Top 4 U Shaped Metal Brackets Suppliers (And How to Choose)

Introduction: Navigating the Global Market for u shaped metal brackets

In today’s rapidly evolving global market, sourcing high-quality u-shaped metal brackets poses significant challenges for international B2B buyers. With diverse applications spanning construction, manufacturing, and furniture industries, these brackets are essential for ensuring structural integrity and design versatility. However, the complexities of navigating different suppliers, varying quality standards, and fluctuating costs can overwhelm even the most seasoned procurement professionals. This guide aims to demystify the landscape of u-shaped metal brackets, providing insights into various types, applications, and key factors to consider when selecting suppliers.

Throughout this comprehensive resource, you will discover essential information on the different materials and finishes available, helping you choose the right products for your specific needs. We delve into the intricacies of supplier vetting, emphasizing the importance of quality assurance, certifications, and customer reviews in making informed decisions. Additionally, we address pricing trends and cost-saving strategies that cater to the diverse economic landscapes of regions such as Africa, South America, the Middle East, and Europe, including countries like Brazil and Nigeria.

By leveraging the insights offered in this guide, B2B buyers can confidently navigate the global market for u-shaped metal brackets, ensuring they secure reliable, high-quality products that meet their operational demands while optimizing their procurement processes.

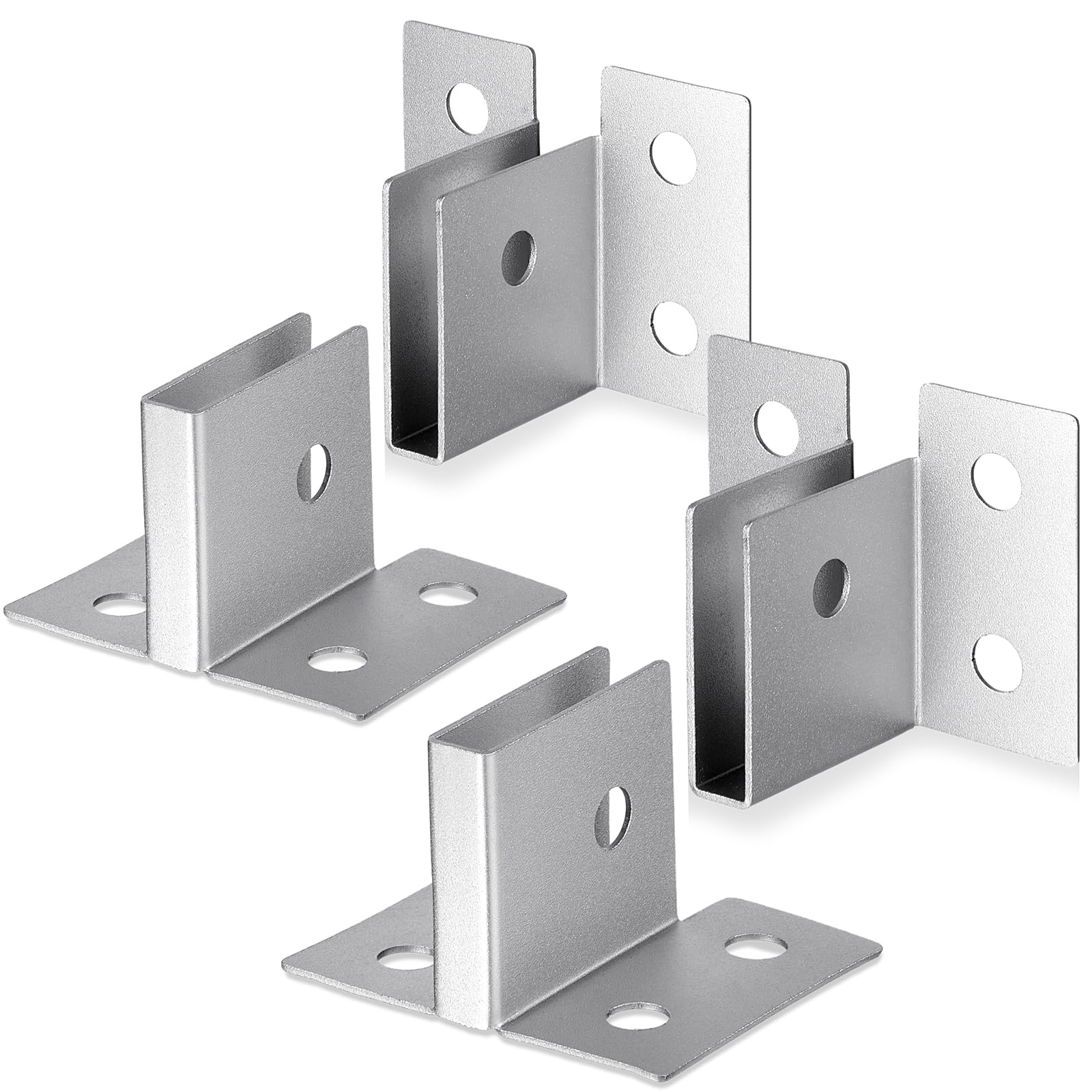

Understanding u shaped metal brackets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard U Brackets | Various hole configurations (2-6 holes), multiple finishes | General construction, shelving, mounting | Pros: Versatile, widely available. Cons: May lack customization options. |

| Heavy-Duty U Brackets | Made from thicker gauge steel, designed for high loads | Industrial applications, structural support | Pros: High strength, durability. Cons: Heavier, potentially higher shipping costs. |

| Decorative U Brackets | Aesthetic designs, available in various colors and finishes | Furniture design, interior decor | Pros: Enhances visual appeal, customizable. Cons: May not be as strong as standard options. |

| Adjustable U Brackets | Features a sliding mechanism for variable length adjustments | HVAC systems, plumbing installations | Pros: Flexible sizing, easy adjustments. Cons: Potential for mechanical failure if misused. |

| Stainless Steel U Brackets | Corrosion-resistant, polished finish | Outdoor applications, marine settings | Pros: Longevity, resistance to environmental factors. Cons: Higher cost compared to standard materials. |

What are the Characteristics and Suitability of Standard U Brackets?

Standard U brackets are typically made from mild steel and come in various configurations, including multiple hole options for versatile mounting solutions. They are widely used in general construction, shelving systems, and mounting applications. When purchasing, buyers should consider the specific load requirements and the environment in which they will be used, as these factors can influence the choice of finish and gauge.

How Do Heavy-Duty U Brackets Stand Out?

Heavy-duty U brackets are constructed from thicker gauge steel, making them ideal for applications requiring significant load-bearing capabilities. They are commonly utilized in industrial settings where structural integrity is paramount. Buyers should evaluate the specific weight loads they anticipate to ensure the chosen bracket can handle the demands of their project, as well as consider the implications of increased weight on shipping and installation.

Why Choose Decorative U Brackets for Your Projects?

Decorative U brackets offer a blend of functionality and aesthetic appeal, available in a variety of colors and styles to enhance interior design. They are often used in furniture design and interior decor projects. While they provide a visual upgrade, buyers must assess their strength and suitability for load-bearing applications, as decorative variants may not support as much weight as their standard counterparts.

What Are the Advantages of Adjustable U Brackets?

Adjustable U brackets feature a sliding mechanism that allows for length adjustments, making them particularly useful in HVAC systems and plumbing installations where flexibility is needed. They enable easy modifications during installation, which can save time and labor costs. However, buyers should be cautious about the potential for mechanical failure if the brackets are not properly installed or maintained.

When Should You Consider Stainless Steel U Brackets?

Stainless steel U brackets are specifically designed for environments that require corrosion resistance, such as outdoor applications or marine settings. Their polished finish not only offers aesthetic appeal but also extends their lifespan in harsh conditions. While the initial cost is higher than standard steel options, the long-term benefits of durability and reduced maintenance costs often justify the investment for B2B buyers.

Key Industrial Applications of u shaped metal brackets

| Industry/Sector | Specific Application of u shaped metal brackets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Building | Joining structural components in framing systems | Provides strong, reliable connections, ensuring safety and compliance with building codes | Material specifications (e.g., gauge, finish), load capacity, and environmental resistance |

| Manufacturing | Supporting machinery and equipment in production lines | Enhances operational efficiency and equipment stability, reducing downtime | Custom sizing options, compatibility with existing setups, and delivery times |

| Electrical & HVAC | Mounting conduits and ductwork for electrical and ventilation systems | Ensures organized and safe installations, improving maintenance access | Corrosion resistance, weight capacity, and ease of installation |

| Furniture & Interior Design | Creating support structures for shelving and displays | Adds aesthetic value while maintaining structural integrity | Design flexibility, color options, and material compatibility |

| Automotive & Aerospace | Securing components in assembly lines and vehicles | Increases reliability and safety in high-stress environments | Compliance with industry standards, load ratings, and sourcing from certified suppliers |

How Are U Shaped Metal Brackets Used in Construction and Building Projects?

In the construction sector, u shaped metal brackets are essential for joining various structural components, such as framing systems. They provide strong, reliable connections that not only ensure safety but also meet stringent building codes. For international buyers, especially in regions like Africa and South America, sourcing brackets that comply with local regulations while offering durability against environmental factors is crucial. Buyers should consider material specifications, such as gauge and finish, to ensure longevity and performance.

What Role Do U Shaped Metal Brackets Play in Manufacturing?

In manufacturing, u shaped metal brackets are widely used to support machinery and equipment along production lines. Their ability to enhance operational efficiency and stabilize equipment helps minimize downtime, which is vital for maintaining productivity. Buyers in the Middle East and Europe should focus on custom sizing options and compatibility with existing setups to ensure seamless integration into their operations. Additionally, delivery timelines can significantly impact production schedules, making timely sourcing a key consideration.

How Are U Shaped Metal Brackets Utilized in Electrical and HVAC Systems?

U shaped metal brackets are integral to mounting conduits and ductwork in electrical and HVAC systems. They ensure organized installations that facilitate maintenance access, thereby improving overall system performance. For buyers in regions like Nigeria and Brazil, it’s important to prioritize brackets with corrosion resistance and appropriate weight capacity to withstand varying environmental conditions. Ease of installation is another critical factor that can affect project timelines and labor costs.

How Do U Shaped Metal Brackets Enhance Furniture and Interior Design?

In the furniture and interior design industry, u shaped metal brackets serve as support structures for shelving and display units. They not only provide structural integrity but also contribute to the aesthetic appeal of the installations. Buyers should look for design flexibility and a variety of color options to match their decor. Compatibility with different materials is also essential, particularly for those sourcing products for bespoke projects in European markets where customization is often requested.

What Are the Applications of U Shaped Metal Brackets in Automotive and Aerospace Industries?

In the automotive and aerospace sectors, u shaped metal brackets are used to secure components during assembly and operation. Their reliability and safety in high-stress environments are critical to maintaining overall vehicle integrity. For international buyers, compliance with industry standards and load ratings is paramount when sourcing these brackets. Furthermore, sourcing from certified suppliers can help ensure that the brackets meet the rigorous demands of these industries, enhancing both performance and safety.

3 Common User Pain Points for ‘u shaped metal brackets’ & Their Solutions

Scenario 1: Sizing Confusion Leads to Project Delays

The Problem: One of the most common challenges faced by B2B buyers of U-shaped metal brackets is accurately determining the correct size for their applications. In industries like construction and manufacturing, using the wrong size can lead to structural issues, project delays, and increased costs. Buyers often find themselves overwhelmed by the variety of sizes and specifications available, leading to frustration and potential project setbacks when brackets do not fit as intended.

The Solution: To mitigate sizing issues, buyers should adopt a systematic approach to measuring and specifying U-shaped brackets. Begin by assessing the specific application requirements, including the materials being joined and the load-bearing capacity needed. Utilize detailed drawings or specifications that include dimensions and tolerances. When sourcing brackets, refer to manufacturer datasheets that provide information on hole sizes, thicknesses, and weight capacities. Always consider ordering a sample batch to test fit before committing to larger orders. Engaging with suppliers who offer customization can also provide tailored solutions that meet unique project specifications.

Scenario 2: Material Selection Complications

The Problem: Material selection for U-shaped metal brackets can be a daunting task. Buyers must navigate various materials, such as stainless steel, galvanized steel, or powder-coated options, each with different properties and price points. This complexity can lead to purchasing decisions that may not align with environmental conditions or the intended use, potentially resulting in premature corrosion, structural failure, or the need for costly replacements.

The Solution: To address material selection complications, buyers should conduct a thorough assessment of the environmental conditions where the brackets will be used. For instance, in coastal areas where saltwater exposure is a concern, opting for stainless steel or hot-dipped galvanized brackets can enhance longevity. Additionally, suppliers often provide insights into the best material choices based on specific applications. Buyers should leverage these resources and consult with engineers or material specialists to ensure they choose the right type of bracket for their needs. Requesting samples of different materials can also help in evaluating the best fit before making larger investments.

Scenario 3: Installation Challenges Leading to Performance Issues

The Problem: Installation of U-shaped metal brackets is critical for ensuring structural integrity, yet many buyers encounter challenges during the process. Improper installation can lead to misalignment, inadequate support, or even catastrophic failures, particularly in heavy-duty applications. This can stem from a lack of clear installation instructions or inadequate tools, leaving teams unsure of best practices, which can compromise safety and efficiency.

The Solution: To overcome installation challenges, it is essential for buyers to prioritize training and preparation. Suppliers should provide comprehensive installation guides and best practices specific to their products. Buyers should invest in training sessions for their installation teams to cover critical aspects such as load distribution, alignment techniques, and the use of appropriate tools. Additionally, using adjustable brackets can help accommodate minor misalignments during installation. Establishing a feedback loop with the installation team can also identify recurring issues, allowing for continuous improvement in the installation process and ensuring optimal performance of U-shaped metal brackets in the long term.

Strategic Material Selection Guide for u shaped metal brackets

When selecting materials for U-shaped metal brackets, it’s essential to consider various factors that affect performance, durability, and application suitability. Below is an analysis of four common materials used in the manufacturing of these brackets, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

What Are the Key Properties of Stainless Steel for U-Shaped Metal Brackets?

Stainless steel, particularly grades like Type 304 and Type 316, is widely used due to its excellent corrosion resistance and strength. It can withstand high temperatures and pressures, making it suitable for various industrial applications. Stainless steel brackets are also non-magnetic and have a polished finish, which enhances their aesthetic appeal.

Pros: High durability, excellent corrosion resistance, and low maintenance requirements. They are ideal for applications exposed to moisture or harsh chemicals.

Cons: The cost of stainless steel is higher compared to other materials. Manufacturing can be complex due to the need for specialized equipment.

Impact on Application: Stainless steel brackets are compatible with a variety of media, including water and chemicals, making them ideal for food processing and pharmaceutical industries.

Considerations for International Buyers: Compliance with international standards such as ASTM A240 for stainless steel is crucial. Buyers in regions like Africa and South America should also consider local availability and pricing fluctuations.

How Does Carbon Steel Compare in Performance for U-Shaped Metal Brackets?

Carbon steel is another common material, known for its high strength and affordability. It is often used in construction and industrial applications where high load-bearing capacity is required.

Pros: Cost-effective and robust, making it suitable for heavy-duty applications. It can be easily welded and fabricated.

Cons: Carbon steel is prone to rust and corrosion unless properly coated or treated. This limits its use in environments with high moisture levels.

Impact on Application: Best suited for indoor applications or environments where exposure to moisture is minimal.

Considerations for International Buyers: Buyers should be aware of the need for protective coatings to enhance durability, especially in humid climates. Compliance with standards like ASTM A36 is also essential.

What Are the Benefits of Using Aluminum for U-Shaped Metal Brackets?

Aluminum is lightweight and resistant to corrosion, making it a popular choice for applications where weight is a concern. It is often used in the automotive and aerospace industries.

Pros: Lightweight, excellent corrosion resistance, and good thermal conductivity. Aluminum brackets are easy to install and transport.

Cons: Lower strength compared to steel, which may limit their use in heavy-load applications. They can be more expensive than carbon steel.

Impact on Application: Ideal for applications requiring lightweight solutions, such as in automotive or portable structures.

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum is important. Additionally, buyers should consider the availability of aluminum in their local markets.

How Does Galvanized Steel Perform for U-Shaped Metal Brackets?

Galvanized steel is carbon steel that has been coated with a layer of zinc to enhance its corrosion resistance. This makes it suitable for outdoor applications.

Pros: Cost-effective with good corrosion resistance, especially in outdoor environments. The galvanization process adds durability.

Cons: The zinc coating can wear off over time, especially in harsh environments, leading to potential corrosion of the underlying steel.

Impact on Application: Suitable for outdoor structures, such as fencing or scaffolding, where exposure to the elements is a concern.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM A123 for galvanized coatings. Understanding local environmental conditions can also inform material choices.

Summary Table of Material Selection for U-Shaped Metal Brackets

| Material | Typical Use Case for u shaped metal brackets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceutical applications | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Carbon Steel | Heavy-duty construction | Cost-effective and robust | Prone to rust without coatings | Low |

| Aluminum | Automotive, aerospace applications | Lightweight and corrosion resistant | Lower strength than steel | Medium |

| Galvanized Steel | Outdoor structures, scaffolding | Good corrosion resistance outdoors | Zinc coating may wear off | Medium |

This guide provides valuable insights for B2B buyers considering U-shaped metal brackets. Understanding the properties and implications of each material can lead to more informed purchasing decisions that align with specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for u shaped metal brackets

What Are the Key Stages in the Manufacturing Process of U-Shaped Metal Brackets?

The manufacturing of U-shaped metal brackets involves several critical stages that ensure the final product meets both structural and aesthetic requirements. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The initial stage involves selecting the right type of metal, which is commonly cold-rolled or hot-rolled steel, stainless steel, or aluminum. The material is cut into sheets according to the specifications required for the U-shaped brackets. This step may involve using laser cutting or shearing techniques to achieve precise dimensions. The choice of material affects the bracket’s strength, corrosion resistance, and overall durability, making this selection crucial for end-use applications. -

Forming Techniques

After the material is prepared, the forming process begins. Techniques like stamping, bending, or die cutting are commonly used to create the U shape. In automated environments, CNC (Computer Numerical Control) machines may be employed to enhance accuracy and repeatability. This stage is pivotal in defining the structural integrity of the brackets, as improper forming can lead to weaknesses or inconsistencies in the final product. -

Assembly Processes

Depending on the design, some U-shaped brackets may require assembly with additional components, such as fasteners or supports. This can involve welding, riveting, or bolting. The assembly process is often automated to ensure efficiency and consistency, particularly for large orders. Quality checks during this stage can help identify any misalignments or defects before the product moves on to the finishing stage. -

Finishing Treatments

The final manufacturing stage involves applying protective coatings or finishes. Options include powder coating, galvanizing, or anodizing, which enhance corrosion resistance and aesthetics. The finishing process is vital, especially for brackets intended for outdoor or harsh environments. A well-applied finish not only improves appearance but also extends the lifespan of the brackets.

How Is Quality Assurance Implemented in U-Shaped Metal Bracket Manufacturing?

Quality assurance (QA) is essential in ensuring that U-shaped metal brackets meet international and industry-specific standards. The QA process generally involves several checkpoints throughout the manufacturing cycle.

-

International Standards Compliance

Many manufacturers adhere to international standards such as ISO 9001, which focuses on quality management systems. These standards ensure that manufacturing processes are consistent and that products meet customer expectations. Additionally, certifications like CE mark or API (American Petroleum Institute) may be relevant depending on the intended application of the brackets. -

Quality Control Checkpoints

Quality control (QC) is typically segmented into three main checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified standards. The checks may include dimensional measurements and material properties tests.

– In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to identify defects early in the process. This can include monitoring forming processes and assembly operations.

– Final Quality Control (FQC): After finishing, the final product undergoes comprehensive testing. This may include load testing, dimensional verification, and surface finish inspections to ensure the brackets meet all required specifications. -

Common Testing Methods for U-Shaped Brackets

Various testing methods are employed to assess the quality and performance of U-shaped metal brackets. These may include:

– Tensile testing to measure the material’s strength.

– Fatigue testing to evaluate how the bracket withstands repeated stress.

– Corrosion resistance testing to ensure longevity in different environments.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is crucial for ensuring product reliability.

-

Supplier Audits

Conducting on-site audits can provide insights into a manufacturer’s quality control systems and processes. During these audits, buyers can evaluate the supplier’s adherence to international standards and assess their manufacturing capabilities. -

Documentation and Reports

Requesting documentation such as quality control reports, certifications, and compliance records is an effective way to evaluate a supplier’s credibility. These documents should detail the results of various tests conducted throughout the manufacturing process. -

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can occur at various stages of production, ensuring that all processes align with agreed-upon standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate specific nuances when it comes to quality control in different regions.

-

Cultural and Regulatory Differences

Understanding the cultural context and regulatory environment in the supplier’s country is essential. Different countries may have varying standards for manufacturing and quality assurance. Buyers should familiarize themselves with these standards to avoid compliance issues. -

Language Barriers

Communication can be a challenge, particularly when discussing technical specifications or quality standards. Utilizing clear documentation and possibly translation services can help mitigate misunderstandings. -

Logistics and Supply Chain Concerns

Ensuring quality control extends beyond manufacturing. Buyers must consider logistics and shipping, as these can impact the condition of brackets upon arrival. Establishing protocols for inspection upon delivery can help address any potential issues caused during transit.

In conclusion, understanding the manufacturing processes and quality assurance measures for U-shaped metal brackets is critical for B2B buyers looking to ensure product integrity and reliability. By emphasizing quality at every stage of production and maintaining clear communication with suppliers, buyers can make informed decisions that support their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘u shaped metal brackets’

In the competitive landscape of B2B procurement, ensuring that you source the right U-shaped metal brackets is crucial for the success of your projects. This guide provides a practical checklist to streamline your sourcing process, helping you to make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements for U-shaped metal brackets. Consider factors such as the load capacity, dimensions, material type (e.g., stainless steel, galvanized), and finish (e.g., powder-coated, electro-galvanized). Having precise specifications will help you communicate effectively with suppliers and ensure the brackets meet your project’s demands.

Step 2: Identify Application Requirements

Understand the specific applications for which you need the brackets. This includes determining the environment (indoor vs. outdoor), exposure to chemicals or moisture, and the types of surfaces they will be mounted on. By identifying these requirements, you can select brackets that are not only functional but also durable and suitable for their intended use.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request company profiles, product catalogs, and references from other clients in similar industries. Look for suppliers with a proven track record in manufacturing U-shaped metal brackets, as well as certifications that demonstrate compliance with international quality standards.

Step 4: Compare Pricing and Terms

Gather quotes from multiple suppliers and compare pricing structures. Be mindful of minimum order quantities, shipping costs, and payment terms. While cost is a significant factor, consider the overall value, including quality, warranty, and after-sales service. A slightly higher initial investment in superior products may lead to lower long-term costs due to reduced maintenance and replacements.

Step 5: Verify Certifications and Compliance

Ensure that the suppliers you are considering have the necessary certifications and compliance with industry standards. This may include ISO certifications, ASTM standards, or local regulatory requirements. Verifying these credentials helps mitigate risks associated with product quality and safety, particularly in regions with strict regulatory frameworks.

Step 6: Assess Lead Times and Delivery Options

Evaluate the lead times and delivery options provided by suppliers. Efficient logistics can significantly impact your project timelines. Request information about their production capacity, shipping methods, and estimated delivery dates to ensure that the supplier can meet your deadlines without compromising quality.

Step 7: Establish Communication Channels

Finally, set up clear communication channels with your chosen supplier. Establish a point of contact for addressing queries, order updates, and potential issues. Open lines of communication facilitate smoother transactions and foster a strong working relationship, which is essential for ongoing procurement needs.

By following this checklist, you can streamline your sourcing process for U-shaped metal brackets, ensuring that your procurement is efficient, reliable, and aligned with your project requirements.

Comprehensive Cost and Pricing Analysis for u shaped metal brackets Sourcing

When sourcing U-shaped metal brackets, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. The complexity of this process can significantly affect your procurement strategy, particularly in regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in U-Shaped Metal Bracket Production?

The cost structure for U-shaped metal brackets encompasses several critical components:

-

Materials: The choice of materials (e.g., stainless steel, galvanized steel, cold-rolled steel) directly impacts costs. Higher-quality materials typically lead to higher prices but offer better durability and performance.

-

Labor: Labor costs can vary widely based on the country of production. For instance, countries with lower labor costs may offer more competitive pricing but could compromise on quality.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, leading to more competitive pricing.

-

Tooling: The investment in tooling is significant, especially for custom or specialized brackets. This cost can be amortized over larger production runs, making bulk purchases more cost-effective.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes can add to overall costs but is essential for maintaining reliability and meeting industry standards.

-

Logistics: Shipping and handling costs are crucial, particularly for international buyers. Factors like distance, shipping method, and customs duties can significantly affect the total cost.

-

Margin: Suppliers typically add a profit margin on top of their costs. This can vary depending on competition and market demand.

What Influences Pricing for U-Shaped Metal Brackets?

Several factors can influence the pricing of U-shaped metal brackets:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for volume discounts. Understanding a supplier’s MOQ can help you negotiate better terms.

-

Specifications and Customization: Custom designs or specifications can increase costs. It’s advisable to clearly communicate your requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Brackets that meet specific industry standards or certifications may come at a premium. Investing in certified products can reduce liability in the long run.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects shipping responsibilities and costs. Understanding these can help you calculate the total landed cost accurately.

How Can Buyers Negotiate Better Prices and Ensure Cost-Efficiency?

International B2B buyers should adopt several strategies to enhance cost-efficiency in sourcing U-shaped metal brackets:

-

Negotiation: Leverage volume commitments or long-term contracts to negotiate better pricing. Suppliers may offer discounts for larger orders or extended partnerships.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the TCO, which includes shipping, handling, installation, and potential maintenance costs. A slightly higher upfront cost may lead to lower overall expenses.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and local market conditions that may impact pricing. Establishing relationships with local suppliers can mitigate some of these risks.

-

Market Research: Conduct thorough market research to understand prevailing prices and the competitive landscape. This knowledge can empower you in negotiations and decision-making.

Conclusion

Understanding the comprehensive cost structure and pricing influences of U-shaped metal brackets is essential for international B2B buyers. By focusing on key cost components and employing strategic negotiation techniques, buyers can optimize their sourcing decisions, ensuring both quality and cost-effectiveness. While indicative prices may vary, informed procurement practices can lead to significant long-term savings and improved project outcomes.

Alternatives Analysis: Comparing u shaped metal brackets With Other Solutions

Exploring Alternative Solutions to U Shaped Metal Brackets

When considering structural support solutions in industrial and commercial applications, B2B buyers often evaluate a range of options. U shaped metal brackets are a popular choice due to their versatility and reliability. However, alternative solutions may provide distinct advantages depending on specific project requirements. This analysis compares U shaped metal brackets to two viable alternatives: L Brackets and Structural Adhesives.

Comparison Table

| Comparison Aspect | U Shaped Metal Brackets | L Brackets | Structural Adhesives |

|---|---|---|---|

| Performance | High load-bearing capacity | Moderate load capacity | Variable, depending on adhesive type |

| Cost | Moderate cost per unit | Generally lower than U brackets | Can be cost-effective for large areas |

| Ease of Implementation | Simple installation with bolts | Easy to install with screws | Requires surface preparation and curing time |

| Maintenance | Low maintenance required | Low maintenance required | May require inspection and reapplication |

| Best Use Case | Ideal for heavy-duty support | Suitable for lighter applications | Great for bonding dissimilar materials |

Detailed Breakdown of Alternatives

L Brackets

L brackets are a common alternative to U shaped metal brackets. They are shaped like an “L,” providing support at right angles, which makes them ideal for corner joints. L brackets are typically less expensive than U shaped brackets, making them a cost-effective solution for projects with budget constraints. However, their load-bearing capacity is generally lower, which may limit their application in heavy-duty scenarios. They are easy to install, requiring only screws or nails, and are low maintenance, making them a practical choice for various applications.

Structural Adhesives

Structural adhesives present a unique solution for joining materials without the need for mechanical fasteners. They can bond a variety of materials, including metals, plastics, and composites. The versatility of structural adhesives allows for creative designs and lightweight assemblies. However, their performance can vary significantly depending on the type of adhesive used, and they often require careful surface preparation and curing time, which can extend the project timeline. While they may be cost-effective for large areas, the initial investment in high-quality adhesives can be significant.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate solution for structural support, B2B buyers should consider multiple factors, including performance, cost, ease of implementation, maintenance, and specific use cases. U shaped metal brackets excel in heavy-duty applications, while L brackets may serve well for lighter tasks at a lower cost. Structural adhesives offer innovative bonding solutions but require more careful consideration of materials and preparation. Understanding the unique advantages and limitations of each option will empower buyers to make informed decisions that align with their project requirements and budget constraints.

Essential Technical Properties and Trade Terminology for u shaped metal brackets

What Are the Key Technical Properties of U-Shaped Metal Brackets?

Understanding the essential technical properties of U-shaped metal brackets is crucial for B2B buyers aiming for optimal performance in their applications. Here are some critical specifications to consider:

-

Material Grade: U-shaped metal brackets are typically made from various materials, including stainless steel, galvanized steel, and cold-rolled steel. Stainless steel (such as Type 304) is preferred for its corrosion resistance, making it ideal for outdoor or humid environments. Galvanized steel offers a protective layer against rust, while cold-rolled steel is known for its strength and durability. Selecting the appropriate material grade ensures longevity and reliability in your specific application.

-

Gauge Thickness: The gauge of the steel, often ranging from 12 to 14 gauge, indicates the thickness of the material. A lower gauge number means a thicker, stronger bracket. This specification is vital for load-bearing applications, as thicker brackets can support more weight without bending or breaking, which is essential in industrial settings.

-

Load Capacity: This property defines the maximum weight a bracket can support. It is typically measured in pounds (lbs) and varies based on the bracket’s material, gauge, and design. Understanding load capacity helps buyers select the right brackets for their projects, ensuring safety and structural integrity.

-

Finish Type: The finish on U-shaped metal brackets can significantly affect their performance and aesthetics. Common finishes include powder-coated, electro-galvanized, and hot-dipped galvanized. Powder coating offers a durable and attractive surface that resists fading and scratching, while galvanization provides corrosion resistance. Choosing the right finish can enhance both the longevity and appearance of the brackets in various applications.

-

Hole Configuration: The number and size of holes in a U-shaped bracket are critical for installation flexibility. Brackets may come with multiple hole options to accommodate various fasteners (e.g., bolts or screws). This feature allows for easier installation and adaptability in different mounting scenarios, making it easier for buyers to integrate them into their systems.

-

Tolerance Levels: Tolerance refers to the acceptable deviation from specified dimensions. In manufacturing, tighter tolerances ensure that brackets fit precisely in their intended applications, which is vital for maintaining structural integrity. Understanding tolerance levels helps buyers avoid installation issues and potential failures.

What Are Common Trade Terms Used in U-Shaped Metal Bracket Procurement?

Familiarity with industry terminology can streamline the procurement process. Here are essential terms B2B buyers should know:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify the quality and compatibility of U-shaped brackets with existing equipment.

-

MOQ (Minimum Order Quantity): MOQ is the minimum number of units a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management, especially for international buyers who may want to optimize shipping costs.

-

RFQ (Request for Quotation): An RFQ is a formal document soliciting price quotes from suppliers for specific products or services. For B2B buyers, issuing an RFQ for U-shaped metal brackets can lead to competitive pricing and better supplier relationships.

-

Incoterms (International Commercial Terms): These are standardized trade terms used in international sales contracts to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers manage logistics effectively and mitigate risks in international transactions.

-

Lead Time: Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is essential for project planning and ensuring that materials arrive on schedule to avoid delays in production.

-

Certification Standards: Many metal brackets must meet specific industry standards, such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization). Knowing these certification requirements can guide buyers in selecting high-quality products that meet regulatory standards.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing U-shaped metal brackets, ensuring optimal performance and compliance in their projects.

Navigating Market Dynamics and Sourcing Trends in the u shaped metal brackets Sector

What Are the Current Market Dynamics Affecting U-Shaped Metal Brackets?

The global market for u-shaped metal brackets is experiencing significant growth driven by various factors. One of the primary drivers is the increasing demand for robust structural components in construction and industrial applications, particularly in emerging markets across Africa, South America, and the Middle East. The expansion of infrastructure projects in these regions is propelling the need for reliable fastening solutions. Furthermore, the trend towards modular construction is gaining traction, which favors the use of versatile brackets that can be adapted to different structural needs.

In terms of technology, advancements in manufacturing processes, such as automated production and precision engineering, are enhancing the quality and consistency of u-shaped metal brackets. International B2B buyers are increasingly leveraging digital platforms to streamline sourcing processes, allowing for better price comparisons and supplier evaluations. The rise of e-commerce in B2B transactions is transforming how buyers interact with suppliers, making it crucial for manufacturers to establish a strong online presence.

Moreover, the impact of geopolitical factors cannot be understated. Tariffs, trade agreements, and regional regulations can significantly affect sourcing strategies and costs. Buyers in regions like Europe and Africa must stay informed about these dynamics to navigate potential challenges effectively.

How Important Is Sustainability and Ethical Sourcing in the U-Shaped Metal Bracket Market?

Sustainability has emerged as a crucial consideration in the sourcing of u-shaped metal brackets. International buyers are increasingly aware of the environmental impact of their procurement choices. The metal industry is often scrutinized for its carbon footprint, prompting manufacturers to adopt more sustainable practices. This includes the use of recycled materials and energy-efficient production methods, which not only reduce environmental harm but also resonate with buyers focused on corporate social responsibility.

Ethical sourcing practices are also gaining prominence. Buyers are urged to ensure that their suppliers adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) can serve as indicators of a supplier’s commitment to sustainability. By prioritizing suppliers who meet these standards, B2B buyers can enhance their brand reputation while contributing to a more sustainable supply chain.

What Is the Brief Evolution of U-Shaped Metal Brackets in B2B?

The evolution of u-shaped metal brackets can be traced back to their initial use in basic structural applications. Over the decades, the demand for stronger, more versatile brackets has led to innovations in design and materials. Initially made from basic steel, advancements in metallurgy have introduced options like stainless steel and galvanized finishes, which offer enhanced durability and corrosion resistance.

As industries have evolved, so too have the applications for u-shaped brackets. Today, they are employed in a wide array of sectors, including construction, automotive, and renewable energy. The integration of smart technologies and automation in manufacturing processes continues to shape the future of these essential components, enabling manufacturers to meet the diverse needs of international B2B buyers.

Through understanding these market dynamics, sustainability considerations, and the historical context of u-shaped metal brackets, international B2B buyers can make informed decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of u shaped metal brackets

-

How do I choose the right u-shaped metal bracket for my project?

Selecting the appropriate u-shaped metal bracket involves considering several factors, including the intended application, load capacity, size, and material. For heavy-duty applications, opt for brackets made from thicker gauge steel or stainless steel for enhanced durability. Measure the area where the bracket will be installed to ensure a proper fit. Additionally, consider any environmental factors, such as exposure to moisture or chemicals, which may necessitate specific finishes like galvanized or powder-coated options. -

What are the common applications for u-shaped metal brackets in B2B projects?

U-shaped metal brackets are versatile and widely used in various applications such as supporting structural beams, joining components in metal framing systems, and mounting equipment to walls. In industrial settings, they can secure electrical conduits, HVAC systems, and shelving. Their flexibility makes them suitable for both commercial and residential projects, including furniture assembly and decorative installations, depending on the design and finish. -

What customization options are available for u-shaped metal brackets?

Many suppliers offer customization options for u-shaped metal brackets, including size, material, finish, and hole configurations. If your project requires specific dimensions or load capacities, inquire about custom manufacturing capabilities. Some manufacturers also provide various color finishes for aesthetic purposes. Always confirm lead times and minimum order quantities (MOQs) for custom orders to ensure they align with your project timelines. -

What is the typical minimum order quantity (MOQ) for u-shaped metal brackets?

MOQs for u-shaped metal brackets can vary significantly among suppliers. While some may offer flexible MOQs for standard products, custom brackets often come with higher minimums, typically ranging from 50 to 100 units. It’s advisable to discuss your specific needs with the supplier, as they may accommodate smaller orders, especially for repeat customers or larger projects. Always verify pricing adjustments related to order sizes. -

How can I ensure the quality of u-shaped metal brackets from international suppliers?

To ensure quality, conduct thorough supplier vetting by requesting certifications, such as ISO standards, and reviewing their quality assurance processes. It’s beneficial to ask for product samples before placing larger orders. Additionally, consider suppliers that have a solid track record and positive reviews from other B2B buyers. Establishing clear communication regarding quality expectations and performance standards is crucial for maintaining product integrity. -

What payment terms should I expect when sourcing u-shaped metal brackets internationally?

Payment terms can vary based on the supplier’s policies and your business relationship. Common arrangements include upfront payments, deposits, or net terms (e.g., net 30 or net 60). Ensure you clarify these terms before finalizing your order. For larger transactions, consider using a Letter of Credit (LC) to safeguard your investment. It’s also wise to discuss any additional costs, such as shipping and customs duties, to avoid unexpected expenses. -

What logistics considerations should I keep in mind when importing u-shaped metal brackets?

When importing, consider shipping methods (air vs. sea), transit times, and associated costs. Ensure that your supplier can provide all necessary documentation for customs clearance, including invoices and packing lists. Familiarize yourself with local import regulations to avoid delays. Additionally, assess whether the supplier offers logistics support, such as freight forwarding services, to streamline the shipping process and mitigate risks. -

How do I handle returns or issues with u-shaped metal brackets?

Establish clear return policies with your supplier before purchasing. Most suppliers will have guidelines for handling defective or incorrectly supplied products, which may include return shipping procedures and timelines. Document any issues thoroughly with photographs and detailed descriptions. Prompt communication with the supplier can often facilitate a resolution, whether through replacements, refunds, or credits for future orders. Always confirm warranty details, as this can influence your return options.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 U Shaped Metal Brackets Manufacturers & Suppliers List

1. Unistrut Store – U Brackets

Domain: unistrutstore.com

Registered: 2018 (7 years)

Introduction: U Brackets are designed to securely join multiple pieces of Unistrut Channel or mount channels to walls or other surfaces. They ensure strong, reliable connections for a variety of structural applications. Available in multiple sizes, they offer flexible mounting solutions for both industrial and commercial projects. Free shipping on orders over $35 applies. Specific products include: Unistrut P10…

2. Wagner – Steel U-Bracket 2 Wide

Domain: shop.wagnercompanies.com

Registered: 1999 (26 years)

Introduction: This company, Wagner – Steel U-Bracket 2 Wide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Madison Iron and Wood – U Bracket – Industrial Style

Domain: madisonironandwood.com

Registered: 2016 (9 years)

Introduction: {“name”: “U Bracket – Industrial Style”, “sizes”: [“6\” x 12\””, “8\” x 12\””], “colors”: [“Matte Black”, “White”, “Bronze”, “Hammered Silver”, “Antique Copper”, “Gold”, “Royal Blue”, “Navy Blue”, “Red”, “Green”, “Bare Metal-Will Rust”], “price”: {“6\” x 12\””: [130.00, 143.00], “8\” x 12\””: [120.00, 130.00]}, “material”: “12-gauge steel”, “finish”: “baked on powder coat with UV inhibitors”, “fea…

4. TPH Supply – Stamped Stainless Steel U Brackets

Domain: tphsupply.com

Registered: 2008 (17 years)

Introduction: [{‘name’: ‘Stamped Stainless Steel, 3/4″ X-High 3″ Long U Bracket For 3/4″ Material – Set of 2’, ‘sku’: ‘0231’, ‘price’: ‘$18’}, {‘name’: ‘Bathroom Stall, Stamped Stainless Steel, “U” Bracket for 1″ Material – Set of 4’, ‘sku’: ‘0191’, ‘price’: ‘$13.50’}, {‘name’: ‘Stamped Stainless Steel, U Bracket For 1-1/4″ Material – Set of 4’, ‘sku’: ‘0194’, ‘price’: ‘$35’}, {‘name’: ‘Stamped Stainless Steel,…

Strategic Sourcing Conclusion and Outlook for u shaped metal brackets

How Can Strategic Sourcing Enhance Your Supply Chain for U-Shaped Metal Brackets?

In the ever-evolving landscape of industrial and commercial applications, the strategic sourcing of U-shaped metal brackets emerges as a pivotal factor in ensuring robust supply chains. By focusing on quality, versatility, and customization, buyers can secure brackets that not only meet their specific requirements but also enhance overall project efficiency. Key insights include leveraging suppliers that offer a variety of finishes and sizes, ensuring compatibility with diverse applications, and considering the long-term performance of materials to mitigate future costs.

Moreover, understanding the regional dynamics and sourcing capabilities is crucial for international buyers, particularly from Africa, South America, the Middle East, and Europe. This awareness allows businesses to identify reliable suppliers that align with their operational needs while optimizing logistics and reducing lead times.

Looking ahead, the demand for U-shaped metal brackets is set to grow, driven by expanding construction and manufacturing sectors. We encourage B2B buyers to act decisively—engage with suppliers who prioritize quality, customization, and sustainable practices. By doing so, you position your business for success in a competitive marketplace, ensuring that your projects are supported by the best materials available.