Top 6 U-Shaped Bracket Suppliers (And How to Choose)

Introduction: Navigating the Global Market for u-shaped bracket

In today’s global market, sourcing reliable u-shaped brackets can pose significant challenges for B2B buyers. With diverse applications ranging from structural support in construction to mounting solutions in industrial settings, the need for high-quality, durable brackets is paramount. However, navigating the multitude of options available can be daunting, especially when considering factors like material specifications, load-bearing capabilities, and compliance with international standards. This comprehensive guide aims to demystify the complexities associated with u-shaped brackets, providing insights into various types, applications, and essential considerations for effective supplier vetting.

Within these pages, international B2B buyers from Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—will find a wealth of actionable information. This guide covers not only the different styles and materials of u-shaped brackets but also delves into cost analysis and sourcing strategies. By equipping buyers with critical knowledge about product specifications and supplier reliability, this resource empowers informed purchasing decisions that can enhance operational efficiency and project success. Whether you are seeking to optimize your supply chain or ensure compliance with local regulations, understanding the global landscape of u-shaped brackets is essential for your business growth and sustainability.

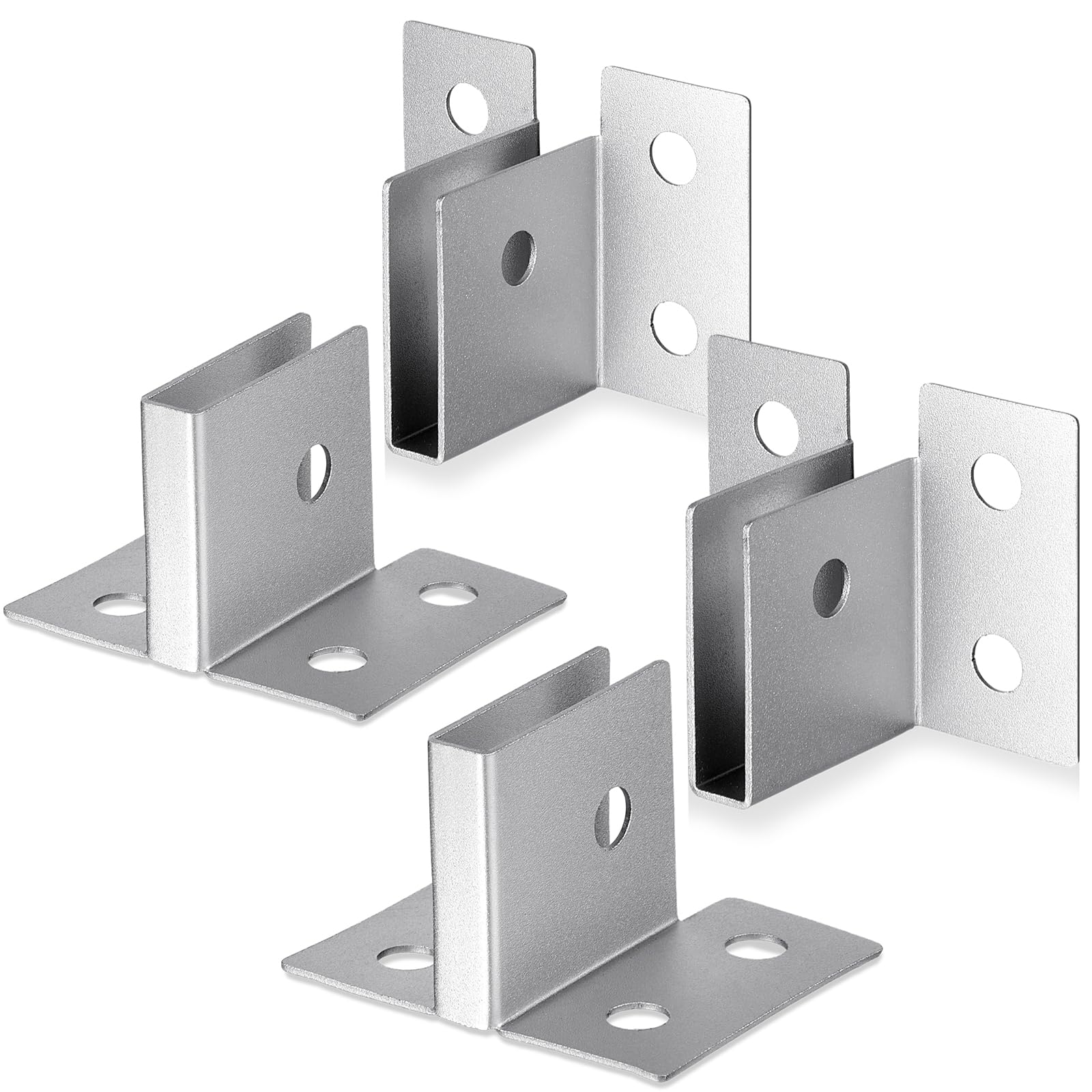

Understanding u-shaped bracket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard U-Brackets | Simple design, various sizes, typically made of metal | General construction, shelving support | Pros: Versatile, easy to install. Cons: Limited load capacity for heavy-duty applications. |

| Heavy-Duty U-Brackets | Thicker materials, reinforced design for heavy loads | Industrial shelving, machinery support | Pros: High load capacity, durable. Cons: Higher cost, may require specialized installation. |

| Adjustable U-Brackets | Features slots or holes for adjustable positioning | Custom installations, modular systems | Pros: Flexibility in design, easy adjustments. Cons: Complexity may increase installation time. |

| U-Brackets with Mounting Holes | Pre-drilled holes for secure fastening | Wall mounting, structural frameworks | Pros: Secure attachment, various configurations. Cons: May limit placement options. |

| Specialized U-Brackets | Designed for specific applications (e.g., sensor mounts) | Automation, electronics, specialized equipment | Pros: Tailored solutions for specific needs. Cons: Limited general use, potentially higher costs. |

What Are the Key Characteristics of Standard U-Brackets?

Standard U-brackets are characterized by their straightforward design and versatility. Typically constructed from metal, they come in various sizes suitable for numerous applications in general construction and shelving support. When considering purchasing standard U-brackets, businesses should evaluate their load requirements, as these brackets may not be ideal for heavy-duty applications. Their ease of installation makes them a popular choice, but buyers should be aware of their limitations in strength.

How Do Heavy-Duty U-Brackets Compare to Standard Options?

Heavy-duty U-brackets are engineered to handle significantly greater loads compared to standard versions. They are constructed from thicker materials and feature a reinforced design, making them ideal for industrial shelving and machinery support. Buyers should consider the initial investment, as these brackets typically come at a higher price point. However, their durability and ability to withstand heavy loads can lead to long-term savings by reducing the need for replacements and maintenance.

Why Choose Adjustable U-Brackets for Custom Installations?

Adjustable U-brackets offer unique features such as slots or holes that allow for customizable positioning. This flexibility makes them particularly suitable for custom installations and modular systems. When purchasing adjustable U-brackets, businesses should assess the complexity of their installation requirements, as the added flexibility may necessitate more time and effort during setup. These brackets are an excellent choice for projects that require adaptability over time.

What Are the Benefits of U-Brackets with Pre-Drilled Mounting Holes?

U-brackets with pre-drilled mounting holes are designed for secure fastening, making them ideal for applications involving wall mounting and structural frameworks. Their key advantage lies in their ability to ensure a secure attachment, which can be crucial in high-stress environments. Buyers should consider the specific configurations required for their projects, as these brackets may limit placement options. However, their straightforward installation process often outweighs these limitations.

How Do Specialized U-Brackets Address Unique Business Needs?

Specialized U-brackets are tailored for specific applications, such as sensor mounts in automation or electronics. These brackets offer solutions that directly address unique business requirements, providing a competitive edge in specialized industries. While they can be more expensive and less versatile than standard options, their targeted design can lead to improved efficiency and functionality in specific projects. Businesses should weigh the benefits of specialization against the potential for limited general use when considering these brackets.

Key Industrial Applications of u-shaped bracket

| Industry/Sector | Specific Application of u-shaped bracket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural support in framing systems | Enhances structural integrity and load distribution | Material durability, load capacity, and compliance with local building codes |

| Automotive | Mounting components in vehicle assembly lines | Streamlines assembly processes and reduces downtime | Precision engineering, corrosion resistance, and compatibility with existing systems |

| Telecommunications | Securing equipment in telecommunication towers | Ensures stability and longevity of critical infrastructure | Weather-resistant materials, ease of installation, and adaptability to various environments |

| HVAC | Supporting ductwork and ventilation systems | Improves airflow efficiency and system reliability | Load ratings, thermal resistance, and customization options for specific projects |

| Renewable Energy | Mounting solar panels and wind turbine components | Facilitates efficient energy production and maintenance | Corrosion resistance, sustainability certifications, and adaptability to various mounting scenarios |

In the construction industry, u-shaped brackets are critical for providing structural support in framing systems. They help distribute loads evenly, ensuring the integrity of walls and roofs. For international buyers, especially in regions like Africa and South America, sourcing brackets that meet local building codes and standards is essential to avoid project delays and ensure safety.

In the automotive sector, these brackets are used extensively in assembly lines to mount various components securely. Their design allows for easy integration into existing systems, which can significantly reduce assembly times and minimize downtime. Buyers must consider precision engineering and corrosion resistance to ensure long-lasting performance in various climates.

Telecommunications infrastructure relies heavily on u-shaped brackets for securing equipment on towers. These brackets must withstand harsh weather conditions while maintaining stability. Buyers should focus on sourcing weather-resistant materials that are easy to install and adaptable to diverse environmental conditions, ensuring the reliability of critical communication networks.

In HVAC applications, u-shaped brackets support ductwork and ventilation systems, contributing to improved airflow and system efficiency. The correct bracket can enhance system reliability and ease of maintenance. Buyers must evaluate load ratings and thermal resistance to ensure the brackets can handle the specific demands of their projects.

Finally, in the renewable energy sector, u-shaped brackets play a vital role in mounting solar panels and wind turbine components. Their ability to facilitate efficient energy production is crucial as the world moves towards sustainable energy sources. International buyers should prioritize sourcing brackets with corrosion resistance and sustainability certifications to ensure they meet the demands of various mounting scenarios.

3 Common User Pain Points for ‘u-shaped bracket’ & Their Solutions

Scenario 1: Sizing Issues When Selecting U-Shaped Brackets

The Problem: A common issue faced by B2B buyers is the difficulty in selecting the right size U-shaped bracket for their projects. Many suppliers offer various sizes, but without clear specifications, it can be challenging to determine which bracket will adequately support the intended load or fit within the given space. This often leads to project delays and increased costs due to the need for returns and exchanges, as well as potential safety risks if the wrong size is used.

The Solution: To effectively address sizing issues, buyers should begin by conducting a thorough assessment of their project requirements. This includes understanding the load capacity needed and the dimensions of the area where the bracket will be installed. Utilizing detailed CAD drawings or engineering specifications can aid in this process. Additionally, engaging with suppliers who provide comprehensive product catalogs, including detailed specifications and application guidelines, can facilitate informed decision-making. Buyers should also consider opting for customizable U-shaped brackets that can be tailored to specific project needs, ensuring a perfect fit and optimal performance.

Scenario 2: Incompatibility with Existing Structures

The Problem: B2B buyers often encounter the challenge of U-shaped brackets being incompatible with existing structures or systems. This can happen when new brackets are introduced into an established framework without adequate consideration of the specifications or materials used in the original design. Such incompatibility can result in ineffective installations, increased labor costs, and potential safety hazards.

The Solution: To mitigate compatibility issues, buyers should perform a comprehensive review of their existing systems before sourcing U-shaped brackets. Collaborating with engineering teams to analyze compatibility can yield beneficial insights. It’s crucial to consult with bracket manufacturers who offer detailed compatibility charts or design support services. Some suppliers even provide engineering consultations to ensure that the chosen brackets will integrate smoothly with existing frameworks. Additionally, choosing adjustable or versatile U-shaped brackets can provide the flexibility needed to accommodate varying structural conditions.

Scenario 3: Quality and Durability Concerns

The Problem: Buyers often express concerns regarding the quality and durability of U-shaped brackets, especially when sourcing from different suppliers across regions like Africa, South America, and Europe. Variations in manufacturing standards can lead to purchasing products that fail to meet performance expectations, resulting in costly repairs or replacements and impacting overall project timelines.

The Solution: To ensure the quality and durability of U-shaped brackets, buyers should prioritize sourcing from reputable suppliers with established track records. Conducting due diligence by reviewing supplier certifications, customer testimonials, and quality assurance processes is essential. Buyers should also request product samples or detailed specifications, including materials and testing standards, before making large purchases. Establishing long-term relationships with trusted manufacturers who can consistently deliver high-quality products will not only enhance project reliability but also foster better communication and support for future projects. Implementing a rigorous quality control process upon receipt of goods can further safeguard against issues related to product durability.

Strategic Material Selection Guide for u-shaped bracket

What Are the Key Materials for U-Shaped Brackets in B2B Applications?

When selecting materials for u-shaped brackets, it is crucial to consider their properties, advantages, disadvantages, and suitability for specific applications. This analysis focuses on four common materials: steel, stainless steel, aluminum, and plastic. Each material presents unique benefits and limitations that can significantly impact performance and cost-effectiveness in various industrial contexts.

How Does Steel Perform as a Material for U-Shaped Brackets?

Steel is one of the most widely used materials for u-shaped brackets due to its high strength and durability. It typically has excellent temperature and pressure ratings, making it suitable for heavy-duty applications. However, steel is prone to corrosion, which can limit its use in humid or chemically aggressive environments unless properly treated or coated.

Pros: High strength-to-weight ratio, cost-effective, readily available.

Cons: Susceptible to rust and corrosion, may require protective coatings.

Impact on Application: Ideal for structural applications in dry environments or when coated.

Considerations for International Buyers: Compliance with ASTM standards is essential, particularly in regions like Europe where stringent quality controls are in place.

What Are the Benefits of Using Stainless Steel for U-Shaped Brackets?

Stainless steel offers superior corrosion resistance compared to regular steel, making it ideal for applications exposed to moisture or chemicals. It maintains structural integrity across a wide range of temperatures and is often used in food processing and medical equipment due to its hygienic properties.

Pros: Excellent corrosion resistance, aesthetic appeal, easy to clean.

Cons: Higher cost compared to regular steel, may be less ductile.

Impact on Application: Suitable for harsh environments and applications requiring cleanliness.

Considerations for International Buyers: Compliance with DIN standards is common in Europe, and buyers should verify grades (e.g., 304, 316) for specific applications.

Why Choose Aluminum for U-Shaped Brackets?

Aluminum is lightweight and offers good corrosion resistance, making it a popular choice for applications where weight is a concern, such as in automotive or aerospace industries. It also has decent strength, although it may not match steel in load-bearing capacity.

Pros: Lightweight, good corrosion resistance, easy to fabricate.

Cons: Lower strength compared to steel, can be more expensive than standard steel.

Impact on Application: Ideal for applications requiring lightweight components without sacrificing too much strength.

Considerations for International Buyers: Commonly conforms to JIS standards in Asia, and buyers should consider the alloy used for optimal performance.

When Is Plastic the Right Choice for U-Shaped Brackets?

Plastic brackets are often used in applications where weight and corrosion resistance are critical, such as in electrical enclosures or plumbing. They can be engineered to withstand specific temperatures and pressures, but their mechanical strength is generally lower than that of metals.

Pros: Lightweight, corrosion-resistant, cost-effective for low-stress applications.

Cons: Limited load-bearing capacity, can degrade under UV exposure.

Impact on Application: Best suited for non-structural applications or where environmental conditions are controlled.

Considerations for International Buyers: Ensure compliance with local regulations regarding material safety and environmental impact.

Summary of Material Properties for U-Shaped Brackets

| Material | Typical Use Case for u-shaped bracket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty structural applications | High strength-to-weight ratio | Susceptible to corrosion | Medium |

| Stainless Steel | Food processing, medical equipment | Excellent corrosion resistance | Higher cost | High |

| Aluminum | Automotive, aerospace applications | Lightweight | Lower strength than steel | Medium |

| Plastic | Electrical enclosures, plumbing | Corrosion-resistant | Limited load-bearing capacity | Low |

This guide aims to equip international B2B buyers with the necessary insights to make informed decisions regarding material selection for u-shaped brackets, ensuring compliance with local standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for u-shaped bracket

What Are the Key Manufacturing Processes for U-Shaped Brackets?

The manufacturing of u-shaped brackets involves several critical stages, each tailored to ensure the structural integrity and functionality of the final product. Understanding these processes is essential for B2B buyers looking for quality and reliability in their purchases.

Material Preparation: What Materials Are Used for U-Shaped Brackets?

Typically, u-shaped brackets are made from various metals, including stainless steel, carbon steel, and aluminum, depending on the application’s requirements. The material is sourced based on its strength, corrosion resistance, and weight considerations. Prior to manufacturing, the materials undergo a thorough inspection to confirm they meet specifications. This includes checking for surface defects, dimensions, and chemical composition.

How Are U-Shaped Brackets Formed?

The forming process is crucial as it shapes the raw materials into the desired u-shaped configuration. Common techniques include:

- Stamping: This method uses a die to cut and shape the metal sheets into brackets. It is efficient for large production runs, ensuring uniformity in shape and size.

- Bending: In this process, metal sheets are bent at specific angles to create the u-shape. This can be achieved using hydraulic press brakes or mechanical benders, allowing for precise control over the angle and radius.

- Welding: For more complex designs, welding may be used to assemble multiple components into a single bracket. This step requires skilled operators to ensure strong, clean welds.

What Are the Assembly and Finishing Steps for U-Shaped Brackets?

After forming, the brackets move to the assembly stage, where additional components, such as screws or additional brackets, may be attached. This step can also include:

- Kitting: Grouping brackets with their necessary hardware for easy installation.

- Packaging: Proper packaging ensures that products remain undamaged during transit.

Finishing processes enhance the durability and aesthetics of u-shaped brackets. Common finishing techniques include:

- Galvanizing: This process involves coating steel with zinc to prevent rusting.

- Powder Coating: A dry powder is applied and then cured under heat, providing a tough and colorful finish.

- Plating: Electroplating may be used to enhance corrosion resistance and improve surface hardness.

What Quality Control Measures Are Critical for U-Shaped Brackets?

Quality assurance is vital in the manufacturing of u-shaped brackets, particularly for B2B buyers who require consistency and reliability. Adherence to international standards, such as ISO 9001, ensures that manufacturers maintain quality management systems throughout their processes.

What Are the Key International and Industry-Specific Standards?

- ISO 9001: Focuses on quality management systems and is recognized globally, ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Particularly relevant for products sold in Europe, this marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For brackets used in the oil and gas industry, adherence to API standards ensures that products meet rigorous performance and safety criteria.

How Are Quality Control Checkpoints Established?

Quality control (QC) checkpoints are integrated into the manufacturing process to ensure that each product meets specified standards. Key checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections are conducted during manufacturing to catch any issues early in the process.

- Final Quality Control (FQC): Completed products undergo thorough testing and inspection before shipment. This may include dimensional checks, strength testing, and corrosion resistance assessments.

What Common Testing Methods Are Used in Quality Control?

Testing methods vary based on the specific application and industry but typically include:

- Tensile Testing: Measures the strength and ductility of materials.

- Fatigue Testing: Assesses how materials perform under repeated stress.

- Corrosion Testing: Evaluates how well the finishing process protects against environmental degradation.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are several actionable steps:

- Supplier Audits: Conducting on-site audits can provide insights into a supplier’s quality management system and manufacturing capabilities.

- Requesting Quality Reports: Suppliers should be able to provide documentation on quality control processes, including results from IQC, IPQC, and FQC.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of product quality before shipment.

What Are the QC and Certification Nuances for International Buyers?

Navigating the certification landscape can be complex for international buyers. Here are several considerations:

- Local Regulations: Understand the specific regulations in your region, as compliance requirements may vary significantly between countries.

- Documentation Requirements: Ensure that suppliers provide all necessary certifications and documentation, including material certifications, test reports, and compliance certificates.

- Language Barriers: When dealing with international suppliers, language can be a barrier. Clear communication regarding quality standards and expectations is essential.

Conclusion: Ensuring Quality in U-Shaped Bracket Manufacturing

For B2B buyers, understanding the manufacturing processes and quality assurance measures for u-shaped brackets is key to making informed purchasing decisions. By focusing on the quality control standards, testing methods, and verification processes, buyers can ensure they are sourcing reliable, high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘u-shaped bracket’

In the fast-paced world of B2B procurement, sourcing components like U-shaped brackets requires a systematic approach to ensure quality, compatibility, and cost-effectiveness. This checklist will guide international buyers through the critical steps necessary to procure U-shaped brackets that meet their specific project needs.

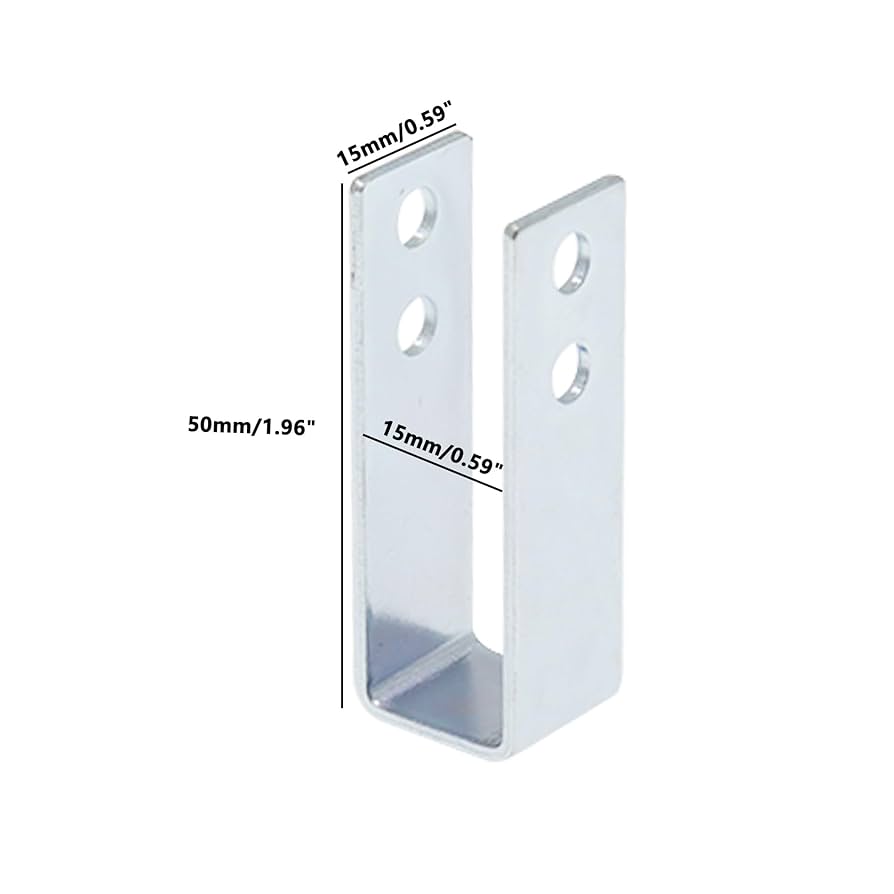

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the U-shaped brackets you need. Consider factors such as size, material, load-bearing capacity, and any specific industry standards that must be adhered to. Knowing your specifications upfront will help you filter suppliers and avoid costly mistakes.

- Size and Dimensions: Ensure you have precise measurements for the brackets, including hole sizes and spacing.

- Material Requirements: Determine if you need stainless steel, galvanized, or another material based on environmental factors like corrosion resistance.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in U-shaped brackets. Utilize industry directories, trade shows, and online platforms to compile a list of potential vendors.

- Supplier Reviews: Look for reviews and testimonials from other businesses in your region to gauge reliability and service quality.

- Industry Experience: Prioritize suppliers with experience in your specific industry, as they are more likely to understand your unique requirements.

Step 3: Evaluate Supplier Certifications

Before committing to a supplier, check for relevant certifications that demonstrate compliance with industry standards. Certifications can indicate a commitment to quality and safety.

- ISO Certification: Suppliers with ISO 9001 certification have established quality management systems, which can be a good indicator of reliability.

- Local Compliance: Ensure the supplier meets local regulatory requirements, especially if you are sourcing from international markets.

Step 4: Request Samples and Product Specifications

Once you have shortlisted potential suppliers, request samples of the U-shaped brackets. This step allows you to assess the quality and ensure that the products meet your specifications.

- Quality Assessment: Evaluate the samples for durability, finish, and overall craftsmanship.

- Technical Documentation: Ask for detailed product specifications, including load ratings and installation instructions.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing structures. Look beyond just the initial cost; consider shipping fees, bulk discounts, and payment terms.

- Total Cost of Ownership: Calculate the total cost including shipping, duties, and potential customs fees to get a clearer picture of the financial implications.

- Flexible Payment Options: Favor suppliers who offer flexible payment terms, which can help with cash flow management.

Step 6: Negotiate Terms and Conditions

Engage in negotiations with your selected supplier(s) to finalize pricing and terms. Clear communication at this stage can prevent misunderstandings later.

- Lead Times: Confirm production and delivery timelines to ensure they align with your project schedule.

- Return Policy: Understand the return and warranty policies in case the products do not meet your expectations upon delivery.

Step 7: Finalize the Order and Monitor Delivery

After agreeing on terms, finalize your order and establish a communication plan for monitoring the delivery process. This step is crucial to ensure timely receipt of your U-shaped brackets.

- Order Confirmation: Keep a record of all order details and confirmations for future reference.

- Delivery Tracking: Stay in contact with the supplier to track the shipment and address any potential issues proactively.

By following this checklist, B2B buyers can streamline the procurement process for U-shaped brackets, ensuring they obtain high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for u-shaped bracket Sourcing

What Are the Key Cost Components in U-Shaped Bracket Sourcing?

When sourcing u-shaped brackets, understanding the cost structure is crucial for making informed purchasing decisions. The main cost components include:

-

Materials: The type of materials used (e.g., steel, aluminum, or plastic) significantly affects costs. High-strength materials or those with specific certifications (like stainless steel for corrosion resistance) typically increase the price.

-

Labor: Labor costs can vary depending on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but it’s essential to balance this with quality and reliability.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Custom designs may require specialized tooling, which can increase upfront costs. However, investing in quality tooling can lead to better long-term efficiency and product quality.

-

Quality Control (QC): Implementing rigorous QC measures ensures product reliability, but adds to overall costs. Buyers should consider the implications of QC on long-term performance versus initial price.

-

Logistics: Shipping costs can vary widely based on distance, shipping method, and Incoterms. Consideration of logistics costs is vital, especially for international transactions.

-

Margin: Supplier profit margins can differ based on their market position, brand reputation, and service level. Understanding the market can provide leverage in negotiations.

How Do Price Influencers Impact U-Shaped Bracket Costs?

Several factors influence the pricing of u-shaped brackets:

-

Volume/MOQ: Suppliers often offer discounts for bulk orders. Understanding minimum order quantities (MOQs) can help in negotiating better pricing.

-

Specifications/Customization: Custom-designed brackets or those with specific features (like corrosion resistance or special finishes) typically come at a premium. Buyers should evaluate the necessity of these specifications against their budget.

-

Materials: The choice of materials impacts both performance and price. For example, aluminum brackets may be lighter and more expensive than steel, but offer different benefits depending on the application.

-

Quality and Certifications: Products with industry certifications may command higher prices but provide assurance of quality. This is especially important in regulated industries where compliance is mandatory.

-

Supplier Factors: The supplier’s reputation, reliability, and service capabilities play a role in pricing. Established suppliers may charge more but offer better support and quality assurance.

-

Incoterms: Understanding Incoterms is crucial for international buyers as they define the responsibilities of buyers and sellers in shipping costs, insurance, and risk of loss. This can significantly affect total landed costs.

What Are the Best Buyer Tips for Cost-Efficiency in U-Shaped Bracket Procurement?

To achieve cost efficiency in sourcing u-shaped brackets, consider the following tips:

-

Negotiate Effectively: Engage in discussions with suppliers to negotiate terms, especially regarding volume discounts and payment terms. Building a relationship can also lead to better deals in the future.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes shipping, installation, maintenance, and potential warranty costs. This holistic view can lead to better decision-making.

-

Understand Pricing Nuances for International Sourcing: International buyers, particularly from Africa, South America, the Middle East, and Europe, should account for currency fluctuations, tariffs, and import duties that can affect overall costs.

-

Research Market Prices: Staying informed about market trends and competitor pricing can provide leverage in negotiations. Online platforms and industry reports can be valuable resources.

-

Consider Local Suppliers: Sourcing from local suppliers can reduce shipping costs and lead times. Additionally, local suppliers may have a better understanding of regional regulations and standards.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on supplier, location, and market conditions. It is advisable for buyers to conduct thorough market research and consult multiple suppliers to obtain accurate pricing information tailored to their specific needs.

Alternatives Analysis: Comparing u-shaped bracket With Other Solutions

When evaluating solutions for securing and supporting structural components, the choice of bracket or fastening system is crucial. U-shaped brackets are popular for their versatility and ease of use, but it’s essential to explore alternative solutions that may offer distinct advantages depending on specific application requirements. This analysis compares the u-shaped bracket against two viable alternatives: channel systems and custom fabricated brackets.

Comparison Table

| Comparison Aspect | U-Shaped Bracket | Channel System | Custom Fabricated Bracket |

|---|---|---|---|

| Performance | Reliable for light to medium loads; strong connections | High load-bearing capacity; adaptable | Tailored to specific load requirements; can be highly efficient |

| Cost | Generally low-cost; competitive pricing | Moderate cost; dependent on length and fittings | Higher initial cost due to customization |

| Ease of Implementation | Quick installation with standard tools | Moderate; requires additional components (channels, fittings) | Time-consuming; needs design and fabrication |

| Maintenance | Minimal; durable materials reduce wear | Moderate; may require periodic checks on fittings | Varies; depends on material and design |

| Best Use Case | Ideal for general-purpose applications in construction and maintenance | Suitable for industrial applications with heavy loads | Best for specialized applications requiring precise specifications |

What Are the Benefits and Drawbacks of Channel Systems as an Alternative?

Channel systems, commonly used in industrial settings, consist of metal channels with various fittings, including u-shaped brackets. Their primary advantage is their flexibility in design, allowing for extensive customization based on project needs. This adaptability makes them suitable for heavy-duty applications, where load-bearing capacity is a priority. However, the installation process is more complex compared to u-shaped brackets, as it requires additional components and may lead to increased labor costs. Additionally, while the upfront costs are moderate, ongoing maintenance can add to total expenses.

How Do Custom Fabricated Brackets Compare?

Custom fabricated brackets offer a tailored solution for unique structural needs. These brackets can be designed to meet specific load requirements and spatial constraints, providing an optimized solution for specialized applications. The primary benefit is their ability to precisely fit the application, potentially enhancing performance and durability. However, this comes at a higher initial cost due to the design and manufacturing processes involved. Moreover, the time required for design and fabrication can delay project timelines, making them less suitable for urgent projects.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

In selecting the right fastening solution, B2B buyers should consider the specific requirements of their projects, including load capacity, installation complexity, and budget. U-shaped brackets are an excellent choice for general applications due to their affordability and ease of use. For projects demanding higher load capacities or customization, channel systems or custom fabricated brackets may be more appropriate despite their higher costs and complexity. Ultimately, understanding the unique demands of each project will guide buyers in making informed decisions that align with their operational goals and financial constraints.

Essential Technical Properties and Trade Terminology for u-shaped bracket

What Are the Key Technical Properties of U-Shaped Brackets?

Understanding the essential technical properties of u-shaped brackets is crucial for B2B buyers, especially when ensuring compatibility with specific applications. Here are some critical specifications to consider:

-

Material Grade

The material used for u-shaped brackets typically includes steel, stainless steel, or aluminum. Each material has different properties affecting durability and corrosion resistance. For example, stainless steel is ideal for applications in humid or corrosive environments, while aluminum is lighter and often used in less demanding applications. Knowing the material grade helps in assessing the bracket’s suitability for particular projects. -

Load Capacity

Load capacity indicates the maximum weight a bracket can support without failing. This specification is vital for structural applications where safety is paramount. Buyers should evaluate the load requirements of their projects to select brackets that meet or exceed these specifications, thus preventing structural failures. -

Tolerance

Tolerance refers to the permissible limit or limits of variation in a physical dimension. In the context of u-shaped brackets, tighter tolerances can ensure a better fit, enhancing the overall stability of the assembly. Understanding tolerance levels can help buyers ensure that the brackets will fit seamlessly with other components, reducing the risk of installation issues. -

Finish Type

The finish of a u-shaped bracket can impact its durability and aesthetic appeal. Common finishes include electro-galvanized, hot-dip galvanized, and powder-coated. Each finish offers different levels of protection against corrosion and wear, which is important in determining the longevity of the bracket in specific environments. -

Dimensions

Standard dimensions (width, height, and hole spacing) are crucial for compatibility with existing structures or components. Buyers must ensure that the dimensions of the u-shaped brackets align with their specific installation requirements to facilitate seamless integration.

What Are Common Trade Terms Used in U-Shaped Bracket Procurement?

Familiarity with industry jargon is essential for effective communication and negotiation in the procurement of u-shaped brackets. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are sold under another company’s brand. In the context of u-shaped brackets, buyers might deal directly with OEMs to obtain high-quality, standardized products tailored to their specifications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps B2B buyers plan their orders efficiently and avoid excess inventory, ensuring they meet their project requirements without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for specific products, such as u-shaped brackets. It is a crucial step in the procurement process, allowing buyers to compare options and negotiate better deals based on detailed specifications. -

Incoterms (International Commercial Terms)

Incoterms are a set of standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and rights during international transactions, minimizing potential disputes. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Knowing the lead times for u-shaped brackets is essential for project planning, as delays can impact construction schedules and overall project timelines. -

Certification

Certification indicates that the product meets specific industry standards or regulations. For u-shaped brackets, certifications might include ISO or ANSI standards, which can assure buyers of the product’s quality and reliability in demanding applications.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge necessary to make informed purchasing decisions regarding u-shaped brackets, ultimately leading to successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the u-shaped bracket Sector

What Are the Key Market Dynamics and Trends in the U-Shaped Bracket Sector?

The u-shaped bracket sector is witnessing significant growth driven by the increasing demand for versatile and robust mounting solutions across various industries. Global drivers include the rise of infrastructure projects in developing regions, particularly in Africa and South America, where construction and industrial activities are expanding rapidly. Additionally, the Middle East’s investment in smart city initiatives and Europe’s focus on renewable energy projects are fueling demand for reliable structural components, including u-shaped brackets.

Emerging B2B tech trends are reshaping how these products are sourced. The integration of digital platforms for procurement is becoming prevalent, allowing international buyers to access a broader range of suppliers and products. Technologies such as 3D printing and CAD design are also enhancing customization capabilities, enabling buyers to specify unique dimensions and materials according to their project needs. Furthermore, the trend towards automation in manufacturing processes is improving production efficiency, resulting in quicker lead times and competitive pricing.

International B2B buyers must remain vigilant about fluctuations in global supply chains, which have been impacted by geopolitical tensions and economic uncertainties. Engaging with suppliers who demonstrate resilience and flexibility in their operations can mitigate risks associated with sourcing delays. Additionally, understanding regional compliance and quality standards is crucial for buyers operating in diverse markets like Germany, Vietnam, and beyond.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing for U-Shaped Brackets?

Sustainability is becoming a critical consideration for B2B buyers in the u-shaped bracket sector. The environmental impact of manufacturing processes, particularly concerning the use of metals and plastics, highlights the need for responsible sourcing. Buyers should prioritize suppliers who utilize sustainable practices, such as recycling materials and minimizing waste during production.

Ethical sourcing is equally important, as it encompasses fair labor practices and compliance with international labor standards. Buyers can enhance their supply chain transparency by selecting manufacturers who are certified by recognized organizations, such as ISO 14001 for environmental management or Fair Trade certifications.

The demand for ‘green’ materials is on the rise, with options like recycled steel and eco-friendly coatings gaining traction. By opting for these materials, companies not only reduce their environmental footprint but also appeal to a growing consumer base that values sustainability. Furthermore, engaging with suppliers who invest in renewable energy sources for their operations can significantly enhance a buyer’s overall sustainability profile.

What Is the Evolution of U-Shaped Brackets in the B2B Context?

The evolution of u-shaped brackets can be traced back to their initial use in basic structural applications. Historically, they were primarily utilized in construction and manufacturing for mounting and support purposes. Over the years, advancements in materials science and engineering have led to the development of more durable and versatile designs, catering to a wider array of applications, including electrical, mechanical, and automation systems.

In recent decades, the introduction of high-strength materials and innovative manufacturing techniques has transformed u-shaped brackets into essential components in modern infrastructure and technology projects. As industries evolve, so too does the need for adaptable and reliable mounting solutions, positioning u-shaped brackets as indispensable elements in various sectors, from construction to advanced manufacturing. This ongoing evolution highlights the importance of staying informed about technological advancements and market trends for B2B buyers looking to optimize their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of u-shaped bracket

-

How do I select the right u-shaped bracket for my application?

Choosing the appropriate u-shaped bracket involves assessing the specific requirements of your application, including load capacity, size, and material. Consider the environment where the bracket will be used, as factors like humidity, temperature, and exposure to chemicals can influence material selection. Additionally, ensure compatibility with existing components, such as strut channels or mounting surfaces. Consulting with suppliers for technical specifications and recommendations can also aid in making an informed decision. -

What materials are commonly used for u-shaped brackets, and how do they affect performance?

U-shaped brackets are typically manufactured from materials like steel, stainless steel, aluminum, and plastic. Steel brackets offer high strength and durability, making them suitable for heavy-duty applications, while stainless steel provides corrosion resistance in humid or outdoor environments. Aluminum brackets are lightweight and resistant to rust, ideal for less demanding applications. The choice of material directly impacts the bracket’s performance, longevity, and suitability for specific environments, so consider your needs carefully. -

What customization options are available for u-shaped brackets?

Many suppliers offer customization options for u-shaped brackets, including size adjustments, hole configurations, and surface finishes. Customization can enhance compatibility with your specific project requirements. Some manufacturers may also provide engineering services to create bespoke designs tailored to your application. Be sure to discuss your needs with potential suppliers to explore available options and associated costs. -

What is the minimum order quantity (MOQ) for u-shaped brackets?

Minimum order quantities for u-shaped brackets can vary significantly by supplier and product type. Some manufacturers may allow small orders, while others might set a higher MOQ to justify production costs. It’s essential to clarify this upfront when engaging with suppliers, especially if you’re sourcing for a project with limited demand. Negotiating terms can sometimes yield flexibility, particularly for long-term partnerships. -

What payment terms should I expect when sourcing u-shaped brackets internationally?

Payment terms for international purchases can range from upfront payment to net 30 or net 60 days, depending on the supplier’s policies and your business relationship. Common methods include wire transfers, letters of credit, and online payment platforms. It’s crucial to discuss and agree on payment terms before placing an order, as this can impact your cash flow and project timelines. -

How do I ensure quality assurance for u-shaped brackets from international suppliers?

To ensure quality assurance, request detailed product specifications, certifications, and samples from suppliers before placing an order. Implement a quality control process that includes inspection upon receipt and periodic checks during production if possible. Many companies also benefit from third-party inspections to verify compliance with industry standards. Establishing clear communication regarding quality expectations will help mitigate risks associated with defects. -

What logistics considerations should I keep in mind when importing u-shaped brackets?

Logistics for importing u-shaped brackets include shipping methods, lead times, and customs regulations. Evaluate the most cost-effective shipping options, such as sea freight for bulk orders or air freight for urgent needs. Ensure compliance with customs documentation and tariffs to avoid delays. Collaborating with a logistics partner can streamline this process, helping you navigate complexities specific to your country or region. -

What are the common applications of u-shaped brackets in various industries?

U-shaped brackets are versatile and used across numerous industries, including construction, automotive, electronics, and manufacturing. In construction, they support structural components, while in automotive applications, they may secure parts within vehicles. In electronics, these brackets can mount sensors and devices. Understanding the specific applications relevant to your industry can help in selecting the right type of bracket for your needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 U-Shaped Bracket Manufacturers & Suppliers List

1. Unistrut – U Shaped Fittings

Domain: unistrutohio.com

Registered: 2002 (23 years)

Introduction: Unistrut U Shaped Fittings (1-5/8″) include various types and sizes of fittings. Key details include: 34 products available, finishes such as 304 Stainless Steel (13), Electrogalvanized (30), Hot-Dipped Galvanized (24), and Perma-Green® III (29). Product types include 1-Hole (5), 2-Hole (9), 3-Hole (13), 4-Hole (3), and 5-Hole (1). Notable products include Unistrut P1043A (6 Hole, “U” Shape Fittin…

2. Unistrut Store – U Brackets

Domain: unistrutstore.com

Registered: 2018 (7 years)

Introduction: U Brackets are designed to securely join multiple pieces of Unistrut Channel or mount channels to walls or other surfaces. They ensure strong, reliable connections for various structural applications. Available in multiple sizes, they offer flexible mounting solutions for both industrial and commercial projects. Free shipping on orders over $35 (some conditions apply). Specific products include: U…

3. Shiffle Equip – U Bracket for Bathroom Partitions

Domain: shifflerequip.com

Registered: 1997 (28 years)

Introduction: U bracket for 1/2 inch thick material, 14 gauge, cold rolled, satin stainless steel. Dimensions: 2 inches long. Designed for bathroom partition hardware. Provides additional support for securing objects to walls or surfaces. Benefits include increased stability, strength, and ease of installation. Ideal for both professional and DIY projects.

4. McMaster – U-Brackets and Clamps

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – U-Brackets and Clamps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Banner Engineering – Heavy-Duty Die-Cast Bracket

Domain: bannerengineering.com

Registered: 1998 (27 years)

Introduction: This company, Banner Engineering – Heavy-Duty Die-Cast Bracket, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Cascade Iron Co – Heavy Duty Double Shelf Bracket

Domain: cascadeironco.com

Registered: 2018 (7 years)

Introduction: Heavy Duty Double Shelf Bracket, designed for durability and strength, suitable for supporting shelves in various settings. Made from high-quality materials, it ensures stability and can hold significant weight. Ideal for both residential and commercial use, providing a reliable solution for shelving needs.

Strategic Sourcing Conclusion and Outlook for u-shaped bracket

In the rapidly evolving landscape of industrial components, strategic sourcing of u-shaped brackets offers significant advantages for international B2B buyers. By prioritizing quality, durability, and versatility, companies can ensure that they select brackets that not only meet immediate project requirements but also contribute to long-term operational efficiency. Sourcing from reputable manufacturers with proven track records, such as Unistrut and Banner Engineering, can enhance supply chain reliability and reduce downtime.

Moreover, understanding regional market demands and leveraging local suppliers can help businesses navigate logistical challenges while optimizing costs. As buyers from Africa, South America, the Middle East, and Europe explore sourcing options, focusing on customized solutions tailored to specific applications will be paramount.

Looking ahead, the market for u-shaped brackets is set to expand, driven by advancements in manufacturing techniques and increasing demand across various sectors. Buyers are encouraged to engage actively with suppliers, seek innovative solutions, and prioritize sustainability in their sourcing strategies. By doing so, they will not only enhance their competitive edge but also contribute to a more resilient global supply chain.