The Definitive Guide to 3X3 Square Tubing 20 Ft Price: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for 3×3 square tubing 20 ft price

In the fast-evolving landscape of global manufacturing, sourcing high-quality 3×3 square tubing at competitive prices presents a significant challenge for B2B buyers. The quest for reliable suppliers often involves navigating complex pricing structures, material specifications, and varying application needs. This comprehensive guide is designed to empower international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe, including Vietnam and Germany—by providing a deep dive into the factors influencing the price of 20 ft 3×3 square tubing.

Throughout this guide, we will explore various types of square tubing, including steel and aluminum options, and their respective applications across multiple industries such as construction, automotive, and agriculture. Additionally, we will address essential aspects of supplier vetting, including quality assurance practices and logistics considerations, to ensure that you make informed purchasing decisions.

By equipping you with actionable insights into pricing trends, material characteristics, and sourcing strategies, this guide aims to enhance your procurement process. Whether you are looking to expand your supply chain or optimize your existing partnerships, understanding the nuances of 3×3 square tubing pricing will enable you to navigate the global market with confidence and efficiency.

Understanding 3×3 square tubing 20 ft price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hot Rolled Steel | Produced at high temperatures; less expensive; durable | Structural applications, construction | Pros: Cost-effective; strong. Cons: Prone to rust without coating. |

| Cold Rolled Steel | Produced at room temperature; smoother finish; higher strength | Precision applications, automotive | Pros: Higher strength; better surface finish. Cons: More expensive than hot rolled. |

| Galvanized Steel | Coated with zinc for corrosion resistance; longer lifespan | Fencing, outdoor structures | Pros: Durable in harsh environments; low maintenance. Cons: Higher upfront cost. |

| Aluminum | Lightweight; corrosion-resistant; versatile | Aerospace, automotive, and architectural | Pros: Lightweight; excellent corrosion resistance. Cons: Generally more expensive. |

| Surplus Steel | Less-than-prime quality; available at reduced prices | Various structural applications | Pros: Cost-effective; suitable for non-critical uses. Cons: May have imperfections. |

What are the Characteristics of Hot Rolled Steel Square Tubing?

Hot rolled steel square tubing is created by rolling steel at high temperatures, which makes it easier to shape and form. This type is favored for structural applications in construction due to its strength and cost-effectiveness. However, it is more susceptible to corrosion, necessitating protective coatings for outdoor use. B2B buyers should consider the application environment and the need for additional surface treatments when purchasing.

How Does Cold Rolled Steel Differ from Hot Rolled Steel?

Cold rolled steel square tubing is manufactured at room temperature, resulting in a smoother surface finish and increased strength. This makes it ideal for precision applications, such as automotive parts and machinery. While it is more expensive than hot rolled steel, the enhanced properties justify the investment for many businesses. Buyers should evaluate their strength requirements and budget constraints when selecting this type.

Why Choose Galvanized Steel for Outdoor Applications?

Galvanized steel square tubing is coated with zinc, providing excellent corrosion resistance, which is crucial for outdoor applications like fencing and agricultural structures. This type offers a longer lifespan, reducing maintenance costs over time. While the initial price is higher than uncoated options, the long-term savings and durability make it an attractive choice for B2B buyers focused on sustainability and cost efficiency.

What are the Advantages of Using Aluminum Square Tubing?

Aluminum square tubing is known for its lightweight nature and exceptional corrosion resistance, making it suitable for various industries, including aerospace and automotive. Its versatility allows for a wide range of applications, from structural supports to decorative elements. However, it typically comes at a higher price point than steel options. B2B buyers should weigh the benefits of lower weight and corrosion resistance against their budget and application needs.

How Can Surplus Steel Benefit B2B Buyers?

Surplus steel square tubing, categorized as less-than-prime quality, is available at reduced prices, making it an attractive option for various structural applications. While it may have imperfections, it can still serve well in non-critical applications, such as temporary structures or internal supports. B2B buyers should consider the specific requirements of their projects and whether the cost savings align with their quality standards when opting for surplus materials.

Key Industrial Applications of 3×3 square tubing 20 ft price

| Industry/Sector | Specific Application of 3×3 square tubing 20 ft price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural framework for buildings and infrastructure | Provides durability and strength to support loads | Ensure compliance with local building codes and regulations |

| Automotive | Chassis and structural components in vehicle manufacturing | Enhances vehicle stability and safety | Focus on material grade and finish to meet industry standards |

| Agriculture | Fencing and support structures for farms | Protects crops and livestock, ensuring productivity | Consider weather resistance and material treatment for longevity |

| Renewable Energy | Framework for solar panel mounts | Increases efficiency by providing stable support | Evaluate compatibility with solar panel systems and local conditions |

| Furniture Manufacturing | Base frames for custom furniture | Allows for unique designs and robust construction | Look for customization options and finish preferences |

How is ‘3×3 square tubing 20 ft price’ Used in Construction?

In the construction industry, 3×3 square tubing is commonly used as a structural framework for buildings and infrastructure projects. Its robust nature allows it to support significant loads, making it ideal for both residential and commercial applications. International B2B buyers should ensure that the tubing meets local building codes and regulations, which can vary significantly across regions such as Africa, South America, and Europe. Additionally, sourcing from reputable suppliers who can guarantee quality and compliance is crucial.

What Role Does ‘3×3 Square Tubing’ Play in Automotive Manufacturing?

The automotive industry utilizes 3×3 square tubing for chassis and various structural components. This tubing provides the necessary strength and rigidity to enhance vehicle stability and safety during operation. Buyers in this sector must pay attention to the material grade and finish, as these factors directly influence performance and durability. Sourcing from manufacturers that adhere to international automotive standards will ensure that the components meet safety regulations.

How is ‘3×3 Square Tubing’ Beneficial in Agriculture?

In agriculture, 3×3 square tubing serves as fencing and support structures for farms, playing a critical role in protecting crops and livestock. Its durability helps maintain the integrity of enclosures, thereby promoting productivity and efficiency in farming operations. International buyers should consider the weather resistance and treatment of the tubing, as these factors are vital for longevity in diverse climates, particularly in regions like Africa and South America.

What Applications Does ‘3×3 Square Tubing’ Have in Renewable Energy?

The renewable energy sector employs 3×3 square tubing as a framework for solar panel mounts. This application is essential for maximizing the efficiency of solar installations by providing a stable and reliable support structure. Buyers should evaluate compatibility with solar panel systems and consider local environmental conditions, which can affect performance. Sourcing from suppliers with experience in renewable energy applications will ensure that the materials used are suitable for the intended purpose.

How is ‘3×3 Square Tubing’ Used in Furniture Manufacturing?

In the furniture manufacturing industry, 3×3 square tubing is utilized for base frames in custom furniture designs. This application allows manufacturers to create unique and robust furniture pieces that meet specific aesthetic and functional requirements. Buyers should look for suppliers that offer customization options and various finish preferences to align with their design goals. Ensuring the quality and strength of the tubing is essential to guarantee the longevity of the finished products.

3 Common User Pain Points for ‘3×3 square tubing 20 ft price’ & Their Solutions

Scenario 1: Navigating Price Fluctuations in Global Markets

The Problem: B2B buyers often face unpredictable price fluctuations for materials like 3×3 square tubing, particularly in international markets. These fluctuations can be exacerbated by factors such as tariffs, supply chain disruptions, and local demand. A buyer in Africa, for instance, may find that the price they were quoted last week has increased significantly due to a sudden rise in steel demand or a change in local import tariffs, leading to budget overruns and project delays.

The Solution: To mitigate the impact of price volatility, buyers should implement a flexible procurement strategy. This involves establishing long-term relationships with multiple suppliers across different regions. Regularly reviewing market trends, subscribing to industry newsletters, and joining relevant trade associations can provide insights into pricing trends. Additionally, consider locking in prices through forward contracts or bulk purchasing agreements. This not only secures a stable price but also ensures priority access during times of high demand.

Scenario 2: Ensuring Compliance with Local Regulations

The Problem: Different countries have varying standards and regulations for steel products, including 3×3 square tubing. A buyer from South America might encounter challenges when sourcing square tubing that meets local building codes or environmental regulations. Failing to comply can result in costly fines, project halts, or even legal issues.

The Solution: It is crucial for buyers to conduct thorough research on local regulations before making a purchase. Engaging with local experts or consultants who understand the regulatory landscape can provide valuable guidance. Additionally, working with suppliers who are familiar with these regulations can simplify compliance. Ensure that all necessary certifications and documentation are provided with the materials. This proactive approach not only minimizes risks but also enhances the buyer’s credibility with clients and stakeholders.

Scenario 3: Quality Assurance and Material Specifications

The Problem: When sourcing 3×3 square tubing, buyers often struggle with ensuring the quality and specifications of the product. This is particularly important for structural applications where material integrity is paramount. A buyer in the Middle East may receive shipments that do not meet the required specifications, leading to project delays and additional costs for reordering or reworking.

The Solution: To avoid quality discrepancies, buyers should establish clear material specifications based on project requirements before engaging suppliers. Requesting detailed product information, including material grade, coating, and mechanical properties, can help ensure alignment. Conducting supplier audits and requesting samples for testing can further validate quality. Additionally, consider sourcing from suppliers that offer third-party certification for their products. This not only guarantees compliance with industry standards but also provides peace of mind that the materials will perform as expected in their intended applications.

By addressing these common pain points with strategic approaches, B2B buyers can streamline their procurement processes for 3×3 square tubing, ensuring they achieve both cost efficiency and project success.

Strategic Material Selection Guide for 3×3 square tubing 20 ft price

What Are the Key Materials for 3×3 Square Tubing and Their Properties?

When selecting materials for 3×3 square tubing, especially at a length of 20 feet, it is crucial to consider various factors that will impact performance, cost, and suitability for specific applications. Below, we analyze four common materials—steel, aluminum, galvanized steel, and stainless steel—highlighting their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Steel Perform as a Material for 3×3 Square Tubing?

Steel is the most commonly used material for square tubing due to its high strength and durability. It typically has a high tensile strength, making it suitable for structural applications. Steel can withstand high temperatures and pressures, which is beneficial in construction and automotive industries. However, it is prone to corrosion if not properly treated.

Pros: Steel offers excellent strength-to-weight ratios and is cost-effective compared to other materials. It is widely available and can be easily fabricated into various shapes.

Cons: The primary disadvantage of steel is its susceptibility to rust and corrosion, which necessitates protective coatings or treatments. Additionally, it can be heavier than alternatives, impacting transport costs.

For international buyers, it is important to ensure compliance with standards such as ASTM for steel grades, especially when sourcing from different regions.

What Advantages Does Aluminum Bring to 3×3 Square Tubing?

Aluminum square tubing is known for its lightweight properties and resistance to corrosion. It is particularly advantageous in applications where weight reduction is critical, such as in aerospace and automotive sectors. Aluminum also has good thermal and electrical conductivity.

Pros: The lightweight nature of aluminum reduces shipping costs and makes it easier to handle on-site. Its corrosion resistance extends the lifespan of products without requiring additional coatings.

Cons: Aluminum is generally more expensive than steel and has lower tensile strength, which may limit its use in heavy-duty applications. Additionally, it can be more complex to weld and fabricate.

International buyers should consider regional preferences for aluminum alloys and ensure compliance with standards like JIS or DIN, which may affect material selection.

Why Choose Galvanized Steel for 3×3 Square Tubing?

Galvanized steel is steel that has been coated with zinc to enhance its corrosion resistance. This makes it suitable for outdoor applications or environments where moisture is prevalent, such as in agricultural or marine settings.

Pros: The zinc coating provides long-lasting protection against rust and corrosion, making galvanized steel a durable option for outdoor structures. It retains the strength of steel while offering enhanced weather resistance.

Cons: The galvanization process can increase costs compared to standard steel. Additionally, if the coating is damaged, the underlying steel can corrode quickly.

For B2B buyers, it is essential to verify that the galvanization meets local standards to ensure longevity and performance in specific environments.

What Makes Stainless Steel a Premium Choice for 3×3 Square Tubing?

Stainless steel is known for its exceptional corrosion resistance and aesthetic appeal. It is often used in applications where hygiene is critical, such as in food processing and medical equipment.

Pros: Stainless steel offers a high level of durability and is resistant to rust, making it ideal for harsh environments. Its aesthetic finish is also a plus in architectural applications.

Cons: The primary drawback is its cost, which is significantly higher than that of carbon steel or aluminum. Additionally, it can be more challenging to fabricate and weld.

International buyers should ensure compliance with relevant standards such as ASTM and verify the grade of stainless steel to meet specific application requirements.

Summary Table of Material Selection for 3×3 Square Tubing

| Material | Typical Use Case for 3×3 Square Tubing 20 ft price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural applications in construction | High strength and durability | Prone to rust without treatment | Medium |

| Aluminum | Lightweight structures in aerospace and automotive | Lightweight and corrosion-resistant | Higher cost and lower strength | High |

| Galvanized Steel | Outdoor structures, agricultural applications | Excellent corrosion resistance | Increased cost from galvanization | Medium |

| Stainless Steel | Food processing and medical equipment | Superior corrosion resistance | High cost and fabrication complexity | High |

This analysis provides a comprehensive overview of the material options for 3×3 square tubing, aiding international B2B buyers in making informed decisions based on their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 3×3 square tubing 20 ft price

What Are the Key Stages in the Manufacturing Process of 3×3 Square Tubing?

The manufacturing of 3×3 square tubing, particularly the 20-foot variety, involves several critical stages, each requiring precision and adherence to industry standards. Understanding these stages is essential for B2B buyers to assess product quality and suitability for their specific applications.

Material Preparation: How Is Raw Material Selected and Processed?

The process begins with the selection of raw materials, typically steel or aluminum, which must meet specific grade requirements based on the intended use of the tubing. Commonly used materials include structural steel (like ASTM A500) or aluminum alloys (like 6061-T6) for their strength and durability.

Once the material is selected, it undergoes cutting to size, where large rolls of metal or pre-cut sheets are trimmed to the required dimensions for the tubing. This initial preparation is crucial as it sets the foundation for the entire manufacturing process.

What Techniques Are Used in the Forming Stage of Square Tubing?

In the forming stage, the cut metal sheets are subjected to a series of processes to create the square shape. The most common techniques include:

-

Roll Forming: Metal strips are passed through a series of rollers that gradually shape them into a square profile. This method is efficient for producing long lengths of tubing.

-

Welding: After forming, the edges of the metal strips are welded together. This can be done through techniques like High-Frequency Resistance Welding (HFRW) or TIG welding, ensuring a strong and seamless joint.

-

Hydroforming: In some cases, hydroforming may be employed where high-pressure fluid is used to expand the metal into the desired shape. This technique allows for more complex designs and can improve the structural integrity of the tubing.

How Is the Finishing Process Conducted for 3×3 Square Tubing?

Once the tubing is formed, it undergoes a finishing process that may include:

-

Cutting: The tubing is cut to the specified lengths, often 20 feet for standard applications. Precision cutting ensures that the final product meets dimensional tolerances.

-

Surface Treatment: To enhance corrosion resistance, the square tubing may be galvanized, painted, or coated with a protective layer. Galvanization is particularly popular for outdoor applications, while powder coating offers aesthetic versatility.

-

Inspection: Before the final product is packaged, an initial quality check is performed to ensure that the dimensions and finish meet specifications.

What Quality Assurance Measures Are Implemented in the Production of Square Tubing?

Quality assurance is paramount in the manufacturing of 3×3 square tubing, ensuring that the products meet international standards and customer expectations.

Which International Standards Are Relevant for Square Tubing?

B2B buyers should be familiar with several international quality standards that govern the production of square tubing:

-

ISO 9001: This standard outlines the criteria for a quality management system and is crucial for ensuring consistent quality in manufacturing processes.

-

CE Marking: In Europe, CE marking indicates that products conform to health, safety, and environmental protection standards. This is particularly important for buyers in the European market.

-

API Standards: For applications in the oil and gas industry, adherence to API standards ensures the tubing can withstand harsh environments.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated throughout the manufacturing process, with several checkpoints established to ensure product integrity:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet the required specifications.

-

In-Process Quality Control (IPQC): During manufacturing, various parameters such as dimensions, weld integrity, and surface finish are monitored to detect any deviations early in the process.

-

Final Quality Control (FQC): After production, the finished tubing undergoes a comprehensive inspection that includes dimensional checks, visual inspections, and non-destructive testing methods like ultrasonic or magnetic particle testing to identify any internal flaws.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should adopt several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall compliance with international standards.

-

Requesting Quality Reports: Suppliers should provide detailed quality assurance reports that outline testing results, certifications, and compliance with industry standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the product quality before shipment. This is especially crucial for international buyers to ensure that products meet local regulations and standards.

What Are the Nuances of Quality Certification for International Buyers?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the nuances of quality certification is essential:

-

Local Regulations: Different regions may have specific regulations regarding metal products. Buyers should be aware of these to ensure compliance.

-

Traceability: Ensure that the supplier can provide traceability for the materials used in the production of the tubing, which is critical for maintaining quality and accountability.

-

Cultural Considerations: Communication styles and business practices can vary significantly across regions. Establishing a clear understanding of quality expectations and standards is vital for successful international transactions.

Conclusion: Ensuring Quality in Your Purchase of 3×3 Square Tubing

In summary, understanding the manufacturing processes and quality assurance measures for 3×3 square tubing is crucial for B2B buyers seeking reliable suppliers. By familiarizing themselves with production techniques, quality standards, and verification methods, buyers can make informed decisions that align with their project requirements and industry regulations. This knowledge not only facilitates better supplier relationships but also ensures the procurement of high-quality materials that meet specific application needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3×3 square tubing 20 ft price’

Introduction

This practical sourcing guide provides a structured checklist for B2B buyers looking to procure 3×3 square tubing at a length of 20 feet. Given the variety of suppliers and material specifications, this checklist will help you navigate the procurement process effectively, ensuring that you secure quality products at competitive prices while minimizing risks.

Step 1: Define Your Technical Specifications

Before initiating any procurement process, clearly define the technical specifications of the square tubing you require. This includes material type (steel, aluminum, etc.), wall thickness, and any specific coatings or treatments (e.g., galvanized or powder-coated).

– Why it’s important: Proper specifications ensure that you receive materials that meet your project needs and comply with industry standards.

– What to look for: Refer to engineering drawings or project requirements to avoid miscommunication with suppliers.

Step 2: Research Market Pricing

Conduct thorough research on the current market pricing for 3×3 square tubing measuring 20 feet.

– Why it’s important: Understanding the price range helps you recognize fair offers and avoid overpaying.

– What to look for: Compare prices from multiple suppliers and consider factors like bulk discounts, shipping costs, and delivery times.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, vet them thoroughly to ensure reliability and quality.

– Why it’s important: A trustworthy supplier is critical to the success of your procurement and project delivery.

– What to look for: Request company profiles, certifications, case studies, and references from previous clients within your industry.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant industry certifications and comply with international standards.

– Why it’s important: Certifications indicate that the supplier meets quality and safety standards, reducing the risk of material failure.

– What to look for: Look for ISO certifications, material test certifications, and compliance with ASTM or other relevant standards.

Step 5: Request Samples and Test Materials

Before finalizing your order, request samples of the 3×3 square tubing to evaluate quality.

– Why it’s important: Physical samples allow you to assess material properties, finish, and dimensions before bulk purchasing.

– What to look for: Check for consistency in dimensions, surface finish, and any visible defects in the samples.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate the terms and conditions of the sale, including price, payment terms, and delivery schedules.

– Why it’s important: Clear terms help prevent misunderstandings and ensure that both parties are aligned on expectations.

– What to look for: Pay attention to warranty clauses, return policies, and penalties for late deliveries.

Step 7: Finalize the Order and Confirm Logistics

After agreeing on terms, finalize your order and confirm the logistics for delivery.

– Why it’s important: Proper logistics management ensures that the materials arrive on time and in good condition.

– What to look for: Confirm shipping methods, tracking options, and handling procedures with the supplier to avoid delays.

By following this checklist, you can streamline your procurement process for 3×3 square tubing, ensuring that you secure the best quality materials at competitive prices while minimizing potential risks.

Comprehensive Cost and Pricing Analysis for 3×3 square tubing 20 ft price Sourcing

What Are the Key Cost Components for 3×3 Square Tubing 20 ft Pricing?

When sourcing 3×3 square tubing at 20 ft lengths, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The type of metal—steel, aluminum, or galvanized options—significantly affects pricing. For instance, aluminum is often more expensive than steel but offers advantages like corrosion resistance.

-

Labor: Labor costs depend on the region of production and the complexity of manufacturing processes. Regions with higher labor costs can impact the overall price.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient production methods can help minimize these costs.

-

Tooling: Custom fabrication may require specialized tooling, which can add to the initial investment but may reduce per-unit costs for larger orders.

-

Quality Control (QC): Ensuring compliance with international standards may involve additional QC costs. Certifications can also influence the price.

-

Logistics: Transportation costs vary by distance and mode of shipping. International shipments may incur additional duties and tariffs, particularly for buyers in regions like Africa or South America.

-

Margin: Suppliers will factor in their desired profit margin, which can vary based on market conditions and competition.

How Do Pricing Influencers Affect 3×3 Square Tubing Costs?

Several factors can influence the pricing of 3×3 square tubing, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically secure better pricing. Suppliers often have tiered pricing structures that reward bulk purchases.

-

Specifications and Customization: Custom dimensions or finishes can increase costs. Standard sizes are usually more economical.

-

Material Quality and Certifications: Higher-quality materials or certified products (e.g., ASTM, ISO standards) often come at a premium but can lead to better performance and longevity.

-

Supplier Factors: Reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding shipping terms like FOB (Free On Board) or CIF (Cost, Insurance, Freight) is vital, as they determine who bears the costs and risks during transportation.

What Are the Best Buyer Tips for Negotiating 3×3 Square Tubing Prices?

When negotiating prices for 3×3 square tubing, consider the following strategies:

-

Conduct Market Research: Familiarize yourself with current market prices and trends. This knowledge will empower you to negotiate better deals.

-

Leverage Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors like durability, maintenance costs, and potential savings from bulk orders.

-

Build Relationships with Suppliers: Establishing a rapport with suppliers can lead to better pricing and terms. Long-term partnerships often result in more favorable conditions.

-

Be Open to Alternatives: If a supplier cannot meet your price, consider alternative materials or specifications that might reduce costs without compromising quality.

-

Negotiate Payment Terms: Flexible payment terms can ease cash flow concerns and may lead to discounts for prompt payments.

What Should International Buyers Consider Regarding Pricing Nuances?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, pricing nuances can vary significantly:

-

Currency Fluctuations: Keep an eye on currency exchange rates as they can affect the total cost of your order.

-

Import Duties and Taxes: Be aware of your country’s import regulations and potential tariffs, which can significantly increase the final cost.

-

Shipping Times and Costs: Factor in the logistics involved in international shipping. Delays can lead to increased costs if expedited shipping becomes necessary.

-

Cultural and Regional Differences: Understanding local market conditions and supplier norms can lead to more effective negotiations.

Disclaimer on Indicative Prices

Prices for 3×3 square tubing can fluctuate due to market conditions, material availability, and supplier pricing strategies. Always request updated quotes and consider all cost factors when making purchasing decisions.

Alternatives Analysis: Comparing 3×3 square tubing 20 ft price With Other Solutions

Understanding Alternatives in the Context of 3×3 Square Tubing Pricing

In the competitive B2B landscape, understanding alternatives to standard products like 3×3 square tubing is crucial for buyers seeking cost-effective and efficient solutions. This analysis focuses on comparing the price and utility of 3×3 square tubing with two viable alternatives: rectangular tubing and cold-formed steel sections. Each option has unique attributes that can affect purchasing decisions, depending on the specific application and budget constraints.

Comparison Table

| Comparison Aspect | 3X3 Square Tubing 20 Ft Price | Rectangular Tubing | Cold-Formed Steel Sections |

|---|---|---|---|

| Performance | High structural integrity, versatile in applications | Good load-bearing capacity, offers more flexibility in design | Excellent for lightweight structures, high strength-to-weight ratio |

| Cost | Moderate to high; varies by supplier | Generally lower than square tubing | Typically lower due to manufacturing efficiency |

| Ease of Implementation | Straightforward installation; requires standard tools | Similar ease of installation; may require custom fittings | Requires specialized tools for assembly |

| Maintenance | Low maintenance; resistant to corrosion (if galvanized) | Similar durability, but depends on coating | May require additional protective coatings for longevity |

| Best Use Case | Ideal for structural support, frames, and fencing | Best for applications needing varied dimensions and shapes | Excellent for lightweight applications like partition walls and lightweight frames |

Detailed Breakdown of Alternatives

Rectangular Tubing

Rectangular tubing is a strong alternative to 3×3 square tubing, particularly in applications where space optimization is critical. With its varying dimensions, rectangular tubing can be tailored to fit specific structural requirements, making it highly versatile. The cost is generally lower, which can be a significant factor for budget-conscious projects. However, while it provides good load-bearing capacity, it may not match the sheer strength of square tubing in certain scenarios. Additionally, installation remains straightforward, similar to square tubing.

Cold-Formed Steel Sections

Cold-formed steel sections offer an efficient alternative for lightweight construction needs. These sections are manufactured from sheet steel that is rolled into shape, resulting in a high strength-to-weight ratio. This makes them an ideal choice for projects where weight savings are crucial, such as in the automotive or aerospace industries. The cost of cold-formed steel is often lower than that of square tubing, primarily due to the streamlined manufacturing process. However, installation may require specialized tools and expertise, which could increase overall project costs. Moreover, while these sections are durable, they may need additional protective coatings to enhance corrosion resistance, impacting long-term maintenance.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between 3×3 square tubing and its alternatives, B2B buyers should carefully consider their specific project requirements, including load-bearing needs, budget constraints, and installation capabilities. Each option presents distinct advantages and trade-offs. For projects demanding robust structural integrity, square tubing might be the best choice. Conversely, if cost or space optimization is a priority, rectangular tubing or cold-formed steel sections could be more suitable. Ultimately, assessing the unique demands of the project will guide buyers to the most effective and economical solution.

Essential Technical Properties and Trade Terminology for 3×3 square tubing 20 ft price

What Are the Key Technical Properties of 3×3 Square Tubing?

When sourcing 3×3 square tubing at a length of 20 feet, understanding its technical specifications is critical for making informed purchasing decisions. Here are several essential properties to consider:

-

Material Grade

The most common materials for square tubing include steel (such as A500 or A36) and aluminum (like 6061-T6). The material grade significantly influences the tubing’s strength, weight, and resistance to corrosion. For instance, A500 steel tubing is often preferred for structural applications due to its high tensile strength, making it essential for industries such as construction and manufacturing. -

Wall Thickness

Wall thickness, measured in gauges or inches, affects the tubing’s load-bearing capacity and durability. For 3×3 square tubing, typical wall thicknesses range from 1/8 inch to 1/4 inch. Thicker walls provide greater strength and resistance to deformation, which is crucial in applications such as scaffolding or heavy-duty framing. -

Length Tolerance

Tolerance refers to the allowable deviation from specified dimensions. For 20-foot lengths, maintaining proper tolerance is vital for ensuring compatibility with other components and structural integrity. A standard tolerance for square tubing might be ±1/8 inch, which is significant for precision in construction or manufacturing processes. -

Finish

The finish of the square tubing, such as galvanized, powder-coated, or bare, affects its aesthetic appeal and resistance to environmental factors. Galvanized finishes provide excellent corrosion resistance, making them ideal for outdoor applications, while powder coatings can enhance the tubing’s appearance and UV resistance. -

Weight Per Foot

Understanding the weight per foot of 3×3 square tubing helps in estimating shipping costs and load capacity when used in construction. Heavier tubing may require more robust support structures, impacting overall project design and cost.

Which Trade Terms Should B2B Buyers Know for 3×3 Square Tubing?

Familiarity with industry-specific terminology is essential for effective communication and negotiation in B2B transactions. Here are several key terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of square tubing, knowing the OEM can help buyers ensure they are purchasing quality products that meet their specifications. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity a supplier is willing to sell. Understanding this term is crucial for budgeting and inventory planning, especially for international buyers who may face higher shipping costs for smaller orders. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific quantities of products. Buyers should utilize RFQs to gather competitive pricing and establish relationships with multiple suppliers, ensuring the best value for their procurement needs. -

Incoterms

Short for International Commercial Terms, Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is vital for international transactions, as they can significantly impact overall costs and liability during transport. -

Lead Time

Lead time is the amount of time from placing an order to receiving the product. In industries where time is critical, understanding lead times can help buyers plan their projects more effectively and avoid delays. -

Custom Cuts

Custom cuts refer to modifications made to standard sizes of square tubing to meet specific project requirements. Knowing whether a supplier offers custom cuts can be advantageous for projects requiring unique dimensions.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing 3×3 square tubing, ultimately leading to successful procurement and project execution.

Navigating Market Dynamics and Sourcing Trends in the 3×3 square tubing 20 ft price Sector

What Are the Key Market Drivers and Trends Affecting 3×3 Square Tubing Prices?

The global market for 3×3 square tubing, particularly in the 20 ft length category, is significantly influenced by various factors. The demand for durable and versatile materials in construction, automotive, and manufacturing sectors is a primary driver. Emerging markets in Africa, South America, and the Middle East are witnessing rapid urbanization and industrialization, leading to increased demand for structural components, including square tubing. Additionally, Europe continues to maintain a robust market due to its established infrastructure and ongoing renovation projects.

Technological advancements in manufacturing processes, such as automation and precision cutting, are reshaping sourcing trends. B2B buyers are increasingly turning to e-commerce platforms for procurement, allowing for more competitive pricing and streamlined logistics. The rise of digital supply chains is enabling buyers to access a wider range of suppliers, enhancing transparency and efficiency in transactions. Moreover, there is a growing trend towards bulk purchasing and long-term contracts, which can stabilize pricing amidst fluctuating raw material costs.

How Is Sustainability Shaping the 3×3 Square Tubing Market?

Sustainability and ethical sourcing have become pivotal in shaping the procurement strategies of B2B buyers. The environmental impact of steel production, including carbon emissions and resource depletion, has led to a significant shift towards sustainable practices. Buyers are increasingly seeking suppliers who can demonstrate compliance with environmental regulations and sustainability certifications.

Green certifications, such as LEED (Leadership in Energy and Environmental Design) and ISO 14001, are becoming critical for suppliers to secure contracts. Additionally, the use of recycled materials in the production of 3×3 square tubing is gaining traction, appealing to environmentally conscious buyers. Sustainable sourcing not only minimizes environmental harm but also enhances brand reputation and customer loyalty. As international trade regulations increasingly favor sustainable practices, B2B buyers must prioritize ethical supply chains to remain competitive.

What Is the Historical Context Behind the 3×3 Square Tubing Market?

The evolution of square tubing can be traced back to the industrial revolution when steel became a fundamental material for construction and manufacturing. Initially, square tubing was primarily used for structural applications due to its strength and versatility. Over the decades, advancements in metallurgy and manufacturing processes have expanded its applications across various sectors, including automotive and agricultural industries.

The 20 ft length of 3×3 square tubing has become a standard in many regions, facilitating easier transportation and installation in construction projects. As markets have globalized, the sourcing of square tubing has become more complex, with buyers needing to navigate international supply chains and compliance standards. Today, the market is characterized by a focus on innovation, sustainability, and responsiveness to global economic shifts, positioning square tubing as a critical component in modern infrastructure development.

Conclusion

Navigating the dynamics of the 3×3 square tubing market requires an understanding of global drivers, emerging trends, and the importance of sustainability. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, staying informed about these factors is essential for making strategic procurement decisions. As the market evolves, embracing technology and sustainable practices will be crucial for maintaining competitiveness and meeting the growing demand for structural materials.

Frequently Asked Questions (FAQs) for B2B Buyers of 3×3 square tubing 20 ft price

-

How do I determine the right supplier for 3×3 square tubing?

Choosing the right supplier involves several key factors. Start by assessing their reputation through reviews and testimonials from other B2B clients. Verify their certifications and compliance with international standards, which is crucial for quality assurance. Additionally, request samples to evaluate the material’s quality and finish. Ensure the supplier has a solid logistics network to facilitate timely deliveries, especially if you are sourcing internationally from regions like Africa or Europe. -

What is the average price for 3×3 square tubing at 20 ft?

The price for 3×3 square tubing at 20 ft can vary widely based on factors such as material type (steel or aluminum), finish (galvanized or uncoated), and market demand. Generally, prices range from $150 to $400 per piece, depending on these variables. It’s advisable to obtain quotes from multiple suppliers to compare prices and negotiate the best deal, especially when ordering in bulk. -

What are the minimum order quantities (MOQs) for 3×3 square tubing?

Minimum order quantities can differ significantly among suppliers. Some may allow orders as low as 10 pieces, while others might require a minimum of 50 or more, particularly for customized products. When sourcing internationally, consider logistics costs and potential tariffs, which could impact your overall budget. Always confirm MOQs with your supplier before placing an order to ensure they align with your project needs. -

Can I customize the specifications of 3×3 square tubing?

Many suppliers offer customization options for 3×3 square tubing, including varying lengths, wall thicknesses, and finishes. If you have specific requirements, communicate these clearly to your supplier. They may provide options for cut-to-length services or special coatings, which can be advantageous for your project. Be aware that custom orders may have longer lead times and minimum order requirements. -

What payment terms should I expect when ordering 3×3 square tubing?

Payment terms can vary by supplier and region. Common arrangements include upfront payment, a deposit with the balance due upon delivery, or net 30/60 terms for established customers. For international transactions, consider using secure payment methods like letters of credit or escrow services to protect your investment. Always clarify payment terms before finalizing your order to avoid any misunderstandings. -

What quality assurance measures should I look for?

Quality assurance is vital when sourcing 3×3 square tubing. Ensure that your supplier follows industry standards and has certifications like ISO 9001. Request documentation such as mill test reports or compliance certificates that verify the material’s quality. Some suppliers may also offer third-party inspection services, which can provide additional assurance regarding the tubing’s structural integrity and performance. -

How do logistics and shipping affect the price of 3×3 square tubing?

Logistics and shipping can significantly influence the overall cost of 3×3 square tubing. Factors such as distance, shipping method (air freight vs. sea freight), and customs duties can add to your expenses. When sourcing internationally, it is essential to factor in these costs when comparing suppliers. Consider discussing freight options with your supplier to determine the most cost-effective shipping solutions. -

What are the common applications for 3×3 square tubing in various industries?

3×3 square tubing is versatile and widely used across various sectors, including construction, automotive, and agriculture. In construction, it serves as structural support for buildings and frameworks. The automotive industry utilizes it for chassis and support structures, while agricultural applications include fencing and equipment frames. Understanding these applications can help you select the right tubing for your specific project needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 3X3 Square Tubing 20 Ft Price Manufacturers & Suppliers List

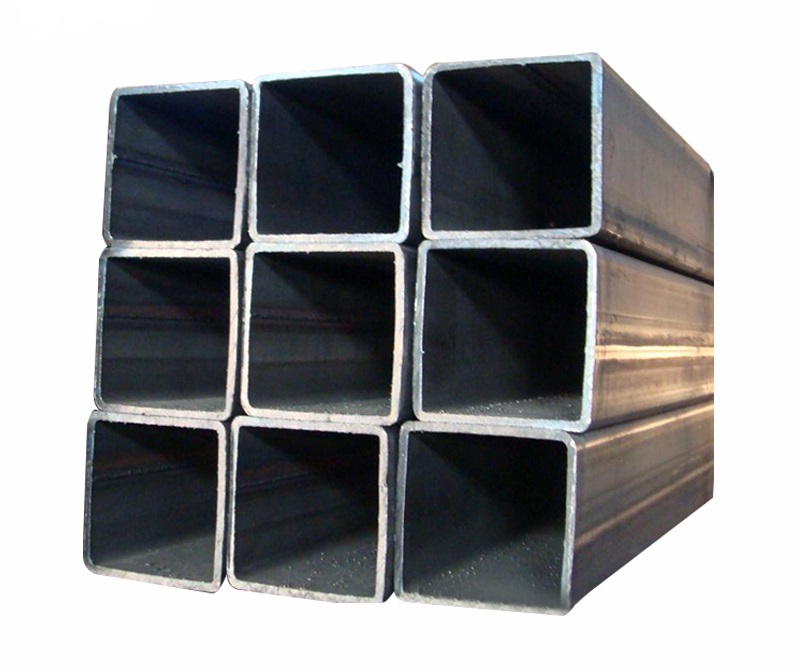

1. MetalsDepot® – Steel Square Tube

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: MetalsDepot® – Buy Steel Square Tube Online! Square Steel Tube is a welded structural grade tubing available in type A513 or A500 Grade B. Ideal for structural applications, general fabrication, manufacturing, and repairs. Widely used in industrial maintenance, agricultural implements, transportation equipment, truck beds, trailers, and frames. Box-shape configuration provides greater strength and…

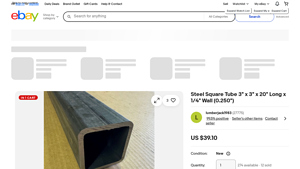

2. Steel Square Tube – 3 x 3 x 20 Long

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Steel Square Tube”, “Dimensions”: “3” x 3″ x 20″ Long”, “Wall Thickness”: “1/4″ (0.250″)”, “Condition”: “New”, “Price”: “$39.10”, “Delivery”: “$14.00 delivery in 2–4 days”, “Quantity Available”: “274”, “Item Number”: “203829121086”}

3. MK Metal – 6061-T6 Aluminum Square Tube

Domain: mkmetal.net

Registered: 1999 (26 years)

Introduction: {“Alloy”:”6061-T6″,”Dimensions”:{“Side 1″:”3 in”,”Side 2″:”3 in”,”Thickness”:”0.188 in”,”Length”:”20 ft”},”Weight per Foot (SQFT)”:”2.538″,”Price per Piece”:”$416.49″}

4. Texas Iron and Metal – Surplus Square Tubing

Domain: texasironandmetal.com

Registered: 1999 (26 years)

Introduction: Surplus & Excess Square Tubing for Sale – Less-Than-Prime© Surplus Square Tubing. Multi-functional product with applications in automotive and agriculture. Provides stability for vehicle construction, building projects, and fencing. Available in stock sizes or custom cuts. Inventory includes various widths, grades, and sizes of reduced-price, high-quality steel products. Key sizes include: 1/2″, 1…

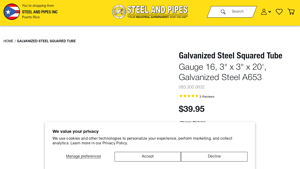

5. Steel & Pipes – Galvanized Steel Squared Tube

Domain: store.steelandpipes.com

Registered: 1999 (26 years)

Introduction: {“Product Name”: “Galvanized Steel Squared Tube”, “Material”: “Galvanized Steel”, “Material Grade”: “A-653”, “Gauge”: 16, “Dimensions”: {“Height”: “3””, “Width”: “3””, “Length”: “20′”}, “Wall Thickness”: “.065””, “Tensile Strength”: “58,000 psi”, “Yield Strength”: “46,000 psi”, “Elongation”: “23%”, “Weight Per Foot”: “2.59 lbs”, “Total Weight”: “51.8 lbs”, “Cuttable”: “Yes”, “Price”: “$39.95”, …

6. Facebook – Square Steel Tubes

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Square steel tubes for sale in Fort Worth, Texas

7. Steel Supply LP – Red Oxide Primed Square Tubing

Domain: steelsupplylp.com

Registered: 2005 (20 years)

Introduction: Red Oxide Primed Square Tubing available in various sizes, wall thicknesses, and lengths. Lengths offered: 20 and 24 feet. Excellent water-resistance for rust and corrosion prevention. Commonly used for building fences, requiring only a final coat of paint. Custom cuts available with a processing time of 1-2 days. Non-returnable once cut. Tolerance on cut lengths may be +/- 1/8 inch. Shipping from…

Strategic Sourcing Conclusion and Outlook for 3×3 square tubing 20 ft price

How Can Strategic Sourcing Enhance Your Procurement of 3×3 Square Tubing?

In the competitive landscape of international B2B procurement, strategic sourcing of 3×3 square tubing is essential for optimizing costs and ensuring quality. By leveraging insights into market trends, price fluctuations, and supplier capabilities, buyers can secure favorable pricing and reliable supply chains. Understanding the local market dynamics in regions such as Africa, South America, the Middle East, and Europe enables businesses to make informed decisions that align with their operational needs.

International buyers should prioritize building relationships with reputable suppliers who offer transparent pricing and a range of product options. This approach not only facilitates better negotiation outcomes but also fosters trust and collaboration, critical factors for long-term success. Additionally, considering alternative materials and specifications can lead to significant cost savings without compromising quality.

Looking ahead, the demand for 3×3 square tubing is expected to grow, driven by various industries including construction and manufacturing. As market conditions evolve, maintaining a proactive sourcing strategy will be crucial. Buyers are encouraged to stay informed about industry developments and engage with suppliers to explore innovative solutions. By doing so, they can position themselves strategically to capitalize on future opportunities in this dynamic market.