The Definitive Guide to X Ray Proof Bags: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for x ray proof bags

In an increasingly interconnected world, sourcing high-quality x-ray proof bags is a critical challenge for businesses aiming to protect sensitive materials during transport and storage. As international trade expands, the need for reliable packaging solutions that ensure confidentiality and safety has never been more pressing. This comprehensive guide serves as an essential resource for B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, particularly in countries like Germany and Nigeria.

Covering a wide array of topics, this guide delves into the various types of x-ray proof bags available, their specific applications across different industries, and the critical aspects of supplier vetting to ensure quality and compliance. Additionally, we will explore cost considerations and shipping logistics, enabling businesses to make informed purchasing decisions that align with their operational needs and budget constraints.

By equipping buyers with actionable insights and a thorough understanding of the market landscape, this guide empowers companies to navigate the complexities of sourcing x-ray proof bags confidently. Whether you are looking to protect valuable documents, sensitive materials, or consumer products, understanding the nuances of this specialized packaging will enhance your supply chain’s efficiency and security.

Understanding x ray proof bags Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard X-Ray Bags | Available in multiple sizes, heat sealable, UV and gas proof | Shipping sensitive items, storage of valuables | Pros: Versatile, cost-effective. Cons: Limited customization options. |

| Smell Proof Bags | Tamper-evident, stylish designs, effective odor control | Discreet storage for cannabis and pharmaceuticals | Pros: Aesthetically pleasing, excellent odor retention. Cons: May not be as durable as standard bags. |

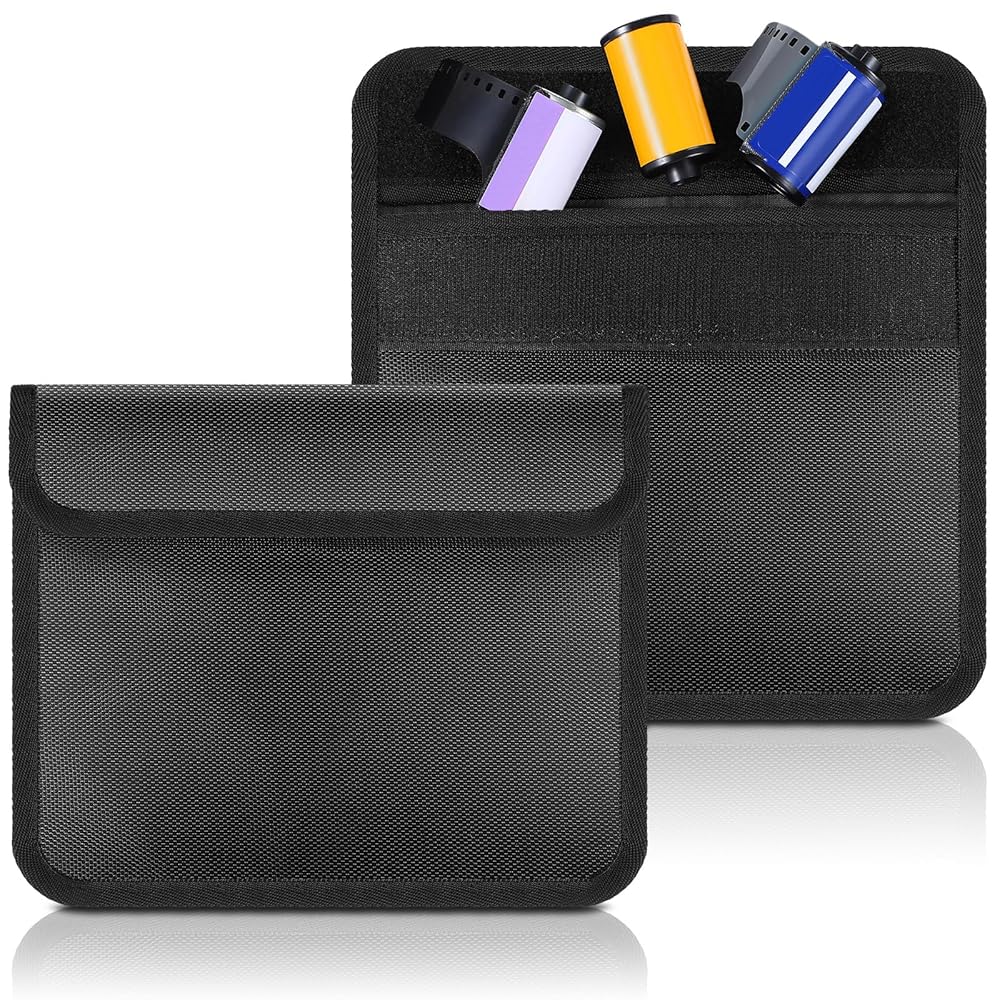

| Film Protection Bags | Specialized for x-ray film, layered for enhanced protection | Medical, photography industries | Pros: Tailored for specific needs, robust protection. Cons: Higher cost due to specialized design. |

| Customizable Bags | Made to order, various sizes and features available | Specific industry needs, promotional uses | Pros: Tailored solutions, meets unique requirements. Cons: Longer lead times, potentially higher costs. |

| Value Packs | Mixed sizes and types in one package | Bulk purchasing, varied storage needs | Pros: Cost-effective, flexible options. Cons: May include less frequently used sizes. |

What Are the Characteristics of Standard X-Ray Bags?

Standard x-ray bags are designed to provide a reliable barrier against x-ray exposure while being versatile enough for various applications. These bags come in multiple sizes, making them suitable for both personal and commercial use. They are heat sealable and provide excellent protection against UV rays and gases, ensuring that contents remain safe during shipping or storage. Businesses often consider these bags for shipping sensitive items or storing valuables, as they offer a cost-effective solution without compromising on quality.

How Do Smell Proof Bags Enhance Product Security?

Smell proof bags are particularly popular in industries where odor control is crucial, such as cannabis and pharmaceuticals. These bags not only provide x-ray protection but also feature tamper-evident designs and stylish aesthetics. Their ability to retain odors makes them ideal for discreet storage. B2B buyers appreciate these bags for their combination of functionality and appearance, although they may not be as durable as standard x-ray bags, which could be a consideration for long-term storage needs.

What Makes Film Protection Bags Unique?

Film protection bags are specifically designed for the medical and photography industries, providing enhanced protection for x-ray films and sensitive materials. These bags are constructed with layered materials that prevent exposure to x-rays, ensuring that the integrity of the film is maintained. B2B purchasers in medical and photography sectors find these bags essential for safeguarding their products, although the specialized nature of these bags often comes with a higher price point.

Why Consider Customizable Bags for Specific Industry Needs?

Customizable bags are a solution for businesses that require tailored storage options. These bags can be made to order in various sizes and features, catering to specific industry needs or promotional purposes. While they provide the advantage of meeting unique requirements, buyers should be aware of longer lead times and potentially higher costs associated with customization. This option is ideal for businesses looking to enhance their brand identity or meet specific regulatory compliance.

How Do Value Packs Offer Flexibility for B2B Buyers?

Value packs consist of a mixed assortment of bag sizes and types, making them an economical choice for businesses with varied storage needs. They allow for bulk purchasing, which can lead to significant savings. However, buyers should consider that these packs may include sizes that are less frequently used, which could lead to waste. Overall, value packs provide flexibility and cost efficiency, making them appealing for businesses looking to stock up on essential packaging solutions.

Key Industrial Applications of x ray proof bags

| Industry/Sector | Specific Application of x ray proof bags | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Secure transport of sensitive medical supplies | Protects against x-ray exposure, maintaining product integrity | Ensure compliance with international shipping regulations and standards |

| Electronics Manufacturing | Storage of sensitive electronic components | Prevents damage from x-ray exposure, ensuring quality control | Look for bags with anti-static properties and custom sizing options |

| Food and Beverage | Packaging for specialty foods and beverages | Preserves freshness and prevents contamination | Consider bags that are food-safe and meet health regulations |

| Photography | Protection of film and sensitive photographic materials | Safeguards against x-ray damage during transit | Verify compatibility with specific film types and sizes |

| Security and Law Enforcement | Transport of sensitive evidence and materials | Ensures confidentiality and protection of evidence | Focus on durability and tamper-evident features for security assurance |

How Are X-Ray Proof Bags Used in Pharmaceuticals?

In the pharmaceutical industry, x-ray proof bags are crucial for transporting sensitive medical supplies, including pharmaceuticals and biological samples. These bags protect against x-ray exposure, which can compromise the efficacy of certain medications. International B2B buyers need to ensure that the bags comply with shipping regulations and maintain product integrity during transit. Sourcing high-quality, certified x-ray proof bags can prevent costly losses and ensure compliance with health regulations.

What Role Do X-Ray Proof Bags Play in Electronics Manufacturing?

Electronics manufacturers rely on x-ray proof bags to store and transport sensitive components, such as circuit boards and semiconductors. These bags prevent damage from x-ray exposure, which can lead to malfunction or failure of electronic products. Buyers should prioritize bags with anti-static properties to mitigate the risk of static discharge. Furthermore, custom sizing options are essential for accommodating various component sizes, ensuring optimal protection throughout the supply chain.

How Are X-Ray Proof Bags Beneficial in the Food and Beverage Sector?

In the food and beverage industry, x-ray proof bags are increasingly used for packaging specialty products, such as artisanal cheeses and high-end spirits. These bags preserve freshness and prevent contamination during storage and transport. For international buyers, it is critical to select bags that are food-safe and compliant with health regulations in their respective markets. Proper sourcing can enhance brand reputation by ensuring product quality and safety.

Why Are X-Ray Proof Bags Important for Photography?

Photographers and studios utilize x-ray proof bags to protect film and sensitive photographic materials from x-ray damage during transit, especially when traveling through airports. The bags safeguard the integrity of the images, preventing irreparable damage. Buyers in this sector must verify that the bags are compatible with specific film types and sizes to ensure comprehensive protection. This attention to detail can significantly enhance the quality of the final photographic products.

How Do X-Ray Proof Bags Support Security and Law Enforcement?

In security and law enforcement, x-ray proof bags are essential for the secure transport of sensitive evidence and materials. These bags ensure confidentiality and protection against unauthorized access or exposure. When sourcing these bags, buyers should focus on durability and tamper-evident features to guarantee security throughout the chain of custody. Ensuring high-quality standards in sourcing can safeguard the integrity of critical evidence in legal proceedings.

3 Common User Pain Points for ‘x ray proof bags’ & Their Solutions

Scenario 1: Ensuring Authenticity in X-Ray Proof Bags

The Problem: In the B2B market, buyers often face challenges with counterfeit products, particularly with x-ray proof bags. Many suppliers offer cheaper alternatives that do not provide the necessary protection, leading to potential losses and reputational damage. Buyers may struggle to discern which products are genuinely effective and compliant with industry standards, risking investment in subpar items that fail to protect valuable assets during transport or storage.

The Solution: To ensure authenticity, B2B buyers should prioritize sourcing from reputable manufacturers with a proven track record. Conduct thorough research on suppliers, looking for certifications and quality assurance processes. It’s beneficial to request samples and conduct independent testing to verify the bags’ x-ray proof capabilities. Additionally, establishing long-term relationships with trusted suppliers can facilitate better pricing and product consistency, ensuring that all purchases meet the required safety standards. By leveraging vendor audits and reviews, businesses can build a reliable supply chain that mitigates risks associated with counterfeit products.

Scenario 2: Balancing Cost and Quality for Bulk Orders

The Problem: Many businesses require x-ray proof bags in large quantities, often leading to budget constraints. While price is a significant factor, compromising on quality can result in inadequate protection for sensitive items. B2B buyers often find themselves in a dilemma between selecting cheaper options and ensuring that they receive durable and reliable products that fulfill their protective functions.

The Solution: To strike a balance between cost and quality, buyers should consider implementing a tiered purchasing strategy. This involves negotiating bulk purchase agreements with suppliers, which can lead to significant discounts while maintaining quality. Additionally, exploring flexible packaging options, such as mixed-size packs, allows for optimized inventory management without overcommitting to one size or type. Conducting a total cost of ownership analysis can also help in understanding the long-term savings associated with higher-quality bags, including reduced risk of damage to valuable items. Engaging in collaborative purchasing with other businesses can further enhance buying power and reduce costs.

Scenario 3: Adapting to Diverse Regulatory Standards

The Problem: Companies operating internationally often encounter diverse regulatory standards regarding packaging and transportation, including the use of x-ray proof bags. Compliance with these varying regulations can be complex and daunting, particularly for businesses that may not have dedicated legal or compliance teams. Missteps can lead to significant fines and disruptions in supply chains.

The Solution: To navigate these challenges, B2B buyers should stay informed about international regulations governing packaging and transportation in their specific industries. Engaging with legal experts or consultants who specialize in international trade can provide valuable insights into compliance requirements. Buyers should also seek suppliers who demonstrate an understanding of these regulations and offer products that meet the necessary standards across different regions. Creating a compliance checklist for x-ray proof bags, tailored to each market, can streamline the purchasing process and ensure adherence to all applicable laws. By fostering open communication with suppliers about regulatory changes, businesses can adapt swiftly and maintain compliance, ensuring smooth operations in all target markets.

Strategic Material Selection Guide for x ray proof bags

When selecting materials for x-ray proof bags, it is essential to consider the properties and performance characteristics that meet the needs of various applications. This guide analyzes several common materials used in the production of x-ray proof bags, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Mylar in X-Ray Proof Bags?

Mylar, a polyester film, is frequently used in x-ray proof bags due to its strong barrier properties. It provides excellent resistance to moisture, gases, and UV light, making it suitable for preserving sensitive contents. Mylar can withstand temperatures ranging from -70°C to 150°C, ensuring durability under various conditions.

Pros: Mylar is lightweight, cost-effective, and offers good tensile strength, making it ideal for mass production. It also has a high level of clarity, allowing for easy visibility of contents.

Cons: While Mylar is durable, it can be prone to punctures and tears if not handled carefully. Additionally, it may not provide adequate protection against extreme physical impacts.

Impact on Application: Mylar is compatible with a wide range of media, including electronics and pharmaceuticals, making it a versatile choice for various industries.

Considerations for International Buyers: Buyers should ensure that Mylar bags comply with international standards such as ASTM and DIN, especially when shipping sensitive items across borders.

How Does Aluminum Foil Enhance Protection in X-Ray Proof Bags?

Aluminum foil is another common material used in x-ray proof bags, known for its exceptional barrier properties against light, moisture, and gases. It is highly effective at blocking x-rays due to its dense structure.

Pros: Aluminum foil is highly durable and resistant to corrosion, making it suitable for long-term storage of sensitive items. Its ability to reflect heat also adds an extra layer of protection.

Cons: The rigidity of aluminum foil can make it less flexible than other materials, potentially limiting its use in applications requiring custom shapes or sizes. Additionally, it is generally more expensive than Mylar.

Impact on Application: Aluminum foil is ideal for applications involving food packaging and pharmaceuticals, where protection from light and moisture is critical.

Considerations for International Buyers: Buyers should verify compliance with food safety regulations and other industry standards, particularly in regions with stringent packaging regulations.

What Role Does Polyethylene Play in X-Ray Proof Bags?

Polyethylene (PE) is a widely used plastic that can be engineered to provide varying levels of thickness and strength. In x-ray proof bags, it is often used as an outer layer to enhance durability and sealability.

Pros: Polyethylene is lightweight, cost-effective, and offers good chemical resistance. It can be heat-sealed easily, making it convenient for manufacturers.

Cons: While it provides decent protection, polyethylene is less effective against x-rays compared to Mylar and aluminum foil. Its lower tensile strength can also lead to wear and tear over time.

Impact on Application: Polyethylene is suitable for applications where moisture protection is essential but where x-ray protection is not the primary concern, such as in general storage.

Considerations for International Buyers: Buyers should ensure that the polyethylene used meets relevant international standards, particularly in industries like healthcare and food packaging.

How Do Composite Materials Benefit X-Ray Proof Bags?

Composite materials, which combine two or more materials, are increasingly popular in the production of x-ray proof bags. These materials can be engineered to provide enhanced properties, such as improved strength and barrier performance.

Pros: Composites can be tailored to specific applications, offering a balance between flexibility and durability. They often provide superior protection against x-rays, moisture, and physical damage.

Cons: The manufacturing process for composite materials can be more complex and costly, which may impact the final price of the bags.

Impact on Application: Composites are ideal for high-value items that require robust protection, such as electronics and sensitive medical equipment.

Considerations for International Buyers: Buyers should assess the certifications and compliance of composite materials with international standards, ensuring they meet the necessary safety and quality benchmarks.

Summary Table of Material Selection for X-Ray Proof Bags

| Material | Typical Use Case for x-ray proof bags | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mylar | Electronics, pharmaceuticals | Lightweight and cost-effective | Prone to punctures and tears | Low |

| Aluminum Foil | Food packaging, pharmaceuticals | Exceptional barrier properties | Less flexible, higher cost | Med |

| Polyethylene | General storage | Cost-effective and easy to seal | Less effective against x-rays | Low |

| Composite | High-value electronics, medical gear | Tailored properties for specific needs | Complex manufacturing process | High |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for x-ray proof bags, helping them make informed decisions that align with their specific requirements and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for x ray proof bags

What Are the Key Stages in the Manufacturing Process of X-Ray Proof Bags?

The manufacturing process of x-ray proof bags involves several critical stages that ensure the final product meets stringent quality and functional requirements. Understanding these stages can empower B2B buyers to make informed decisions when sourcing from suppliers.

1. Material Preparation: What Materials Are Used?

The first stage of manufacturing begins with the selection and preparation of materials. X-ray proof bags are typically made from specialized materials designed to block x-ray penetration. These often include a blend of heavy-duty polymers and alloys that have been specifically engineered for this purpose. The materials are sourced from certified suppliers to ensure compliance with international safety standards.

During this phase, materials undergo rigorous testing for their x-ray shielding capabilities, durability, and resistance to environmental factors such as moisture and UV light. Suppliers often perform initial quality checks to confirm that the raw materials meet specified standards before proceeding to the next stage.

2. Forming: How Are the Bags Shaped?

The forming stage involves cutting and shaping the prepared materials into the desired bag sizes. Techniques such as die-cutting and heat sealing are commonly employed. This is a crucial phase as the dimensions of the bags must be precise to ensure they can effectively hold items while providing the necessary protection.

Advanced machinery is typically used in this stage, including automated cutting tools and heat sealers. The use of automated systems minimizes human error and enhances consistency across production runs. B2B buyers should inquire about the machinery used and the skill level of the operators involved, as these factors can significantly impact the quality of the final product.

3. Assembly: What Happens During the Assembly Process?

Once the bags are formed, they undergo an assembly process that may include adding features like tamper-evident seals or additional closures. This stage is particularly important for x-ray proof bags that are designed for high-security applications, such as transporting sensitive materials.

Quality assurance during assembly focuses on ensuring that each bag is sealed correctly and that all features function as intended. Suppliers may implement an assembly line system, where multiple operators are responsible for different aspects of the bag construction. It’s beneficial for buyers to understand the assembly workflow, as it can influence lead times and overall product availability.

4. Finishing: What Quality Checks Are Conducted?

The finishing stage involves final quality checks and the addition of any branding or labeling. This includes inspections for visual defects, ensuring that all seals are airtight, and confirming that the bags meet the specified x-ray protection standards.

Suppliers often conduct a final inspection before packaging the bags for shipment. This is a critical checkpoint for quality assurance, where any defective items can be identified and removed from the batch. B2B buyers should request information about the finishing processes and the specific quality checks that are performed.

How Is Quality Assurance Implemented in the Production of X-Ray Proof Bags?

Quality assurance (QA) is a cornerstone of the manufacturing process for x-ray proof bags, ensuring that products meet international standards and customer expectations. Understanding the QA practices can help B2B buyers evaluate suppliers effectively.

What International Standards Are Relevant for X-Ray Proof Bags?

Several international standards govern the production of x-ray proof bags. The most notable among these is ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 ensures that suppliers consistently produce high-quality products and can enhance customer satisfaction.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) certifications for certain applications are also crucial. Suppliers should be able to provide evidence of these certifications to assure buyers of their commitment to quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) in the manufacturing process typically involves several checkpoints:

-

Incoming Quality Control (IQC): Materials are inspected upon arrival at the manufacturing facility. This initial check ensures that all materials meet the required specifications before they enter the production process.

-

In-Process Quality Control (IPQC): During manufacturing, samples of the bags are taken at various stages to ensure compliance with quality standards. This may include checks for dimensions, sealing integrity, and material properties.

-

Final Quality Control (FQC): Before products are packaged, a final inspection is conducted. This step verifies that the bags are free from defects and meet all specified requirements, including x-ray protection capabilities.

B2B buyers should inquire about these QC checkpoints and ask for documentation that confirms compliance with established standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are several strategies for effective verification:

What Documentation Should Buyers Request?

Buyers should request detailed documentation that outlines the supplier’s quality control processes. This includes:

- Certificates of compliance with international standards (e.g., ISO, CE).

- Quality assurance manuals that describe the QC procedures.

- Test reports from third-party laboratories verifying the x-ray protection capabilities of the bags.

How Can Audits and Inspections Be Conducted?

Conducting audits and inspections is another effective way to verify supplier quality. Buyers can arrange for third-party audits of manufacturing facilities to assess compliance with quality standards. This process can provide valuable insights into the supplier’s operations and their commitment to quality.

In addition, buyers may consider utilizing third-party inspection services before shipment. These services can conduct inspections to ensure that the products meet the agreed-upon specifications.

What Nuances Should International Buyers Consider?

When sourcing x-ray proof bags from international suppliers, there are several nuances to consider:

-

Regulatory Compliance: Different countries have varying regulations regarding the importation of protective packaging. Buyers should ensure that the products meet the regulatory standards of their home country.

-

Cultural Sensitivity: Understanding local practices and communication styles can enhance supplier relationships. Buyers should be aware of cultural differences that may impact negotiations and partnerships.

-

Currency and Payment Terms: International transactions can involve complex currency exchange rates and payment terms. Buyers should clarify these details upfront to avoid misunderstandings.

By understanding the manufacturing processes and quality assurance practices for x-ray proof bags, B2B buyers can make informed decisions and establish successful partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘x ray proof bags’

In the competitive landscape of international trade, sourcing high-quality x-ray proof bags is crucial for ensuring the protection of sensitive materials. This guide provides a systematic approach for B2B buyers to effectively procure these essential products. Follow these steps to navigate the sourcing process with confidence.

Step 1: Define Your Technical Specifications

Establishing clear technical requirements is the foundation of a successful procurement process. Consider the size, durability, and specific features of the x-ray proof bags you need. For instance, assess whether you require bags that are also UV, oxygen, and gas-proof, as these additional protective features can enhance the security of your contents.

- Size Variations: Determine the dimensions that fit your products, whether large, medium, or small.

- Material Quality: Look for bags made from high-grade materials with a heavy coating of blended alloys and synthetics for optimal protection.

Step 2: Research Potential Suppliers

Thorough research is essential to identify reliable suppliers. Explore various online platforms, industry directories, and trade shows to compile a list of potential vendors. A diverse supplier base will give you options and leverage in negotiations.

- Supplier Background: Investigate the history and reputation of each supplier in the market.

- Customer Reviews: Look for testimonials and case studies that highlight the supplier’s reliability and product quality.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify the certifications of potential suppliers. Compliance with international standards ensures that the products meet safety and quality benchmarks. Certifications such as ISO or industry-specific credentials can be indicators of a supplier’s commitment to quality.

- Quality Assurance: Confirm if the supplier adheres to quality management systems that ensure consistent product performance.

- Material Safety: Ensure the materials used in the bags are certified safe for your intended applications.

Step 4: Request Samples for Testing

Obtaining samples allows you to assess the quality and functionality of the x-ray proof bags firsthand. Test these samples under conditions that mimic actual usage to evaluate their performance.

- Durability Tests: Check for puncture resistance and sealing quality to ensure that the bags can withstand transportation and storage conditions.

- X-Ray Protection: Verify that the bags effectively block x-rays as advertised, protecting sensitive contents.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers and compare them not only based on price but also on terms of service, such as minimum order quantities, shipping costs, and payment terms. This will help you identify the best overall value.

- Bulk Discounts: Inquire about pricing structures for larger orders, as many suppliers offer significant discounts for bulk purchases.

- Hidden Costs: Pay attention to additional fees, such as shipping or handling, which can impact your total expenditure.

Step 6: Establish Clear Communication Channels

Effective communication with your selected supplier is vital. Ensure that you have designated points of contact for any inquiries or issues that may arise during the procurement process.

- Response Time: Gauge the supplier’s responsiveness during initial communications as this often reflects their customer service commitment.

- Language and Cultural Considerations: Especially in international transactions, consider any language barriers or cultural differences that may affect communication.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, draft a clear and comprehensive purchase agreement. This document should outline all terms, including delivery schedules, warranties, and return policies, to protect both parties.

- Legal Review: If necessary, consult with legal experts to ensure the agreement meets all regulatory requirements and protects your interests.

- Payment Methods: Confirm accepted payment methods and any terms related to payment schedules.

By following these steps, B2B buyers can streamline the sourcing of x-ray proof bags, ensuring a successful procurement process that meets their operational needs.

Comprehensive Cost and Pricing Analysis for x ray proof bags Sourcing

Understanding the cost structure and pricing dynamics of x-ray proof bags is crucial for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. This analysis will delve into the various components that influence the pricing of these essential packaging solutions, as well as actionable insights for buyers looking to optimize their sourcing strategies.

What Are the Key Cost Components in Sourcing X-Ray Proof Bags?

-

Materials: The primary cost driver for x-ray proof bags is the materials used. These bags are typically made from specialized blends of alloys and synthetic materials designed to provide effective x-ray protection. The quality and composition of these materials significantly influence the overall cost, with higher-grade materials leading to a higher price point.

-

Labor: Labor costs encompass wages for workers involved in the manufacturing process, including those responsible for assembly, quality control, and packaging. In regions with higher labor costs, such as parts of Europe, the overall price of the bags may increase.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs, but they are still a critical factor in the final pricing.

-

Tooling: Custom tooling for specialized bag sizes or features can add to initial costs. Buyers seeking unique specifications should anticipate these additional expenses, especially if they require molds or machines that are not already part of a supplier’s inventory.

-

Quality Control (QC): Ensuring that the bags meet international safety and quality standards incurs costs related to testing and inspections. Certifications can further add to the price but may be necessary for compliance in certain markets.

-

Logistics: Shipping and handling costs are significant, particularly for international orders. Factors such as distance, shipping method, and freight charges can vary widely, impacting the total cost.

-

Margin: Suppliers will apply a margin based on the overall cost structure and market demand. This margin can vary based on competition and perceived value, particularly for high-quality or certified products.

How Do Price Influencers Affect the Sourcing of X-Ray Proof Bags?

-

Volume/MOQ: Minimum Order Quantities (MOQs) can greatly affect pricing. Larger orders typically reduce the per-unit cost due to economies of scale. Buyers should evaluate their needs to balance inventory levels with cost savings.

-

Specifications and Customization: Customized bags with specific dimensions or features (e.g., tamper-evident seals) will generally incur higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials Quality and Certifications: The presence of certifications can enhance the perceived value of x-ray proof bags. Buyers should consider the cost-benefit ratio of investing in certified products that may provide better protection and compliance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is essential for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of goods, influencing buyer decisions.

What Are the Best Practices for Negotiating Prices and Maximizing Cost Efficiency?

-

Leverage Volume Discounts: When placing large orders, negotiate for volume discounts. Suppliers are often willing to provide better pricing for bulk purchases.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but the total cost over the product’s lifecycle, including shipping, storage, and disposal. This comprehensive view can reveal more cost-effective options.

-

Research Multiple Suppliers: Don’t settle for the first quote. Comparing multiple suppliers can provide insights into market pricing and help identify the best value.

-

Stay Informed About Market Trends: Understanding regional market dynamics can provide leverage in negotiations. For instance, being aware of changes in material costs or labor rates can help buyers make informed decisions.

-

Build Long-Term Relationships: Establishing a good relationship with suppliers can lead to better pricing, priority service, and insights into new products or innovations.

Conclusion

In summary, B2B buyers of x-ray proof bags should navigate a complex landscape of cost components and pricing influencers. By understanding these elements and employing strategic sourcing practices, buyers can enhance their procurement processes while ensuring they receive high-quality products tailored to their specific needs. While prices can vary significantly, being informed and proactive can lead to more favorable outcomes in the competitive international market.

Alternatives Analysis: Comparing x ray proof bags With Other Solutions

Introduction: Exploring Packaging Alternatives for X-Ray Protection

In the realm of secure packaging solutions, x-ray proof bags stand out for their ability to shield contents from x-ray detection while providing additional protective features. However, various alternatives exist that may cater to specific needs or offer unique advantages. This analysis compares x-ray proof bags with other viable solutions, helping B2B buyers make informed decisions based on performance, cost, and ease of implementation.

Comparison Table

| Comparison Aspect | X Ray Proof Bags | Smell-Proof Mylar Bags | Anti-X-Ray Film Bags |

|---|---|---|---|

| Performance | High protection against x-ray scanning and environmental factors (UV, moisture) | Excellent smell-proofing, moderate visibility | Designed specifically for film protection against x-ray damage |

| Cost | Moderate to high, depending on size and order quantity | Generally low to moderate; bulk options available | Varies widely; typically higher for specialized film bags |

| Ease of Implementation | Simple heat sealing, customizable sizes | Ready-to-use, no special tools required | Requires careful handling and may need specific sealing methods |

| Maintenance | Reusable with care; durable materials | Single-use or limited reuse; easy to store | Limited reuse; must be stored properly to maintain effectiveness |

| Best Use Case | Secure transport of sensitive items and documents | Storage of cannabis products or other odor-sensitive items | Protection of photographic film and sensitive materials from x-ray exposure |

Detailed Breakdown of Alternatives

1. Smell-Proof Mylar Bags

Smell-proof Mylar bags are a popular alternative, especially within the cannabis industry. They excel at keeping odors contained, making them ideal for products that require discretion. However, while they offer limited protection against moisture and light, they do not provide the same level of x-ray protection as x-ray proof bags. These bags are typically available at a lower cost, making them an attractive option for businesses looking for budget-friendly packaging solutions.

2. Anti-X-Ray Film Bags

Anti-x-ray film bags are specifically designed for protecting photographic film and other sensitive materials from x-ray damage. These bags can be effective in environments where film exposure to x-rays is a concern, such as during airport security checks. However, they are generally more expensive and are not as versatile as x-ray proof bags, which provide broader protection against various environmental factors. Additionally, these bags may require careful handling and specific sealing methods, which can complicate their use in a fast-paced business environment.

Conclusion: Choosing the Right Solution for Your Needs

When considering packaging solutions, B2B buyers must evaluate their specific needs regarding product protection, cost efficiency, and ease of use. X-ray proof bags offer unparalleled protection against x-ray scanning and environmental factors, making them ideal for sensitive items that require secure transport. Conversely, alternatives like smell-proof Mylar bags provide cost-effective odor containment, while anti-x-ray film bags serve a niche market focused on film protection. Ultimately, the choice will depend on the unique requirements of the business, the nature of the products being protected, and the budget constraints.

Essential Technical Properties and Trade Terminology for x ray proof bags

What Are the Key Technical Properties of X-Ray Proof Bags?

When sourcing x-ray proof bags, understanding their technical specifications is crucial for ensuring product efficacy and compliance with industry standards. Here are several critical properties to consider:

-

Material Composition

The effectiveness of x-ray proof bags largely depends on their material makeup. High-quality bags often utilize a blend of alloys and synthetic materials, specifically engineered to block x-ray radiation. This specialized coating not only prevents x-ray penetration but also provides additional benefits such as UV, oxygen, and moisture resistance. For B2B buyers, selecting bags made from high-grade materials ensures that sensitive items are protected during transit and storage. -

Thickness and Layering

The thickness of the bag plays a vital role in its protective capabilities. Thicker bags generally provide better x-ray shielding and durability. Multi-layered constructions enhance these properties, combining different materials to maximize protection while maintaining flexibility. Buyers should consider the balance between thickness and weight, especially for shipping purposes, to optimize costs without compromising on security. -

Heat Sealability

The ability to heat seal x-ray proof bags is essential for secure storage. These bags are designed to be sealed using standard household irons or impulse sealers, which allows users to customize bag sizes according to their needs. This feature is particularly useful for businesses that require tailored solutions, as it enhances the usability of the bags for various applications. -

Tamper-Evidence

Many x-ray proof bags come with tamper-evident seals that provide an additional layer of security. This feature is vital for businesses in sectors where product integrity is paramount, such as pharmaceuticals and high-value electronics. Tamper-evident designs not only deter unauthorized access but also instill confidence in end consumers regarding the safety of the contents. -

Size Variability

X-ray proof bags are available in various sizes, from small sachets to large storage bags. This size range allows businesses to select appropriate bags for different products, whether for retail, shipment, or secure storage. For international buyers, understanding size specifications is key to meeting local regulations and logistical requirements.

What Trade Terminology Should B2B Buyers Know for X-Ray Proof Bags?

Familiarity with industry jargon can facilitate smoother negotiations and procurement processes. Here are some common terms relevant to x-ray proof bags:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of x-ray proof bags, OEM suppliers can customize products according to specific buyer requirements, which is crucial for businesses looking to differentiate their offerings. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for buyers to gauge initial investment and stock levels, particularly for startups or businesses entering new markets. Negotiating favorable MOQs can lead to significant cost savings. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products or services. For x-ray proof bags, issuing an RFQ allows buyers to compare prices and terms from multiple suppliers, helping to identify the best value. -

Incoterms (International Commercial Terms)

These are a set of predefined international rules that clarify the responsibilities of buyers and sellers in global trade. Familiarity with Incoterms is crucial for B2B transactions, particularly when shipping x-ray proof bags across borders, as they define aspects like shipping costs, insurance, and risk transfer. -

Lead Time

This refers to the time taken from placing an order to receiving the product. Understanding lead times is vital for inventory management, especially for businesses that depend on timely deliveries of x-ray proof bags for operational efficiency. -

Certification Standards

Many x-ray proof bags must meet specific industry standards or certifications to ensure quality and safety. Buyers should inquire about these certifications to ensure compliance with local regulations and industry best practices.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the most suitable x-ray proof bags for their business needs.

Navigating Market Dynamics and Sourcing Trends in the x ray proof bags Sector

What Are the Key Market Dynamics and Trends Impacting the X-Ray Proof Bags Sector?

The x-ray proof bags market is experiencing notable growth driven by increasing security concerns, particularly in international shipping and travel. As global trade expands, so does the need for effective solutions to protect sensitive items from x-ray exposure. Emerging markets in Africa and South America are witnessing a surge in demand, fueled by rising e-commerce activities and regulatory requirements for secure packaging. Additionally, advancements in material science are leading to the development of higher-quality bags that offer enhanced protection, which is particularly appealing to B2B buyers looking for reliable solutions.

Technology is playing a crucial role in sourcing trends within this sector. B2B buyers are increasingly leveraging e-commerce platforms and digital supply chains to streamline procurement processes. The use of data analytics is also on the rise, enabling companies to make informed decisions based on market trends and consumer preferences. In Europe, particularly in Germany, there is a growing emphasis on product certification and compliance with international safety standards, which influences purchasing decisions. Buyers are advised to focus on suppliers who can demonstrate quality assurance through certifications and positive customer testimonials.

How Is Sustainability Shaping the Sourcing of X-Ray Proof Bags?

Sustainability has become a critical consideration for B2B buyers in the x-ray proof bags sector. The environmental impact of packaging materials is under scrutiny, prompting companies to seek suppliers that prioritize eco-friendly practices. This shift is particularly evident in regions such as Europe, where regulations surrounding plastic use are becoming increasingly stringent.

Ethical sourcing is also gaining traction, with buyers favoring suppliers who adhere to responsible manufacturing practices. This includes the use of recyclable materials and transparent supply chains. Certifications such as the Forest Stewardship Council (FSC) and Cradle to Cradle (C2C) are becoming valuable indicators of a supplier’s commitment to sustainability. B2B buyers should consider engaging with manufacturers that offer products made from recycled or biodegradable materials to align with corporate sustainability goals.

What Is the Historical Context of X-Ray Proof Bags in B2B Markets?

The evolution of x-ray proof bags can be traced back to the growing need for privacy and security in various industries, including pharmaceuticals, electronics, and personal valuables. Initially developed for medical applications, these bags have expanded into broader markets as awareness of their protective capabilities has increased.

In the early 2000s, advancements in materials technology allowed for the creation of more durable and effective x-ray proof bags. This period marked a significant shift, as manufacturers began to focus on the dual function of protecting against x-ray exposure and maintaining product integrity. Today, the market is characterized by a diverse range of products tailored to meet specific industry needs, underscoring the importance of innovation in driving growth within the sector.

This historical context is essential for B2B buyers, as it highlights the ongoing evolution of product offerings and the importance of selecting suppliers who are committed to continuous improvement and quality assurance.

Frequently Asked Questions (FAQs) for B2B Buyers of x ray proof bags

-

How do I ensure the quality of x-ray proof bags before purchasing?

To ensure the quality of x-ray proof bags, it’s essential to vet suppliers by requesting product samples and certifications that demonstrate compliance with international safety standards. Look for detailed specifications about the materials used, such as layered alloys and synthetics, which contribute to the bags’ protective features. Additionally, inquire about the manufacturing process and any quality assurance measures in place, such as third-party testing or customer reviews. Engaging in direct communication with the supplier can provide further insights into their reliability and product quality. -

What are the key features to look for in x-ray proof bags?

When sourcing x-ray proof bags, prioritize features such as effective x-ray shielding, durability, water and UV resistance, and the ability to seal securely. Check if the bags can preserve odors, as this is crucial for certain applications. It’s also beneficial to consider the size options available, as different dimensions will cater to various packaging needs. Finally, ensure the bags are user-friendly, allowing for easy sealing with common tools like household irons or impulse sealers. -

What is the minimum order quantity (MOQ) for x-ray proof bags?

The minimum order quantity (MOQ) for x-ray proof bags can vary significantly among suppliers. Typically, MOQs may range from a few hundred to several thousand units, depending on the manufacturer and the specific bag type. It’s advisable to discuss your requirements directly with potential suppliers to negotiate terms that suit your business needs. Many suppliers also offer discounts on larger orders, which can be beneficial for businesses planning to scale. -

Can I customize the size and design of x-ray proof bags?

Yes, most manufacturers offer customization options for size, design, and even branding on x-ray proof bags. If you have specific dimensions or unique branding needs, communicate these to the supplier during your inquiry. Customization might incur additional costs, but it can significantly enhance your product presentation and market appeal. Ensure that the supplier has the capability to meet your specifications without compromising on the protective features of the bags. -

What payment terms should I expect when purchasing x-ray proof bags?

Payment terms for x-ray proof bags typically vary by supplier and may include options such as upfront payment, partial payment, or net payment terms based on the order size. Common methods include wire transfers, PayPal, or letters of credit, particularly for international transactions. Always clarify payment terms before finalizing your order to avoid any misunderstandings. It’s wise to establish a clear contract outlining the terms to protect both parties. -

How can I verify the credibility of a supplier for x-ray proof bags?

To verify a supplier’s credibility, conduct thorough research by checking their business registration, industry certifications, and customer reviews. Look for testimonials from previous clients, especially those in your region or industry, to gauge reliability and service quality. Additionally, consider visiting their manufacturing facility if possible, or request references to ensure they have a solid track record in producing high-quality x-ray proof bags. -

What are the logistics considerations when importing x-ray proof bags?

When importing x-ray proof bags, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose a shipping method that balances cost and delivery speed, such as air freight for urgent needs or sea freight for larger orders. Familiarize yourself with the customs duties and import regulations in your country to avoid unexpected fees. It’s also beneficial to work with a logistics provider experienced in international shipping to streamline the process. -

What quality assurance measures should be in place for x-ray proof bags?

Quality assurance measures for x-ray proof bags should include rigorous testing protocols to ensure compliance with safety and performance standards. This may involve third-party testing for x-ray resistance, durability, and sealing effectiveness. Suppliers should provide documentation of these tests and certifications. Regular audits of the manufacturing process and feedback mechanisms for clients can also enhance quality control, ensuring that the bags consistently meet buyer expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 X Ray Proof Bags Manufacturers & Suppliers List

1. Gamut Packaging – X Ray Smell Proof Bags

Domain: gamutpackaging.com

Registered: 2024 (1 years)

Introduction: X Ray Smell Proof Bags collection featuring stylish and functional Mylar bags designed to keep products discreet and fresh. Combines tamper-evident security with sleek aesthetics. Options in glossy and matte finishes. Sizes range from compact 2g bags to larger 28g exit bags. Key products include: 1. Tamper Evident | Matte Black Vista Mylar Bags (No Tear Notch) | 3in x 4.5in – 1g – 1000 Count – Pri…

2. Beyin Packing – X-Ray Proof Bags

Domain: beyinpacking.com

Registered: 2019 (6 years)

Introduction: X-ray proof bags manufactured in China, designed to protect sensitive items from X-ray scanning. Suitable for various applications including medical, legal, and security purposes. Available in different sizes and customizable options. Made from high-quality materials to ensure durability and effectiveness.

3. ScrapingDog – Instagram Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact us at [email protected] for scraping Instagram. Let us know how many pages you want to scrape per month.

Strategic Sourcing Conclusion and Outlook for x ray proof bags

In the evolving landscape of x-ray proof bags, strategic sourcing remains a cornerstone for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Understanding the nuances of quality, material specifications, and supplier credibility is crucial. Key takeaways emphasize the importance of selecting reputable manufacturers that adhere to stringent quality standards, ensuring the bags provide genuine x-ray protection and meet diverse needs.

Investing in high-quality x-ray proof bags not only safeguards valuable items from unauthorized access but also enhances the overall security and integrity of shipments. As the demand for such products continues to rise, particularly in industries requiring strict confidentiality and protection, buyers should prioritize building long-term partnerships with trusted suppliers.

Looking ahead, the market for x-ray proof bags is poised for growth, driven by innovations in materials and design. Now is the time to explore sourcing opportunities and align with suppliers who can deliver both quality and value. Engage with manufacturers to discuss customized solutions that meet your specific requirements and stay ahead in this competitive space. Your proactive approach today will secure a safer tomorrow for your business.