Parini Cast Iron Cookware Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for parini cast iron cookware

In the competitive landscape of kitchenware, sourcing high-quality Parini cast iron cookware presents a unique challenge for international B2B buyers. As culinary trends evolve and consumer demand for durable, multifunctional cookware rises, it becomes crucial for businesses in Africa, South America, the Middle East, and Europe to understand the nuances of sourcing these essential kitchen tools. This guide is designed to equip buyers with comprehensive insights into the various types of Parini cast iron products, their applications, and how to effectively vet suppliers.

Throughout this guide, you will explore the diverse range of Parini cookware, from Dutch ovens to skillets, each crafted to deliver exceptional cooking performance and longevity. We will delve into practical applications, cost considerations, and supplier selection strategies, ensuring that you can make informed purchasing decisions that align with your business needs. Additionally, we will highlight the value of Parini’s commitment to quality craftsmanship and affordability, making it an attractive option for budget-conscious culinary enterprises.

By leveraging the actionable insights and expert recommendations within this guide, you can confidently navigate the global market for Parini cast iron cookware, enhancing your product offerings and meeting the demands of discerning customers across various regions. Prepare to elevate your sourcing strategy and unlock new opportunities in the cookware sector.

Understanding parini cast iron cookware Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Parini Dutch Oven | Thick cast iron construction, enameled surface | Restaurants, catering services | Pros: Excellent heat retention; versatile cooking. Cons: Heavy and requires maintenance. |

| Parini Cast Iron Skillet | Seasoned for natural nonstick, retains high heat | Culinary schools, home kitchens | Pros: Durable; ideal for various cooking methods. Cons: Needs seasoning; can be heavy. |

| Parini Grill Pan | Ribbed surface for grilling, lightweight design | Food trucks, casual dining establishments | Pros: Creates grill marks; easy to handle. Cons: Limited cooking capacity. |

| Parini Casserole Dish | Deep design, versatile for baking and stovetop use | Bakeries, meal prep businesses | Pros: Multi-functional; good for large portions. Cons: Bulky for storage. |

| Parini Pizza Cooker | Mimics professional pizza oven, nonstick surface | Pizzerias, catering events | Pros: High-temperature cooking; consistent results. Cons: Niche use; may require special handling. |

What Are the Key Characteristics of Parini Dutch Ovens?

The Parini Dutch Oven is renowned for its thick cast iron construction and enameled surface, which allows for even heat distribution and moisture retention. This makes it ideal for slow-cooking stews, braising meats, and baking bread. B2B buyers in the restaurant and catering sectors will find this cookware invaluable for its ability to enhance flavor and texture in dishes. However, the weight and need for proper maintenance can be drawbacks for some buyers.

How Does the Parini Cast Iron Skillet Stand Out?

The Parini Cast Iron Skillet is seasoned for natural nonstick performance, making it suitable for frying, sautéing, baking, and broiling. Its ability to retain high heat makes it a favorite among culinary schools and home kitchens alike. B2B buyers should consider the skillet’s versatility and durability, although the requirement for regular seasoning and its heavier weight may present challenges for some users.

What Advantages Does the Parini Grill Pan Offer?

The Parini Grill Pan features a ribbed surface that allows for effective grilling, while its lightweight design makes it easy to handle. This cookware is particularly useful for food trucks and casual dining establishments that need to prepare grilled items quickly and efficiently. While it offers the advantage of creating appealing grill marks, its limited cooking capacity may not meet the demands of larger operations.

Why Choose the Parini Casserole Dish for Your Business?

The Parini Casserole Dish is designed for versatility, suitable for both baking and stovetop cooking. Its deep design allows for the preparation of larger portions, making it ideal for bakeries and meal prep businesses. While the multi-functional nature of this dish is a significant advantage, its bulkiness can be a consideration for storage in smaller kitchens.

What Makes the Parini Pizza Cooker a Unique Option?

The Parini Pizza Cooker is designed to replicate the intense dry heat of a professional pizza oven, featuring a nonstick surface for easy cleanup. This cookware is particularly beneficial for pizzerias and catering events, where consistent, high-temperature cooking is essential for quality. However, its niche application may limit its appeal for some businesses, and special handling may be required to maintain performance.

Key Industrial Applications of parini cast iron cookware

| Industry/Sector | Specific Application of parini cast iron cookware | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Restaurant kitchens for diverse cooking methods | High durability and heat retention for consistent results | Bulk purchasing options, warranty, and service support |

| Catering Services | Event catering for large-scale meal preparation | Ability to cook and serve large portions efficiently | Versatile sizes and ease of transport |

| Food Production | Food processing facilities for batch cooking | Consistent heat distribution for uniform cooking | Compliance with food safety standards and material sourcing |

| Culinary Education | Cooking schools for training aspiring chefs | Hands-on experience with quality cookware | Availability of educational discounts and bulk orders |

| Retail | Kitchenware retailers for consumer sales | Attractive product range appealing to budget-conscious buyers | Marketing support and product availability |

How is Parini Cast Iron Cookware Used in the Hospitality Industry?

In restaurant kitchens, Parini cast iron cookware is ideal for a variety of cooking methods, from sautéing to baking. Its exceptional heat retention and even heat distribution allow chefs to achieve consistent cooking results, which is crucial in maintaining food quality and customer satisfaction. For international buyers, considerations include bulk purchasing options and warranty services to ensure long-term use in a high-demand environment.

What Role Does Parini Cookware Play in Catering Services?

Catering services benefit from Parini cast iron cookware due to its ability to prepare large quantities of food efficiently. Its durability ensures that the cookware can withstand the rigors of transport and repeated use, making it an excellent choice for event catering. Buyers should consider the versatility of sizes available and the ease of transport, which are essential for catering operations across various locations.

How is Parini Cookware Applied in Food Production?

In food production facilities, Parini cast iron cookware is utilized for batch cooking, where consistency is key. The cookware’s ability to evenly distribute heat helps in cooking large quantities uniformly, reducing the risk of undercooked or overcooked items. International buyers must ensure that the cookware complies with food safety standards and consider the sourcing of materials to maintain quality and safety in food production processes.

Why is Parini Cookware Essential for Culinary Education?

Culinary schools use Parini cast iron cookware to provide students with hands-on experience in using high-quality kitchen tools. The cookware is designed to withstand various cooking techniques, allowing aspiring chefs to learn the fundamentals of cooking with durable materials. Buyers in this sector should look for educational discounts and bulk order options to equip their kitchens effectively.

How Can Retailers Benefit from Parini Cookware?

Retailers can leverage Parini cast iron cookware by offering a range of affordable and functional kitchen essentials that appeal to budget-conscious consumers. The attractive design and reputation for quality make these products appealing in a competitive market. Key sourcing considerations for retailers include marketing support from the manufacturer and ensuring a steady supply of inventory to meet consumer demand.

3 Common User Pain Points for ‘parini cast iron cookware’ & Their Solutions

Scenario 1: Sourcing Quality Cast Iron Cookware at Competitive Prices

The Problem: B2B buyers, especially those in emerging markets like Africa and South America, often face challenges in sourcing high-quality cast iron cookware at competitive prices. Many suppliers may offer subpar products that do not meet international quality standards, leading to customer dissatisfaction and potential returns. This issue can be compounded by fluctuating import tariffs and shipping costs, making it essential for buyers to find a reliable supplier who balances quality and affordability.

The Solution: To overcome this challenge, B2B buyers should establish relationships with reputable manufacturers like Parini, known for their commitment to quality and affordability. Conduct thorough market research to understand pricing trends and evaluate suppliers based on customer reviews and product guarantees. Consider placing bulk orders to negotiate better pricing and ensure consistent quality. Additionally, request samples to assess the cookware’s performance and durability before committing to larger orders. By carefully vetting suppliers and leveraging relationships, buyers can secure high-quality cookware that meets their needs without compromising on budget.

Scenario 2: Ensuring Longevity and Performance of Cast Iron Cookware

The Problem: Many B2B buyers struggle with the maintenance and care of cast iron cookware, which can impact the longevity and performance of the products. Improper care can lead to rust, loss of seasoning, and diminished non-stick properties, ultimately affecting customer satisfaction and increasing replacement costs. This is particularly concerning for commercial kitchens where performance consistency is crucial.

The Solution: Educating staff on the proper maintenance of Parini cast iron cookware is essential to ensuring its longevity. Buyers should invest in training programs that cover the importance of seasoning, cleaning, and storage of cast iron products. Specific guidelines include using non-metal utensils to preserve the surface, avoiding drastic temperature changes that could cause cracking, and regularly applying a light coat of oil to maintain the seasoning. Additionally, consider developing a comprehensive care manual that can be distributed to staff and included with product orders. By implementing these practices, businesses can maximize the lifespan of their cookware, leading to enhanced performance and customer satisfaction.

Scenario 3: Addressing Performance Variability in Diverse Cooking Environments

The Problem: B2B buyers in regions with varying cooking techniques and temperature controls often encounter performance variability with cast iron cookware. Differences in heat sources, such as gas, electric, or induction, can lead to inconsistent cooking results. This can frustrate chefs and affect the overall quality of dishes served, especially in multi-national chains that aim for uniformity across locations.

The Solution: To mitigate performance variability, buyers should ensure that the cast iron cookware they source is compatible with different heat sources. Parini cast iron cookware is designed to provide excellent heat retention and distribution, making it versatile for various cooking methods. When selecting products, buyers should specify the intended cooking environments and ask for recommendations on which cookware works best with those conditions. Providing chefs with detailed usage instructions tailored to their specific cooking environment can also help achieve consistent results. Additionally, consider investing in heat distribution tools, such as induction plates or heat diffusers, to enhance the performance of the cookware across different settings. By addressing these factors, businesses can ensure that their cast iron cookware meets the demands of diverse cooking practices while maintaining high culinary standards.

Strategic Material Selection Guide for parini cast iron cookware

What Are the Key Properties of Cast Iron in Parini Cookware?

Cast iron is renowned for its exceptional heat retention and distribution, making it an ideal material for cookware. Its ability to withstand high temperatures without warping is crucial for various cooking methods, including frying, baking, and slow cooking. Cast iron cookware can tolerate temperatures exceeding 500°F (260°C) and can be used on stovetops or in ovens. However, it is susceptible to rust if not properly seasoned and maintained, which is an important consideration for international buyers in humid regions.

What Are the Advantages and Disadvantages of Using Cast Iron?

The primary advantage of cast iron cookware is its durability. When properly cared for, cast iron can last a lifetime, making it a cost-effective investment for both consumers and businesses. Additionally, cast iron provides a natural non-stick surface when seasoned correctly, enhancing cooking performance. However, the manufacturing complexity of cast iron can lead to higher production costs compared to other materials. The weight of cast iron cookware can also be a drawback, particularly for consumers who prefer lightweight options.

How Does Material Selection Impact Application in Different Regions?

For B2B buyers in regions like Africa, South America, and the Middle East, the compatibility of cast iron with various cooking media is essential. Cast iron performs well with high-fat cooking methods, making it suitable for frying and sautéing. However, buyers should be aware of local cooking practices and preferences, as these may influence the demand for specific cookware types. Compliance with international standards such as ASTM and DIN is also crucial, ensuring that the cookware meets safety and quality requirements in different markets.

What Should International Buyers Consider When Sourcing Cast Iron Cookware?

International buyers should consider the logistics of sourcing cast iron cookware, including shipping costs and import regulations. In regions with high humidity, like parts of Africa and the Middle East, it is vital to ensure that the cookware is well-seasoned to prevent rust. Additionally, understanding local preferences for cookware design and functionality can enhance marketability. Buyers should also evaluate the sustainability practices of manufacturers, as eco-friendly production methods are increasingly important in global markets.

| Material | Typical Use Case for parini cast iron cookware | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Dutch ovens, skillets, and casserole dishes | Excellent heat retention and durability | Heavy and requires maintenance to prevent rust | High |

| Enameled Cast Iron | Dutch ovens and specialty pots | Non-reactive surface for acidic foods | Higher manufacturing costs and weight | High |

| Carbon Steel | Frying pans and woks | Lighter than cast iron, versatile | Requires seasoning and can warp under high heat | Medium |

| Stainless Steel | Cookware for boiling and sautéing | Corrosion-resistant and easy to clean | Poor heat retention compared to cast iron | Medium |

This analysis provides a comprehensive overview of the materials used in Parini cast iron cookware, focusing on the properties, advantages, disadvantages, and considerations for international B2B buyers. By understanding these factors, buyers can make informed decisions that align with their market needs and customer preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for parini cast iron cookware

What Are the Main Stages in the Manufacturing Process of Parini Cast Iron Cookware?

The manufacturing process of Parini cast iron cookware involves several critical stages that ensure the final product meets high standards of quality and performance.

-

Material Preparation: The process begins with the selection of high-grade iron ore, which is subjected to melting in a furnace. This melting process is carefully controlled to achieve the right chemical composition and temperature. The molten iron is then poured into molds to form the basic shapes of cookware items, such as skillets, Dutch ovens, and casserole dishes.

-

Forming: After the initial casting, the cookware undergoes a forming process. This may involve additional heating and shaping to achieve the desired thickness and contour. Techniques such as sand casting or die casting are commonly used, allowing for intricate designs and uniform thickness.

-

Assembly: Once the individual pieces are formed, they are assembled. This stage may include attaching handles, lids, or any additional components. The assembly is often done manually or with semi-automated processes to ensure precision and care.

-

Finishing: The finishing stage includes cleaning, seasoning, and coating the cookware. For Parini cast iron, this often involves seasoning with vegetable oils to create a natural non-stick surface. The cookware is also inspected for any defects and may undergo additional treatments, such as enamel coating, to enhance durability and aesthetic appeal.

How Is Quality Assurance Implemented in Parini Cast Iron Cookware Manufacturing?

Quality assurance is a cornerstone of Parini’s manufacturing process, ensuring that every piece of cookware meets rigorous standards.

-

International Standards Compliance: Parini adheres to international quality management standards, such as ISO 9001, which emphasizes a process-based approach to quality assurance. This certification demonstrates a commitment to maintaining consistent quality across all manufacturing processes.

-

Industry-Specific Certifications: Depending on the market, Parini may also comply with other relevant industry standards, such as CE marking for products sold in the European Economic Area, ensuring they meet health, safety, and environmental protection standards.

-

Quality Control Checkpoints: The quality control process includes multiple checkpoints throughout the manufacturing cycle:

– Incoming Quality Control (IQC): This stage involves inspecting raw materials upon delivery to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): During manufacturing, operators perform checks at various stages to identify and rectify any issues in real-time.

– Final Quality Control (FQC): After finishing, each piece undergoes a comprehensive inspection to verify that it meets all specifications and quality standards before packaging.

What Testing Methods Are Commonly Used for Parini Cast Iron Cookware?

To guarantee the performance and safety of its cookware, Parini employs various testing methods:

-

Thermal Testing: Cookware is subjected to thermal cycling tests to assess its ability to withstand high temperatures without warping or cracking. This is crucial for cast iron products, which must retain heat effectively.

-

Durability Testing: Parini conducts mechanical testing, including impact resistance and scratch tests, to evaluate the cookware’s durability under everyday use. This ensures that handles remain secure and the cooking surface remains intact.

-

Non-Toxicity Testing: For products with coatings, tests are performed to ensure that they are free from harmful substances such as lead or cadmium, complying with health and safety regulations.

How Can B2B Buyers Verify Supplier Quality Control Processes?

International B2B buyers can take several steps to verify the quality control processes of Parini or any cookware supplier:

-

Supplier Audits: Conducting on-site audits is one of the most effective ways to assess a supplier’s manufacturing and quality control processes. This allows buyers to see firsthand how products are made and the quality assurance measures in place.

-

Quality Assurance Reports: Requesting detailed quality assurance reports can provide insights into the supplier’s testing methods, inspection results, and adherence to international standards. These reports should outline specific metrics, such as defect rates and compliance with certifications.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control processes. These agencies can perform random checks during production and before shipment to ensure that products meet specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing Parini cast iron cookware from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of certain nuances:

-

Regional Standards and Regulations: Different regions may have specific standards for cookware. Buyers should ensure that the products comply with local regulations and certifications, such as FDA compliance in the U.S. or LFGB standards in Germany.

-

Cultural Expectations: The expectations for cookware quality may vary across cultures. For instance, European buyers often prioritize durability and design, while buyers in emerging markets may focus more on affordability and functionality.

-

Logistics and Shipping Considerations: Quality control does not end at the factory. Buyers must consider the conditions during shipping and storage, which can affect product integrity. Ensuring proper handling and storage conditions is crucial to maintaining quality.

Conclusion: Ensuring Quality in Parini Cast Iron Cookware Sourcing

For B2B buyers seeking to source Parini cast iron cookware, understanding the manufacturing processes and quality assurance protocols is essential. By focusing on international standards, implementing robust quality control measures, and verifying supplier practices, buyers can ensure they receive high-quality, durable products that meet their culinary needs. Investing time in the procurement process will ultimately lead to better partnerships and successful business outcomes in the cookware market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parini cast iron cookware’

In the competitive landscape of cookware sourcing, particularly for Parini cast iron cookware, it is essential for B2B buyers to follow a structured approach. This checklist serves as a comprehensive guide to ensure that you make informed purchasing decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before you start sourcing, clearly outline the technical specifications you require for Parini cast iron cookware. Consider factors such as size, weight, and finish (e.g., enameled or seasoned). Knowing these details will help you narrow down your options and communicate effectively with suppliers.

Step 2: Research Supplier Credentials

Verify the credentials of potential suppliers to ensure they meet industry standards. Look for certifications such as ISO and safety compliance that indicate a commitment to quality. A reputable supplier should provide documentation to support their claims, enhancing your confidence in their products.

Step 3: Evaluate Product Quality

Assess the quality of Parini cast iron cookware by requesting samples or visiting the manufacturing facility if possible. Examine the craftsmanship, material integrity, and overall durability. Pay attention to customer reviews and testimonials to gauge the performance of the cookware in real-world settings.

Step 4: Analyze Pricing Structures

Understand the pricing models offered by different suppliers. Request detailed quotes that break down costs, including shipping, taxes, and any potential discounts for bulk purchases. Comparing pricing will help you identify the best value while ensuring that quality is not compromised.

Step 5: Check for After-Sales Support

Inquire about the after-sales services provided by suppliers, including warranty terms and customer service support. Reliable after-sales support is crucial, especially for cookware that may require maintenance or replacement parts. A supplier that stands behind their products will enhance your overall purchasing experience.

Step 6: Confirm Shipping and Delivery Terms

Clarify shipping options and delivery timelines with your selected suppliers. Ensure that they can meet your logistical requirements, especially if you operate in regions with specific import regulations. Understanding shipping costs and lead times will help you plan your inventory effectively.

Step 7: Build a Relationship with Your Supplier

Once you have selected a supplier, focus on building a long-term relationship. Regular communication and feedback can foster collaboration and lead to better pricing and product innovations in the future. A strong partnership can significantly benefit your business as market demands evolve.

By following this practical sourcing checklist, B2B buyers can navigate the procurement of Parini cast iron cookware with confidence, ensuring that they select products that meet their operational needs while establishing trustworthy supplier relationships.

Comprehensive Cost and Pricing Analysis for parini cast iron cookware Sourcing

What Are the Key Cost Components in Sourcing Parini Cast Iron Cookware?

When sourcing Parini cast iron cookware, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality of raw materials significantly impacts pricing. Parini cookware is primarily made from cast iron, which is durable and provides excellent heat retention. The sourcing of high-grade cast iron may involve higher upfront costs but ensures longevity and performance.

-

Labor: Labor costs can vary depending on the region of manufacturing. Countries with lower labor costs may offer competitive pricing, but this can affect quality. It is essential to consider the skill level of the workforce and the associated labor costs when evaluating suppliers.

-

Manufacturing Overhead: This includes utilities, rent, and indirect labor associated with production. Efficient production processes can minimize overhead costs, which can then be reflected in the pricing of the cookware.

-

Tooling: The initial investment in molds and equipment for cast iron cookware production can be substantial. This cost is often amortized over the production volume, making it important to discuss the minimum order quantities (MOQs) with suppliers.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the cookware meets performance standards and safety certifications. These additional checks can add to the overall cost, but they are vital for maintaining product integrity and customer satisfaction.

-

Logistics: Shipping costs play a significant role, especially for international buyers. Factors such as distance, shipping method, and customs duties will influence the final price of the cookware.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the competitive landscape and negotiating effectively can help secure more favorable terms.

How Do Price Influencers Affect the Cost of Parini Cast Iron Cookware?

Several factors can influence the pricing of Parini cast iron cookware, including:

-

Volume and Minimum Order Quantities (MOQs): Higher order volumes often lead to lower per-unit costs. Suppliers may offer tiered pricing based on the quantity ordered, which can be advantageous for larger businesses.

-

Specifications and Customization: Custom features or specific design requests can increase costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Materials and Quality Certifications: Premium materials or certifications (e.g., FDA, ISO) can elevate the price. Buyers should ensure that the quality aligns with their target market’s expectations.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their track record, while newer or less-known suppliers may offer competitive pricing to gain market share.

-

Incoterms: Understanding the Incoterms used in the agreement can help buyers manage costs effectively. Terms such as FOB (Free On Board) and CIF (Cost, Insurance, and Freight) can significantly influence the total landed cost of the cookware.

What Are the Best Tips for B2B Buyers When Sourcing Parini Cast Iron Cookware?

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, consider the following tips:

-

Negotiation: Engage in open discussions with suppliers regarding pricing and terms. Don’t hesitate to negotiate on MOQs, payment terms, and delivery schedules to achieve a more favorable deal.

-

Cost-Efficiency: Conduct a Total Cost of Ownership (TCO) analysis, considering not just the purchase price but also logistics, warehousing, and potential return rates. This holistic view will help in making informed purchasing decisions.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and their impact on pricing. It’s advisable to lock in prices and terms early in the negotiation process to mitigate risks associated with exchange rates.

-

Research and Compare Suppliers: Take the time to research various suppliers and compare their offerings. Look for reviews, certifications, and product samples to ensure you are making a sound investment.

Disclaimer on Indicative Prices

Please note that the prices for Parini cast iron cookware can vary based on the factors outlined above. It is advisable to obtain quotes directly from suppliers to get the most accurate and current pricing information tailored to your specific needs.

Alternatives Analysis: Comparing parini cast iron cookware With Other Solutions

Understanding Alternatives to Parini Cast Iron Cookware

When evaluating cookware options, it’s essential for international B2B buyers to consider various alternatives that meet their culinary needs. Parini cast iron cookware is a well-regarded choice for its quality and affordability, but there are other viable options that can also deliver excellent cooking results. This analysis compares Parini cast iron cookware with two notable alternatives: enameled cast iron cookware and stainless steel cookware.

Comparison Table

| Comparison Aspect | Parini Cast Iron Cookware | Enameled Cast Iron Cookware | Stainless Steel Cookware |

|---|---|---|---|

| Performance | Excellent heat retention and even cooking | Good heat retention, but less even than cast iron | Quick heating, not as good for slow cooking |

| Cost | Affordable | Generally higher price point | Mid-range pricing |

| Ease of Implementation | Requires seasoning for optimal performance | Ready to use, no seasoning needed | Easy to use, no special care needed |

| Maintenance | Requires regular seasoning and care | Low maintenance, easy to clean | Dishwasher safe, very low maintenance |

| Best Use Case | Ideal for slow cooking, baking, and frying | Great for baking, stews, and serving | Best for sautéing, boiling, and quick meals |

Detailed Breakdown of Alternatives

Enameled Cast Iron Cookware

Enameled cast iron cookware is a popular alternative known for its aesthetic appeal and versatility. Unlike traditional cast iron, it comes with a smooth enamel coating that eliminates the need for seasoning, making it easier to maintain. This type of cookware excels in heat retention and is ideal for braising and baking. However, it typically comes at a higher price point and is prone to chipping if mishandled. B2B buyers seeking a blend of performance and ease may find enameled cast iron a worthwhile investment.

Stainless Steel Cookware

Stainless steel cookware is another alternative that offers a different set of advantages. It heats quickly and evenly, making it perfect for sautéing and other fast cooking methods. This cookware is highly durable, resistant to staining and scratching, and generally dishwasher safe, which simplifies cleaning. However, it doesn’t retain heat as well as cast iron, which can affect cooking techniques that require steady, prolonged heat. For B2B buyers focused on versatility and low maintenance, stainless steel cookware could be an attractive option.

Conclusion: How to Choose the Right Cookware Solution

Selecting the right cookware depends on your specific culinary needs and operational considerations. For businesses targeting home cooks who value tradition and durability, Parini cast iron cookware offers an exceptional balance of affordability and performance. However, if ease of use and low maintenance are paramount, enameled cast iron or stainless steel options may serve better. B2B buyers should evaluate their target market’s preferences, cooking styles, and budget constraints when making a decision, ensuring the chosen cookware aligns with their brand values and customer expectations.

Essential Technical Properties and Trade Terminology for parini cast iron cookware

What Are the Key Technical Properties of Parini Cast Iron Cookware?

Understanding the technical specifications of Parini cast iron cookware is crucial for B2B buyers looking to ensure quality and performance in their product offerings. Here are several critical specifications to consider:

1. Material Composition

Parini cast iron cookware is primarily made from high-quality cast iron, often enameled for added durability and ease of cleaning. Cast iron’s superior heat retention and even heat distribution make it ideal for slow cooking, baking, and frying. For B2B buyers, sourcing cookware made from genuine cast iron guarantees long-lasting performance and customer satisfaction.

2. Thickness

The thickness of cast iron cookware typically ranges from 3/16 to 1/4 inches. A thicker base allows for better heat retention and reduces the chances of warping under high temperatures. For buyers, this specification is essential as it directly impacts the cookware’s longevity and cooking efficiency, ensuring that customers receive products that perform consistently over time.

3. Enameled Surface

Many Parini cast iron products feature an enameled surface that provides a non-reactive cooking environment, making it suitable for acidic ingredients. This coating not only enhances the aesthetic appeal but also simplifies maintenance by preventing rust. B2B purchasers should prioritize enameled options as they cater to a broader range of culinary applications and are easier to clean.

4. Temperature Resistance

Parini cast iron cookware can typically withstand temperatures up to 500°F (260°C) or more. This high-temperature tolerance allows for versatility in cooking methods, from stovetop frying to oven baking. For B2B buyers, understanding temperature resistance is vital in recommending cookware that meets diverse cooking needs for restaurants or retail environments.

5. Weight

The weight of cast iron cookware varies, with larger pieces weighing significantly more than smaller ones. A heavier design contributes to better heat retention but may pose challenges for some users. Buyers should consider the target market’s preferences regarding weight, as it can influence purchasing decisions, especially in regions where mobility and ease of handling are prioritized.

6. Handle Design

Ergonomically designed handles enhance the usability of cast iron cookware. Features such as riveted construction and heat-resistant materials are essential for safe handling. B2B buyers should assess handle design as it plays a critical role in user experience and safety, which are paramount for repeat purchases.

What Are Common Trade Terminology and Jargon Related to Parini Cast Iron Cookware?

Familiarity with industry jargon is essential for effective communication between suppliers and buyers. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of cookware, understanding OEM relationships can help buyers identify potential customization options and improve their product offerings.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers to negotiate their purchasing strategy effectively, ensuring they meet supply chain demands without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. Utilizing RFQs allows buyers to compare costs and terms from different manufacturers, facilitating informed purchasing decisions for Parini cast iron cookware.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and delivery. Understanding these terms helps B2B buyers navigate logistics and mitigate risks associated with international transactions.

5. Lead Time

Lead time is the duration from order placement to delivery. Knowing the lead time for Parini cast iron cookware is vital for inventory management and ensuring timely availability for customers.

6. Quality Assurance (QA)

QA refers to the systematic process of ensuring that products meet specified quality standards. B2B buyers should prioritize suppliers with robust QA processes, as this impacts the reliability and performance of Parini cast iron cookware in the market.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions that enhance their product offerings and meet customer expectations effectively.

Navigating Market Dynamics and Sourcing Trends in the parini cast iron cookware Sector

What are the Current Market Dynamics and Key Trends Affecting Parini Cast Iron Cookware?

The global cookware market is witnessing significant growth, driven by increased consumer interest in home cooking and culinary experiences. The Parini cast iron cookware segment, in particular, is benefitting from rising health consciousness among consumers, who are shifting towards durable and sustainable cooking options. In regions like Africa, South America, the Middle East, and Europe, buyers are increasingly looking for affordable yet high-quality cookware that can withstand heavy use.

Emerging trends in B2B sourcing include the adoption of e-commerce platforms for bulk purchases, which allows international buyers to streamline procurement processes. Additionally, the integration of digital tools for inventory management and supply chain optimization is becoming prevalent. Buyers are also focusing on versatility, as products like Parini’s cast iron skillets can serve multiple cooking methods—from frying to baking—making them attractive for diverse culinary applications.

Moreover, the demand for innovative features, such as non-stick coatings and heat retention properties, is shaping product development. For example, Parini’s enameled cast iron Dutch ovens are designed to distribute heat evenly, catering to both professional chefs and home cooks. As competition intensifies, manufacturers that offer a combination of quality, affordability, and modern design will stand out in the global market.

How is Sustainability and Ethical Sourcing Reshaping B2B Relationships in the Cookware Industry?

In today’s market, sustainability has become a pivotal factor influencing B2B relationships and sourcing decisions. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to prioritize suppliers who engage in ethical sourcing practices. For Parini cast iron cookware, this involves using responsibly sourced materials that minimize ecological footprints and ensure product longevity.

The importance of ethical supply chains cannot be overstated, as consumers increasingly demand transparency regarding the origins of their cookware. Suppliers that can provide certifications for sustainable practices, such as ISO 14001 for environmental management, will likely gain a competitive edge. Moreover, the use of recycled materials in production and adherence to fair labor practices are becoming key considerations for international buyers.

Green certifications, such as the Forest Stewardship Council (FSC) for wood products or Energy Star ratings for appliances, are also gaining traction. By aligning with these standards, Parini can not only enhance its brand reputation but also cater to the growing segment of eco-conscious consumers, thus fostering loyalty and trust among B2B partners.

What is the Historical Evolution of Parini Cookware and Its Impact on the B2B Sector?

Parini Cookware has its roots in a commitment to providing quality kitchen essentials at accessible prices. Founded with the vision of making high-performance cookware available to everyday cooks, Parini has evolved significantly over the years. Initially focusing on basic cookware, the brand has expanded its offerings to include a diverse range of products, including cast iron skillets and Dutch ovens, which resonate with modern culinary trends.

This evolution reflects a broader shift in consumer preferences towards durable and versatile cookware. Parini’s emphasis on quality craftsmanship and innovative design has not only enhanced its market position but also established it as a trusted partner for B2B buyers. The brand’s focus on affordability without compromising quality has made it particularly appealing to international markets, where buyers are often budget-conscious yet demand high standards in cookware.

As Parini continues to innovate and adapt to market dynamics, its historical commitment to quality and value remains a cornerstone of its strategy, ensuring that it meets the evolving needs of B2B buyers worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of parini cast iron cookware

-

How do I ensure the quality of Parini cast iron cookware before purchasing?

To ensure the quality of Parini cast iron cookware, request product samples or certifications that demonstrate adherence to international quality standards. Evaluate the craftsmanship by checking for even seasoning, smooth surfaces, and sturdy construction. Additionally, inquire about customer feedback and performance reviews from other B2B buyers. Engaging directly with the manufacturer can also provide insights into their quality control processes and material sourcing. -

What are the recommended minimum order quantities (MOQs) for Parini cast iron cookware?

Minimum order quantities for Parini cast iron cookware may vary based on the specific product line and supplier. Typically, MOQs can range from 50 to 500 units. It is advisable to discuss MOQs with your supplier during negotiations to find a balance that meets your inventory needs while ensuring cost-effectiveness. Many suppliers may offer flexibility for first-time buyers or bulk orders, so be sure to explore all options. -

What payment terms are typically offered for purchasing Parini cookware?

Payment terms for purchasing Parini cookware can vary by supplier but commonly include options such as upfront payment, 30% deposit with the balance due before shipment, or net 30/60 terms. It’s crucial to establish clear payment terms during negotiations to protect your financial interests. Additionally, consider discussing options for letters of credit or escrow services for larger orders to enhance security. -

How can I customize my order of Parini cast iron cookware?

Customization options for Parini cast iron cookware may include personalized branding, specific color selections, or unique packaging. To initiate the customization process, contact your supplier to discuss available options and any associated costs. Keep in mind that customization may affect lead times, so it’s essential to plan accordingly and communicate your requirements clearly to avoid delays. -

What logistics considerations should I keep in mind when importing Parini cookware?

When importing Parini cookware, consider factors such as shipping methods, customs clearance, and potential tariffs or duties applicable in your region. Collaborate with a logistics partner experienced in international shipping to ensure compliance with regulations and timely delivery. Additionally, assess the lead times and warehouse capabilities to manage inventory effectively upon arrival. -

How can I vet suppliers of Parini cast iron cookware for reliability?

To vet suppliers of Parini cast iron cookware, conduct thorough research on their business history, reputation, and customer reviews. Request references from previous clients and check for any certifications or industry affiliations. Additionally, consider visiting their manufacturing facilities if feasible, or arrange virtual meetings to assess their operational capabilities and commitment to quality. -

What is the expected lifespan of Parini cast iron cookware with proper care?

With proper care, Parini cast iron cookware can last for decades, providing exceptional durability and performance. Regular maintenance, such as seasoning and avoiding harsh cleaning methods, will extend the lifespan significantly. Educate your customers on the best practices for maintaining cast iron, as this will enhance their cooking experience and satisfaction with the product. -

How does Parini cookware compare to other brands in terms of functionality and price?

Parini cookware is known for its balance of affordability and high-quality performance, making it a competitive option in the market. Compared to other brands, Parini often offers similar functionality, such as excellent heat retention and versatility, at a more accessible price point. Conduct a market analysis to compare features, warranty offerings, and user reviews to ensure you make an informed decision that meets your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Parini Cast Iron Cookware Manufacturers & Suppliers List

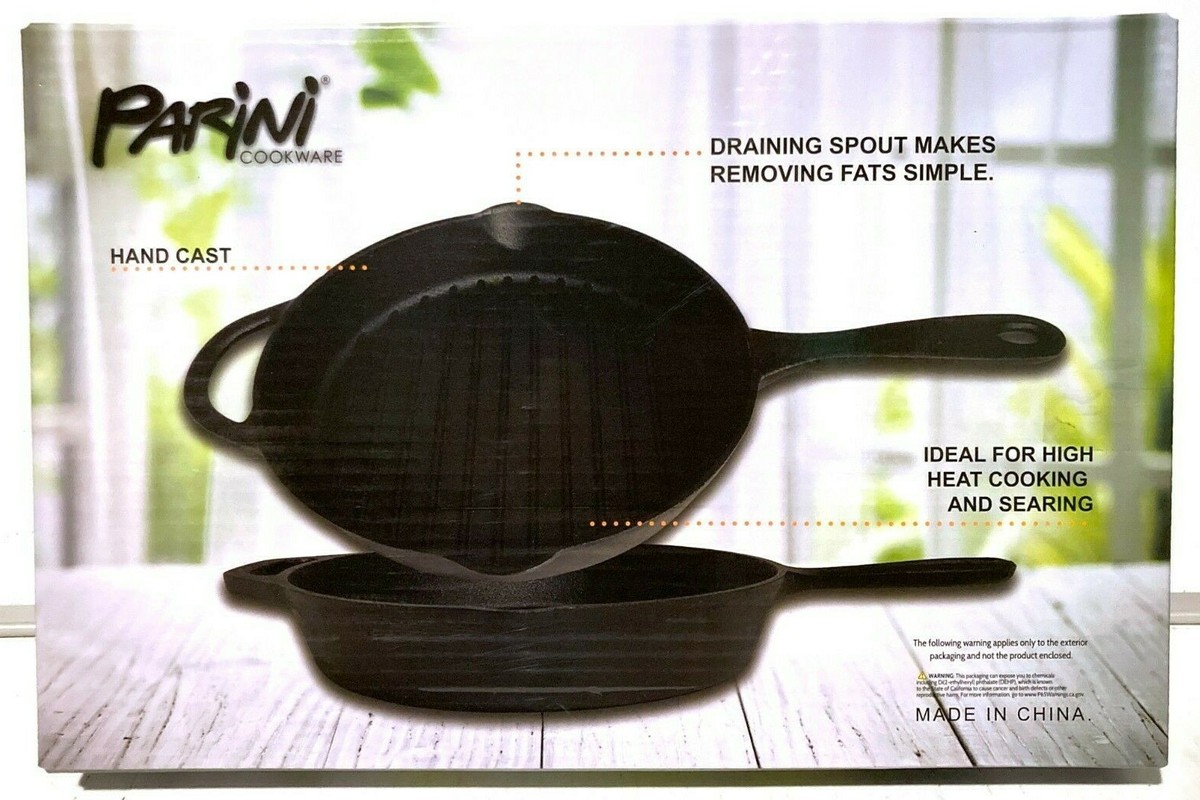

1. Parini – Kitchen Cookware Collection

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Parini cookware includes a variety of kitchen items such as a revolving spice rack, dutch ovens, a small slow cooker, a salad spinner, drink shaker, bowls, and plates. The cookware is associated with promotions from casinos and is part of a larger company based in China. Some users have reported mixed experiences, particularly with the salad spinner, which had a durability issue.

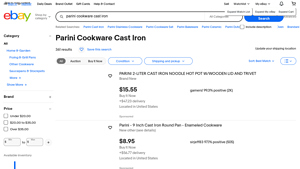

2. Parini – Cast Iron Skillet 10 Golden Oil Collection

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Parini Cookware Cast Iron includes various items such as skillets, dutch ovens, and casserole pans. Key products include:

– Parini Cast Iron Skillet 10″ Golden Oil Collection – Brand New, $39.95, Free delivery.

– Parini Cast Iron Casserole Ombré Yellow & Orange, 1.5 Qt, Pre-Owned, $27.98 + $14.49 delivery.

– Parini Dutch Oven Cast Iron 4 Quart, Pre-Seasoned, Brand New, $31.49, Free returns.

– Pari…

3. Parini – Cookware Set

Domain: poshmark.com

Registered: 2011 (14 years)

Introduction: This company, Parini – Cookware Set, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Facebook – Marketplace Items for Sale

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Marketplace Items for Sale, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for parini cast iron cookware

As the global demand for quality cookware continues to rise, Parini cast iron cookware stands out as a reliable choice for international B2B buyers. The brand’s commitment to quality craftsmanship, affordability, and functionality ensures that businesses can meet the diverse culinary needs of their customers. By sourcing Parini products, buyers benefit from a reputation for durability and performance, making them ideal for both everyday cooking and specialized culinary applications.

Strategic sourcing of Parini cookware not only enhances product offerings but also strengthens supplier relationships, ensuring consistent supply and support. With a focus on materials like cast iron, known for excellent heat retention and even cooking, buyers can confidently promote Parini products as essential kitchen tools that elevate the cooking experience.

Looking ahead, the opportunity for growth in emerging markets such as Africa, South America, and the Middle East is significant. By aligning with Parini’s values of quality and innovation, international buyers can position themselves favorably within these markets. Now is the time to explore the range of Parini cast iron cookware and consider how it can enhance your product portfolio. Embrace this opportunity to deliver quality and value to your customers while strengthening your competitive edge.