Unlocking Value: A Strategic Analysis of the Ar500 Steel 4X8 Sheet Price Market

Introduction: Navigating the Global Market for ar500 steel 4×8 sheet price

In the dynamic landscape of international trade, sourcing AR500 steel 4×8 sheets presents a unique set of challenges for B2B buyers. This high-strength, abrasion-resistant steel is essential for various applications, including mining, construction, and military equipment. However, navigating the complexities of pricing, quality, and supplier reliability can be daunting, particularly for businesses in regions like Africa, South America, the Middle East, and Europe, such as Nigeria and Saudi Arabia.

This comprehensive guide aims to demystify the AR500 steel 4×8 sheet market by providing detailed insights into the types of AR500 products available, their applications, and the factors influencing pricing. We will explore the nuances of supplier vetting, ensuring that buyers can make informed decisions that align with their specific operational needs and budget constraints. Additionally, the guide will highlight key trends in the global market, offering actionable strategies for negotiating favorable terms and maximizing value.

By equipping international B2B buyers with the knowledge and tools necessary to navigate this competitive landscape, this guide empowers businesses to secure high-quality AR500 steel at competitive prices, ultimately enhancing their supply chain resilience and operational efficiency.

Understanding ar500 steel 4×8 sheet price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AR500 Standard | High hardness, impact toughness, and abrasion resistance. | Mining, construction, armored vehicles. | Pros: Excellent wear resistance. Cons: Higher cost compared to standard steel. |

| AR500F Formable | Formable variant, treated for better welding and forming. | Material handling, custom fabrication. | Pros: Versatile for custom shapes. Cons: Limited availability in some regions. |

| AR500 Plate | Available in various thicknesses, typically 0.25″ to 0.50″. | Heavy-duty equipment, industrial machinery. | Pros: Durable and long-lasting. Cons: Heavier weight may increase shipping costs. |

| AR500 Custom Cut | Tailored dimensions for specific applications. | Specialized industrial applications. | Pros: Exact fit for projects. Cons: Longer lead times for custom orders. |

| AR500 Coil | Coiled form for large-scale applications. | Bulk manufacturing, automotive parts. | Pros: Cost-effective for large volumes. Cons: Requires additional processing for cutting. |

What are the Characteristics of AR500 Standard Steel Sheets?

AR500 Standard steel sheets are known for their exceptional hardness, typically reaching up to 534 BHN. This makes them ideal for high-impact applications, such as mining and construction, where wear resistance is crucial. Buyers should consider the balance between cost and durability, as AR500 tends to be pricier than conventional steel. The investment pays off in longevity and performance, particularly in environments prone to abrasion and impact.

Why Choose AR500F Formable Steel Sheets?

AR500F is a specialized formable variant designed to withstand high wear while allowing for better welding and forming capabilities. This makes it particularly suitable for applications in material handling and custom fabrication. When purchasing, B2B buyers should evaluate the specific requirements of their projects, as AR500F can provide flexibility in design without compromising on strength. However, availability may vary by region, making sourcing a potential challenge.

How Do AR500 Plates Differ from Other Variants?

AR500 plates are available in a range of thicknesses, typically from 0.25″ to 0.50″, making them suitable for heavy-duty applications, including industrial machinery and armored vehicles. Their durability ensures a long service life, but the increased weight can lead to higher shipping costs. Buyers should weigh the benefits of durability against logistical expenses when considering AR500 plates for their projects.

What Are the Advantages of Custom Cut AR500 Steel?

Custom cut AR500 steel sheets offer the advantage of tailored dimensions, ensuring that they fit specific project requirements perfectly. This is particularly beneficial for specialized industrial applications where standard sizes may not suffice. Buyers should be aware that while custom cuts provide a precise fit, they may also involve longer lead times and potential price premiums. Evaluating project timelines is essential when considering this option.

Why Consider AR500 Coil for Large-Scale Applications?

AR500 coil steel is an economical choice for large-scale applications, especially in bulk manufacturing and automotive parts production. Its coiled form allows for easier handling and processing, making it a cost-effective option for high-volume needs. However, buyers must factor in the need for additional processing to cut the coil into usable sheets, which could add time and labor costs. This option is best suited for businesses with ongoing large-scale requirements.

Key Industrial Applications of ar500 steel 4×8 sheet price

| Industry/Sector | Specific Application of ar500 steel 4×8 sheet price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining | Wear plates for heavy machinery and equipment | Extended equipment lifespan and reduced downtime | Ensure local suppliers can provide custom sizes and expedited delivery. |

| Military & Defense | Armor plating for vehicles and protective barriers | Enhanced safety and durability in hostile environments | Verify compliance with international standards for defense materials. |

| Construction | Structural components in high-impact areas | Increased structural integrity and safety | Assess compatibility with local building codes and regulations. |

| Agriculture | Liners and chutes in bulk handling equipment | Improved efficiency and reduced maintenance costs | Look for suppliers who can offer tailored solutions for specific machinery. |

| Oil & Gas | Protective barriers and wear-resistant components | Minimization of equipment failure and operational disruptions | Consider sourcing from suppliers with experience in harsh environments. |

How is AR500 Steel 4×8 Sheet Price Used in Mining Applications?

In the mining industry, AR500 steel 4×8 sheets are primarily utilized as wear plates for heavy machinery. These sheets withstand extreme abrasion from materials like rocks and minerals, significantly extending the lifespan of equipment such as loaders and excavators. This durability translates into reduced downtime and maintenance costs, making it a valuable investment for mining operations. International buyers should prioritize suppliers who can provide custom dimensions and rapid delivery to meet project timelines, especially in remote locations.

What Are the Applications of AR500 Steel in Military and Defense?

AR500 steel is crucial in military and defense sectors, where it is used for armor plating on vehicles and protective barriers. Its high hardness ensures that it can withstand ballistic impacts, providing enhanced safety for personnel in conflict zones. When sourcing AR500 steel for defense applications, buyers must ensure compliance with international standards and certifications, as well as consider the supplier’s ability to deliver in high-stakes environments.

How Does AR500 Steel Benefit Construction Projects?

In construction, AR500 steel 4×8 sheets serve as structural components in high-impact areas, such as bridges and industrial buildings. The material’s superior strength and resistance to wear enhance the overall integrity and safety of structures. Buyers from regions like Africa and South America should evaluate local regulations and building codes to ensure that their sourcing aligns with safety standards, and they should seek suppliers who can provide documentation and certifications for the materials.

What Role Does AR500 Steel Play in Agriculture?

Agriculture professionals use AR500 steel 4×8 sheets for liners and chutes in bulk handling equipment, such as grain silos and feed hoppers. The material’s resistance to wear minimizes the frequency of replacements, leading to lower maintenance costs and improved operational efficiency. When sourcing AR500 steel for agricultural applications, buyers should look for suppliers who can offer customized solutions tailored to specific machinery and operational needs.

How is AR500 Steel Essential for Oil & Gas Operations?

In the oil and gas industry, AR500 steel is utilized for protective barriers and wear-resistant components that endure harsh operational conditions. Its durability helps minimize equipment failures, thereby reducing operational disruptions and costs. International buyers should consider suppliers experienced in providing materials suited for extreme environments, as well as those who can ensure timely delivery to maintain project schedules.

3 Common User Pain Points for ‘ar500 steel 4×8 sheet price’ & Their Solutions

Scenario 1: Difficulty in Comparing Prices Across Suppliers

The Problem: B2B buyers often find themselves overwhelmed by the lack of standardized pricing for AR500 steel 4×8 sheets. Different suppliers might quote vastly different prices, which can lead to confusion and frustration. Without a clear understanding of what constitutes a fair price, buyers may worry about overpaying or compromising on quality. This issue is particularly pronounced in international markets where shipping costs and tariffs can further complicate the pricing landscape.

The Solution: To navigate this pricing dilemma, B2B buyers should conduct thorough market research to establish a baseline for AR500 steel prices. Start by reaching out to multiple suppliers to request quotes, ensuring to specify the exact specifications needed (thickness, finish, and any custom cuts). Additionally, leverage online platforms and forums where industry professionals discuss pricing trends. Compare these quotes against industry standards published by organizations or trade associations. Once you have a range of prices, it will be easier to identify outliers and negotiate better deals. Don’t forget to factor in shipping costs and delivery timelines when making your comparisons to ensure a holistic view of the total price.

Scenario 2: Uncertainty About Material Specifications and Quality

The Problem: Another common pain point for B2B buyers is the uncertainty surrounding the material specifications of AR500 steel. Buyers may struggle to understand the differences between various grades and forms of AR500 steel, which can lead to mispurchases. For instance, choosing a non-formable version when a formable variant is required can result in significant operational setbacks, including delays and increased costs.

The Solution: To alleviate this concern, buyers should invest time in understanding the technical specifications of AR500 steel. Familiarize yourself with the terminology and standards related to hardness, thickness, and treatment processes. Request Material Test Reports (MTRs) from suppliers to verify the specifications and ensure that the steel meets the required standards for your application. Additionally, consider collaborating with a metallurgical engineer or a trusted consultant who can provide insights tailored to your specific needs. By establishing a clear set of requirements and validating supplier claims, buyers can confidently procure the right material for their projects.

Scenario 3: Challenges in Timely Delivery and Logistics Management

The Problem: Timeliness in delivery can pose a significant challenge for B2B buyers, especially when sourcing AR500 steel from international suppliers. Delays in shipping can disrupt project timelines and lead to increased costs, particularly for industries like construction or manufacturing that rely on just-in-time inventory practices. Buyers may also face difficulties in tracking shipments and managing logistics, leading to uncertainty about when materials will arrive.

The Solution: To mitigate delivery challenges, B2B buyers should establish clear logistics protocols with their suppliers from the outset. Prioritize suppliers who offer reliable shipping options and have a proven track record of on-time deliveries. Utilize freight forwarding services that specialize in international shipping to streamline the process and maintain visibility on your shipments. Additionally, incorporate buffer time into your project schedules to account for potential delays. Regular communication with suppliers and freight forwarders can also help track shipments more effectively and address issues before they escalate. By proactively managing logistics, buyers can reduce the risk of delays and keep projects on track.

Strategic Material Selection Guide for ar500 steel 4×8 sheet price

What Are the Key Properties of AR500 Steel for B2B Applications?

AR500 steel is recognized for its exceptional hardness, typically rated at 500 BHN (Brinell Hardness Number), making it highly resistant to wear and impact. This material is engineered for high-performance applications, particularly in environments where abrasion is a primary concern, such as mining, construction, and military uses. Its high carbon content contributes to its strength and durability, while the alloying elements enhance its toughness, allowing it to withstand heavy impacts without fracturing.

What Are the Advantages and Disadvantages of Using AR500 Steel?

Pros: The primary advantage of AR500 steel is its durability. It can endure extreme wear and tear, making it ideal for heavy-duty applications. Its ability to be custom cut to various dimensions allows for flexibility in manufacturing processes. Additionally, AR500 steel is often more cost-effective than other high-strength materials, especially when considering its longevity and reduced maintenance needs.

Cons: However, AR500 steel does have limitations. Its high hardness can make it more challenging to weld compared to softer steels, requiring specialized techniques and equipment. Furthermore, while it offers good corrosion resistance, it is not entirely immune to rust, particularly in humid or corrosive environments. International buyers should also be aware of the need for compliance with local standards and regulations, which can vary significantly across regions.

How Does AR500 Steel Impact Specific Applications?

AR500 steel is particularly suited for applications involving high-impact and abrasive environments. For example, in mining equipment, its hardness reduces wear from rocks and minerals, extending the life of machinery. In military applications, it is used for armor plating due to its ability to absorb and dissipate energy from ballistic impacts. However, buyers must consider the specific media compatibility and environmental conditions of their applications, such as exposure to chemicals or extreme temperatures.

What Should International B2B Buyers Consider When Sourcing AR500 Steel?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several factors are crucial. Compliance with international standards such as ASTM, DIN, or JIS is essential for ensuring product quality and safety. Additionally, understanding local market dynamics, including import tariffs and shipping logistics, can significantly impact the total cost of acquisition. Buyers should also consider the availability of local suppliers and the potential for expedited shipping options to reduce lead times.

Summary of Material Selection for AR500 Steel 4×8 Sheet Pricing

| Material | Typical Use Case for ar500 steel 4×8 sheet price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| AR500 Steel | Armor plating, mining equipment, industrial machinery | Exceptional hardness and wear resistance | Difficult to weld; potential for rust | Medium |

| AR500F Steel | Formable applications in mining and material handling | Enhanced formability and weldability | Limited to specific applications; higher cost than standard steel | Medium-High |

| AR450 Steel | General industrial applications requiring moderate abrasion resistance | Good balance of hardness and toughness | Less wear-resistant than AR500 | Medium |

| AR600 Steel | Heavy-duty applications requiring maximum wear resistance | Superior hardness for extreme conditions | More brittle; limited formability | High |

This analysis provides a comprehensive overview of AR500 steel’s properties, advantages, and considerations for international B2B buyers. Understanding these factors is crucial for making informed purchasing decisions that align with specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for ar500 steel 4×8 sheet price

What Are the Key Stages in the Manufacturing Process of AR500 Steel Sheets?

The manufacturing of AR500 steel sheets involves several critical stages that ensure the final product meets high-performance standards.

Material Preparation: What Steps Are Involved?

The process begins with the selection of high-quality raw materials, primarily high-carbon steel alloys, known for their strength and hardness. During material preparation, steel slabs are often subjected to heat treatment to enhance their properties before they undergo forming. This initial stage is crucial, as the quality of the raw material directly impacts the durability and performance of the finished product.

How Is AR500 Steel Formed?

Forming is a pivotal phase in the manufacturing process. The steel slabs are heated and then processed through various techniques such as rolling or forging to achieve the desired thickness and dimensions. For AR500 sheets, the typical thickness is around 0.25 to 0.5 inches. Precision in this stage is vital, as any deviation can lead to subpar performance in applications requiring high wear resistance.

What Is Involved in the Assembly and Finishing of AR500 Steel Sheets?

After forming, the sheets are assembled and subjected to finishing processes. This may include cutting to size, grinding, and surface treatment to achieve the desired finish and enhance corrosion resistance. The final product is typically available in standard dimensions like 4×8 feet, making it suitable for various applications, including armored vehicles and industrial machinery.

How Is Quality Assurance Ensured in AR500 Steel Production?

Ensuring the quality of AR500 steel sheets is paramount, particularly for B2B buyers who rely on the durability and performance of these materials.

What International Standards Govern AR500 Steel Quality?

Manufacturers of AR500 steel sheets often adhere to international quality standards, such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates that the manufacturer has established processes to ensure consistent quality in their products. Additionally, industry-specific certifications such as CE (Conformité Européenne) or API (American Petroleum Institute) can further validate the quality of the steel for specific applications.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is a multi-faceted process that includes several checkpoints throughout the manufacturing stages:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor parameters such as thickness, hardness, and dimensional accuracy.

- Final Quality Control (FQC): Once the sheets are finished, they undergo a thorough inspection to verify that they meet all specifications before shipping.

What Testing Methods Are Commonly Used to Ensure AR500 Steel Quality?

Various testing methods are employed to assess the mechanical properties and durability of AR500 steel sheets. These include:

- Hardness Testing: Typically performed using the Brinell or Rockwell methods to determine surface hardness, which is crucial for wear resistance.

- Tensile Testing: Measures the steel’s strength and ductility to ensure it can withstand heavy forces without fracturing.

- Impact Testing: Evaluates the material’s toughness and its ability to absorb energy during sudden impacts.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier QC is essential. Here are several strategies:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures in place.

- Requesting Quality Reports: Suppliers should provide documentation of their quality control processes and testing results, which can be reviewed for compliance with international standards.

- Third-party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the product quality and adherence to specifications.

What Are the Quality Certification Nuances for International B2B Buyers?

Navigating the complexities of quality certification can be challenging for international B2B buyers. Understanding the specific certifications relevant to AR500 steel sheets in different regions is crucial. For example, European buyers may prioritize CE marking, while those in the Middle East might require compliance with local standards.

Moreover, it’s important for buyers to recognize that certifications may vary in terms of their recognition and acceptance across different countries. Thus, establishing a clear communication channel with suppliers regarding certification requirements can mitigate potential issues related to product quality and compliance.

Conclusion: Why Is Quality Assurance Crucial for AR500 Steel Sheets?

In summary, the manufacturing process and quality assurance of AR500 steel sheets are critical for ensuring the product’s performance in demanding applications. B2B buyers must thoroughly understand the manufacturing stages, quality control measures, and testing methods to make informed purchasing decisions. By verifying supplier quality through audits and certifications, buyers can ensure that they receive high-quality materials that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ar500 steel 4×8 sheet price’

This guide aims to provide international B2B buyers with a clear and actionable checklist for sourcing AR500 steel 4×8 sheets. Understanding the nuances of procurement in this specialized market is crucial for ensuring quality and cost-effectiveness.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for AR500 steel sheets. Consider factors such as thickness, size, and specific grades needed for your application. This clarity will help you communicate effectively with potential suppliers and ensure you receive accurate quotes.

Step 2: Research Market Pricing Trends

Understanding current market prices is essential for negotiating effectively. Research various suppliers to gauge the price range for AR500 steel 4×8 sheets. Factors such as thickness, supplier location, and market demand can significantly influence pricing. Utilize online platforms and industry reports to get a comprehensive view.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Verify their experience with AR500 steel and ensure they have a reputation for quality and reliability.

- Check Certifications: Confirm that suppliers meet industry standards and possess necessary certifications, such as ISO 9001.

- Review Customer Feedback: Look for testimonials or reviews to gauge customer satisfaction.

Step 4: Request Detailed Quotes

Once you have identified potential suppliers, request detailed quotations that include pricing, lead times, and shipping options. Ensure that the quotes break down costs for the sheets, any additional services (like custom cutting), and shipping fees. This transparency will aid in comparing suppliers effectively.

Step 5: Assess Shipping and Delivery Options

Evaluate the shipping and delivery options provided by your potential suppliers. Consider the estimated lead times and shipping costs, especially for international shipments. Some suppliers may offer expedited shipping, which could be beneficial depending on your project timelines.

- Customs Considerations: Be aware of any customs duties or tariffs that may apply when importing steel sheets into your region.

Step 6: Negotiate Payment Terms

Discuss payment terms with your selected supplier before finalizing the order. Flexible payment options can help manage cash flow effectively. Options may include partial payments upfront, letters of credit, or payment upon delivery.

Step 7: Finalize the Order and Confirm Details

Once you have selected a supplier, finalize the order by confirming all details in writing. This should include specifications, prices, delivery dates, and payment terms. Having everything documented helps prevent misunderstandings and ensures accountability on both sides.

By following this checklist, B2B buyers can streamline the procurement process for AR500 steel 4×8 sheets, ensuring they receive quality materials at competitive prices.

Comprehensive Cost and Pricing Analysis for ar500 steel 4×8 sheet price Sourcing

What Are the Key Cost Components in AR500 Steel Pricing?

When sourcing AR500 steel sheets, particularly the 4×8 size, several cost components come into play. The primary factors include material costs, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The cost of raw steel is a significant portion of the total price. AR500 steel is valued for its high hardness and wear resistance, which contributes to its higher material costs compared to standard carbon steels.

-

Labor: Labor costs are incurred during the cutting, shaping, and finishing processes. These costs can vary based on the complexity of the order and the skill level required.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: Custom tooling may be necessary for specific orders, affecting the overall cost. Investment in advanced tooling can enhance precision but may require significant upfront costs.

-

Quality Control: Ensuring that the AR500 sheets meet specified standards incurs additional costs. Certifications and testing contribute to the overall price but are crucial for maintaining quality and reliability.

-

Logistics: Transportation costs vary significantly based on the distance from the supplier and the mode of shipping. For international buyers, understanding these costs is vital for accurate budgeting.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure business viability. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect AR500 Steel Sheet Costs?

Several factors influence the pricing of AR500 steel sheets, particularly for international buyers:

-

Volume/MOQ: Purchasing in larger quantities can lead to significant discounts. Suppliers often have minimum order quantities (MOQs), and exceeding these can yield better pricing.

-

Specifications and Customization: Custom dimensions or specific hardness requirements can increase the cost. Buyers should be clear about their specifications to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher quality materials or specific certifications (like ISO or ASTM) can increase the price. These certifications often ensure compliance with industry standards, which is crucial for certain applications.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding the agreed terms of delivery (like FOB, CIF, or EXW) can impact the overall cost. These terms define who is responsible for shipping, insurance, and tariffs, which is especially important for international transactions.

What Tips Can Help Buyers Negotiate Better Prices for AR500 Steel?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, can adopt several strategies to enhance cost efficiency:

-

Negotiate Pricing: Establishing a good relationship with suppliers can lead to better pricing and terms. Don’t hesitate to ask for discounts based on order size or long-term contracts.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost of ownership, including shipping, handling, and potential tariffs. This holistic view can lead to smarter purchasing decisions.

-

Understand Pricing Nuances: Familiarize yourself with local market conditions and pricing trends for AR500 steel. Awareness of fluctuations can provide leverage in negotiations.

-

Compare Suppliers: Solicit quotes from multiple suppliers to understand the market range. This comparison can help in negotiating better terms and ensuring you’re getting a competitive price.

-

Leverage Local Partnerships: Establish relationships with local distributors or agents who understand the market dynamics and can assist in navigating logistics and customs processes.

Conclusion

While sourcing AR500 steel sheets involves various cost components and price influencers, B2B buyers can optimize their purchasing strategies through informed negotiations and a comprehensive understanding of the total cost of ownership. By leveraging these insights, international buyers can secure competitive pricing and ensure quality in their procurement processes.

Disclaimer: Prices mentioned are indicative and subject to change based on market conditions and supplier policies.

Alternatives Analysis: Comparing ar500 steel 4×8 sheet price With Other Solutions

When evaluating the price of AR500 steel 4×8 sheets, it’s crucial for B2B buyers to consider viable alternatives that can meet their specific needs while potentially offering cost savings or enhanced performance. Below is a comparative analysis of AR500 steel against two alternative solutions: AR400 steel sheets and UHMW (Ultra-High Molecular Weight Polyethylene) panels. This analysis will help buyers make informed decisions based on their operational requirements.

| Comparison Aspect | Ar500 Steel 4X8 Sheet Price | AR400 Steel Sheets | UHMW Panels |

|---|---|---|---|

| Performance | High hardness (up to 534 BHN), excellent wear resistance, suitable for heavy impact | Lower hardness (400 BHN), good for moderate wear applications | Excellent abrasion resistance, lightweight, impact-resistant |

| Cost | Approximately $300-$600 per sheet, depending on thickness and supplier | Typically $250-$500 per sheet, depending on thickness and supplier | Generally $150-$350 per panel, depending on size and supplier |

| Ease of Implementation | Requires cutting and welding expertise | Easier to handle and weld compared to AR500 | Simple to install, no welding needed |

| Maintenance | Low maintenance, but may require surface treatment for corrosive environments | Low maintenance, similar to AR500 | Minimal maintenance, resistant to chemicals and moisture |

| Best Use Case | Ideal for armored applications, mining equipment, and heavy-duty machinery | Suitable for less severe wear applications, like chutes and hoppers | Best for applications requiring low friction and lightweight properties, such as conveyor systems |

What Are the Advantages and Disadvantages of AR400 Steel Sheets Compared to AR500 Steel?

AR400 steel is a viable alternative for applications where extreme hardness is not essential. With a hardness of 400 BHN, AR400 steel is easier to fabricate and weld, making it a more user-friendly option for some projects. Its cost is generally lower than that of AR500, which can be a significant consideration for budget-conscious buyers. However, it may not provide the same level of wear resistance and longevity under extreme conditions, making it less suitable for high-impact applications.

How Does UHMW Compare to AR500 Steel Sheets in Performance and Cost?

UHMW panels offer a lightweight alternative to steel, known for their excellent abrasion resistance and impact resistance. They are particularly effective in applications where weight reduction is essential, such as in conveyor systems or material handling. The cost of UHMW is generally lower than AR500, providing a cost-effective solution for many industries. However, UHMW panels may not withstand the same level of heat or heavy impact as AR500 steel, limiting their use in certain high-stress environments.

How Can B2B Buyers Choose the Right Material for Their Needs?

Selecting the appropriate material depends on various factors, including the specific application, budget constraints, and performance requirements. For applications requiring extreme durability and high impact resistance, AR500 steel remains a top choice. Conversely, if the application demands ease of installation and moderate wear resistance, AR400 steel may be more suitable. For projects prioritizing weight reduction and cost-effectiveness, UHMW panels could be the best fit. Buyers should carefully evaluate their operational needs and consult with material experts to make the most informed decision.

Essential Technical Properties and Trade Terminology for ar500 steel 4×8 sheet price

What Are the Key Technical Properties of AR500 Steel 4×8 Sheets?

When considering AR500 steel sheets, particularly in the 4×8 size, several technical properties are essential for B2B buyers to understand. These specifications determine the material’s performance in various applications and influence pricing and sourcing decisions.

-

Material Grade: AR500 is a high-carbon alloy steel known for its exceptional hardness and wear resistance, with a Brinell hardness number (BHN) of 500 or greater. This characteristic makes it ideal for applications requiring high abrasion resistance, such as mining equipment and armored vehicles. Understanding the grade helps buyers assess its suitability for specific industrial needs.

-

Thickness: AR500 sheets are available in various thicknesses, typically ranging from 0.119 inches to 1 inch or more. The thickness impacts the sheet’s strength and weight, influencing both transportation costs and structural integrity in end-use applications. B2B buyers should select thickness based on the operational demands of their projects.

-

Dimensions: Standard dimensions for AR500 sheets, such as the common 4×8 size, are critical for compatibility with existing designs and machinery. Custom sizes may also be available, allowing for tailored solutions. Knowing the dimensions helps in estimating material usage and minimizing waste.

-

Tolerances: Tolerances refer to the allowable variations in dimensions and properties of the steel sheets. For AR500, precise tolerances ensure that the sheets fit correctly in their intended applications. Tighter tolerances can lead to higher costs but may be necessary for critical applications.

-

Weight: The weight of AR500 steel sheets is influenced by their thickness and dimensions. Understanding the weight is essential for logistical planning, as heavier sheets may incur higher shipping costs and require specialized handling equipment.

-

Formability and Weldability: While AR500 is primarily known for its hardness, certain variants (like AR500F) are designed to be more formable and easier to weld. This property is particularly important for buyers in industries that require customization and fabrication of the steel sheets.

What Are Common Trade Terms Associated with AR500 Steel Pricing?

Navigating the procurement of AR500 steel sheets involves familiarizing oneself with industry-specific terminology. Understanding these terms can streamline communication and improve negotiation outcomes.

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For AR500 sheets, OEMs might be involved in creating protective equipment or machinery that requires high-strength steel components.

-

MOQ (Minimum Order Quantity): MOQ specifies the smallest number of units a supplier is willing to sell. Understanding the MOQ is crucial for B2B buyers, as it can affect inventory management and budgeting, especially for smaller companies or those with limited immediate needs.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and terms for specific quantities of materials. For AR500 steel sheets, an RFQ can help buyers compare prices and terms from different suppliers, leading to better purchasing decisions.

-

Incoterms: International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in international shipping. Familiarity with Incoterms is vital for B2B transactions involving AR500 steel, as they dictate shipping costs, insurance, and liability during transit.

-

Lead Time: This term refers to the time it takes from placing an order to receiving the goods. For AR500 steel sheets, understanding lead times is important for project planning and ensuring timely delivery, especially in industries with tight schedules.

-

Custom Cuts: Many suppliers offer the option for custom cuts, allowing buyers to specify dimensions that suit their project requirements. This flexibility can reduce waste and enhance efficiency in material use, making it an attractive option for many B2B buyers.

In summary, understanding both the technical properties of AR500 steel sheets and the associated trade terminology is essential for making informed purchasing decisions. This knowledge not only aids in selecting the right materials but also enhances communication with suppliers and improves overall procurement efficiency.

Navigating Market Dynamics and Sourcing Trends in the ar500 steel 4×8 sheet price Sector

What Are the Key Market Dynamics Influencing AR500 Steel 4×8 Sheet Pricing?

The global market for AR500 steel sheets is primarily driven by the increasing demand for high-strength, abrasion-resistant materials across various industries, including mining, construction, and defense. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe look for robust solutions to withstand extreme wear, AR500 steel has emerged as a preferred choice. The ongoing urbanization and industrialization in these regions have amplified the demand for durable materials, thus influencing pricing trends.

Emerging technologies in sourcing, such as automated procurement systems and online marketplaces, are reshaping the purchasing landscape. These platforms facilitate quick comparisons of prices and supplier capabilities, enabling buyers to make informed decisions efficiently. Additionally, the rise of digital supply chain management tools allows for improved visibility and traceability of materials, which is crucial for buyers concerned about compliance and quality.

In terms of market dynamics, fluctuating raw material costs, geopolitical tensions, and trade policies significantly impact AR500 steel pricing. For example, tariffs on steel imports can lead to increased costs for buyers in certain regions, while currency fluctuations can affect pricing competitiveness. B2B buyers must remain agile in adapting their sourcing strategies to navigate these complexities effectively.

How Is Sustainability and Ethical Sourcing Shaping the AR500 Steel Market?

Sustainability is becoming increasingly important in the B2B landscape, with buyers prioritizing ethical sourcing practices and environmentally friendly materials. For AR500 steel, this translates into a growing demand for suppliers that adhere to sustainable production methods and possess certifications that demonstrate their commitment to reducing environmental impact.

The environmental concerns associated with steel production, such as carbon emissions and resource depletion, have prompted many companies to explore greener alternatives and processes. Buyers are now seeking AR500 steel from suppliers who can showcase their sustainability efforts, such as using recycled materials or adopting energy-efficient manufacturing techniques. Green certifications, such as ISO 14001, are becoming vital for suppliers aiming to attract environmentally conscious buyers.

Moreover, the push for ethical sourcing extends to labor practices within the supply chain. B2B buyers are increasingly scrutinizing their suppliers to ensure fair labor practices and responsible sourcing of raw materials. This trend not only enhances brand reputation but also aligns with the corporate social responsibility goals of many organizations.

What Is the Historical Context of AR500 Steel and Its Evolution in the Market?

The evolution of AR500 steel can be traced back to the need for high-performance materials capable of withstanding extreme conditions. Initially developed for military applications, AR500 steel has expanded into various sectors, including construction and mining, due to its exceptional hardness and durability.

Over the years, advancements in metallurgical processes have enhanced the properties of AR500 steel, making it more versatile and accessible to a broader range of industries. The introduction of various thicknesses and custom-cut options has further facilitated its use in specialized applications, catering to the unique needs of B2B buyers.

Today, AR500 steel is recognized not only for its strength and resistance to abrasion but also for its adaptability in diverse environments. As industries continue to evolve, the demand for AR500 steel is expected to grow, making it a significant player in the global steel market.

Frequently Asked Questions (FAQs) for B2B Buyers of ar500 steel 4×8 sheet price

-

How do I find reliable suppliers for AR500 steel 4×8 sheets?

Finding reliable suppliers involves thorough research and vetting processes. Start by seeking recommendations from industry contacts or utilizing platforms like Alibaba and ThomasNet. Evaluate potential suppliers based on their certifications, production capacity, and customer reviews. Request samples to assess material quality and verify their adherence to international standards. Establish communication to gauge responsiveness and willingness to customize your orders. Ensure they have a solid logistics plan for international shipping, especially if you’re sourcing from regions like Africa, South America, or the Middle East. -

What are the typical prices for AR500 steel 4×8 sheets?

Prices for AR500 steel 4×8 sheets can vary significantly based on thickness, supplier, and market conditions. Generally, you can expect prices to range from $250 to $600 per sheet, depending on the specifications. Keep in mind that additional costs may arise from customization, shipping, and import duties. To secure the best deal, consider obtaining quotes from multiple suppliers and compare their offerings. Staying updated on market trends can also help you anticipate price fluctuations. -

What factors influence the pricing of AR500 steel sheets?

Several factors influence the pricing of AR500 steel sheets, including raw material costs, production processes, and shipping expenses. Market demand and supply dynamics can lead to price fluctuations, particularly in international trade. Additionally, customization options such as cut sizes or additional treatments can impact the overall cost. Currency exchange rates may also play a role if you’re importing from different countries. It’s essential to factor in these elements when budgeting for your purchase. -

What is the minimum order quantity (MOQ) for AR500 steel sheets?

Minimum order quantities for AR500 steel sheets can vary by supplier. Typically, many manufacturers set an MOQ ranging from 1 to 5 sheets for standard sizes. However, if you’re looking for customized orders or larger quantities, some suppliers may require a higher MOQ. It’s advisable to clarify these details during your initial discussions with potential suppliers to avoid unexpected costs or delays. Additionally, negotiating terms can sometimes lead to lower MOQs, especially for long-term partnerships. -

Can I customize the thickness and dimensions of AR500 steel sheets?

Yes, most suppliers offer customization options for AR500 steel sheets, allowing you to specify desired thicknesses and dimensions. Common thicknesses range from 0.119 inches to 2 inches, but suppliers may accommodate your specific requirements. Custom cutting services are often available, and it’s essential to communicate your needs clearly to ensure accuracy. Be aware that customized orders may have longer lead times and additional costs, so factor this into your planning. -

What payment terms should I expect when purchasing AR500 steel?

Payment terms can vary by supplier but typically include options such as advance payments, net 30, or net 60 days. For international transactions, expect to use methods like bank transfers, letters of credit, or secure payment platforms. It’s crucial to discuss and agree upon payment terms before finalizing your order to avoid misunderstandings. Ensure that the supplier provides a pro forma invoice detailing costs, shipping, and terms to protect your interests. -

How do I ensure quality assurance for my AR500 steel sheets?

To ensure quality assurance, request certifications and quality control documentation from your supplier. Many reputable manufacturers adhere to industry standards, such as ISO certifications, which can provide assurance of material integrity. Additionally, consider conducting independent inspections or requiring third-party testing for large orders. Establishing a clear agreement on quality expectations before the order is placed can help mitigate risks associated with subpar materials. -

What are the logistics considerations for importing AR500 steel sheets?

When importing AR500 steel sheets, consider factors such as shipping methods, customs regulations, and potential tariffs. Work with suppliers who have experience in international shipping to ensure compliance with local laws and efficient delivery. It’s vital to account for lead times and potential delays at customs, particularly in regions like Africa or the Middle East. Collaborating with a freight forwarder can also simplify the logistics process, helping you navigate the complexities of international trade.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Ar500 Steel 4X8 Sheet Price Manufacturers & Suppliers List

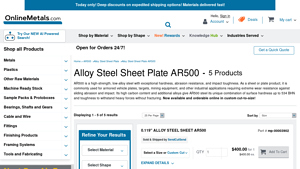

1. Online Metals – AR500 Steel Sheet/Plate

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: AR500 Steel Sheet/Plate – Thickness: 0.119 inches, High-strength low-alloy steel, Exceptional hardness (up to 534 BHN), Abrasion resistance, Impact toughness, Common applications: armored vehicle plates, targets, mining equipment, Industrial use requiring extreme wear resistance, Custom cut-to-size available, Ships in 2-3 business days, Price: $400.00 for 1, Made in the USA, DFARS compliant, Mill …

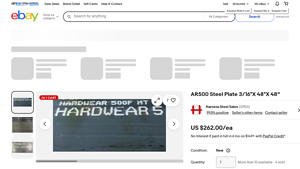

2. Harness Steel – AR500 Steel Plate

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “AR500 Steel Plate”, “Thickness”: “3/16 inch”, “Dimensions”: “48 x 48 inches”, “Condition”: “New”, “Price”: “$262.00 each”, “Shipping Cost”: “$353.50”, “Estimated Delivery”: “Wed, Sep 10 – Tue, Sep 16”, “Seller”: “Harness Steel Sales”, “Seller Feedback”: “99.5% positive feedback”, “Bulk Savings”: {“1”: “$262.00”, “2”: “$248.90”, “3”: “$235.80”, “4”: “$230.56”, “5”: “$230.56”, “6”:…

3. Sniper’s Hide – AR500 Steel Sheets

Domain: snipershide.com

Registered: 2000 (25 years)

Introduction: 4’x8′ sheet AR500; thickness: 3/8 inch; weight: approximately 15 pounds per square foot; local suppliers may offer different pricing; larger sheets available (8’x20′); potential for custom cuts from larger sheets; prices discussed in a community forum context.

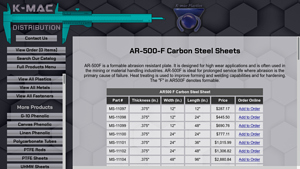

4. KMAC – AR500 Carbon Steel Plates

Domain: kmac-distribution.com

Registered: 2006 (19 years)

Introduction: AR500 Carbon Steel Plates and Sheets, Thickness: .187 to 1.00 in, Formable abrasion resistant plate, Designed for high wear applications, Ideal for mining or material handling industries, Heat treated for improved forming and welding capabilities, Part numbers and pricing for various dimensions available.

5. Steel Warehouse – AR500 Steel

Domain: steelwarehouse.com

Registered: 1997 (28 years)

Introduction: AR500 Steel is a type of abrasion resistant steel with a surface hardness of 477-534 BHN. It is a high-carbon steel alloy that offers greater impact and sliding abrasion resistance compared to other types of AR steel. AR500 is less malleable, making it less weldable and formable. Steel Warehouse supplies AR500 in thicknesses ranging from .25″ to 2.00″ with widths of 48″ to 65″ and standard sizes o…

6. DM Steel – Hot Rolled AR500 Plate 3/8

Domain: dmsteel.com

Registered: 2006 (19 years)

Introduction: Hot Rolled Abrasion Resistant AR500 Plate 3/8″

7. SE Steel Pipe – AR500 Steel

Domain: sesteelpipe.com

Registered: 2018 (7 years)

Introduction: AR500 steel is a reliable and durable material widely used in construction, manufacturing, and automotive industries. The cost of AR500 steel ranges from $20 to $50 per pound, depending on thickness and size. A common size, the 4×8 sheet of AR500 steel, costs between $150 and $300, influenced by thickness and supplier. Factors affecting the cost include supplier, location, thickness, and size. Tip…

8. Integrity MFG – Abrasion Resistant Steel Plates

Domain: integritymfgllc.com

Registered: 2012 (13 years)

Introduction: Abrasion Resistant Steel Plates, Weight: 180 kg, Product Code: Abrasion 1076361

9. Metals USA – Steel Plate Solutions

Domain: metalsusa.com

Registered: 1997 (28 years)

Introduction: Metals USA offers a variety of steel plate and sheet products including: 1. ASTM A36 Steel Plate – 36,000 PSI minimum yield strength, used in construction projects. 2. ASTM A572 Steel Plate – High strength low alloy steel with 50 ksi yield strength and 65 ksi tensile strength. 3. ASTM A516 PVQ Plate – Pressure vessel quality steel for high pressure applications. 4. High Strength Low Alloy Steel Pl…

Strategic Sourcing Conclusion and Outlook for ar500 steel 4×8 sheet price

How Can Strategic Sourcing Enhance Your AR500 Steel Procurement?

In conclusion, the pricing landscape for AR500 steel 4×8 sheets reflects a complex interplay of demand, supply chain dynamics, and market fluctuations. International B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe, should prioritize strategic sourcing to ensure they secure competitive pricing and high-quality materials. By leveraging relationships with trusted suppliers and understanding regional market trends, businesses can mitigate risks associated with price volatility and supply disruptions.

The value of strategic sourcing lies not only in cost savings but also in establishing reliable partnerships that enhance procurement efficiency. As industries increasingly demand durable materials for applications like mining and construction, positioning your company to navigate these challenges will be crucial.

Looking ahead, staying informed about market trends, technological advancements, and geopolitical factors will empower buyers to make informed decisions. Embrace the opportunity to refine your sourcing strategies and consider engaging with suppliers who offer customization and expedited shipping options to meet your specific needs. Your proactive approach today can lead to a more resilient supply chain tomorrow.