affects ride comfort and handling on uneven surfaces. For instance, a bike equipped with long-travel suspension can absorb shocks from rough terrains better than one with a standard setup. Similarly, the braking system, which may include hydraulic disc brakes, is vital for safety and control. Evaluating these features can help buyers ensure that the bike meets specific operational requirements.

What Common Trade Terms Should B2B Buyers Know When Purchasing Diesel Dirt Bikes?

Understanding industry terminology is crucial for navigating the procurement process effectively. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to the original manufacturer of the bike or its components. In the context of diesel dirt bikes, purchasing OEM parts ensures compatibility and quality, which is essential for maintaining performance and reliability.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. For B2B buyers, knowing the MOQ is vital for budgeting and inventory management. This is particularly relevant when sourcing diesel dirt bikes or parts in bulk for fleets or rental services.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a quote on specific products or services. B2B buyers should use RFQs to solicit competitive pricing and terms from multiple suppliers, ensuring they secure the best deal for diesel dirt bikes.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms helps B2B buyers clarify shipping costs, insurance, and delivery responsibilities, which is crucial for international transactions involving diesel dirt bikes.

5. Warranty and Service Agreements

Warranty refers to the manufacturer’s promise to repair or replace parts of the bike within a specified period. Service agreements outline maintenance responsibilities and costs. Both are critical for B2B buyers to consider, as they directly impact the total cost of ownership and long-term reliability of the diesel dirt bikes.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed purchasing decisions that align with their operational needs and budget considerations.

Navigating Market Dynamics and Sourcing Trends in the diesel dirt bike for sale Sector

What Are the Key Market Trends Influencing Diesel Dirt Bike Sales?

The diesel dirt bike market is witnessing a notable shift driven by several global factors. The increasing demand for versatile and fuel-efficient vehicles in regions like Africa and South America is propelling the growth of diesel-powered dirt bikes. These bikes offer significant advantages, particularly in remote areas where fuel accessibility is a concern. Moreover, the rising trend of adventure tourism is amplifying the need for robust, all-terrain vehicles capable of handling diverse environments.

Emerging technologies such as electric hybrid systems are also making inroads, presenting opportunities for manufacturers to innovate. B2B buyers are increasingly focusing on sourcing motorcycles that not only meet performance standards but also align with sustainability goals. Additionally, the integration of IoT and smart technologies into motorcycles is gaining traction, allowing for better tracking, maintenance, and user experiences.

Market dynamics are further influenced by the competitive pricing strategies adopted by manufacturers. With the entry of new players in the diesel dirt bike sector, international buyers are presented with a wider range of options. This competitive landscape compels suppliers to enhance their product offerings and customer service, thereby improving the overall purchasing experience for B2B buyers across various markets, including Europe and the Middle East.

How Is Sustainability Shaping Sourcing Decisions in the Diesel Dirt Bike Industry?

Sustainability is becoming a critical factor in the sourcing of diesel dirt bikes. The environmental impact of manufacturing processes, including emissions and resource depletion, is prompting B2B buyers to prioritize suppliers who demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials and adherence to ethical sourcing guidelines.

In the quest for sustainable solutions, manufacturers are increasingly investing in ‘green’ certifications and materials that reduce their carbon footprint. These certifications not only enhance brand reputation but also appeal to environmentally conscious buyers. Moreover, the lifecycle assessment of products is gaining importance, with buyers looking for motorcycles that are durable and can be easily recycled or repurposed at the end of their life cycle.

The emphasis on ethical supply chains also extends to labor practices, where buyers are more inclined to partner with companies that uphold fair labor standards and contribute positively to local communities. As the global market becomes more interconnected, the pressure to adopt sustainable practices will likely escalate, making it imperative for B2B buyers to align their sourcing strategies with these values.

What Is the Historical Context of Diesel Dirt Bikes and Their Evolution?

The evolution of diesel dirt bikes can be traced back to military applications, where reliability and fuel efficiency were paramount. The Kawasaki KLR650, originally designed for military use, was modified to accommodate diesel fuel, enabling it to operate seamlessly alongside other military vehicles. This adaptation highlighted the bike’s versatility and its potential for civilian markets.

Over the years, the diesel dirt bike segment has grown, with manufacturers exploring innovative technologies and design improvements to enhance performance and sustainability. The shift from purely gasoline-powered engines to diesel and hybrid models reflects a broader trend in the automotive industry toward more efficient and environmentally friendly options. Today, diesel dirt bikes are recognized not only for their durability and fuel economy but also for their ability to meet the demands of diverse terrains, making them an attractive option for international B2B buyers looking to invest in reliable off-road vehicles.

Frequently Asked Questions (FAQs) for B2B Buyers of diesel dirt bike for sale

-

How do I solve supply chain issues when sourcing diesel dirt bikes?

To address supply chain issues, consider establishing strong relationships with multiple suppliers to mitigate risks. Diversifying your sourcing options can help ensure a steady supply of parts and bikes. Additionally, work with suppliers who have a proven track record of reliability and flexibility. Utilize technology for real-time tracking of shipments, and maintain clear communication regarding delivery timelines to anticipate any potential delays. Lastly, consider local assembly options to reduce reliance on international shipping. -

What is the best diesel dirt bike for off-road conditions?

When selecting a diesel dirt bike for off-road conditions, the Kawasaki KLR 650 is often recommended due to its robust design and fuel efficiency. It features a single-cylinder engine that delivers substantial torque, making it ideal for navigating rough terrains. Additionally, its adaptability to run on various fuels, including diesel and biodiesel, enhances its versatility in remote locations. Ensure to assess the bike’s suspension, weight, and tire quality to match the specific off-road environments you expect to encounter. -

How can I vet suppliers for diesel dirt bikes?

To vet suppliers effectively, start by researching their reputation through online reviews, industry forums, and trade references. Request documentation of their certifications and compliance with international quality standards, such as ISO certifications. Conduct on-site visits if possible to evaluate their manufacturing processes and quality control measures. Additionally, inquire about their experience in exporting to your region and their ability to provide after-sales support. Trustworthiness and responsiveness are key indicators of a reliable supplier. -

What customization options are available for diesel dirt bikes?

Customization options for diesel dirt bikes can include modifications to engine performance, suspension upgrades, and personalized aesthetics such as color and graphics. Some manufacturers offer packages that allow for tailored specifications based on the intended use, whether for recreational purposes or heavy-duty applications. Discuss your specific requirements with the supplier to understand the extent of customization they can provide, including lead times and associated costs. -

What is the minimum order quantity (MOQ) for diesel dirt bikes?

The MOQ for diesel dirt bikes varies by supplier and can depend on factors such as production capabilities and order specifications. Generally, MOQs can range from a few units to several dozen. When negotiating, consider discussing your projected demand and the potential for future orders, as suppliers may be willing to lower the MOQ for strategic partnerships. Always confirm the MOQ in writing to avoid misunderstandings later. -

What payment terms should I expect when purchasing diesel dirt bikes internationally?

Payment terms for international purchases can vary widely among suppliers. Common arrangements include a deposit upfront (typically 30-50%) with the balance due prior to shipping. Some suppliers may offer letters of credit or financing options for larger orders. Always clarify the payment methods accepted, such as bank transfers or escrow services, and ensure you understand any currency exchange implications. Negotiating favorable terms can help improve cash flow and mitigate risks associated with international transactions. -

What quality assurance practices should I look for when sourcing diesel dirt bikes?

Quality assurance practices to look for include adherence to international standards, comprehensive testing procedures, and certifications like ISO 9001. Inquire about the supplier’s quality control processes, including inspections at various production stages and final product testing. Request samples or product demonstrations to evaluate quality firsthand. Establishing clear quality expectations in your contract can also protect your interests and ensure accountability. -

How do logistics and shipping work for international orders of diesel dirt bikes?

Logistics for international orders typically involve coordinating with freight forwarders to handle shipping, customs clearance, and delivery. Discuss the shipping methods available, such as sea or air freight, and their respective costs and transit times. Ensure the supplier provides necessary documentation for customs, including invoices and packing lists. Familiarize yourself with import regulations in your country to avoid delays. Consider partnering with logistics experts who can facilitate smoother operations and provide guidance on best practices.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Diesel Dirt Bike For Sale Manufacturers & Suppliers List

1. Kawasaki – KLR 650 Dirt Bike

Domain: cycletrader.com

Registered: 2000 (25 years)

Introduction: {“make”:”Kawasaki”,”model”:”KLR 650″,”category”:”Dirt Bike”,”engine_type”:”Single-Cylinder”,”displacement”:”39.8 cu. in. (652 cc)”,”bore_and_stroke”:”Bore: 3.94 in.”,”available_colors”:”Various”,”new_model_years”:[2024,2025],”used_model_years”:[2022],”price_range”:{“new”:{“min”:5464,”max”:6999},”used”:{“min”:4599,”max”:5999}}}

2. Facebook – Military Diesel KLR

3. Kawasaki – KL650-A HDT Military Diesel KLR

Domain: advrider.com

Registered: 2001 (24 years)

Introduction: 2000 Kawasaki KL650-A HDT Military Diesel KLR; diesel-powered motorcycle; converted to run on diesel, jet fuel, or kerosene; approximately 200 units produced; 30 horsepower; excellent fuel economy; high torque; designed for military use; known for reliability in logistics; last known lowest mileage KLR decommissioned; auctioned by Mecum; previously sold for about $5,000 USD on surplus market; rare…

4. Kawasaki – Utility Vehicles and Motorcycles

Domain: govplanet.com

Registered: 2007 (18 years)

Introduction: Kawasaki equipment for sale includes various models of utility vehicles, motorcycles, and wheel loaders. Key models listed are: 4010, 4010 Mule, 4010 Trans, 85ZV, 95Z, 95ZV2, K20WHA, KRX 1000, MULE 4000 TRANS, Mule PRO-DXT, Mule Pro FX, Mule Pro-FXT, Ninja ZX10R, PRO-DX, and PRO-DXT. Locations include the United States and New Zealand. Equipment is available through auctions, with options for onli…

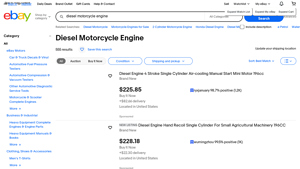

5. Diesel – 196cc Motorcycle Engine

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Diesel Motorcycle Engine details include: 4 Stroke, Single Cylinder, Air-cooling, Manual Start, Mini Motor, 196cc. Prices range from approximately $194.61 to $233.48, with options for ‘Buy It Now’ and ‘Best Offer’. Free delivery is available in 2-4 days, and items are located in the United States with free returns.

Strategic Sourcing Conclusion and Outlook for diesel dirt bike for sale

As the demand for efficient and versatile transportation solutions grows, particularly in regions like Africa, South America, the Middle East, and Europe, the strategic sourcing of diesel dirt bikes presents a unique opportunity for B2B buyers. These motorcycles, exemplified by models like the Kawasaki KLR 650, offer not only robust performance in challenging terrains but also the advantage of running on widely available fuels such as diesel, jet fuel, and kerosene. This capability significantly reduces logistical complexities, especially for industries reliant on extensive supply chains.

Investing in diesel dirt bikes can enhance operational efficiency and reduce fuel costs, making them an attractive option for businesses involved in agriculture, logistics, and military applications. Furthermore, the growing popularity of these bikes among off-road enthusiasts can open new market avenues for distributors and retailers.

Looking ahead, international buyers should prioritize strategic partnerships with manufacturers and distributors to ensure access to quality products and support. By aligning with reliable suppliers, businesses can capitalize on this trend and meet the evolving demands of their markets. Engage in proactive sourcing today to secure a competitive edge in the burgeoning diesel dirt bike segment.