Top 7 Mini Graders For Sale Suppliers (And How to Choose)

Introduction: Navigating the Global Market for mini graders for sale

Navigating the global market for mini graders for sale can pose significant challenges for B2B buyers, particularly in identifying reliable suppliers and understanding the various models available. As construction projects demand precision and efficiency, sourcing the right mini grader becomes crucial for ensuring optimal performance on job sites across diverse terrains. This guide provides a comprehensive overview of mini graders, covering essential aspects such as types, applications, supplier vetting processes, and cost considerations.

By delving into the specifications and functionalities of various mini graders, this resource empowers international B2B buyers—especially those from Africa, South America, the Middle East, and Europe, including Germany and Saudi Arabia—to make informed purchasing decisions. Whether you are looking for equipment suited for road construction, landscaping, or earthmoving, this guide highlights the most suitable options available in the market.

Additionally, understanding the nuances of the global supply chain, including factors like import regulations and local market trends, will enhance your procurement strategy. With actionable insights and expert recommendations, this guide aims to equip you with the knowledge needed to navigate the complexities of the mini grader market, ensuring your projects are completed on time and within budget.

Understanding mini graders for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compact Mini Graders | Smaller size, typically under 10,000 lbs, versatile blade | Residential grading, landscaping | Pros: Easy maneuverability, lower cost. Cons: Limited power for large projects. |

| Standard Mini Graders | Mid-range size, 10,000 – 20,000 lbs, powerful engines | Road maintenance, small construction jobs | Pros: Good balance of power and size. Cons: Can be less efficient in tight spaces. |

| All-Terrain Mini Graders | Enhanced traction, adjustable blade angles, rugged design | Mining, forestry, remote site projects | Pros: Excellent performance in rough terrain. Cons: Higher initial investment. |

| Electric Mini Graders | Battery-powered, low emissions, quieter operation | Urban construction, eco-friendly projects | Pros: Reduced environmental impact, lower operating costs. Cons: Limited range and power. |

| Specialty Mini Graders | Custom attachments for specific tasks (e.g., snow removal) | Niche applications like snow removal | Pros: Versatile for specific tasks. Cons: May require additional training for operators. |

What Are the Characteristics of Compact Mini Graders?

Compact mini graders are designed for smaller jobs where maneuverability is essential. Weighing less than 10,000 lbs, these machines are perfect for residential grading and landscaping projects. Their smaller size allows them to operate in tight spaces, making them ideal for urban environments. When purchasing, buyers should consider the machine’s power relative to their specific grading needs, as these models may struggle with larger projects.

How Do Standard Mini Graders Fit into B2B Applications?

Standard mini graders, ranging from 10,000 to 20,000 lbs, strike a balance between power and versatility. They are commonly used in road maintenance and small construction jobs, offering a robust solution for various grading tasks. Buyers should assess their project requirements to ensure the grader’s power aligns with the demands of the work, as these machines can efficiently handle moderate-sized projects while still being manageable in tighter areas.

What Makes All-Terrain Mini Graders Unique?

All-terrain mini graders are built to tackle challenging environments, featuring enhanced traction and adjustable blade angles. These machines are often utilized in mining, forestry, and remote site projects where traditional graders may falter. For B2B buyers, the investment in an all-terrain model pays off in terms of performance and durability in rugged conditions, although the initial cost may be higher compared to standard models.

Why Consider Electric Mini Graders for Urban Projects?

Electric mini graders are becoming increasingly popular in urban construction due to their low emissions and quieter operation. These battery-powered machines are ideal for eco-friendly projects where environmental impact is a concern. However, buyers should evaluate the range and power limitations of electric models, particularly for larger projects, to ensure they meet operational needs without compromising efficiency.

What Are the Benefits of Specialty Mini Graders?

Specialty mini graders come equipped with custom attachments designed for specific tasks, such as snow removal or trenching. These machines are particularly valuable in niche applications where versatility is required. Buyers should consider the additional training that operators may need to effectively use these specialized features, but the investment can yield significant returns in productivity for targeted projects.

Key Industrial Applications of mini graders for sale

| Industry/Sector | Specific Application of mini graders for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Site preparation and grading for foundations | Ensures stable and level foundations, reducing future repair costs | Assess machine specifications for terrain adaptability and size constraints. |

| Road Maintenance | Resurfacing and repairing roadways | Enhances road safety and longevity, minimizing disruptions | Check for attachments like scarifiers for efficient material removal. |

| Agriculture | Land leveling and soil preparation | Increases crop yield by providing optimal planting conditions | Evaluate engine power and blade versatility for varying soil types. |

| Mining | Grading access roads and site leveling | Improves transport efficiency and site accessibility | Consider durability and maintenance support for harsh environments. |

| Landscaping | Creating contours and slopes for aesthetic designs | Enhances property value and design appeal | Look for compact models suitable for tight spaces and maneuverability. |

How Are Mini Graders Used in the Construction Sector?

In the construction industry, mini graders are vital for site preparation and grading, particularly for foundations and roadworks. They efficiently level the ground and create smooth surfaces, which are essential for building stability. By utilizing mini graders, construction firms can reduce the likelihood of future structural issues caused by uneven ground. International buyers from regions like Africa and South America should focus on sourcing models that can handle varied terrain, ensuring they meet local project requirements.

What Role Do Mini Graders Play in Road Maintenance?

Mini graders are indispensable in road maintenance, where they are employed for resurfacing and repairing existing roadways. Their precision in grading helps maintain smooth surfaces, enhancing safety for vehicles and pedestrians alike. This application is particularly relevant in regions with fluctuating weather patterns, as proper maintenance can mitigate damage from elements like rain and snow. Buyers should prioritize models equipped with effective blade systems and consider the availability of parts and service support in their region.

How Are Mini Graders Beneficial for Agriculture?

In agriculture, mini graders are used for land leveling and soil preparation, which are crucial for maximizing crop yield. By ensuring an even surface, these machines facilitate better water drainage and soil management, leading to healthier crops. For international buyers, understanding local soil conditions and selecting graders with the appropriate power and blade configurations is essential to optimize agricultural productivity.

Why Are Mini Graders Important in the Mining Industry?

In the mining sector, mini graders are employed for grading access roads and leveling sites, enhancing transport efficiency and site accessibility. These machines can navigate rugged terrains and assist in maintaining the roads that connect remote mining locations. Buyers in regions like the Middle East and Europe should consider the durability and operational efficiency of mini graders, ensuring they can withstand the demanding conditions often found in mining operations.

How Do Mini Graders Enhance Landscaping Projects?

Mini graders are increasingly used in landscaping to create contours and slopes that enhance the aesthetic appeal of properties. Their ability to finely grade and shape the land allows for intricate designs, such as gardens and recreational areas. For B2B buyers focused on landscaping, it’s important to select compact models that offer maneuverability and precision, especially in urban settings where space may be limited.

3 Common User Pain Points for ‘mini graders for sale’ & Their Solutions

Scenario 1: Sourcing Reliable Mini Graders Amidst Limited Local Options

The Problem:

B2B buyers in regions such as Africa and South America often encounter a significant challenge when sourcing mini graders for sale. Limited local availability can lead to inflated prices and a lack of reliable suppliers. Buyers may also struggle to find machines that meet specific project requirements, which can result in delays and increased operational costs. This scarcity can be particularly frustrating for businesses needing equipment quickly to meet project deadlines.

The Solution:

To effectively source reliable mini graders, buyers should expand their search beyond local suppliers. Utilizing online marketplaces and auction sites can provide access to a broader inventory. Buyers should actively participate in auctions or use “Buy Now” options to secure machines that meet their criteria. It’s essential to research and identify reputable sellers with positive reviews and a history of successful transactions. Additionally, engaging with industry forums or local construction associations can lead to recommendations for trustworthy suppliers, ensuring that buyers can acquire the equipment they need at competitive prices.

Scenario 2: Understanding Technical Specifications and Features

The Problem:

Many B2B buyers lack the technical expertise to fully comprehend the specifications of mini graders, which can lead to purchasing decisions based on incomplete information. This knowledge gap often results in selecting machines that do not fit the project requirements, ultimately causing operational inefficiencies and increased costs. For instance, a buyer may overlook critical features such as blade size, engine power, or hydraulic capabilities, which are essential for specific grading tasks.

The Solution:

Buyers should prioritize education and research before making a purchase. Engaging with manufacturers’ websites, attending webinars, or consulting with equipment specialists can provide valuable insights into the technical specifications of mini graders. Buyers should create a checklist of essential features based on their project needs, such as grading depth, machine weight, and hydraulic system capabilities. Additionally, requesting product demonstrations or virtual tours can help buyers visualize the equipment’s functionality, ensuring they select a machine that aligns with their operational requirements. Leveraging this knowledge will lead to more informed purchasing decisions and improved project outcomes.

Scenario 3: Navigating Maintenance and Operational Costs

The Problem:

After acquiring mini graders, many buyers are unprepared for the ongoing maintenance and operational costs associated with these machines. Issues such as fuel consumption, wear and tear on components, and the need for skilled operators can quickly escalate expenses. For businesses operating on tight margins, unexpected costs can significantly impact profitability and project viability, creating a need for better financial planning.

The Solution:

To mitigate maintenance and operational costs, buyers should conduct a thorough analysis of the total cost of ownership (TCO) before making a purchase. This includes evaluating the expected fuel efficiency, maintenance intervals, and parts availability for the selected model. Investing in training for operators can also reduce wear and tear on the equipment, as skilled operators are less likely to misuse the machinery. Furthermore, establishing a preventive maintenance schedule can prolong the lifespan of the mini grader and reduce the frequency of costly repairs. Buyers should also consider negotiating maintenance agreements with suppliers or manufacturers, which can provide peace of mind and predictable costs for upkeep. By proactively managing these aspects, businesses can optimize their investment in mini graders and enhance their operational efficiency.

Strategic Material Selection Guide for mini graders for sale

What Materials Are Commonly Used in Mini Graders for Sale?

When considering the purchase of mini graders, the choice of materials is crucial for performance, durability, and cost-effectiveness. Below, we analyze four common materials used in mini graders, focusing on their key properties, advantages and disadvantages, and specific considerations for international B2B buyers.

Steel: The Backbone of Mini Graders

Key Properties: Steel is known for its high tensile strength and durability, making it ideal for heavy-duty applications. It typically has a temperature rating that can withstand extreme conditions, and its corrosion resistance can be enhanced through galvanization or coatings.

Pros & Cons: The primary advantage of steel is its strength and longevity, which translates to lower maintenance costs over time. However, it can be heavy, increasing the overall weight of the grader, which may affect fuel efficiency. Additionally, manufacturing complexities can arise when fabricating intricate components.

Impact on Application: Steel components are essential in the frame and blade of mini graders, providing the necessary support and precision for grading tasks. It is compatible with various media, including soil, gravel, and asphalt.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards, such as ASTM or DIN, for material quality. Corrosion resistance is particularly important in humid or coastal environments.

Aluminum: Lightweight and Versatile

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance. It has a lower melting point than steel, making it easier to work with during manufacturing.

Pros & Cons: The major advantage of aluminum is its weight, which can enhance fuel efficiency and maneuverability. However, it is generally less durable than steel, making it less suitable for heavy-duty applications. The cost can also be higher compared to steel.

Impact on Application: Aluminum is often used in non-structural components, such as body panels and certain attachments, where weight savings are critical. Its corrosion resistance makes it suitable for applications in wet or corrosive environments.

Considerations for International Buyers: Buyers in Europe, particularly in countries like Germany, may prefer aluminum for its lightweight properties. Compliance with European standards for material safety and environmental impact is essential.

Composite Materials: Innovation in Grading Technology

Key Properties: Composites combine materials like fiberglass and resin to create lightweight, strong components. They offer excellent corrosion resistance and can be engineered for specific performance characteristics.

Pros & Cons: The key advantage of composites is their ability to be tailored for specific applications, providing high strength-to-weight ratios. However, they can be more expensive to produce and may require specialized manufacturing techniques.

Impact on Application: Composites are often used in components that require both strength and reduced weight, such as certain attachments or panels. They are compatible with a variety of grading applications, including those involving corrosive materials.

Considerations for International Buyers: Buyers should be aware of the specific standards for composites in their region, as regulations can vary significantly. For example, compliance with ASTM standards may be necessary in the U.S. and Canada.

Rubber: Essential for Mobility and Traction

Key Properties: Rubber is known for its flexibility and shock-absorbing qualities. It has good resistance to abrasion and can withstand a wide range of temperatures.

Pros & Cons: The primary advantage of rubber is its ability to provide traction and reduce vibrations, enhancing operator comfort. However, it can wear out more quickly than metal components, leading to higher replacement costs.

Impact on Application: Rubber is commonly used in tires and seals, ensuring effective mobility and preventing leaks in hydraulic systems. Its compatibility with various terrains makes it a versatile choice for mini graders.

Considerations for International Buyers: In regions with rough terrain, such as parts of Africa and South America, selecting high-quality rubber components is crucial. Buyers should ensure that the rubber used complies with local standards for durability and performance.

Summary Table of Material Selection for Mini Graders

| Material | Typical Use Case for mini graders for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and blade construction | High strength and durability | Heavier, affects fuel efficiency | Medium |

| Aluminum | Body panels and non-structural components | Lightweight, enhances fuel efficiency | Less durable than steel | High |

| Composite | Specialized attachments and panels | Tailored performance characteristics | Higher production costs | High |

| Rubber | Tires and seals | Provides traction and comfort | Wears out faster, higher replacement costs | Medium |

This guide provides B2B buyers with a comprehensive overview of material options for mini graders, focusing on performance, cost, and international compliance considerations. By understanding these factors, buyers can make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for mini graders for sale

What Are the Key Stages in the Manufacturing Process for Mini Graders?

The manufacturing process for mini graders involves several critical stages that ensure each unit meets industry standards and customer expectations. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality raw materials, primarily steel and other alloys, known for their strength and durability. Suppliers often conduct rigorous material testing to verify that the materials meet specific mechanical and chemical properties. This is crucial, as the performance of the mini grader is heavily reliant on the integrity of its materials.

-

Forming: Once materials are prepared, they undergo forming processes such as cutting, bending, and welding. Advanced techniques like laser cutting are often employed to achieve precision in shaping components like the grader’s blade and frame. This stage may also involve the use of computer numerical control (CNC) machines to ensure accuracy and repeatability.

-

Assembly: The assembly stage is where individual components are brought together to form the complete mini grader. Skilled technicians follow detailed assembly instructions, integrating parts such as the engine, hydraulic systems, and electrical components. Quality checks at this stage are critical to ensure that each part fits correctly and operates as intended.

-

Finishing: The finishing stage involves surface treatments such as painting, powder coating, or galvanizing to protect against corrosion and wear. This not only enhances the aesthetic appeal but also extends the lifespan of the equipment. Manufacturers often use automated processes to ensure consistency in finish quality.

How Is Quality Assurance Implemented in Mini Grader Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that mini graders meet both international standards and customer specifications. The QA process typically involves several checkpoints and compliance with relevant standards.

-

International Standards: Many manufacturers adhere to ISO 9001, a quality management standard that outlines requirements for an organization’s quality management system (QMS). Compliance with ISO 9001 helps ensure that the manufacturing processes are efficient and that products consistently meet customer and regulatory requirements.

-

Industry-Specific Certifications: In addition to ISO standards, mini graders must often meet specific industry certifications such as CE marking in Europe and API standards in the oil and gas sector. These certifications indicate that the equipment complies with relevant safety and environmental regulations.

-

Quality Checkpoints: Throughout the manufacturing process, several quality control (QC) checkpoints are established:

– Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Ongoing inspections are conducted during the manufacturing process to catch defects early.

– Final Quality Control (FQC): Before the mini graders are shipped, a comprehensive inspection is performed to verify that each unit meets all quality standards. -

Common Testing Methods: Testing methods vary but often include pressure tests, hydraulic function tests, and performance evaluations. Non-destructive testing (NDT) techniques, such as ultrasonic or radiographic testing, may also be employed to assess material integrity without causing damage.

What Are the Best Practices for B2B Buyers to Verify Supplier Quality Control?

For B2B buyers, particularly those in diverse regions such as Africa, South America, the Middle East, and Europe, ensuring supplier quality is essential to mitigate risks associated with purchasing heavy equipment like mini graders. Here are some best practices:

-

Conduct Supplier Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes, quality control systems, and adherence to industry standards. Audits should assess the supplier’s QMS, certifications, and compliance with international standards.

-

Request Quality Assurance Reports: Suppliers should be able to provide documentation that outlines their quality control processes, including results from IQC, IPQC, and FQC checks. These reports can help buyers understand how quality is maintained throughout the manufacturing process.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can add an additional layer of verification. These independent auditors can assess the quality of the mini graders before shipment, ensuring they meet specified standards.

-

Understand Certification Nuances: Buyers should be aware of the specific certifications required in their region. For example, CE marking is mandatory for products sold within the European Economic Area, while different standards may apply in the Middle East or Africa. Understanding these nuances can help buyers ensure compliance and avoid regulatory issues.

-

Evaluate After-Sales Support: Finally, consider the supplier’s after-sales service and support. A robust warranty and service agreement can indicate a manufacturer’s confidence in their product quality and their commitment to customer satisfaction.

How Do International Standards Affect Quality Assurance for Mini Graders?

International standards play a critical role in shaping the quality assurance processes for mini graders. By adhering to recognized standards, manufacturers can enhance their credibility and ensure their products are accepted in global markets.

-

Global Market Access: Compliance with international standards like ISO 9001 and CE marking enables manufacturers to access broader markets. Buyers in regions such as Europe and the Middle East often require these certifications as a prerequisite for purchasing.

-

Consistency and Reliability: Standards establish benchmarks for quality, ensuring that mini graders produced in different facilities or countries maintain a consistent level of performance and safety. This is particularly important for B2B buyers who may be sourcing equipment from multiple suppliers.

-

Risk Management: Adhering to international quality standards helps mitigate risks associated with equipment failures and safety concerns. Buyers can be more confident in the reliability of products that meet these rigorous standards.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for mini graders is essential for B2B buyers aiming to make informed purchasing decisions. By focusing on the key stages of manufacturing, adhering to international standards, and implementing best practices for verifying supplier quality, buyers can enhance their procurement strategies and ensure they are investing in reliable, high-quality equipment.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mini graders for sale’

Introduction

This practical sourcing guide is designed to assist international B2B buyers in procuring mini graders for sale. With the increasing demand for efficient earthmoving equipment in regions such as Africa, South America, the Middle East, and Europe, understanding the procurement process is essential. This checklist will help streamline your buying journey, ensuring you make informed decisions that align with your project requirements.

Step 1: Define Your Technical Specifications

Before searching for mini graders, clearly outline your technical requirements. Consider factors such as the type of grading tasks, machine size, power, and additional features like GPS systems or hydraulic attachments. A well-defined specification will help you communicate effectively with suppliers and ensure that the equipment meets your operational needs.

Step 2: Research Reliable Suppliers

Invest time in identifying reputable suppliers specializing in mini graders. Look for companies with a solid track record, positive customer feedback, and industry certifications. Make sure to check their online presence, including reviews and ratings from previous buyers, as this can provide insights into their reliability and service quality.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request detailed company profiles, case studies, and references from clients in similar industries or geographical regions. This step is vital as it helps you gauge the supplier’s experience and ability to deliver equipment that meets your specific needs.

Step 4: Verify Equipment Condition

If purchasing used mini graders, ensure you conduct a comprehensive inspection of the equipment. Look for signs of wear and tear, check the hydraulic systems, engine performance, and blade condition. Understanding the equipment’s condition can prevent unexpected maintenance costs and downtime in the future.

Step 5: Assess Compliance with Local Regulations

Familiarize yourself with the regulatory requirements for heavy machinery in your country. Ensure that the mini graders comply with local safety and environmental standards. This is crucial to avoid legal issues and ensure smooth operations once the equipment is in use.

Step 6: Negotiate Pricing and Terms

Once you have selected a potential supplier, engage in negotiations regarding pricing and payment terms. Be clear about your budget and explore options for financing or leasing, if necessary. A well-negotiated deal can lead to cost savings and favorable terms that benefit your project.

Step 7: Finalize the Purchase Agreement

Before completing the transaction, review the purchase agreement carefully. Ensure it includes all agreed-upon terms, warranties, and delivery timelines. A well-documented agreement protects both parties and provides a reference point for future communications.

By following this checklist, B2B buyers can navigate the procurement process for mini graders with confidence, ensuring they select the right equipment to meet their operational demands.

Comprehensive Cost and Pricing Analysis for mini graders for sale Sourcing

What Are the Key Cost Components in Mini Graders for Sale?

Understanding the cost structure of mini graders is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The core materials for mini graders typically consist of high-strength steel for the frame, hydraulic components, and advanced technology systems for precision grading. The quality of these materials directly impacts the durability and performance of the equipment.

-

Labor: Labor costs can vary significantly depending on the region and the skill level of the workforce. Skilled labor is essential for the assembly and quality assurance processes, ensuring that the machines meet rigorous performance standards.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help minimize these overheads, translating into better pricing for buyers.

-

Tooling: Tooling costs are associated with the machinery and equipment used in the production of mini graders. Investing in advanced tooling can enhance production efficiency and product quality.

-

Quality Control (QC): Rigorous QC processes ensure that each mini grader meets safety and performance standards. This may involve testing components and final products, contributing to overall costs but ultimately ensuring reliability.

-

Logistics: Transportation costs can vary widely based on the distance from the manufacturer to the buyer, as well as the shipping method. For international buyers, understanding Incoterms is essential to clarify responsibilities and costs associated with shipping.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This margin can vary based on the supplier’s position in the market and their operational efficiency.

How Do Price Influencers Impact Mini Grader Costs?

Several factors can influence the pricing of mini graders, which are important for B2B buyers to consider:

-

Volume/MOQ: Purchasing in bulk can lead to significant cost savings. Suppliers often offer discounts for larger orders, making it beneficial for buyers to negotiate based on their projected needs.

-

Specifications and Customization: Custom-built mini graders tailored to specific project requirements can incur additional costs. Buyers should weigh the benefits of customization against their budgets.

-

Materials and Quality Certifications: Higher-quality materials and certifications can drive up costs but are crucial for ensuring long-term durability and performance. Buyers should assess whether the investment in quality aligns with their operational needs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Well-established suppliers may charge a premium for their products, reflecting their experience and the trust they have built in the market.

-

Incoterms: Understanding shipping terms is vital for international transactions. Different Incoterms can affect the total landed cost of the mini graders, as they define who bears the responsibility for shipping, insurance, and tariffs.

What Are the Best Practices for B2B Buyers in Mini Grader Sourcing?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance sourcing effectiveness:

-

Negotiation: Engage suppliers in discussions to understand pricing structures and explore potential discounts, especially for bulk purchases. Transparency about your needs can foster better negotiation outcomes.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes initial purchase price, maintenance, and operational costs over the equipment’s lifespan. This approach can help identify the most cost-effective options in the long run.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and geopolitical factors that might influence pricing. Establishing contracts in stable currencies can mitigate risk.

-

Inspection and Due Diligence: Before finalizing a purchase, conduct thorough inspections of used mini graders. Ensure that all components, including hydraulic systems and control mechanisms, meet your operational standards.

Disclaimer on Indicative Prices

It is important to note that pricing for mini graders can vary significantly based on the factors discussed above. The prices mentioned in various marketplaces can serve as indicative figures, but buyers should conduct their own research and consult with suppliers for accurate quotes tailored to their specific requirements.

Alternatives Analysis: Comparing mini graders for sale With Other Solutions

Understanding Alternatives to Mini Graders for Sale

When considering equipment for grading and earth-moving tasks, B2B buyers often weigh their options between various technologies and methods. While mini graders are a popular choice due to their versatility and precision, other solutions may also meet specific project requirements. This analysis will compare mini graders against two viable alternatives: Skid Steer Loaders with Grading Attachments and Motor Graders.

Comparison Table

| Comparison Aspect | Mini Graders For Sale | Skid Steer Loaders with Grading Attachments | Motor Graders |

|---|---|---|---|

| Performance | High precision in grading, versatile for various terrains | Moderate precision; effective for smaller projects | Exceptional precision; designed for large-scale grading |

| Cost | $100,000 – $250,000 | $30,000 – $80,000 (for the loader, attachments extra) | $100,000 – $500,000 |

| Ease of Implementation | Requires skilled operators; setup can be quick | Generally easier to operate; attachments can be switched out quickly | Requires skilled operators; longer setup time |

| Maintenance | Moderate; parts can be costly | Lower; widely available parts and support | Higher; specialized parts and repairs needed |

| Best Use Case | Small to medium projects requiring precision | Landscaping, small road work, and tight spaces | Large construction and road projects needing extensive grading |

Detailed Breakdown of Alternatives

Skid Steer Loaders with Grading Attachments

Skid steer loaders equipped with grading attachments are versatile machines ideal for smaller grading projects. They are generally less expensive than mini graders, making them an attractive option for companies with budget constraints. The ease of operation and the ability to switch attachments quickly enhance their efficiency on the job site. However, their performance may not match the precision of mini graders, particularly on larger or more complex grading tasks. Additionally, while they require less maintenance, the operator still needs a good understanding of grading techniques to achieve optimal results.

Motor Graders

Motor graders are heavy-duty machines specifically designed for grading and leveling surfaces. They offer exceptional precision and are suitable for large-scale construction projects, road maintenance, and even airport runways. While they are generally more expensive than mini graders, their performance on extensive projects justifies the investment. However, motor graders require skilled operators and can be more cumbersome to maneuver in tight spaces. Maintenance can also be costly, as specialized parts are often needed. For large infrastructure projects, motor graders may be the most effective solution, but they may be overkill for smaller jobs.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right grading equipment depends on several factors including project size, budget, and required precision. For small to medium projects where budget is a constraint, skid steer loaders with grading attachments may provide the best value. Conversely, for extensive grading tasks that demand high precision and capability, investing in a motor grader or mini grader for sale could be more beneficial. Ultimately, understanding the specific needs of your project will guide you in choosing the most effective solution for your grading requirements.

Essential Technical Properties and Trade Terminology for mini graders for sale

When considering the procurement of mini graders for sale, it is crucial to understand the essential technical properties and industry-specific terminology that will guide informed purchasing decisions. Below are key specifications and trade terms that are invaluable for B2B buyers, particularly those operating in diverse international markets.

What Are the Key Technical Properties of Mini Graders?

-

Engine Power (HP or kW)

– The engine power of a mini grader, typically measured in horsepower (HP) or kilowatts (kW), indicates its capacity to perform tasks efficiently. Higher power ratings often translate to better performance in challenging terrain and improved productivity. For B2B buyers, selecting a grader with adequate engine power ensures that it can handle the specific demands of their projects. -

Operating Weight

– The operating weight of a mini grader affects its stability and effectiveness during grading operations. Heavier machines generally provide better traction and stability, making them suitable for more complex tasks. Understanding the weight helps buyers assess whether the mini grader can perform optimally in their operational environment, particularly in regions with varied soil conditions. -

Blade Length and Type

– The blade length and type (e.g., straight, curved, or angled) are critical specifications that impact grading precision and efficiency. Longer blades allow for wider grading swaths, while different blade types can be tailored for specific applications, such as road construction or landscaping. Buyers should consider their specific grading needs when evaluating blade options. -

Hydraulic System

– A mini grader’s hydraulic system, including the number of hydraulic cylinders and their configuration, determines its maneuverability and grading finesse. A robust hydraulic system enhances the machine’s ability to perform fine grading tasks. For B2B operations, investing in graders with advanced hydraulic systems can lead to better project outcomes and reduced labor costs. -

Transmission Type

– The transmission type (manual or automatic) influences the ease of operation and control. Automatic transmissions can simplify operation, particularly for less experienced operators, while manual systems might provide more control for skilled users. Understanding transmission options helps buyers assess the learning curve and operational efficiency of their workforce. -

Grade Control Technology

– Modern mini graders often come equipped with advanced grade control systems, including GPS and laser-guided technologies. These systems enhance grading accuracy and reduce rework, which is critical in large-scale projects. For B2B buyers, investing in technology-enhanced graders can lead to significant long-term savings by optimizing resource use.

What Are Common Trade Terms Related to Mini Graders?

-

OEM (Original Equipment Manufacturer)

– This term refers to the company that manufactures the original parts of the equipment. Buyers should prioritize OEM parts for their reliability and compatibility, ensuring optimal performance and longevity of the mini grader. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest amount of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to gauge inventory and pricing strategies, especially when procuring multiple units or parts. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a quote for specific products or services. This process is critical in B2B transactions as it allows buyers to compare pricing and terms before making purchasing decisions. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers to understand their cost obligations and risks during the procurement process. -

Warranty Period

– The warranty period specifies the duration during which the manufacturer will cover repairs or replacements for defects. A solid warranty can provide peace of mind for buyers, ensuring support in case of equipment failures. -

Lead Time

– Lead time refers to the time taken from placing an order to the delivery of the equipment. Understanding lead times is crucial for B2B buyers to plan their projects and manage schedules effectively.

By familiarizing themselves with these technical properties and industry terms, international buyers can make more informed decisions when sourcing mini graders, ultimately ensuring that they invest in equipment that meets their operational needs and enhances project efficiency.

Navigating Market Dynamics and Sourcing Trends in the mini graders for sale Sector

What are the Current Market Dynamics and Key Trends in the Mini Graders for Sale Sector?

The global market for mini graders is experiencing dynamic shifts driven by various factors. Key among these is the growing demand for efficient construction and maintenance equipment across emerging markets, particularly in Africa, South America, and the Middle East. As urbanization accelerates, governments and private entities are investing heavily in infrastructure projects, creating a significant demand for mini graders that can perform precise grading and earthmoving tasks with minimal footprint.

Technological advancements are also shaping the market. The integration of GPS and telematics in mini graders enhances precision and operational efficiency, allowing for real-time monitoring and management of equipment performance. B2B buyers are increasingly looking for machinery that not only meets operational needs but also offers connectivity features for better fleet management. Additionally, the rise of online auction platforms and marketplaces is transforming the procurement process, providing buyers with broader access to both new and used mini graders, thus fostering competitive pricing.

Emerging trends also indicate a shift towards more versatile equipment. Mini graders are being designed to accommodate various attachments, allowing them to perform multiple functions such as trenching, snow removal, and material spreading, which appeals to businesses looking for cost-effective, multi-functional machinery.

How Does Sustainability Influence Sourcing Trends in the Mini Graders for Sale Market?

Sustainability and ethical sourcing are becoming central to procurement strategies in the mini graders sector. With increasing awareness of environmental impacts, buyers are prioritizing equipment that aligns with sustainable practices. This includes sourcing from manufacturers that utilize eco-friendly materials and processes, ensuring the machinery has a lower carbon footprint throughout its lifecycle.

Moreover, buyers are increasingly seeking certifications that demonstrate a commitment to sustainability. Green certifications, such as ISO 14001 for environmental management, assure buyers that the manufacturers adhere to stringent environmental standards. This is particularly important in regions like Europe, where regulatory frameworks are becoming more rigorous in terms of environmental compliance.

Investing in mini graders that are energy-efficient and equipped with lower-emission engines not only supports corporate sustainability goals but also positions businesses favorably in increasingly eco-conscious markets. As such, buyers should consider the long-term operational costs and benefits of purchasing greener machinery, which often includes lower fuel consumption and reduced maintenance needs.

What is the Historical Context of Mini Graders in the B2B Market?

The evolution of mini graders has been influenced by the need for more compact and efficient grading solutions in urban construction. Initially, motor graders were large, cumbersome machines primarily used for major road construction. However, as urban development intensified, the demand for smaller, more maneuverable equipment grew, leading to the development of mini graders.

These machines have evolved significantly, incorporating advanced technologies that enhance their functionality and ease of use. The shift from purely mechanical to hydraulic systems, along with the introduction of digital controls, has made mini graders more accessible and user-friendly for operators. This evolution reflects the broader trends in the construction equipment industry towards increased efficiency, versatility, and sustainability, making mini graders an essential asset for modern construction projects globally.

As the market continues to grow, international B2B buyers must stay informed about these trends to make strategic purchasing decisions that align with their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of mini graders for sale

-

How do I choose the right mini grader for my project needs?

When selecting a mini grader, consider the specific requirements of your project, such as the terrain, the type of work (grading, ditching, etc.), and the scale of operations. Evaluate the machine’s horsepower, blade length, and hydraulic capabilities to ensure it meets your performance expectations. Additionally, factor in the availability of attachments and whether the grader can accommodate future needs. Consulting with experienced operators or equipment specialists can also provide valuable insights. -

What are the leading brands of mini graders available internationally?

Some of the top brands for mini graders include Caterpillar, John Deere, Komatsu, and Volvo. These manufacturers are recognized for their reliability, advanced technology, and strong after-sales support. When sourcing, check the availability of parts and service in your region, as this can significantly impact maintenance costs and downtime. -

What should I look for during a mini grader inspection?

When inspecting a mini grader, focus on critical components such as the engine condition, hydraulic systems, blade sharpness, and wear on tires or tracks. Check for any signs of oil leaks, rust, or damage to the frame and cab. Ensure that the controls are responsive and that all safety features are functional. A thorough inspection can help you avoid costly repairs down the line. -

What are the typical payment terms when purchasing mini graders in B2B transactions?

Payment terms can vary widely depending on the supplier and the size of the order. Common practices include upfront payments, financing options, or payment upon delivery. For international transactions, consider using letters of credit or escrow services to secure the transaction. Always negotiate terms that protect both parties and ensure clarity on payment schedules and methods. -

How can I verify the credibility of a mini grader supplier?

To vet a supplier, conduct thorough research that includes checking their business history, customer reviews, and industry reputation. Request references from previous clients and ask about their experiences regarding product quality and after-sales support. Additionally, verify if the supplier is certified and compliant with international trade regulations, which can further assure their credibility. -

What is the minimum order quantity (MOQ) for mini graders?

The MOQ for mini graders can vary based on the manufacturer or supplier. Some may allow single-unit purchases, while others may require bulk orders to achieve competitive pricing. Always clarify the MOQ before initiating negotiations to ensure it aligns with your project needs and budget constraints. -

What are the logistics considerations for importing mini graders?

Logistics for importing mini graders involve several factors, including shipping methods, customs clearance, and local regulations. Choose a reliable freight forwarder experienced in heavy machinery transport to navigate these complexities. Ensure you have all necessary documentation, such as invoices, shipping manifests, and customs declarations, to facilitate smooth clearance. -

How can I ensure quality assurance when buying mini graders?

To ensure quality, request detailed specifications and certifications for the mini graders you are considering. Many suppliers offer warranties and service agreements that can provide peace of mind regarding the equipment’s performance. Additionally, consider conducting a pre-shipment inspection to verify the condition of the machinery before it leaves the supplier’s facility, ensuring it meets your standards and requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Mini Graders For Sale Manufacturers & Suppliers List

1. Bingham Equipment – Motor Graders

Domain: binghamequipment.com

Registered: 1999 (26 years)

Introduction: New & Used Motor Graders for Sale | Road Grader | Bingham Equipment Company. Motor graders are designed for precise grading, optimizing efficiency by reducing the need for multiple machines. They deliver precise grading and ground leveling, as well as trenching and ditching for construction, mining, forestry, and airport runways, ensuring a stable foundation for years to come.

2. Motor Graders – Used Equipment for Sale

Domain: govplanet.com

Registered: 2007 (18 years)

Introduction: Motor Graders for sale from various manufacturers including Cat, Champion, John Deere, and Komatsu. Available types include used motor graders with options for auction, online auction, sealed auction, buy now, and make offer. Total of 72 motor graders listed. Popular models include Cat 14L AWD, John Deere 670CH, Komatsu GD675-3E0, and Champion 720A Series V. Prices range from $5,000 to $999,999. L…

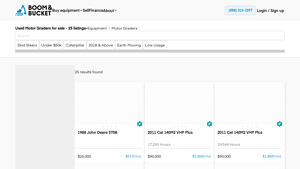

3. John Deere – 1988 570B

Domain: boomandbucket.com

Registered: 2020 (5 years)

Introduction: Used Motor Graders for sale – 25 listings. Popular makes include Bobcat, Case, Caterpillar, Chevrolet, Ford, Freightliner, Genie, GMC, International, JLG, John Deere, Peterbilt, Terex. Price range: Under $50k, with listings from $21,500 to $450,980. Key models include: 1988 John Deere 570B ($25,000), 2011 Cat 140M2 VHP Plus (17,250 Hours, $90,000), 2017 Cat 160M3 (4,952 Hours, $214,965), 2023 John…

4. John Deere – Motor Graders

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Motor Graders for sale on eBay include brands such as John Deere, CAT, Champion, Le Galion, and Komatsu. Related categories include Crawler Dozers & Loaders, Utility 2 Axle Trailers, Ditch Witch Heavy Equipment, Trenchers, and Buckets. Specific listings include: 1) 1997 GEHL MG690 Maintainer Motor Grader/Front End Loader – Pre-Owned, $24,995.00 or Best Offer. 2) Caterpillar 12M Motor Grader – Avai…

5. Graders – Key Product

Domain: machineryline.info

Introduction: Key product details include various models of graders such as Caterpillar 140K, 140H, 140G, 140M, and XCMG GR1803. Prices range from approximately €19,610 to €161,800 depending on the model and year of manufacture. Engine power varies from 67.95 kW (92.45 HP) to 316 kW (430 HP), with fuel types primarily being diesel. Suspension types include air/air and hydraulic. The year of manufacture ranges f…

6. IronPlanet – Motor Graders

Domain: ironplanet.com

Registered: 1999 (26 years)

Introduction: Motor Graders for Sale at IronPlanet. Motor Graders, also known as road graders, are heavy equipment used for setting the final grade on roads or construction sites. They typically have three axles with a cutting blade positioned between the first and second axle, and may include a rear ripper. The blade can be hydraulically tilted for precise grading. Available models from top manufacturers inclu…

7. Motor Graders – Ritchie Bros. Auctioneers

Domain: rbauction.com

Registered: 1995 (30 years)

Introduction: Road & Motor Graders For Sale | Ritchie Bros. Auctioneers

Key Product Details:

– Categories: Motor Graders

– Locations: United States (74), Canada (55), Middle East (14), Europe (11), Oceania (8)

– Makes: Cat (92), John Deere (31), Champion (18), Volvo (13), Komatsu (5)

– Models: 140G (9), 14H (6), 140 H (5), 120G (4), 14G (4)

– Usage: Various hours (e.g., 1,880 hr, 566 hr, 12,963 hr, etc.)

– Bu…

Strategic Sourcing Conclusion and Outlook for mini graders for sale

In summary, strategic sourcing of mini graders presents an invaluable opportunity for international buyers seeking efficiency and reliability in their construction projects. With their ability to provide precise grading and ground leveling, mini graders reduce the need for multiple machines, thereby optimizing operational costs. Buyers should prioritize reputable brands such as Caterpillar, John Deere, and Komatsu, known for their durability and advanced technology.

Conducting thorough inspections and understanding the value retention of these machines will ensure that investments are sound and that operational capabilities are maximized. Moreover, as the demand for infrastructure development continues to rise in regions such as Africa, South America, and the Middle East, the need for high-quality heavy equipment becomes more pronounced.

Looking ahead, international buyers are encouraged to explore diverse sourcing options—from new to used equipment—to meet their specific project needs. By leveraging auctions and private sales, businesses can secure competitive pricing and superior machinery. Engage with trusted suppliers today to take the next step towards enhancing your operational efficiency and achieving project success.