Top 5 Plat Stainless Steel 304 Suppliers (And How to Choose)

Introduction: Navigating the Global Market for plat stainless steel 304

In today’s competitive landscape, international B2B buyers face the crucial challenge of sourcing high-quality plat stainless steel 304. With its remarkable corrosion resistance and versatility, 304 stainless steel is increasingly favored across various industries, from food processing to architectural applications. However, navigating the global market can be daunting, particularly for buyers from regions such as Africa, South America, the Middle East, and Europe, where the demand for reliable and durable materials is on the rise.

This comprehensive guide offers a deep dive into the world of plat stainless steel 304, covering essential topics such as types, applications, and the nuances of supplier vetting. Additionally, we will explore cost considerations and market trends that impact procurement decisions. By equipping B2B buyers with actionable insights and best practices, this guide empowers you to make informed purchasing decisions that align with your business needs and operational goals.

Understanding the intricacies of sourcing plat stainless steel 304 is not just about finding the right material; it’s about securing a competitive edge in your industry. Whether you’re in Nigeria, Brazil, or elsewhere, this guide is your roadmap to successfully navigating the complexities of the global stainless steel market, ensuring you select the best suppliers and products for your projects.

Understanding plat stainless steel 304 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 304 Stainless Steel Plate | Excellent corrosion resistance, good weldability | Food processing, marine applications, architecture | Pros: Versatile, durable, and cost-effective. Cons: May require protective coatings in aggressive environments. |

| 304L Stainless Steel Plate | Lower carbon content, better for welding | Chemical processing, oil refineries | Pros: Reduces carbide precipitation. Cons: Slightly higher cost than standard 304. |

| 304 Stainless Steel Sheet | Thinner, lighter than plates, easy to fabricate | Appliance manufacturing, automotive components | Pros: Lightweight, easy to handle. Cons: Less structural strength compared to plates. |

| 304/304L Dual Certified | Combines properties of both 304 and 304L | Versatile applications across industries | Pros: Flexibility in applications. Cons: May complicate inventory management. |

| 304 Stainless Steel Coil | Rolled form, ideal for continuous processes | Construction, HVAC systems | Pros: Efficient for large-scale manufacturing. Cons: Requires specialized handling and storage. |

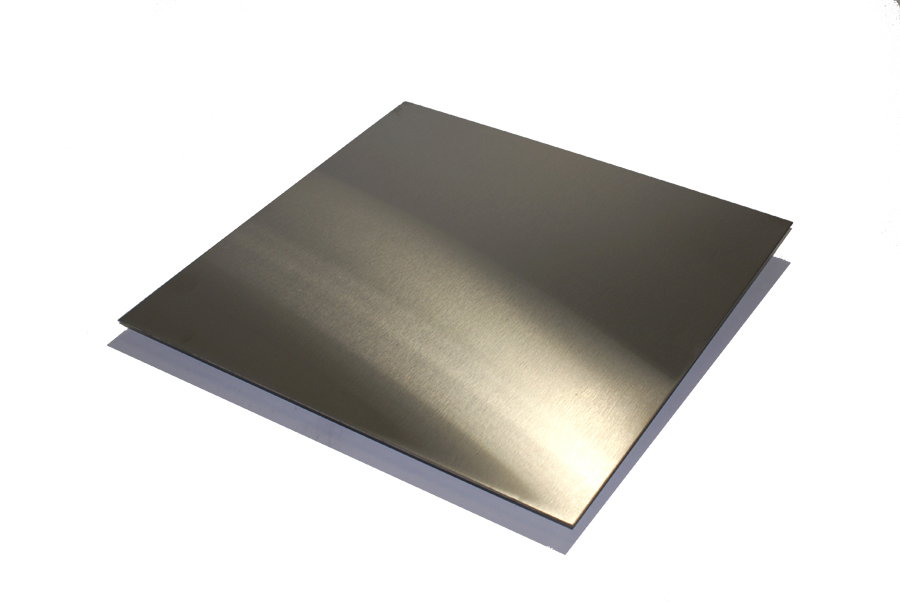

What Are the Characteristics of 304 Stainless Steel Plate?

304 Stainless Steel Plate is known for its excellent corrosion resistance and high strength, making it a popular choice in various industries. Its good weldability allows for easy fabrication, which is essential for projects in food processing, marine environments, and architectural applications. When purchasing, buyers should consider the thickness and finish, as these can impact performance in specific environments. Additionally, while the material is cost-effective, it may necessitate protective coatings in more aggressive settings.

Why Choose 304L Stainless Steel Plate for Welding Applications?

304L Stainless Steel Plate features a lower carbon content than standard 304, which significantly enhances its weldability. This makes it an ideal option for industries like chemical processing and oil refining, where structural integrity is paramount. Buyers should weigh the benefits of reduced carbide precipitation against the slightly higher cost compared to standard 304. The choice of 304L is particularly advantageous in environments subject to high temperatures or corrosive conditions.

How Does 304 Stainless Steel Sheet Differ from Plates?

304 Stainless Steel Sheet is thinner and lighter than plates, offering ease of handling and fabrication. This makes it suitable for applications such as appliance manufacturing and automotive components. Buyers should consider the sheet’s thickness and mechanical properties, as these will affect its performance in structural applications. While sheets are easier to work with, they may not provide the same level of structural strength as thicker plates, which is a critical factor for certain projects.

What Benefits Does 304/304L Dual Certified Stainless Steel Offer?

The 304/304L Dual Certified option combines the advantageous properties of both grades, allowing for flexibility in various applications. It is particularly useful in industries where both welding and corrosion resistance are required. Buyers should be aware that while this dual certification offers versatility, it may complicate inventory management due to the need to track different specifications. However, the ability to adapt to multiple applications can justify this complexity.

In What Situations Is 304 Stainless Steel Coil Most Efficient?

304 Stainless Steel Coil is ideal for continuous manufacturing processes, particularly in construction and HVAC systems. Its rolled form allows for efficient handling and storage, making it a preferred choice for large-scale projects. When considering coils, buyers should evaluate the specific requirements of their manufacturing processes, including width and thickness. While coils can streamline production, they require specialized handling to maintain quality and prevent damage during storage and transport.

Key Industrial Applications of plat stainless steel 304

| Industry/Sector | Specific Application of plat stainless steel 304 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Manufacturing of food processing equipment | Excellent corrosion resistance and hygiene compliance | Ensure compliance with food safety standards; consider local regulations and certifications. |

| Oil and Gas | Construction of refinery equipment and pipelines | High strength and durability in harsh environments | Assess the material’s resistance to specific chemicals and temperatures; consider local sourcing logistics. |

| Pharmaceutical | Production of pharmaceutical machinery and storage tanks | Non-reactive properties, ensuring product integrity | Verify compliance with health regulations; consider supplier certifications and traceability. |

| Architecture and Design | Use in architectural facades and structural components | Aesthetic appeal combined with durability and low maintenance | Evaluate design flexibility; ensure availability of various finishes and thicknesses. |

| Marine Applications | Boat and ship components | Resistance to saltwater corrosion, enhancing longevity | Check for marine-grade specifications; consider the impact of local climates on material performance. |

How is plat stainless steel 304 utilized in the food and beverage industry?

In the food and beverage sector, plat stainless steel 304 is essential for manufacturing equipment such as tanks, conveyors, and processing machinery. Its excellent corrosion resistance ensures that it can withstand exposure to various food acids and cleaning chemicals, making it ideal for maintaining hygiene and safety standards. B2B buyers in this industry must consider compliance with food safety regulations and certifications, as well as the availability of specific finishes that enhance cleanliness and reduce bacterial growth.

What role does plat stainless steel 304 play in the oil and gas industry?

In the oil and gas industry, plat stainless steel 304 is commonly used in the construction of refinery equipment and pipelines. Its high strength and durability make it suitable for handling extreme temperatures and pressures, as well as exposure to corrosive substances. For international buyers, especially in regions like Africa and the Middle East, sourcing considerations should include the material’s compatibility with specific chemicals used in their operations and the logistical aspects of transporting heavy materials.

Why is plat stainless steel 304 favored in pharmaceutical manufacturing?

The pharmaceutical sector relies on plat stainless steel 304 for its manufacturing machinery and storage tanks due to its non-reactive properties, which help maintain the integrity of sensitive products. This material ensures that no contaminants leach into the pharmaceuticals, complying with stringent health regulations. Buyers in this field must prioritize suppliers that offer certified products and can provide traceability of materials to meet regulatory requirements.

How does plat stainless steel 304 enhance architectural designs?

In architecture, plat stainless steel 304 is utilized for facades and structural components, combining aesthetic appeal with durability. Its ability to withstand environmental stressors while maintaining a polished look makes it a popular choice for modern designs. B2B buyers need to evaluate the design flexibility offered by suppliers and ensure that a variety of finishes and thicknesses are available to meet specific project requirements.

What advantages does plat stainless steel 304 offer in marine applications?

In marine applications, plat stainless steel 304 is used for components in boats and ships due to its resistance to saltwater corrosion, which significantly enhances the longevity of marine vessels. Buyers must consider the specific marine-grade specifications required for different components and assess how local environmental conditions might impact the material’s performance over time. This is crucial for ensuring the safety and reliability of marine operations.

3 Common User Pain Points for ‘plat stainless steel 304’ & Their Solutions

Scenario 1: Sourcing Quality Stainless Steel 304 Plates

The Problem: International B2B buyers often struggle with sourcing high-quality 304 stainless steel plates that meet specific industry standards. With varying suppliers across different regions, there is a risk of receiving subpar materials that do not comply with necessary certifications or specifications. This can lead to project delays, increased costs, and compromised product integrity. Buyers in regions like Africa and South America may face additional challenges due to fluctuating import regulations and tariffs, making it even more essential to ensure the quality of the materials sourced.

The Solution: To mitigate this risk, buyers should prioritize suppliers who are ISO certified and provide comprehensive documentation regarding the material’s compliance with ASTM A240 and other relevant standards. Conducting thorough research on suppliers, including reading reviews and asking for references, can help establish reliability. Additionally, buyers should consider requesting samples or conducting material tests to verify quality before committing to large orders. Engaging with local distributors who understand regional regulations can also streamline the procurement process, ensuring that the sourced materials adhere to necessary compliance requirements.

Scenario 2: Understanding Mechanical Properties for Specific Applications

The Problem: Buyers may often find themselves uncertain about the mechanical properties of 304 stainless steel plates and how these properties affect their specific applications. For instance, the tensile and yield strength, along with elongation percentages, can significantly influence the performance of the plates in demanding environments. Without a clear understanding of these properties, buyers risk selecting inappropriate materials, leading to failures in applications such as food processing, construction, or marine environments.

The Solution: To address this issue, buyers should educate themselves on the mechanical properties of 304 stainless steel plates, including tensile strength (90,000 PSI), yield strength (minimum 40,000 PSI), and elongation (50% minimum for 2” samples). Consulting with metallurgical engineers or suppliers who can provide insights into how these properties affect performance in specific applications is invaluable. Buyers should also evaluate their project requirements against the specifications of 304 stainless steel to ensure compatibility. Utilizing tools like material calculators can assist in making informed decisions, ultimately enhancing the reliability and performance of their end products.

Scenario 3: Managing Cost-Effectiveness in Bulk Orders

The Problem: Cost management is a critical pain point for B2B buyers, especially when ordering stainless steel plates in bulk. The high upfront costs can strain budgets, and buyers may find it challenging to balance quality and cost. In regions with fluctuating market prices, such as in the Middle East and parts of Europe, the unpredictability of pricing can further complicate procurement strategies, leading to potential financial losses or project overruns.

The Solution: To optimize cost-effectiveness, buyers should take advantage of bulk purchasing discounts offered by suppliers. Negotiating long-term contracts with preferred vendors can help secure fixed pricing and ensure supply consistency. Additionally, buyers should explore local suppliers to reduce shipping costs and import duties. Implementing a just-in-time inventory system can minimize holding costs while ensuring that materials are available when needed. Regularly reviewing and comparing supplier quotes can also help identify the best deals, ensuring that quality is not compromised for cost. Engaging in collaborative purchasing with other companies in the same industry can further enhance purchasing power and reduce overall costs.

Strategic Material Selection Guide for plat stainless steel 304

What Are the Key Properties of Plat Stainless Steel 304?

Plat stainless steel 304, often referred to as 18-8 stainless steel, is known for its excellent corrosion resistance and mechanical properties. It performs well in various environments, including industrial and marine settings, making it a popular choice for many applications. Key properties include:

- Corrosion Resistance: 304 stainless steel exhibits strong resistance to oxidation and corrosion, especially in environments with moderate exposure to chemicals and humidity.

- Temperature and Pressure Ratings: It can withstand temperatures up to 870°C (1600°F) in intermittent service and up to 925°C (1700°F) in continuous service, making it suitable for high-temperature applications.

- Formability and Weldability: This material is easily formed and welded, allowing for versatile manufacturing processes.

What Are the Pros and Cons of Using Plat Stainless Steel 304?

When considering plat stainless steel 304, businesses should weigh its advantages and disadvantages carefully:

- Pros:

- Durability: Its robust nature ensures longevity, reducing the need for frequent replacements.

- Cost-Effectiveness: While it may have a higher initial cost compared to carbon steel, its durability leads to lower lifecycle costs.

-

Versatility: Suitable for various applications, from food processing to architectural components.

-

Cons:

- Cost: The initial investment can be higher than other materials, which may deter some buyers.

- Manufacturing Complexity: While it is easy to work with, certain fabrication processes may require specialized equipment or techniques.

- Not Heat-Treatable: Unlike some other alloys, 304 cannot be hardened through heat treatment, which may limit its application in high-stress environments.

How Does Plat Stainless Steel 304 Impact Specific Applications?

The choice of plat stainless steel 304 can significantly influence application performance. For instance:

- Media Compatibility: It is ideal for applications involving food, beverages, and pharmaceuticals due to its non-reactive nature. However, it may not be suitable for environments with high concentrations of chlorides, which can lead to pitting corrosion.

- Structural Components: Its mechanical properties make it suitable for moderately stressed structural applications, but it may not be the best choice for highly stressed environments.

What Should International B2B Buyers Consider When Sourcing Plat Stainless Steel 304?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several factors must be considered:

- Compliance with Standards: Ensure that the material meets international standards such as ASTM, DIN, or JIS, as these can vary by region.

- Local Preferences: Certain regions may have preferences for specific grades or finishes. Understanding local market demands is crucial.

- Logistics and Supply Chain: Consider the availability of suppliers and the logistics involved in transporting the material to ensure timely delivery and cost efficiency.

Summary Table of Material Selection for Plat Stainless Steel 304

| Material | Typical Use Case for plat stainless steel 304 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plat Stainless Steel 304 | Food processing equipment, architectural trim | Excellent corrosion resistance and durability | Higher initial cost compared to carbon steel | Medium |

| 304L Stainless Steel | Dairy and beverage processing | Low carbon content improves weldability | Slightly lower strength than standard 304 | Medium |

| 316 Stainless Steel | Marine applications, chemical processing | Superior corrosion resistance in chloride-rich environments | Higher cost and less availability | High |

| Cold Rolled Steel | Structural applications, automotive parts | Cost-effective for high-volume applications | Lower corrosion resistance than stainless | Low |

This analysis provides a comprehensive overview of plat stainless steel 304 and its alternatives, equipping B2B buyers with the insights needed to make informed material selections.

In-depth Look: Manufacturing Processes and Quality Assurance for plat stainless steel 304

What Are the Key Stages in the Manufacturing Process of Plat Stainless Steel 304?

The manufacturing process for plat stainless steel 304 involves several critical stages that ensure the material meets industry standards and specifications. Understanding these stages can help B2B buyers make informed purchasing decisions.

Material Preparation: How Is Raw Material Selected?

The first step in manufacturing plat stainless steel 304 is the careful selection and preparation of raw materials. Typically, the primary components include iron, chromium (18-20%), and nickel (8-11%), which provide the alloy with its corrosion resistance and mechanical properties. The materials undergo stringent inspection upon arrival at the manufacturing facility to verify their quality and compliance with industry standards.

Once the raw materials are approved, they are processed into slabs or billets through processes like melting in an electric arc furnace (EAF) or induction furnace. This stage is crucial as it sets the foundation for the material’s overall quality. High-quality raw materials lead to better final products, which is a key consideration for international buyers.

How Is Plat Stainless Steel 304 Formed?

The next stage involves forming the material into plates through hot or cold rolling.

-

Hot Rolling: In this method, the slabs are heated above their recrystallization temperature and then rolled to the desired thickness. This technique helps improve the material’s mechanical properties and eliminates internal stresses.

-

Cold Rolling: This process involves rolling the material at room temperature. It enhances the surface finish and provides tighter tolerances, making it suitable for applications requiring precision.

Following the rolling process, the plates are often annealed to relieve stresses and enhance ductility. This heat treatment also improves the corrosion resistance of stainless steel 304, making it suitable for various applications.

What Finishing Techniques Are Commonly Used?

Finishing techniques play a significant role in the final quality of plat stainless steel 304. Common finishing methods include:

- Pickling: This chemical process removes surface oxides and scales, ensuring a clean surface for further processing.

- Passivation: This technique enhances corrosion resistance by forming a protective oxide layer on the surface.

- Polishing: For applications requiring aesthetic appeal, polishing can be applied to achieve a reflective surface finish.

These finishing processes not only improve the appearance of the plates but also enhance their performance in demanding environments.

What Quality Assurance Measures Are Implemented in the Production of Plat Stainless Steel 304?

Quality assurance (QA) is a critical aspect of the manufacturing process, particularly for international B2B buyers who require reliable products. The following QA measures are typically implemented:

Which International Standards Are Relevant for Stainless Steel 304?

Compliance with international standards is essential for ensuring product quality. Most manufacturers adhere to ISO 9001:2015, which specifies requirements for a quality management system. This certification demonstrates a commitment to quality and continuous improvement.

In addition to ISO standards, manufacturers may also comply with industry-specific standards such as:

- ASTM A240: Covers the specifications for stainless steel plates.

- ASME SA-240: Relevant for materials used in pressure vessels and heat exchangers.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

What Are the Key QC Checkpoints During Production?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure that the final product meets specifications. Common QC checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify their quality and compliance with specifications.

- In-Process Quality Control (IPQC): Quality checks are conducted at various stages during production, including after forming and finishing processes. This ensures that any deviations from standards are identified and corrected promptly.

- Final Quality Control (FQC): Before shipping, the final product undergoes thorough inspections to ensure it meets the required specifications and standards.

What Testing Methods Are Commonly Used for Quality Assurance?

Testing methods vary but typically include:

- Mechanical Testing: This includes tensile tests to determine yield strength, elongation, and tensile strength.

- Chemical Analysis: Spectrometry and other techniques are used to analyze the chemical composition, ensuring it meets the required specifications.

- Non-Destructive Testing (NDT): Methods such as ultrasonic testing and radiography help identify internal flaws without damaging the material.

These testing methods provide B2B buyers with confidence in the integrity and quality of the products they purchase.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially in regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is paramount. Here are actionable steps to ensure quality assurance:

What Should Buyers Look for in Supplier Audits?

- Audit Reports: Request recent audit reports from suppliers to assess their compliance with quality standards.

- Certifications: Verify that the supplier holds relevant certifications (e.g., ISO 9001, ASTM) and ensure they are up to date.

- Third-Party Inspections: Consider engaging third-party inspection services to conduct independent evaluations of the supplier’s processes and products.

What Are the Nuances for International B2B Buyers?

When dealing with international suppliers, buyers should be aware of the following nuances:

- Cultural Differences: Understand the cultural context of suppliers, as this can impact communication and quality expectations.

- Regulatory Compliance: Ensure that products meet the regulatory requirements of the buyer’s country, including import standards.

- Supply Chain Transparency: Seek suppliers that provide transparency in their supply chain processes, which can help mitigate risks related to quality and compliance.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for plat stainless steel 304 is crucial for B2B buyers. By focusing on these aspects, buyers can make informed decisions and establish strong relationships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plat stainless steel 304’

In the competitive landscape of B2B procurement, sourcing ‘plat stainless steel 304’ requires a strategic approach to ensure quality and cost-effectiveness. This guide provides a step-by-step checklist to assist international buyers in making informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for meeting your project requirements. Consider factors such as thickness, width, length, and finish of the stainless steel plate. Precise specifications help avoid misunderstandings with suppliers and ensure the material meets industry standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of stainless steel 304 plates. Look for suppliers with a solid track record in your region, especially in Africa, South America, the Middle East, and Europe. Utilize online directories, industry associations, and trade shows to gather information.

Step 3: Evaluate Supplier Certifications

Before engaging with a supplier, verify their certifications. Look for ISO 9001:2015 or equivalent quality management certifications, as these indicate a commitment to quality and process improvement. Additionally, check for industry-specific certifications such as ASTM compliance to ensure the material meets necessary standards.

Step 4: Request and Compare Quotes

Obtain quotes from multiple suppliers to compare pricing, delivery times, and payment terms. Ensure that the quotes are detailed, specifying the type of stainless steel, any processing requirements, and additional costs like shipping. This comparative analysis will help you negotiate better terms.

Step 5: Assess Quality Assurance Processes

Investigate the quality assurance processes of potential suppliers. Inquire about their inspection methods, testing protocols, and return policies. A supplier with stringent quality control measures is more likely to deliver products that meet your expectations and reduce the risk of defects.

Step 6: Check References and Reviews

Ask for references from previous clients and review online testimonials. This feedback can provide insights into the supplier’s reliability, customer service, and product quality. Engaging with other businesses that have sourced similar materials can reveal potential red flags or confirm a supplier’s reputation.

Step 7: Finalize Terms and Place Your Order

Once you’ve selected a supplier, finalize the terms of your order. Ensure that all agreements are documented, including delivery schedules, payment terms, and any warranties or guarantees. Clear communication and documentation will help mitigate risks and ensure a smooth transaction.

By following these steps, B2B buyers can confidently navigate the procurement of ‘plat stainless steel 304’, ensuring they partner with reliable suppliers and secure high-quality materials for their projects.

Comprehensive Cost and Pricing Analysis for plat stainless steel 304 Sourcing

What Are the Key Cost Components in Sourcing 304 Stainless Steel Plate?

When sourcing 304 stainless steel plate, it’s essential to understand the various cost components involved. The primary costs include:

-

Materials: The cost of raw stainless steel fluctuates based on global market prices influenced by demand, supply chain dynamics, and the price of alloying elements like nickel and chromium. Buyers should monitor these prices regularly as they can significantly impact overall costs.

-

Labor: Labor costs encompass the wages of workers involved in manufacturing, cutting, and processing the steel plates. Regions with higher labor costs can affect pricing, making it crucial to consider the location of the supplier.

-

Manufacturing Overhead: This includes indirect costs such as utilities, equipment maintenance, and administrative expenses incurred during production. Efficient production processes can reduce overhead and consequently lower the price for buyers.

-

Tooling: The cost of tools and machinery used in the manufacturing process can be substantial. Custom orders may require specialized tooling, leading to additional expenses that should be factored into the total price.

-

Quality Control (QC): Ensuring that the steel plates meet the required standards involves inspection and testing, which incur costs. High-quality certifications (like ASTM A240) may also come with a premium, but they guarantee product reliability.

-

Logistics: Shipping and handling costs are significant, particularly for international buyers. Factors such as distance, transportation mode, and local customs duties can all affect the final cost.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding this margin can help buyers negotiate better deals.

How Do Pricing Influencers Impact the Cost of 304 Stainless Steel Plates?

Several factors influence pricing in the B2B stainless steel market:

-

Volume and Minimum Order Quantity (MOQ): Purchasing larger quantities often results in lower per-unit costs. Negotiating for bulk discounts can lead to significant savings.

-

Specifications and Customization: Customized products may incur additional costs. Buyers should clearly define their specifications to avoid unexpected charges.

-

Quality and Certifications: Higher quality standards and certifications can increase costs, but they may be necessary for specific applications. Buyers should weigh the importance of these factors against their budget.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more but can offer better service and assurance of quality.

-

Incoterms: The terms of delivery (Incoterms) dictate who is responsible for shipping, insurance, and tariffs. Understanding these terms can help buyers calculate total costs accurately.

What Tips Can Help B2B Buyers Optimize Costs When Sourcing 304 Stainless Steel Plates?

To maximize cost efficiency in sourcing 304 stainless steel plates, buyers should consider the following strategies:

-

Negotiate Effectively: Build strong relationships with suppliers and negotiate prices based on volume, payment terms, and delivery schedules. A collaborative approach can lead to better terms.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors like maintenance, potential downtime, and resale value to understand the overall cost implications.

-

Understand Pricing Nuances: Different regions may have varying pricing structures due to local market conditions, currency fluctuations, and transportation costs. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to make informed decisions.

-

Request Indicative Prices: Always request quotes and indicative prices from multiple suppliers. This practice not only provides a benchmark for negotiations but also reveals market trends.

Disclaimer on Indicative Prices

Prices for 304 stainless steel plates can vary significantly based on market conditions, supplier negotiations, and order specifications. It is advisable for buyers to consult with multiple suppliers and request current quotes to obtain the most accurate pricing information tailored to their specific needs.

Alternatives Analysis: Comparing plat stainless steel 304 With Other Solutions

Exploring Alternatives to Plat Stainless Steel 304

When selecting materials for industrial applications, it is crucial to evaluate alternatives that can meet specific requirements. Plat stainless steel 304 is a widely used material known for its excellent corrosion resistance and versatility. However, there are other options available that may suit different operational needs, cost constraints, or performance expectations. This analysis will compare plat stainless steel 304 with two viable alternatives: carbon steel and aluminum alloy.

Comparison Table

| Comparison Aspect | Plat Stainless Steel 304 | Carbon Steel | Aluminum Alloy |

|---|---|---|---|

| Performance | Excellent corrosion resistance; high durability; good for food, chemical, and marine applications | Lower corrosion resistance; strong, suitable for structural applications | Lightweight; good corrosion resistance; excellent thermal and electrical conductivity |

| Cost | Moderate to high; price varies with market demand | Low; widely available and cost-effective | Moderate; generally higher than carbon steel but lower than stainless steel |

| Ease of Implementation | Readily weldable and formable; requires specific methods for cutting | Easy to work with; can be cut and welded using standard methods | Can be welded; requires specialized techniques for cutting and forming |

| Maintenance | Low maintenance due to corrosion resistance | Higher maintenance; prone to rust without protective coating | Low maintenance; corrosion-resistant but may require protective coatings in harsh environments |

| Best Use Case | Food processing, chemical equipment, architectural applications | Structural frameworks, automotive components, general manufacturing | Aerospace, automotive parts, and applications requiring lightweight materials |

Detailed Breakdown of Alternatives

Carbon Steel

Carbon steel is a common alternative that provides strength and durability at a lower cost compared to plat stainless steel 304. It excels in structural applications where corrosion resistance is not a primary concern. However, it is prone to rusting and requires regular maintenance or protective coatings to prolong its lifespan. Carbon steel is often favored in construction and manufacturing due to its affordability and ease of fabrication.

Aluminum Alloy

Aluminum alloys are an excellent lightweight alternative that offers good corrosion resistance and thermal conductivity. They are particularly advantageous in applications where weight reduction is essential, such as in the aerospace and automotive industries. However, aluminum alloys may require specialized fabrication techniques, which can increase implementation costs. While they provide a good balance between performance and weight, their cost can be a factor compared to carbon steel and stainless steel.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting a material, B2B buyers must assess their specific application requirements, including performance characteristics, budget constraints, and maintenance considerations. Plat stainless steel 304 is ideal for environments where corrosion resistance is critical, while carbon steel may be more suitable for structural applications where cost is a major factor. Aluminum alloys provide a lightweight option that excels in specific industries but may come with higher processing costs. By carefully evaluating these alternatives, buyers can make informed decisions that align with their operational goals and financial parameters.

Essential Technical Properties and Trade Terminology for plat stainless steel 304

What Are the Key Technical Properties of Plat Stainless Steel 304?

Stainless steel 304, often referred to as 18-8 due to its composition of approximately 18% chromium and 8% nickel, is a versatile and widely utilized material in various industries. Understanding its technical properties is crucial for B2B buyers looking to make informed purchasing decisions.

-

Material Grade: The grade designation (304) signifies that this stainless steel is part of the austenitic family, known for excellent corrosion resistance and formability. This is vital for applications in food processing, chemical industries, and architectural elements, where exposure to moisture and corrosive substances is common.

-

Tensile Strength: Typically around 90,000 PSI, tensile strength indicates the material’s ability to withstand tension without breaking. High tensile strength is essential for structural applications, ensuring durability and reliability in demanding environments.

-

Yield Strength: With a minimum yield strength of 40,000 PSI, this property defines the point at which the material begins to deform permanently. Understanding yield strength is crucial for engineers and manufacturers to ensure that components can bear the required loads without failure.

-

Thickness Tolerance: The industry standard for thickness tolerance in stainless steel plates can range from ±0.01 inches to ±0.25 inches, depending on the specific requirements. Maintaining precise tolerances is essential for applications where fit and alignment are critical, such as in machinery and fabrication.

-

Corrosion Resistance: Stainless steel 304 offers excellent resistance to a variety of corrosive environments, including industrial atmospheres and marine conditions. This property is particularly important for B2B buyers in industries such as food processing and oil refining, where equipment longevity is paramount.

-

Weldability: 304 stainless steel can be readily welded using various methods without significant loss of corrosion resistance. This is a key consideration for manufacturers who need to join materials in the fabrication process.

What Are Common Trade Terms Related to Plat Stainless Steel 304?

Familiarity with industry-specific terminology can streamline the procurement process and enhance communication between buyers and suppliers.

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for businesses sourcing components for assembly or manufacturing.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management, especially for businesses operating with tight margins.

-

RFQ (Request for Quote): An RFQ is a standard business process in which a buyer requests pricing and other details from suppliers. Submitting an RFQ can facilitate competitive bidding, ensuring that buyers receive the best price and terms.

-

Incoterms (International Commercial Terms): These are predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help businesses avoid misunderstandings regarding shipping costs, insurance, and delivery responsibilities.

-

Lead Time: This term refers to the amount of time it takes for an order to be fulfilled. Understanding lead times is crucial for supply chain management and planning, ensuring that projects remain on schedule.

-

Surface Finish: The surface treatment of stainless steel can affect its appearance and corrosion resistance. Common finishes include No. 1 (hot rolled) and No. 2B (cold rolled), and specifying the desired finish is important for aesthetic and functional performance.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategies, ensuring that they select the right materials for their specific applications while navigating the complexities of international trade effectively.

Navigating Market Dynamics and Sourcing Trends in the plat stainless steel 304 Sector

What Are the Key Market Dynamics and Trends Influencing the Plat Stainless Steel 304 Sector?

The plat stainless steel 304 market is characterized by a robust demand driven by its versatility and durability across various industries, including construction, automotive, and food processing. Global drivers such as urbanization in Africa and South America, infrastructural development in the Middle East, and stringent regulations in Europe regarding safety and quality are propelling this demand. Emerging trends such as digital procurement platforms and AI-driven supply chain analytics are revolutionizing how international B2B buyers source materials. These technologies enhance transparency, optimize inventory management, and reduce lead times, making it easier for companies to navigate the complexities of global sourcing.

Additionally, sustainability has become a focal point in purchasing decisions. Buyers are increasingly seeking suppliers who can demonstrate a commitment to environmentally friendly practices, such as recycling and responsible sourcing. This trend is particularly pronounced in Europe, where regulatory frameworks are pushing for reduced carbon footprints and improved sustainability metrics. As a result, suppliers that prioritize sustainability in their operations are likely to gain a competitive edge in the market.

How Is Sustainability and Ethical Sourcing Impacting the Plat Stainless Steel 304 Market?

The environmental impact of stainless steel production, including energy consumption and waste generation, has led to a growing emphasis on sustainability within the B2B landscape. Buyers are now more informed and concerned about the lifecycle of materials they procure. Ethical sourcing has become essential, with companies increasingly demanding transparency regarding the origins of their materials and the conditions under which they are produced.

In response, manufacturers are adopting ‘green’ certifications such as ISO 14001 for environmental management and utilizing recycled materials in their production processes. This not only reduces the environmental footprint but also appeals to eco-conscious buyers. Moreover, suppliers who can provide documentation of their sustainability practices and certifications are more likely to attract international buyers who prioritize ethical supply chains. As the market evolves, the ability to demonstrate sustainability will likely become a crucial factor influencing purchasing decisions.

What Is the Historical Context of the Plat Stainless Steel 304 Market?

The development of stainless steel dates back to the early 20th century, with the introduction of 304 stainless steel in the 1920s. Initially, its resistance to corrosion and excellent mechanical properties made it a material of choice for various applications, from kitchenware to industrial equipment. Over the decades, the demand for stainless steel, particularly 304, has steadily increased, driven by advancements in manufacturing processes and an expanding range of applications.

As industries have evolved, so too has the production of stainless steel. The introduction of automated manufacturing technologies has improved efficiency and reduced costs, enabling wider accessibility for international buyers. Today, the plat stainless steel 304 sector continues to grow, supported by a global push towards sustainable practices and the increasing importance of ethical sourcing, setting the stage for future developments in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of plat stainless steel 304

-

How do I ensure the quality of 304 stainless steel plates before purchasing?

To ensure the quality of 304 stainless steel plates, request material certifications from suppliers that confirm compliance with relevant standards, such as ASTM A240. Conducting third-party inspections can provide additional assurance. Additionally, review the supplier’s quality control processes and certifications, like ISO 9001, to gauge their commitment to quality. Evaluating customer reviews and case studies can also help in understanding the supplier’s reliability. -

What are the key specifications to look for in 304 stainless steel plates?

When sourcing 304 stainless steel plates, focus on specifications such as thickness, width, length, and finish (e.g., No. 1 finish or polished). Confirm that the material complies with ASTM A240 and other relevant standards. Pay attention to mechanical properties like tensile strength and yield strength, as well as corrosion resistance ratings. Understanding the chemical composition, particularly the nickel and chromium content, is essential for assessing its suitability for specific applications. -

What are the typical applications for 304 stainless steel plates in different industries?

304 stainless steel plates are widely used in various industries due to their excellent corrosion resistance and formability. Common applications include food and beverage processing equipment, dairy, chemical containers, and architectural elements. They are also used in marine environments and for manufacturing components in oil refineries and nuclear reactors. Understanding these applications can help buyers choose the right product for their specific needs. -

What is the minimum order quantity (MOQ) for 304 stainless steel plates?

Minimum order quantities for 304 stainless steel plates can vary significantly among suppliers. Some may allow small orders, while others may require a minimum of several tons to optimize production and shipping costs. It is essential to clarify the MOQ with potential suppliers upfront and consider consolidating orders with other products to meet the MOQ if necessary. Bulk purchasing can also lead to cost savings. -

How can I vet suppliers of 304 stainless steel plates effectively?

To effectively vet suppliers, start by researching their industry reputation through online reviews and testimonials. Request references from previous clients to gauge satisfaction levels. Check for certifications such as ISO 9001 and industry-specific standards. Evaluate their production capabilities, delivery timelines, and after-sales support. Engaging in direct communication can also provide insight into their responsiveness and reliability. -

What payment terms should I expect when sourcing 304 stainless steel plates internationally?

Payment terms for international transactions can vary widely. Common arrangements include letters of credit, advance payments, or net terms (e.g., 30, 60, or 90 days). It’s crucial to negotiate terms that provide security for both parties. Consider discussing options for escrow services or partial payments upon delivery to mitigate risks. Always ensure that terms are clearly defined in the purchase agreement. -

What logistics considerations should I keep in mind when importing 304 stainless steel plates?

Logistics for importing 304 stainless steel plates involve evaluating shipping options, lead times, and customs clearance processes. Choose reliable freight forwarders experienced in handling metal shipments. Ensure compliance with import regulations in your country, including tariffs and documentation requirements. It’s also wise to factor in insurance to protect your investment during transit, and consider warehouse options if long-term storage is necessary. -

Can I customize the dimensions and finishes of 304 stainless steel plates?

Yes, many suppliers offer customization options for dimensions and finishes of 304 stainless steel plates. When placing an order, specify your required thickness, width, length, and preferred finish (such as brushed or polished). Customization may affect lead times and costs, so it’s important to discuss these factors with the supplier. Confirm that they have the necessary equipment and capabilities to meet your specifications before finalizing the order.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Plat Stainless Steel 304 Manufacturers & Suppliers List

1. Metals Depot – T304 Stainless Steel Sheet

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: {“Product Name”: “T304 Stainless Steel Sheet”, “Material”: “304 Stainless Steel”, “Corrosion Resistance”: “Good corrosion resistance to many chemical corrodents, industrial atmospheres, and marine environments”, “Magnetism”: “May become slightly magnetic when worked”, “Heat Treatment”: “Not heat treatable”, “Grain Direction”: “Random and not guaranteed unless specified or custom quoted”, “Specific…

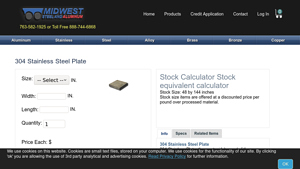

2. Midwest Steel Supply – 304 Stainless Steel Plate

Domain: midweststeelsupply.com

Registered: 2005 (20 years)

Introduction: 304 Stainless Steel Plate, available sizes: 3/16, 1/4, 5/16, 3/8, 1/2, 5/8, 3/4, 1, 1-1/4, 1-1/2, 1-3/4, 2, 2-1/2, 3, 4 inches. Stock size: 48 by 144 inches. Price range: $0.15 to $2323.6706 USD. Standard cut tolerance: -.00″/+.125″. Material specifications: ASTM A-240, ASME SA-240, A666, AMS-5639, ASTM A276, A479. Features good corrosion resistance, formability, and weldability. Dual certified 30…

3. Fast Metals – Stainless Steel Plate 304/304L

Domain: fastmetals.com

Registered: 2013 (12 years)

Introduction: Stainless Steel Plate 304/304L No. 1 Finish, 20% Off Purchases Over $200, Use Code FASTMETALS20

4. Castle Metals – 304 Stainless Steel Plate 0.3125 IN Thick

Domain: castlemetals.com

Registered: 1996 (29 years)

Introduction: {“Item”:”3048″,”Shape”:”Plate”,”Temper”:”0.3125 IN Thick Plate”,”Material”:”304-304L STAINLESS Hot Rolled, PKL, Annealed”,”Dimensions”:”60.0000 IN Width X 240.0000 IN Length”,”Specifications”:[“AMS.5513″,”AMS.5511″,”ASME.SA240″,”ASTM.A240″,”ASTM.A262″,”ASTM.A480″,”UNS.S30400″,”UNS.S30403″],”Weight”:”13.7457 LBS/SFT”,”Availability”:”In Stock”,”Part Number/Job Number”:”3048″,”Description”:”Stainless…

5. Industrial Metal Supply – 304 Stainless Steel Sheet and Plate

Domain: industrialmetalsupply.com

Registered: 1999 (26 years)

Introduction: 304 Stainless Steel Sheet and Plate

– Tolerance: Thickness, Width, Length

– Material: 304 Stainless Steel

– Properties: High tensile strength, high resistance to rust, high fabrication ability, cost-effective, versatile, excellent weight-bearing properties, high corrosion resistance, superior durability, high strength-to-weight ratio, fair resistance to thermal and electrical conductivity, ease of…

Strategic Sourcing Conclusion and Outlook for plat stainless steel 304

As the global demand for 304 stainless steel plate continues to rise, strategic sourcing becomes essential for businesses looking to optimize their supply chains. This material’s exceptional corrosion resistance and formability make it a preferred choice across various industries, including food processing, architecture, and marine applications. By engaging with reliable suppliers and leveraging bulk purchasing strategies, B2B buyers can secure favorable pricing and ensure consistent quality.

Understanding the specifications and applications of 304 stainless steel is critical for making informed purchasing decisions. Buyers in regions like Africa, South America, the Middle East, and Europe should prioritize suppliers who offer comprehensive product catalogs and customizable options to meet specific project requirements.

Looking ahead, the trend towards sustainable sourcing practices is likely to shape the stainless steel market. Businesses that proactively adapt to these changes will not only enhance their operational efficiency but also position themselves as leaders in their respective markets.

To capitalize on these opportunities, international buyers are encouraged to conduct thorough market research, build strong supplier relationships, and remain agile in their sourcing strategies. Embrace the future of stainless steel procurement to drive innovation and success in your operations.