Top 3 4 X 8 Ceiling Panels Suppliers (And How to Choose)

Introduction: Navigating the Global Market for 4 x 8 ceiling panels

In the dynamic landscape of international construction and design, sourcing high-quality 4 x 8 ceiling panels can pose significant challenges for B2B buyers. With varying regional standards, material preferences, and compliance regulations, navigating the complexities of this market requires a strategic approach. This comprehensive guide addresses the multifaceted nature of 4 x 8 ceiling panels, encompassing a variety of types such as decorative, functional, and acoustic options, along with their diverse applications in residential and commercial settings.

This resource empowers international buyers—particularly those from Africa, South America, the Middle East, and Europe, including markets like Vietnam and Saudi Arabia—to make informed purchasing decisions. By detailing critical aspects such as supplier vetting processes, pricing structures, and installation considerations, this guide not only simplifies the sourcing journey but also enhances cost-effectiveness and quality assurance.

As you explore the intricacies of the global market for 4 x 8 ceiling panels, you will gain valuable insights into identifying reliable suppliers and selecting the right products tailored to your specific project needs. Whether you are looking to enhance aesthetic appeal, improve acoustics, or ensure durability in high-traffic environments, this guide is your essential tool for successful procurement in a competitive marketplace.

Understanding 4 x 8 ceiling panels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Acoustic Panels | Sound-absorbing materials, often with a textured finish | Offices, auditoriums, restaurants | Pros: Enhanced sound quality; Cons: Can be more expensive. |

| PVC Ceiling Panels | Lightweight, moisture-resistant, easy to clean | Bathrooms, kitchens, commercial spaces | Pros: Durable and water-resistant; Cons: Limited aesthetic options. |

| Mineral Fiber Panels | Fire-resistant, good insulation properties | Educational institutions, healthcare facilities | Pros: Excellent fire safety; Cons: Can absorb moisture if not sealed. |

| Wood Panels | Natural aesthetic, available in various finishes | High-end retail, hospitality | Pros: Attractive appearance; Cons: Higher maintenance and cost. |

| Fiberglass Reinforced Plastic (FRP) Panels | Moisture-resistant, easy to clean, durable | Food processing, healthcare environments | Pros: High durability; Cons: Limited design options. |

What are Acoustic Panels and Their Benefits for B2B Buyers?

Acoustic panels are designed to absorb sound, making them ideal for environments where noise control is essential. These panels are often made from specialized sound-absorbing materials with textured finishes that enhance their aesthetic appeal. B2B buyers in sectors like hospitality, education, and corporate offices often invest in acoustic panels to improve sound quality in meeting rooms and dining areas. However, their higher price point can be a consideration for budget-conscious buyers.

How Do PVC Ceiling Panels Serve Commercial Spaces?

PVC ceiling panels are a popular choice for areas that require moisture resistance, such as bathrooms and kitchens. Their lightweight nature makes them easy to install, and they are available in various designs that can mimic more expensive materials. Businesses in the hospitality and food service sectors appreciate PVC panels for their durability and ease of cleaning. However, the limited aesthetic options may not appeal to every buyer seeking a unique look.

What Makes Mineral Fiber Panels a Preferred Choice?

Mineral fiber panels are known for their excellent fire-resistance and insulation properties, making them suitable for educational institutions and healthcare facilities. These panels help maintain a safe environment while providing thermal comfort. B2B buyers prioritize these panels for their compliance with safety regulations. However, they must consider that mineral fiber can absorb moisture if not properly sealed, which may lead to issues in humid environments.

Why Choose Wood Panels for High-End Applications?

Wood panels offer a natural and sophisticated aesthetic that appeals to high-end retail and hospitality sectors. Available in various finishes, they can enhance the ambiance of any space. While the visual appeal is a significant advantage, B2B buyers must weigh this against higher maintenance requirements and costs. The initial investment may be justified by the long-term value and customer impressions they create.

How Do Fiberglass Reinforced Plastic (FRP) Panels Meet Industry Needs?

FRP panels are designed for high durability and moisture resistance, making them ideal for food processing and healthcare environments. Their easy-to-clean surfaces stand up to rigorous sanitation protocols, which is crucial for compliance in these industries. B2B buyers appreciate the low maintenance and long-lasting nature of FRP panels. However, the limited design options may not meet the aesthetic needs of every commercial application.

Key Industrial Applications of 4 x 8 ceiling panels

| Industry/Sector | Specific Application of 4 x 8 Ceiling Panels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Acoustic ceiling panels in hotels and restaurants | Enhances guest comfort and experience through noise reduction | Look for panels with sound absorption properties and aesthetic appeal. |

| Healthcare | Hygienic ceiling panels in hospitals and clinics | Maintains sanitary conditions and supports infection control | Ensure panels are easy to clean and meet health regulations. |

| Retail | Decorative ceiling panels in retail spaces | Creates an inviting atmosphere that can boost customer engagement | Consider panels that offer design flexibility and durability. |

| Education | Durable ceiling panels in schools and universities | Provides a safe and conducive learning environment | Focus on lightweight and easy-to-install options for quick renovations. |

| Industrial Facilities | Moisture-resistant panels in manufacturing settings | Protects infrastructure from damage and reduces maintenance costs | Source panels that are resistant to chemicals and moisture. |

How Are 4 x 8 Ceiling Panels Used in the Hospitality Sector?

In the hospitality industry, 4 x 8 ceiling panels are commonly used to create acoustic ceilings in hotels and restaurants. These panels significantly reduce noise levels, enhancing guest comfort and experience. International buyers should prioritize panels with sound-absorbing properties that align with the aesthetic of their establishments. Additionally, sourcing panels that meet fire safety regulations is critical, especially in regions with stringent building codes.

What Role Do 4 x 8 Ceiling Panels Play in Healthcare Environments?

In healthcare settings, 4 x 8 ceiling panels are essential for maintaining hygienic conditions. Hospitals and clinics utilize these panels to create sterile environments that help control infections. Buyers in this sector should look for panels that are easy to clean, resistant to mold, and compliant with health regulations. The ability to withstand harsh cleaning protocols is paramount, particularly in high-traffic areas.

How Do Retail Spaces Benefit from 4 x 8 Ceiling Panels?

Retail spaces leverage 4 x 8 ceiling panels to enhance the shopping experience through attractive design and improved acoustics. Decorative panels can create an inviting atmosphere that encourages customer engagement and increases dwell time. Retailers should focus on sourcing panels that offer a variety of design options and durability to withstand the wear and tear of a busy environment, ensuring a long-lasting investment.

Why Are 4 x 8 Ceiling Panels Important in Educational Institutions?

In educational settings, 4 x 8 ceiling panels are used to create durable and safe environments for students. These panels can help reduce noise levels, creating a conducive atmosphere for learning. Buyers from educational institutions should seek lightweight options that are easy to install, facilitating quick renovations or upgrades. Additionally, panels should meet safety standards to ensure the well-being of students and staff.

What Advantages Do 4 x 8 Ceiling Panels Offer in Industrial Facilities?

In industrial facilities, moisture-resistant 4 x 8 ceiling panels are critical for protecting infrastructure from environmental damage. These panels help maintain a clean and organized workspace, reducing maintenance costs over time. When sourcing for this application, buyers should prioritize panels that are resistant to chemicals and moisture, ensuring longevity and compliance with industry standards.

3 Common User Pain Points for ‘4 x 8 ceiling panels’ & Their Solutions

Scenario 1: Sourcing Quality Materials at Competitive Prices

The Problem: B2B buyers often struggle to find reliable suppliers who offer high-quality 4 x 8 ceiling panels at competitive prices. This challenge is exacerbated in international markets, where fluctuating currencies and varying shipping costs can lead to unexpected budget overruns. Buyers may encounter suppliers with inconsistent product quality or limited selections, making it difficult to meet both aesthetic and functional requirements for their projects.

The Solution: To effectively source 4 x 8 ceiling panels, buyers should establish relationships with multiple suppliers and leverage digital platforms that facilitate price comparisons and customer reviews. Utilize sourcing platforms that specialize in building materials, ensuring they have robust supplier vetting processes. Additionally, consider bulk purchasing agreements or long-term contracts with trusted suppliers to secure better pricing and consistent quality. Request samples to assess the material firsthand and ensure it meets specific project standards, including durability and finish. By diversifying the supplier base and negotiating terms upfront, buyers can mitigate risks and manage costs effectively.

Scenario 2: Ensuring Compliance with Local Building Codes

The Problem: Different regions have unique building codes and regulations that impact the installation of ceiling panels. B2B buyers may find themselves in a situation where their chosen 4 x 8 ceiling panels do not comply with local fire safety, insulation, or soundproofing standards. This oversight can lead to costly delays, fines, or the need for expensive rework, jeopardizing project timelines and budgets.

The Solution: Before making a purchase, buyers should conduct thorough research on local building codes relevant to ceiling installations in their region. This can be achieved by consulting with local building authorities or working with experienced contractors who understand the regulatory landscape. Suppliers often provide documentation on product compliance, including fire ratings and insulation properties. It’s advisable to request this documentation during the procurement process. Buyers should also consider working with architects or engineers during the design phase to ensure that their selections align with all necessary regulations. By prioritizing compliance upfront, buyers can avoid setbacks and ensure the longevity and safety of their installations.

Scenario 3: Managing Installation Challenges and Labor Costs

The Problem: Installing 4 x 8 ceiling panels can be labor-intensive, especially for larger commercial projects. B2B buyers may face difficulties in managing installation timelines, ensuring skilled labor availability, and controlling associated costs. Poorly executed installations can lead to visible seams, uneven surfaces, and other aesthetic issues that affect the overall quality of the project.

The Solution: To streamline installation and manage costs effectively, buyers should invest in comprehensive training for their installation teams or collaborate with professional installers who specialize in ceiling panel systems. Providing detailed installation guides and resources from manufacturers can significantly improve the installation process. Additionally, consider using pre-fabricated panels or modular systems that simplify installation, reduce labor time, and minimize the risk of errors. Setting clear timelines and expectations with the installation team can also help in managing the project more efficiently. Ultimately, focusing on quality installation practices will yield better results and enhance the durability and visual appeal of the ceiling panels, protecting the investment over time.

Strategic Material Selection Guide for 4 x 8 ceiling panels

When selecting materials for 4 x 8 ceiling panels, it’s essential to understand the properties, advantages, and limitations of common materials used in their production. This analysis will focus on four prevalent materials: PVC, gypsum board, fiberglass reinforced plastic (FRP), and plywood. Each material has unique characteristics that cater to different applications and market demands.

What Are the Key Properties of PVC Ceiling Panels?

PVC (Polyvinyl Chloride) panels are lightweight, moisture-resistant, and easy to install. They exhibit excellent thermal insulation properties and can withstand a range of temperatures without warping or degrading. PVC panels are also resistant to corrosion and chemicals, making them suitable for environments like kitchens and bathrooms.

Pros and Cons: The primary advantage of PVC is its low maintenance requirement and durability. However, they may not be as aesthetically pleasing as other materials and can have a higher upfront cost compared to traditional options. Additionally, while they are easy to install, the manufacturing complexity can lead to variability in quality.

Impact on Application: PVC ceiling panels are particularly effective in humid environments, making them ideal for commercial spaces in tropical regions of Africa and South America. International buyers should ensure compliance with local building codes, which may dictate the use of specific materials for moisture-prone areas.

Why Choose Gypsum Board for Ceiling Panels?

Gypsum board, commonly known as drywall, is a widely used material for ceiling panels due to its fire resistance and soundproofing qualities. It is relatively inexpensive and easy to work with, making it a popular choice for both residential and commercial applications.

Pros and Cons: Gypsum board is cost-effective and provides a smooth finish, but it is susceptible to moisture damage and requires careful installation to avoid cracking. Its weight can also be a concern in certain applications, necessitating additional support structures.

Impact on Application: Gypsum board is compliant with various international standards, including ASTM and DIN, which is crucial for buyers in Europe and the Middle East. However, in humid climates, it may require additional treatment or moisture-resistant variants to ensure longevity.

What Are the Benefits of Fiberglass Reinforced Plastic (FRP) Panels?

FRP panels are known for their exceptional durability and impact resistance. They are lightweight and can be easily installed in various settings, including industrial and commercial spaces. FRP panels are also resistant to moisture, chemicals, and extreme temperatures.

Pros and Cons: The key advantage of FRP is its ability to withstand harsh environments, making it ideal for food processing facilities and laboratories. However, the initial cost can be higher than other materials, and installation may require specialized skills.

Impact on Application: For international buyers, FRP panels meet stringent hygiene standards, making them suitable for food-safe environments. Buyers should confirm compliance with local regulations, especially in the Middle East and Europe, where food safety is heavily regulated.

How Does Plywood Compare as a Ceiling Panel Material?

Plywood offers a natural aesthetic and is often used in residential applications for its warmth and versatility. It is relatively strong and can be treated for moisture resistance, making it suitable for a variety of environments.

Pros and Cons: The primary advantage of plywood is its aesthetic appeal and ease of customization. However, it can be more expensive than other materials, and its performance can vary based on the type of wood used. Additionally, untreated plywood is susceptible to moisture damage.

Impact on Application: Plywood is favored in regions where natural materials are preferred, such as parts of Europe and South America. Buyers should ensure that the plywood complies with local environmental standards, particularly regarding sustainable sourcing.

Summary Table of Material Selection for 4 x 8 Ceiling Panels

| Material | Typical Use Case for 4 x 8 Ceiling Panels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Moisture-prone areas like kitchens and bathrooms | Low maintenance and durable | Higher upfront cost and aesthetic limitations | Medium |

| Gypsum Board | Residential and commercial interiors | Cost-effective and smooth finish | Susceptible to moisture damage | Low |

| Fiberglass Reinforced Plastic (FRP) | Industrial and food processing facilities | Exceptional durability and moisture resistance | Higher initial cost and specialized installation | High |

| Plywood | Residential applications with a natural look | Aesthetic appeal and customization | More expensive and moisture susceptibility | Medium |

This guide provides a comprehensive overview of material options for 4 x 8 ceiling panels, helping international B2B buyers make informed decisions based on their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 4 x 8 ceiling panels

What Are the Key Stages in the Manufacturing Process of 4 x 8 Ceiling Panels?

The manufacturing process for 4 x 8 ceiling panels involves several critical stages that ensure the final product meets both aesthetic and functional requirements. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: Selecting the Right Components

The first step in manufacturing 4 x 8 ceiling panels is material preparation. Common materials used include fiberglass, PVC, wood, and various composites. Each material is selected based on its intended application, durability, aesthetic appeal, and cost-effectiveness.

During this stage, raw materials undergo rigorous quality checks to ensure they meet industry standards. For instance, wood may be treated to prevent warping and decay, while plastics are often sourced from reputable suppliers to guarantee consistency in quality.

How Are Ceiling Panels Formed?

After material preparation, the next stage is forming. This involves shaping the raw materials into the desired panel size and thickness. Techniques such as extrusion for plastics or press molding for composites are commonly used.

In the case of wood panels, processes like tongue-and-groove or shiplap techniques may be employed to enhance the installation ease. The forming stage also includes cutting the panels to the precise dimensions of 4 x 8 feet, ensuring uniformity across batches.

What Happens During Assembly?

Once the panels are formed, the assembly stage begins. This stage may involve laminating decorative finishes or reinforcing the panels with additional layers for enhanced durability. For instance, some manufacturers opt to add a moisture-resistant layer to fiberglass panels, making them suitable for high-humidity environments.

Adhesives and mechanical fasteners are often used during assembly to ensure that layers bond securely. Quality assurance teams monitor this process closely to identify any potential defects or inconsistencies.

Which Finishing Techniques Are Commonly Used?

The final stage in the manufacturing process is finishing. This includes surface treatments such as painting, varnishing, or applying protective coatings. Finishing not only improves the aesthetic appeal of the panels but also enhances their resistance to scratches, stains, and moisture.

Specialized techniques like UV coating or powder coating may be employed to provide additional durability and a longer lifespan for the panels. This stage is crucial, as the finish can significantly affect the product’s performance and marketability.

What Quality Assurance Measures Are Essential for 4 x 8 Ceiling Panels?

Quality assurance is a vital component of the manufacturing process for 4 x 8 ceiling panels. Ensuring that products meet international standards not only guarantees customer satisfaction but also helps mitigate risks associated with non-compliance.

Which International Standards Should Buyers Consider?

For B2B buyers, understanding the relevant international standards is crucial. ISO 9001, a globally recognized standard for quality management systems, sets the benchmark for quality assurance. Compliance with ISO 9001 indicates that the manufacturer has established processes to improve customer satisfaction and ensure consistent product quality.

Additionally, other certifications such as CE (Conformité Européenne) for products sold within the European Union, and API (American Petroleum Institute) standards for panels used in specific industrial applications, can provide further assurance of product quality and safety.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to maintaining high manufacturing standards. Typically, these checkpoints are categorized into three main phases:

-

Incoming Quality Control (IQC): This phase involves inspecting raw materials before they enter the production line. Suppliers are often required to provide certificates of compliance with industry standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, QC teams monitor production at various stages. This includes checking for dimensional accuracy, surface finish quality, and structural integrity.

-

Final Quality Control (FQC): Once the panels are completed, a final inspection is conducted to ensure they meet all specifications before packaging and shipping. This may involve testing for moisture resistance, fire safety ratings, and aesthetic defects.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should adopt a proactive approach to verify supplier quality control. Here are several strategies:

-

Audits: Conducting on-site audits of manufacturing facilities allows buyers to assess quality control processes firsthand. This can include reviewing documentation, observing production lines, and checking compliance with international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insight into their QC processes. These reports should outline testing methods, results, and corrective actions taken for any identified issues.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct audits and testing to verify that the products meet specified quality standards before shipment.

What Are the Quality Control Nuances for International Buyers?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding regional compliance requirements and quality nuances is essential. Different markets may have unique regulations that affect product specifications, testing protocols, and certification processes.

Buyers should ensure that suppliers are familiar with local regulations and can provide appropriate certifications. This may include understanding the requirements for environmental sustainability, safety standards, and import/export regulations specific to their region.

By prioritizing quality assurance and thorough supplier evaluation, B2B buyers can mitigate risks and enhance their supply chain reliability when sourcing 4 x 8 ceiling panels globally.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘4 x 8 ceiling panels’

Introduction

Sourcing 4 x 8 ceiling panels can be a complex process, particularly for B2B buyers in diverse international markets. This guide provides a systematic checklist to ensure a successful procurement experience. By following these steps, buyers can make informed decisions that align with their project requirements and business objectives.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. Consider factors such as material type (e.g., plywood, fiberglass reinforced plastic), thickness, weight, and fire rating. Defining these specifications will help streamline communication with suppliers and ensure that the products meet your project’s needs.

- Material Considerations: Different projects may require specific materials based on aesthetic preferences or environmental conditions.

- Compliance Standards: Ensure that the chosen materials comply with local building codes and regulations, especially in regions with strict safety standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers. Look for companies that specialize in 4 x 8 ceiling panels and have a proven track record in your target market.

- Industry Experience: Focus on suppliers with experience in your specific industry, as they will better understand your unique requirements.

- Product Range: Check if the supplier offers a variety of products, which can be beneficial for future projects or bulk orders.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

- Quality Assurance: Inquire about quality control processes to ensure the products meet your specifications.

- Customer Feedback: Look for testimonials or reviews from past clients to gauge supplier reliability and service quality.

Step 4: Request Samples

Always request samples before finalizing your order. This step is vital for assessing the quality, finish, and suitability of the ceiling panels for your project.

- Physical Assessment: Evaluate the samples for durability, texture, and color to ensure they align with your design vision.

- Installation Compatibility: Consider how well the samples fit with your existing structures or other materials.

Step 5: Verify Supplier Certifications

Ensure that your chosen supplier holds the necessary certifications and complies with industry standards. This verification is crucial for maintaining safety and quality.

- ISO Certifications: Look for suppliers with ISO certifications that indicate adherence to international quality management standards.

- Local Regulations: Ensure compliance with local regulations, especially in markets with strict building codes.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, negotiate terms that protect your interests. This includes pricing, delivery timelines, payment terms, and warranties.

- Clear Agreements: Document all terms clearly to avoid misunderstandings later in the process.

- Flexibility: Discuss options for future orders or adjustments in case project requirements change.

Step 7: Plan Logistics and Delivery

Finally, develop a logistics plan for the delivery of your ceiling panels. Consider factors such as shipping methods, lead times, and potential customs regulations if sourcing internationally.

- Shipping Options: Evaluate different shipping methods for cost-effectiveness and reliability.

- Customs Clearance: Understand the customs processes involved to avoid delays and additional costs.

By following this comprehensive checklist, B2B buyers can effectively navigate the sourcing process for 4 x 8 ceiling panels, ensuring quality products that meet their project demands.

Comprehensive Cost and Pricing Analysis for 4 x 8 ceiling panels Sourcing

In the competitive landscape of 4 x 8 ceiling panels, understanding the comprehensive cost structure and pricing dynamics is essential for B2B buyers, especially those operating in diverse international markets such as Africa, South America, the Middle East, and Europe. This analysis delves into the key components of cost, the factors influencing pricing, and practical tips for buyers aiming to optimize their sourcing strategies.

What Are the Key Cost Components for 4 x 8 Ceiling Panels?

The overall cost of 4 x 8 ceiling panels comprises several crucial components:

-

Materials: The choice of raw materials significantly impacts pricing. For instance, panels made from high-quality plywood, fiberglass-reinforced plastics (FRP), or decorative finishes will typically be more expensive than standard drywall. Each material offers different durability, aesthetics, and maintenance requirements.

-

Labor: Labor costs are associated with both manufacturing and installation. Factors such as regional wage differences and the complexity of installation can lead to variations in labor expenses. In regions with high labor costs, buyers may need to factor in additional expenses for skilled labor.

-

Manufacturing Overhead: This encompasses fixed and variable costs related to production, including utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help mitigate overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: Initial setup costs for production tools and molds can be substantial, especially for customized designs. Buyers looking for specific features or unique aesthetics should be aware that these costs can be passed on in the final pricing.

-

Quality Control (QC): Ensuring that products meet safety and quality standards involves additional costs. High-quality certifications can enhance a product’s marketability but may also increase the price.

-

Logistics: Shipping costs can vary widely depending on distance, freight methods, and the chosen Incoterms. International shipping can add layers of complexity, especially with customs duties and import taxes.

-

Margin: Suppliers typically add a profit margin that reflects their operational risks and market positioning. Understanding the average margins in different regions can aid in negotiations.

What Factors Influence Pricing for 4 x 8 Ceiling Panels?

Several factors can affect the pricing of ceiling panels:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs with suppliers to achieve favorable pricing.

-

Specifications and Customization: Custom designs or specific performance characteristics (e.g., fire ratings, moisture resistance) can increase costs. Buyers should weigh the benefits of customization against potential price hikes.

-

Materials and Quality Certifications: Premium materials and recognized quality certifications (e.g., LEED, ISO standards) can justify higher prices. Buyers should assess whether these features align with their project requirements.

-

Supplier Factors: Supplier reputation, reliability, and historical performance can influence pricing. Established suppliers may charge a premium for their proven track record.

-

Incoterms: The chosen Incoterm can significantly affect total costs, as it defines responsibilities regarding shipping, insurance, and tariffs. Buyers should fully understand these terms to avoid unexpected expenses.

What Are Some Effective Buyer Tips for Sourcing 4 x 8 Ceiling Panels?

To optimize sourcing strategies, buyers should consider the following:

-

Negotiate Effectively: Establish clear communication with suppliers about pricing structures and be willing to negotiate terms. Leverage volume orders to secure better rates.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the purchase price. Consider installation, maintenance, and longevity in the overall cost assessment.

-

Be Aware of Pricing Nuances for International Markets: Understand regional market dynamics, including currency fluctuations, local demand, and competition. Pricing strategies may vary significantly between regions such as Africa and Europe.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can provide insight into market rates and help identify competitive pricing.

-

Stay Informed: Regularly review market trends and material costs, as these can fluctuate based on economic conditions and supply chain disruptions.

Disclaimer

The prices and cost structures mentioned in this analysis are indicative and may vary based on specific supplier agreements, market conditions, and regional economic factors. Always conduct thorough due diligence when sourcing materials to ensure compliance and value.

Alternatives Analysis: Comparing 4 x 8 ceiling panels With Other Solutions

Exploring Alternative Solutions to 4 x 8 Ceiling Panels

When considering ceiling solutions for various commercial or industrial applications, it is essential to evaluate alternatives to 4 x 8 ceiling panels. These alternatives can offer different benefits in terms of performance, cost, ease of implementation, maintenance, and specific use cases. Below is a comparison of 4 x 8 ceiling panels against two viable alternatives: Acoustic Ceiling Tiles and Fiberglass Reinforced Plastic (FRP) Panels.

| Comparison Aspect | 4 X 8 Ceiling Panels | Acoustic Ceiling Tiles | Fiberglass Reinforced Plastic (FRP) Panels |

|---|---|---|---|

| Performance | Durable, aesthetic, and versatile | Excellent sound absorption | High durability and moisture resistance |

| Cost | Moderate cost per panel | Generally lower initial cost | Higher upfront cost but long-term savings |

| Ease of Implementation | Straightforward installation | Easy to install with grid systems | Requires professional installation |

| Maintenance | Low maintenance, easy to clean | Needs periodic cleaning | Very low maintenance, easy to sanitize |

| Best Use Case | Commercial spaces, retail environments | Offices, schools, and healthcare | Food processing areas, industrial settings |

In-Depth Analysis of Alternatives

Acoustic Ceiling Tiles

Acoustic ceiling tiles are designed primarily for sound management, making them ideal for environments where noise reduction is crucial, such as offices and schools. They are often lightweight and easy to install using grid systems, which can significantly reduce labor costs. However, while they generally have a lower initial cost, their performance in terms of durability may not match that of 4 x 8 ceiling panels. Additionally, acoustic tiles may require regular cleaning to maintain their appearance and sound-absorbing properties.

Fiberglass Reinforced Plastic (FRP) Panels

FRP panels are a highly durable option that offers excellent moisture resistance, making them suitable for environments prone to humidity, such as food processing facilities and chemical plants. They provide superior impact resistance and are easy to clean, which is essential in maintaining sanitary conditions. However, the initial investment for FRP panels is typically higher compared to 4 x 8 ceiling panels, and their installation often requires professional expertise. Despite this, their long-term durability and low maintenance needs can lead to cost savings over time.

Making the Right Choice for Your Business Needs

When selecting a ceiling solution, B2B buyers must consider several factors, including the specific environment in which the panels will be installed, budget constraints, and maintenance capabilities. If sound absorption is a priority, acoustic ceiling tiles may be the best choice. For environments that require moisture resistance and easy maintenance, FRP panels stand out. Conversely, for a balance of aesthetics, durability, and moderate costs, 4 x 8 ceiling panels remain a strong contender. Ultimately, the decision should align with the operational requirements and long-term goals of the business.

Essential Technical Properties and Trade Terminology for 4 x 8 ceiling panels

What Are the Key Technical Properties of 4 x 8 Ceiling Panels?

Understanding the technical specifications of 4 x 8 ceiling panels is crucial for B2B buyers to ensure they meet project requirements and standards. Here are some essential properties to consider:

1. Material Grade

The material grade indicates the quality and durability of the ceiling panels. Common materials include PVC, gypsum, plywood, and fiberglass-reinforced plastic (FRP). Each material offers different benefits; for example, FRP is highly resistant to moisture and chemicals, making it ideal for environments prone to humidity. Selecting the right material is essential for ensuring longevity and performance in various applications.

2. Thickness

Thickness is a critical specification that affects the panel’s strength and insulation properties. Common thicknesses for 4 x 8 ceiling panels range from 1/8 inch to 1/4 inch. Thicker panels generally provide better sound insulation and durability, which is particularly important in commercial settings where noise control is a priority.

3. Fire Rating

Fire ratings classify the materials based on their ability to resist fire. Common classifications include Class A, B, and C. Class A panels have the highest fire resistance, making them suitable for high-risk environments. Ensuring compliance with local building codes regarding fire safety is vital for project approval and safety standards.

4. Weight

The weight of the panels can influence installation methods and structural requirements. For instance, lighter panels are easier to handle and install but may require additional support in some applications. Understanding the weight helps in planning logistics, including shipping and handling, which is especially relevant for international buyers.

5. Tolerance

Tolerance refers to the allowable deviation from specified dimensions. Maintaining strict tolerances is crucial for ensuring that panels fit properly during installation. Poor tolerance can lead to gaps or misalignments, impacting both aesthetics and functionality. Buyers should inquire about the manufacturer’s tolerance standards to ensure quality control.

Which Trade Terminology Should B2B Buyers Know for 4 x 8 Ceiling Panels?

Familiarity with industry jargon can facilitate smoother communication and transactions. Here are some common terms that B2B buyers should be aware of:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. When sourcing 4 x 8 ceiling panels, understanding whether a product is OEM can indicate the quality and reliability of the panels, as these products are often built to higher standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for budget planning and inventory management. Knowing the MOQ helps buyers determine whether a supplier fits their purchasing needs, particularly in regions where storage space may be limited.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and other relevant information. It typically includes specifications, quantities, and delivery requirements. Crafting a clear RFQ can lead to better pricing and terms, ensuring that all parties are aligned before proceeding with orders.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and risks, making it easier to negotiate contracts and manage international logistics.

5. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for project scheduling and inventory management. Buyers should factor in lead times when planning installations to avoid delays that could impact project timelines.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, negotiate better terms, and ensure that their projects involving 4 x 8 ceiling panels are executed efficiently and effectively.

Navigating Market Dynamics and Sourcing Trends in the 4 x 8 ceiling panels Sector

What Are the Key Market Dynamics and Trends Affecting the 4 x 8 Ceiling Panels Sector?

The global market for 4 x 8 ceiling panels is experiencing notable growth driven by increasing urbanization, rising construction activities, and a surge in demand for aesthetically pleasing and functional interior solutions. Notably, regions such as Africa, South America, the Middle East, and parts of Europe are witnessing rapid infrastructural development, which is propelling the demand for ceiling panels. Emerging technologies such as Building Information Modeling (BIM) and advanced manufacturing techniques are also reshaping sourcing strategies. These technologies enhance project efficiency, reduce lead times, and facilitate better collaboration among stakeholders, making them essential tools for B2B buyers.

Moreover, the market is seeing a shift towards lightweight and easy-to-install ceiling panels, which not only reduce labor costs but also improve installation speed. This trend is particularly relevant for buyers in fast-developing regions who prioritize efficiency and cost-effectiveness. Additionally, the increasing popularity of modular construction is influencing the design and material choices for ceiling panels, as modular systems often require standardized dimensions, such as the 4 x 8 format, to optimize space and reduce waste.

How Are Sustainability and Ethical Sourcing Influencing B2B Decisions in the 4 x 8 Ceiling Panels Market?

Sustainability has become a key consideration for B2B buyers in the 4 x 8 ceiling panels sector. The environmental impact of production processes and materials is under scrutiny, pushing manufacturers to adopt greener practices. This includes using sustainable raw materials, such as reclaimed wood or recycled plastics, which can significantly reduce the carbon footprint of ceiling panels. Buyers are increasingly seeking products that come with certifications such as Forest Stewardship Council (FSC) or Leadership in Energy and Environmental Design (LEED), which validate the sustainability of materials used.

Moreover, ethical sourcing is crucial in today’s market landscape. Buyers are encouraged to engage with suppliers who maintain transparency in their supply chains, ensuring fair labor practices and minimizing environmental degradation. This shift towards ethical sourcing not only aligns with corporate social responsibility goals but also enhances brand reputation, which is increasingly important in competitive markets. As consumers become more environmentally conscious, B2B buyers can leverage these sustainable practices as a selling point in their offerings.

What Is the Evolution of the 4 x 8 Ceiling Panels Market?

The evolution of the 4 x 8 ceiling panels market can be traced back to the early 20th century when traditional materials such as plaster and wood dominated the interior design landscape. Over the decades, innovations in materials and manufacturing techniques have introduced a variety of options, including lightweight gypsum and fiberglass-reinforced panels. The introduction of modular designs in the 1960s and 70s further revolutionized the market, allowing for easier installation and customization.

Today, the market is characterized by a diverse range of materials, including metal, vinyl, and eco-friendly options, catering to the varying aesthetic and functional needs of modern consumers. The shift towards sustainability and technological advancements continues to shape the future of the 4 x 8 ceiling panels sector, paving the way for innovative solutions that meet the demands of a rapidly changing global market.

Frequently Asked Questions (FAQs) for B2B Buyers of 4 x 8 ceiling panels

-

1. How do I choose the right 4 x 8 ceiling panels for my project?

Selecting the right 4 x 8 ceiling panels depends on several factors, including the intended application, aesthetic preferences, and environmental conditions. Consider the material—options like PVC, MDF, or wood—based on durability and moisture resistance. For commercial spaces, panels with fire ratings and easy-clean surfaces are essential. Additionally, assess the design and finish that aligns with your brand’s image. Consulting with suppliers for samples and technical specifications can also aid in making an informed decision. -

2. What is the best material for 4 x 8 ceiling panels in humid environments?

For humid environments, fiberglass reinforced plastic (FRP) panels are often the best choice due to their moisture resistance and durability. These panels are designed to withstand high humidity and are easy to clean, making them suitable for areas like kitchens and bathrooms. Additionally, vinyl panels offer good moisture resistance while providing various design options. Always check the product specifications for moisture ratings to ensure compliance with local building codes. -

3. How can I verify the credibility of a supplier for 4 x 8 ceiling panels?

To verify a supplier’s credibility, conduct thorough research, including checking online reviews, industry certifications, and references from previous clients. Request samples to assess product quality firsthand. It’s also beneficial to inquire about their manufacturing processes and compliance with international standards, such as ISO certifications. Engaging in direct communication to gauge their responsiveness and professionalism can provide further insights into their reliability as a supplier. -

4. What are the typical minimum order quantities (MOQs) for 4 x 8 ceiling panels?

Minimum order quantities (MOQs) for 4 x 8 ceiling panels can vary significantly based on the supplier and material type. Generally, MOQs can range from as low as 10 panels to over 100 panels for specialized or customized products. Discussing your specific needs with suppliers can sometimes lead to flexible arrangements, especially for bulk orders or long-term partnerships. Always clarify MOQs before finalizing your order to ensure it aligns with your project requirements. -

5. What payment terms should I expect when purchasing 4 x 8 ceiling panels internationally?

Payment terms for international purchases of 4 x 8 ceiling panels can vary widely by supplier. Common terms include advance payment, net 30, or net 60 days after invoice. It’s advisable to negotiate terms that suit your cash flow while ensuring the supplier feels secure. In some cases, using letters of credit or escrow services can provide added security for both parties. Always clarify payment methods accepted, such as wire transfers, credit cards, or PayPal. -

6. How do I ensure quality assurance (QA) for my order of ceiling panels?

To ensure quality assurance (QA) for your order, request detailed product specifications and certifications from the supplier. Implement a QA process that includes pre-shipment inspections, where third-party services can evaluate the panels against agreed standards. Establishing a clear communication channel with the supplier regarding any defects or discrepancies is crucial. Additionally, consider purchasing samples before placing a bulk order to assess the quality firsthand. -

7. What logistics considerations should I keep in mind when importing 4 x 8 ceiling panels?

When importing 4 x 8 ceiling panels, consider factors such as shipping methods, customs regulations, and import duties. It’s essential to work with logistics providers experienced in handling building materials to navigate potential challenges. Ensure that the supplier provides proper documentation, including bills of lading and certificates of origin. Additionally, factor in lead times for production and shipping to align with your project schedule, allowing for any unforeseen delays. -

8. Are there customization options available for 4 x 8 ceiling panels?

Yes, many suppliers offer customization options for 4 x 8 ceiling panels, including various finishes, colors, and textures. Depending on the supplier, you may also be able to request specific designs or dimensions to fit unique project requirements. Discussing your customization needs upfront can help the supplier provide tailored solutions. However, be aware that custom orders may have longer lead times and higher costs, so plan accordingly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 4 X 8 Ceiling Panels Manufacturers & Suppliers List

1. Decorative Ceiling Tiles – Wall Panels & Murals

Domain: decorativeceilingtiles.net

Registered: 2007 (18 years)

Introduction: 4×8 MirroFlex Wall Panels, Decorative Wall Panels, 3D Wall Panels, Seamless Wall Panels, Faux Tin Wall Panels, PVC Wall Panels, NuMetal Metal Laminates, Acoustic Panels, Custom Wall Murals & Partitions, Peel and Stick Wall Panels, Tub and Shower Walls, Wainscot, Rustic Steel Wainscot, Mosaic Wood Wall Panels, Fretwork Wall Panels, Interior Slat Wall Panels, Exterior Slat Wall Panels, Louver Panels…

2. Design the Space – Rustic Plywood Paneling

Domain: designthespace.com

Registered: 2006 (19 years)

Introduction: Rustic Plywood Paneling | Random Grooved Panels

– Product Type: Plywood Paneling

– Available Sizes: 4×8 panels

– Collections: Rustic Collection, Designer Collection, Cabin Collection, Hunting Camp Collection, High Mountain Lodge Collection, Classic Random Planked Collection, Wainscot Paneling Collection

– Panel Thickness Options: 2.7mm (1/8″), 3.6mm (3/16″), 5.2mm (1/4″)

– Approximate Weights: 2.7…

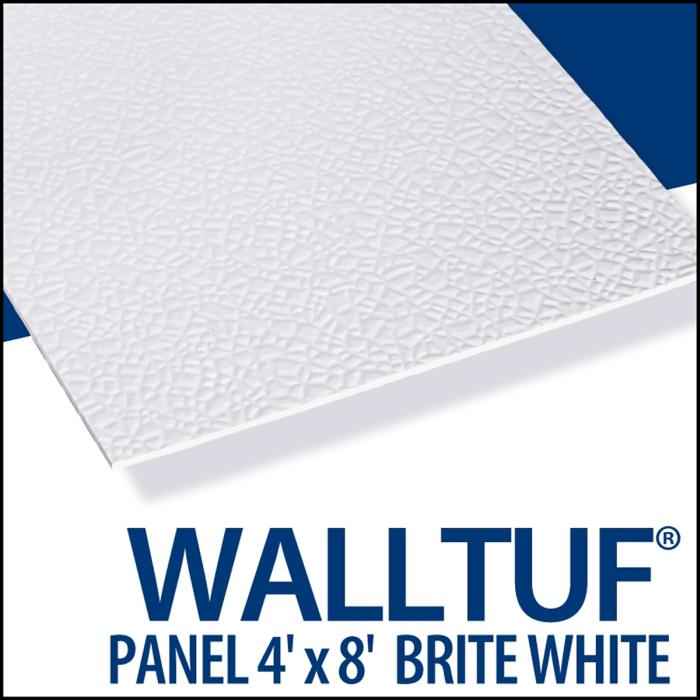

3. Panolam – FRP Embossed Panel

Domain: dsisupply.com

Registered: 2002 (23 years)

Introduction: This company, Panolam – FRP Embossed Panel, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for 4 x 8 ceiling panels

In navigating the complex landscape of sourcing 4 x 8 ceiling panels, international buyers must emphasize strategic procurement to optimize both cost and quality. Key takeaways include understanding the diverse range of materials available—such as FRP and plywood—that cater to specific needs like durability, aesthetic appeal, and compliance with regional building codes. Additionally, leveraging local suppliers can significantly reduce shipping costs and enhance delivery times, a crucial factor for projects with tight timelines.

Strategic sourcing not only mitigates risks associated with supply chain disruptions but also fosters partnerships that can lead to favorable pricing and product innovation. For buyers in Africa, South America, the Middle East, and Europe, a proactive approach in evaluating suppliers based on their reliability, product range, and responsiveness is essential.

Looking ahead, the demand for versatile and sustainable building materials is set to rise. Buyers should position themselves to capitalize on emerging trends by exploring innovative products and solutions. Engage with suppliers now to secure a competitive edge and ensure your projects are equipped with the best materials available. Your strategic sourcing decisions today will shape the success of your projects tomorrow.