R-32 Refrigerant Price: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for r-32 refrigerant price

In an increasingly competitive landscape, sourcing R-32 refrigerant at the right price poses a significant challenge for international B2B buyers. As a low global warming potential (GWP) refrigerant and a preferred alternative to R-410A, R-32 is recognized for its efficiency and environmental benefits. However, fluctuating prices and varying availability across different markets can complicate procurement strategies. This guide is designed to equip you with the insights needed to navigate the complexities of R-32 refrigerant pricing.

This comprehensive resource covers essential aspects of R-32 refrigerant, including its applications in HVAC systems, typical pricing structures, and strategies for vetting suppliers. We’ll delve into the various forms of R-32, its benefits, and how it compares to other refrigerants. Additionally, we’ll explore market trends and factors influencing costs, providing you with actionable insights to optimize your purchasing decisions.

Whether you operate in Africa, South America, the Middle East, or Europe, understanding the nuances of R-32 refrigerant pricing can significantly enhance your procurement strategy. By leveraging this guide, you will be empowered to make informed choices that not only meet your operational needs but also align with sustainability goals. Embrace the opportunity to enhance your supply chain efficiency and secure competitive pricing for R-32 refrigerant, ensuring your business remains at the forefront of the HVAC industry.

Understanding r-32 refrigerant price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bulk R-32 Refrigerant | Typically sold in large cylinders (20 lbs or more) | HVAC contractors, commercial refrigeration | Pros: Cost-effective for bulk purchases; Cons: Requires storage space and handling considerations. |

| Reclaimed R-32 Refrigerant | Recycled refrigerant, often less expensive | Environmental compliance, cost-sensitive projects | Pros: Lower cost; eco-friendly; Cons: May have limited availability and varying quality. |

| R-32 in Small Tanks | Smaller cylinders (5-10 lbs), portable | Residential HVAC, small business applications | Pros: Convenient and easy to handle; Cons: Higher per-pound cost compared to bulk. |

| R-32 Blends | Mixtures with other refrigerants for specific applications | Specialized HVAC systems, industrial cooling | Pros: Tailored performance; Cons: Complexity in handling and potential regulatory challenges. |

| R-32 with Compliance Features | Products designed to meet specific regulations (e.g., low GWP) | Regulatory-sensitive markets, green certifications | Pros: Meets stringent environmental standards; Cons: Potentially higher upfront costs. |

What Are the Characteristics of Bulk R-32 Refrigerant?

Bulk R-32 refrigerant is typically available in larger cylinders, often weighing 20 lbs or more. This type is favored by HVAC contractors and commercial refrigeration businesses due to its cost-effectiveness for high-volume needs. When purchasing, businesses should consider storage requirements and handling protocols, as the larger size can pose logistical challenges. Additionally, buyers benefit from lower per-pound pricing when buying in bulk, making it an attractive option for ongoing projects.

Why Choose Reclaimed R-32 Refrigerant?

Reclaimed R-32 refrigerant is a cost-effective alternative, as it is recycled from existing systems. This type appeals to businesses focused on environmental compliance and cost sensitivity. While it can offer significant savings, buyers must be mindful of potential quality variations and availability issues. Companies should also consider the certifications of the supplier to ensure they meet environmental regulations.

What Are the Advantages of R-32 in Small Tanks?

R-32 refrigerant in smaller tanks, typically ranging from 5 to 10 lbs, provides a portable solution ideal for residential HVAC applications and small business needs. This option is convenient for contractors who require mobility and ease of use on job sites. However, the trade-off is that the per-pound cost is generally higher than bulk purchases. Businesses should evaluate their specific needs to determine if the convenience justifies the price.

How Do R-32 Blends Work in Specialized Applications?

R-32 blends involve combining R-32 with other refrigerants to achieve specific performance characteristics tailored to particular applications. These blends are commonly used in specialized HVAC systems and industrial cooling setups. While they offer enhanced performance, buyers should be aware of the complexities involved in handling and potential regulatory challenges, especially in regions with strict environmental laws. Understanding the blend’s composition and its compatibility with existing systems is crucial for effective purchasing decisions.

What Are the Compliance Features of R-32 Products?

R-32 refrigerants designed with compliance features are tailored to meet specific environmental regulations, such as low global warming potential (GWP) standards. These products are increasingly sought after in markets that prioritize sustainability and green certifications. While they may come with a higher initial cost, the long-term benefits include compliance with evolving regulations and potential eligibility for incentives. Buyers should assess their market’s regulatory landscape to determine the best fit for their needs.

Key Industrial Applications of r-32 refrigerant price

| Industry/Sector | Specific Application of r-32 refrigerant price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC Systems | Used in air conditioning units and heat pumps | Improved energy efficiency and lower operational costs | Ensure compliance with local regulations and certifications |

| Refrigeration | Applied in commercial refrigeration systems | Enhanced cooling performance with lower GWP | Source from trusted suppliers with bulk availability |

| Automotive | Utilized in automotive air conditioning systems | Cost-effective and environmentally friendly | Verify compatibility with existing systems and components |

| Industrial Processes | Employed in chillers for industrial cooling | Reduces greenhouse gas emissions and energy usage | Assess logistics for safe transport and storage |

| Residential Cooling | Implemented in residential AC units | Provides effective cooling while minimizing costs | Evaluate supplier reliability and delivery timelines |

How is R-32 Refrigerant Price Used in HVAC Systems?

R-32 refrigerant is increasingly utilized in HVAC systems, especially in air conditioning units and heat pumps. Its application leads to improved energy efficiency, with potential savings of up to 12% compared to R-410A systems. For international buyers, particularly from regions like Africa and South America, sourcing R-32 requires understanding local regulations regarding refrigerants, ensuring that the products meet environmental standards. Additionally, buyers should consider suppliers that provide necessary fittings and tools for installation, as R-32 systems may require specific equipment.

What Role Does R-32 Refrigerant Price Play in Commercial Refrigeration?

In the commercial refrigeration sector, R-32 is favored for its effective cooling capabilities and reduced global warming potential (GWP). Businesses in the food and beverage industry can benefit from its application in refrigeration systems, leading to better product preservation and reduced energy costs. For B2B buyers in the Middle East and Europe, it is crucial to partner with suppliers that offer bulk purchasing options and ensure timely delivery, especially in regions with high demand for refrigeration solutions.

How is R-32 Refrigerant Price Relevant to Automotive Applications?

The automotive industry employs R-32 in air conditioning systems due to its efficiency and lower environmental impact. This refrigerant offers a more sustainable option for car manufacturers looking to meet stringent emissions regulations. Buyers in South America and Europe must confirm that R-32 is compatible with their existing systems, as well as verify supplier certifications to ensure quality and compliance with automotive standards.

Why is R-32 Refrigerant Price Important for Industrial Processes?

In industrial settings, R-32 is utilized in chillers for cooling processes, providing a significant advantage in reducing energy consumption and greenhouse gas emissions. Industries such as manufacturing and pharmaceuticals can leverage R-32 to enhance operational efficiency while adhering to environmental regulations. B2B buyers should evaluate the logistics of sourcing R-32, considering factors like safe transport and storage requirements, particularly in regions with stringent safety regulations.

How Does R-32 Refrigerant Price Affect Residential Cooling Solutions?

R-32 is increasingly being adopted in residential air conditioning units, offering homeowners effective cooling solutions with lower energy costs. Its application not only improves energy efficiency but also contributes to a smaller carbon footprint. For international buyers, particularly in developing markets, selecting a reliable supplier that can ensure consistent availability and support during installation is essential to maximizing the benefits of R-32 in residential applications.

3 Common User Pain Points for ‘r-32 refrigerant price’ & Their Solutions

Scenario 1: Fluctuating R-32 Refrigerant Prices Impacting Budgeting

The Problem: B2B buyers often face significant challenges with the volatile pricing of R-32 refrigerant. Fluctuations can occur due to various factors, such as supply chain disruptions, geopolitical tensions, or changes in regulatory standards. This unpredictability makes it difficult for HVAC contractors and distributors to accurately budget for refrigerant purchases, potentially leading to financial strain or project delays if costs exceed allocated budgets. For businesses operating in regions like Africa or South America, where economic conditions can be unstable, this volatility can be particularly pronounced.

The Solution: To mitigate the impact of fluctuating prices, B2B buyers should adopt a proactive sourcing strategy. This includes establishing long-term relationships with multiple suppliers to create a competitive landscape for pricing. Additionally, buyers can consider locking in prices through contracts that include fixed pricing for a specified duration. Engaging in bulk purchasing can also provide leverage for negotiating better rates. Utilizing online platforms that offer volume discounts and price tracking can help buyers stay informed about market trends and make timely purchasing decisions. By implementing these strategies, businesses can better manage their budgets and reduce the risks associated with price volatility.

Scenario 2: Understanding the Total Cost of Ownership for R-32 Refrigerant

The Problem: Many B2B buyers focus solely on the upfront price of R-32 refrigerant without considering the total cost of ownership (TCO). This oversight can lead to unexpected expenses related to maintenance, system compatibility, and energy efficiency. For example, if a buyer selects a cheaper refrigerant that is not compatible with their existing systems, they may incur additional costs for system retrofits or replacements, which can outweigh initial savings.

The Solution: To address this issue, buyers should conduct a comprehensive analysis of the total cost of ownership before making a purchase. This analysis should include not only the purchase price of R-32 refrigerant but also factors such as installation costs, energy efficiency ratings, and potential savings over time. Buyers should collaborate with HVAC engineers to assess the compatibility of R-32 with their existing systems and evaluate the long-term benefits of using a refrigerant with lower global warming potential (GWP). By taking a holistic approach to purchasing decisions, businesses can ensure they invest in refrigerants that provide both economic and environmental advantages.

Scenario 3: Compliance with Regulatory Standards for R-32 Refrigerant

The Problem: Navigating the complex regulatory landscape surrounding refrigerants can be a significant pain point for B2B buyers. Regulations regarding the use of R-32 refrigerant can vary widely by region and may change over time. For instance, certain jurisdictions may impose restrictions or bans on specific refrigerants due to environmental concerns. This uncertainty can complicate sourcing decisions and lead to potential non-compliance penalties.

The Solution: To stay compliant, B2B buyers must remain informed about the latest regulatory developments in their respective markets. This can be achieved by subscribing to industry newsletters, attending relevant trade shows, and engaging with professional associations focused on HVAC and refrigerant standards. Additionally, working closely with suppliers who are knowledgeable about compliance issues can provide valuable insights and ensure that the refrigerants being purchased meet local regulations. Buyers should also consider investing in training programs for their staff to ensure they are well-versed in the legal requirements associated with refrigerant handling and usage. By prioritizing compliance, businesses can avoid costly fines and maintain a positive reputation in the market.

Strategic Material Selection Guide for r-32 refrigerant price

What Are the Key Materials for R-32 Refrigerant Applications?

When considering the selection of materials for R-32 refrigerant systems, several factors come into play, including performance, durability, cost, and compliance with international standards. Here, we analyze four common materials used in R-32 applications: copper, aluminum, stainless steel, and plastic. Each material has unique properties that influence its suitability for various HVAC systems.

How Does Copper Perform with R-32 Refrigerant?

Copper is a widely used material in HVAC applications due to its excellent thermal conductivity and corrosion resistance. It can withstand high pressures, making it suitable for refrigerant lines. Copper’s temperature rating typically ranges from -40°C to 150°C, which is adequate for most HVAC applications involving R-32.

Pros: Copper offers durability and reliability, with a long service life. Its high thermal conductivity enhances system efficiency, reducing energy costs.

Cons: The primary drawback is its cost, which can be higher than alternatives like aluminum. Additionally, copper systems require careful installation to prevent leaks, and they are susceptible to corrosion in certain environments.

Impact on Application: Copper is highly compatible with R-32, but its use may require specific brazing techniques to ensure optimal performance and prevent leaks.

Considerations for International Buyers: Compliance with standards such as ASTM B280 for copper tubing is crucial. Buyers should also consider local regulations regarding refrigerant handling and installation practices.

Why Choose Aluminum for R-32 Refrigerant Systems?

Aluminum is another common material used in HVAC systems due to its lightweight nature and good corrosion resistance. It has a lower temperature rating than copper, typically around -30°C to 120°C, which can limit its use in certain applications.

Pros: Aluminum is generally less expensive than copper, making it an attractive option for cost-sensitive projects. Its lightweight nature simplifies installation and reduces shipping costs.

Cons: While aluminum is corrosion-resistant, it can be less durable than copper, particularly under high-pressure conditions. It also has lower thermal conductivity, which may impact system efficiency.

Impact on Application: Aluminum is compatible with R-32, but care must be taken to ensure proper fittings and connections to prevent leaks.

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum extrusions is essential. Buyers should also be aware of local preferences for material selection based on climate and application.

What Are the Benefits of Using Stainless Steel with R-32 Refrigerant?

Stainless steel is known for its exceptional corrosion resistance and strength, making it suitable for high-pressure applications. It has a temperature rating similar to copper, allowing it to perform well in various HVAC systems.

Pros: The durability of stainless steel leads to a longer lifespan and reduced maintenance costs. Its resistance to corrosion makes it ideal for applications in humid or corrosive environments.

Cons: Stainless steel is typically more expensive than both copper and aluminum, which can impact project budgets. Additionally, it is heavier, which may complicate installation.

Impact on Application: Stainless steel is compatible with R-32 and can handle the pressures and temperatures associated with modern HVAC systems.

Considerations for International Buyers: Compliance with standards such as ASTM A312 for stainless steel pipes is important. Buyers should also consider the availability of skilled labor for installation.

How Do Plastics Fit into R-32 Refrigerant Applications?

Plastic materials, such as polyvinyl chloride (PVC) and polyethylene (PE), are increasingly used in HVAC systems, particularly for insulation and non-pressurized applications. They are lightweight and resistant to corrosion.

Pros: Plastics are cost-effective and easy to handle, making them suitable for various applications. Their insulation properties can enhance system efficiency.

Cons: Plastics generally have lower temperature and pressure ratings compared to metals, which limits their use in high-pressure refrigerant lines. They may also degrade over time when exposed to UV light.

Impact on Application: While plastics can be used in conjunction with R-32 systems, they are typically limited to non-pressurized components or insulation.

Considerations for International Buyers: Compliance with standards such as ASTM D1784 for PVC is necessary. Buyers should also evaluate the environmental impact of plastic materials in their specific regions.

Summary Table of Material Selection for R-32 Refrigerant

| Material | Typical Use Case for r-32 refrigerant price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Refrigerant lines and coils | Excellent thermal conductivity | Higher cost and installation complexity | High |

| Aluminum | Lightweight components and ducts | Cost-effective and lightweight | Lower durability and thermal conductivity | Medium |

| Stainless Steel | High-pressure applications | Exceptional corrosion resistance | Higher cost and heavier weight | High |

| Plastic | Insulation and non-pressurized applications | Cost-effective and easy to handle | Limited temperature/pressure rating | Low |

This analysis provides international B2B buyers with actionable insights into material selection for R-32 refrigerant systems, helping to ensure compliance and performance in diverse applications across various regions.

In-depth Look: Manufacturing Processes and Quality Assurance for r-32 refrigerant price

What Are the Main Stages in the Manufacturing Process of R-32 Refrigerant?

The manufacturing process of R-32 refrigerant involves several critical stages, ensuring that the final product meets industry standards for performance and safety.

-

Material Preparation: The primary raw material for R-32 is difluoromethane (R-32), which is sourced through a series of chemical processes. Manufacturers begin by selecting high-purity chemicals to minimize impurities that could affect the refrigerant’s performance. This stage often involves the distillation of raw materials to achieve the desired purity levels.

-

Forming: In this stage, the prepared materials undergo chemical reactions in controlled environments. Typically, the synthesis of R-32 involves fluorination processes, where the raw materials are reacted with fluorine gas under specific temperature and pressure conditions. This requires specialized equipment to handle the reactive substances safely and efficiently.

-

Assembly: After synthesis, R-32 is transferred to storage tanks. Here, it is blended with other refrigerants if necessary, although R-32 is primarily a single-component refrigerant. The assembly stage also includes filling cylinders or containers, which are often done in automated facilities to ensure precision and reduce the risk of contamination.

-

Finishing: The final stage involves packaging and labeling the refrigerant cylinders. This includes adding safety labels in compliance with international regulations. Proper labeling is essential for transportation and handling, ensuring that users are aware of the refrigerant’s properties and safety measures.

How Do Quality Assurance Processes Ensure the Reliability of R-32 Refrigerant?

Quality assurance (QA) is a cornerstone of the manufacturing process for R-32 refrigerant, ensuring that each batch produced meets stringent performance and safety standards.

-

International Standards: Manufacturers often adhere to ISO 9001, which sets out criteria for a quality management system. Compliance with this standard demonstrates the manufacturer’s commitment to quality and continuous improvement. Additionally, industry-specific standards such as CE marking in Europe and API standards in the U.S. further enforce quality and safety benchmarks.

-

Quality Control Checkpoints: Throughout the manufacturing process, several quality control checkpoints are established:

– Incoming Quality Control (IQC): This involves inspecting raw materials before production to ensure they meet the required specifications.

– In-Process Quality Control (IPQC): During manufacturing, samples are taken at various stages to monitor consistency and quality.

– Final Quality Control (FQC): Before packaging, final tests are conducted to verify that the refrigerant meets all specifications, including purity, pressure, and other physical properties. -

Common Testing Methods: Testing methods for R-32 refrigerant typically include gas chromatography for purity analysis, pressure testing for leak detection, and flammability tests to assess safety. These tests ensure that the refrigerant performs efficiently and safely in HVAC systems.

How Can B2B Buyers Verify the Quality Control Measures of R-32 Suppliers?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is crucial.

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing practices and quality assurance processes. Audits should focus on compliance with international standards and specific industry regulations.

-

Quality Assurance Reports: Requesting detailed QA reports from suppliers can help B2B buyers assess the effectiveness of their quality control measures. These reports should include information on testing results, quality metrics, and any corrective actions taken in response to non-conformance.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s facilities and products. These inspections typically involve checking compliance with relevant standards and verifying that the manufacturing processes adhere to established protocols.

What Are the Quality Control and Certification Nuances for International Buyers?

International B2B buyers face unique challenges when sourcing R-32 refrigerant due to varying regulations and certification requirements in different regions.

-

Regulatory Compliance: Different countries have specific regulations governing the use and sale of refrigerants. For example, the European Union has stringent regulations regarding the environmental impact of refrigerants, which may affect pricing and availability. Buyers must ensure that their suppliers comply with these regulations to avoid penalties and ensure market access.

-

Certification Requirements: Certifications such as ISO 14001 for environmental management can be particularly relevant for buyers focused on sustainability. Suppliers with these certifications demonstrate a commitment to reducing their environmental footprint, which can be a significant selling point in markets with strong environmental regulations.

-

Documentation and Traceability: Buyers should prioritize suppliers that provide comprehensive documentation for their products, including certificates of analysis (COA) and material safety data sheets (MSDS). These documents ensure traceability and provide critical information about the refrigerant’s properties, safety, and compliance with regulations.

Conclusion: Making Informed Decisions on R-32 Refrigerant Sourcing

For international B2B buyers, understanding the manufacturing processes and quality assurance protocols for R-32 refrigerant is essential for making informed sourcing decisions. By focusing on suppliers with robust quality control measures, adherence to international standards, and proven track records, buyers can secure reliable products that meet their operational needs while ensuring compliance with regional regulations. Engaging in thorough audits, requesting detailed quality reports, and considering third-party inspections will further strengthen the buyer’s position in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘r-32 refrigerant price’

To assist international B2B buyers in effectively sourcing R-32 refrigerant, this checklist outlines essential steps to ensure a successful procurement process. With R-32 being a preferred choice for modern HVAC applications due to its efficiency and reduced environmental impact, following this guide will help you make informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for sourcing the right R-32 refrigerant. Consider factors such as the refrigerant’s purity, compatibility with existing systems, and specific applications (e.g., heat pumps, chillers). This clarity will help you communicate effectively with suppliers and ensure that the products meet your operational needs.

Step 2: Research Market Pricing Trends

Understanding current market pricing trends for R-32 refrigerant is vital. Prices can fluctuate based on regional demand, supply chain factors, and regulatory changes. Utilize online resources, industry reports, and pricing databases to gather insights. This knowledge empowers you to negotiate better deals and avoid overpaying.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. Request detailed company profiles, product certifications, and customer testimonials. Look for suppliers with a proven track record in your region, as local knowledge can significantly impact service quality and delivery times.

- Check Industry Experience: Suppliers with extensive experience in refrigerants are more likely to understand your specific needs and provide reliable products.

- Examine Compliance: Ensure that the supplier adheres to local regulations and international standards for refrigerants.

Step 4: Request Samples and Technical Data Sheets

Obtaining samples and technical data sheets from potential suppliers is a critical step in the evaluation process. Samples allow you to assess the refrigerant’s quality firsthand, while technical data sheets provide essential information on handling, safety, and performance characteristics.

- Review Safety Protocols: Understanding the safety measures associated with R-32 will help you ensure compliance in your operations.

- Analyze Performance Metrics: Look for data that showcases the efficiency and efficacy of the refrigerant in various applications.

Step 5: Negotiate Terms and Conditions

Once you have selected a supplier, it’s time to negotiate the terms and conditions of the purchase. Discuss pricing, payment terms, delivery schedules, and any volume discounts available. Clear agreements can prevent misunderstandings and ensure timely delivery.

- Consider Long-term Relationships: If you plan to purchase regularly, explore options for establishing a long-term partnership, which can lead to better pricing and service.

Step 6: Verify Logistics and Distribution Capabilities

Assess the logistics and distribution capabilities of your chosen supplier. Ensure they can meet your delivery timelines and have the capacity to handle orders of your size.

- Check for Local Availability: Suppliers with local warehouses can often provide faster delivery times, reducing downtime for your operations.

- Understand Shipping Regulations: Familiarize yourself with any import/export regulations related to refrigerants in your region to avoid delays.

Step 7: Monitor Post-Purchase Support and Feedback

After the purchase, maintain communication with your supplier regarding post-purchase support. Monitor the performance of the R-32 refrigerant in your systems and provide feedback to the supplier. This collaboration can lead to improved service and product offerings in the future.

By following this checklist, B2B buyers can navigate the complexities of sourcing R-32 refrigerant effectively, ensuring they make informed decisions that align with their business needs.

Comprehensive Cost and Pricing Analysis for r-32 refrigerant price Sourcing

What Are the Key Cost Components in R-32 Refrigerant Pricing?

When analyzing the pricing of R-32 refrigerant, it is essential to understand the various cost components involved in its production and distribution. The primary factors include:

-

Materials: The cost of raw materials for R-32 refrigerant is influenced by global supply chain dynamics. Being a single-component refrigerant, R-32 benefits from a more straightforward sourcing process compared to blends, potentially reducing costs.

-

Labor: Labor costs are incurred during the manufacturing process, including skilled technicians for production and quality control. Regions with lower labor costs can provide competitive pricing but may affect product quality.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility management. Efficient manufacturing processes can lower these overhead costs, allowing suppliers to offer more competitive prices.

-

Tooling: Specialized equipment for filling and packaging R-32 refrigerant can add to the initial investment. Suppliers with optimized tooling processes may pass these savings onto buyers.

-

Quality Control (QC): Rigorous QC processes ensure that R-32 meets regulatory standards and performance specifications. While these processes add to costs, they are critical for maintaining compliance, especially in markets with strict environmental regulations.

-

Logistics: Transportation and storage costs can vary significantly based on the supplier’s location and the buyer’s destination. For international buyers, understanding Incoterms and associated freight charges is crucial for total cost calculations.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This margin can fluctuate based on competition and market demand.

How Do Price Influencers Affect R-32 Refrigerant Costs?

Several factors influence the pricing of R-32 refrigerant, and understanding these can help buyers make informed purchasing decisions:

-

Volume/MOQ: Bulk purchasing often leads to discounts. Buyers looking to source R-32 in larger quantities should negotiate minimum order quantities (MOQ) to secure better pricing.

-

Specifications and Customization: Custom specifications can lead to higher costs. Standardized products are generally cheaper, so buyers should assess whether customization is necessary for their applications.

-

Materials and Quality Certifications: Suppliers offering higher-quality materials and certifications (like ISO or environmental certifications) may charge a premium. Buyers should weigh the benefits of certified products against their costs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers might charge more due to their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding the terms of shipping and handling is vital. Incoterms dictate who bears the costs and risks during transportation. Buyers should clarify these terms to avoid unexpected expenses.

What Are Some Essential Buyer Tips for Sourcing R-32 Refrigerant?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially if purchasing in bulk. Leverage competitive quotes from multiple suppliers to secure favorable terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs, including maintenance, efficiency, and disposal. R-32 is known for its energy efficiency, which can lead to lower operational costs over time.

-

Be Aware of Pricing Nuances: Different regions may experience price fluctuations due to local regulations, tariffs, or market demand. Buyers should stay informed about the market conditions in their respective regions.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing, priority service, and access to new products or technologies.

Disclaimer on Pricing Information

Pricing for R-32 refrigerant can vary widely based on numerous factors, including market conditions, supplier pricing strategies, and regional regulations. The prices mentioned in this analysis are indicative and may not reflect current market rates. Buyers are encouraged to conduct thorough market research and obtain multiple quotes before making purchasing decisions.

Alternatives Analysis: Comparing r-32 refrigerant price With Other Solutions

Exploring Alternatives to R-32 Refrigerant Pricing

In today’s competitive HVAC landscape, businesses are increasingly seeking sustainable and cost-effective refrigerant solutions. R-32 has emerged as a popular choice due to its efficiency and lower global warming potential (GWP). However, it’s essential for B2B buyers to consider alternative refrigerants and technologies that may meet their needs more effectively or economically. Below, we compare R-32 refrigerant pricing with two viable alternatives: R-410A and R-454B.

| Comparison Aspect | R-32 Refrigerant Price | R-410A | R-454B |

|---|---|---|---|

| Performance | Up to 12% more efficient than R-410A | Good performance, but less efficient than R-32 | Comparable efficiency to R-32 with lower GWP |

| Cost | Approximately $319 for 20 lbs | Approximately $420 for 20 lbs | Approximately $449 for 20 lbs |

| Ease of Implementation | Requires specific fittings and tools | Widely compatible with existing systems | May require new equipment for optimal performance |

| Maintenance | Moderate maintenance; trained personnel needed | Established maintenance practices | Similar maintenance needs as R-32 |

| Best Use Case | Ideal for new installations and retrofits | Common in existing systems; good for replacements | Suited for those prioritizing low GWP solutions |

In-Depth Look at Alternatives

R-410A

R-410A is a widely used refrigerant that has been a standard in the HVAC industry for many years. While it is effective for cooling and heating applications, it has a higher GWP than R-32. This makes it less favorable in terms of environmental impact. The initial cost of R-410A is higher, averaging around $420 for a 20 lb cylinder, which can affect overall project budgets. However, R-410A is compatible with many existing systems, making it easier for businesses with older equipment to replace refrigerants without needing significant system modifications.

R-454B

R-454B is considered a next-generation refrigerant that offers a balance between performance and environmental responsibility. Its GWP is lower than that of R-410A, making it a more sustainable option. Pricing for R-454B is typically around $449 for a 20 lb cylinder. While it offers similar efficiency to R-32, the implementation may require new equipment or system modifications, which can add to upfront costs. R-454B is an excellent choice for businesses looking to future-proof their operations while reducing their carbon footprint.

Making the Right Choice for Your Business

When evaluating refrigerant options, B2B buyers must assess their unique operational needs, budget constraints, and long-term sustainability goals. R-32 may present a compelling value proposition for new installations due to its efficiency and lower cost compared to R-410A. However, businesses currently using R-410A may find it more convenient to continue with it, especially if they have existing infrastructure designed for this refrigerant. On the other hand, R-454B is an attractive alternative for those focused on minimizing environmental impact, albeit at a slightly higher price point.

Ultimately, the choice between R-32, R-410A, and R-454B should align with your company’s operational strategy, environmental commitments, and budgetary considerations. By carefully analyzing these aspects, you can make a well-informed decision that supports your business objectives while ensuring compliance with evolving regulations.

Essential Technical Properties and Trade Terminology for r-32 refrigerant price

What Are the Key Technical Properties of R-32 Refrigerant and Their Importance to B2B Buyers?

Understanding the technical specifications of R-32 refrigerant is crucial for B2B buyers in the HVAC and refrigeration sectors. Here are some key properties that decision-makers should be aware of:

-

Global Warming Potential (GWP)

– R-32 has a GWP of 675, making it a low-GWP refrigerant compared to its predecessor, R-410A, which has a GWP of 2088. This property is critical for companies aiming to comply with international environmental regulations and sustainability goals. The lower GWP also translates to lower carbon taxes in regions where such policies are enforced, affecting overall cost-effectiveness. -

Efficiency Rating

– R-32 is known for its superior energy efficiency, reportedly up to 12% more efficient than R-410A in cooling applications. This efficiency not only leads to reduced operational costs but also enhances the performance of HVAC systems, making it a more attractive option for contractors and end-users alike. -

Flammability Classification

– Classified as an A2L refrigerant, R-32 is mildly flammable. This characteristic necessitates specific safety protocols during storage, handling, and installation. B2B buyers must ensure that their personnel are trained in handling such refrigerants and that their equipment is compliant with relevant safety standards, impacting both procurement and operational procedures. -

Single Component Refrigerant

– R-32 is a pure refrigerant, meaning it is a single-component substance. This property simplifies the charging and recharging process, as there is no need to mix different refrigerants. For businesses, this translates to reduced training requirements and fewer chances for errors during maintenance, making R-32 a more user-friendly option. -

Refrigerant Type: HFO

– R-32 is categorized as a hydrofluoroolefin (HFO), which indicates it is part of a newer generation of refrigerants designed to have less environmental impact. This classification can influence purchasing decisions, as many companies are seeking to transition to more eco-friendly alternatives. -

Compatibility with Existing Systems

– R-32 is compatible with a wide range of HVAC systems, including mini-splits and heat pumps, which facilitates its adoption. Businesses looking to upgrade or retrofit existing systems can consider R-32 without significant modifications, thus minimizing downtime and costs.

What Are Common Trade Terms Related to R-32 Refrigerant Pricing?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several key terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of R-32, an OEM might provide HVAC systems specifically designed to utilize this refrigerant. Understanding OEM relationships can help buyers gauge the reliability and quality of their equipment. -

MOQ (Minimum Order Quantity)

– This term refers to the smallest number of units a supplier is willing to sell. For R-32 refrigerants, knowing the MOQ can affect procurement strategies, especially for businesses looking to manage inventory costs effectively. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to invite them to submit price proposals for specific quantities of goods or services. B2B buyers should utilize RFQs to gather competitive pricing for R-32 refrigerants, ensuring they receive the best possible deal. -

Incoterms (International Commercial Terms)

– These are a set of pre-defined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Understanding Incoterms is crucial for B2B buyers to assess delivery costs and risks associated with transporting R-32 refrigerants across borders. -

Lead Time

– This term refers to the amount of time between placing an order and receiving the goods. For businesses relying on R-32, knowing the lead time can help in planning inventory levels and ensuring timely project execution. -

Freight Forwarding

– This involves the coordination of shipping goods from one place to another. For international buyers of R-32, understanding freight forwarding services can optimize logistics and reduce costs associated with transportation and customs clearance.

By grasping these essential properties and trade terminologies, B2B buyers can make informed decisions regarding R-32 refrigerant purchases, ensuring they meet their operational and environmental goals effectively.

Navigating Market Dynamics and Sourcing Trends in the r-32 refrigerant price Sector

What Are the Key Market Dynamics Influencing R-32 Refrigerant Prices?

The R-32 refrigerant market is currently experiencing significant growth, driven by several global factors. The transition towards low global warming potential (GWP) refrigerants, prompted by international climate agreements and regulations, is a primary driver. R-32, recognized for its reduced environmental impact compared to traditional refrigerants like R-410A, is gaining traction across various regions, particularly in emerging markets such as Africa, South America, and Southeast Asia. These regions are witnessing rapid urbanization and an increasing demand for efficient cooling solutions, which further propels the adoption of R-32.

In terms of sourcing trends, digitalization is reshaping the procurement landscape. B2B buyers are increasingly leveraging e-commerce platforms for sourcing refrigerants, facilitating easier access to competitive pricing and bulk purchasing options. The integration of supply chain technologies, such as blockchain and IoT, is also enhancing transparency and efficiency, allowing buyers to track the provenance and quality of their refrigerants. Moreover, the market is seeing a growing emphasis on supplier reliability and service quality, with buyers prioritizing suppliers who can offer timely delivery and robust after-sales support.

How Is Sustainability Influencing B2B Sourcing of R-32 Refrigerant?

The environmental impact of refrigerants is a pressing concern in today’s market. R-32 is lauded for its lower GWP, making it a preferred choice for businesses aiming to reduce their carbon footprint. As a result, B2B buyers are increasingly prioritizing sustainability in their sourcing decisions. This trend is not merely a regulatory requirement; it has become a vital component of corporate social responsibility initiatives. Companies are now seeking suppliers who can demonstrate commitment to ethical sourcing practices and sustainability certifications.

Ethical supply chains are crucial, as they ensure that the refrigerants are produced and distributed in a manner that minimizes environmental harm. Buyers should look for suppliers with recognized certifications, such as ISO 14001 for environmental management, which indicate adherence to sustainable practices. Additionally, the demand for ‘green’ refrigerants is prompting suppliers to innovate and invest in cleaner technologies, further enhancing the appeal of R-32 in the marketplace. By choosing R-32, businesses not only comply with environmental regulations but also position themselves as leaders in sustainability within their respective industries.

What Is the Evolution of R-32 Refrigerant in the B2B Market?

The evolution of R-32 as a refrigerant has been marked by its introduction as a low-GWP alternative to R-410A in the early 2010s. Initially adopted in Japan, R-32 has since expanded its footprint globally, with over 230 countries now utilizing it in various HVAC applications. Its efficiency—up to 12% greater than R-410A—combined with its lower environmental impact, has made it a preferred choice for manufacturers and contractors alike.

As regulations surrounding refrigerants become more stringent, the demand for R-32 is expected to continue growing. This shift is particularly relevant for international B2B buyers, as they navigate the complexities of compliance and sustainability in their procurement processes. The trend towards R-32 reflects a broader move within the HVAC industry to embrace more environmentally friendly technologies, which is likely to shape the market for years to come.

In conclusion, understanding these market dynamics, sustainability considerations, and the historical context of R-32 will empower B2B buyers to make informed sourcing decisions that align with their business objectives and environmental commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of r-32 refrigerant price

-

How do I determine the current price of R-32 refrigerant?

To find the current price of R-32 refrigerant, you can visit reputable suppliers’ websites that specialize in refrigerants. Prices can vary significantly based on location, supplier, and the quantity purchased. For bulk orders, many suppliers offer volume discounts, so it’s advisable to request quotes from multiple vendors to compare pricing. Additionally, consider checking local regulations, as they may affect availability and pricing in your region. -

What factors affect the price of R-32 refrigerant?

The price of R-32 refrigerant is influenced by several factors, including supply and demand dynamics, shipping costs, and local market conditions. Additionally, variations in import tariffs and regulations in different countries can impact pricing. Seasonal demand fluctuations in HVAC systems may also affect prices, particularly during peak installation periods. Always consider the long-term cost-effectiveness of R-32 as a low-GWP alternative compared to older refrigerants. -

What is the minimum order quantity (MOQ) for R-32 refrigerant?

Minimum order quantities for R-32 refrigerant can vary significantly among suppliers. Typically, MOQs may range from a single cylinder to several hundred pounds, depending on the supplier’s policies and your location. For larger projects or businesses, negotiating a favorable MOQ can lead to better pricing and terms. Always clarify MOQs with potential suppliers before placing an order to ensure it aligns with your purchasing capabilities. -

How can I vet suppliers of R-32 refrigerant?

To effectively vet suppliers, start by checking their reputation within the industry. Look for reviews and testimonials from other B2B buyers. Verify their compliance with international regulations regarding refrigerant sales, including proper licensing and certifications. It’s also beneficial to ask for references and inquire about their sourcing practices to ensure they provide high-quality products. Establishing a relationship with suppliers who prioritize transparency and customer service is crucial for long-term partnerships. -

What payment terms should I expect when purchasing R-32 refrigerant?

Payment terms for R-32 refrigerant can vary widely among suppliers. Common terms include upfront payment, net 30, or net 60 days. Some suppliers may offer discounts for early payment or bulk purchases. It’s essential to discuss payment options during negotiations to find a mutually agreeable arrangement. Ensure that payment terms align with your cash flow and budgeting strategies, especially if you’re sourcing large quantities. -

Are there any special considerations for shipping R-32 refrigerant internationally?

Shipping R-32 refrigerant internationally requires careful attention to regulations governing hazardous materials. Ensure that your supplier complies with all shipping regulations, including proper labeling and documentation. Depending on your destination, customs clearance procedures may apply, which can affect delivery timelines. It’s advisable to work with logistics partners experienced in handling refrigerants to navigate these complexities smoothly. -

What quality assurance measures should I look for in R-32 refrigerant?

Quality assurance measures are critical when sourcing R-32 refrigerant. Look for suppliers that provide certifications or documentation confirming the refrigerant’s purity and compliance with industry standards. Additionally, inquire about the supplier’s testing protocols and quality control processes. Reliable suppliers should be willing to share details about their sourcing and handling practices to ensure you receive a high-quality product. -

Can R-32 refrigerant be customized for specific applications?

While R-32 is a standardized refrigerant, some suppliers may offer customization options, such as specific packaging sizes or blends for unique applications. It’s essential to communicate your specific needs with potential suppliers, especially if you require bulk quantities or specialized handling. Discussing your applications upfront can help suppliers recommend the best solutions and ensure that the refrigerant meets your operational requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 R-32 Refrigerant Price Manufacturers & Suppliers List

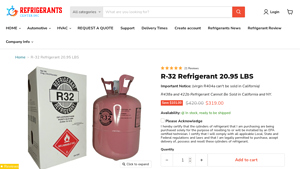

1. Refrigerants Center – R-32 Refrigerant 20LB

Domain: refrigerantscenter.com

Registered: 2019 (6 years)

Introduction: R-32 Refrigerant 20LB

– Weight: 20.95 lbs

– Price: $319.00 (original price $420.00, saving $101.00)

– Availability: In stock, ready to be shipped

– Certification: Must be purchased by EPA certified technicians

– Efficiency: Up to 12% more efficient than R410A

– Environmental Impact: Low GWP approved replacement for R410A

– Usage: Can be added or recharged in both liquid and gas states

– Connection…

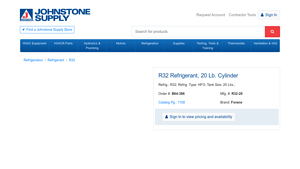

2. Forane – R32 Refrigerant 20 Lbs.

Domain: johnstonesupply.com

Registered: 1996 (29 years)

Introduction: {“Refrigerant”:”R32″,”Refrigerant Type”:”HFO”,”Tank Size”:”20 Lbs.”,”Order Number”:”B64-386″,”Internal Product ID”:””,”Catalog Page”:”1158″,”Manufacturer Number”:”R32-20″,”Brand”:”Forane”,”Shipping Weight”:”33.00 lbs”,”Shipping Width”:”9.50 in”,”Shipping Length”:”9.50 in”,”Shipping Height”:”16.50 in”,”Hazmat”:”Yes”,”Country of Origin”:”United States”,”Description”:”Forane® 32 A2L refrigerant is cl…

3. Ability Refrigerants – R32 Refrigerant 20 LBS

Domain: abilityrefrigerants.com

Registered: 2016 (9 years)

Introduction: This company, Ability Refrigerants – R32 Refrigerant 20 LBS, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

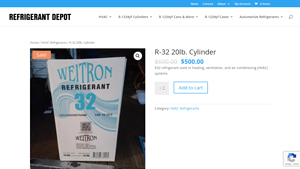

4. Refrigerant Depot – R-32 20lb. Cylinder

Domain: refrigerantdepot.com

Registered: 2012 (13 years)

Introduction: {“name”: “R-32 20lb. Cylinder”, “price”: “$500.00”, “original_price”: “$600.00”, “description”: “R32 refrigerant, also known as difluoromethane, is an hydrofluorocarbon (HFC) used in heating, ventilation, and air conditioning (HVAC) systems. It has higher energy efficiency and lower environmental impact compared to other refrigerants.”, “category”: “HVAC Refrigerants”, “requirements”: “You must fi…

5. HVAC – Refrigerant Charging Rates

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Charging rates for refrigerant vary among HVAC professionals. Some examples include: 1. $33/lb for R32 or R410A. 2. A flat rate of $129 for the first pound and $49 for each additional pound of R410A. 3. $100+ for R410A in the Chicagoland/NWI area. 4. $129 per lb in the Champaign area. 5. $70-100 as a small business rate, with some companies charging $200 for the first pound and around $70 for each…

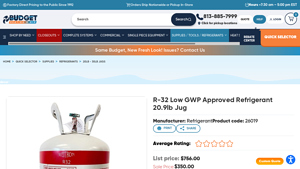

6. Refrigerant – R-32 Low GWP Approved Refrigerant 20.9lb Jug

Domain: budgetheating.com

Registered: 2005 (20 years)

Introduction: {“Product Name”: “R-32 Low GWP Approved Refrigerant 20.9lb Jug”, “Product Code”: “26019”, “Manufacturer”: “Refrigerant”, “List Price”: “$756.00”, “Sale Price”: “$350.00”, “Savings”: “$406.00”, “SKU”: “26019”, “Availability”: “In Stock”, “Shipping”: “Calculated at Checkout”, “Refrigerant Type”: “R-32”, “Features”: [“2025 Low GWP approved replacement of R410A refrigerant”, “Up to 12% more efficient …

7. Sanford – R32 Refrigerant

Domain: choosesanford.com

Registered: 2013 (12 years)

Introduction: R32 Refrigerant:

– Global Warming Potential (GWP): 675

– Ozone Depletion Potential (ODP): 0

– Efficiency: 40% more efficient than R-410A

– Price:

– 1 lb: $11.02

– 20 lb cylinder: $220.44

– Benefits:

– Eco-friendly with lower GWP

– Zero ozone damage

– Lower energy bills due to higher efficiency

– Consistent cooling performance

– Considerations:

– Requires EPA 608 Certific…

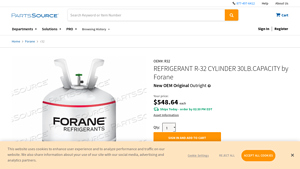

8. Forane – R-32 Refrigerant Cylinder 30lb Capacity

Domain: partssource.com

Registered: 1995 (30 years)

Introduction: {“item”:”REFRIGERANT R-32 CYLINDER 30LB.CAPACITY”,”OEM”:”Forane”,”OEM #”:”R32″,”condition”:”New OEM Original”,”returnable”:”No”,”warranty”:”Mfr Warranty”,”country_of_origin”:”USA”,”price”:”$548.64 each”}

Strategic Sourcing Conclusion and Outlook for r-32 refrigerant price

In the rapidly evolving landscape of HVAC systems, R-32 refrigerant stands out as a viable, eco-friendly alternative to traditional refrigerants like R-410A. With its lower global warming potential (GWP) and enhanced energy efficiency, R-32 is already the choice of over 230 countries, offering significant advantages for both environmental compliance and operational cost savings. For B2B buyers, understanding the pricing dynamics of R-32 is crucial for strategic sourcing, particularly as it impacts the total cost of ownership in HVAC applications.

Strategic sourcing of R-32 can lead to substantial savings, especially when leveraging bulk purchasing and establishing long-term supplier relationships. Competitive pricing options are available across various suppliers, with many offering volume discounts and prompt shipping. Buyers should prioritize suppliers who not only provide competitive pricing but also ensure product quality and regulatory compliance.

Looking ahead, as global regulations tighten around refrigerants, R-32 will likely become even more critical for HVAC systems. International buyers from Africa, South America, the Middle East, and Europe should act proactively to secure their supply chains and capitalize on the advantages of R-32. Engaging with reliable suppliers now can position your business favorably in the competitive HVAC market.