The Definitive Guide to Vodka Square Bottle: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for vodka square bottle

Navigating the global market for vodka square bottles presents a unique set of challenges for international B2B buyers, particularly those in emerging markets across Africa, South America, the Middle East, and Europe. The task of sourcing high-quality vodka bottles that not only meet regulatory standards but also resonate with local tastes and branding strategies can be daunting. In this comprehensive guide, we delve into various types of vodka square bottles, their applications in different markets, and effective strategies for supplier vetting.

Understanding the intricacies of pricing, shipping logistics, and design options is crucial for making informed purchasing decisions that align with your business objectives. Whether you are a distributor seeking to enhance your product portfolio or a retailer looking to attract discerning customers, this guide empowers you with the knowledge needed to navigate complex supply chains and select the right products.

With insights tailored specifically for B2B buyers in diverse regions such as Nigeria and Vietnam, we aim to facilitate connections between buyers and suppliers, ensuring that you can confidently invest in vodka square bottles that elevate your brand presence and meet market demand. Engage with us as we explore innovative design features, cost-effective sourcing strategies, and the latest market trends that shape the vodka industry today.

Understanding vodka square bottle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heritage Bottle | Unique design, often with awards for taste/design | Premium brands, limited editions | Pros: High perceived value, collectible. Cons: Higher cost, limited availability. |

| Craft Distilled Bottle | Distilled multiple times, often from unique grains | Boutique distilleries, artisanal brands | Pros: High-quality product, unique flavors. Cons: May have inconsistent supply, higher pricing. |

| Custom-Designed Bottle | Tailored shapes and designs, often with branding | Private labels, brand launches | Pros: Strong brand identity, customizable. Cons: MOQ requirements, longer lead times. |

| Standard Square Bottle | Basic square shape, typically mass-produced | Large retailers, mainstream brands | Pros: Cost-effective, widely available. Cons: Less differentiation in market. |

| Eco-Friendly Bottle | Made from recycled materials or sustainable processes | Green brands, eco-conscious consumers | Pros: Appeals to eco-conscious market. Cons: Potentially higher costs, limited designs. |

What Are the Characteristics of Heritage Bottles in the Vodka Industry?

Heritage bottles are characterized by their unique and often ornate designs, which can include award-winning features for both taste and aesthetics. These bottles are typically marketed as premium products, appealing to consumers who value craftsmanship and exclusivity. B2B buyers in the luxury segment may find these bottles suitable for limited editions or special releases, although they may come with higher costs and limited availability, impacting inventory strategies.

How Do Craft Distilled Bottles Stand Out for B2B Buyers?

Craft distilled bottles are distinguished by their production methods, often involving multiple distillation processes and unique grain sources. This results in a clean and neutral flavor profile, making them ideal for mixing in cocktails. B2B buyers, especially those representing boutique distilleries or artisanal brands, should consider these bottles for their high-quality offerings. However, the inconsistent supply and higher price point may require careful inventory management.

Why Consider Custom-Designed Bottles for Branding?

Custom-designed bottles offer brands the opportunity to create a distinctive identity through tailored shapes and personalized branding. This option is particularly appealing for private labels and new product launches, where standing out on retail shelves is crucial. While these bottles can enhance brand perception, buyers must be prepared for minimum order quantity (MOQ) requirements and potentially longer lead times for production.

What Are the Advantages of Standard Square Bottles?

Standard square bottles are the most commonly used in the vodka market, known for their cost-effectiveness and mass production capabilities. They serve mainstream brands and large retailers well, providing a reliable option for high-volume sales. However, their generic nature may lead to less differentiation in a competitive market, making it essential for buyers to consider branding strategies to enhance visibility.

How Do Eco-Friendly Bottles Appeal to Modern Consumers?

Eco-friendly bottles are made from recycled materials or produced using sustainable practices, catering to a growing market of environmentally conscious consumers. B2B buyers looking to align with green initiatives can leverage these bottles to enhance their brand image. While they may carry higher costs and fewer design options, the appeal to eco-friendly markets can justify the investment, especially in regions where sustainability is a priority.

Key Industrial Applications of vodka square bottle

| Industry/Sector | Specific Application of vodka square bottle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Beverage Manufacturing | Packaging for premium vodka brands | Enhances brand image and shelf appeal, attracting consumers | Quality of glass, customization options, compliance with regulations |

| Hospitality | Serving and showcasing vodka in bars and restaurants | Unique presentation boosts customer experience and sales | Bulk purchasing options, durability, and design flexibility |

| Retail | Retail display and merchandising of vodka products | Eye-catching design increases visibility and sales potential | Packaging design, shipping logistics, and branding opportunities |

| Events and Catering | Customized vodka bottles for events and private parties | Personalized branding and memorable experiences for guests | Minimum order quantities, customization capabilities, and lead times |

| Export and Distribution | Exporting vodka in square bottles to international markets | Streamlined logistics and compliance with international standards | Shipping regulations, packaging durability, and cost-effectiveness |

How Is the Vodka Square Bottle Used in Beverage Manufacturing?

In the beverage manufacturing sector, vodka square bottles serve as essential packaging for premium vodka brands. Their unique design not only enhances the aesthetic appeal of the product but also provides functional benefits such as ease of storage and transport. Manufacturers can benefit from high-quality glass that showcases the clarity of the vodka, while also allowing for customization in branding. International B2B buyers should focus on sourcing bottles that meet specific regulatory requirements in their respective markets, ensuring compliance and safety.

What Role Do Vodka Square Bottles Play in Hospitality?

In hospitality, vodka square bottles are frequently used for serving and showcasing vodka in bars and restaurants. Their distinctive shape adds a touch of elegance to the beverage presentation, thus enhancing the overall customer experience. This can lead to increased sales as customers are more likely to purchase visually appealing products. Buyers in this sector should consider factors like durability and design flexibility when sourcing bottles, as they need to withstand high-volume usage while still maintaining aesthetic appeal.

How Are Vodka Square Bottles Utilized in Retail Settings?

Retailers leverage vodka square bottles for effective display and merchandising of vodka products. The striking visual impact of square bottles can significantly increase product visibility on shelves, attracting consumers’ attention and driving sales. For international retailers, sourcing bottles that allow for branding opportunities—such as silk screen printing or unique labeling—is crucial. Additionally, considerations around shipping logistics and packaging design are essential to ensure that products arrive safely and ready for display.

How Do Customized Vodka Bottles Benefit Events and Catering?

Customized vodka bottles are increasingly popular in the events and catering industry, where they can serve as unique branding opportunities for weddings, corporate events, and private parties. This personalization not only enhances the guest experience but also creates memorable takeaways that can promote the brand long after the event. B2B buyers in this sector should focus on minimum order quantities, customization capabilities, and lead times to ensure they can meet specific event needs without delays.

What Are the Considerations for Exporting Vodka Square Bottles?

In the export and distribution sector, vodka square bottles are an effective choice for international markets due to their streamlined logistics and compliance with various shipping standards. The square shape allows for efficient packing and transport, minimizing shipping costs. Buyers should pay close attention to shipping regulations and ensure that the packaging is durable enough to withstand international transit. Cost-effectiveness is also a key consideration for maintaining competitive pricing in foreign markets.

3 Common User Pain Points for ‘vodka square bottle’ & Their Solutions

Scenario 1: Navigating Compliance and Regulations for Vodka Packaging

The Problem:

B2B buyers often encounter significant challenges when it comes to ensuring that their vodka square bottles comply with local and international regulations. This is particularly pertinent in regions like Africa and South America, where regulations can vary widely between countries. Buyers may struggle with understanding the specific labeling requirements, bottle sizes, and even the materials used in production. Non-compliance can lead to costly fines, product recalls, or even a complete halt in distribution, which can negatively impact brand reputation and market share.

The Solution:

To mitigate these compliance risks, it is essential for buyers to conduct thorough research on the regulatory landscape in their target markets. Partnering with local legal experts or compliance consultants can provide invaluable insights into the specific requirements for vodka packaging in different regions. Additionally, sourcing square bottles from manufacturers who are well-versed in international compliance standards can significantly reduce the burden. When placing orders, buyers should specify their need for compliance documentation, which can include certifications or proof of adherence to local regulations. This proactive approach not only streamlines the import process but also builds trust with consumers who prioritize quality and safety in their purchasing decisions.

Scenario 2: Achieving Brand Differentiation in a Saturated Market

The Problem:

In a competitive vodka market, standing out is a major concern for B2B buyers. With numerous brands offering similar products, many companies find it difficult to differentiate their vodka square bottles. This challenge is exacerbated by the fact that vodka is a clear spirit with no inherent flavor, making packaging design a critical factor in attracting consumers. Buyers often feel pressured to develop unique and eye-catching designs that convey the quality and essence of their brand without incurring excessive costs.

The Solution:

Investing in custom bottle designs can be a game-changer for brand differentiation. Buyers should collaborate closely with packaging designers and manufacturers to create unique square bottle shapes and labels that reflect their brand identity. Utilizing innovative printing techniques such as silk screening or frosted finishes can enhance the visual appeal without significantly increasing costs. Additionally, small batch production runs can allow brands to test various designs in the market before committing to larger orders. Engaging in consumer feedback loops through surveys or focus groups can also provide insights into which designs resonate most with potential buyers, ensuring that the final product not only stands out on shelves but also meets consumer preferences.

Scenario 3: Managing Supply Chain Challenges for Consistent Quality

The Problem:

B2B buyers often face difficulties in maintaining consistent quality and supply of vodka square bottles, which can disrupt production schedules and affect inventory management. Variability in manufacturing processes or delays in shipping can lead to shortages, forcing companies to compromise on quality or rush to find alternative suppliers. This not only impacts the brand’s image but can also lead to increased operational costs and lost sales opportunities.

The Solution:

To address these supply chain challenges, buyers should establish long-term relationships with reliable manufacturers that have proven track records of quality and timely delivery. Conducting regular audits of suppliers and maintaining open lines of communication can help identify potential issues before they escalate. Additionally, diversifying the supplier base can provide a safety net against disruptions; by having multiple options for sourcing square bottles, buyers can ensure a steady supply chain. Implementing inventory management software can also aid in tracking stock levels and automating reordering processes, allowing businesses to plan better and avoid shortages. By prioritizing quality assurance and proactive supply chain management, buyers can safeguard their operations against unexpected challenges.

Strategic Material Selection Guide for vodka square bottle

What Are the Key Materials for Vodka Square Bottles?

When selecting materials for vodka square bottles, it is crucial to consider various factors such as durability, cost, manufacturing complexity, and compliance with international standards. Below are the common materials used in the production of vodka square bottles, along with their respective properties, advantages, disadvantages, and considerations for international buyers.

Glass: The Classic Choice for Vodka Bottles

Key Properties:

Glass is renowned for its excellent barrier properties, preventing gas and moisture exchange. It is also resistant to corrosion and can withstand high temperatures, making it suitable for various filling processes.

Pros & Cons:

Glass bottles are highly durable and provide an upscale feel, which can enhance brand perception. However, they are heavier than other materials, which can increase shipping costs. Manufacturing glass bottles can be complex and requires significant energy input.

Impact on Application:

Glass is compatible with a wide range of alcoholic beverages, including vodka, and does not impart any flavors or odors. This ensures that the product’s purity is maintained.

Considerations for International Buyers:

Buyers should be aware of the varying regulations regarding glass packaging in different regions. Compliance with standards such as ASTM or DIN is essential, especially in markets like Europe and South America, where sustainability is increasingly prioritized.

PET Plastic: A Lightweight Alternative

Key Properties:

Polyethylene Terephthalate (PET) is a lightweight, flexible material that offers good resistance to impact and moisture. It has a temperature tolerance of up to 60°C (140°F), making it suitable for room temperature storage.

Pros & Cons:

The primary advantage of PET is its light weight, which reduces shipping costs significantly. However, it is not as rigid as glass and may not provide the same premium feel. Additionally, PET can be susceptible to scratching and may not offer the same level of barrier protection as glass.

Impact on Application:

PET is compatible with vodka and other spirits, but it may not be suitable for long-term storage due to potential leaching of chemicals over time.

Considerations for International Buyers:

Buyers should ensure that PET bottles comply with local regulations regarding food and beverage safety. In regions like Africa and the Middle East, where recycling practices may vary, the environmental impact of using PET should also be considered.

Aluminum: The Modern Packaging Solution

Key Properties:

Aluminum is lightweight, durable, and offers excellent resistance to corrosion. It can withstand high pressures, making it suitable for carbonated beverages as well.

Pros & Cons:

Aluminum bottles provide a unique aesthetic appeal and are highly recyclable, aligning with sustainability trends. However, they can be more expensive to produce than glass or PET and may require specialized manufacturing processes.

Impact on Application:

Aluminum is compatible with vodka and can help maintain the beverage’s quality by blocking light and air exposure. However, it may require an internal coating to prevent interaction with the liquid.

Considerations for International Buyers:

Buyers should consider the regulatory landscape regarding aluminum packaging in their target markets. Compliance with standards such as JIS in Japan or EU regulations can impact product acceptance.

Cardboard: Sustainable Packaging Option

Key Properties:

Cardboard is biodegradable and offers a lightweight alternative for secondary packaging. It is not typically used for primary vodka containers but can be effective for shipping and branding.

Pros & Cons:

Cardboard is cost-effective and aligns with sustainability initiatives. However, it lacks the durability and moisture resistance of glass or plastic, making it unsuitable for direct contact with liquids.

Impact on Application:

While cardboard cannot be used as a primary container, it is excellent for secondary packaging, providing branding opportunities and protection during transport.

Considerations for International Buyers:

Buyers should ensure that cardboard packaging complies with international shipping standards and consider the environmental regulations in their regions, particularly in Europe where sustainability is a key concern.

Summary Table of Material Selection for Vodka Square Bottles

| Material | Typical Use Case for vodka square bottle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Primary packaging for premium vodka | Excellent barrier properties | Heavier, higher shipping costs | High |

| PET Plastic | Lightweight alternative for vodka | Reduces shipping costs | Less rigid, potential leaching | Medium |

| Aluminum | Unique packaging solution for spirits | Highly recyclable, durable | Higher production costs | High |

| Cardboard | Secondary packaging for branding | Cost-effective and sustainable | Not suitable for direct contact | Low |

This strategic material selection guide provides valuable insights for B2B buyers looking to source vodka square bottles, enabling informed decisions that align with product requirements and market expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for vodka square bottle

What Are the Main Stages in the Manufacturing Process of Vodka Square Bottles?

The manufacturing process of vodka square bottles involves several critical stages, each designed to ensure the final product meets high-quality standards.

Material Preparation

The journey begins with the selection of raw materials, primarily glass, which is known for its inert properties, ensuring that it does not react with the vodka. Manufacturers typically use high-quality silica sand, soda ash, and limestone as primary ingredients. These materials are carefully measured and mixed to form a batch that meets specific chemical compositions.

Forming Techniques

Once the batch is prepared, it undergoes a melting process in a furnace at temperatures exceeding 1,600 degrees Celsius. The molten glass is then shaped into square bottles using various forming techniques, such as blow molding or press molding. In blow molding, air is introduced into the molten glass to create the desired shape, while press molding involves pressing the glass into a mold to achieve uniformity. The choice of technique can influence the bottle’s thickness and strength, which are crucial for handling and transportation.

Assembly and Finishing

After forming, the bottles are cooled gradually in an annealing lehr to relieve internal stresses. This step is vital in ensuring durability and preventing cracking. Once cooled, the bottles may undergo additional processes such as surface finishing, where techniques like silk-screen printing or hot stamping are applied for branding purposes. These finishing touches not only enhance aesthetic appeal but also serve to protect the bottle from scratches and other damage.

What Quality Control Measures Are Essential for Vodka Square Bottles?

Quality control (QC) is a critical aspect of the vodka square bottle manufacturing process, ensuring that each bottle meets international standards and customer expectations.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with several international standards that govern the manufacturing and quality assurance of glass products. One of the most relevant is ISO 9001, which outlines the criteria for a quality management system. Compliance with ISO 9001 indicates that a manufacturer consistently provides products that meet customer and regulatory requirements.

Additionally, specific industry standards such as CE marking (Conformité Européenne) and API (American Petroleum Institute) certifications may apply, especially if bottles are intended for specific markets or applications. These certifications assure buyers of the product’s safety, reliability, and quality.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integrated at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon receipt to ensure they meet specified standards. Testing for purity, size, and composition is common.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring occurs. This includes checking temperatures in the furnace, monitoring the forming process, and ensuring that the cooling rates are optimal.

-

Final Quality Control (FQC): Once the bottles are finished, they undergo a comprehensive inspection that includes visual checks for defects, dimensional accuracy, and pressure testing for strength.

What Testing Methods Are Commonly Used in Quality Assurance?

Manufacturers employ various testing methods to validate the quality of vodka square bottles. Common techniques include:

-

Visual Inspection: Trained quality inspectors examine each bottle for defects, such as bubbles, cracks, or irregular shapes.

-

Dimensional Testing: Tools such as calipers and gauges measure the dimensions of the bottles to ensure they conform to specified tolerances.

-

Pressure Testing: This method assesses the strength of the bottles under pressure, ensuring they can withstand handling and transportation.

-

Chemical Testing: Samples may undergo chemical analysis to confirm that the glass does not leach harmful substances into the vodka.

How Can B2B Buyers Verify Supplier Quality Control Processes?

To ensure that suppliers maintain high-quality standards, B2B buyers should engage in thorough verification processes:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and compliance with international standards firsthand.

-

Quality Reports: Requesting detailed quality assurance reports can provide insights into the supplier’s testing methods, results, and any corrective actions taken for non-compliance issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality processes and products. This is particularly beneficial for international buyers who may not have the capacity to perform audits themselves.

What Are the QC and Certification Nuances for International Buyers?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding local regulations and certifications is vital. Different countries may have specific requirements regarding packaging materials, labeling, and product safety.

Buyers should ensure that suppliers are familiar with these regulations and can provide the necessary documentation to facilitate smoother customs clearance. Additionally, understanding the nuances of international trade agreements can aid in navigating potential tariffs or trade barriers that may affect the import of vodka square bottles.

By ensuring that manufacturers adhere to stringent quality control measures and international standards, B2B buyers can confidently source high-quality vodka square bottles that meet their operational needs and consumer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vodka square bottle’

In the competitive market of vodka, sourcing square bottles that align with your brand’s identity and operational needs is essential. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process effectively.

1. Define Your Technical Specifications

Before engaging suppliers, clearly outline the specifications of the square bottles you require. Consider factors such as size (e.g., 750ml or 1L), material (glass or plastic), and design features (e.g., weight, shape). This step is crucial as it sets the foundation for your procurement process, ensuring you find bottles that not only meet regulatory requirements but also resonate with your brand image.

2. Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in square vodka bottles. Use industry directories, trade shows, and online platforms to compile a list of potential partners. This step is vital to ensure you have a broad selection of suppliers to choose from, which can enhance your negotiating power and help you find the best fit for your needs.

3. Verify Supplier Certifications

Ensure that your chosen suppliers possess the necessary certifications and comply with international standards. Look for certifications such as ISO, FDA approval, or other relevant local and international quality standards. Verifying these credentials is important as it mitigates risks associated with product safety and quality.

4. Request Samples for Evaluation

Before placing a large order, request samples of the square bottles to assess their quality and suitability. Examine the bottle’s clarity, design integrity, and weight to ensure they meet your standards. This step allows you to evaluate the product firsthand, minimizing the risk of dissatisfaction after bulk orders.

5. Assess Customization Options

If branding is a priority, inquire about customization capabilities, such as silk screening, labeling, or unique mold designs. Customization can significantly enhance your product’s market appeal, making it stand out on the shelf. Discuss minimum order quantities and lead times for customized products to align with your production schedule.

6. Evaluate Pricing and Payment Terms

Request detailed quotes from your shortlisted suppliers, including pricing structures, payment terms, and potential bulk discounts. Compare these quotes not only based on price but also consider the total cost of ownership, including shipping and handling fees. Understanding the financial implications is essential for maintaining budgetary control and ensuring profitability.

7. Establish Communication and Support

Effective communication is key to a successful supplier relationship. Ensure that the supplier has a responsive support team to address any inquiries or issues that may arise during the procurement process. Establishing a clear line of communication can facilitate smoother transactions and foster a long-term partnership.

By following this checklist, B2B buyers can make informed decisions when sourcing square vodka bottles, ensuring they select the best suppliers for their operational and branding needs.

Comprehensive Cost and Pricing Analysis for vodka square bottle Sourcing

What Are the Key Cost Components for Sourcing Vodka Square Bottles?

When evaluating the costs associated with sourcing vodka square bottles, several components need to be considered. The primary cost factors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The type of glass used for the bottles significantly impacts the cost. High-quality, lead-free glass is preferred for premium vodka brands, which can increase material costs. Custom designs and finishes, such as frosted or colored glass, further add to material expenses.

-

Labor: Labor costs vary based on the manufacturing location. Countries with higher labor rates will typically see increased production costs. Automation in manufacturing can reduce labor costs but may require substantial initial investment.

-

Manufacturing Overhead: This includes utilities, rent, and general operational expenses incurred during production. Overhead costs can fluctuate based on local economic conditions and the scale of production.

-

Tooling: Custom molds for unique bottle shapes or designs require investment. The tooling cost can be amortized over larger production runs, making it essential to consider the minimum order quantities (MOQs).

-

Quality Control (QC): Rigorous quality checks are crucial, especially for brands focusing on premium segments. Implementing comprehensive QC processes incurs additional costs but ensures consistency and quality, which can prevent costly recalls or brand damage.

-

Logistics: Shipping costs can vary significantly based on distance, weight, and chosen shipping method. International buyers must consider duties and tariffs, which can add to the total cost.

-

Margin: Suppliers will include a margin based on their operational costs and market positioning. This margin can vary widely depending on the supplier’s reputation and the exclusivity of the product.

How Do Price Influencers Impact Vodka Square Bottle Sourcing?

Several factors influence the pricing of vodka square bottles, particularly for B2B buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

-

Volume/MOQ: Suppliers often offer better pricing for larger orders due to economies of scale. Understanding the minimum order quantities required by suppliers is crucial for cost efficiency.

-

Specifications/Customization: Custom designs, such as unique shapes or branding, can significantly increase costs. Buyers should balance the desire for differentiation with budget constraints.

-

Materials: The choice of materials affects both cost and perceived quality. Buyers should weigh the benefits of premium materials against their budget and target market.

-

Quality/Certifications: Certifications (e.g., food safety standards) can influence both the cost and marketability of the product. Brands that emphasize quality often invest more in compliance, which can be reflected in pricing.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their experience and quality assurance, while newer suppliers might offer competitive rates to attract business.

-

Incoterms: Understanding Incoterms is essential for international buyers to clarify responsibilities regarding shipping, insurance, and tariffs. This knowledge can help in negotiating better terms and avoiding unexpected costs.

What Are Essential Tips for Negotiating Vodka Square Bottle Prices?

Negotiating prices for vodka square bottles requires a strategic approach. Here are some actionable tips for B2B buyers:

-

Leverage Volume Discounts: If possible, consolidate orders to meet higher MOQs that can unlock better pricing structures.

-

Consider Total Cost of Ownership: Focus not just on the purchase price but also on the total cost of ownership, including shipping, handling, and potential wastage.

-

Research and Compare Suppliers: Gather quotes from multiple suppliers to understand the market rate. This information can provide leverage during negotiations.

-

Be Clear on Specifications: Clearly outline your requirements to avoid misunderstandings that could lead to increased costs.

-

Explore Flexible Payment Terms: Negotiating favorable payment terms can improve cash flow and reduce immediate financial pressure.

-

Build Long-term Relationships: Establishing a good rapport with suppliers can lead to better pricing and priority during production shortages.

Disclaimer on Indicative Prices

It is essential to note that prices for vodka square bottles can vary widely based on the factors discussed. The examples provided are indicative and may not represent current market conditions. Buyers should conduct thorough market research and supplier evaluation to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing vodka square bottle With Other Solutions

Exploring Alternatives to the Vodka Square Bottle: A Comparative Analysis

In the competitive landscape of vodka packaging, the choice of bottle design is critical for branding, consumer perception, and product differentiation. While the square vodka bottle has gained traction for its unique aesthetic and functional advantages, several alternative packaging solutions exist. This analysis will compare the vodka square bottle with two viable alternatives: the traditional round bottle and the eco-friendly packaging solution.

Comparison Table

| Comparison Aspect | Vodka Square Bottle | Traditional Round Bottle | Eco-Friendly Packaging |

|---|---|---|---|

| Performance | High visibility; unique design | Standard design; widely accepted | Sustainable; lightweight |

| Cost | Moderate ($21 – $45) | Typically lower ($10 – $30) | Varies; often higher upfront |

| Ease of Implementation | Requires custom molds | Easier to source | Requires sourcing from green suppliers |

| Maintenance | Durable, easy to clean | Durable but can be prone to breakage | May require special handling |

| Best Use Case | Premium brands seeking differentiation | Mass-market brands | Brands focused on sustainability |

Detailed Breakdown of Alternatives

Traditional Round Bottle

The traditional round bottle remains a popular choice for many vodka brands due to its familiarity and ease of production. It typically costs less to manufacture and source, making it an attractive option for mass-market brands. The round design is also more forgiving in terms of labeling and branding, as it allows for a variety of graphics and designs to be applied easily.

However, the downside is that it lacks the distinctive appeal of square bottles, which can make it harder for brands to stand out on shelves. Additionally, while round bottles are durable, they are more susceptible to breakage compared to their square counterparts, especially in high-volume distribution scenarios.

Eco-Friendly Packaging

Eco-friendly packaging solutions, such as biodegradable or recycled materials, are gaining traction as consumers become more environmentally conscious. These options often align well with brands that prioritize sustainability in their marketing and product offerings. Eco-friendly packaging can enhance brand image and appeal to a growing demographic of eco-conscious consumers.

The primary drawback, however, is the cost. Eco-friendly materials can be more expensive to procure, which may not be feasible for every brand, particularly those targeting budget-conscious consumers. Additionally, sourcing from sustainable suppliers can introduce complexities in the supply chain that may not exist with traditional packaging methods.

Conclusion: How to Choose the Right Packaging Solution

When selecting a packaging solution for vodka, B2B buyers must carefully consider their brand positioning, target market, and budget constraints. The vodka square bottle excels in creating a premium image and standing out in a crowded marketplace, making it suitable for high-end brands. In contrast, traditional round bottles offer cost-effectiveness and ease of sourcing for mass-market products. Lastly, eco-friendly packaging is ideal for brands committed to sustainability, albeit at a potentially higher cost. Ultimately, the choice will depend on the strategic goals of the brand and the specific needs of the target market.

Essential Technical Properties and Trade Terminology for vodka square bottle

What Are the Key Technical Properties of a Vodka Square Bottle?

When sourcing vodka square bottles, understanding the technical specifications is crucial for ensuring product quality, branding effectiveness, and market competitiveness. Here are essential properties to consider:

-

Material Grade

Vodka square bottles are typically made from high-quality glass or PET (polyethylene terephthalate). Glass offers superior clarity and an upscale aesthetic, while PET provides lightweight and shatter-resistant options. For B2B buyers, selecting the right material impacts shipping costs, consumer perception, and overall product safety. -

Capacity and Dimensions

Standard capacities for vodka square bottles are often 375ml, 750ml, or 1 liter. Dimensions can vary, but a common design is a square bottle with a broad shoulder and heavy base. These specifications are essential for retailers and distributors, as they influence shelf space, packaging, and consumer appeal. -

Neck Finish and Closure Type

The neck finish refers to the design of the bottle’s opening, which can accommodate various closure types such as corks, screw caps, or synthetic closures. This detail is critical for product security and preservation, impacting both shelf life and customer satisfaction. -

Labeling Area

A straight body panel design allows for effective label application, which is vital for branding and compliance with regulations. The labeling area must be adequate to display essential information clearly, as well as any promotional graphics. This aspect is significant for B2B buyers focusing on branding strategies and market positioning. -

Customization Options

Customization capabilities, such as silk screen printing, hot stamping, or frosted finishes, allow brands to differentiate their products in a competitive market. B2B buyers should consider the minimum order quantities and lead times associated with custom designs to ensure alignment with marketing campaigns.

What Are Common Trade Terms Related to Vodka Square Bottles?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or products that are used in another company’s product. For vodka square bottles, this could involve manufacturers that create bottles for various brands under private label agreements, allowing brands to focus on marketing while outsourcing production. -

MOQ (Minimum Order Quantity)

This term indicates the smallest number of units a supplier is willing to sell in one order. For vodka bottles, MOQs can vary significantly based on customization and material. Understanding MOQs helps buyers manage inventory and cash flow effectively. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers invite suppliers to submit price quotes for a specific product or service. B2B buyers should issue RFQs to multiple manufacturers for vodka square bottles to compare pricing, quality, and delivery terms. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Common Incoterms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Familiarity with Incoterms helps buyers understand shipping costs, risks, and obligations. -

Lead Time

This term refers to the amount of time from placing an order to its delivery. For vodka square bottles, lead times can vary based on production schedules and customization requirements. Understanding lead times is crucial for inventory planning and ensuring product availability in the market. -

Customs Clearance

This process involves the preparation and submission of documentations required for importing goods into a country. B2B buyers must be aware of customs clearance procedures to avoid delays and additional costs when importing vodka square bottles from international suppliers.

These technical properties and trade terms are essential for B2B buyers in the vodka industry, providing a foundation for informed decision-making and successful procurement strategies.

Navigating Market Dynamics and Sourcing Trends in the vodka square bottle Sector

What Are the Key Trends in the Global Vodka Square Bottle Market?

The vodka square bottle market is experiencing significant transformations driven by evolving consumer preferences and innovative packaging solutions. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly seeking unique designs that enhance brand visibility and consumer appeal. The trend towards premiumization is notable, with brands focusing on distinctive bottle shapes and high-quality materials to differentiate themselves in a crowded marketplace. For instance, square bottles not only offer a modern aesthetic but also facilitate efficient stacking and storage, making them appealing for both retail and shipping.

Moreover, advancements in technology are shaping sourcing practices within the sector. The rise of e-commerce platforms has enabled buyers to access a broader range of suppliers, facilitating direct purchasing and reducing lead times. B2B buyers are leveraging data analytics to make informed decisions regarding market demand and inventory management. Additionally, the use of sustainable materials in bottle production is gaining traction, aligning with the growing consumer demand for eco-friendly products. This shift is not only beneficial for brand reputation but also helps in meeting regulatory requirements in various markets.

How Can Sustainability and Ethical Sourcing Impact the Vodka Square Bottle Industry?

Sustainability is becoming a critical factor in the sourcing strategies of B2B buyers in the vodka square bottle sector. The environmental impact of packaging materials is under scrutiny, prompting brands to adopt eco-friendly practices. This includes using recycled glass or alternative materials that reduce carbon footprints. Suppliers who can demonstrate their commitment to sustainability through certifications, such as FSC (Forest Stewardship Council) or ISO 14001, are more likely to attract environmentally conscious buyers.

Ethical sourcing is equally important, as consumers increasingly prefer brands that prioritize transparency in their supply chains. For international buyers, ensuring that suppliers adhere to fair labor practices and environmental regulations is essential. This not only mitigates risks but also enhances brand loyalty among consumers who value corporate responsibility. By choosing suppliers who prioritize sustainable and ethical practices, B2B buyers can contribute to a more sustainable future while also meeting the rising demand for socially responsible products.

How Has the Vodka Square Bottle Market Evolved Over Time?

The evolution of the vodka square bottle market reflects broader changes in consumer behavior and branding strategies. Initially, vodka was primarily packaged in traditional round bottles, but as competition intensified, brands began experimenting with various shapes to stand out. The square bottle design emerged as a popular choice, offering both aesthetic appeal and practical advantages in storage and display.

In recent years, the focus on design has intensified, with brands investing significantly in creating visually striking bottles that resonate with target audiences. This shift has been supported by marketing research indicating that packaging plays a crucial role in consumer perception, especially for products like vodka that are often perceived as homogeneous. As a result, the square bottle has become synonymous with premium quality, enabling brands to command higher price points and foster brand loyalty among discerning consumers.

In summary, the vodka square bottle sector is poised for continued growth, driven by innovative design, sustainability, and ethical sourcing practices that resonate with today’s global consumers. B2B buyers who stay ahead of these trends will be well-positioned to capitalize on emerging opportunities in this dynamic market.

Frequently Asked Questions (FAQs) for B2B Buyers of vodka square bottle

-

How do I choose the right supplier for vodka square bottles?

Choosing the right supplier involves assessing several key factors. Start by researching the supplier’s reputation in the market, checking for reviews and testimonials from other B2B clients. Evaluate their product quality by requesting samples and confirming they meet industry standards. Additionally, consider their manufacturing capabilities, lead times, and flexibility in handling custom orders. Communication is crucial; a responsive supplier can make the process smoother. Finally, verify their compliance with international regulations and certifications relevant to your region. -

What is the best material for vodka square bottles?

The best material for vodka square bottles is glass, particularly because it preserves the purity of the spirit and enhances shelf appeal. Glass bottles provide an airtight seal, protecting the vodka from external contaminants while allowing for intricate designs that can elevate brand visibility. Additionally, glass is recyclable, making it an environmentally friendly option. For brands targeting luxury markets, opt for thick, high-quality glass that conveys a premium feel. Consider customization options like frosted or colored glass for added differentiation. -

What are the minimum order quantities (MOQs) for vodka square bottles?

Minimum order quantities (MOQs) for vodka square bottles can vary significantly by supplier and the complexity of customization. Typically, MOQs range from 1,000 to 5,000 units for standard designs. However, suppliers may offer lower MOQs for non-customized bottles or during promotional periods. It’s essential to discuss your needs with potential suppliers to find flexible options that suit your budget and inventory requirements. Always clarify MOQs upfront to avoid unexpected costs later in the ordering process. -

What customization options are available for vodka square bottles?

Customization options for vodka square bottles are extensive and can significantly enhance your brand identity. Common options include silk-screen printing, hot stamping, and label application for unique branding. You can also choose from various bottle shapes, sizes, and colors to stand out on the shelf. Some suppliers offer additional features like embossed logos or decorative caps. Discuss your design ideas with the supplier to create mockups and ensure they can meet your specific branding requirements. -

What payment terms should I expect when ordering vodka square bottles?

Payment terms vary by supplier, but common practices include a deposit upon order confirmation (typically 30-50%) and the balance due before shipping. Some suppliers may offer credit terms for established clients or larger orders. Be sure to clarify payment methods accepted (e.g., bank transfer, credit card) and any applicable fees. It’s advisable to have a clear agreement in place to avoid misunderstandings and ensure both parties are aligned on payment timelines. -

How can I ensure quality assurance for my vodka square bottles?

To ensure quality assurance, request samples before placing a bulk order. This allows you to assess the materials, design, and overall craftsmanship. Additionally, inquire about the supplier’s quality control processes, including inspections during production and before shipment. Some suppliers may provide third-party testing certifications to validate the quality of their bottles. Establish clear communication regarding your quality expectations and consider including them in your purchase agreement. -

What logistics considerations should I keep in mind for international shipping of vodka square bottles?

When planning for international shipping, consider the costs, transit times, and potential customs duties associated with your order. Work with suppliers who have experience in international logistics to streamline the process. Confirm that the packaging meets export standards to minimize damage during transit. It’s also beneficial to understand the local regulations regarding alcohol packaging and importation in your target market to avoid delays or penalties upon arrival. -

What are the key trends in vodka bottle design that I should be aware of?

Current trends in vodka bottle design focus on sustainability, minimalism, and unique shapes that capture consumer attention. Eco-friendly materials and packaging are increasingly popular, reflecting consumer demand for environmentally responsible products. Additionally, sleek and modern designs, often with bold graphics or unique textures, are gaining traction. Consider how your bottle design can tell a story or convey your brand’s values to resonate with consumers in competitive markets. Staying abreast of these trends can help differentiate your product on the shelf.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Vodka Square Bottle Manufacturers & Suppliers List

1. Double Cross – Heritage Vodka 750ml

Domain: doublecrossvodka.com

Registered: 2006 (19 years)

Introduction: {“name”: “Double Cross Vodka 750ml – Heritage Bottle”, “size”: “750ml”, “type”: “Heritage Bottle”, “price”: “$44.99”, “shipping”: “$10 FLAT Rate Shipping on 1 Bottle | FREE Shipping on 2+ Bottles!”, “limited_edition”: true, “awards”: “ONLY VODKA EVER TO WIN GOLD IN BOTH TASTE AND DESIGN – IWSC”}

2. Eleven Square Vodka – Premium Clean Distilled Spirit

Domain: athenswestend.com

Registered: 2018 (7 years)

Introduction: {“name”: “Eleven Square Vodka”, “price”: “$21.25”, “distillation”: “Distilled 6 times”, “base_ingredient”: “non-GM corn”, “origin”: “Nebraska’s Golden Triangle”, “characteristics”: “very clean, neutral vodka”, “alcohol_content”: “40%/80 Proof”, “bottle_size”: “750mL”, “pickup_info”: “Bottles of spirits may be picked up at West End Distillery ONLY. We are not permitted to deliver or sell spirits by…

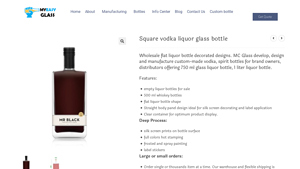

3. My Easy Glass – Square Vodka Liquor Bottle

Domain: myeasyglass.com

Registered: 2018 (7 years)

Introduction: Product Name: Square vodka liquor glass bottle

Capacity: 750 ml, 375 ml

Shape: Square

Color: Clear

Cap: Cork

Features:

– Straight body panel design ideal for silk screen decorating and label application

– Clear container for optimum product display

– Available for large or small orders (MOQ: 5000 pcs)

Custom Services:

– Silk printing, decal, frosted, label sticker

– Custom mold glass bottles as …

4. Double Cross – Square Glass Decorative Bottle

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“item_name”:”Double Cross Vodka Square Glass Bottle”,”condition”:”Used”,”brand”:”Double Cross”,”volume”:”750 ml”,”description”:”EMPTY – 750 ml. This bottle has been discontinued by Double Cross. Square Glass Decorative Bottle in a striking monolithic design.”,”item_number”:”166849803402″,”price”:”$14.49″,”shipping_info”:”Est. delivery Tue, Sep 23 – Wed, Oct 1 from Manitowoc, WI, United States. Re…

5. Long Glory – Vodka Brandy Square Bottle

Domain: longgloryglass.com

Registered: 2023 (2 years)

Introduction: {“Product Name”: “Vodka Brandy Square Bottle 160ml Liquor Packaging”, “Material”: “Super flint glass”, “Weight”: “250g”, “Bottle Height”: “88 mm”, “Bottle Diameter”: “63.2 mm”, “Inside Diameter of Mouth”: “16.8 mm”, “Outside Diameter of Mouth”: “26.4 mm”, “Cap Options”: [“Cork”, “Swing”, “Guala”, “Glass”], “MOQ”: “20GP/40GP”, “Logo Options”: “Customer’s Logo or decoration”, “Pieces per Paper Skin”…

6. Ant Packaging – Custom Super Flint Glass Bottles

Domain: antpackaging.com

Registered: 2019 (6 years)

Introduction: Material: Super Flint Glass, Capacity: 750ml, Color: Blue, Customization: Bottle Types, Logo Printing, Engraving on Lids, Sticker/Label, Packing Box, Sample: Free sample, MOQ: 10000 pcs (Customized MOQ: 10000 pcs), Packing: Carton or wooden pallet packaging, Shipment: Sea shipment, air shipment, express, door to door shipment service available, OEM/ODM Service: Accepted, Certificate: FDA/LFGB/SGS/…

7. Jingbo – Glass Square Vodka Bottle

Domain: jingbobottles.com

Registered: 2022 (3 years)

Introduction: {“product_name”:”Glass Square Vodka Bottle”,”capacity”:”750 ml”,”main_material”:”super flint glass”,”cap_type”:”screw cap (cork available upon request)”,”mass_options”:[420, 480, 520, 580, 620, 650],”minimum_order_quantity”:”1x 40 GP”,”pieces_per_case”:[24, 20, 12, 6],”place_of_origin”:”Shandong, China”,”characteristics”:”Translucent”,”design_features”:”slender shape, geometric design, contemporar…

Strategic Sourcing Conclusion and Outlook for vodka square bottle

As the vodka market continues to evolve, the strategic sourcing of square bottles emerges as a critical factor for international buyers. The unique design of square bottles not only enhances product visibility but also serves as a powerful branding tool, differentiating offerings in a competitive landscape. With the rising demand for premium spirits, investing in high-quality packaging can significantly enhance perceived value and consumer appeal.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize suppliers that offer customizable options, ensuring that their branding resonates with local markets. Moreover, sourcing partners that provide flexible order quantities and efficient shipping solutions can streamline the supply chain, allowing businesses to respond swiftly to market demands.

Looking ahead, the importance of innovative packaging will only grow. By leveraging strategic sourcing of square vodka bottles, businesses can position themselves favorably in the market. We encourage international buyers to explore partnerships that align with their brand vision and to stay ahead of trends that shape consumer preferences. Embrace the opportunity to enhance your product offering and drive sales through thoughtful packaging solutions.