The Definitive Guide to Dragon Ball Stick Shift Knob: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for dragon ball stick shift knob

In the dynamic landscape of automotive accessories, sourcing high-quality dragon ball stick shift knobs presents a unique challenge for international B2B buyers. As enthusiasts seek to enhance the driving experience with personalized touches, understanding the nuances of this niche market becomes essential. This guide aims to provide a comprehensive overview of the dragon ball stick shift knob market, covering various types, applications, and customization options available to meet diverse customer needs.

From the playful aesthetics of anime-inspired designs to the robust materials that ensure durability, buyers will gain insights into the key features that distinguish premium products in this category. Additionally, the guide addresses the critical aspects of supplier vetting, including quality assurance, manufacturing standards, and shipping logistics—essential for ensuring reliable procurement from regions such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Vietnam.

By equipping B2B buyers with actionable knowledge on pricing structures, product specifications, and market trends, this guide empowers informed purchasing decisions. Whether you are a retailer looking to expand your inventory or a distributor seeking reliable partnerships, understanding the global market for dragon ball stick shift knobs will enable you to cater effectively to the growing demand for unique automotive accessories.

Understanding dragon ball stick shift knob Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Dragon Ball Shift Knob | 54mm diameter, acrylic material, multiple star options | Automotive retail, aftermarket accessories | Pros: Affordable, lightweight, fun design. Cons: May lack durability compared to metal options. |

| Heavy-Duty Aluminum Shift Knob | Made from aluminum, custom engraving options | Heavy-duty vehicles, custom car shops | Pros: Durable, customizable, premium feel. Cons: Higher price point, limited color options. |

| Custom Laser Engraved Knob | Personalized designs, available in various materials | Gifts, promotional items, specialized automotive shops | Pros: Unique branding opportunities, high customization. Cons: Longer lead times for production. |

| Threaded Metal Insert Knob | Metal threading for secure fit, no plastic threads | Performance vehicles, racing enthusiasts | Pros: Secure fit, increased longevity. Cons: Heavier than standard options, may require specific adapters. |

| Multi-Adapter Shift Knob | Comes with multiple adapters for various thread sizes | Universal fit for diverse vehicle types | Pros: Versatile, easy installation. Cons: May require additional adapters for specific vehicles. |

What Are the Key Characteristics of Standard Dragon Ball Shift Knobs?

Standard Dragon Ball shift knobs are typically made from acrylic, featuring a diameter of 54mm and offering a fun design with various star options. These knobs are primarily suited for automotive retail and aftermarket accessories, appealing to a broad audience of car enthusiasts. While they are affordable and lightweight, their acrylic construction may not provide the same durability as metal alternatives, which could be a consideration for B2B buyers focused on longevity.

How Do Heavy-Duty Aluminum Shift Knobs Differ from Other Options?

Heavy-duty aluminum shift knobs are designed for enhanced durability and can be customized with laser engraving. These knobs are particularly suitable for heavy-duty vehicles and custom car shops where a premium feel is desired. While they provide a high level of customization and longevity, their higher price point and limited color options may deter some budget-conscious buyers.

Why Choose Custom Laser Engraved Knobs for Branding?

Custom laser engraved knobs offer a unique opportunity for branding and personalization, making them ideal for gifts or promotional items. They can be produced in various materials, catering to specialized automotive shops looking to differentiate their offerings. However, the lead times for production can be longer, which is a crucial consideration for B2B buyers needing quick turnaround times.

What Are the Advantages of Threaded Metal Insert Knobs?

Threaded metal insert knobs are engineered for a secure fit, eliminating the risk of cracking associated with plastic threads. They are particularly favored in performance vehicles and among racing enthusiasts who prioritize longevity and reliability. While these knobs offer a more secure attachment and greater durability, they tend to be heavier and may require specific adapters, which should be factored into purchasing decisions.

How Do Multi-Adapter Shift Knobs Enhance Versatility?

Multi-adapter shift knobs come equipped with several adapters, allowing for compatibility with various thread sizes. This versatility makes them a great choice for businesses catering to a diverse range of vehicle types. While they simplify installation and enhance usability, buyers should be aware that additional adapters may be necessary for certain vehicles, which could complicate the purchasing process.

Key Industrial Applications of dragon ball stick shift knob

| Industry/Sector | Specific Application of dragon ball stick shift knob | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Customization | Used in aftermarket vehicle upgrades for personalizing car interiors. | Enhances vehicle aesthetics and personalization, appealing to enthusiasts. | Quality of materials, compatibility with various vehicle models, and customization options. |

| Motorsports and Racing | Employed in race cars for improved grip and control during gear shifts. | Provides better performance and handling, crucial for competitive racing. | Durability under high-stress conditions and specific thread sizes for racing applications. |

| Retail and E-commerce | Sold as part of merchandise for anime and gaming enthusiasts. | Attracts niche markets, boosting sales through themed automotive accessories. | Shipping logistics, bulk purchasing options, and licensing for branded products. |

| Vehicle Restoration and Classic Cars | Used in restoring vintage vehicles to maintain authenticity. | Preserves the historical value and aesthetic of classic cars. | Authenticity of design, adherence to original specifications, and availability of custom fittings. |

| Car Rentals and Fleet Services | Utilized in rental vehicles to enhance customer experience. | Differentiates offerings and enhances user satisfaction. | Cost-effectiveness, ease of installation, and availability of various adapters for different vehicles. |

In the automotive customization industry, dragon ball stick shift knobs are popular for enhancing the aesthetic appeal of vehicles. They provide a unique and playful touch, making them attractive to car enthusiasts looking to personalize their rides. Buyers in this sector should prioritize quality materials and compatibility with a range of vehicle models to ensure customer satisfaction.

Within motorsports and racing, these shift knobs are critical for improving grip and control during high-speed gear shifts. The enhanced tactile feedback allows drivers to execute precise movements, which is essential for competitive racing. Buyers must consider the durability of materials to withstand extreme conditions and ensure the knobs fit specific racing vehicle requirements.

In the retail and e-commerce sector, dragon ball shift knobs serve as merchandise for fans of anime and gaming. These products tap into niche markets, allowing businesses to attract dedicated customers. Key considerations for sourcing include shipping logistics and bulk purchasing options, as well as ensuring compliance with any licensing requirements for branded products.

For those involved in vehicle restoration and classic cars, dragon ball shift knobs can be used to maintain authenticity while adding a unique flair to vintage vehicles. This application is particularly appealing to collectors who value the historical integrity of their cars. Buyers need to ensure that the design adheres to original specifications and that custom fittings are available to match specific vehicle models.

Lastly, in the car rentals and fleet services, dragon ball shift knobs can enhance the customer experience by offering a fun and distinctive feature in rental vehicles. This differentiation can lead to increased customer satisfaction and loyalty. Businesses should focus on cost-effectiveness and the ease of installation, as well as ensuring a variety of adapters are available to accommodate different vehicle types.

3 Common User Pain Points for ‘dragon ball stick shift knob’ & Their Solutions

Scenario 1: Sourcing High-Quality Dragon Ball Shift Knobs

The Problem: One major challenge faced by B2B buyers, especially those catering to niche markets in regions like Africa and South America, is sourcing high-quality dragon ball shift knobs that meet both aesthetic and functional requirements. Many suppliers offer products that may look appealing but are made from inferior materials, leading to durability issues or unsatisfactory customer experiences. This can result in costly returns, negative reviews, and potential damage to the buyer’s reputation in a competitive market.

The Solution: To overcome this challenge, buyers should prioritize sourcing from reputable manufacturers that provide detailed product specifications, including material composition and manufacturing processes. It is crucial to request samples before committing to bulk orders, as this allows buyers to evaluate the product’s quality firsthand. Additionally, look for suppliers that offer customizable options, including weight, color, and thread size, to ensure that the knobs fit a range of vehicles popular in your target markets. Establishing a relationship with suppliers who can guarantee consistent quality and reliability will help mitigate risks associated with product defects.

Scenario 2: Compatibility Issues with Vehicle Models

The Problem: Another pain point for B2B buyers is the compatibility of dragon ball shift knobs with various vehicle models, particularly with the diversity of cars found in markets across the Middle East and Europe. Buyers often find themselves with inventory that does not fit specific vehicle types, leading to excess stock and reduced sales. This issue can be exacerbated by a lack of clear information regarding fitment options from suppliers.

The Solution: To address compatibility issues, B2B buyers should conduct thorough market research to understand the most common vehicle models in their target regions. When sourcing dragon ball shift knobs, ensure that suppliers offer a variety of adapters and thread sizes. Providing detailed product listings that include fitment information and compatibility charts can also help buyers make informed decisions. Collaborating with suppliers who offer made-to-fit options for late model vehicles can further enhance inventory management and sales potential.

Scenario 3: Customization Challenges for Branding

The Problem: For businesses looking to differentiate their offerings, customization is key. However, many B2B buyers encounter challenges when trying to customize dragon ball shift knobs with logos or unique designs. Finding suppliers that provide high-quality customization options, like laser engraving, can be difficult, and those that do may have high minimum order quantities or lengthy lead times, which can be a barrier for smaller businesses.

The Solution: To navigate the customization landscape effectively, buyers should seek suppliers that specialize in bespoke products and have flexible minimum order requirements. Building a partnership with manufacturers that offer quick turnaround times for customization can significantly enhance the buyer’s ability to meet market demands. Furthermore, utilizing digital tools to visualize custom designs before production can reduce errors and ensure that the final product aligns with branding objectives. Engaging in open communication with suppliers about specific customization needs can lead to innovative solutions and strengthen business relationships.

Strategic Material Selection Guide for dragon ball stick shift knob

What Are the Key Materials for Dragon Ball Stick Shift Knobs?

When selecting materials for dragon ball stick shift knobs, several options stand out based on their properties, manufacturing considerations, and suitability for various applications. Here, we analyze four common materials: acrylic, aluminum, stainless steel, and composite materials.

How Does Acrylic Perform for Dragon Ball Shift Knobs?

Acrylic is a popular choice for dragon ball shift knobs due to its vibrant colors and ability to mimic glass without the fragility. Key properties include good transparency, lightweight, and moderate scratch resistance. Acrylic can withstand temperatures up to 80°C (176°F) and offers decent impact resistance.

Pros: Acrylic is relatively inexpensive and easy to mold into intricate shapes, making it suitable for custom designs. It’s also lightweight, which can enhance user comfort during gear shifts.

Cons: However, acrylic is less durable than metals and can become discolored over time, especially under UV exposure. It is also more susceptible to scratching compared to harder materials.

Impact on Application: Acrylic is suitable for general automotive applications but may not withstand extreme conditions, such as high temperatures or heavy use in off-road vehicles.

Considerations for International Buyers: Buyers should ensure compliance with local standards for automotive components, as acrylic may not meet certain durability requirements in regions with harsher climates.

What Benefits Does Aluminum Offer for Shift Knobs?

Aluminum is another favored material, known for its lightweight yet robust nature. It provides excellent corrosion resistance and can handle temperatures up to 150°C (302°F) without deforming.

Pros: The primary advantage of aluminum is its durability and resistance to wear and tear. It can be anodized for additional aesthetic appeal and to enhance its protective properties.

Cons: The manufacturing process for aluminum can be more complex and costly than acrylic. Additionally, if not properly anodized, it may be prone to scratching and oxidation over time.

Impact on Application: Aluminum shift knobs are well-suited for performance vehicles and can withstand rigorous driving conditions, making them ideal for international markets where durability is paramount.

Considerations for International Buyers: Compliance with ASTM standards for aluminum products is crucial, particularly in regions like Europe and the Middle East, where quality regulations are stringent.

Why Choose Stainless Steel for Dragon Ball Shift Knobs?

Stainless steel is renowned for its exceptional strength and corrosion resistance, making it an excellent choice for automotive applications. It can withstand high temperatures (up to 200°C or 392°F) and is highly resistant to rust and tarnishing.

Pros: The durability of stainless steel ensures a long lifespan, making it a cost-effective choice in the long run. Its aesthetic appeal also adds a premium feel to the vehicle’s interior.

Cons: The main downside is the higher cost associated with stainless steel compared to other materials. Additionally, its weight might not be ideal for all users, particularly in performance applications where every gram counts.

Impact on Application: Stainless steel is suitable for high-performance vehicles and can endure extreme conditions, making it a preferred choice in many international markets.

Considerations for International Buyers: Buyers should be aware of compliance with international standards such as DIN for stainless steel products, ensuring quality and reliability.

What Role Do Composite Materials Play in Shift Knob Design?

Composite materials, often a blend of plastics and fibers, offer unique properties that can be tailored for specific applications. They can be designed to be lightweight while maintaining strength and durability.

Pros: Composites can be engineered for specific performance characteristics, such as enhanced grip or aesthetic appeal. They are also resistant to temperature fluctuations and corrosion.

Cons: The manufacturing process can be complex and may lead to higher costs. Additionally, not all composite materials are suitable for high-stress applications, which may limit their use in performance vehicles.

Impact on Application: Composites are versatile and can be used in various automotive applications, though they may not be as widely accepted in traditional markets.

Considerations for International Buyers: Buyers should verify the material specifications and compliance with local automotive standards, particularly in regions with stringent regulations.

Summary Table of Material Selection for Dragon Ball Shift Knobs

| Material | Typical Use Case for dragon ball stick shift knob | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acrylic | General automotive applications | Lightweight and vibrant colors | Less durable, prone to scratching | Low |

| Aluminum | Performance vehicles | Durable and corrosion-resistant | Higher manufacturing complexity | Medium |

| Stainless Steel | High-performance vehicles | Exceptional strength and longevity | Higher cost, heavier weight | High |

| Composite | Custom applications | Tailored performance characteristics | Complex manufacturing process | Medium |

This guide provides a comprehensive overview of material options for dragon ball stick shift knobs, offering valuable insights for international B2B buyers looking to make informed decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for dragon ball stick shift knob

What Are the Key Stages in the Manufacturing Process of Dragon Ball Stick Shift Knobs?

The manufacturing of Dragon Ball stick shift knobs involves several key stages that ensure high-quality products suitable for diverse international markets. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: Selecting the Right Components

The first stage in the manufacturing process is material preparation. Manufacturers typically utilize high-quality materials such as acrylic, aluminum, and stainless steel. For instance, the shift knobs are often made from transparent amber acrylic, which is both lightweight and durable. These materials are chosen for their aesthetic appeal and functional properties, such as resistance to scratches and impact.

Once the materials are selected, they undergo a thorough quality check to ensure they meet the required specifications. This includes evaluating the material’s density, color consistency, and resistance to environmental factors, which is crucial for international buyers who may face different climates.

How Are Dragon Ball Shift Knobs Formed?

After material preparation, the next step is forming the shift knobs. This process typically involves molding or machining the acrylic into the desired shape, often resembling the iconic Dragon Ball design. For plastic components, injection molding is commonly used, where heated plastic is injected into a mold to create the desired shape. For metal components, CNC machining may be employed to ensure precision and uniformity.

The forming process also includes creating the threaded inserts. Manufacturers prioritize using metal inserts to prevent the common issues associated with plastic threads, which can crack or strip over time. These metal inserts contribute significantly to the longevity and reliability of the product.

What Does the Assembly Process Entail?

Once the individual components are formed, they move on to the assembly stage. This step typically involves attaching the threaded inserts to the knobs and ensuring they are secure. Quality assurance during assembly is critical, as any misalignment can lead to poor user experience and product failure.

Some manufacturers also offer customization options, such as laser engraving logos or designs on the knobs. This customization is done after the assembly to ensure that the integrity of the knob is maintained and that the engraving does not compromise its structural integrity.

How Is the Finishing Process Conducted?

The final stage of manufacturing is finishing, which includes polishing and coating the knobs to enhance their appearance and durability. This may involve applying a protective coating to the surface to prevent scratches and enhance the aesthetic appeal. Manufacturers may use various techniques, such as buffing or applying a clear coat, to achieve a smooth and shiny finish.

Quality control checks are implemented at this stage to ensure that each knob meets the aesthetic and functional standards before packaging and shipping.

What Quality Assurance Practices Are Essential for Dragon Ball Shift Knobs?

Quality assurance (QA) is a critical component of the manufacturing process for Dragon Ball stick shift knobs, ensuring that products meet international standards and customer expectations.

Which International Standards Are Relevant for Quality Assurance?

Many manufacturers adhere to international quality standards, such as ISO 9001, which focuses on quality management systems. Compliance with these standards helps ensure that processes are efficient and that products consistently meet customer requirements.

In addition to ISO standards, manufacturers may also comply with industry-specific certifications, such as CE marking for European markets, which indicates compliance with health, safety, and environmental protection standards. For buyers in the Middle East, compliance with the Gulf Cooperation Council (GCC) standards may also be essential.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are vital throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): During the manufacturing stages, various checks are performed to identify defects or inconsistencies in real-time.

- Final Quality Control (FQC): This final inspection ensures that the finished products meet all quality standards before shipment.

These checkpoints help identify issues early in the process, reducing the risk of defects in the final product.

What Common Testing Methods Are Used in Quality Control?

Manufacturers typically employ several testing methods to ensure product quality. Common methods include:

- Visual Inspections: These are conducted to identify any obvious defects in appearance or finish.

- Mechanical Testing: This involves assessing the strength and durability of the threaded inserts and overall knob structure.

- Environmental Testing: Products may be subjected to various environmental conditions to assess their performance under different climates.

Such testing methods are crucial for international buyers who need assurance that products will perform reliably in various conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability.

What Steps Can Buyers Take to Verify Supplier QC?

-

Conduct Audits: Buyers should consider conducting supplier audits to review their quality control processes firsthand. This can provide insights into the manufacturer’s adherence to international standards and their commitment to quality.

-

Request Quality Reports: Manufacturers should be willing to provide quality assurance documentation, including inspection reports and compliance certificates. This transparency is vital for building trust.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control practices. These inspections can be scheduled at various stages of the manufacturing process.

-

Check References and Reviews: Buyers should seek references from other clients and review feedback to gauge the supplier’s reliability and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances, including differing regulations and standards across regions. Understanding these nuances is crucial for successful procurement.

- Regulatory Compliance: Each region may have specific regulations that must be adhered to, and suppliers should be well-versed in these requirements.

- Cultural Considerations: Communication and business practices may vary significantly across cultures. Buyers should be aware of these differences to foster effective partnerships.

- Logistics and Shipping: Quality control does not end at manufacturing. Buyers should consider how products are packaged and transported, as these factors can also impact product quality upon arrival.

By understanding the manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing Dragon Ball stick shift knobs, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dragon ball stick shift knob’

This guide aims to provide B2B buyers with a practical checklist for sourcing Dragon Ball stick shift knobs, ensuring a streamlined procurement process. The unique design and cultural appeal of these products make them popular among automotive enthusiasts. As you navigate the market, follow these steps to secure quality products that meet your specifications.

Step 1: Define Your Technical Specifications

Before starting your search, it’s crucial to outline the technical requirements for the shift knobs. This includes the size, material, and thread specifications that will fit the vehicles of your target market. Be specific about dimensions, such as diameter and height, as well as the types of adapters needed (e.g., M8, M10, M12).

- Example Specifications:

- Diameter: 54mm (2.12 inches)

- Material: Transparent acrylic or heavy-weight metal

- Thread options: M8x1.25, M10x1.25, M12x1.25

Step 2: Research Potential Suppliers

Start by identifying suppliers that specialize in automotive accessories, particularly shift knobs. Look for manufacturers or distributors with a solid reputation in the market, especially those that offer custom options.

- Key Considerations:

- Check their product range for variety.

- Verify their experience in international shipping to regions like Africa, South America, and the Middle East.

Step 3: Evaluate Supplier Certifications

Before committing to a supplier, confirm their certifications and quality standards. This is vital for ensuring product reliability and compliance with international trade regulations.

- What to Look For:

- ISO certifications indicating adherence to quality management systems.

- Any specific automotive industry standards that apply to their products.

Step 4: Request Samples

Once you’ve narrowed down your list, request samples of the Dragon Ball shift knobs. This allows you to assess the quality, feel, and finish of the products firsthand.

- Sample Evaluation Criteria:

- Check for material durability and comfort during use.

- Ensure that the threading fits your specifications without issues.

Step 5: Negotiate Terms and Conditions

Engage in discussions with suppliers regarding pricing, minimum order quantities, and payment terms. Negotiating favorable terms can lead to better margins and improved cash flow for your business.

- Important Negotiation Points:

- Discuss bulk pricing and discounts for larger orders.

- Clarify shipping terms and timelines to ensure timely delivery.

Step 6: Verify Customer Support and Return Policies

Understanding the supplier’s customer support and return policies is essential for a smooth transaction. Effective communication can prevent potential issues during the procurement process.

- Key Aspects to Review:

- Availability of customer support for inquiries or issues.

- Return and refund policies in case the products do not meet expectations.

Step 7: Finalize Your Order and Monitor Delivery

After selecting your supplier and negotiating terms, finalize your order. Keep track of the shipping process to ensure timely delivery, especially if you are catering to an event or a specific launch.

- Delivery Monitoring Tips:

- Use tracking services provided by the supplier.

- Maintain communication to address any potential delays proactively.

Following this checklist will help B2B buyers efficiently source Dragon Ball stick shift knobs, ensuring quality products that meet market demands while streamlining the procurement process.

Comprehensive Cost and Pricing Analysis for dragon ball stick shift knob Sourcing

What Are the Key Cost Components in Sourcing Dragon Ball Stick Shift Knobs?

When analyzing the cost structure for sourcing dragon ball stick shift knobs, several components must be considered. Materials play a significant role, with options ranging from acrylic to metal inserts, impacting both durability and aesthetics. For example, high-quality acrylic may be more expensive but offers better scratch resistance and a premium feel.

Labor costs are another critical factor, particularly if the production process involves skilled craftsmanship, such as custom laser engraving or detailed assembly. Manufacturing overhead includes expenses related to factory operations, such as utilities and equipment maintenance, which should be factored into the unit price.

Tooling costs are relevant, especially for custom designs or specific vehicle fitments that require specialized molds or machinery. Quality control (QC) measures ensure that each product meets safety and performance standards, adding another layer of cost. Finally, logistics expenses, including shipping, customs duties, and warehousing, can vary significantly based on the destination and volume of goods ordered.

How Do Pricing Influencers Impact the Cost of Dragon Ball Stick Shift Knobs?

Several price influencers can affect the final cost of dragon ball stick shift knobs. Volume or minimum order quantities (MOQs) can lead to significant price breaks; larger orders typically reduce the per-unit cost. Additionally, the choice of specifications and customization—such as color, design, or fitment options—can lead to variations in pricing.

The quality of materials used directly correlates with the price. For instance, knobs made from durable aluminum or stainless steel will generally be priced higher than those made from basic plastics or lower-grade materials. Supplier factors, including their reputation, production capacity, and geographical location, can also influence pricing.

Understanding Incoterms is crucial for international buyers. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly impact the total landed cost.

What Buyer Tips Can Help in Negotiating Costs for Dragon Ball Stick Shift Knobs?

B2B buyers should approach negotiations with a clear understanding of their needs and the market landscape. Negotiation strategies can include leveraging volume purchases for discounts or inquiring about bundled shipping options to minimize logistics costs.

Consider the Total Cost of Ownership (TCO), which encompasses not just the purchase price but also maintenance, durability, and potential replacement costs. For example, investing in higher-quality materials may yield long-term savings by reducing the frequency of replacements.

When sourcing from regions like Africa, South America, the Middle East, and Europe, buyers should be aware of pricing nuances. Currency fluctuations and import duties can affect final costs, so it’s prudent to lock in prices where possible and consider local suppliers for reduced shipping times and costs.

Lastly, always request a disclaimer for indicative prices. Market conditions can fluctuate, and prices may vary based on demand, production costs, and material availability. Having a clear understanding of these dynamics will empower buyers to make informed decisions while sourcing dragon ball stick shift knobs.

Alternatives Analysis: Comparing dragon ball stick shift knob With Other Solutions

When considering the purchase of a shift knob, particularly one inspired by popular culture like the Dragon Ball stick shift knob, it is essential to evaluate various alternatives available in the market. Each option has unique features, price points, and suitability for different customer needs. This analysis will compare the Dragon Ball stick shift knob with two other alternatives: a standard performance shift knob and a custom-designed shift knob.

Comparison Table

| Comparison Aspect | Dragon Ball Stick Shift Knob | Standard Performance Shift Knob | Custom-Designed Shift Knob |

|---|---|---|---|

| Performance | Comfortable grip; adds personality | Ergonomic design for precision | Tailored ergonomics based on user input |

| Cost | $19.95 | $25 – $50 | $100+ depending on design |

| Ease of Implementation | Easy installation with adapters | Direct fit for most vehicles | Requires consultation and possibly longer lead time |

| Maintenance | Low, acrylic surface is durable | Moderate, may require occasional cleaning | Varies; depends on material and finish |

| Best Use Case | Ideal for anime fans; casual driving | Performance-focused driving enthusiasts | Unique branding or personalization needs |

Detailed Breakdown of Alternatives

Standard Performance Shift Knob

The standard performance shift knob is designed with ergonomics in mind, providing a comfortable grip that enhances driving precision. Priced between $25 and $50, these knobs often feature a straightforward installation process, making them suitable for a wide range of vehicles. However, they may lack the personal flair that a themed knob like the Dragon Ball offers, making them less appealing to fans of pop culture.

Custom-Designed Shift Knob

Custom-designed shift knobs are the premium option, often exceeding $100, and are tailored to the specific preferences of the buyer. These knobs can be crafted from various materials, allowing for unique aesthetics and functionality. While they offer the highest level of personalization, the process can be time-consuming, requiring consultations and adjustments based on user feedback. Maintenance may also vary depending on the materials used, which can impact long-term durability and upkeep.

Conclusion: How to Choose the Right Shift Knob for Your Needs

For B2B buyers looking to procure shift knobs for resale or as part of a vehicle customization service, the choice between the Dragon Ball stick shift knob and its alternatives should be guided by the target market’s preferences and needs. If appealing to a niche audience of anime fans, the Dragon Ball option provides a fun, unique product that differentiates from standard offerings. Conversely, if the focus is on performance and precision, standard performance knobs may be more appropriate. Finally, for businesses aiming to offer bespoke products that cater to individual tastes, custom-designed knobs present an opportunity for high-margin sales. Understanding these dynamics will empower buyers to make informed decisions that align with their market strategy.

Essential Technical Properties and Trade Terminology for dragon ball stick shift knob

What Are the Essential Technical Properties of Dragon Ball Stick Shift Knobs?

When considering the procurement of dragon ball stick shift knobs, understanding key technical specifications is crucial for ensuring product quality and compatibility. Here are the primary properties to evaluate:

-

Material Composition

Dragon ball shift knobs are typically made from high-quality materials such as acrylic, aluminum, or stainless steel. Acrylic provides a visually appealing and lightweight option, while metals like aluminum offer durability and a premium feel. The choice of material affects not only aesthetics but also the longevity and performance of the product in different environments. -

Diameter and Size Specifications

Commonly, dragon ball shift knobs have a diameter of approximately 54mm (2.12 inches). It’s essential to match the knob’s size with the vehicle’s shifter for optimal fitment. A well-fitted knob ensures a comfortable grip and enhances the driving experience, while incorrect sizing can lead to installation challenges and affect functionality. -

Thread Size and Compatibility

Shift knobs come with various thread sizes, such as M8x1.25, M10x1.25, and M12x1.25. Understanding the thread specifications is vital for ensuring compatibility with different vehicles. Buyers should confirm the thread size of their vehicle’s shifter to prevent misfits and the associated costs of returns or exchanges. -

Weight and Balance

The weight of a shift knob can influence gear shifting dynamics. Heavier knobs often provide a more stable feel during shifts, which can enhance control and comfort. Buyers should consider their preferences for weight and balance when selecting a knob, as this can affect overall driving satisfaction. -

Finish and Surface Treatment

The surface finish of the shift knob impacts both aesthetics and durability. Options may include glossy, matte, or textured finishes. A high-quality finish not only enhances the look but also contributes to scratch resistance and ease of cleaning, which is particularly important in high-use environments.

What Are Common Trade Terms Related to Dragon Ball Stick Shift Knobs?

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For dragon ball shift knobs, OEM products ensure that parts meet the original specifications of the vehicle manufacturer, which is critical for compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. Understanding the MOQ is crucial for budgeting and inventory management. Buyers should consider their sales forecasts to ensure they can meet the MOQ without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific quantities of products. When sourcing dragon ball shift knobs, submitting an RFQ can help buyers obtain competitive pricing and better understand the supplier’s capabilities. -

Incoterms (International Commercial Terms)

These are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for understanding shipping costs, risks, and responsibilities when importing shift knobs from different regions. -

Lead Time

Lead time refers to the amount of time from placing an order to receiving the product. Understanding lead times helps buyers plan their inventory and ensure they have products available when needed, which is particularly important in markets with high demand.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing dragon ball stick shift knobs, ensuring they select the right products for their market needs.

Navigating Market Dynamics and Sourcing Trends in the dragon ball stick shift knob Sector

What Are the Key Market Dynamics and Trends Influencing the Dragon Ball Stick Shift Knob Sector?

The dragon ball stick shift knob market is experiencing a surge, driven by both the automotive aftermarket and the growing popularity of automotive personalization. This trend is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where car enthusiasts seek unique ways to enhance their vehicle interiors. The demand for customizable products is on the rise, and suppliers are responding with a variety of designs, colors, and materials. For B2B buyers, this creates opportunities to source distinctive products that cater to diverse customer preferences.

Emerging technology is also shaping the sector. E-commerce platforms are increasingly facilitating global trade, allowing suppliers from one region to reach buyers in another with ease. Features like custom laser engraving and various fitment options for different vehicle models are becoming standard. As a result, international buyers must stay updated on technological advancements that can enhance product offerings and streamline the purchasing process.

Additionally, market dynamics reflect a shift toward lightweight and durable materials, such as aluminum and high-grade acrylic, which improve both the aesthetic and functional aspects of shift knobs. This evolution is driven by consumer expectations for quality and longevity, prompting suppliers to innovate continually. Consequently, B2B buyers need to prioritize partnerships with manufacturers that can deliver on these fronts while also being adaptable to changing market demands.

How Can Sustainability and Ethical Sourcing Impact the Dragon Ball Stick Shift Knob Supply Chain?

Sustainability is becoming an increasingly important factor in the sourcing decisions of international B2B buyers. The environmental impact of manufacturing processes and materials used in products like dragon ball stick shift knobs is under scrutiny. Buyers should consider suppliers that utilize eco-friendly materials, such as recycled aluminum or bio-based plastics, which help minimize the carbon footprint of their products.

Ethical sourcing practices are also essential. Buyers are encouraged to engage with manufacturers who prioritize fair labor practices and transparency throughout their supply chains. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainable practices. As consumer awareness grows, B2B buyers who align their sourcing strategies with sustainability goals can enhance their brand reputation and appeal to environmentally conscious consumers.

Moreover, integrating sustainable practices can lead to cost savings in the long run. For example, efficient resource management and waste reduction initiatives can lower production costs, benefiting both suppliers and buyers. In a market that increasingly values corporate responsibility, aligning sourcing strategies with sustainability goals can yield significant competitive advantages.

What Is the Historical Context of the Dragon Ball Stick Shift Knob Market?

The dragon ball stick shift knob market has evolved from a niche automotive accessory to a popular choice among car enthusiasts and casual drivers alike. Initially inspired by the iconic Japanese anime series “Dragon Ball,” these shift knobs have gained traction due to their unique design and cultural significance. The early 2000s saw a rise in demand as anime culture permeated various aspects of consumer life, including automotive customization.

As the automotive aftermarket expanded, so did the variety of options available for shift knobs. Manufacturers began producing knobs in various materials and designs, catering to a broad audience. This diversification has allowed B2B buyers to source products that not only meet functional needs but also resonate with cultural trends.

Today, the market is characterized by a blend of traditional craftsmanship and modern technology, with suppliers leveraging e-commerce platforms to reach global audiences. The ongoing evolution of design and customization options continues to attract a diverse clientele, making the dragon ball stick shift knob a staple in vehicle personalization. As this trend grows, B2B buyers must remain vigilant in sourcing innovative products that align with consumer preferences while maintaining quality and sustainability standards.

Frequently Asked Questions (FAQs) for B2B Buyers of dragon ball stick shift knob

-

How do I choose the right Dragon Ball stick shift knob for my vehicle?

Selecting the appropriate Dragon Ball stick shift knob involves understanding your vehicle’s specifications, including the thread size and type of adapter needed. Common thread sizes include M8, M10, and M12, which are critical for ensuring a secure fit. It’s advisable to consult with your vehicle’s manual or reach out to suppliers who can provide detailed fitment options. Customization is also an option, allowing you to select colors and styles that suit your brand or personal preference. -

What is the best material for a Dragon Ball stick shift knob?

The best material for a Dragon Ball stick shift knob largely depends on durability and aesthetic preferences. High-quality options include acrylic, which offers a smooth finish and scratch resistance, and metal options like aluminum or stainless steel for enhanced durability. Each material has its benefits: acrylic is often lighter and comes in vibrant colors, while metal provides a premium feel and longevity. When sourcing, consider the material’s weight and how it will complement your vehicle’s interior. -

What customization options are available for Dragon Ball shift knobs?

Customization options for Dragon Ball shift knobs can vary by supplier but often include laser engraving of logos, text, and choosing specific colors or finishes. Some manufacturers also allow for different designs based on the number of stars featured within the knob. Discuss your customization needs with suppliers to explore available options, minimum order quantities (MOQs), and potential costs associated with bespoke designs. -

What are the typical minimum order quantities (MOQs) for bulk purchases?

Minimum order quantities for Dragon Ball stick shift knobs can vary significantly among suppliers. Generally, MOQs can range from as low as 50 units to several hundred, depending on the manufacturer and the level of customization required. It’s crucial to discuss MOQs upfront with potential suppliers to ensure they align with your purchasing capabilities and business needs, particularly if you are looking to enter new markets or expand your product offerings. -

How can I vet suppliers of Dragon Ball stick shift knobs?

To effectively vet suppliers, consider several factors: check their reputation through online reviews and industry references, assess their product quality via samples, and inquire about their manufacturing processes. Certifications for quality assurance, such as ISO standards, can also indicate reliability. Establishing communication to discuss their production capabilities, lead times, and after-sales service can further ensure you partner with a trustworthy supplier. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely among international suppliers, but common practices include upfront deposits (typically 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer net terms (e.g., net 30 or net 60 days) for established businesses. Ensure to negotiate terms that align with your cash flow and consider using secure payment methods like letters of credit or escrow services to protect your transaction. -

What quality assurance measures should be in place for bulk orders?

Quality assurance measures are critical when sourcing Dragon Ball stick shift knobs in bulk. Suppliers should provide detailed product specifications and samples before full production. Regular inspections during the manufacturing process and final quality checks before shipment should be standard practice. Request documentation of quality assurance protocols and certifications to ensure that the products meet your expectations and relevant industry standards. -

What logistics considerations should I keep in mind when importing from abroad?

Logistics considerations include understanding shipping options, costs, and timelines based on your location. Factor in customs duties, taxes, and potential delays at customs when planning your import. Collaborating with a logistics partner experienced in international shipping can help streamline the process. Additionally, ensure your supplier can provide the necessary documentation for customs clearance to avoid complications during transit.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Dragon Ball Stick Shift Knob Manufacturers & Suppliers List

1. Twisted Shifterz – Dragon Ball Shift Knobs

Domain: twistedshifterz.com

Registered: 2011 (14 years)

Introduction: Dragon Ball Shift Knobs available in various sizes and colors. Custom options for laser engraving and color logos. Fitment options for automatic, manual, and 4×4 shifters. Thread size fitment guide provided. Options include 3 speed, 4 speed, 5 speed, 6 speed, and 7 speed shift knobs. Materials include stainless steel, billet aluminum, and weighted composite. Nostalgic style knobs and artist series…

2. Top JDM Store – Dragon Ball Z Shift Knob

Domain: topjdmstore.com

Registered: 2018 (7 years)

Introduction: Product Name: Dragon Ball Z Shift Knob

Price: $19.95 USD (for each star, $99.95 for all 7 stars)

Diameter: 54mm (2.12 inches)

Material: Transparent Amber Acrylic

Features: Seven Red Stars in the knob, smooth to the touch, light scratch resistant acrylic, high quality threaded shift knob with a threaded metal insert (no plastic threads)

Color: Orange

Fitment: Comes with 3 kinds of fittings: 8MM, 10…

3. Bullitt – New Shift Knob Collection

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: New shift knob for Bullitt, includes 7 Dragon Ball shift knobs, available on eBay.

4. JONJEA – Round Dragon Ball 4 Star Shift Knob

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Round Dragon Ball 4 Star Shift Knob Manual Gear Shifter Head with 3 Adapters”, “Condition”: “New”, “Brand”: “JONJEA”, “Material”: [“Aluminum”, “Acrylic”], “Type”: “Shift Knob”, “Manufacturer Part Number”: “SK-1004”, “Quantity Available”: 5, “Price”: “$12.99/ea or Best Offer”, “Shipping”: “Does not ship to Turkey”, “Location”: “Chino, California, United States”, “Returns”: “Seller…

5. 1320 Performance – Dragon Ball Z Shift Knob

Domain: 1320performance.com

Registered: 2015 (10 years)

Introduction: {“product_name”:”Dragon Ball Z shift knob”,”thread_size”:”12×1.25″,”price”:”$19.95″,”availability”:”In Stock”,”diameter”:”54mm (2.12 inches)”,”material”:”Transparent Amber Acrylic with Red Stars”,”features”:”Smooth to the touch, light scratch resistant, high quality threaded metal insert, no plastic threads”,”installation_note”:”Never bottom out the shift knob on the shifter when tightening. Only …

6. Etsy – Dragon Ball Stick Shift Knob

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: Dragon Ball Stick Shift Knob, Free shipping, Arrives within 7 days, Ships from United States, Various designs available, Includes multiple adapters for manual transmission.

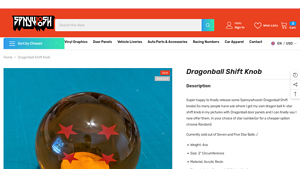

7. SpinnyWhoosh – Dragonball Shift Knob

Strategic Sourcing Conclusion and Outlook for dragon ball stick shift knob

In today’s competitive automotive accessory market, the Dragon Ball stick shift knob stands out as a unique product that appeals to a diverse customer base, from anime enthusiasts to car customization aficionados. B2B buyers should prioritize strategic sourcing to leverage the variety of options available, including custom designs, materials, and fitment specifications. By understanding regional preferences—such as the demand for high-quality, durable materials and customization features—buyers can effectively cater to their clientele across Africa, South America, the Middle East, and Europe.

Furthermore, establishing relationships with suppliers who offer robust inventory and customization capabilities will ensure a steady supply of popular products. As the market for automotive accessories continues to grow, particularly among younger demographics, investing in distinctive and culturally relevant products like the Dragon Ball shift knob can drive sales and enhance brand loyalty.

Looking ahead, international buyers are encouraged to explore partnerships with manufacturers that emphasize quality and design innovation. By integrating unique products into their offerings, businesses can capture new market segments and solidify their position as leaders in the automotive accessories industry. Embrace the opportunity to transform your inventory with products that resonate with consumers and watch your business thrive.