The Definitive Guide to Unbreakable Oil Burner Pipe: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for unbreakable oil burner pipe

The increasing demand for durable and efficient equipment in the oil-burning industry has led to a surge in interest for unbreakable oil burner pipes. As B2B buyers navigate the complexities of sourcing these innovative products, they often face the challenge of balancing quality, cost, and supplier reliability. This comprehensive guide aims to demystify the global market for unbreakable oil burner pipes, providing essential insights into various types, applications, and the critical factors for supplier vetting.

From understanding the latest advancements in materials to evaluating cost structures, this guide equips international buyers—especially those in Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam—with the knowledge needed to make informed purchasing decisions. By highlighting key considerations such as durability, maintenance, and aesthetic appeal, we empower businesses to select the right products that align with their operational needs and budget constraints.

Whether you are a seasoned buyer or new to the market, this guide is your roadmap to navigating the unbreakable oil burner pipe landscape, ensuring you can confidently invest in products that deliver exceptional value and performance.

Understanding unbreakable oil burner pipe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High Borosilicate Glass Pipe | Made from 5mm thick borosilicate glass for superior durability and heat resistance. | Wholesale distribution to smoke shops and online retailers. | Pros: High durability, excellent heat resistance. Cons: Higher initial cost compared to standard glass pipes. |

| Bubbler Oil Burner Pipe | Combines oil burning with water filtration for smoother hits. | Specialty smoke shops and premium product lines. | Pros: Enhanced smoking experience, reduced harshness. Cons: Slightly bulkier than traditional pipes. |

| Compact Oil Burner Pipe | Smaller design for portability and ease of use. | Retail sales targeting consumers on-the-go. | Pros: Convenient for travel, discreet use. Cons: Limited capacity for larger sessions. |

| Jumbo Oil Burner Pipe | Larger size designed for group settings or extended use. | Wholesale for events, parties, and social gatherings. | Pros: Suitable for multiple users, enhanced smoking sessions. Cons: Less portable, requires more storage space. |

| Multi-Function Oil Burner Pipe | Versatile design that can function as both an oil burner and a traditional pipe. | Cross-market opportunities in various smoking accessory categories. | Pros: Cost-effective, multifunctional. Cons: Complexity may deter some users. |

What Are the Characteristics of High Borosilicate Glass Pipes?

High borosilicate glass pipes are crafted from thick, reinforced glass that offers exceptional durability and heat resistance. This makes them ideal for both casual and heavy users who require a reliable smoking accessory. B2B buyers should consider the advantages of sourcing these pipes for retail, as they appeal to customers looking for quality and longevity, reducing the need for frequent replacements.

How Do Bubbler Oil Burner Pipes Enhance the Smoking Experience?

Bubbler oil burner pipes integrate water filtration into the smoking process, resulting in smoother hits and a more enjoyable experience. This type of pipe is particularly suited for specialty smoke shops that cater to connoisseurs seeking premium products. For B2B buyers, offering bubblers can differentiate their inventory and attract a niche market willing to pay a premium for enhanced functionality.

Why Choose Compact Oil Burner Pipes for Portability?

Compact oil burner pipes are designed for portability, making them an excellent choice for consumers who value discretion and convenience. These pipes are particularly appealing to B2B buyers targeting younger demographics or urban customers who may prefer smoking on-the-go. While they may have a reduced capacity, their practicality can lead to higher sales volumes in retail settings.

What Are the Benefits of Jumbo Oil Burner Pipes for Group Settings?

Jumbo oil burner pipes are ideal for social gatherings or events, as their larger size accommodates multiple users. B2B buyers can leverage this feature by marketing these pipes for parties or festivals, tapping into a market that values shared experiences. However, buyers should be mindful of the storage and transport challenges that larger pipes may present.

How Do Multi-Function Oil Burner Pipes Appeal to Diverse Markets?

Multi-function oil burner pipes serve both as oil burners and traditional smoking pipes, providing versatility that can attract a broader customer base. B2B buyers can capitalize on this feature by promoting these pipes in various categories, appealing to both casual users and serious enthusiasts. The complexity of these pipes may deter some buyers, but the cost-effectiveness of having a dual-purpose product can be a significant selling point.

Key Industrial Applications of unbreakable oil burner pipe

| Industry/Sector | Specific Application of Unbreakable Oil Burner Pipe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Used in oil extraction and refining processes | Enhances operational efficiency and reduces downtime due to breakage | Ensure compliance with industry standards and certifications |

| Chemical Manufacturing | Utilized in chemical reactions involving oils | Provides durability under high temperatures and pressure, minimizing maintenance costs | Look for high-quality materials that withstand corrosive substances |

| Food and Beverage | Employed in flavor extraction and infusion processes | Ensures purity and prevents contamination during extraction | Prioritize food-grade materials and ease of cleaning |

| Pharmaceutical | Used in the production of essential oils and extracts | Guarantees consistent quality and reliability in production | Verify adherence to safety regulations and material certifications |

| Renewable Energy | Implemented in biofuel production processes | Increases longevity and reliability in high-stress environments | Consider suppliers with a proven track record in renewable energy applications |

How is the Unbreakable Oil Burner Pipe Used in the Oil and Gas Industry?

In the oil and gas sector, unbreakable oil burner pipes are critical for both extraction and refining processes. Their durability minimizes the risk of breakage during operations, which can lead to costly downtime and operational inefficiencies. Buyers in this industry should prioritize suppliers that offer pipes compliant with rigorous industry standards to ensure safety and reliability, especially in harsh environments.

What Role Does the Unbreakable Oil Burner Pipe Play in Chemical Manufacturing?

In chemical manufacturing, these pipes are essential for conducting reactions involving oils, where high temperatures and pressures are common. The use of unbreakable pipes reduces the frequency of maintenance and replacement, thereby lowering operational costs. B2B buyers should seek high-quality, reinforced materials that can withstand corrosive substances, ensuring longevity and safety in their production processes.

How is the Unbreakable Oil Burner Pipe Beneficial in Food and Beverage Applications?

Within the food and beverage industry, unbreakable oil burner pipes are utilized in flavor extraction and infusion processes. Their robust design prevents contamination and ensures the purity of the extracted oils, which is crucial for maintaining product quality. Buyers should focus on sourcing food-grade materials that are easy to clean, as this is vital for compliance with health regulations and maintaining product integrity.

In What Ways Does the Pharmaceutical Sector Utilize Unbreakable Oil Burner Pipes?

The pharmaceutical industry employs unbreakable oil burner pipes in the production of essential oils and extracts, where consistency and reliability are paramount. These pipes enhance the overall quality of production while ensuring that the extracted compounds remain uncontaminated. International buyers must verify that the materials used meet safety regulations and have the necessary certifications to ensure safe pharmaceutical applications.

How Does the Renewable Energy Sector Benefit from Unbreakable Oil Burner Pipes?

In renewable energy, unbreakable oil burner pipes are increasingly used in biofuel production processes. Their ability to withstand high-stress environments ensures a longer lifespan, which is essential for maintaining continuous production. Buyers should consider suppliers with experience in renewable energy applications, as this will guarantee that the pipes meet the specific requirements of this rapidly evolving industry.

3 Common User Pain Points for ‘unbreakable oil burner pipe’ & Their Solutions

Scenario 1: Frequent Breakage Leading to High Replacement Costs

The Problem: B2B buyers often encounter the frustrating issue of fragile oil burner pipes that break easily, resulting in constant replacements. This not only leads to increased operational costs but also affects the reliability of their service offerings. For businesses that rely on these pipes for production or retail, the downtime caused by breakage can severely impact their bottom line. Moreover, sourcing replacements on short notice can lead to supply chain disruptions, particularly in regions where shipping logistics are less predictable.

The Solution: To mitigate breakage, B2B buyers should prioritize sourcing unbreakable oil burner pipes made from high-quality materials like reinforced borosilicate glass. When evaluating suppliers, it’s essential to request detailed product specifications, including thickness and material properties, to ensure they meet durability standards. Establishing partnerships with manufacturers that offer warranties or satisfaction guarantees can further protect investments. Additionally, buyers should consider bulk purchasing to reduce unit costs, ensuring they have a sufficient inventory on hand to minimize operational disruptions.

Scenario 2: Difficulty in Cleaning and Maintenance

The Problem: Another pain point for buyers is the maintenance and cleaning of oil burner pipes. Traditional pipes often accumulate residue that can compromise performance and flavor quality, necessitating frequent and labor-intensive cleaning. This not only takes time away from core business activities but can also lead to inconsistent product quality, ultimately affecting customer satisfaction. In regions with limited access to specialized cleaning solutions, this issue becomes even more pronounced.

The Solution: Unbreakable oil burner pipes designed with ease of maintenance in mind can significantly alleviate this challenge. Buyers should seek out models that feature smooth, non-porous surfaces which resist residue buildup. It’s advisable to ask suppliers about the recommended cleaning methods and tools to ensure optimal upkeep. Incorporating a regular maintenance schedule into operations can also help keep pipes in top condition, thus enhancing their longevity. Additionally, training staff on proper cleaning techniques can streamline the process and ensure consistent performance, further improving product quality.

Scenario 3: Aesthetic Limitations Affecting Market Appeal

The Problem: Many B2B buyers face challenges related to the aesthetic appeal of oil burner pipes. Traditional glass options may be prone to aesthetic flaws like scratches or discoloration after repeated use, which can deter customers looking for visually appealing products. In competitive markets, especially in regions like Africa and South America, the visual appeal of smoking accessories can significantly influence purchasing decisions, and businesses may struggle to attract customers with less appealing products.

The Solution: When sourcing unbreakable oil burner pipes, buyers should prioritize options that combine durability with aesthetic design. Look for suppliers that offer a variety of styles, colors, and finishes to cater to different customer preferences. Request samples to assess not only the durability but also the visual appeal of the products before placing larger orders. Furthermore, consider branding opportunities, such as custom designs or engravings, which can enhance the product’s marketability. By offering visually appealing and durable products, businesses can differentiate themselves in the market, thereby attracting a broader customer base.

Strategic Material Selection Guide for unbreakable oil burner pipe

What Are the Best Materials for Unbreakable Oil Burner Pipes?

When selecting materials for unbreakable oil burner pipes, it is essential to consider their performance characteristics, manufacturing complexities, and suitability for various applications. Below is an analysis of three common materials used in the production of these pipes.

1. High Borosilicate Glass

Key Properties: High borosilicate glass is known for its excellent thermal resistance and low thermal expansion coefficient. It can withstand temperatures up to 500°C and is resistant to thermal shock, making it ideal for high-heat applications.

Pros & Cons: The primary advantage of high borosilicate glass is its durability and resistance to breakage under stress. However, it can be more expensive than standard glass and requires specialized manufacturing techniques, which may increase production costs.

Impact on Application: This material is highly compatible with various oils and solvents, ensuring a clean burning experience. Its clarity also allows users to observe the burning process, enhancing usability.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM E438 for glass quality. Additionally, understanding local regulations regarding glass products is crucial.

2. Reinforced Polycarbonate

Key Properties: Reinforced polycarbonate is known for its high impact resistance and ability to withstand temperatures up to 120°C. It is also lightweight, making it easier to handle and transport.

Pros & Cons: The key advantage of polycarbonate is its unbreakable nature, which significantly reduces the risk of damage during use. However, it is less resistant to high temperatures compared to glass, which may limit its application in high-heat scenarios.

Impact on Application: Polycarbonate is suitable for applications where safety is a concern, as it minimizes the risk of shattering. However, it may not be compatible with all types of oils, particularly those that are highly corrosive.

Considerations for International Buyers: Buyers should be aware of the specific chemical compatibility of polycarbonate with various oils. Compliance with safety standards, such as ISO 9001, is also essential for ensuring product quality.

3. Silicone

Key Properties: Silicone is flexible and can withstand temperatures ranging from -60°C to 200°C. It is chemically resistant and does not react with most oils and solvents.

Pros & Cons: The flexibility of silicone allows for easy handling and storage, making it a popular choice for portable oil burners. However, it may not provide the same level of heat resistance as glass, potentially limiting its effectiveness in high-temperature applications.

Impact on Application: Silicone’s chemical resistance makes it suitable for various media, but it may not deliver the same aesthetic appeal as glass. This could affect customer preferences, especially in markets focused on design.

Considerations for International Buyers: Buyers in Europe and the Middle East should ensure that the silicone used complies with food safety standards, particularly if the pipes are intended for consumable products. Understanding local regulations regarding silicone products is also critical.

Summary Table

| Material | Typical Use Case for unbreakable oil burner pipe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High Borosilicate Glass | High-temperature oil burning | Excellent thermal resistance | Higher manufacturing cost | High |

| Reinforced Polycarbonate | Portable oil burners | Unbreakable and lightweight | Limited high-temperature resistance | Medium |

| Silicone | Flexible, portable applications | Chemical resistance and flexibility | Lower heat resistance compared to glass | Low |

This strategic material selection guide provides essential insights for international B2B buyers, facilitating informed decisions when sourcing unbreakable oil burner pipes that meet their specific needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for unbreakable oil burner pipe

What Are the Key Stages in the Manufacturing Process of Unbreakable Oil Burner Pipes?

Manufacturing unbreakable oil burner pipes involves several critical stages that ensure the final product meets high durability and performance standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The foundation of a high-quality oil burner pipe lies in the selection of materials. Manufacturers typically use high borosilicate glass due to its superior thermal resistance and durability. This glass is sourced from reputable suppliers who provide materials that comply with international standards. Before processing, the glass is inspected for purity and quality, ensuring it is free from defects or impurities.

-

Forming: In this stage, the prepared glass is subjected to various techniques such as blowing, molding, or pressing. Advanced machinery is employed to shape the glass into the desired form of the oil burner pipe. Depending on the design, techniques like blow molding might be used to create intricate shapes while ensuring uniform thickness. This is crucial for maintaining the pipe’s strength and aesthetic appeal.

-

Assembly: After forming, the individual components of the oil burner pipe are assembled. This may involve the integration of additional features like bowls or downstems, which are often made from the same high-quality glass. The assembly process is meticulous, requiring skilled labor to ensure that all parts fit together seamlessly and that the structural integrity of the pipe is maintained.

-

Finishing: The final stage involves polishing, cleaning, and sometimes coating the pipes to enhance their durability and appearance. Manufacturers often use specialized cleaning solutions to remove any residues from the forming process. The pipes may also be subjected to surface treatments to increase their resistance to scratches and thermal shock. Quality control checks are conducted throughout the finishing process to ensure that each pipe meets the required specifications.

What Quality Control Measures Are Essential for Unbreakable Oil Burner Pipes?

Quality assurance is paramount in the manufacturing of unbreakable oil burner pipes, ensuring that they meet international standards and customer expectations. The following quality control measures are typically employed:

-

International Standards Compliance: Many manufacturers adhere to ISO 9001 standards, which outline a framework for quality management systems. This certification ensures that the manufacturing processes are consistent and that products meet customer and regulatory requirements. Additionally, industry-specific certifications like CE (Conformité Européenne) or API (American Petroleum Institute) may be relevant, depending on the target market.

-

Quality Control Checkpoints: Effective quality control involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival at the manufacturing facility. Only materials that meet predefined standards are accepted for production.

– In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to ensure that each stage meets quality benchmarks. This includes monitoring the forming and assembly processes.

– Final Quality Control (FQC): After finishing, the pipes undergo a thorough inspection to check for defects, functionality, and compliance with design specifications. This step often includes testing for thermal resistance and structural integrity. -

Common Testing Methods: Manufacturers may employ various testing methods to evaluate the durability and performance of oil burner pipes. These methods include:

– Thermal Shock Testing: Pipes are subjected to rapid temperature changes to assess their resistance to thermal stress.

– Drop Testing: Pipes are dropped from specified heights to evaluate their impact resistance.

– Visual Inspections: Trained personnel inspect each pipe for visual defects such as chips, cracks, or bubbles.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are several actionable steps:

-

Conduct Supplier Audits: Regular audits of potential suppliers can provide insights into their manufacturing practices and quality control measures. Audits should assess compliance with international standards and the effectiveness of their quality management systems.

-

Request Quality Assurance Reports: Buyers should ask for detailed quality assurance reports that document the quality control processes, testing results, and any certifications the supplier holds. This documentation should include results from both IQC and FQC stages.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These inspections can be scheduled at various stages of the production process, offering an additional layer of assurance.

-

Evaluate Certification and Compliance: Buyers should verify that the supplier holds relevant certifications (e.g., ISO 9001, CE) and that these certifications are up to date. This can often be done through online databases or directly with the certifying bodies.

-

Assess Feedback and Reviews: Researching customer feedback and reviews about the supplier can also provide valuable insights into their reliability and product quality. Engaging with previous customers can help identify any recurring issues or highlight strengths.

What Are the Unique Quality Control Challenges for International B2B Buyers?

International buyers face specific challenges when ensuring the quality of unbreakable oil burner pipes. These challenges can include:

-

Regulatory Differences: Different countries have varying regulations regarding materials and manufacturing processes. Buyers must be aware of the regulations in their respective countries and ensure that suppliers comply with both local and international standards.

-

Logistical Complexities: Shipping products internationally can introduce risks such as damage during transit. Buyers should consider suppliers that provide robust packaging and shipping guarantees to minimize these risks.

-

Cultural and Communication Barriers: Engaging with suppliers from different regions may lead to misunderstandings regarding quality expectations. Clear communication and establishing mutual understanding of quality standards are essential to mitigate these risks.

-

Currency Fluctuations and Payment Terms: Economic factors can impact the cost and availability of materials, which may affect quality. Buyers should establish transparent payment terms and consider locking in prices where possible.

By understanding the manufacturing processes and quality assurance measures for unbreakable oil burner pipes, B2B buyers can make informed decisions that align with their quality expectations and business needs. This proactive approach not only ensures product reliability but also fosters long-term partnerships with reputable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘unbreakable oil burner pipe’

Introduction

This sourcing guide is designed to assist B2B buyers in procuring unbreakable oil burner pipes. With the increasing demand for durable and reliable smoking accessories, understanding the sourcing process is essential for ensuring quality, affordability, and supplier reliability. Follow this checklist to navigate the complexities of sourcing effectively.

Step 1: Define Your Technical Specifications

Begin by outlining the specific technical requirements for the unbreakable oil burner pipes you intend to purchase. This includes material specifications (e.g., high borosilicate glass), dimensions, and design features such as thickness and heat resistance.

- Why It Matters: Clearly defined specifications help in identifying suitable suppliers and ensuring the products meet your quality standards.

- What to Look For: Ensure that the specifications align with market needs and customer preferences in your target regions.

Step 2: Research Market Trends

Conduct thorough research on current market trends related to unbreakable oil burner pipes. Analyze competitor offerings, pricing strategies, and consumer preferences in your target markets, such as Africa, South America, the Middle East, and Europe.

- Why It Matters: Understanding market trends enables you to position your offerings competitively and identify potential gaps in the market.

- What to Look For: Data on popular styles, materials, and price points can inform your purchasing decisions and marketing strategies.

Step 3: Identify Potential Suppliers

Compile a list of potential suppliers who specialize in unbreakable oil burner pipes. Utilize platforms such as Alibaba, trade shows, and industry directories to find reputable manufacturers.

- Why It Matters: A diverse supplier pool allows for better negotiation and comparison of quality and pricing.

- What to Look For: Prioritize suppliers with positive reviews, verified certifications, and a history of reliability in fulfilling orders.

Step 4: Verify Supplier Certifications

Before finalizing any deals, verify that your chosen suppliers possess the necessary certifications and quality assurances. This may include ISO certifications or compliance with relevant safety standards.

- Why It Matters: Certifications are indicators of a supplier’s commitment to quality and can prevent future compliance issues.

- What to Look For: Request documentation and confirm the authenticity of certifications through the issuing bodies.

Step 5: Request Samples for Testing

Request samples of the unbreakable oil burner pipes to assess their quality and performance firsthand. Testing samples will help you evaluate the product’s durability, heat resistance, and overall functionality.

- Why It Matters: Testing samples before bulk orders minimizes the risk of receiving subpar products and ensures they meet your specifications.

- What to Look For: Pay attention to the materials used, construction quality, and user experience during testing.

Step 6: Negotiate Terms and Pricing

Engage in negotiations with your selected suppliers to establish favorable terms, including pricing, payment conditions, and delivery timelines. Aim for a balance between cost and quality.

- Why It Matters: Effective negotiation can lead to significant cost savings and better overall contract terms.

- What to Look For: Be clear about your budget and the potential for long-term partnerships, which can lead to better pricing in the future.

Step 7: Establish a Quality Assurance Process

Once you’ve finalized your supplier, establish a quality assurance process to monitor the production and delivery of the unbreakable oil burner pipes. This may include periodic inspections and feedback loops.

- Why It Matters: A robust quality assurance process ensures that the products consistently meet your standards, reducing returns and enhancing customer satisfaction.

- What to Look For: Implement clear criteria for quality checks and maintain open communication with your supplier for continuous improvement.

By following this checklist, B2B buyers can confidently source unbreakable oil burner pipes that meet their needs while ensuring quality and reliability in their supply chain.

Comprehensive Cost and Pricing Analysis for unbreakable oil burner pipe Sourcing

What Are the Key Cost Components for Unbreakable Oil Burner Pipe Sourcing?

When sourcing unbreakable oil burner pipes, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the price. High-quality borosilicate glass, known for its durability and heat resistance, is often used. The thickness of the glass (e.g., 5mm) can also affect costs, as thicker glass typically provides better durability but at a higher price.

-

Labor: Labor costs vary based on the region of production. Countries with lower labor costs may offer more competitive pricing, but this must be balanced with quality considerations. Skilled artisans are often needed for the crafting of these pipes, and their expertise can add to the overall cost.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, facility maintenance, and equipment depreciation. A manufacturer with efficient production processes may offer lower overhead costs, which can translate to better pricing for buyers.

-

Tooling: The initial setup for manufacturing can require significant investment in tooling and machinery. The cost of these tools is typically amortized over production runs, meaning larger orders can benefit from lower per-unit costs.

-

Quality Control (QC): Ensuring product quality is essential, especially for items used in smoking. Rigorous QC processes can add to costs but are necessary for maintaining brand reputation and customer satisfaction.

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and the terms of delivery. Buyers should consider the total logistics costs, including customs duties, when evaluating the final price.

-

Margin: Suppliers will add a margin to cover their costs and ensure profitability. This margin can vary based on market conditions, competition, and the supplier’s operational efficiency.

How Do Price Influencers Affect the Cost of Unbreakable Oil Burner Pipes?

Several factors can influence the pricing of unbreakable oil burner pipes:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for bulk pricing, reducing the per-unit cost significantly. Buyers should inquire about MOQs to leverage better pricing.

-

Specifications and Customization: Custom designs or specific features may increase costs. Buyers should clarify their needs upfront to get accurate pricing.

-

Materials and Quality Certifications: Products made from premium materials or those that come with certifications (e.g., food-grade, heat-resistant) may command higher prices due to the assurance of quality.

-

Supplier Factors: The reputation and reliability of the supplier can also affect price. Established suppliers may charge more for their experience and quality assurance, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the delivery terms (like FOB, CIF, etc.) is crucial. Different Incoterms can impact the final cost significantly based on who bears the shipping risks and costs.

What Are the Best Tips for Buyers to Ensure Cost-Efficiency When Sourcing?

B2B buyers should consider the following strategies for cost-effective sourcing of unbreakable oil burner pipes:

-

Negotiate Pricing: Engage in discussions with suppliers to negotiate better terms. Highlighting potential for repeat business can be a persuasive tactic.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider maintenance, replacement frequency, and operational costs. Investing in higher-quality pipes may reduce long-term costs.

-

Research Market Prices: Stay informed about market trends and price fluctuations. This knowledge can empower buyers during negotiations.

-

Consider Local Suppliers: For buyers in regions like Africa or South America, sourcing from local manufacturers can reduce shipping costs and lead times, enhancing overall value.

-

Understand International Pricing Nuances: Different regions may have unique pricing structures influenced by local demand, economic conditions, and import tariffs. Being aware of these factors can aid in making better purchasing decisions.

Conclusion: What Should Buyers Remember About Pricing?

As you navigate the sourcing of unbreakable oil burner pipes, keep in mind that pricing can vary widely based on numerous factors. Always request detailed quotations that break down costs to better understand what you are paying for. This practice not only aids in budget management but also helps in ensuring that you are making the most informed purchasing decisions tailored to your specific needs.

Alternatives Analysis: Comparing unbreakable oil burner pipe With Other Solutions

Exploring Alternatives for Unbreakable Oil Burner Pipes

When considering solutions for oil burning needs, it is essential to evaluate various products available in the market. While the unbreakable oil burner pipe offers distinct advantages, alternatives exist that may suit different operational requirements and budget constraints. This analysis highlights the key differences between the unbreakable oil burner pipe and other viable solutions.

| Comparison Aspect | Unbreakable Oil Burner Pipe | Traditional Glass Oil Burner Pipe | Silicone Oil Burner Pipe |

|---|---|---|---|

| Performance | High durability; withstands drops and heat | Prone to breakage under stress; good for light use | Flexible; withstands heat but may affect flavor |

| Cost | Moderate pricing; offers long-term savings | Low initial cost but frequent replacements increase overall expenses | Similar to unbreakable options; durable but may vary by brand |

| Ease of Implementation | User-friendly; compatible with standard setups | Simple to use; widely available | Easy to use but may require specific accessories |

| Maintenance | Low maintenance; easy to clean | Requires careful handling and regular cleaning | Generally easy to clean; resistant to staining |

| Best Use Case | Ideal for high-frequency use; commercial applications | Suitable for occasional users or casual settings | Great for travel or outdoor use due to flexibility |

Detailed Breakdown of Alternatives

Traditional Glass Oil Burner Pipe

Traditional glass oil burner pipes are widely recognized for their aesthetic appeal and simple design. They are generally more affordable upfront compared to unbreakable options. However, their fragility means users often face frequent breakages, leading to higher long-term costs and inconvenience. While they provide a satisfactory smoking experience, their susceptibility to damage makes them less suitable for environments where durability is essential.

Silicone Oil Burner Pipe

Silicone oil burner pipes present a modern alternative, known for their flexibility and resilience. Unlike glass, silicone is nearly indestructible, making it an excellent choice for users who prioritize durability and portability. However, some users report that silicone can affect the flavor of the smoke, which may be a drawback for purists seeking the best taste experience. Additionally, while they are easy to clean, some silicone models may require specific accessories for optimal performance.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right oil burner pipe depends on various factors, including usage frequency, budget, and desired performance. The unbreakable oil burner pipe stands out for its durability and long-term value, making it an ideal choice for commercial settings or frequent users. In contrast, traditional glass pipes might appeal to casual users who prioritize low initial costs, while silicone pipes offer flexibility and portability for outdoor enthusiasts. Evaluating these aspects will help B2B buyers make informed decisions that align with their operational needs and budget considerations.

Essential Technical Properties and Trade Terminology for unbreakable oil burner pipe

What Are the Key Technical Properties of an Unbreakable Oil Burner Pipe?

When evaluating unbreakable oil burner pipes, several technical properties are essential for ensuring quality and performance in a B2B context. Below are critical specifications that buyers should consider:

-

Material Grade

Unbreakable oil burner pipes are typically made from high borosilicate glass, known for its superior thermal resistance and durability. This material can withstand high temperatures without breaking or deforming, which is crucial for safety and longevity. Understanding the specific grade of borosilicate used can help buyers assess quality and performance. -

Thickness

The thickness of the glass plays a significant role in durability. Pipes made from 5mm or thicker glass offer enhanced resistance to impact and thermal shock. A thicker pipe not only reduces the likelihood of breakage but also improves heat retention, allowing for a better oil-burning experience. Buyers should ensure that the thickness meets their operational needs to minimize replacement costs. -

Heat Resistance

High-quality unbreakable oil burner pipes can typically withstand temperatures up to 600°C (1112°F) without losing structural integrity. This property is vital for maintaining performance and safety during use. Buyers should inquire about the heat resistance specifications to ensure they align with their intended applications. -

Design and Aesthetics

The design of the pipe, including ergonomic features and aesthetic appeal, can influence user experience. A well-designed pipe can enhance functionality and user satisfaction. Buyers should consider how the design fits into their product offerings and market demands, as visual appeal can be a significant selling point. -

Ease of Maintenance

Properties that facilitate cleaning and maintenance, such as smooth internal surfaces, are essential for maintaining product integrity and hygiene. Pipes designed for easy disassembly or with non-stick coatings can reduce downtime and improve user satisfaction, making them more attractive to potential buyers.

What Are Common Trade Terms Related to Unbreakable Oil Burner Pipes?

Understanding industry jargon can significantly enhance communication and negotiation with suppliers. Here are some common terms relevant to B2B transactions involving unbreakable oil burner pipes:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of oil burner pipes, buyers might work with OEMs to customize products to their specifications, ensuring they meet unique market needs. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is crucial for buyers to manage inventory effectively and assess initial investment requirements. It can also impact pricing, as larger orders often qualify for discounts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Buyers should provide detailed specifications when sending an RFQ for unbreakable oil burner pipes to receive accurate and comparable quotes, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms can help buyers understand shipping costs, risks, and delivery responsibilities, which is critical when sourcing products from global suppliers. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for inventory management and ensuring that stock levels meet demand. Buyers should communicate their needs clearly to suppliers to minimize delays.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing unbreakable oil burner pipes, ultimately leading to better procurement outcomes and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the unbreakable oil burner pipe Sector

What Are the Current Market Dynamics and Key Trends for Unbreakable Oil Burner Pipes?

The global market for unbreakable oil burner pipes is experiencing a significant transformation driven by several key factors. Firstly, the demand for durable smoking accessories is rising as consumers seek products that offer longevity and reliability. This trend is particularly pronounced in emerging markets across Africa, South America, the Middle East, and Europe, where buyers are increasingly prioritizing quality over cost. Advanced manufacturing technologies, such as the use of high borosilicate glass, are enabling suppliers to produce pipes that withstand high temperatures and physical stress, further attracting B2B buyers looking for dependable solutions.

Moreover, e-commerce platforms are revolutionizing the sourcing landscape, allowing international buyers to access a broader range of products and suppliers. With the rise of online marketplaces, businesses can easily compare prices and quality, leading to more informed purchasing decisions. Additionally, the trend toward customization is gaining traction, with manufacturers offering bespoke solutions to cater to specific market needs. This adaptability is essential for businesses aiming to differentiate themselves in a competitive market.

As sustainability becomes a focal point for many industries, the unbreakable oil burner pipe sector is not exempt. Buyers are increasingly looking for products that are not only durable but also environmentally friendly, pushing suppliers to adopt sustainable practices and materials.

How Are Sustainability and Ethical Sourcing Impacting the Unbreakable Oil Burner Pipe Market?

Environmental considerations are reshaping the unbreakable oil burner pipe market, emphasizing the importance of sustainability and ethical sourcing. The production of traditional glass pipes often involves processes that can be harmful to the environment, prompting a shift toward more sustainable alternatives. Manufacturers are now exploring eco-friendly materials and techniques that reduce waste and energy consumption, which resonate well with environmentally conscious buyers.

Ethical supply chains are crucial in ensuring that raw materials are sourced responsibly. Buyers are increasingly demanding transparency from suppliers regarding their sourcing practices. Certifications such as ISO 14001 for environmental management and other ‘green’ labels can serve as indicators of a supplier’s commitment to sustainability. These certifications not only enhance brand reputation but also attract a growing segment of consumers who prioritize ethical consumption.

Additionally, the use of recyclable materials in the production of unbreakable oil burner pipes is becoming more prevalent. This trend not only reduces the environmental impact but also appeals to B2B buyers looking to align their purchasing decisions with their corporate social responsibility (CSR) goals.

What Is the Brief Evolution of Unbreakable Oil Burner Pipes in the B2B Market?

The evolution of unbreakable oil burner pipes can be traced back to the limitations of traditional glass pipes, which were often fragile and prone to breakage. The introduction of high borosilicate glass marked a significant breakthrough, offering a material that combines strength with aesthetic appeal. Over the years, manufacturers have focused on refining the design and production processes, resulting in pipes that not only last longer but also provide a superior smoking experience.

As the market matured, the emergence of innovative manufacturing techniques and online platforms facilitated global access to these products. This accessibility has allowed B2B buyers from diverse regions to source high-quality, durable pipes without compromising on design or functionality. The continuous feedback loop from consumers has also driven manufacturers to innovate further, ensuring that unbreakable oil burner pipes remain at the forefront of the smoking accessory market.

Frequently Asked Questions (FAQs) for B2B Buyers of unbreakable oil burner pipe

-

How do I ensure the durability of unbreakable oil burner pipes?

To ensure the durability of unbreakable oil burner pipes, focus on suppliers that use high-quality, reinforced materials such as borosilicate glass. Request detailed specifications regarding the thickness and heat resistance of the pipes. Additionally, inquire about the manufacturing process and any quality assurance measures in place, such as inspections and testing for breakage resistance. Establishing a relationship with reputable suppliers will also help in acquiring products that meet your durability expectations. -

What is the best type of unbreakable oil burner pipe for commercial use?

For commercial use, the best type of unbreakable oil burner pipe is typically one made from thick borosilicate glass, as it offers superior heat resistance and durability. Consider options that feature a design suited for high-volume usage, such as those with enhanced airflow or integrated water filtration systems. It’s also beneficial to evaluate the size and style that aligns with your customer preferences, ensuring a balance between functionality and aesthetic appeal. -

What customization options are available for unbreakable oil burner pipes?

Many manufacturers offer customization options for unbreakable oil burner pipes, including variations in size, color, and design. You can request branding options, such as logo engraving or specific color schemes to align with your brand identity. Additionally, inquire about the possibility of bespoke designs tailored to your market’s preferences. Always communicate your requirements clearly to ensure that the supplier can meet your customization needs effectively. -

What are the typical minimum order quantities (MOQs) for unbreakable oil burner pipes?

Minimum order quantities (MOQs) for unbreakable oil burner pipes can vary significantly between suppliers. Generally, MOQs range from 10 to 100 pieces, depending on the manufacturer and the complexity of the order. It is advisable to negotiate MOQs to suit your business requirements, especially if you are testing the market or need a smaller initial inventory. Make sure to clarify the MOQ during your discussions with potential suppliers to avoid any surprises. -

What payment terms should I expect when sourcing unbreakable oil burner pipes?

Payment terms for sourcing unbreakable oil burner pipes can vary, but common practices include a 30% deposit upfront with the balance due upon shipment. Some suppliers may offer more flexible terms, such as net 30 or net 60 days, especially for established relationships. Always confirm payment methods accepted (e.g., bank transfer, credit card, PayPal) and ensure that you are comfortable with the terms. Negotiating favorable terms can enhance your cash flow and build trust with suppliers. -

How do I vet suppliers for unbreakable oil burner pipes?

To vet suppliers for unbreakable oil burner pipes, start by researching their reputation through online reviews and testimonials. Request references from other B2B buyers and assess their responsiveness to inquiries. Additionally, evaluate their production capabilities by asking for certifications, such as ISO standards, and inquire about their quality control processes. Conducting factory visits or using third-party inspection services can further ensure that the supplier meets your expectations for product quality and reliability. -

What logistics considerations should I keep in mind when importing unbreakable oil burner pipes?

When importing unbreakable oil burner pipes, consider factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable logistics partner who can handle international shipping efficiently and provide tracking capabilities. Familiarize yourself with the import requirements of your country, including documentation and compliance with safety standards. Additionally, factor in lead times for production and shipping to ensure timely delivery to your customers. -

What quality assurance measures should I ask suppliers about?

When sourcing unbreakable oil burner pipes, inquire about the quality assurance measures suppliers have in place. Ask if they perform regular inspections during production and if they conduct final product testing for durability and safety. Certifications from recognized quality assurance organizations can also provide additional assurance of product quality. Establishing clear quality expectations and obtaining samples for testing can help ensure that the products meet your standards before placing larger orders.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Unbreakable Oil Burner Pipe Manufacturers & Suppliers List

1. Smoke Mega – Unbreakable Oil Burner Pipe

Domain: smokemega.com

Registered: 2023 (2 years)

Introduction: The unbreakable oil burner pipe is designed for durability and performance, made from high-quality, reinforced Pyrex glass that resists cracks and breakage. It combines exceptional strength with sleek design, ensuring a long-lasting and hassle-free experience. The pipes are easy to clean and maintain, available in various sizes and styles, including jumbo, bubbler, and compact options. They are co…

2. Lotus Smoke – Unbreakable Oil Burner Pipes

Domain: lotussmokeandgift.com

Registered: 2024 (1 years)

Introduction: Collection: Unbreakable Oil Burner Pipes 2025 | Fast/Free Shipping

– Durable Design: Crafted from high-quality silicone, flexible and unbreakable, easy to clean and maintain.

– Stylish Options: Available in multiple colors and designs, sleek and modern look.

– Convenient Size: Portable and lightweight, perfect for on-the-go use.

– Price Range: From $11.99 to $46.99.

– Availability: 42 products in …

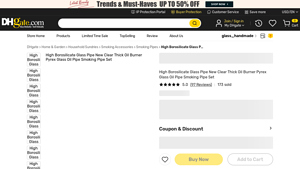

3. DHgate – Thick Pyrex Glass Oil Burner Pipe Set

Domain: dhgate.com

Registered: 2004 (21 years)

Introduction: {“Product Name”: “Thick Pyrex Glass Oil Burner Pipe Set”, “Material”: “High Borosilicate Glass”, “Color”: “Clear”, “Size”: “10cm”, “Category”: “Smoking Pipes”, “Item Code”: “543063516”, “Features”: “Durable and tough, handmade”, “Min Order”: “1”, “Stock Availability”: “99990 in stock (CN)”, “Reviews”: {“Total”: 97, “Rating”: 5.0, “5 Star”: 94, “4 Star”: 2, “3 Star”: 1}, “Package Options”: “10/20/5…

4. Lotus Glass – Unbreakable Oil Burner Pipes

Domain: lotusglassusa.com

Registered: 2017 (8 years)

Introduction: Wholesale Unbreakable Oil Burner Pipes Suppliers | Made of durable materials such as Pyrex glass | Designed for oil-based concentrates | Extra-thick and superior quality glass for durability | Unique designs available | Benefits include colder and smoother hits, increased taste and fragrance | High-quality, robust materials | Creative designs | Silent and smooth air movement | Simple cleaning and …

5. MS Glass Pipe – Unbreakable Oil Burner Pipe

Domain: msglasspipe.com

Registered: 2023 (2 years)

Introduction: Unbreakable Oil Burner Pipe: Designed for efficient vaporization of essential oils and concentrates. Made from high borosilicate glass, reinforced glass, or Pyrex glass for durability and thermal shock resistance. Lightweight, compact, and portable. Features include high-temperature resistance, exceptional durability, safety in use (non-porous, inert materials), and ease of cleaning. Ideal for qui…

6. Etsy – Unique Oil Burner Pipes

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: Unique Oil Burner Pipes available on Etsy with over 1,000 items listed. Products include various types of smoking pipes such as wooden pipes, glass pipes, and handcrafted options. Key features include free shipping, items arriving within 7 days, and a variety of price points with discounts available. Notable products include Thor the Thunder-God Tobacco Pipe, Galaxy Glass Pipe, and personalized ha…

7. ScrapingDog – Instagram Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: scraping Instagram, contact [email protected], specify number of pages to scrape per month

8. AOG Wholesale – Oil Burners & Accessories

Domain: aogwholesale.com

Registered: 2015 (10 years)

Introduction: Wholesale Oil Burners Pipes and Accessories. Free shipping on orders over $2,000.00. Various brands available including AFM, Big Mom, Biigo, Cheech, Empire, Eyce, Galaxy, GRAV, Headway, Honeybee, Lookah, Lucky Goat, Ooze, Roast & Toast, Roor, Space King, T.A.G., T’ataoo, White Rhino. Product categories include hand pipes, oil burners, oil bubblers, water pipes, and pipe accessories. Hand pipes ava…

Strategic Sourcing Conclusion and Outlook for unbreakable oil burner pipe

The unbreakable oil burner pipe represents a significant advancement in durability and reliability for international buyers. By prioritizing strategic sourcing, businesses can enhance their product offerings while minimizing costs associated with frequent replacements. The innovative materials used in these pipes, such as high borosilicate glass, not only ensure longevity but also maintain optimal performance, making them an attractive option for diverse markets, including Africa, South America, the Middle East, and Europe.

As buyers navigate the competitive landscape, understanding the benefits of these pipes will empower them to make informed purchasing decisions. The combination of affordability and quality positions unbreakable oil burner pipes as a smart investment, particularly for businesses seeking to enhance customer satisfaction and loyalty.

Looking ahead, as the market for durable smoking accessories continues to grow, now is the ideal time for international buyers to capitalize on these innovations. By integrating unbreakable oil burner pipes into their inventory, businesses can position themselves as leaders in quality and reliability. Explore the opportunities available and strengthen your product lineup today to meet the evolving demands of your customers.