Top 6 Hesco Bastion For Sale Suppliers (And How to Choose)

Introduction: Navigating the Global Market for hesco bastion for sale

In today’s volatile global landscape, securing vital infrastructure with reliable solutions like HESCO bastions is paramount for businesses and governments alike. International B2B buyers face the critical challenge of sourcing effective protective barriers that not only meet safety standards but also provide versatility across various applications—from military operations to humanitarian efforts and flood defense. This guide serves as a comprehensive resource, detailing the types of HESCO bastions available, their diverse applications, and the essential criteria for vetting suppliers.

By delving into factors such as cost considerations, deployment efficiency, and the innovative designs that define HESCO products, this guide empowers decision-makers from regions like Africa, South America, the Middle East, and Europe—including key markets such as Saudi Arabia and Germany—to make informed purchasing decisions. Understanding the nuances of HESCO bastions will enable buyers to select solutions that not only enhance security but also align with their operational needs and budget constraints.

Navigating this complex market requires a clear understanding of product specifications and supplier reliability. This guide aims to simplify that process, ensuring that buyers can confidently procure HESCO bastions that safeguard personnel, assets, and critical infrastructure in an increasingly unpredictable world.

Understanding hesco bastion for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| HESCO® MIL | Innovative design for rapid deployment; protects personnel and assets. | Military operations, humanitarian missions | Pros: Quick setup, robust protection. Cons: Higher initial investment. |

| HESCO® Recoverable | Flat-packed units; requires minimal manpower for assembly. | Temporary military bases, disaster response | Pros: Efficient logistics, cost-effective for short-term use. Cons: May not withstand extreme conditions long-term. |

| HESCO® Flood Barriers | Specifically designed for flood protection; deployable in various terrains. | Flood defense, environmental protection | Pros: Quick deployment, effective in mitigating flood risks. Cons: Limited use outside flood scenarios. |

| HESCO® Guard Post | Provides ballistic and blast protection; modular design. | Security checkpoints, critical infrastructure | Pros: Versatile application, strong defensive capabilities. Cons: Requires more space for installation. |

| HESCO® Accommodation Bunker | Offers overhead blast protection; designed for personnel safety. | Military and civilian accommodation in conflict zones | Pros: Enhanced safety, modular for various uses. Cons: May require significant groundwork. |

What are the characteristics and suitability of HESCO® MIL products for B2B buyers?

HESCO® MIL products are designed with an innovative structure that allows for rapid deployment and robust protection of personnel and assets in military and humanitarian contexts. These units are particularly suitable for operations requiring immediate defense solutions, such as conflict zones or disaster areas. When considering a purchase, B2B buyers should evaluate the balance between initial investment and the long-term security benefits provided by these high-performance barriers.

How do HESCO® Recoverable units stand out in temporary setups?

HESCO® Recoverable units are unique in their flat-packed design, allowing for quick assembly with minimal manpower and equipment. This makes them ideal for temporary military bases or disaster response scenarios where speed and efficiency are crucial. Buyers should consider logistical aspects and the potential for reusability, as these units can be disassembled and transported easily, providing significant value in dynamic environments.

Why are HESCO® Flood Barriers essential for environmental protection?

HESCO® Flood Barriers are specifically engineered for flood defense applications, offering quick deployment capabilities in various terrains. Their effectiveness in mitigating flood risks makes them invaluable for governments and organizations involved in environmental protection and disaster management. Buyers must assess the specific flood risks in their operational areas to ensure these barriers meet their protective needs.

What advantages do HESCO® Guard Posts provide for security applications?

HESCO® Guard Posts are designed to offer both ballistic and blast protection, making them suitable for security checkpoints and critical infrastructure. Their modular design allows for flexible configurations based on site requirements. B2B buyers should consider the space and installation requirements, as well as the overall security needs of their operations, to maximize the effectiveness of these protective structures.

How do HESCO® Accommodation Bunkers enhance personnel safety?

HESCO® Accommodation Bunkers provide essential overhead blast protection and are tailored for personnel safety in conflict zones. Their modular nature allows for various configurations to accommodate different operational needs. When purchasing, buyers should evaluate the groundwork required for installation and the potential for integration with existing security measures to ensure comprehensive safety for personnel.

Key Industrial Applications of hesco bastion for sale

| Industry/Sector | Specific Application of hesco bastion for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Defense and Military | Rapid deployment of defensive perimeters | Provides quick, robust protection for personnel and assets | Assess durability, ease of transport, and rapid assembly capabilities. |

| Humanitarian Aid and Disaster Relief | Temporary shelters and barriers during crises | Offers immediate safety and security in unstable environments | Evaluate compliance with international humanitarian standards and ease of setup. |

| Oil and Gas | Security barriers for remote facilities | Protects critical infrastructure from threats and sabotage | Consider environmental resilience and local regulations for installation. |

| Flood Management | Flood defense systems in vulnerable areas | Mitigates flood damage, protecting assets and communities | Review local climate conditions and material longevity in harsh environments. |

| Construction and Civil Engineering | Site security and material storage solutions | Ensures safety and organization on construction sites | Look into compliance with local safety standards and transportation logistics. |

How is HESCO Bastion Utilized in Defense and Military Applications?

In defense and military sectors, HESCO bastions are primarily used for the rapid deployment of defensive perimeters. These systems can be quickly assembled to create secure barriers, effectively protecting personnel and critical assets in volatile environments. The ease of transport and setup is crucial for military operations, especially in remote locations or during emergencies. Buyers in this sector should prioritize the durability and assembly speed of these units to ensure they meet operational demands.

What Role Does HESCO Bastion Play in Humanitarian Aid and Disaster Relief?

HESCO bastions serve as vital tools in humanitarian aid and disaster relief efforts, providing temporary shelters and barriers during crises. These structures can be deployed swiftly to create safe zones for displaced populations, ensuring immediate protection from environmental threats and security risks. For international buyers, especially in regions prone to conflict or natural disasters, it is essential to evaluate the compliance of these products with humanitarian standards and their ease of setup under pressure.

How Can HESCO Bastion Enhance Security in the Oil and Gas Industry?

In the oil and gas sector, HESCO bastions are deployed as security barriers around remote facilities to safeguard against potential threats and sabotage. These robust barriers ensure that critical infrastructure remains protected, particularly in politically unstable regions. When sourcing HESCO products for this application, businesses should consider the environmental resilience of materials and adherence to local regulations regarding installation and safety.

Why Are HESCO Bastions Important for Flood Management?

HESCO bastions are increasingly used in flood management strategies, especially in areas vulnerable to flooding. These barriers can be quickly erected to prevent floodwaters from damaging property and infrastructure, thus protecting both assets and communities. For buyers, it is crucial to assess the local climate conditions and the longevity of materials used in these barriers to ensure effective flood mitigation.

How Do HESCO Bastions Support Construction and Civil Engineering Projects?

In construction and civil engineering, HESCO bastions provide site security and effective material storage solutions. By creating secure perimeters, these structures help maintain safety and organization on construction sites, reducing the risk of theft and accidents. Buyers in this sector should focus on compliance with local safety standards and the logistics of transporting these systems to ensure they can be integrated seamlessly into ongoing projects.

3 Common User Pain Points for ‘hesco bastion for sale’ & Their Solutions

Scenario 1: Concerns About Deployment Time and Labor Costs

The Problem: Many B2B buyers, especially in regions experiencing conflict or natural disasters, face urgent needs for rapid deployment of protective barriers. However, the traditional barriers often require extensive manpower and time for setup. This can lead to significant delays in securing vulnerable areas, increasing risk and potentially incurring higher costs due to additional security measures or damages during the interim. Buyers may find themselves questioning whether the investment in HESCO bastions justifies the cost when considering deployment efficiency.

The Solution: HESCO bastions are designed for quick assembly and can be deployed with minimal manpower. Buyers should focus on the flat-packed models that allow for rapid setup—over 1,000 feet can be deployed in under five minutes. To optimize deployment, organizations should train local teams on the assembly process to ensure readiness during emergencies. Additionally, establishing relationships with local suppliers can streamline the logistics of acquiring fill material, thus reducing both time and costs. Regular drills and simulations can enhance efficiency and preparedness, ensuring that the barriers are set up swiftly when needed.

Scenario 2: Doubts About Product Quality and Performance

The Problem: In international markets, especially in developing regions, buyers may harbor skepticism about the quality and durability of imported products like HESCO bastions. Concerns about the ability of these barriers to withstand local environmental challenges—such as extreme weather conditions or potential attacks—can complicate purchasing decisions. Buyers may hesitate to invest in these products without reliable proof of their performance, leading to frustration and potential project delays.

The Solution: Buyers should seek comprehensive product specifications and performance certifications from manufacturers. Requesting case studies or testimonials from past clients who have successfully deployed HESCO bastions in similar environments can also provide reassurance. Additionally, buyers should consider collaborating with local engineering firms to conduct field tests, ensuring that the barriers meet specific local conditions. Establishing a clear understanding of the warranty and support services offered by the manufacturer can also mitigate concerns about product performance.

Scenario 3: Managing Compliance and Regulatory Challenges

The Problem: International buyers must navigate a complex landscape of regulations and compliance requirements when purchasing military-grade products like HESCO bastions. In regions such as the Middle East and Europe, differing laws regarding importation, use, and storage of defense-related materials can create significant hurdles. This complexity can lead to delays in procurement, increased costs, and legal risks if not properly managed.

The Solution: Buyers should engage legal and compliance experts familiar with both local and international regulations governing defense equipment. Conducting thorough due diligence before purchasing HESCO bastions can prevent legal issues down the line. It is advisable to work closely with the supplier to ensure all documentation is accurate and meets regulatory standards. Additionally, joining industry associations or forums can provide valuable insights and updates on changing regulations, helping organizations stay compliant and informed throughout the procurement process.

Strategic Material Selection Guide for hesco bastion for sale

What Materials Are Commonly Used in HESCO Bastions?

When considering the purchase of HESCO bastions, it is crucial to understand the materials used in their construction. The choice of material directly affects the performance, durability, and cost-effectiveness of these protective barriers. Below, we analyze four common materials used in HESCO bastions, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Steel in HESCO Bastions?

Steel is one of the most widely used materials for HESCO bastions due to its strength and durability. Key properties include high tensile strength, excellent corrosion resistance when galvanized, and the ability to withstand extreme temperatures and pressures.

Pros: Steel is highly durable, making it suitable for long-term deployment. It is also cost-effective in large quantities, which is beneficial for large-scale projects.

Cons: While galvanized steel offers corrosion resistance, it may require additional coatings in harsh environments to prevent rust. Manufacturing complexity can increase if custom shapes or sizes are required.

Impact on Application: Steel bastions are particularly effective in military and humanitarian operations, where they may be exposed to various environmental conditions.

Considerations for International Buyers: Compliance with standards such as ASTM A123 for hot-dip galvanized coatings is essential. Buyers in regions like Saudi Arabia and Germany should ensure that the steel meets local regulations and specifications.

How Does Polypropylene Enhance HESCO Bastion Performance?

Polypropylene is a lightweight, durable plastic that is often used in the fabric of HESCO bastions. Its key properties include excellent chemical resistance, UV stability, and a high melting point.

Pros: Polypropylene is resistant to a wide range of chemicals, making it suitable for various environments. Its lightweight nature allows for easier handling and faster deployment.

Cons: While it is durable, polypropylene may not provide the same level of structural strength as steel. Additionally, it can be more expensive than traditional materials when considering large-scale applications.

Impact on Application: This material is particularly useful in flood defense scenarios, where chemical exposure may occur.

Considerations for International Buyers: Buyers should verify that the polypropylene used complies with international standards for environmental safety and durability, particularly in regions prone to extreme weather conditions.

What Role Does Concrete Play in HESCO Bastions?

Concrete is often used in conjunction with other materials to enhance the structural integrity of HESCO bastions. Its key properties include high compressive strength and excellent fire resistance.

Pros: Concrete provides a robust barrier against blasts and ballistic threats, making it ideal for military applications. It is also cost-effective for large installations.

Cons: The weight of concrete can complicate transportation and installation. Additionally, it requires longer curing times, which can delay deployment.

Impact on Application: Concrete is particularly effective in permanent installations where long-term durability is required.

Considerations for International Buyers: Compliance with standards such as DIN 1045 for structural concrete is crucial. Buyers in Europe, especially Germany, should ensure that the concrete meets local building codes.

How Does Geotextile Fabric Contribute to HESCO Bastion Functionality?

Geotextile fabric is often used in conjunction with other materials to provide additional support and filtration. Its key properties include high tensile strength and excellent permeability.

Pros: The fabric allows for effective drainage while preventing soil erosion, which enhances the stability of the bastion. It is also lightweight and easy to transport.

Cons: Geotextile fabric may degrade over time when exposed to UV light unless treated. Its effectiveness can be compromised if not properly installed.

Impact on Application: This material is particularly beneficial in flood-prone areas where soil stabilization is critical.

Considerations for International Buyers: Buyers should ensure that the geotextile fabric complies with standards such as ASTM D4751 for permeability and filtration.

Summary Table of Material Selection for HESCO Bastions

| Material | Typical Use Case for HESCO Bastion for Sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Military and humanitarian operations | High durability and strength | May require additional corrosion protection | Medium |

| Polypropylene | Flood defense scenarios | Lightweight and chemically resistant | Less structural strength compared to steel | Medium |

| Concrete | Permanent installations | Excellent blast and ballistic resistance | Heavy and requires longer installation time | Low |

| Geotextile Fabric | Soil stabilization in flood-prone areas | Effective drainage and soil erosion prevention | UV degradation over time | Medium |

This analysis provides a comprehensive overview of the materials commonly used in HESCO bastions, highlighting their properties, advantages, and considerations for international buyers. Understanding these factors is essential for making informed purchasing decisions in the B2B market.

In-depth Look: Manufacturing Processes and Quality Assurance for hesco bastion for sale

What Are the Key Stages in the Manufacturing Process of HESCO Bastions?

The manufacturing process of HESCO bastions involves several critical stages that ensure the final product meets the high standards required for protective barriers. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation

The first stage focuses on sourcing high-quality materials, predominantly steel mesh and geotextiles. These materials are selected based on their durability and resistance to environmental factors. The steel mesh is often galvanized to prevent corrosion, enhancing longevity. Suppliers must ensure that all raw materials comply with international standards, such as ISO 9001, which governs quality management systems.

Forming

In the forming stage, the prepared materials undergo various processes to create the structural components of the bastions. This involves cutting the steel mesh to specific dimensions and shaping it to form the desired structure. Advanced techniques such as welding and bending are utilized to ensure the integrity and strength of the bastion walls. Automated machinery is often employed to achieve precision in forming, which is crucial for the overall quality of the product.

Assembly

During assembly, the formed components are put together to create the final bastion structure. This stage may involve the use of specialized equipment for joining the components securely. The assembly process is designed to be efficient, allowing for rapid deployment in the field. The assembly of HESCO bastions can be done with minimal manpower, which is particularly advantageous for large-scale operations.

Finishing

The finishing stage involves applying protective coatings and conducting final inspections to ensure that the bastions meet quality standards. This may include painting or powder-coating the steel components to enhance durability and resistance to weather conditions. Additionally, any sharp edges are smoothed out to prevent injury during handling and installation.

How Is Quality Assurance Integrated into HESCO Bastion Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for HESCO bastions, ensuring that each unit adheres to stringent safety and performance standards. The QA process is structured around several international and industry-specific standards.

Relevant International Standards

Manufacturers of HESCO bastions are often required to comply with international standards such as ISO 9001, which outlines the criteria for a quality management system. This certification demonstrates a commitment to continuous improvement and customer satisfaction. Other relevant certifications may include CE marking for products sold within the European Economic Area, and API specifications for certain applications.

Key Quality Control Checkpoints

Quality control (QC) checkpoints are strategically integrated throughout the manufacturing process. These typically include:

-

Incoming Quality Control (IQC): At this initial stage, all incoming materials are inspected for compliance with specifications. This includes verifying certificates of conformity and conducting random sampling tests.

-

In-Process Quality Control (IPQC): During the manufacturing phases, continuous monitoring ensures that processes remain within defined parameters. This may involve regular inspections and tests at various points, such as after forming and before assembly.

-

Final Quality Control (FQC): Once the bastions are assembled, a comprehensive inspection is conducted to ensure that each unit meets the required standards. This includes checking for structural integrity, surface finishes, and dimensions.

What Testing Methods Are Commonly Used in HESCO Bastion Quality Assurance?

Testing methods play a vital role in verifying the performance and safety of HESCO bastions. Several common methods are employed to assess various aspects of the product:

-

Destructive Testing: This includes tests that evaluate the strength and durability of the materials used. Examples are tensile strength tests and impact resistance tests, which help determine how the bastion will perform under extreme conditions.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or magnetic particle testing are used to detect flaws or defects in materials without causing damage. These methods are crucial for ensuring the structural integrity of the bastion without compromising its usability.

-

Environmental Testing: Given that HESCO bastions are often deployed in various climates, environmental testing simulates conditions like extreme heat, cold, and moisture. This ensures that the products maintain their performance characteristics regardless of the environment.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for ensuring product reliability. Here are several strategies to confirm supplier quality:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, equipment, and quality control measures directly. This hands-on approach provides insight into the supplier’s commitment to quality.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports that outline the results of various tests conducted during the manufacturing process. These reports should include data from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. These agencies can conduct audits and testing, ensuring that the products meet required standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate several nuances related to quality control when sourcing HESCO bastions. Understanding these aspects can significantly impact procurement decisions:

-

Certification Recognition: Different regions may have varying standards and certifications. Buyers should ensure that the supplier’s certifications are recognized in their own country to avoid compliance issues.

-

Cultural Differences in Quality Standards: Quality expectations may differ across regions. Buyers should communicate their specific requirements clearly and understand the supplier’s quality assurance practices to align expectations.

-

Import Regulations: Buyers must be aware of import regulations that may affect the quality of products. Ensuring that products meet both local and international standards is crucial for smooth procurement and deployment.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing HESCO bastions, ensuring that they receive reliable, high-quality protective solutions tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hesco bastion for sale’

Introduction

In the competitive landscape of B2B procurement, sourcing HESCO bastions effectively is crucial for ensuring the safety and security of infrastructure and personnel. This guide offers a step-by-step checklist to assist international buyers in making informed decisions when purchasing HESCO bastions. By following these steps, you can streamline your procurement process, mitigate risks, and ensure compliance with your operational requirements.

Step 1: Define Your Technical Specifications

Clearly outline your specific needs before approaching suppliers. This includes understanding the size, type, and application of the HESCO bastions required for your project. Consider factors such as:

– Environment: Will the bastions be used in urban, military, or humanitarian contexts?

– Protection Level: Determine the necessary level of ballistic and blast protection based on potential threats.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers with a proven track record in delivering HESCO products. Look for companies that specialize in military or civil engineering sectors. Key considerations include:

– Experience: Choose suppliers with extensive experience in your geographic region and relevant applications.

– Customer Reviews: Investigate reviews and testimonials from previous clients to gauge reliability and product performance.

Step 3: Evaluate Supplier Certifications

Verify that your potential suppliers possess the necessary certifications and quality assurances. This step is essential to ensure compliance with international standards and regulations. Focus on:

– ISO Certifications: Check for ISO 9001 certification or equivalent, indicating a commitment to quality management.

– Product Testing: Ensure the supplier conducts rigorous testing for durability and safety, especially for critical applications.

Step 4: Request Detailed Proposals

Once you have shortlisted suppliers, request detailed proposals that include product specifications, pricing, and delivery timelines. This will help you compare options effectively. Pay attention to:

– Cost Breakdown: Analyze the pricing structure to identify any hidden costs.

– Lead Times: Understand the expected delivery schedule to align with your project timelines.

Step 5: Verify After-Sales Support

Assess the level of after-sales support offered by the supplier. Reliable after-sales service is crucial for addressing any issues that may arise post-purchase. Key aspects to evaluate include:

– Warranty Terms: Understand the warranty provided for the HESCO bastions.

– Technical Support: Ensure that the supplier offers ongoing technical support and training if necessary.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations to finalize the terms of the purchase. This step is vital to protect your interests and ensure clarity in the agreement. Focus on:

– Payment Terms: Discuss payment options and schedules to find a mutually beneficial arrangement.

– Delivery and Installation: Clarify responsibilities for delivery and any installation services required.

Step 7: Finalize the Purchase Agreement

Ensure that all agreed-upon terms are documented in a formal purchase agreement. This document should outline all specifications, costs, delivery dates, and warranty information. Important elements to include are:

– Compliance Clauses: Ensure that the agreement includes clauses regarding compliance with local regulations.

– Dispute Resolution: Define procedures for resolving any disputes that may arise during the transaction.

By following this checklist, you will be well-equipped to navigate the complexities of sourcing HESCO bastions, ensuring that your procurement aligns with your operational needs and security objectives.

Comprehensive Cost and Pricing Analysis for hesco bastion for sale Sourcing

What Are the Key Cost Components in Sourcing HESCO Bastions?

When evaluating the cost structure for sourcing HESCO bastions, several key components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of raw materials is a significant factor, particularly for HESCO bastions that require high-quality, durable materials to ensure effectiveness. The price of steel, for example, can fluctuate based on global demand and supply dynamics, impacting overall costs.

-

Labor: Labor costs vary depending on the manufacturing location. Countries with lower labor costs may offer more competitive pricing but could also affect quality and lead times.

-

Manufacturing Overhead: This includes utilities, rent, and operational expenses associated with production. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Initial tooling costs for customized or unique designs can be substantial. Buyers should consider whether they require off-the-shelf solutions or tailored products, as this will influence the overall cost.

-

Quality Control: Ensuring the products meet safety and performance standards involves additional costs. Investing in robust QC processes can enhance product reliability and reduce the risk of failures in the field.

-

Logistics: Shipping and handling costs can vary significantly based on the distance and mode of transport. International buyers should factor in customs duties and potential tariffs when calculating total logistics costs.

-

Margin: Suppliers will typically include a margin that reflects their business model, market positioning, and the level of service provided.

How Do Price Influencers Affect HESCO Bastion Costs?

Several factors can influence the pricing of HESCO bastions, particularly for international B2B buyers.

-

Volume/MOQ: Purchasing in larger quantities often leads to reduced per-unit costs. Suppliers may offer discounts for minimum order quantities (MOQs), which can be beneficial for large-scale projects.

-

Specifications and Customization: Custom features or specifications can increase costs due to additional material and labor requirements. It’s essential for buyers to clearly define their needs upfront to avoid unexpected expenses.

-

Materials: The choice of materials not only affects pricing but also impacts the durability and performance of the bastions. Higher-grade materials generally command a premium but can result in lower total costs over time due to increased longevity.

-

Quality and Certifications: Products that meet international quality standards or certifications may come at a higher price point. These certifications can be crucial for projects involving government contracts or sensitive environments.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge higher prices but could offer better service and support.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) can significantly affect logistics costs and responsibilities. Understanding the implications of terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is crucial for total cost estimation.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing HESCO Bastions?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several strategies to enhance cost-efficiency when sourcing HESCO bastions.

-

Negotiation: Engage in discussions with suppliers to negotiate prices, especially for larger orders. Suppliers may be willing to lower prices for bulk purchases or long-term contracts.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the initial purchase price. Consider factors like maintenance, durability, and potential replacement costs over the product’s lifespan.

-

Pricing Nuances: Be aware of regional pricing differences and economic conditions that may affect costs. For instance, fluctuations in currency exchange rates can impact the final pricing for international buyers.

-

Supplier Research: Conduct thorough research on potential suppliers. Look for reviews, case studies, and previous project successes to ensure reliability and quality.

-

Plan for Lead Times: Understand the lead times associated with production and shipping. Early planning can help avoid rush fees and ensure timely project completion.

In conclusion, sourcing HESCO bastions involves a comprehensive understanding of the various cost components and pricing influencers. By leveraging strategic negotiation and considering the total cost of ownership, international buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that prices can vary widely based on numerous factors, so it’s essential to request indicative quotes tailored to specific requirements.

Alternatives Analysis: Comparing hesco bastion for sale With Other Solutions

Understanding Alternatives to HESCO Bastion Solutions

In the rapidly evolving landscape of security and infrastructure protection, businesses often seek alternatives to traditional solutions like HESCO bastions. This analysis compares HESCO bastions with two viable alternatives: Modular Concrete Barriers (MCBs) and Portable Security Fencing. Each option offers unique benefits and challenges, making it essential for B2B buyers to assess their specific needs before making a decision.

Comparison Table

| Comparison Aspect | HESCO Bastion For Sale | Modular Concrete Barriers | Portable Security Fencing |

|---|---|---|---|

| Performance | Excellent blast and ballistic protection; rapid deployment capabilities | High structural integrity; effective against vehicle threats | Good deterrence; limited blast protection |

| Cost | Moderate to high initial investment | Higher upfront costs; long-term durability can justify expense | Lower initial cost; limited lifespan |

| Ease of Implementation | Quick assembly; requires minimal manpower | Requires heavy machinery for installation | Easy to set up with minimal tools |

| Maintenance | Low maintenance; durable materials | Requires occasional repairs; durable | Moderate maintenance; less durable |

| Best Use Case | Military applications, emergency situations | Long-term installations, urban security | Temporary events, crowd control |

In-Depth Look at Alternatives

Modular Concrete Barriers (MCBs)

Modular concrete barriers are heavy-duty structures designed for high-impact scenarios. They excel in providing robust protection against vehicle ramming and explosive threats. However, their installation often requires heavy machinery, making them less suitable for rapid deployment situations. While the initial costs can be higher, their longevity and durability can offer a better return on investment for long-term projects.

Portable Security Fencing

Portable security fencing is a flexible solution that offers ease of setup and mobility. This type of fencing can be quickly deployed for temporary events or crowd control scenarios. While it provides good deterrent capabilities, it lacks the robust protection against blasts and ballistic threats that HESCO bastions and MCBs offer. Additionally, the lifespan of portable fencing is generally shorter, which may lead to more frequent replacements.

Conclusion: How to Choose the Right Solution for Your Needs

When considering security solutions, B2B buyers must evaluate their specific requirements, including the context of use, budget constraints, and the level of protection needed. HESCO bastions are ideal for scenarios requiring rapid deployment and high-level protection, particularly in military and emergency situations. Modular concrete barriers suit long-term urban security needs, while portable security fencing is best for temporary setups. By understanding the strengths and weaknesses of each option, businesses can make informed decisions that align with their operational goals and risk management strategies.

Essential Technical Properties and Trade Terminology for hesco bastion for sale

What Are the Key Technical Properties of HESCO Bastions?

When evaluating HESCO bastions for purchase, understanding the essential technical specifications is crucial for ensuring optimal performance in various applications, from military defense to flood control. Here are some of the critical specifications to consider:

-

Material Grade

HESCO bastions are primarily constructed from high-tensile galvanized steel wire mesh, which is coated with a protective layer to resist corrosion. The material grade is essential as it determines the bastion’s durability and longevity in harsh environments, making it vital for B2B buyers who require reliable infrastructure solutions. -

Tolerance Levels

Tolerance refers to the acceptable limits of variation in a physical dimension or measured value. For HESCO bastions, maintaining strict tolerances in dimensions (such as height, width, and depth) ensures uniformity and structural integrity when assembled. This is particularly important for projects requiring precision in installation and effectiveness of the barrier. -

Fill Capacity

The fill capacity indicates how much earth, sand, or gravel can be used to fill the bastion. Most HESCO units can be filled to a specified capacity that ensures maximum stability and protection against external threats. Understanding fill capacity helps buyers assess how many units will be necessary for their specific application and the type of fill material required. -

Deployment Speed

The deployment speed of HESCO bastions is a significant factor in emergency situations. Many models can be set up rapidly, allowing for the establishment of defensive or protective barriers in less than five minutes. This quick deployment is crucial for military and humanitarian operations where time is of the essence. -

Load-Bearing Capacity

Load-bearing capacity defines the maximum load a bastion can support without risk of failure. This is particularly relevant for applications that may involve heavy equipment or personnel. Knowing the load-bearing specifications allows buyers to select the appropriate type of bastion for their intended use. -

Environmental Resistance

HESCO bastions are designed to withstand various environmental conditions, including extreme temperatures and moisture. This property is vital for international buyers operating in diverse climates, ensuring that the product will perform effectively regardless of geographical challenges.

What Are the Common Trade Terms Associated with HESCO Bastions?

Navigating the procurement process involves familiarizing oneself with industry terminology. Here are some essential trade terms related to HESCO bastions:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or products that are then marketed by another company. In the context of HESCO bastions, understanding whether the supplier is an OEM can provide insights into product quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For buyers, knowing the MOQ is essential for budgeting and inventory planning, especially when sourcing HESCO bastions for large-scale projects. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products. For buyers looking to purchase HESCO bastions, issuing an RFQ can help compare prices and terms from multiple suppliers, ensuring competitive offers. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is crucial for understanding shipping costs and risk management in the procurement of HESCO bastions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for project planning, especially in urgent situations where timely delivery of HESCO bastions can impact operational effectiveness. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and performance of the product. Knowing the warranty terms for HESCO bastions can help buyers assess the risk and longevity of their investment.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing HESCO bastions, ensuring they select the right solutions for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the hesco bastion for sale Sector

What Are the Key Market Dynamics and Trends in the HESCO Bastion for Sale Sector?

The HESCO bastion market is experiencing significant growth, driven by the increasing need for rapid deployment and effective defense solutions across various sectors, including military, humanitarian aid, and infrastructure protection. Global instability, rising geopolitical tensions, and an uptick in natural disasters are prompting governments and organizations to invest in robust protective measures. Particularly in regions such as Africa, South America, the Middle East, and Europe, the demand for HESCO products is amplified by the necessity for efficient and scalable defense solutions.

Emerging B2B tech trends are reshaping sourcing strategies in this market. Digital platforms and e-commerce solutions are facilitating easier access to HESCO products, allowing buyers to compare specifications, prices, and supplier credentials swiftly. Additionally, innovations in manufacturing techniques, such as modular design and advanced materials, are enhancing the efficiency and effectiveness of HESCO bastions. Buyers are increasingly interested in customizable solutions that can be adapted to specific operational requirements, reflecting a shift towards more personalized and strategic sourcing approaches.

International buyers must also navigate varying regulatory environments and compliance standards, particularly in regions like the Middle East and Europe, where procurement processes may be influenced by political considerations or regional stability. This dynamic landscape necessitates a keen understanding of local market conditions and supplier capabilities to ensure timely and effective sourcing of HESCO products.

How Is Sustainability Influencing Sourcing Decisions for HESCO Bastions?

Sustainability is becoming a critical factor in the sourcing of HESCO bastions, as environmental concerns and ethical supply chain practices gain traction among international buyers. The production of these barriers can have significant environmental impacts, from resource extraction to manufacturing processes. As such, buyers are increasingly seeking suppliers who prioritize sustainable practices, such as using recycled materials and minimizing waste.

The demand for ‘green’ certifications is on the rise, with B2B buyers looking for assurance that their suppliers adhere to environmental standards. Certifications such as ISO 14001 (Environmental Management) and eco-labels can serve as key differentiators in a competitive market. Buyers are also encouraged to engage with suppliers who demonstrate transparency in their sourcing practices, ensuring that materials are procured responsibly and ethically.

Furthermore, the integration of sustainability into product design is critical. For example, HESCO bastions that employ lightweight materials not only reduce transport emissions but also enhance ease of deployment. As companies increasingly adopt Corporate Social Responsibility (CSR) initiatives, aligning sourcing strategies with sustainability goals can improve brand reputation and customer loyalty, particularly in markets sensitive to environmental issues.

What Is the Historical Context Behind the HESCO Bastion Market?

The HESCO bastion originated in the early 1980s, developed as a response to the need for effective, portable defensive barriers in military applications. Initially designed for use in combat zones, these products quickly gained recognition for their rapid deployment capabilities and durability. Over the decades, the HESCO bastion has evolved to meet the demands of various sectors, including humanitarian aid and disaster relief efforts.

As global threats have diversified, so too has the application of HESCO products. From military installations to flood defenses, the versatility of HESCO solutions has made them invaluable in protecting critical infrastructure and personnel. This evolution reflects a broader trend in the defense sector, where innovation and adaptability are paramount to meeting emerging security challenges. Today, international B2B buyers recognize the HESCO bastion not only as a protective measure but as a strategic asset in risk management and operational resilience.

Frequently Asked Questions (FAQs) for B2B Buyers of hesco bastion for sale

-

How do I choose the right HESCO bastion for my project?

Selecting the appropriate HESCO bastion involves assessing your specific needs, such as the level of protection required, the environment, and the intended use (military, humanitarian, or civilian). Evaluate the various models available, including options for rapid deployment and flood defense. Additionally, consider factors like site conditions, fill material availability, and assembly requirements. Collaborating with experienced suppliers can provide insights into the best solution tailored to your project. -

What are the benefits of using HESCO bastions for flood protection?

HESCO bastions are highly effective for flood protection due to their quick deployment and robust construction. They can be filled with local materials, making them adaptable to various environments. Their design allows for the creation of barriers that can withstand significant water pressure, protecting critical infrastructure from flooding. This versatility makes them a preferred choice for emergency response situations in both urban and rural settings. -

What customization options are available for HESCO bastions?

Customization of HESCO bastions can include varying sizes, fill materials, and protective features depending on your specific requirements. Some suppliers offer tailored solutions that meet local regulations or project specifications. Discussing your project needs with manufacturers can lead to bespoke designs that enhance functionality, such as increased height for greater protection or integrated features for specific environmental challenges. -

What is the minimum order quantity (MOQ) for HESCO bastions?

The minimum order quantity for HESCO bastions can vary by supplier and model. Generally, manufacturers may set MOQs based on production costs and logistics. For large-scale projects, negotiating lower MOQs may be possible, especially when establishing a long-term partnership. It’s advisable to directly contact suppliers to discuss your requirements and explore options that align with your project scale. -

What payment terms should I expect when purchasing HESCO bastions internationally?

Payment terms for international purchases of HESCO bastions typically include options such as advance payment, letters of credit, or payment upon delivery. Terms may vary based on supplier policies, order size, and buyer-supplier relationships. It is crucial to clarify payment expectations early in negotiations to avoid misunderstandings. Additionally, consider discussing currency fluctuations and associated risks when dealing with international transactions. -

How can I ensure the quality of HESCO bastions before purchase?

To ensure the quality of HESCO bastions, request certifications and product specifications from suppliers. Look for manufacturers that adhere to international standards for safety and durability. Conducting site visits, if possible, or seeking third-party inspections can also provide assurance of product quality. Additionally, customer reviews and case studies can offer insights into the performance of the bastions in real-world scenarios. -

What logistics considerations should I keep in mind when sourcing HESCO bastions?

Logistics for sourcing HESCO bastions include evaluating shipping options, delivery times, and potential customs regulations. Understanding the lead time required for production and transportation is essential for planning your project timeline. Coordinate with suppliers to confirm shipping methods that align with your delivery needs, and ensure compliance with local regulations to facilitate smooth customs clearance upon arrival. -

How do I vet suppliers when purchasing HESCO bastions internationally?

Vetting suppliers involves researching their reputation, experience, and customer feedback. Request references and case studies to assess their track record with similar projects. It’s also beneficial to verify their certifications and compliance with industry standards. Engaging in direct communication and asking detailed questions about their manufacturing processes can further help evaluate their capabilities, ensuring you partner with a reliable supplier for your needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Hesco Bastion For Sale Manufacturers & Suppliers List

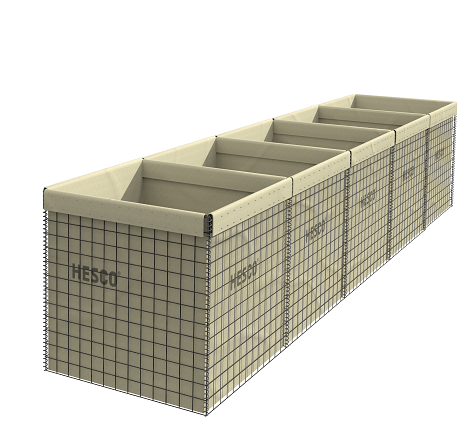

1. HESCO – Rapid Defences Series

Domain: hesco.com

Registered: 2000 (25 years)

Introduction: HESCO offers a range of products designed for protection and defense, including: 1. RAPID DEFENCES MIL – Innovative design for safeguarding personnel, vehicles, and critical assets. 2. RAPID DEFENCES R – Flat packed units that can be assembled quickly with minimal manpower. 3. RAPID DEFENCES RAID – Deploys over 1,000 feet of defensive barriers in under 5 minutes. 4. HESCO® ARMOR 800 SERIES – Milit…

2. Shengsen – Hesco Barrier Walls

Domain: shengsengabion.com

Registered: 2022 (3 years)

Introduction: Hesco Barrier Wall Wholesale at Factory Price – Shengsen

Key Product Details:

– Professional manufacturing for Hesco barrier bastion with on-demand sizes.

– Daily production output: 260+ tons.

– Quality inspection: 3 times throughout production.

– Served over 70 countries and regions.

– Certifications: ISO9001:2015, ISO14001:2015, ISO45001:2015, TüVRheinland Verified.

Applications:

– Used as a b…

3. Metalfencetech – Heavy-Duty Hesco Barrier

Domain: metalfencetech.com

Registered: 2016 (9 years)

Introduction: Heavy-Duty Hesco Barrier for Defense, Flood Control, and Environmental Protection. Designed for military, environmental, and emergency scenarios. Features durable zinc-coated steel welded mesh and non-woven geotextile lining. Quick deployment, robust performance, and adaptability. Specifications include: Steel Wire Composition: 0.1% carbon max steel; Wire Thickness: 3.5mm to 5.0mm; Wire Tensile St…

4. Welded Fence Panel – Hesco Barrier

Domain: weldedfencepanel.com

Registered: 2020 (5 years)

Introduction: Hesco Barrier, also known as hesco bastion, hesco defense wall, sand cage, welded gabion box, is a prefabricated, multi-cellular system made of zinc coated steel welded mesh and lined with non-woven geo-textile. It can be extended and joined using provided joining pins, is easy to install with minimal manpower and commonly available equipment, and is filled with sand or stone to create a defense w…

5. KESCO – Mil 12 Hesco Barriers

Domain: defensive-barrier.com

Registered: 2018 (7 years)

Introduction: Product Name: Mil 12 Hesco Barriers for Flood Control and Military Fortifications

Place of Origin: China

Brand Name: KESCO

Certification: ISO, CE, SGS, COC

Model Number: Mil 12

Material: Galvanized, Galfan coated wire

Geotextile: Heavy duty, non-woven, permeable polypropylene fabric

Geotextile Color: Beige or green

Mesh Hole Size: 3″ x 3″

Unit Size: 2.13m x 1.06m x 33m (Height x Width x Length)

Ce…

6. HESCO Barriers – Sourcing Options in Canada

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: HESCO Barriers, sourcing options in Canada, alternatives to HESCO barriers, erosion control baskets, gabion baskets, railroad ties, razor wire.

Strategic Sourcing Conclusion and Outlook for hesco bastion for sale

Why is Strategic Sourcing Crucial for HESCO Bastion Purchases?

In the evolving landscape of global defense and infrastructure, strategic sourcing of HESCO bastions presents a unique opportunity for international B2B buyers. By prioritizing quality, efficiency, and adaptability, organizations can significantly enhance their protective capabilities. HESCO’s innovative designs ensure rapid deployment and robust defense against various threats, making them an invaluable asset for military, humanitarian, and civil applications.

What are the Key Benefits of Investing in HESCO Bastions?

Investing in HESCO bastions not only safeguards critical assets but also streamlines operational effectiveness. Their modularity allows for quick assembly with minimal manpower, providing a cost-effective solution for urgent needs. Furthermore, the commitment to safety and advanced engineering behind HESCO products underscores their reliability, reinforcing buyer confidence in their strategic procurement decisions.

How Can International Buyers Leverage This Insight?

Looking ahead, international buyers from regions like Africa, South America, the Middle East, and Europe should leverage these insights to enhance their sourcing strategies. Engaging with HESCO’s offerings can lead to fortified infrastructures and improved safety protocols. As the demand for security solutions continues to grow, now is the time to explore partnerships that can provide advanced protective measures. Act decisively to secure HESCO bastions and fortify your operations against emerging threats.