Medical Infrared Forehead Thermometer: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for medical infrared forehead thermometer

In today’s rapidly evolving healthcare landscape, sourcing reliable medical infrared forehead thermometers presents a significant challenge for international B2B buyers. With the increasing demand for non-contact temperature measurement solutions—particularly in the wake of global health crises—organizations must navigate a complex marketplace filled with diverse products and suppliers. This guide serves as a comprehensive resource, covering various types of infrared thermometers, their applications in clinical and non-clinical settings, and the critical factors to consider during supplier vetting.

From understanding the technological specifications to evaluating cost-effectiveness, this guide empowers decision-makers in Africa, South America, the Middle East, and Europe—such as those in Saudi Arabia and Germany—to make informed purchasing decisions. It highlights the importance of compliance with international standards, including FDA and CE certifications, ensuring that buyers can confidently invest in quality products that meet their operational needs. By offering actionable insights into market trends and supplier reliability, this guide positions B2B buyers to effectively enhance their health screening processes and maintain safety in their environments.

Navigating the global market for medical infrared forehead thermometers has never been more critical, and with the right information, you can secure the best solutions for your organization’s unique requirements.

Understanding medical infrared forehead thermometer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Non-Contact Infrared Thermometer | Measures temperature from a distance (2-15 cm); dual modes (body/surface) | Health screenings in workplaces, airports | Pros: Fast, hygienic, minimal maintenance; Cons: Limited medical diagnostic capabilities. |

| Clinical Infrared Thermometer | Higher accuracy, often FDA/CE certified; specific for clinical settings | Hospitals, clinics, and emergency services | Pros: Reliable for clinical use; Cons: Generally more expensive than non-contact models. |

| Forehead Thermometer with Alarm | Features an alarm for elevated temperatures; easy to use | Schools, public events, and offices | Pros: Alerts for fever detection; Cons: May require calibration for accuracy. |

| Wall-Mounted Thermometer | Fixed installation; often integrated with access control systems | Entrances of hospitals, offices, and schools | Pros: Hands-free operation; Cons: Installation costs and less mobility. |

| Portable Infrared Thermometer | Compact design; battery-operated for easy transport | Field operations, mobile clinics | Pros: Versatile and convenient; Cons: Battery life may be limited. |

What Are the Key Characteristics of Non-Contact Infrared Thermometers?

Non-contact infrared thermometers are designed to measure body temperature without physical contact, typically within a range of 2 to 15 cm. They often feature dual measurement modes, allowing users to switch between body and surface temperature readings. This type is ideal for high-traffic areas where rapid temperature screening is essential, such as airports and workplaces. For B2B buyers, the ease of use and minimal need for disinfection make these devices attractive, although they are not suitable for precise medical diagnostics.

How Do Clinical Infrared Thermometers Differ from Other Types?

Clinical infrared thermometers are specifically designed for use in healthcare settings, offering higher accuracy and often receiving FDA or CE certification. They are suitable for hospitals and clinics where precise temperature readings are crucial for patient care. B2B buyers should consider the reliability and regulatory compliance of these devices, which may justify a higher price point compared to non-contact models. However, their specialized nature limits their use outside clinical environments.

What Are the Advantages of Forehead Thermometers with Alarm Features?

Forehead thermometers equipped with alarm functions provide immediate alerts for elevated temperatures, making them useful in environments like schools and public events. These devices are user-friendly and designed for quick screenings, enhancing safety protocols. For B2B buyers, the alert feature can be a significant advantage, although the need for periodic calibration may be a consideration for long-term accuracy.

Why Choose Wall-Mounted Infrared Thermometers for High Traffic Areas?

Wall-mounted infrared thermometers are fixed installations that facilitate hands-free operation, making them suitable for entrances of hospitals, offices, and schools. They can often be integrated with access control systems, streamlining the screening process. While they offer the convenience of automatic operation, B2B buyers should be aware of the initial installation costs and the potential need for ongoing maintenance.

What Makes Portable Infrared Thermometers Ideal for Field Operations?

Portable infrared thermometers are compact and battery-operated, allowing for easy transport and versatile usage in field operations, such as mobile clinics. Their convenience and adaptability make them appealing for various applications, from emergency response to outdoor events. However, B2B buyers should consider the limitations of battery life and the potential need for frequent recharging, especially in high-demand scenarios.

Key Industrial Applications of medical infrared forehead thermometer

| Industry/Sector | Specific Application of medical infrared forehead thermometer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Patient screening in hospitals and clinics | Rapid and accurate temperature readings for effective triage | Compliance with medical standards (FDA, CE), accuracy specifications, and ease of use in high-volume settings |

| Education | Temperature checks in schools and universities | Ensures student and staff safety by identifying fevers early | Portable design, battery life, and ability to handle multiple users quickly |

| Hospitality | Guest screening in hotels and restaurants | Enhances safety protocols and guest confidence | Non-contact design, fast measurement time, and robust data storage capabilities |

| Manufacturing | Employee health monitoring in factories | Reduces the spread of illness, ensuring operational continuity | Durability, accuracy under varying environmental conditions, and ease of integration into existing health protocols |

| Event Management | Crowd screening at large events and conferences | Quick identification of potential health risks | High measurement range, portability, and non-contact usage for efficiency |

How is a medical infrared forehead thermometer used in healthcare settings?

In healthcare facilities, medical infrared forehead thermometers are essential for patient screening during triage. They allow healthcare professionals to quickly assess body temperature without physical contact, minimizing the risk of cross-contamination. This is particularly crucial in high-traffic areas such as emergency rooms or outpatient clinics. International buyers should prioritize devices with FDA or CE certifications to ensure compliance with local regulations, alongside models that provide rapid response times and accurate readings within the required temperature ranges.

What role does a medical infrared forehead thermometer play in educational institutions?

In educational environments, these thermometers are used to monitor the health of students and staff. Schools can implement routine temperature checks to prevent the spread of infectious diseases, thereby ensuring a safer learning atmosphere. For buyers in Africa, South America, or Europe, it’s vital to choose thermometers that are portable and easy to operate, as well as those that can store multiple readings to track temperature trends over time.

How can the hospitality industry benefit from medical infrared forehead thermometers?

Hotels and restaurants utilize infrared forehead thermometers to screen guests upon entry, enhancing safety protocols and building customer trust. By quickly identifying individuals with elevated temperatures, establishments can take immediate action to protect the health of other guests and staff. When sourcing these devices, buyers should consider models that are user-friendly and provide quick readings, as well as those that can handle high volumes of guests efficiently.

Why are medical infrared forehead thermometers important in manufacturing?

In manufacturing, these thermometers are employed for employee health monitoring to prevent outbreaks of illness on the production floor. By screening workers before shifts, companies can maintain productivity and reduce absenteeism. Buyers in this sector should focus on thermometers that are durable and can function effectively in various environmental conditions, ensuring consistent accuracy and reliability.

How do event management companies utilize medical infrared forehead thermometers?

Event management firms employ these thermometers for crowd screening at large gatherings, such as concerts or conferences. This application is vital for ensuring public safety and compliance with health regulations. Buyers should look for thermometers that are lightweight and easy to transport, with features that allow for quick and efficient screening of large groups, ensuring minimal disruption to event flow.

3 Common User Pain Points for ‘medical infrared forehead thermometer’ & Their Solutions

Scenario 1: Inconsistent Temperature Readings Affecting Screening Efficacy

The Problem: B2B buyers in healthcare or industrial settings often face challenges with inconsistent temperature readings from infrared forehead thermometers. These discrepancies can arise due to factors such as environmental conditions, improper usage, or differences in device calibration. Such inconsistencies can lead to false positives or negatives in fever screening, potentially exposing staff and customers to health risks, and undermining the trust in the screening process. This problem is especially critical in regions with varying climate conditions, where external temperatures can affect readings.

The Solution: To mitigate this issue, it is crucial to prioritize the selection of high-quality, FDA-cleared infrared thermometers that comply with international standards. Buyers should ensure that the devices offer a clear specification for accuracy and measurement range, ideally with an accuracy of ±0.2°C or better. Furthermore, educating staff on proper usage is vital; users should maintain the recommended distance (usually between 5 to 15 cm) and avoid taking readings in direct sunlight or high-heat environments. Implementing routine calibration checks and maintaining a controlled ambient temperature can also enhance measurement reliability. Establishing a protocol for documenting and analyzing temperature readings can help identify patterns and refine the screening process, ensuring a more effective and trustworthy system.

Scenario 2: High Costs and Supply Chain Challenges in Procurement

The Problem: B2B buyers often encounter significant financial pressures and logistical hurdles when procuring medical infrared forehead thermometers. Fluctuating prices, import tariffs, and supply chain disruptions can lead to unexpected costs and delays, complicating the procurement process. This is particularly challenging for buyers in regions with strict import regulations or during global health crises when demand surges.

The Solution: To navigate these challenges, B2B buyers should build relationships with multiple suppliers to diversify their sourcing options and reduce dependence on a single vendor. Conducting thorough market research can help identify competitive pricing and reliable manufacturers, particularly those who have established themselves in target markets like Africa, South America, or Europe. Furthermore, negotiating bulk purchase agreements can lower costs and create a buffer against future price increases. Buyers should also consider suppliers that offer guarantees or warranties, which can provide additional assurance regarding product quality. Leveraging technology for inventory management and forecasting can help maintain optimal stock levels, reducing the risk of shortages while optimizing cash flow.

Scenario 3: Difficulty in Ensuring Compliance with Regulatory Standards

The Problem: Compliance with various regional and international regulations is a significant concern for B2B buyers of medical infrared forehead thermometers. Each region may have different standards, such as CE marking in Europe or FDA approval in the United States, and failing to comply can result in legal ramifications, financial penalties, or product recalls. This challenge is magnified in countries with evolving regulatory frameworks, where keeping up with compliance can be time-consuming and complex.

The Solution: Buyers should prioritize sourcing thermometers that are not only FDA-cleared but also comply with the specific regulations of their target markets. This involves conducting thorough due diligence on potential suppliers to ensure they provide the necessary certifications and documentation. Engaging with regulatory consultants or legal experts can provide clarity on compliance requirements and help navigate the complexities of international regulations. Additionally, maintaining ongoing communication with suppliers regarding any regulatory changes can facilitate timely updates to product offerings. Regular audits and assessments of procurement processes can also ensure adherence to compliance standards, safeguarding the organization against potential liabilities.

Strategic Material Selection Guide for medical infrared forehead thermometer

What Are the Common Materials Used in Medical Infrared Forehead Thermometers?

When selecting materials for medical infrared forehead thermometers, several factors must be considered, including performance, durability, cost, and compliance with international standards. Below, we analyze four common materials used in the construction of these devices, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Plastic Impact the Performance of Infrared Forehead Thermometers?

Key Properties: Plastic is lightweight and can be molded into complex shapes, making it ideal for the ergonomic design of thermometers. It typically has a temperature resistance of around -20°C to 60°C, which is suitable for most ambient conditions.

Pros & Cons: The main advantages of plastic include its low cost and ease of manufacturing. However, plastics may not be as durable as other materials and can be prone to degradation over time, especially when exposed to UV light or high temperatures.

Impact on Application: Plastic is compatible with various cleaning agents, which is critical for maintaining hygiene in medical settings. However, it may not withstand harsh sterilization methods.

Considerations for International Buyers: Compliance with regulations such as FDA and CE marking is crucial. Buyers from regions like Europe and the Middle East should ensure that the plastic used meets the relevant safety standards, such as EN 60601 for medical devices.

What Role Does Metal Play in Thermometer Construction?

Key Properties: Metals like aluminum and stainless steel offer excellent durability and corrosion resistance. They can withstand higher temperatures, making them suitable for environments where temperature fluctuations are common.

Pros & Cons: The advantages of using metal include enhanced durability and a premium feel, which can be appealing in high-end markets. However, metals are generally more expensive and may complicate the manufacturing process due to their weight and the need for more robust assembly techniques.

Impact on Application: Metal components can provide better shielding against electromagnetic interference, which is essential for accurate readings. However, they may not be as effective in non-contact applications if not designed carefully.

Considerations for International Buyers: Buyers should look for compliance with ASTM and DIN standards. For instance, thermometers intended for the European market must adhere to the EN 60601 standard, which governs the safety and performance of medical electrical equipment.

How Do Glass Components Enhance Thermometer Functionality?

Key Properties: Glass is often used for lenses and display screens due to its clarity and resistance to scratching. It can withstand a wide range of temperatures, typically from -50°C to 300°C.

Pros & Cons: The primary advantage of glass is its durability and aesthetic appeal. However, it is heavier and more fragile than plastic or metal, which can lead to breakage during transport or use.

Impact on Application: Glass components can enhance the accuracy of infrared readings by providing a clear path for the infrared sensor. However, they require careful handling and may complicate the design due to their weight.

Considerations for International Buyers: Buyers should ensure that glass components comply with safety standards to prevent breakage and ensure user safety. This is especially important in regions with stringent regulations, such as Germany.

What Are the Benefits of Electronic Components in Thermometers?

Key Properties: Electronic components, including sensors and microcontrollers, are essential for the functionality of infrared thermometers. They typically operate within a temperature range of -40°C to 125°C.

Pros & Cons: The advantages of electronic components include high accuracy and quick response times. However, they can be sensitive to environmental conditions, such as humidity and temperature extremes.

Impact on Application: High-quality electronic components can significantly enhance the thermometer’s performance, providing accurate readings within seconds. However, they may require more complex manufacturing processes and quality control.

Considerations for International Buyers: It is crucial to ensure that electronic components meet international standards for safety and performance, such as IEC 60601-1, particularly for markets in Africa and South America, where regulations may vary.

Summary Table of Material Selection for Medical Infrared Forehead Thermometers

| Material | Typical Use Case for medical infrared forehead thermometer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and casing | Lightweight and cost-effective | Less durable, prone to UV degradation | Low |

| Metal | Structural components and sensors | Durable and corrosion-resistant | Higher cost, complex manufacturing | Medium |

| Glass | Lenses and display screens | High clarity and scratch resistance | Heavy and fragile | Medium |

| Electronic Components | Sensors and microcontrollers | High accuracy and quick response | Sensitive to environmental conditions | High |

This analysis provides a comprehensive overview of the materials commonly used in medical infrared forehead thermometers, offering valuable insights for international B2B buyers seeking to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for medical infrared forehead thermometer

What Are the Key Stages in the Manufacturing Process of Medical Infrared Forehead Thermometers?

Manufacturing medical infrared forehead thermometers involves several critical stages designed to ensure high-quality, reliable products. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-grade materials, such as plastics for the casing and advanced sensors for temperature measurement. The materials must meet stringent medical device standards to ensure safety and effectiveness. Suppliers often provide certifications for raw materials, which should be verified by B2B buyers.

-

Forming: This stage involves shaping the prepared materials into the required components. For plastic casings, injection molding is a common technique, allowing for precise dimensions and surface finishes. Advanced technologies like 3D printing may also be utilized for prototyping, enabling rapid adjustments based on initial testing results.

-

Assembly: Once the components are formed, they are assembled into a complete device. This process often involves automated systems for placing sensors and electronic circuits, followed by manual assembly for parts requiring intricate handling. Each unit is typically assembled under controlled conditions to minimize contamination.

-

Finishing: The final stage involves testing and finishing touches, including the application of coatings for durability and aesthetics. This may also encompass the addition of user interfaces, like LED displays and control buttons, ensuring that the product is user-friendly and meets ergonomic standards.

What Quality Assurance Measures Are Essential for Medical Infrared Forehead Thermometers?

Quality assurance is crucial in the production of medical infrared forehead thermometers, as these devices are often used in critical health monitoring contexts. Several international and industry-specific standards guide the QA process.

-

International Standards: Compliance with ISO 9001 is vital, as it outlines the requirements for a quality management system. Additionally, adherence to IEC 60601-1 ensures the safety and effectiveness of medical electrical equipment. For B2B buyers, these certifications are strong indicators of a manufacturer’s commitment to quality.

-

Industry-Specific Standards: Products must also comply with CE marking requirements in Europe, which certifies that they meet health, safety, and environmental protection standards. For buyers in regions like Saudi Arabia, understanding local regulations and ensuring compliance with Saudi Food and Drug Authority (SFDA) standards is essential.

-

Quality Control Checkpoints: Effective quality control involves several checkpoints during the manufacturing process:

– Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during assembly helps catch defects early. This includes checking electronic connections and sensor calibrations.

– Final Quality Control (FQC): Each finished thermometer undergoes rigorous testing, including temperature accuracy tests and functional assessments to confirm compliance with performance standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to ensure the suppliers they engage with maintain high-quality standards. Here are actionable strategies:

-

Conduct Supplier Audits: Regular audits of manufacturing facilities can provide insights into production capabilities and quality control practices. These audits should assess adherence to international standards and internal quality processes.

-

Request Quality Reports: Suppliers should provide documentation of their quality control measures, including testing results and compliance certificates. Buyers should review these reports to ensure that they align with their standards and expectations.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of a supplier’s quality control practices. This is particularly useful for international transactions where buyers may not have direct oversight.

-

Understand Certification Nuances: Different regions may have varying certification requirements. For example, while CE marking is crucial for European markets, FDA clearance is essential for the U.S. market. Buyers should familiarize themselves with these nuances to ensure compliance.

What Testing Methods Are Commonly Used in Quality Control of Medical Infrared Forehead Thermometers?

Testing methods for medical infrared forehead thermometers are designed to ensure accuracy, reliability, and safety. Common testing procedures include:

-

Calibration Tests: To verify accuracy, thermometers are calibrated against standardized temperature sources. This ensures that readings fall within specified tolerances, typically ±0.4°F (±0.2°C) for body temperature measurements.

-

Environmental Testing: Devices are tested under various environmental conditions to assess performance stability. This includes testing at different ambient temperatures and humidity levels, simulating real-world usage scenarios.

-

Safety Testing: Compliance with safety standards like IEC 60601-1 requires thorough electrical safety tests, including insulation resistance and leakage current tests, to ensure that the device poses no risk to users.

-

User Experience Testing: Assessing the usability of the thermometer is also crucial. This involves evaluating the user interface, display readability, and overall ergonomics to ensure that the product is intuitive and accessible.

How Do Regional Market Considerations Affect Quality Assurance in Medical Device Manufacturing?

When sourcing medical infrared forehead thermometers, B2B buyers must consider regional market requirements that can impact quality assurance processes:

-

Africa: In many African countries, regulatory frameworks are still developing. Buyers should ensure that suppliers comply with WHO guidelines and local health authority regulations.

-

South America: Regulatory bodies like ANVISA in Brazil require compliance with specific testing and certification processes. Buyers should verify that suppliers are well-versed in these requirements.

-

Middle East: Countries like Saudi Arabia have strict standards governed by the SFDA. Understanding these regulations is crucial for ensuring that products are market-ready.

-

Europe: The CE marking process can be intricate, requiring extensive documentation and compliance with multiple directives. Buyers in Europe must ensure that suppliers have robust quality systems in place to facilitate this process.

Conclusion

For B2B buyers in the medical device sector, understanding the manufacturing processes and quality assurance measures of medical infrared forehead thermometers is essential. By focusing on supplier audits, quality reports, and compliance with international standards, buyers can ensure they source reliable and effective medical devices that meet the needs of their markets. This proactive approach not only mitigates risks but also enhances the overall purchasing experience.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘medical infrared forehead thermometer’

To ensure a successful procurement process for medical infrared forehead thermometers, this practical sourcing guide outlines essential steps for B2B buyers. These steps will help you navigate the complexities of sourcing, ensuring that you select a high-quality product that meets your needs and complies with relevant regulations.

Step 1: Define Your Technical Specifications

Before you begin the sourcing process, it is crucial to clearly define your technical specifications. This includes understanding the measurement range, accuracy, and response time you require. For instance, a thermometer should ideally measure human body temperatures within the range of 32°C to 42.5°C (89.6°F to 108.5°F) with a high degree of accuracy to ensure reliable results.

- Measurement Modes: Look for models that offer both body and surface temperature measurement modes.

- Resolution and Accuracy: A thermometer with a resolution of 0.1°C and an accuracy of ±0.5°C is generally preferable.

Step 2: Research Regulatory Compliance

Ensure that the products you consider comply with necessary regulatory standards such as FDA clearance or CE marking. Compliance with these standards indicates that the device has undergone rigorous testing for safety and efficacy.

- Documentation: Request copies of certification documents from suppliers.

- Local Regulations: Be aware of any additional local regulations that may apply in your region, especially if you are sourcing from different countries.

Step 3: Evaluate Potential Suppliers

Conduct a thorough evaluation of potential suppliers to gauge their reliability and quality of products. Look for suppliers with a proven track record in the medical equipment sector.

- Company Background: Review company profiles, including years in business and market reputation.

- Customer References: Request references or case studies from other businesses that have purchased similar products.

Step 4: Assess Product Features and Usability

Examine the features of the infrared forehead thermometers you are considering. User-friendly designs can significantly impact efficiency, especially in high-traffic environments.

- Non-contact Design: Ensure the thermometer operates effectively at a distance of 2 to 5 cm to minimize cross-contamination.

- Display and Memory Functions: Look for devices with backlit displays and memory functions that can store multiple readings for easy access.

Step 5: Compare Pricing and Warranty Options

Once you have a shortlist of suppliers, compare their pricing structures along with warranty options. Pricing can vary significantly based on features and supplier reputation.

- Bulk Purchase Discounts: Inquire about discounts for bulk purchases, as this can lead to significant cost savings.

- Warranty Terms: A longer warranty period often indicates manufacturer confidence in product quality, providing peace of mind.

Step 6: Conduct a Trial Purchase

Before making a large commitment, consider a trial purchase of a small batch of thermometers. This allows you to test the product’s performance and usability in your specific environment.

- Feedback from Staff: Gather feedback from users to identify any issues or additional training needs.

- Performance Evaluation: Assess whether the device meets your initial specifications and expectations.

Step 7: Finalize Your Purchase Agreement

Once you are satisfied with the product and supplier, finalize your purchase agreement. Ensure that all terms, including delivery timelines, payment terms, and after-sales support, are clearly defined.

- Contract Details: Include clauses for returns or exchanges in case the product does not meet your expectations.

- Communication Channels: Establish clear communication channels for ongoing support and service inquiries.

Following these steps will not only streamline your procurement process but also ensure that you invest in a reliable medical infrared forehead thermometer that meets your operational needs.

Comprehensive Cost and Pricing Analysis for medical infrared forehead thermometer Sourcing

What Are the Key Cost Components in Sourcing Medical Infrared Forehead Thermometers?

When sourcing medical infrared forehead thermometers, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used, such as infrared sensors and plastic housings, significantly influence pricing. Higher-quality components may incur a higher cost but often lead to better accuracy and reliability.

-

Labor: Labor costs can vary based on the production location. Countries with lower labor costs may offer more competitive pricing, but this could impact quality control.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, factory rent, and administrative expenses. Efficient manufacturing processes can help reduce these costs.

-

Tooling: Initial setup costs for molds and production tools are essential to consider, especially for custom designs. This upfront investment can be substantial but is amortized over larger production runs.

-

Quality Control (QC): Rigorous quality checks and certifications (e.g., FDA, CE) are vital for medical devices. These processes add to the overall cost but are necessary to ensure compliance with international standards.

-

Logistics: Shipping costs can vary significantly based on the destination, volume, and chosen shipping method. Understanding Incoterms is essential for clarifying responsibilities and costs associated with transportation.

-

Margin: Suppliers typically mark up prices to cover their costs and profit. The margin can vary based on supplier reputation, reliability, and market demand.

How Do Price Influencers Affect the Cost of Medical Infrared Forehead Thermometers?

Several factors influence the pricing of medical infrared forehead thermometers, including:

-

Volume/MOQ: Purchasing in larger quantities often results in lower unit prices. Suppliers may offer discounts for minimum order quantities, making it financially advantageous for buyers to consolidate orders.

-

Specifications and Customization: Custom features, such as specific temperature ranges or added functionalities, can increase costs. Buyers should weigh the benefits of customization against the additional expense.

-

Materials and Quality Certifications: High-quality materials and certifications can drive up costs. Buyers in regions with strict regulatory standards may prioritize certified products, affecting overall pricing.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products due to perceived quality and service levels.

-

Incoterms: Understanding shipping terms can significantly impact final costs. Different Incoterms assign various responsibilities for shipping and customs, which can affect pricing strategies.

What Are Essential Buyer Tips for Negotiating Costs?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, it’s essential to consider several strategies:

-

Negotiation: Leverage your position as a buyer by discussing volume discounts or exploring alternative suppliers. Building a long-term relationship with suppliers can also lead to better pricing over time.

-

Cost-Efficiency: Assess the total cost of ownership rather than focusing solely on purchase price. Consider factors like maintenance, durability, and warranty services, as these can lead to savings in the long run.

-

Pricing Nuances for International Transactions: Be aware of currency fluctuations and import duties that may affect final costs. Consider locking in prices or negotiating terms that account for these variables.

-

Research and Compare: Conduct thorough market research to compare pricing across suppliers. This can provide leverage during negotiations and help identify the best value for your needs.

Disclaimer on Indicative Prices

Prices for medical infrared forehead thermometers can vary widely based on the factors discussed. The examples provided in sourcing materials are indicative and may not reflect current market conditions. Always consult with suppliers for the most accurate and up-to-date pricing information tailored to your specific requirements.

Alternatives Analysis: Comparing medical infrared forehead thermometer With Other Solutions

Introduction to Alternatives in Temperature Measurement Solutions

In the healthcare and industrial sectors, the demand for reliable and efficient temperature measurement solutions has surged, particularly in response to global health challenges. While medical infrared forehead thermometers have gained popularity due to their non-contact nature and quick response times, various alternatives exist that cater to specific needs and contexts. Understanding these options is crucial for B2B buyers looking to implement effective temperature screening methods in their operations.

| Comparison Aspect | Medical Infrared Forehead Thermometer | Digital Oral Thermometer | Thermal Imaging Camera |

|---|---|---|---|

| Performance | Fast readings (1 second) | Slower (30 seconds) | Real-time monitoring |

| Cost | Moderate ($30 – $150) | Low ($5 – $20) | High ($1,000+) |

| Ease of Implementation | User-friendly, minimal training needed | Simple, straightforward | Requires training and setup |

| Maintenance | Low, minimal cleaning required | Moderate, needs regular cleaning | High, requires calibration and maintenance |

| Best Use Case | Mass screening in public spaces | Individual checks at home or clinics | Surveillance in large areas or events |

Detailed Breakdown of Alternatives

Digital Oral Thermometer

Digital oral thermometers are widely used for individual temperature checks, especially in clinical settings. They are cost-effective and provide accurate readings within a few seconds to a minute, depending on the model. However, they require direct contact with the patient, which can pose hygiene risks, especially in high-traffic environments. Their affordability makes them suitable for home use or small clinics, but they are not ideal for mass screenings.

Thermal Imaging Camera

Thermal imaging cameras offer a sophisticated solution for temperature measurement, capable of scanning multiple individuals simultaneously. They provide real-time monitoring and can identify elevated skin temperatures, making them valuable in crowded areas like airports or large events. However, these systems come with high costs and require trained personnel for effective operation and interpretation of results. Maintenance is also more complex, as these cameras need regular calibration and servicing to ensure accuracy.

Conclusion: Choosing the Right Temperature Measurement Solution

When selecting a temperature measurement solution, B2B buyers should carefully consider their specific needs, operational scale, and budget. Medical infrared forehead thermometers stand out for mass screening due to their speed and ease of use, making them suitable for public health monitoring. In contrast, digital oral thermometers excel in personal use and smaller settings, while thermal imaging cameras are ideal for large venues requiring real-time monitoring. By evaluating these factors, businesses can make informed decisions that align with their operational objectives and health safety protocols.

Essential Technical Properties and Trade Terminology for medical infrared forehead thermometer

What Are the Key Technical Properties of Medical Infrared Forehead Thermometers?

Medical infrared forehead thermometers are critical tools for non-contact temperature measurement, especially in healthcare settings. Understanding their technical properties is essential for B2B buyers to ensure they select devices that meet regulatory standards and operational needs.

1. Measurement Range

The measurement range specifies the temperatures that the thermometer can accurately assess. For body temperature, typical ranges are between 89.6°F to 108.5°F (32.0°C to 42.5°C). Understanding this range is crucial for applications in fever screening, as using a thermometer outside its range can lead to inaccurate readings, potentially impacting health outcomes.

2. Accuracy

Accuracy is a pivotal specification that indicates how close the thermometer’s readings are to the actual temperature. Common accuracy tolerances are ±0.4°F (±0.2°C) for body temperature measurements. High accuracy is essential for reliable data collection in clinical settings, helping to prevent misdiagnosis or unnecessary interventions.

3. Resolution

Resolution refers to the smallest increment that the thermometer can display. A resolution of 0.1°F (0.1°C) allows for precise readings and can be particularly important in monitoring slight changes in temperature. This property is vital for healthcare providers who need detailed information for patient assessment.

4. Field of View and Measuring Distance

The field of view and measuring distance determine how far the thermometer needs to be from the subject to obtain an accurate reading. Most devices operate effectively at a distance of 2 to 5.9 inches (5 to 15 cm). This non-contact feature reduces the risk of cross-contamination, making these thermometers suitable for high-traffic areas such as hospitals and airports.

5. Storage Capacity

Many infrared thermometers can store a limited number of previous readings, typically up to 32. This feature allows for easy monitoring of temperature trends, which can be crucial in environments where multiple readings are taken frequently. B2B buyers should consider this feature for operational efficiency.

6. Certifications

Certifications such as FDA clearance and CE marking indicate compliance with safety and quality standards. These certifications assure buyers that the product meets regulatory requirements, which is essential for international trade, particularly in regions like Europe and the Middle East.

What Are Common Trade Terms Related to Medical Infrared Forehead Thermometers?

Understanding trade terminology is essential for navigating the procurement process effectively. Here are some key terms that B2B buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end product. In the context of medical thermometers, OEM partnerships can offer buyers customized solutions, allowing them to brand products under their own name while leveraging the manufacturer’s expertise.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for buyers to understand, as it impacts inventory management and cash flow. Knowing the MOQ can help companies plan their purchases more effectively.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing and other details for specific products. For medical thermometers, an RFQ can help buyers gather multiple quotes, allowing them to compare prices and terms to make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to clarify shipping costs, risks, and delivery responsibilities, especially when importing medical devices from different regions.

5. CE Marking

CE marking indicates that a product complies with EU safety, health, and environmental protection standards. For buyers in Europe, this certification is essential as it signifies that the thermometer can be legally marketed in the European Economic Area.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing medical infrared forehead thermometers, ensuring compliance, accuracy, and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the medical infrared forehead thermometer Sector

What are the Global Drivers Influencing the Medical Infrared Forehead Thermometer Market?

The medical infrared forehead thermometer market has seen substantial growth, driven primarily by the increasing demand for non-contact temperature measurement solutions, particularly in response to global health crises like the COVID-19 pandemic. Countries in Africa, South America, the Middle East, and Europe are witnessing a surge in adoption due to heightened awareness of health and safety protocols in public spaces, workplaces, and healthcare facilities. Furthermore, advancements in infrared technology are improving the accuracy and speed of temperature readings, making these devices more appealing to international B2B buyers.

Key trends include the integration of digital technologies, such as Bluetooth connectivity for data sharing and cloud storage capabilities. This shift towards smart devices is particularly relevant for organizations looking to streamline health monitoring processes and maintain compliance with health regulations. Additionally, as consumer expectations evolve, suppliers are increasingly offering customizable solutions that cater to specific industries, from hospitality to healthcare, which is vital for B2B buyers in diverse markets like Saudi Arabia and Germany.

How is Sustainability and Ethical Sourcing Impacting the Medical Infrared Forehead Thermometer Market?

Sustainability and ethical sourcing have become critical factors for B2B buyers in the medical infrared forehead thermometer sector. The environmental impact of manufacturing processes and materials used in these devices is under scrutiny, prompting companies to adopt greener practices. Suppliers are increasingly seeking certifications such as ISO 14001, which demonstrates a commitment to environmental management, and CE marking, which assures compliance with European health and safety standards.

Moreover, the demand for ethically sourced materials is growing, especially in regions like Europe where regulatory frameworks are stringent. B2B buyers are now prioritizing suppliers who can guarantee responsible sourcing of components and materials. This includes the use of recyclable packaging and minimizing waste during production. By choosing suppliers with strong sustainability credentials, buyers can not only enhance their corporate social responsibility profiles but also mitigate risks associated with supply chain disruptions and regulatory non-compliance.

What is the Brief Evolution of Medical Infrared Forehead Thermometers?

The evolution of medical infrared forehead thermometers can be traced back to the late 20th century when initial prototypes were developed for non-invasive temperature measurements. Early models were primarily used in hospital settings, but technological advancements in the 2000s led to greater accuracy and user-friendliness. The integration of infrared technology allowed for quicker readings without physical contact, paving the way for widespread adoption in both medical and consumer markets.

The COVID-19 pandemic accelerated this trend, leading to an explosive growth in demand. Today, these thermometers are essential tools in various sectors, including healthcare, education, and hospitality, where rapid screening is vital. As a result, manufacturers are continually innovating, focusing on enhancing features such as data management capabilities and user interface design, making these devices more accessible and valuable for B2B buyers across different regions.

Frequently Asked Questions (FAQs) for B2B Buyers of medical infrared forehead thermometer

-

How do I ensure the accuracy of a medical infrared forehead thermometer?

To guarantee the accuracy of a medical infrared forehead thermometer, choose devices that comply with international standards such as ASTM E1965 and have been FDA cleared or CE marked. Regular calibration is crucial; inquire with suppliers about their calibration process and frequency. Additionally, ensure the thermometer is used within its specified distance and environmental conditions. Training staff on proper usage can also minimize errors and enhance reliability during temperature screenings. -

What is the best infrared thermometer for large-scale health screenings?

For large-scale health screenings, look for thermometers that offer fast response times (1 second or less) and a non-contact design to minimize cross-contamination. Models with memory functions to store previous readings and adjustable alarm settings for high temperatures are beneficial. Consider those that operate effectively in diverse environmental conditions and have a wide measurement range (e.g., 32°C to 42.5°C). Verify that the selected model is FDA cleared or CE certified for added assurance. -

What are the typical payment terms for purchasing medical infrared forehead thermometers internationally?

Payment terms can vary significantly among suppliers. Common terms include payment in advance, letters of credit, or net 30/60 days after delivery. When negotiating, consider using secure methods like PayPal or bank transfers that offer buyer protection. It’s advisable to establish clear payment schedules in the contract to avoid potential disputes and ensure a smooth transaction process. -

What factors should I consider when vetting suppliers for infrared thermometers?

When vetting suppliers, check for certifications such as ISO 13485 for quality management systems in medical devices. Review their product portfolio for FDA clearance or CE marking to ensure compliance with safety standards. Request references or testimonials from previous clients, and assess their capacity for bulk orders and customization options. Additionally, evaluate their responsiveness and customer service, as these factors will affect your ongoing relationship. -

Can I customize infrared thermometers for my brand?

Many manufacturers offer customization options for infrared thermometers, including branding, packaging, and specific feature adjustments. Discuss your requirements with potential suppliers during the initial inquiry. Be clear about your desired specifications and the minimum order quantities (MOQs) for customization. Keep in mind that customization may impact pricing and lead times, so factor these elements into your decision-making process. -

What is the minimum order quantity (MOQ) for medical infrared forehead thermometers?

The MOQ for medical infrared forehead thermometers can vary widely among suppliers, typically ranging from 50 to several hundred units. Factors influencing MOQ include the manufacturer’s production capacity, the complexity of the product, and customization requests. It’s advisable to communicate your anticipated needs upfront to negotiate favorable terms, especially if you plan to establish a long-term supply relationship. -

What logistics considerations should I keep in mind when importing thermometers?

When importing medical infrared thermometers, consider shipping methods, customs clearance, and potential tariffs. Air freight is faster but may be costlier, while sea freight is more economical for larger shipments. Ensure compliance with local regulations regarding medical device imports, including necessary documentation and certifications. Partnering with a reliable freight forwarder can help navigate these complexities and ensure timely delivery. -

How do I manage quality assurance for imported infrared thermometers?

To manage quality assurance for imported infrared thermometers, establish clear quality control standards with your supplier before placing orders. Request samples for testing and verification of accuracy and functionality. Consider third-party inspections before shipment to ensure compliance with specifications. Additionally, maintain a robust return policy for defective items, and keep communication channels open with the supplier for any quality-related issues that may arise post-delivery.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Medical Infrared Forehead Thermometer Manufacturers & Suppliers List

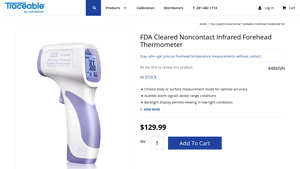

1. Traceable – FDA Cleared Noncontact Infrared Forehead Thermometer

Domain: traceable.com

Registered: 2003 (22 years)

Introduction: Product Name: FDA Cleared Noncontact Infrared Forehead Thermometer

Model Number: 4486NN

Price: $129.99

Measurement Modes: Body and Surface

Body Temperature Range: 89.6 to 108.5°F (32.0 to 42.5°C)

Surface Temperature Range: 32 to 140°F (0 to 60°C)

Infrared Accuracy:

– Body Mode: ±1.5°F (±0.8°C) below 89.6°F; ±0.5°F (±0.3°C) from 93.2 to 96.6°F; ±0.4°F (±0.2°C) from 96.8 to 102.2°F; ±0.5°F (±0.3°C)…

2. DIKANG – Medical Non-Contact Infrared Thermometer

Domain: massagewarehouse.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “DIKANG™ Medical Non-Contact Infrared Thermometer (HG-01)”, “Item Number”: “740 0083”, “Price”: “$32.39”, “Rating”: “20 % of 100 (1 Review)”, “Satisfaction Guarantee”: “100% satisfaction guarantee with a 30-day return policy.”, “Price Match Guarantee”: “Valid for 30 days from purchase against competitors in the continental US.”, “Measuring Distance”: “2CM-5CM”, “Temperature Range”…

3. Spirit Industrial – JZIKi Medical Infrared Forehead Thermometer

Domain: spiritindustrial.com

Registered: 2020 (5 years)

Introduction: Product Name: JZIKi Medical Infrared Forehead Thermometer

Price: $16.99 (Retail Price: $29.99, You Save: $13.00, 43% off)

Part Number: 10704001

Availability: Limited Inventory

Key Features:

– No contact response in one second with high precision

– Combination of human body and object measuring options

– Switch between measuring human body temperature and surface temperature

– Readings in Celsius a…

4. Nexinno Tech – PC828 Medical Digital Infrared Thermometer

Domain: nexinnotech.com

Registered: 2017 (8 years)

Introduction: Model: PC828

Type: Medical Digital Infrared Thermometer

Measurement Modes: Forehead and object surface (contact-free)

Distance: 3-5 cm

Measurement Duration: 1 second

Precision: Body ±0.2 ˚C, Surface ±1.0 ˚C

Measurement Range: Body 32.0~42.9 ˚C, Surface 0.0~100 ˚C, Animal 32.0~45.0 ˚C

Display Resolution: 0.1 ˚C / 0.1 ˚F

Memory: 32 sets

Battery Life: 2000+ measurements

Features: Fever alarm, auto sh…

5. Calsikon – Forehead Thermometer

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Brand”:”Calsikon”,”Type”:”Forehead Thermometer”,”Condition”:”New”,”Item Number”:”256657091189″,”Price”:”$4.95″,”Delivery”:”$5.24 delivery in 2–4 days”,”Returns Accepted”:”Yes”,”Quantity Available”:”1″}

Strategic Sourcing Conclusion and Outlook for medical infrared forehead thermometer

In the evolving landscape of healthcare, the strategic sourcing of medical infrared forehead thermometers is critical for organizations aiming to enhance their screening capabilities and maintain safety protocols. These devices offer non-contact temperature measurement, significantly reducing the risk of cross-contamination and streamlining the process of monitoring large groups, a necessity in both clinical and public settings. Key features such as quick response times, multiple measurement modes, and compliance with international standards (like FDA and CE certifications) are essential for ensuring reliability and accuracy.

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the diverse range of available products and their specifications is vital. Prioritizing suppliers who provide comprehensive support, competitive pricing, and favorable return policies can enhance procurement strategies.

As we look to the future, the demand for efficient, reliable medical devices will continue to rise. Buyers are encouraged to proactively engage with suppliers, assess product offerings, and leverage strategic partnerships to ensure they are equipped to meet the challenges ahead. Investing in quality infrared thermometers not only enhances operational efficiency but also supports public health initiatives globally.