Sma Extension Cable: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for sma extension cable

In the fast-evolving landscape of telecommunications and wireless technology, sourcing reliable SMA extension cables is a critical challenge for B2B buyers. These essential components facilitate seamless connectivity between antennas and devices, ensuring optimal signal strength and performance. However, with a multitude of options available on the global market, identifying the right type, quality, and supplier can be daunting. This comprehensive guide addresses these challenges by delving into various SMA extension cable types, their specific applications across industries, and essential factors to consider during the supplier vetting process.

International buyers, particularly those from Africa, South America, the Middle East, and Europe, will find actionable insights tailored to their unique market conditions. From understanding the technical specifications and compatibility with diverse wireless protocols to evaluating cost structures and durability, this guide empowers decision-makers to make informed purchasing choices. By equipping yourself with knowledge on SMA cables, you can enhance your procurement strategies and ensure that your operations are supported by high-quality, low-loss coaxial solutions. Whether you are in telecommunications, GPS, or other RF applications, this resource will serve as your roadmap to navigating the complexities of the global SMA extension cable market effectively.

Understanding sma extension cable Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| SMA Male to SMA Female | Standard configuration for antenna connections; versatile. | Cellular networks, GPS, RF applications. | Pros: Widely compatible, easy to source. Cons: Signal loss over longer distances. |

| SMA Female to SMA Female | Allows for extension between two female connectors. | Used in setups requiring flexibility in connection points. | Pros: Useful for bulkhead connections. Cons: Less common; might need adapters. |

| SMA Male to Male | Enables direct connection between two male SMA connectors. | Industrial applications, testing environments. | Pros: Simplifies connection without adapters. Cons: Limited applications in consumer use. |

| SMA Right Angle Connector | Space-saving design; ideal for tight installations. | Telecommunications, compact device setups. | Pros: Reduces stress on cables. Cons: May limit signal quality if not properly installed. |

| Low-Loss SMA Extension Cable | High-quality coaxial cable design minimizes signal attenuation. | High-performance applications like 5G, LTE, and GPS. | Pros: Superior signal integrity. Cons: Higher cost compared to standard cables. |

What are the characteristics of SMA Male to SMA Female extension cables?

SMA Male to SMA Female extension cables are the most common type, designed for connecting antennas to various devices such as routers and modems. They are versatile and available in various lengths, making them suitable for numerous applications, including cellular networks and GPS systems. When purchasing, consider the cable length needed and ensure compatibility with your existing hardware to minimize signal loss over extended distances.

How do SMA Female to SMA Female extension cables function in B2B setups?

SMA Female to SMA Female extension cables are essential for applications requiring connections between two female connectors. They are often used in setups where flexibility in connection points is necessary, such as in complex telecommunications systems. Buyers should evaluate their specific connection needs and ensure they have the appropriate adapters if required, as this type of cable is less common.

In which scenarios are SMA Male to Male cables advantageous?

SMA Male to Male cables are designed for direct connections between two male SMA connectors, making them ideal for industrial applications and testing environments. These cables simplify connections by eliminating the need for additional adapters. However, their use is limited in consumer settings, so buyers should assess their specific application requirements before purchasing.

What benefits do right angle SMA connectors provide in installations?

Right Angle SMA connectors are designed to save space and reduce stress on cables, making them ideal for tight installations in telecommunications and compact device setups. These connectors can help maintain the integrity of the cable by preventing bends that could lead to signal degradation. Buyers should ensure proper installation to maximize performance, as improper use can still affect signal quality.

Why should B2B buyers consider low-loss SMA extension cables?

Low-loss SMA extension cables feature high-quality coaxial designs that significantly minimize signal attenuation, making them suitable for high-performance applications such as 5G, LTE, and GPS. While these cables may come at a higher cost, the investment often pays off in improved signal integrity and reliability. Buyers should weigh the benefits of enhanced performance against their budget and specific application needs.

Key Industrial Applications of sma extension cable

| Industry/Sector | Specific Application of SMA Extension Cable | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Connecting antennas to cellular base stations | Enhances signal strength and coverage for mobile networks | Ensure compatibility with existing equipment and local regulations |

| Transportation & Logistics | GPS and tracking systems for fleet management | Improves accuracy of tracking and navigation systems | Look for low-loss cables to minimize signal degradation over distance |

| Satellite Communications | Extending connections for satellite dishes and receivers | Ensures reliable communication links for data transmission | Consider environmental durability for outdoor installations |

| Industrial Automation | Integrating sensors and RF devices in manufacturing | Facilitates real-time data collection and process optimization | Verify temperature and pressure ratings for specific industrial environments |

| Radio Communications | Connecting ham radios and other RF devices | Enhances communication clarity and range for emergency services | Assess cable length and loss characteristics for optimal performance |

How Are SMA Extension Cables Used in Telecommunications?

In the telecommunications sector, SMA extension cables are crucial for connecting antennas to cellular base stations. This connection is vital for enhancing signal strength and coverage, especially in remote or densely populated areas. International buyers should consider sourcing cables that comply with local telecommunications regulations and ensure compatibility with their existing equipment. Low-loss coaxial designs are preferred to minimize signal degradation, particularly in regions with challenging terrain, such as mountainous areas in Brazil or Nigeria.

What Role Do SMA Extension Cables Play in Transportation and Logistics?

SMA extension cables are instrumental in GPS and tracking systems within the transportation and logistics industry. They connect GPS antennas to vehicles, ensuring precise tracking and navigation capabilities. This is particularly beneficial for fleet management, where real-time data is critical. Buyers in Africa and South America should prioritize cables that offer durability and low signal loss to maintain accuracy over long distances, especially in regions with varying climate conditions.

Why Are SMA Extension Cables Essential for Satellite Communications?

In satellite communications, SMA extension cables extend connections between satellite dishes and receivers, ensuring reliable data transmission. This is vital for industries reliant on satellite technology, such as broadcasting and remote data collection. When sourcing these cables, international buyers must consider the environmental durability of the cables to withstand outdoor conditions, particularly in the Middle East, where high temperatures and dust can affect performance.

How Do SMA Extension Cables Facilitate Industrial Automation?

In the realm of industrial automation, SMA extension cables are used to integrate sensors and RF devices within manufacturing processes. This integration allows for real-time data collection, which can significantly enhance operational efficiency and process optimization. Buyers should ensure that the selected cables meet specific temperature and pressure ratings suitable for their industrial environments, especially in Europe, where regulatory compliance is stringent.

What Benefits Do SMA Extension Cables Provide in Radio Communications?

SMA extension cables are vital for connecting ham radios and other RF devices, enhancing communication clarity and range for emergency services and amateur radio enthusiasts. This is particularly important in regions where reliable communication is crucial during emergencies. Buyers should assess the cable length and loss characteristics to ensure optimal performance, especially in remote areas of South America and Africa where signal strength can be compromised.

3 Common User Pain Points for ‘sma extension cable’ & Their Solutions

Scenario 1: Ensuring Signal Integrity Over Long Distances

The Problem:

B2B buyers often face the challenge of signal degradation when extending the reach of their antennas using SMA extension cables. This issue is particularly critical in environments where high-frequency signals, such as those used in 4G and 5G communications, are essential for optimal performance. As distance increases, the potential for signal loss also rises, leading to decreased data transmission quality. Buyers in regions with vast geographical expanses, such as Africa and South America, may find that standard SMA cables do not meet their needs, resulting in unreliable connectivity and increased operational costs.

The Solution:

To combat signal loss, it is vital to select SMA extension cables that are specifically designed to minimize attenuation. Look for cables made from double-shielded, low-loss coaxial designs, like LMR-100 or LMR-400 equivalents, which provide superior signal integrity over longer distances. Additionally, always verify the specifications for each cable, ensuring they are rated for the frequency ranges required by your applications. Employing a torque wrench during installation will also help maintain optimal connector tightness without damaging the cables, thus preserving signal quality. For long-distance deployments, consider using a combination of shorter cables and high-quality connectors to maintain performance while managing costs effectively.

Scenario 2: Overcoming Environmental Challenges

The Problem:

In regions with harsh environmental conditions, such as extreme temperatures, humidity, or exposure to contaminants, standard SMA extension cables may fail prematurely. This can lead to increased maintenance costs and downtime, which are particularly detrimental for businesses operating in sectors such as telecommunications or remote monitoring. Buyers may struggle to find cables that can withstand these challenges without compromising performance.

The Solution:

Investing in high-quality SMA extension cables with robust materials is crucial. Look for cables that feature durable outer jackets made from PVC or similar materials designed for outdoor use. Additionally, ensure that the connectors are constructed from corrosion-resistant materials such as brass or stainless steel. For applications exposed to severe weather, consider cables that are specifically rated for outdoor use and have enhanced moisture resistance. Always consult with suppliers to ensure the cables meet the necessary environmental ratings for your specific conditions, thereby reducing the likelihood of failure and associated costs.

Scenario 3: Navigating Compatibility Issues

The Problem:

Another common pain point for B2B buyers is ensuring that the SMA extension cables they purchase are compatible with their existing equipment. Incompatible connectors can lead to connection failures, inefficiencies, and unnecessary expenses, particularly in industries reliant on specific communication technologies. Buyers may find themselves frustrated when trying to match cable types with varying connector formats, such as SMA male to female or reverse polarity SMA.

The Solution:

To avoid compatibility issues, it is essential to conduct thorough research on the equipment specifications before sourcing SMA extension cables. Document the types of connectors in use and the specifications of the devices to which the cables will connect. When sourcing cables, opt for suppliers that provide comprehensive product descriptions and compatibility information. Additionally, consider using adapter cables or bulkhead connectors if your setup requires different connector types. By taking these proactive steps, businesses can ensure seamless integration of their SMA extension cables with existing systems, thereby enhancing operational efficiency and reducing costly installation errors.

Strategic Material Selection Guide for sma extension cable

What Are the Key Materials Used in SMA Extension Cables?

When selecting SMA extension cables, the choice of materials significantly influences performance, durability, and compatibility. Here, we analyze four common materials used in the construction of SMA extension cables, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Copper

Key Properties: Copper is renowned for its excellent electrical conductivity, making it a preferred choice for the center conductor in SMA cables. It typically operates well in a temperature range of -40°C to 85°C and offers good corrosion resistance when properly coated.

Pros & Cons: The primary advantage of copper is its high conductivity, which minimizes signal loss. However, it is susceptible to corrosion if exposed to moisture without protective coatings, which can lead to performance degradation over time. Additionally, copper is relatively expensive compared to other materials.

Impact on Application: Copper’s superior conductivity is crucial for applications requiring high-frequency transmission, such as 5G networks and GPS systems. However, its susceptibility to corrosion necessitates careful consideration in humid or coastal regions.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that copper cables comply with local standards, such as ASTM or ISO certifications, to guarantee quality and performance.

2. Polyethylene (PE)

Key Properties: Polyethylene is often used as dielectric insulation due to its excellent electrical insulating properties and temperature resistance, typically ranging from -40°C to 85°C. It also offers good moisture resistance.

Pros & Cons: PE is lightweight and cost-effective, making it a popular choice for cable insulation. However, it may not withstand high temperatures as well as other materials, which could limit its application in extreme environments.

Impact on Application: PE’s moisture resistance makes it suitable for outdoor applications, where exposure to the elements is a concern. However, in high-temperature environments, alternative materials like PTFE might be more appropriate.

Considerations for International Buyers: Buyers should verify that the PE used meets relevant international standards for insulation materials, particularly in regions with varying climate conditions.

3. PTFE (Polytetrafluoroethylene)

Key Properties: PTFE is known for its exceptional thermal stability, operating effectively in temperatures ranging from -200°C to 260°C. It also provides excellent chemical resistance and low friction properties.

Pros & Cons: The main advantage of PTFE is its ability to maintain performance in extreme conditions, making it ideal for high-frequency applications. However, it is more expensive than PE and can be more challenging to manufacture and handle.

Impact on Application: PTFE’s properties make it suitable for high-performance applications, such as military and aerospace technologies, where reliability is critical. Its chemical resistance also makes it ideal for environments with aggressive media.

Considerations for International Buyers: When sourcing PTFE cables, buyers should ensure compliance with international standards, particularly in industries with stringent safety regulations, such as telecommunications and aerospace.

4. PVC (Polyvinyl Chloride)

Key Properties: PVC is commonly used for the outer jacket of SMA cables due to its durability and resistance to abrasion and moisture. It typically operates effectively in temperatures from -15°C to 60°C.

Pros & Cons: The advantages of PVC include its affordability and excellent mechanical properties. However, it may not be suitable for high-temperature applications and can degrade under UV exposure unless specifically treated.

Impact on Application: PVC is widely used in general-purpose applications where cost-effectiveness and durability are required. However, its limitations in extreme conditions may necessitate alternative materials for specialized applications.

Considerations for International Buyers: Buyers should check for compliance with local regulations regarding the use of PVC, especially in regions with strict environmental standards.

Summary Table of Material Selection for SMA Extension Cables

| Material | Typical Use Case for SMA Extension Cable | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-frequency applications (5G, GPS) | Excellent electrical conductivity | Susceptible to corrosion | High |

| Polyethylene | General outdoor applications | Lightweight and cost-effective | Limited high-temperature performance | Low |

| PTFE | Military and aerospace applications | Exceptional thermal stability | Higher cost and manufacturing complexity | High |

| PVC | General-purpose applications | Durable and abrasion-resistant | Not suitable for high temperatures or UV exposure | Medium |

This guide serves as a strategic resource for international B2B buyers, providing critical insights into material selection for SMA extension cables. Understanding these materials will enable informed purchasing decisions that align with specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for sma extension cable

What Are the Key Stages in the Manufacturing Process of SMA Extension Cables?

The manufacturing of SMA extension cables involves several critical stages that ensure high performance and reliability. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: Sourcing Quality Components

The initial step in the manufacturing process is sourcing high-quality materials. The primary components include the center conductor, dielectric insulation, shielding, and outer jacket.

- Center Conductor: Typically made from solid or stranded copper, which offers excellent conductivity.

- Dielectric Insulation: Commonly composed of polyethylene or PTFE, this material separates the center conductor from the shielding and is crucial for maintaining signal integrity.

- Shielding: A double-shielded design, utilizing both foil and braided shielding, minimizes signal loss and interference.

- Outer Jacket: Usually made from durable PVC or similar materials, the outer jacket provides protection against environmental factors.

Once sourced, materials undergo rigorous inspection to ensure they meet specified standards, such as electrical conductivity and mechanical strength.

How Is the Forming Process Conducted for SMA Cables?

The forming process involves shaping and preparing the materials for assembly. This includes cutting the coaxial cable to the desired lengths and preparing the connectors.

- Cutting: The coaxial cable is cut to length based on customer specifications. Precision cutting is vital to minimize signal loss over long distances.

- Connector Preparation: SMA connectors are threaded and designed for secure attachment. The connectors are prepared by removing insulation and ensuring proper fit.

Advanced machinery is used to ensure accuracy in these processes, which is crucial for maintaining consistent performance across all cables produced.

What Techniques Are Used in the Assembly of SMA Extension Cables?

Assembly is a critical phase where individual components come together to form the finished product. Key techniques include:

- Termination: The prepared coaxial cable is terminated with SMA connectors. This involves careful crimping or soldering to ensure a secure connection that can withstand mechanical stress.

- Torque Application: Proper torque is applied during the installation of connectors to prevent damage and ensure optimal performance. A torque wrench is often used to achieve the required specifications.

- Insulation: After connector installation, additional insulation may be applied to enhance durability and weather resistance, particularly for outdoor applications.

Quality control measures are implemented throughout the assembly to check for consistency and adherence to specifications.

What Finishing Processes Enhance the Quality of SMA Extension Cables?

Finishing processes contribute to the overall durability and functionality of SMA extension cables. These processes include:

- Testing: Each cable undergoes rigorous testing to ensure it meets performance standards. Tests may include checking for signal loss, impedance, and continuity.

- Labeling: Finished products are labeled with specifications, including length, type, and performance characteristics, for easy identification.

- Packaging: Cables are packaged securely to prevent damage during transportation. Packaging often includes protective materials to shield against physical impacts.

These finishing touches ensure that the cables are ready for shipping and meet international shipping standards.

What Quality Assurance Measures Are Commonly Applied to SMA Extension Cables?

Quality assurance is integral to the manufacturing process of SMA extension cables, ensuring that the final product meets both international standards and customer expectations.

Which International Standards Should B2B Buyers Consider?

B2B buyers should be aware of various international standards that govern the quality of SMA extension cables. Key certifications include:

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers aiming to demonstrate consistent quality and reliability.

- CE Marking: Indicates compliance with EU safety and environmental regulations, making it crucial for buyers in Europe.

- API Certifications: Relevant for manufacturers in industries such as oil and gas, where stringent quality standards are necessary.

How Are Quality Control Checkpoints Implemented?

Quality control checkpoints are strategically placed throughout the manufacturing process. These checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Ongoing inspections are conducted during the manufacturing stages to identify defects early in the process.

- Final Quality Control (FQC): Finished products undergo comprehensive testing and inspection before being packaged and shipped.

Each of these checkpoints helps to mitigate risks and ensure that only high-quality products reach the market.

What Testing Methods Are Commonly Used for SMA Extension Cables?

Testing methods play a crucial role in assessing the performance and reliability of SMA extension cables. Common testing methods include:

- Electrical Testing: This involves measuring signal loss, impedance, and continuity to ensure that the cable performs as expected.

- Environmental Testing: Cables may be subjected to extreme temperature, humidity, and abrasion tests to simulate real-world conditions.

- Mechanical Testing: Stress tests are conducted to ensure that cables can withstand physical strain without failure.

These testing methods provide confidence in the product’s performance, particularly for B2B buyers who rely on the cables for critical applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is essential to ensure reliability and performance. Key strategies include:

- Conducting Audits: Requesting audits of the manufacturing facility can provide insights into the quality control processes and adherence to international standards.

- Reviewing Quality Reports: Suppliers should provide detailed quality reports that outline testing results, certifications, and compliance with industry standards.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality practices and product reliability.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers, particularly those from regions like Africa, South America, and the Middle East, should be aware of specific nuances regarding quality control:

- Regulatory Compliance: Different regions may have varying regulations, making it essential to ensure that suppliers comply with local laws.

- Supply Chain Transparency: Understanding the entire supply chain can help mitigate risks associated with quality and delivery timelines.

- Cultural Considerations: Building strong relationships with suppliers can enhance communication and collaboration, leading to better quality outcomes.

By focusing on these factors, international buyers can make informed decisions when selecting suppliers for SMA extension cables.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sma extension cable’

In the fast-evolving landscape of telecommunications and wireless connectivity, sourcing the right SMA extension cables is crucial for ensuring optimal performance and reliability. This guide provides a structured checklist for B2B buyers, particularly those operating in diverse international markets such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. Consider the frequency range, cable length, and connector types (SMA male or female) necessary for your application.

– Compatibility: Ensure the cables can seamlessly integrate with your existing equipment, such as routers, antennas, or modems.

– Performance Metrics: Look for specifications like low-loss and double-shielded coaxial designs that minimize signal attenuation.

Step 2: Research Market Trends and Applications

Understanding current market trends and applications for SMA extension cables can help you make informed purchasing decisions. Research the latest advancements in wireless technologies, including 4G, 5G, and IoT solutions.

– Industry Use Cases: Identify which sectors (telecommunications, GPS, industrial applications) are utilizing SMA cables to gauge demand.

– Future-Proofing: Consider how your choices may impact future scalability and compatibility with emerging technologies.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Quality Assurance: Inquire about their quality control processes and certifications (e.g., ISO 9001).

– Technical Support: Assess the level of technical support and customer service they offer, as this can be vital post-purchase.

Step 4: Assess Product Quality and Durability

Investigate the materials and construction quality of the SMA extension cables. High-quality cables are typically made from solid copper for the center conductor and feature robust insulation and shielding.

– Environmental Resistance: Ensure the cables can withstand various environmental conditions, especially if they will be used outdoors.

– Warranty and Guarantees: Check for warranties or satisfaction guarantees to protect your investment.

Step 5: Request Samples and Test Performance

Once you have shortlisted potential suppliers, request samples to evaluate the product quality firsthand. Testing the cables in real-world applications can reveal critical performance insights.

– Signal Strength Tests: Conduct tests to measure signal loss over the length of the cable.

– Connector Integrity: Assess the strength and reliability of the connectors under different conditions.

Step 6: Negotiate Terms and Pricing

Engage in discussions regarding pricing, payment terms, and delivery schedules. Understanding the full cost structure will help you budget effectively.

– Volume Discounts: Inquire about bulk purchasing options or discounts for long-term contracts.

– Lead Times: Clarify the expected delivery times, especially if you have urgent project deadlines.

Step 7: Finalize the Purchase and Plan for Logistics

After selecting your preferred supplier, finalize the order and plan for logistics. Ensure you have a clear understanding of shipping methods and any customs requirements that may apply.

– Tracking and Communication: Request tracking details to monitor shipment progress.

– Post-Purchase Support: Confirm the availability of after-sales support for installation or troubleshooting needs.

By following this structured checklist, B2B buyers can enhance their procurement process for SMA extension cables, ensuring they meet both current and future connectivity demands.

Comprehensive Cost and Pricing Analysis for sma extension cable Sourcing

What are the Key Cost Components in SMA Extension Cable Manufacturing?

When sourcing SMA extension cables, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality of materials directly influences the performance and durability of SMA extension cables. High-grade components like double-shielded low-loss coaxial cables, gold-plated connectors, and robust outer jackets are essential. Prices vary based on material quality, which can affect the overall cost significantly.

-

Labor: Labor costs involve skilled technicians for cable assembly and quality assurance. Regions with lower labor costs may offer competitive pricing, but this can impact the quality of workmanship.

-

Manufacturing Overhead: This includes expenses related to the facility, equipment maintenance, utilities, and administrative costs. Efficient manufacturing processes can minimize these overheads, allowing for more competitive pricing.

-

Tooling Costs: Specialized tools and molds for cable assembly can incur substantial initial investments. However, these costs are amortized over time, making them less impactful for larger production runs.

-

Quality Control (QC): Implementing stringent quality control measures ensures reliability and performance. While it adds to the cost, it is vital for minimizing returns and maintaining customer satisfaction.

-

Logistics: Transportation and warehousing costs can vary greatly, especially for international shipments. Factors such as distance, shipping method, and destination country (e.g., Brazil, Nigeria) play a significant role in overall logistics expenses.

-

Margin: Suppliers will add a profit margin on top of their costs, influenced by market demand, competition, and the perceived value of their products.

How Do Price Influencers Affect SMA Extension Cable Sourcing?

Several factors can influence the pricing of SMA extension cables, impacting B2B buyers’ sourcing decisions:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to significant discounts. Suppliers are more likely to negotiate better pricing for larger orders, which can be beneficial for businesses with consistent demand.

-

Specifications and Customization: Custom lengths, special connectors, or unique shielding requirements can increase costs. Buyers should evaluate their specific needs against potential price increases for custom solutions.

-

Materials and Quality Certifications: Higher-quality materials may incur higher upfront costs but can lead to lower Total Cost of Ownership (TCO) due to increased durability and lower failure rates. Certifications (like ISO) can also add to the cost but assure buyers of product reliability.

-

Supplier Factors: Supplier reputation, location, and production capabilities can affect pricing. Established suppliers with a track record of quality may command higher prices, while emerging suppliers might offer competitive rates.

-

Incoterms: The terms of trade (Incoterms) dictate the responsibilities of buyers and sellers regarding transportation costs, insurance, and risk. Understanding these terms can help buyers avoid unexpected expenses.

What Are the Best Negotiation Tips for International Buyers?

B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to enhance cost-efficiency:

-

Research Market Prices: Understanding the standard pricing for SMA extension cables helps in negotiating fair terms. Leverage price benchmarks from multiple suppliers.

-

Build Relationships: Establishing a rapport with suppliers can lead to better terms and willingness to negotiate on pricing and delivery times.

-

Discuss Total Cost of Ownership: Emphasize the long-term benefits of quality cables, which may justify higher initial costs. Suppliers may be more willing to offer discounts if they recognize the potential for repeat business.

-

Utilize Incoterms Knowledge: Leverage your understanding of Incoterms to negotiate favorable shipping terms, potentially reducing logistics costs.

-

Be Open to Alternatives: If a supplier cannot meet your price point, consider alternative solutions such as different specifications or materials that can provide a cost-effective outcome.

Conclusion: Understanding the Cost and Pricing Landscape

In conclusion, comprehending the cost structure and price influencers for SMA extension cables is crucial for international B2B buyers. By leveraging this knowledge, businesses can enhance their sourcing strategies, optimize costs, and make informed purchasing decisions. Always remember that prices may fluctuate based on market dynamics, so it’s essential to seek multiple quotes and assess the value offered by each supplier before finalizing any purchase.

Alternatives Analysis: Comparing sma extension cable With Other Solutions

Exploring Alternatives to SMA Extension Cables

In the world of wireless communication, SMA extension cables are widely recognized for their reliability and performance. However, various alternative solutions exist that may better suit specific applications or preferences. This analysis delves into the performance, cost, ease of implementation, maintenance, and best use cases of SMA extension cables compared to other technologies, such as RF over Fiber and Ethernet cables with adapters.

| Comparison Aspect | SMA Extension Cable | RF over Fiber | Ethernet with Adapters |

|---|---|---|---|

| Performance | High signal integrity, low loss | Extremely high bandwidth, low loss | Good for data, limited RF capacity |

| Cost | Moderate cost, varies by length | Higher initial investment | Generally lower cost |

| Ease of Implementation | Simple to install, plug-and-play | Requires specialized installation | Easy installation with existing infrastructure |

| Maintenance | Low maintenance; durable | Moderate; fiber optics can be fragile | Low; robust, but adapters may require checks |

| Best Use Case | Short-range RF applications, outdoor antennas | Long-distance data transmission | Networking in industrial settings |

Understanding RF over Fiber as an Alternative

RF over Fiber technology uses fiber optic cables to transmit RF signals. This method allows for extremely high bandwidth and low signal loss over long distances, making it ideal for applications that require high data rates and low latency, such as telecommunications and broadcasting. However, the initial investment can be significant, and the installation requires specialized knowledge to handle fiber optics safely. Additionally, while fiber optics are highly durable, they can be more susceptible to physical damage compared to traditional coaxial cables.

Evaluating Ethernet with Adapters

Ethernet cables paired with appropriate adapters can serve as an alternative for data transmission in environments where RF signals are not critical. This method is generally cost-effective, especially for businesses that already have a wired network infrastructure in place. Ethernet is straightforward to install, and maintenance is minimal as long as the cabling is not exposed to environmental hazards. However, Ethernet cables have limitations in terms of RF signal transmission and might not support the same range of frequencies as SMA extension cables. This makes them less suitable for applications requiring robust RF connectivity, such as outdoor antennas or cellular networks.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between SMA extension cables and alternatives like RF over Fiber or Ethernet with adapters, B2B buyers must consider their specific operational requirements. If high-frequency RF performance and minimal signal loss are paramount, SMA extension cables are likely the best choice. Conversely, for applications needing extensive bandwidth over long distances, RF over Fiber could be more advantageous despite the higher costs and complexity. Lastly, for businesses seeking a cost-effective solution within existing infrastructure, Ethernet with adapters may suffice, provided the RF requirements are not stringent. Understanding these factors will ensure that businesses make informed decisions that align with their technical needs and budget constraints.

Essential Technical Properties and Trade Terminology for sma extension cable

What Are the Key Technical Properties of SMA Extension Cables?

SMA extension cables are essential components in various wireless applications, requiring a thorough understanding of their technical properties. Here are several critical specifications that B2B buyers should consider:

1. Coaxial Cable Type

The coaxial cable used in SMA extension cables significantly impacts performance. Common types include LMR-100, LMR-200, and LMR-400, which are double-shielded for low signal loss. The choice of coaxial cable type affects the attenuation over distance, with lower-loss cables providing better performance in longer runs. For businesses, selecting the right cable type ensures reliable signal transmission, crucial for maintaining operational efficiency.

2. Connector Gender and Configuration

SMA extension cables come with various connector configurations, such as SMA male to SMA female or SMA female to SMA female. Understanding the specific gender and orientation required for your application is vital for compatibility with existing equipment. This knowledge prevents costly installation errors and ensures seamless integration into existing systems.

3. Impedance

SMA connectors are designed for a 50-ohm impedance, which is standard for most RF applications. Matching the impedance of the SMA extension cable to that of the connected devices is essential to minimize signal reflections and losses. For B2B buyers, ensuring impedance compatibility helps maintain optimal system performance, particularly in high-frequency applications.

4. Torque Specifications

Torque ratings are critical for SMA connectors, indicating the optimal force applied during installation. Adhering to these specifications prevents damage to the connectors and ensures a secure connection. For businesses, understanding torque specifications can lead to fewer maintenance issues and enhanced reliability in field operations.

5. Environmental Durability

SMA extension cables are often exposed to various environmental conditions, making durability a key property. Cables with robust outer jackets (commonly made from PVC or similar materials) can withstand harsh weather, UV radiation, and physical stress. For international buyers, especially in regions like Africa or South America, selecting durable cables reduces replacement frequency and overall maintenance costs.

6. Length Options

SMA extension cables are available in various lengths, typically ranging from a few inches to over 150 feet. It’s essential for buyers to consider the required length for their specific applications, as longer cables can introduce additional signal loss. Understanding the trade-off between length and performance is crucial for achieving the desired system effectiveness.

What Are Common Trade Terms Related to SMA Extension Cables?

In the B2B landscape, familiarity with specific jargon can enhance communication and negotiation. Here are several key terms relevant to SMA extension cables:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s product. In the context of SMA extension cables, OEMs may provide tailored cables for specific devices, ensuring compatibility and performance.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of products a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory and cash flow effectively, especially when sourcing SMA extension cables from international suppliers.

3. RFQ (Request for Quotation)

An RFQ is a formal document requesting pricing and terms from suppliers. For businesses looking to procure SMA extension cables, issuing an RFQ can streamline the purchasing process and ensure competitive pricing.

4. Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and responsibilities associated with purchasing SMA extension cables from global suppliers.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. Knowing the lead time for SMA extension cables is essential for project planning and ensuring timely deployment of communication systems.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when procuring SMA extension cables, enhancing operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the sma extension cable Sector

What Are the Current Trends Driving the SMA Extension Cable Market?

The SMA extension cable market is experiencing significant growth, driven by the global demand for robust wireless communication solutions. Key drivers include the rapid expansion of 5G networks, which require high-quality, low-loss coaxial cables to ensure optimal signal strength over longer distances. Additionally, the increasing adoption of IoT devices across various industries—from agriculture to telecommunications—further propels the need for versatile SMA extension cables that can support a variety of wireless protocols, including Wi-Fi, GPS, and RFID.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing high-performance cables that can withstand harsh environmental conditions. Emerging trends include a shift towards custom lengths and configurations, allowing businesses to meet specific operational requirements. Furthermore, buyers are prioritizing suppliers who offer transparency in their manufacturing processes and supply chains, reflecting a growing demand for reliability and quality assurance.

In terms of market dynamics, competition is intensifying, leading suppliers to innovate continuously. Many companies are investing in advanced manufacturing techniques to enhance cable durability and reduce signal loss. As a result, international buyers are encouraged to evaluate not only the technical specifications of SMA extension cables but also the reputation and certifications of the manufacturers they engage with.

How Is Sustainability Shaping the Sourcing of SMA Extension Cables?

Sustainability is becoming a critical factor in the sourcing of SMA extension cables. B2B buyers are increasingly aware of the environmental impacts associated with cable production, including the depletion of natural resources and waste generation. Consequently, there is a pressing need for suppliers to adopt ethical sourcing practices and implement sustainable manufacturing processes.

One way suppliers are addressing these concerns is by utilizing eco-friendly materials and adopting certifications that demonstrate their commitment to sustainability. Buyers should look for cables that feature recyclable or biodegradable components, as well as those that come with certifications such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment). These certifications ensure that the products comply with environmental standards and are produced with minimal ecological impact.

Additionally, ethical supply chains are gaining traction, with companies being held accountable for their labor practices and sourcing methods. Buyers are encouraged to partner with manufacturers who prioritize fair labor practices and maintain transparency regarding their supply chains. This not only enhances brand reputation but also contributes to a more sustainable and responsible industry overall.

What Is the Historical Context of SMA Extension Cables for B2B Buyers?

The evolution of SMA extension cables dates back to the development of RF (radio frequency) connectors in the mid-20th century. Originally designed for military and aerospace applications, SMA connectors were introduced as a compact and reliable solution for microwave signals. Over the years, advancements in materials and manufacturing techniques have led to the widespread adoption of SMA extension cables in commercial and industrial sectors.

As wireless technology advanced, particularly with the advent of cellular networks and satellite communications, the need for high-performance coaxial cables became paramount. The introduction of low-loss coaxial designs revolutionized the market, allowing for longer distances without significant signal degradation. Today, SMA extension cables are integral to various applications, including telecommunications, GPS, and industrial automation, making them an essential component for B2B buyers seeking reliable communication solutions.

In summary, understanding the market dynamics, sustainability trends, and historical context of SMA extension cables equips international B2B buyers with valuable insights to make informed sourcing decisions. This knowledge enables them to select high-quality products that meet their operational needs while aligning with ethical and environmental standards.

Frequently Asked Questions (FAQs) for B2B Buyers of sma extension cable

-

How do I solve signal loss issues with SMA extension cables?

Signal loss can occur due to cable length and quality. To minimize this, select high-quality, low-loss coaxial cables such as LMR-100 or LMR-400 equivalents, which are designed to reduce attenuation. Additionally, ensure that connections are secure and use appropriate torque settings during installation to avoid over-tightening or loosening connectors, which can also lead to signal degradation. -

What is the best SMA extension cable for outdoor use?

For outdoor applications, choose SMA extension cables that are rated for all climates and conditions. Look for cables with a durable outer jacket, such as PVC or polyethylene, which can withstand environmental stresses. Double-shielded designs are preferable as they provide additional protection against moisture and physical wear, ensuring reliable performance in harsh weather. -

What customization options are available for SMA extension cables?

Many suppliers offer customization options for SMA extension cables, including cable length, connector types, and materials. You can specify the desired length from a range of options and request specific connector configurations, such as SMA male to female or right-angled connectors. Discuss your requirements with suppliers to ensure they can meet your unique application needs. -

What is the minimum order quantity (MOQ) for SMA extension cables?

The minimum order quantity (MOQ) for SMA extension cables varies by supplier. Typically, MOQs can range from a few units to several hundred, depending on the manufacturer and the specific cable configuration. It is advisable to contact potential suppliers directly to understand their MOQ policies and whether they can accommodate smaller orders, especially if you are a new buyer. -

How can I vet suppliers for SMA extension cables?

To vet suppliers effectively, assess their industry reputation, certifications, and customer reviews. Check if they have ISO certifications, which indicate adherence to quality standards. Request samples to evaluate the quality of their cables and inquire about their manufacturing processes. Engaging with previous customers for references can also provide insights into their reliability and service. -

What payment terms are typically offered by suppliers of SMA extension cables?

Payment terms can vary widely among suppliers. Common terms include payment in advance, 30-day net terms, or letters of credit for larger orders. It’s crucial to clarify payment methods accepted, such as bank transfers or credit cards, and any applicable fees. Discussing these terms upfront can help avoid misunderstandings later in the purchasing process. -

What quality assurance measures should I expect from SMA extension cable suppliers?

Reputable suppliers will implement rigorous quality assurance (QA) measures, including material inspections, in-process testing, and final quality checks. They should provide documentation, such as test reports and compliance certificates, to verify that their cables meet industry standards. Inquire about their QA processes to ensure that you are sourcing reliable products that meet your performance expectations. -

How do logistics and shipping work for international orders of SMA extension cables?

When ordering SMA extension cables internationally, logistics arrangements depend on the supplier’s capabilities and your location. Discuss shipping options, estimated delivery times, and costs upfront. Many suppliers offer freight forwarding services, while others may require you to arrange shipping. Ensure that all customs documentation is handled properly to avoid delays in delivery and to ensure compliance with import regulations in your country.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Sma Extension Cable Manufacturers & Suppliers List

1. Data Alliance – SMA Cables & Adapters

Domain: data-alliance.net

Registered: 2004 (21 years)

Introduction: SMA Extension Cables, SMA Adapters to All RF Connector Types, SMA Right-Angle Cables & Adapters, SMA to MMCX Cables, SMA to N Cables & Adapters, SMA to U.FL Cables & Adapters, SMA to MHF4 Cables & Adapters, SMA male to SMA male cables, SMA female to SMA female cables, SMA to RP SMA Cables, SMA to FME Cables & Adapters, Dust Cover for SMA & RP-SMA-female.

2. NCD – RP-SMA Antenna Extension Cable

Domain: store.ncd.io

Registered: 2016 (9 years)

Introduction: RP-SMA Male/Female Antenna Extension Cable

3. Teltonika – PR2VM20M Antenna

Domain: teltonika-networks.com

Introduction: {‘Order_code’: ‘PR2VM20M’, ‘Connector_1’: ‘SMA (female)’, ‘Connector_2’: ‘SMA (male)’, ‘Cable_length’: ‘2000 mm’, ‘Frequency_range’: ‘0 – 6000 MHz’, ‘VSWR’: ‘1.35’, ‘Impedance’: ’50 Ω’, ‘Cable_attenuation’: ‘3.5 dB @ 2700 MHz’, ‘Operating_temperature’: ‘–55 °C ~ +155 °C’, ‘Working_voltage’: ‘335 Vmax’, ‘Withstand_voltage’: ‘1000 Vrms’, ‘Durability’: ‘≥ 500 cycles’, ‘Weight’: ’50 g’, ‘HS_Code’: ’85…

4. DataPro – SMA Antenna Extension Cable M-F

Domain: datapro.net

Registered: 1995 (30 years)

Introduction: Product Name: SMA Antenna Extension Cable M-F (Standard Polarity)

Categories: Wireless Antenna Cables

Description: Extend your wireless antenna cable with DataPro’s male to female SMA coaxial cable.

Available Lengths and Prices:

– 3 ft: $22.95 (1 in stock)

– 6 ft: $24.95 (54 in stock)

– 10 ft: $29.95 (2 in stock)

– 15 ft: $34.95 (10 in stock)

– 25 ft: $44.95 (22 in stock)

– Custom build: $22.95 + …

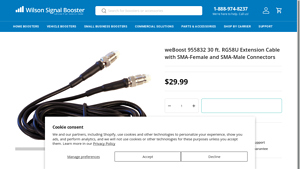

5. weBoost – 30 ft. RG58U Extension Cable

Domain: wilsonsignalbooster.com

Registered: 2012 (13 years)

Introduction: {‘name’: ‘weBoost 955832 30 ft. RG58U Extension Cable’, ‘price’: ‘$29.99’, ‘sku’: ‘955832’, ‘upc’: ‘811815023876’, ‘length’: ’30 feet’, ‘cable_type’: ‘RG-58’, ‘impedance’: ’50 ohm’, ‘connectors’: ‘SMA-Female to SMA-Male’, ‘compatible_boosters’: ‘Drive Reach Mobile, Fleet, RV, OTR, Extreme Marine, Drive X Mobile’, ‘warranty’: ‘2-Year Warranty’, ‘returns’: ’90-Day Returns’, ‘tech_support’: ‘Lifetime…

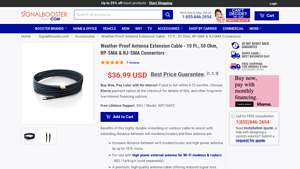

6. Signal Booster – Weather-Proof Antenna Extension Cable

Domain: signalbooster.com

Registered: 2003 (22 years)

Introduction: {“Product Name”: “Weather-Proof Antenna Extension Cable”, “Length”: “10 ft.”, “Impedance”: “50 Ohm”, “Connectors”: {“End 1”: “RP-SMA”, “End 2”: “RJ-SMA”}, “Price”: “$36.99 USD”, “Features”: [“Weatherproof construction”, “Reduced signal loss”, “Compatible with 802.11a/b/g/n Wi-Fi devices”, “Gold plated connectors”, “Flexible and malleable design for easy installation”], “Applications”: [“Extending …

Strategic Sourcing Conclusion and Outlook for sma extension cable

What Are the Key Benefits of Strategic Sourcing for SMA Extension Cables?

In conclusion, strategic sourcing of SMA extension cables is paramount for businesses aiming to enhance their wireless communication capabilities. By partnering with reputable suppliers who offer high-quality, low-loss coaxial cables, companies can ensure optimal signal strength and reliability, which are essential for applications ranging from cellular networking to satellite communications. The versatility and durability of these cables, combined with their compatibility across various technologies, make them a critical component in modern telecommunications infrastructure.

How Can International Buyers Optimize Their Sourcing Strategies?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the focus should be on selecting suppliers that not only provide robust products but also understand regional market dynamics and regulatory requirements. Engaging in strategic sourcing enables businesses to leverage better pricing, ensure quality compliance, and foster long-term supplier relationships that can adapt to evolving technological demands.

What Should Buyers Consider Moving Forward?

As the demand for advanced wireless solutions continues to grow, investing in quality SMA extension cables will be a key differentiator for businesses looking to stay competitive. We encourage you to explore partnerships that align with your operational needs and to consider the long-term benefits of a strategic sourcing approach. Start your journey towards enhanced connectivity and operational efficiency today by reaching out to trusted suppliers in the market.