Is Your Tiger Brand Rice Cooker Parts Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for tiger brand rice cooker parts

In the dynamic landscape of global commerce, sourcing Tiger brand rice cooker parts can pose a unique challenge for international B2B buyers. Whether you’re operating in Africa, South America, the Middle East, or Europe, the complexities of identifying the right components, understanding model specifications, and ensuring the authenticity of suppliers can significantly impact operational efficiency. This comprehensive guide aims to demystify the process of acquiring Tiger rice cooker parts, covering everything from the various types of rice cookers—Induction Heating (IH), Microcomputer (Micom), and Electric—to practical insights on supplier vetting and cost considerations.

Navigating the intricacies of the supply chain for these essential kitchen appliances is crucial for businesses looking to maintain high standards of service and customer satisfaction. By providing detailed information on the applications of different parts, a thorough overview of reputable suppliers, and strategies for effective procurement, this guide empowers B2B buyers to make informed purchasing decisions. Moreover, it highlights the importance of understanding availability timelines for replacement parts, which can vary significantly based on production discontinuation.

As you delve into this resource, you will be equipped with the knowledge necessary to streamline your sourcing process, ultimately enhancing your operational capabilities and fostering stronger customer relationships across diverse markets.

Understanding tiger brand rice cooker parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Induction Heating (IH) Parts | Uses electromagnetic energy for precise cooking control | High-end restaurants, catering | Pros: Efficient cooking, energy-saving. Cons: Higher initial investment. |

| Microcomputer (Micom) Parts | Smart technology for automated cooking and temperature control | Food service operations, meal prep | Pros: Versatile cooking options. Cons: Requires technical knowledge for repairs. |

| Electric Rice Cooker Parts | Basic electric components for standard rice cooking | Small restaurants, home appliance retailers | Pros: Affordable, easy to use. Cons: Limited features compared to IH and Micom. |

| Inner Pot Variations | Different materials (e.g., non-stick, stainless steel) | Retailers, wholesalers of kitchenware | Pros: Customization for different cooking needs. Cons: Compatibility issues with older models. |

| Sealing Gaskets and Accessories | Essential for maintaining steam and pressure | Appliance repair services, retailers | Pros: Critical for performance, easy to replace. Cons: Frequent replacements may be needed. |

What are the distinguishing features of Induction Heating (IH) Parts?

Induction Heating (IH) rice cookers utilize advanced electromagnetic technology to deliver precise temperature control, making them ideal for high-end culinary environments. These parts are essential for restaurants and catering businesses that prioritize efficiency and quality in their rice preparation. While they offer energy savings and superior cooking performance, the initial investment can be significant, making them more suitable for businesses with higher budgets.

How do Microcomputer (Micom) Parts enhance cooking efficiency?

Microcomputer (Micom) rice cookers are equipped with smart technology that automates cooking processes, allowing for customized settings based on rice types and desired textures. This technology is particularly beneficial for food service operations and meal prep companies that require consistency and versatility. However, buyers should consider the technical expertise required for repairs, as these components can be more complex than traditional models.

What are the benefits of Electric Rice Cooker Parts for small businesses?

Electric rice cooker parts are designed for basic rice cooking and are typically more affordable than their IH and Micom counterparts. They are ideal for small restaurants and home appliance retailers that need reliable, easy-to-use cooking solutions. While they may lack advanced features, their straightforward operation and lower price point make them an attractive option for budget-conscious buyers.

Why are Inner Pot Variations important for B2B buyers?

Inner pot variations, available in materials like non-stick and stainless steel, allow businesses to tailor their rice cooking equipment to specific culinary needs. Retailers and wholesalers of kitchenware benefit from offering these customizable options, which can enhance the cooking experience. However, businesses should be aware of potential compatibility issues with older rice cooker models, which could complicate parts replacement.

How do Sealing Gaskets and Accessories contribute to rice cooker performance?

Sealing gaskets and accessories play a crucial role in maintaining the steam and pressure necessary for optimal rice cooking. They are essential for appliance repair services and retailers, ensuring that customers can maintain their rice cookers effectively. While these parts are typically easy to replace, frequent replacements may be necessary, and businesses should factor this into their maintenance budgets.

Key Industrial Applications of tiger brand rice cooker parts

| Industry/Sector | Specific Application of tiger brand rice cooker parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service and Catering | Replacement parts for commercial rice cookers | Ensures consistent food quality and reduces downtime | Availability of parts, lead times, and compatibility with existing equipment |

| Hospitality and Hotels | Maintenance of rice cookers in buffet and dining services | Enhances guest experience through reliable service | Bulk purchasing options and warranty support for parts |

| Retail and Distribution | Stocking spare parts for resale in appliance stores | Increases customer satisfaction and loyalty | Understanding local market demand and import regulations |

| Education and Institutions | Use in institutional kitchens for large-scale meal prep | Streamlines meal preparation processes and consistency | Compliance with safety standards and bulk pricing agreements |

| Health and Wellness Centers | Utilization in meal planning and preparation for dietary needs | Supports healthy eating initiatives and patient care | Sourcing high-quality, durable parts for continuous use |

How Are Tiger Brand Rice Cooker Parts Used in the Food Service and Catering Industry?

In the food service and catering sector, tiger brand rice cooker parts are essential for maintaining the functionality of commercial rice cookers. These parts, such as inner pots and steam vents, ensure that rice is cooked to perfection, which is crucial for maintaining food quality. Downtime due to equipment failure can lead to significant financial losses, so having readily available replacement parts minimizes disruptions. B2B buyers in this sector must consider the availability of parts, lead times for delivery, and compatibility with existing cooking equipment to ensure seamless operations.

What Role Do Tiger Brand Rice Cooker Parts Play in the Hospitality and Hotel Sector?

In hospitality settings, tiger brand rice cooker parts are vital for the upkeep of rice cookers used in buffets and dining services. Reliable equipment enhances the guest experience by providing consistently cooked rice, which is a staple in many cuisines. Hotels often face high demands during peak seasons, making it essential to have a quick sourcing strategy for replacement parts. Buyers should prioritize bulk purchasing options and warranty support to ensure they can meet guest expectations without interruption.

Why Are Tiger Brand Rice Cooker Parts Important for Retail and Distribution?

Retailers and distributors benefit from stocking tiger brand rice cooker parts to meet consumer demand for replacements. By offering these parts, stores can enhance customer satisfaction, as consumers often seek quick fixes for their appliances. Understanding local market trends and customer preferences is crucial for effective inventory management. Additionally, buyers should be aware of import regulations that may affect the sourcing of these parts in different regions.

How Do Educational Institutions Utilize Tiger Brand Rice Cooker Parts?

Educational institutions often rely on tiger brand rice cooker parts for large-scale meal preparation in cafeterias. These parts help streamline cooking processes, ensuring that meals are prepared efficiently and consistently. With a focus on healthy eating, institutions must comply with safety standards, making it essential for them to source high-quality, durable parts. Establishing bulk pricing agreements can also lead to significant cost savings for these organizations.

What Benefits Do Health and Wellness Centers Gain from Tiger Brand Rice Cooker Parts?

Health and wellness centers use tiger brand rice cooker parts to support meal planning and preparation for dietary needs. Reliable rice cookers equipped with quality parts enable these facilities to provide nutritious meals that align with health initiatives. Sourcing durable parts is crucial, as these centers often operate on tight schedules and require equipment that can withstand frequent use. Buyers should prioritize suppliers that can guarantee consistent quality and availability of parts to support their operations.

3 Common User Pain Points for ‘tiger brand rice cooker parts’ & Their Solutions

Scenario 1: Difficulty in Identifying the Correct Rice Cooker Parts

The Problem: B2B buyers often face challenges in identifying the specific parts needed for their Tiger brand rice cookers. With various models and numerous components, the task can become overwhelming. Misidentifying parts can lead to costly mistakes, such as ordering incompatible items, causing delays in repairs or maintenance, and ultimately affecting customer satisfaction. For businesses relying on these appliances for food service, the stakes are particularly high.

The Solution: To streamline the parts identification process, buyers should utilize the resources provided by Tiger Corporation. First, ensure you have the correct model number of the rice cooker, which can typically be found on the bottom of the appliance or in the user manual. Tiger’s website offers a dedicated section for parts lookup where you can input the model number to find compatible components. Additionally, consider creating a comprehensive parts inventory list based on the models you own. This proactive approach will facilitate faster ordering and reduce the risk of errors. Establish relationships with local distributors who can provide insights into parts availability and lead times, further enhancing your operational efficiency.

Scenario 2: Limited Availability of Discontinued Parts

The Problem: As models of Tiger rice cookers are discontinued, sourcing replacement parts can become a significant challenge for B2B buyers. This issue is particularly pressing for businesses that have older models still in service, as they may not find necessary components readily available. Without the right parts, businesses can face extended downtimes, which can lead to lost revenue and diminished customer trust.

The Solution: To navigate the issue of discontinued parts, buyers should be proactive in understanding the parts supply policy of Tiger Corporation. The company maintains performance parts for repair for up to ten years after a model is discontinued. Thus, it’s crucial to keep track of model discontinuation announcements and stock up on essential parts while they are still available. Moreover, consider establishing partnerships with aftermarket parts suppliers who may offer compatible alternatives. Regularly check forums and community groups where other B2B users share insights about sourcing hard-to-find parts. This collaborative approach can provide valuable leads on where to find discontinued parts and keep your equipment running smoothly.

Scenario 3: Understanding the Differences Between Rice Cooker Types

The Problem: With various types of Tiger rice cookers available—such as Induction Heating (IH), Microcomputer (Micom), and Electric models—B2B buyers often struggle to understand the unique parts and maintenance needs of each type. This confusion can lead to improper parts ordering and ineffective maintenance strategies, ultimately resulting in operational inefficiencies.

The Solution: To mitigate this issue, buyers should invest time in educating themselves about the specific features and parts associated with each type of rice cooker. Tiger Corporation provides detailed information about the distinctions between IH, Micom, and Electric rice cookers on their website. Additionally, consider creating a comparison chart that outlines the key components and maintenance needs of each type. This resource will serve as a quick reference for ordering parts and performing maintenance. Training staff responsible for equipment upkeep on these differences can also enhance operational knowledge. Regular workshops or training sessions can ensure that your team is well-informed about the specific needs of each rice cooker type, leading to better maintenance practices and reduced downtime.

Strategic Material Selection Guide for tiger brand rice cooker parts

What Are the Common Materials Used in Tiger Brand Rice Cooker Parts?

When selecting parts for Tiger brand rice cookers, understanding the materials used is crucial for ensuring product performance, durability, and compliance with international standards. Below are analyses of four common materials used in the manufacturing of these parts.

How Does Stainless Steel Perform in Rice Cooker Parts?

Stainless steel is a widely used material in rice cookers, particularly for inner pots and exterior casings. Its key properties include excellent corrosion resistance, high-temperature tolerance, and durability. Stainless steel can withstand the high-pressure environment of cooking without deforming or rusting.

Pros: Stainless steel is durable and easy to clean, making it suitable for food-related applications. It also offers a sleek aesthetic, appealing to consumers.

Cons: The primary drawbacks include its relatively high cost compared to plastic and its weight, which can make the final product heavier. Additionally, manufacturing processes for stainless steel can be more complex and energy-intensive.

Impact on Application: Stainless steel is compatible with various cooking media, including water and steam, ensuring consistent cooking results. However, it may not be suitable for acidic foods, which can lead to pitting corrosion.

Considerations for International Buyers: Compliance with food safety standards such as FDA (USA) or EFSA (Europe) is essential. Buyers should also consider the material’s compliance with local standards like ASTM or DIN.

What Role Does Aluminum Play in Rice Cooker Parts?

Aluminum is often used for inner pots and heating elements due to its excellent thermal conductivity and lightweight nature. It heats up quickly and evenly, which is vital for cooking rice efficiently.

Pros: Aluminum is cost-effective and lightweight, making it easier to handle and transport. Its thermal properties allow for quick cooking times.

Cons: However, aluminum is prone to corrosion, especially when exposed to acidic or salty foods. It may also react with certain ingredients, affecting the taste of the food.

Impact on Application: While aluminum is suitable for most rice cooking applications, its compatibility with acidic media is limited. This can lead to leaching, which is a concern for health-conscious consumers.

Considerations for International Buyers: Buyers should ensure that aluminum parts meet international safety standards and are anodized or coated to prevent corrosion and food contamination.

How Does Plastic Factor into Rice Cooker Parts?

Plastic is commonly used for external components and some internal parts, such as lids and handles. It is lightweight and can be molded into various shapes, making it versatile.

Pros: Plastic is cost-effective and can be produced in various colors and designs, enhancing product appeal. It is also resistant to corrosion and does not conduct heat, which is beneficial for safety.

Cons: The main disadvantages include lower durability compared to metals and potential issues with heat resistance. Some plastics may warp or degrade over time, especially under high temperatures.

Impact on Application: While plastics are generally safe for food contact, their performance can be compromised in high-heat environments. It is essential to use food-grade plastics that comply with safety regulations.

Considerations for International Buyers: Buyers should verify that the plastics used are BPA-free and meet local regulations regarding food safety and material compliance.

What About Silicone in Rice Cooker Parts?

Silicone is increasingly used for gaskets and seals in rice cookers due to its flexibility and heat resistance. It can withstand high temperatures without degrading, making it ideal for sealing applications.

Pros: Silicone is highly durable, flexible, and resistant to extreme temperatures. It also provides excellent sealing properties, preventing steam from escaping during cooking.

Cons: The primary limitation of silicone is its cost, which is generally higher than that of traditional rubber or plastic. Additionally, it may not be suitable for all applications, such as those requiring high structural integrity.

Impact on Application: Silicone’s compatibility with high temperatures makes it suitable for steam cooking, but it may not be ideal for parts exposed to direct heat.

Considerations for International Buyers: International buyers should ensure that silicone parts comply with food safety standards and are free from harmful additives.

Summary Table of Material Selection for Tiger Brand Rice Cooker Parts

| Material | Typical Use Case for tiger brand rice cooker parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Inner pots, exterior casings | Excellent durability and corrosion resistance | Higher cost and weight | High |

| Aluminum | Inner pots, heating elements | Lightweight and good thermal conductivity | Prone to corrosion and reactivity | Medium |

| Plastic | Lids, handles | Cost-effective and versatile | Lower durability and heat resistance | Low |

| Silicone | Gaskets, seals | High durability and heat resistance | Higher cost and limited structural integrity | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers looking to procure Tiger brand rice cooker parts, ensuring they make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for tiger brand rice cooker parts

What Are the Key Stages in the Manufacturing Process of Tiger Brand Rice Cooker Parts?

The manufacturing process for Tiger brand rice cooker parts involves several critical stages that ensure the production of high-quality components. Understanding these stages is essential for B2B buyers who are sourcing parts for resale or integration into their products.

Material Preparation: What Materials Are Used for Rice Cooker Parts?

The first stage involves selecting high-quality materials that meet the functional requirements of each part. Common materials include stainless steel for inner pots, heat-resistant plastics for external housings, and silicone for gaskets. Each material is chosen based on its durability, thermal resistance, and safety standards. Suppliers often conduct tests to verify the integrity of raw materials, ensuring they meet industry standards before moving to the next stage.

How Are Rice Cooker Parts Formed and Assembled?

Once materials are prepared, the forming process begins. This can involve stamping, molding, or machining, depending on the part’s complexity. For instance, the inner pot may be formed through precision stamping to ensure the correct dimensions and fit.

After forming, the assembly stage follows. Parts are meticulously fitted together, often using automated machinery to enhance precision and reduce human error. This stage may include the integration of electronic components in models equipped with microcomputer controls, ensuring that all electrical connections are secure and functional.

What Finishing Techniques Are Employed for Quality Assurance?

Finishing processes, such as polishing, coating, and painting, are crucial for enhancing the aesthetic and functional properties of the parts. For instance, stainless steel components are polished to prevent corrosion and improve appearance, while non-stick coatings are applied to inner pots to enhance usability. These finishing techniques not only improve the product’s visual appeal but also extend its lifespan and functionality.

What Quality Assurance Measures Are in Place for Tiger Brand Rice Cooker Parts?

Quality assurance (QA) is paramount in the manufacturing of Tiger brand rice cooker parts. B2B buyers should be aware of the various measures and international standards that govern quality control.

Which International Standards Are Relevant for Quality Assurance?

Tiger Corporation adheres to international quality standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, products may also be certified under CE (Conformité Européenne) regulations, ensuring they meet European safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to ensure that each part meets specified standards. These include:

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line.

- In-Process Quality Control (IPQC): This stage involves monitoring the production process itself, ensuring that each part is being manufactured according to specifications.

- Final Quality Control (FQC): Once assembly is complete, FQC tests the finished products to verify their functionality and adherence to quality standards.

How Can B2B Buyers Verify the Quality Control Processes of Suppliers?

For B2B buyers, verifying the quality control processes of suppliers is essential to ensure the reliability of the parts they are sourcing.

What Auditing Practices Should Be Followed?

Conducting audits is a critical method for assessing a supplier’s quality assurance practices. Buyers can request to see audit reports from third-party organizations that verify compliance with international standards. An on-site audit may also be beneficial, allowing buyers to observe the manufacturing process and quality control measures firsthand.

What Testing Methods Are Commonly Used in Quality Assurance?

Common testing methods include:

- Functional Testing: Verifying that parts perform as intended under various conditions.

- Durability Testing: Assessing how parts withstand wear and tear over time.

- Safety Testing: Ensuring that parts meet safety standards and do not pose any hazards to users.

How Do Quality Control Nuances Differ for International B2B Buyers?

International B2B buyers should be mindful of specific quality control nuances that may affect their procurement processes.

What Are the Regional Compliance Requirements?

For buyers in Africa, South America, the Middle East, and Europe, understanding regional compliance requirements is crucial. For instance, European buyers may prioritize CE certifications, while buyers in Africa may need to consider local safety standards. It is essential to communicate these requirements clearly with suppliers to ensure compliance and avoid potential issues.

How Can Buyers Navigate Different Quality Expectations?

Different markets may have varying expectations regarding quality. B2B buyers must conduct thorough market research to understand these differences and communicate their expectations to suppliers. This understanding can help in negotiating terms and ensuring that the parts sourced meet the required quality standards.

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Processes Essential for B2B Buyers?

For international B2B buyers, a comprehensive understanding of the manufacturing processes and quality assurance measures for Tiger brand rice cooker parts is essential. This knowledge not only aids in making informed purchasing decisions but also fosters stronger supplier relationships. By prioritizing quality and compliance, buyers can ensure they are sourcing reliable parts that meet both their operational needs and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tiger brand rice cooker parts’

In this practical sourcing guide, we aim to provide B2B buyers with a comprehensive checklist for procuring Tiger brand rice cooker parts. This step-by-step approach will help streamline the procurement process, ensuring you make informed decisions while minimizing potential risks associated with sourcing.

Step 1: Identify Required Parts and Model Specifications

Begin by determining the specific parts needed for the Tiger rice cookers you intend to service or sell. This includes understanding the model numbers and the corresponding parts compatible with each model.

– Why it matters: Accurate identification of parts prevents unnecessary purchases and ensures compatibility.

– Tip: Utilize the manufacturer’s website or manuals to cross-reference model numbers with required parts.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify potential suppliers who specialize in Tiger brand rice cooker parts. Look for suppliers with a proven track record and positive reviews from previous clients.

– Why it matters: Partnering with reliable suppliers minimizes the risk of receiving substandard parts that could affect product performance.

– Tip: Utilize platforms like industry forums, trade directories, and supplier databases to gather information.

Step 3: Verify Supplier Certifications and Quality Standards

Check whether the suppliers adhere to industry certifications and quality standards relevant to appliance parts. Certifications such as ISO 9001 can indicate a commitment to quality management.

– Why it matters: Certification ensures that the parts you procure meet the necessary safety and quality benchmarks.

– Tip: Request copies of certifications and inquire about their quality assurance processes.

Step 4: Evaluate Pricing and Payment Terms

Request quotes from multiple suppliers to compare pricing structures and payment terms. Ensure you understand the total cost, including shipping fees and any potential import duties.

– Why it matters: Understanding pricing helps in budgeting and ensures that you are getting competitive rates.

– Tip: Be wary of prices that seem too low, as they may indicate inferior quality.

Step 5: Assess Lead Times and Availability

Inquire about lead times for the parts you need and their availability. Some parts may have longer lead times due to supply chain issues or limited stock.

– Why it matters: Knowing the lead times allows for better inventory management and planning, reducing the risk of stockouts.

– Tip: Establish a timeline for your procurement process to align with your operational needs.

Step 6: Request Samples if Possible

Whenever feasible, request samples of the parts before placing a large order. This allows you to assess the quality and compatibility firsthand.

– Why it matters: Sampling reduces the risk of investing in parts that do not meet your standards or fit your equipment.

– Tip: Use this opportunity to evaluate the supplier’s responsiveness and customer service.

Step 7: Establish Clear Communication Channels

Ensure that you have established clear lines of communication with your chosen supplier. Discuss expectations, timelines, and any concerns you might have.

– Why it matters: Good communication fosters a positive working relationship and can help resolve issues quickly.

– Tip: Document all agreements and communications to ensure accountability and reference in the future.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing Tiger brand rice cooker parts effectively, ensuring quality, compatibility, and reliability in their procurement process.

Comprehensive Cost and Pricing Analysis for tiger brand rice cooker parts Sourcing

What are the Key Cost Components in Sourcing Tiger Brand Rice Cooker Parts?

When sourcing Tiger brand rice cooker parts, understanding the cost structure is essential for B2B buyers. The key cost components include:

-

Materials: The cost of raw materials is a significant factor. High-quality components, such as stainless steel for inner pots or durable plastics for lids, can drive up costs. Sourcing materials that meet international quality standards may also incur additional expenses.

-

Labor: Labor costs vary by region. For example, manufacturing in countries with lower labor costs may reduce overall expenses, but this can sometimes compromise quality. Skilled labor is often required for precise assembly and quality control.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, equipment maintenance, and factory rent. Efficient manufacturing processes can help minimize these overhead costs.

-

Tooling: Initial tooling costs for production molds or specialized machinery can be significant. These costs are typically amortized over large production runs, making them less impactful per unit when ordered in bulk.

-

Quality Control (QC): Investing in rigorous QC processes ensures that parts meet specifications and reduces the risk of returns or warranty claims. This may involve additional testing and inspections that add to the overall cost.

-

Logistics: Shipping costs can vary widely based on the origin of the parts and the destination market. For international buyers, understanding the logistics involved, including customs duties and freight charges, is crucial.

-

Margin: Supplier margins can vary based on competition, market demand, and the perceived value of the parts. Negotiating favorable terms can significantly impact overall costs.

How Do Price Influencers Affect the Cost of Tiger Brand Rice Cooker Parts?

Several factors influence the pricing of rice cooker parts, particularly for international buyers:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Higher volumes typically lead to lower per-unit costs due to economies of scale. Negotiating MOQs can be beneficial for larger buyers.

-

Specifications and Customization: Customized parts or those that require specific certifications (e.g., CE marking in Europe) may incur additional costs. Standard parts tend to be more cost-effective.

-

Material Quality and Certifications: Parts made from premium materials or that meet specific industry certifications (like ISO or food safety standards) will generally be priced higher. Buyers should weigh the importance of these factors against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can influence price. Established suppliers with proven track records may charge more but offer better quality assurance and customer support.

-

Incoterms: Understanding shipping terms (Incoterms) is critical. FOB (Free On Board) vs. CIF (Cost, Insurance, and Freight) can significantly affect the total landed cost of parts.

What Tips Can Help B2B Buyers Optimize Costs When Sourcing?

-

Negotiate Pricing: Always engage in negotiations with suppliers. Establishing long-term relationships can lead to better pricing and terms.

-

Consider Total Cost of Ownership (TCO): TCO includes purchase price, shipping, customs duties, and future maintenance costs. Analyzing TCO can help identify the most cost-effective options.

-

Conduct Market Research: Understanding the market rates for specific parts can empower buyers during negotiations. Researching competitors and sourcing multiple quotes can reveal price discrepancies.

-

Quality vs. Cost: While lower prices may be tempting, sacrificing quality can lead to higher long-term costs through returns, replacements, or customer dissatisfaction. Balance quality with cost effectively.

-

Stay Informed on Regulations: Different regions may have varying standards for parts. Being aware of these can prevent costly compliance issues and ensure smooth operations.

Conclusion: Navigating Pricing Nuances for International Buyers

B2B buyers from Africa, South America, the Middle East, and Europe must navigate a complex landscape of costs and pricing when sourcing Tiger brand rice cooker parts. By understanding the cost components, price influencers, and employing strategic purchasing tips, buyers can optimize their procurement processes and achieve better outcomes. Keep in mind that prices can fluctuate based on market conditions and supplier capabilities, so remaining adaptable and informed is essential for successful sourcing.

Alternatives Analysis: Comparing tiger brand rice cooker parts With Other Solutions

Introduction: Exploring Alternatives to Tiger Brand Rice Cooker Parts

In the competitive landscape of kitchen appliances, the demand for reliable rice cookers has led to the emergence of various alternatives to Tiger Brand rice cooker parts. As B2B buyers seek to optimize their procurement strategies, understanding the comparative advantages and disadvantages of different solutions is crucial. This analysis focuses on Tiger Brand rice cooker parts and two alternative solutions: generic aftermarket rice cooker parts and multi-cooker appliances.

Comparison Table

| Comparison Aspect | Tiger Brand Rice Cooker Parts | Generic Aftermarket Parts | Multi-Cooker Appliances |

|---|---|---|---|

| Performance | High compatibility and reliability with Tiger models | Variable quality, may lack precise fit | Versatile cooking options, good performance |

| Cost | Higher due to brand reputation | Generally lower, but quality varies | Mid-range to high, depending on brand |

| Ease of Implementation | Easy to install, designed for specific models | May require modifications | Simple operation, often with presets |

| Maintenance | Supported for up to 10 years post-discontinuation | Limited support, warranty issues common | Generally low maintenance, easy to clean |

| Best Use Case | Ideal for maintaining Tiger appliances | Cost-effective for older models | Great for diverse cooking needs, not limited to rice |

Detailed Breakdown of Alternatives

Generic Aftermarket Rice Cooker Parts

Generic aftermarket parts offer a cost-effective solution for buyers looking to replace components in various rice cooker brands, including Tiger. These parts can be significantly cheaper than original equipment manufacturer (OEM) parts. However, the quality and fit can be inconsistent, leading to potential compatibility issues or diminished performance. Buyers should thoroughly vet suppliers to ensure they meet safety and quality standards. While these parts can save money upfront, the risk of malfunction can lead to higher long-term costs.

Multi-Cooker Appliances

Multi-cooker appliances have gained popularity due to their versatility, allowing users to prepare not just rice but a variety of dishes, including stews, soups, and even yogurt. They typically come with advanced features such as programmable settings and automatic pressure control. While they may require a higher initial investment, the ability to replace several kitchen appliances with one can be a significant cost saver. However, users may find that these appliances take longer to master compared to a traditional rice cooker, and their reliance on technology can pose a learning curve for some.

Conclusion: Choosing the Right Solution for B2B Buyers

When selecting the right solution for rice cooker parts or appliances, B2B buyers should consider their specific needs, budget constraints, and the intended use case. Tiger Brand rice cooker parts provide reliability and compatibility for existing Tiger models, making them ideal for businesses focused on maintaining performance and brand integrity. In contrast, generic aftermarket parts may appeal to cost-conscious buyers willing to accept potential quality trade-offs. Finally, multi-cookers present a versatile alternative for those looking to diversify their kitchen capabilities. Ultimately, thorough research and alignment with operational goals will help buyers make informed decisions that suit their business requirements.

Essential Technical Properties and Trade Terminology for tiger brand rice cooker parts

What Are the Key Technical Properties of Tiger Brand Rice Cooker Parts?

In the realm of Tiger brand rice cookers, understanding the essential technical properties of parts is crucial for ensuring functionality and longevity. Here are some critical specifications that B2B buyers should consider:

-

Material Grade

The material used in rice cooker parts, such as inner pots and lids, often includes stainless steel, aluminum, or high-grade plastic. Stainless steel is favored for its durability and resistance to corrosion, while aluminum is lightweight and conducts heat effectively. Understanding material grades helps in evaluating the quality and performance of the parts, which is vital for long-term use. -

Tolerance Levels

Tolerance refers to the allowable variation in the dimensions of a part. For example, the inner pot must fit snugly within the cooker base to maintain efficient heating. Tighter tolerances usually indicate higher quality manufacturing, which translates to better performance and fewer operational issues. Specifying tolerances in procurement ensures that replacement parts will function as intended. -

Thermal Resistance

Parts like the inner pot and heating elements must withstand high temperatures without degrading. Thermal resistance is crucial for safety and performance, as it affects how well the cooker can maintain cooking temperatures. Buyers should verify that parts meet industry standards for thermal resistance to prevent failures during operation. -

Durability Rating

Parts should have a defined durability rating, often based on the number of cycles they can endure before failure. A higher rating suggests that the part can withstand regular use, which is especially important in commercial settings where rice cookers are used frequently. This specification helps businesses minimize downtime and replacement costs. -

Compatibility Specifications

Each Tiger rice cooker model has specific parts designed for it. Compatibility specifications ensure that replacement parts fit correctly and function optimally. Buyers should always check model numbers and specifications to avoid mismatches that could lead to inefficiencies or damage. -

Safety Certifications

Look for parts that have been certified by relevant safety standards organizations. Certifications ensure that the parts meet specific safety and performance criteria, which is particularly important for electrical components. This assurance can mitigate risks associated with product liability.

What Common Trade Terms Should B2B Buyers Know When Purchasing Tiger Rice Cooker Parts?

Understanding industry terminology is essential for effective communication and negotiation in the B2B market. Here are several common trade terms relevant to the procurement of Tiger rice cooker parts:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are sold under another company’s brand name. When sourcing Tiger rice cooker parts, knowing whether a part is OEM can assure buyers of its quality and compatibility with existing products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers to understand because it can affect inventory management and cost-efficiency. Higher MOQs may lead to bulk discounts but can also result in excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific parts. This process helps buyers compare prices and terms from multiple vendors, ultimately aiding in making informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps businesses understand shipping costs, risks, and delivery obligations, which is critical when sourcing parts from international suppliers. -

Lead Time

Lead time refers to the amount of time from placing an order until it is delivered. Understanding lead times is crucial for inventory planning and ensuring that businesses can maintain operations without delays. -

Aftermarket Parts

Aftermarket parts are components produced by third parties that are compatible with the original product. While they may offer cost savings, buyers should assess their quality and reliability compared to OEM parts.

By being well-versed in these technical properties and trade terminology, B2B buyers can make informed decisions that enhance their procurement processes and ultimately contribute to the success of their operations in the rice cooker market.

Navigating Market Dynamics and Sourcing Trends in the tiger brand rice cooker parts Sector

What Are the Current Market Dynamics and Key Trends in the Tiger Brand Rice Cooker Parts Sector?

The global market for Tiger brand rice cooker parts is influenced by several drivers, including the increasing demand for high-quality kitchen appliances in emerging markets such as Africa, South America, and the Middle East. As urbanization accelerates, consumers are seeking reliable and efficient cooking solutions, leading to a surge in the popularity of rice cookers. Moreover, the technological advancements in kitchen appliances—particularly in the areas of induction heating (IH) and microcomputer-controlled (Micom) rice cookers—are shaping purchasing decisions. International B2B buyers should note the growing trend of online procurement platforms, which are facilitating easier access to spare parts and enabling companies to streamline their sourcing processes.

Emerging technologies such as artificial intelligence and machine learning are also impacting the sector by enhancing inventory management and predictive analytics. This allows suppliers to better anticipate demand for specific parts, ensuring that critical components remain in stock. Additionally, as consumers become increasingly aware of product quality and performance, the demand for authentic and OEM parts is rising, pushing B2B buyers to prioritize verified suppliers.

How Is Sustainability and Ethical Sourcing Reshaping the Tiger Brand Rice Cooker Parts Market?

The significance of sustainability in the sourcing of Tiger brand rice cooker parts cannot be overstated. B2B buyers are increasingly prioritizing suppliers that adhere to ethical sourcing practices, which include the responsible procurement of materials and transparent supply chains. As the environmental impact of manufacturing becomes more scrutinized, companies are compelled to demonstrate their commitment to eco-friendly practices.

In this context, green certifications and the use of sustainable materials are gaining traction. Buyers should look for suppliers that offer parts manufactured from recyclable or biodegradable materials, as well as those that maintain energy-efficient production processes. Implementing these practices not only reduces the environmental footprint but also enhances brand reputation among consumers who value sustainability. Furthermore, suppliers that prioritize ethical sourcing are more likely to establish long-term partnerships, ensuring a stable and reliable supply of parts.

What Is the Brief Evolution of the Tiger Brand Rice Cooker Parts Sector?

The Tiger brand has a rich history that dates back to 1923, initially focusing on vacuum flasks before expanding into the kitchen appliance market. The introduction of the rice cooker in the 1950s marked a significant turning point, as it revolutionized cooking methods in many households, particularly in Asia. Over the decades, Tiger has continuously innovated its product line, incorporating advanced technologies such as IH and Micom control systems that cater to evolving consumer needs.

Today, the brand’s commitment to quality and performance is evident in its range of spare parts, which are designed to ensure the longevity of its appliances. The availability of these parts for up to ten years post-discontinuation reflects Tiger’s dedication to customer satisfaction and product reliability. For international B2B buyers, understanding this evolution is crucial, as it highlights the brand’s reputation and the quality assurance associated with its parts, making it a preferred choice in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of tiger brand rice cooker parts

-

1. How do I identify the correct Tiger rice cooker part for replacement?

To identify the correct part for your Tiger rice cooker, first locate the model number, typically found on the bottom or back of the unit. Once you have the model number, visit authorized suppliers or the Tiger Parts Shop online to browse available parts. Ensure you cross-reference your model number with the specific part number to avoid ordering incorrect components. If you are uncertain, consulting customer service or a knowledgeable dealer can also provide clarity. -

2. What are the most commonly needed replacement parts for Tiger rice cookers?

Commonly needed replacement parts for Tiger rice cookers include inner pots, steam vents, and sealing gaskets. These parts are essential for maintaining the functionality and efficiency of your rice cooker. Regular wear and tear can lead to the need for replacements, especially if the cooker is used frequently in a commercial setting. Keep an inventory of these parts to minimize downtime and ensure your operations run smoothly. -

3. What is the minimum order quantity (MOQ) for Tiger rice cooker parts?

The minimum order quantity (MOQ) for Tiger rice cooker parts can vary depending on the supplier and the specific part. Generally, B2B suppliers may set a MOQ to ensure economic viability for bulk orders. It’s advisable to discuss MOQs directly with your chosen supplier, as some may offer flexibility based on your needs or may allow for mixed orders of different parts to meet the MOQ. -

4. Are Tiger rice cooker parts customizable for specific needs?

Customization options for Tiger rice cooker parts are limited, as most parts are standardized for specific models. However, some suppliers may offer customization for bulk orders or specific commercial applications. If you require unique specifications, it’s best to communicate your needs directly with the supplier during the procurement process. They can advise on available options or potential alternatives. -

5. What payment terms are commonly offered by suppliers of Tiger rice cooker parts?

Payment terms can vary widely among suppliers, but common options include net 30, net 60, or payment upfront for first-time orders. Some suppliers may also accept letters of credit or offer financing options for larger orders. It’s essential to clarify these terms before placing an order to ensure they align with your budget and cash flow considerations. -

6. How can I ensure the quality of Tiger rice cooker parts?

To ensure the quality of Tiger rice cooker parts, source them from authorized distributors or reputable suppliers known for their reliability. Look for suppliers who provide warranties or guarantees on their parts, which can indicate confidence in product quality. Additionally, review customer feedback and ratings to gauge the experiences of other buyers, and consider requesting samples for critical components before placing larger orders. -

7. What logistics considerations should I keep in mind when sourcing Tiger rice cooker parts internationally?

When sourcing Tiger rice cooker parts internationally, consider shipping costs, lead times, and customs regulations in your country. Be aware of potential delays at customs that could impact your inventory levels. Working with suppliers who have experience in international shipping can simplify the process. Additionally, ensure you have clear communication regarding shipping terms, insurance, and tracking options for your orders. -

8. How can I vet suppliers for Tiger rice cooker parts effectively?

To vet suppliers for Tiger rice cooker parts, start by researching their reputation in the market, including customer reviews and testimonials. Verify their credentials and whether they are authorized distributors for Tiger products. Establish communication to assess their responsiveness and willingness to provide detailed information about their products. Request references from other B2B clients to gain insights into their reliability and service quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Tiger Brand Rice Cooker Parts Manufacturers & Suppliers List

1. Tiger Corporation – Rice Cookers

Domain: spare-parts.tiger-corporation-us.com

Registered: 2016 (9 years)

Introduction: Rice Cookers include Induction Heating (IH) Rice Cooker, Microcomputer (Micom) Controlled Rice Cooker, and Electric Rice Cooker. The store is located at Tiger Corporation U.S.A., 1815 W. 205th Street, Unit 106, Torrance, CA, 90501. Customer service can be contacted at (866) 558-4437. The store does not accept walk-in customers and requires appointments for pickup and drop-offs.

2. Tiger Corporation – Consumables & Options

Domain: tiger-corporation.com

Registered: 2000 (25 years)

Introduction: Consumables and options can be purchased through the store where the product was purchased or a nearby dealer. Customers should check the item number and color/pattern before consulting with the store. Orders can also be made through the Tiger Parts Shop, which may incur shipping charges or commission fees. Performance parts for repair are available for 10 years after production is discontinued fo…

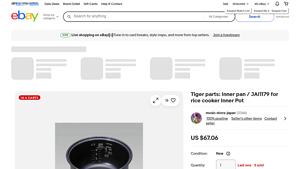

3. Tiger – Inner Pan for Rice Cooker

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”:”Tiger parts: Inner pan / JAI1179 for rice cooker Inner Pot”,”condition”:”New”,”price”:”$67.06″,”shipping_cost”:”$64.72″,”estimated_delivery”:”Wed, Oct 8 – Thu, Nov 6″,”quantity_available”:1,”quantity_sold”:3,”item_number”:”255571528131″,”seller_name”:”music-store-japan”,”seller_feedback”:”100% positive feedback”,”return_policy”:”Seller does not accept returns”,”item_description”:”A brand…

4. Tiger – JNP-LRGVENT Steam Vent

Domain: forumappliances.com

Registered: 2000 (25 years)

Introduction: This company, Tiger – JNP-LRGVENT Steam Vent, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. MINIMARU – Rice Cooker Replacement Parts

Domain: minimaru.com

Registered: 2012 (13 years)

Introduction: Buy Rice Cooker Replacement Parts: Inner Pots & Accessories | MINIMARU Free Shipping over $149*

6. Tiger Corporation – Rice Cooker Spare Parts

Domain: tiger2419.zendesk.com

Registered: 2005 (20 years)

Introduction: Spare parts for Tiger Corporation U.S.A. rice cookers are model specific. To order the correct part, confirm your model number. For rice cooker products, spare parts can be found at the provided link: https://spare-parts.tiger-corporation.com/.

Strategic Sourcing Conclusion and Outlook for tiger brand rice cooker parts

In conclusion, effective strategic sourcing of Tiger brand rice cooker parts is essential for international B2B buyers looking to enhance their operational efficiency and customer satisfaction. Understanding the diverse range of parts, from induction heating components to microcomputer-controlled accessories, allows businesses to maintain the functionality and longevity of their rice cookers. Moreover, the commitment from Tiger Corporation to provide replacement parts for up to ten years post-discontinuation reinforces the reliability and durability of these products, making them an attractive investment.

For businesses in Africa, South America, the Middle East, and Europe, establishing strong supplier relationships and leveraging the availability of genuine parts is critical. This approach not only ensures the seamless operation of appliances but also enhances brand reputation by delivering consistent quality to end-users.

As the demand for high-quality kitchen appliances continues to rise, now is the time to capitalize on the strategic sourcing of Tiger rice cooker parts. Engage with authorized distributors and explore diverse channels to secure the necessary components that will drive your business forward. Embrace this opportunity to strengthen your supply chain and elevate your offerings in the competitive marketplace.