Is Your Plastic Letter Opener Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for plastic letter opener

In today’s fast-paced business environment, sourcing effective office supplies, such as plastic letter openers, can be a daunting task for international B2B buyers. These seemingly simple tools play a crucial role in enhancing productivity by streamlining the correspondence process, yet finding the right supplier who meets quality, price, and delivery expectations across various regions can be challenging. This comprehensive guide is designed to navigate the complexities of the global market for plastic letter openers, offering insights into different types, applications, and key considerations for supplier vetting.

Throughout this guide, you will explore the diverse range of plastic letter openers available in the market, from basic models to customized options that can enhance your brand visibility. We will delve into applications across various industries, helping you identify which products best suit your operational needs. Additionally, we will provide actionable strategies for evaluating suppliers, including factors like production capacity, materials used, and delivery timelines.

By equipping yourself with the knowledge found in this guide, you will be empowered to make informed purchasing decisions that align with your business objectives. This resource is tailored for B2B buyers from Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia, ensuring you can confidently navigate the global landscape of plastic letter openers and enhance your office efficiency.

Understanding plastic letter opener Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Plastic Letter Opener | Lightweight, simple design, often available in various colors | Office supplies, corporate gifts | Pros: Cost-effective, easy to customize. Cons: Basic functionality may not appeal to all brands. |

| Multi-Function Letter Opener | Combines letter opening with additional tools (e.g., ruler, cutter) | Promotional items, trade shows | Pros: Versatile, adds value. Cons: Can be bulkier and more expensive. |

| Eco-Friendly Letter Opener | Made from recycled or biodegradable materials | Sustainability-focused businesses | Pros: Appeals to eco-conscious companies. Cons: May have limited design options. |

| Jumbo Letter Opener | Larger size for easier handling, often includes branding space | Real estate, financial sectors | Pros: Enhanced visibility for branding. Cons: Takes up more desk space. |

| Themed or Custom-Shaped Openers | Unique shapes (e.g., house, car) tailored to specific industries | Event giveaways, niche markets | Pros: High engagement, memorable. Cons: Limited general appeal, potentially higher costs. |

What Are the Characteristics of Standard Plastic Letter Openers?

Standard plastic letter openers are lightweight tools designed primarily for the simple task of opening envelopes. They are typically available in a range of colors and can be customized with company logos, making them a popular choice for office supplies and corporate gifts. These openers are cost-effective, making them suitable for bulk purchases, especially for businesses looking to enhance brand visibility without significant investment. However, their basic functionality may not resonate with all brands, particularly those seeking a more premium feel.

How Do Multi-Function Letter Openers Add Value?

Multi-function letter openers integrate additional features such as rulers or letter cutters, providing added utility for users. This versatility makes them ideal for promotional items at trade shows or corporate events, where showcasing practicality can enhance brand perception. While they typically come at a slightly higher price point, the investment can be justified by the increased value they offer. Buyers should consider the balance between functionality and cost when selecting these products, especially if they aim to impress potential clients or partners.

Why Choose Eco-Friendly Letter Openers?

Eco-friendly letter openers, made from recycled or biodegradable materials, cater to businesses that prioritize sustainability. These products not only fulfill a functional role but also align with corporate social responsibility goals, making them appealing to environmentally conscious companies. While they may have a more limited selection in terms of design and color, the positive impact on brand image can outweigh these drawbacks. Buyers should assess their target audience’s values when considering eco-friendly options.

What Are the Benefits of Jumbo Letter Openers?

Jumbo letter openers provide a larger surface area, making them easier to handle and ideal for branding. These openers are particularly popular in sectors such as real estate and finance, where visibility is crucial. The increased size allows for more prominent logo placement, enhancing brand recognition. However, businesses should consider the trade-off of increased desk space usage when opting for these larger tools, as they may not suit all office environments.

How Do Themed or Custom-Shaped Openers Engage Customers?

Themed or custom-shaped letter openers, designed to represent specific industries or events, offer a unique way to engage customers. These products can create a memorable experience, making them ideal for giveaways at events or in niche markets. While they are often more expensive and may lack broad appeal, their distinctive nature can lead to higher engagement and recall among targeted audiences. Buyers should weigh the potential for increased customer interaction against the higher costs associated with these specialized items.

Key Industrial Applications of plastic letter opener

| Industry/Sector | Specific Application of Plastic Letter Opener | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Office Supplies | Streamlining daily correspondence management | Increases efficiency in handling mail and documents | Durability, ergonomic design, and branding options available |

| Education | Promotional gifts for educational institutions | Enhances brand visibility and engagement with students | Customization options and bulk purchasing capabilities |

| Logistics and Shipping | Essential tool for opening shipment documents and packages | Reduces time spent on unpacking and sorting | Lightweight, safety features, and compliance with packaging standards |

| Corporate Gifting | Personalized gifts for clients and employees | Strengthens relationships and enhances corporate image | Quality material, design options, and cost-effectiveness |

| Event Promotions | Giveaways at trade shows and conferences | Attracts attention and provides practical utility | Custom branding, unique designs, and affordability |

How Are Plastic Letter Openers Used in Various Industries?

Office Supplies: In the office supply sector, plastic letter openers serve as essential tools for employees to efficiently manage daily correspondence. With the rise of remote and hybrid work environments, having a reliable letter opener can significantly reduce the time spent opening mail and sorting through documents. Buyers in this sector should consider sourcing openers that are durable and ergonomic, ensuring they can withstand daily use while also enhancing the user experience.

Education: Educational institutions often utilize plastic letter openers as promotional gifts during orientation events or open houses. These branded items not only serve a practical purpose but also help to enhance the institution’s visibility among students and parents. For international buyers, customization options and bulk purchasing capabilities are critical factors, as they often seek to maximize their marketing budgets while ensuring quality.

Logistics and Shipping: In the logistics and shipping industry, plastic letter openers are invaluable for quickly opening shipment documents and packages. This application is particularly important in fast-paced environments where time is of the essence. Buyers should prioritize lightweight designs that are also equipped with safety features, ensuring compliance with industry standards while enhancing operational efficiency.

Corporate Gifting: Companies often use personalized plastic letter openers as gifts for clients and employees. This practice not only helps strengthen business relationships but also enhances the corporate image. Buyers should focus on sourcing high-quality materials and diverse design options that align with their branding strategies, while also considering cost-effectiveness to ensure a positive return on investment.

Event Promotions: At trade shows and conferences, plastic letter openers are popular giveaway items that attract attention while providing practical utility. They can serve as effective marketing tools that keep a brand in the minds of potential customers long after the event. International buyers should look for suppliers that offer custom branding, unique designs, and affordability to maximize their promotional efforts.

3 Common User Pain Points for ‘plastic letter opener’ & Their Solutions

Scenario 1: Difficulty in Efficiently Processing Large Volumes of Mail

The Problem: In busy offices, especially those handling substantial correspondence daily, time is of the essence. B2B buyers often face the challenge of efficiently processing large volumes of mail. Traditional methods of opening letters can be slow and cumbersome, leading to bottlenecks in operations and decreased productivity. This is particularly critical in sectors like finance or legal services, where timely responses are essential for maintaining client satisfaction and compliance.

The Solution: To address this issue, businesses should invest in high-quality plastic letter openers designed for speed and efficiency. When sourcing these products, consider models that are ergonomically designed and have a sharp, efficient blade to cut through envelopes swiftly. Look for suppliers that offer customizable options, allowing you to imprint your company logo on the letter openers. This not only promotes brand visibility but also encourages employees to use them regularly, thereby improving mail processing times. Implementing a centralized location for these letter openers, such as at reception desks or mailrooms, can streamline the process further. Regular training sessions on effective mail handling practices can also enhance the use of these tools, ensuring that all staff members are well-versed in their benefits and functionalities.

Scenario 2: Concerns About Durability and Quality

The Problem: Many B2B buyers are concerned about the durability and quality of plastic letter openers, especially when purchasing in bulk. In environments where letter openers are frequently used, lower-quality options may break or become ineffective, leading to additional costs for replacements and potentially affecting employee morale. This concern is heightened in regions where shipping times may be longer, making it essential to choose reliable products that withstand daily wear and tear.

The Solution: To mitigate these concerns, buyers should prioritize sourcing plastic letter openers made from high-grade materials, such as ABS plastic, known for its robustness. When evaluating suppliers, request samples to assess the product’s weight, feel, and performance before placing a bulk order. Additionally, consider suppliers that provide warranties or satisfaction guarantees on their products. This approach not only ensures you are investing in durable tools but also gives you leverage in case the products do not meet your expectations. Regularly reviewing product performance and gathering user feedback can help in making informed decisions about future purchases and identifying any potential issues before they escalate.

Scenario 3: Balancing Cost with Functionality

The Problem: B2B buyers often grapple with the challenge of balancing cost with functionality when procuring office supplies, including plastic letter openers. While budget constraints are a significant factor, opting for the cheapest option can lead to poor performance, resulting in frustration for employees and decreased efficiency. This dilemma is especially prominent in competitive markets where every operational decision impacts the bottom line.

The Solution: To find the right balance, buyers should conduct a thorough cost-benefit analysis when selecting plastic letter openers. This involves comparing multiple suppliers not only on price but also on features such as ergonomic design, blade sharpness, and potential for customization. Investing in slightly more expensive models that offer better performance can yield long-term savings by reducing the need for replacements and improving overall productivity. Additionally, consider negotiating bulk pricing or long-term contracts with suppliers, which can further enhance cost-effectiveness while ensuring you acquire high-quality products. Engaging in supplier relationships that allow for flexibility and feedback can also lead to better product offerings tailored to your specific needs, enhancing both functionality and value.

Strategic Material Selection Guide for plastic letter opener

What Are the Key Materials for Plastic Letter Openers?

When selecting materials for plastic letter openers, it is essential to consider various factors that influence performance, cost, and suitability for international markets. Below, we analyze four common materials used in the production of plastic letter openers, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Properties and Considerations for Polypropylene?

Key Properties: Polypropylene (PP) is known for its excellent chemical resistance, low density, and high melting point (around 160°C). It is lightweight yet strong, making it suitable for everyday use.

Pros & Cons: The primary advantage of PP is its durability and resistance to moisture and chemicals, which enhances the longevity of letter openers. However, it can be more expensive than other plastics and may require more complex manufacturing processes to achieve intricate designs.

Impact on Application: Polypropylene is compatible with various printing techniques, allowing for effective branding opportunities. Its lightweight nature makes it easy to handle, which is beneficial for users.

Specific Considerations for International Buyers: Compliance with international standards such as ASTM and REACH is essential, especially in Europe. Buyers from regions like Africa and South America should consider the availability of PP in their local markets and its recyclability, which is increasingly important for sustainability.

How Does ABS Plastic Compare for Letter Openers?

Key Properties: Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic known for its impact resistance and toughness. It has a moderate temperature resistance (around 100°C) and is relatively easy to mold.

Pros & Cons: ABS is cost-effective and offers a good balance between strength and flexibility. However, it is less resistant to UV light, which can lead to fading over time, making it less suitable for outdoor use.

Impact on Application: ABS can be effectively printed on, allowing for vibrant colors and detailed logos, making it a popular choice for promotional items. Its sturdiness ensures that the letter opener can withstand daily use without breaking.

Specific Considerations for International Buyers: Buyers should ensure that ABS products meet local safety standards and regulations, particularly in the Middle East and Europe. The material’s recyclability can also be a selling point in regions with strong environmental regulations.

What Are the Advantages of Using Polystyrene?

Key Properties: Polystyrene (PS) is a versatile plastic that can be solid or foamed. It has a lower melting point (around 100°C) and is known for its rigidity and ease of processing.

Pros & Cons: The primary advantage of PS is its low cost and ease of production, making it suitable for high-volume manufacturing. However, it is more brittle than other materials, which may lead to breakage under stress.

Impact on Application: Polystyrene is suitable for basic letter openers but may not be ideal for heavy-duty applications. Its smooth surface allows for easy printing, making it attractive for branding.

Specific Considerations for International Buyers: Buyers should be aware of the environmental impact of polystyrene, as it is less recyclable than other plastics. Compliance with local regulations regarding single-use plastics is crucial, especially in Europe.

Why Choose Polyethylene for Plastic Letter Openers?

Key Properties: Polyethylene (PE) is known for its flexibility, chemical resistance, and low-density properties. It has a melting point of around 120°C and is available in various densities, affecting its strength and rigidity.

Pros & Cons: The flexibility of PE makes it less likely to break under stress, offering a longer lifespan for letter openers. However, its lower rigidity may not provide the same cutting precision as stiffer materials.

Impact on Application: Polyethylene is suitable for budget-friendly letter openers, especially for promotional giveaways. Its resistance to moisture ensures that it remains functional in various environments.

Specific Considerations for International Buyers: Buyers should consider the availability of recycled PE options, as sustainability is becoming increasingly important. Compliance with international standards for plastic products is also essential.

Summary of Material Selection for Plastic Letter Openers

| Material | Typical Use Case for plastic letter opener | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Everyday office use | Excellent chemical resistance | Higher manufacturing complexity | Medium |

| ABS | Promotional items | Cost-effective with good durability | Less UV resistance | Low |

| Polystyrene | Basic letter openers | Low cost and easy to produce | Brittle under stress | Low |

| Polyethylene | Budget-friendly promotional giveaways | Flexible and moisture-resistant | Lower cutting precision | Low |

This guide provides actionable insights for B2B buyers considering material selection for plastic letter openers, ensuring they make informed decisions that align with their operational needs and market compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic letter opener

What Are the Main Stages of Manufacturing a Plastic Letter Opener?

The manufacturing process of plastic letter openers involves several critical stages, ensuring that the final product meets both functional and aesthetic requirements. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of suitable plastic materials, typically high-density polyethylene (HDPE) or acrylonitrile butadiene styrene (ABS). These materials are chosen for their durability, lightweight properties, and ability to be molded into various shapes. The raw plastic pellets are dried to remove moisture, which can affect the molding process.

-

Forming: The dried plastic is then heated and fed into an injection molding machine, where it is injected into molds designed for the specific shape of the letter opener. This method allows for mass production with high precision and repeatability. The molds are usually made from steel or aluminum to withstand high pressure and temperature during the injection process.

-

Assembly: After the plastic components are formed, they may require additional parts, such as blades or decorative elements. In cases where the letter opener has a multi-functional design (for example, incorporating a letter slitter), these components are assembled either manually or using automated systems.

-

Finishing: The final stage involves surface treatment processes, which may include trimming excess material, applying coatings, or printing logos and designs. Quality checks are performed during this stage to ensure that the products meet the required specifications.

How Is Quality Assurance Implemented in the Manufacturing of Plastic Letter Openers?

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that each letter opener produced meets international standards and customer expectations. The QA process typically aligns with international standards such as ISO 9001 and industry-specific certifications like CE.

-

International Standards: Compliance with ISO 9001 is crucial for manufacturers targeting international markets. This standard provides a framework for establishing a quality management system, focusing on process optimization and continuous improvement. Additionally, CE marking is required for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

-

Quality Control Checkpoints: Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Regular checks are performed during the manufacturing process, particularly during injection molding and assembly, to identify defects early.

– Final Quality Control (FQC): Once the letter openers are completed, they undergo final inspections to verify dimensions, functionality, and surface quality. -

Common Testing Methods: Various testing methods are employed to ensure product quality, including:

– Visual Inspection: Checking for surface defects, color consistency, and overall appearance.

– Dimensional Testing: Using calipers and gauges to ensure that the dimensions of the letter openers conform to design specifications.

– Functional Testing: Assessing the cutting efficiency and safety of the blade.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several strategies buyers can employ:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities and quality management systems in place. This firsthand evaluation can uncover potential issues that may not be visible through documentation alone.

-

Quality Reports: Requesting detailed quality assurance reports from suppliers can provide insights into their QC processes. These reports should outline the results of various testing methods, defect rates, and corrective actions taken for any identified issues.

-

Third-Party Inspections: Engaging third-party inspection services is a reliable method for verifying product quality. These independent organizations can conduct inspections during the manufacturing process and before shipment, ensuring that products meet specified standards.

-

Certification Verification: Buyers should confirm that suppliers possess relevant certifications, such as ISO 9001 and CE. This can often be done through official certification bodies or databases that track compliance.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers face unique challenges and considerations when it comes to quality control. Understanding these nuances can help mitigate risks associated with sourcing plastic letter openers from different regions.

-

Regulatory Compliance: Different countries have varying regulations regarding product safety and quality. Buyers should be aware of the specific requirements for the markets they intend to sell in, including any necessary certifications or testing.

-

Cultural Differences: Cultural attitudes towards quality and compliance can vary significantly between regions. Buyers should consider these differences when establishing expectations and communicating with suppliers.

-

Logistical Considerations: Shipping products internationally can introduce risks related to damage or loss. Buyers should ensure that their suppliers have robust packaging and handling procedures to protect products during transit.

-

Communication Channels: Establishing clear and open lines of communication with suppliers is essential. This includes discussing quality expectations, addressing concerns promptly, and maintaining a collaborative approach to problem-solving.

By understanding the manufacturing processes and quality assurance measures in place for plastic letter openers, B2B buyers can make informed decisions when sourcing these products. This knowledge not only enhances the buyer’s ability to select reliable suppliers but also ensures that the products meet the high standards required in today’s competitive market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic letter opener’

When sourcing plastic letter openers for your business, a structured approach is essential to ensure you select the right product that meets your needs and expectations. This guide provides a step-by-step checklist to facilitate your procurement process, focusing on essential factors that international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for your plastic letter openers. Consider factors such as size, material (e.g., ABS plastic for durability), and design features. This clarity will help streamline your sourcing process and ensure that the products meet your intended use and branding requirements.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers. Utilize online platforms, trade shows, and industry networks to gather a list of manufacturers and distributors. Pay special attention to suppliers that specialize in office supplies and have a strong reputation for quality and reliability in your target regions.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify the certifications and compliance of potential suppliers. Look for quality certifications such as ISO 9001, which indicates adherence to international quality management standards. Additionally, confirm if the materials used are compliant with safety and environmental regulations relevant to your market.

Step 4: Request Samples for Quality Assessment

Always request samples of the plastic letter openers before placing a bulk order. This step allows you to evaluate the product quality firsthand, checking for durability, design, and functionality. Assess the samples against your specifications to ensure they meet your standards.

Step 5: Compare Pricing and Terms

Once you have evaluated multiple suppliers and their samples, compare pricing structures and payment terms. Look for transparency in costs, including shipping and handling fees. Consider negotiating terms that align with your budget while ensuring you receive a quality product.

Step 6: Assess Production and Delivery Timelines

Understand the production and delivery timelines of your selected suppliers. Ensure that they can meet your deadlines, especially if you have specific launch dates or promotional campaigns. A reliable supplier will provide clear timelines and stick to them, minimizing disruptions to your operations.

Step 7: Establish a Communication Plan

Finally, set up a clear communication plan with your chosen supplier. Regular updates and open lines of communication can help address any potential issues promptly. Ensure that you have designated contacts on both sides to facilitate smooth interactions throughout the procurement process.

By following this checklist, B2B buyers can navigate the complexities of sourcing plastic letter openers effectively, ensuring they select the right products from reliable suppliers.

Comprehensive Cost and Pricing Analysis for plastic letter opener Sourcing

What Are the Key Cost Components in Sourcing Plastic Letter Openers?

When analyzing the cost structure for sourcing plastic letter openers, several components come into play. The primary cost factors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier margin.

-

Materials: The choice of plastic significantly impacts cost. Common materials like ABS or PVC are often used due to their durability and cost-effectiveness. However, higher-quality materials or eco-friendly options can elevate the base price.

-

Labor: Labor costs vary by region. Countries with lower wage standards may offer more competitive pricing, but this can also affect quality. It’s crucial to consider the skill level required for production and the associated labor costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and administrative costs. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer better pricing.

-

Tooling: Initial costs for molds and dies can be significant, especially for custom designs. These costs are usually amortized over larger production runs, making it more economical for buyers to order in bulk.

-

Quality Control (QC): Implementing stringent QC measures is essential to ensure product reliability. While this may increase costs, it can prevent larger issues down the line, particularly for international shipments where compliance with local regulations may be required.

-

Logistics: Shipping costs can vary significantly based on the Incoterms agreed upon, the distance from the supplier, and the chosen shipping method. Buyers must account for these costs in their total budget.

-

Margin: Suppliers will include a profit margin, which can vary widely based on market demand, competition, and the perceived value of the product.

How Do Pricing Influencers Affect the Cost of Plastic Letter Openers?

Several factors influence the final pricing of plastic letter openers in the B2B market. Understanding these can help buyers negotiate better terms.

-

Volume/MOQ: Minimum Order Quantities (MOQs) can greatly affect pricing. Higher volume orders often lead to bulk discounts, making it more economical per unit. Suppliers may be more willing to negotiate on price with larger orders.

-

Specifications/Customization: Custom designs or additional features can increase costs. Buyers should weigh the benefits of customization against the price increase.

-

Material Quality/Certifications: Higher-quality materials or those with specific certifications (e.g., eco-friendly, non-toxic) can command higher prices. Buyers in regions with strict regulations may need to prioritize certified products.

-

Supplier Factors: The supplier’s reputation, reliability, and location can affect costs. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) impacts shipping costs and responsibilities. Understanding these terms can help buyers manage overall costs and reduce unexpected expenses.

What Tips Can Help International B2B Buyers Optimize Their Sourcing Strategy?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, optimizing sourcing strategies is crucial.

-

Negotiation: Don’t hesitate to negotiate terms. Suppliers often have some flexibility, especially on larger orders or long-term contracts. Establishing a good relationship can lead to better pricing and terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), not just the initial purchase price. Consider long-term costs associated with quality, maintenance, and potential returns or replacements.

-

Pricing Nuances: Be aware of local market conditions and currency fluctuations that can affect pricing. Engaging with local suppliers or those familiar with your region can mitigate risks associated with international transactions.

-

Research and Due Diligence: Conduct thorough research on potential suppliers. Review their reputation, quality of products, and compliance with local regulations. This due diligence can prevent costly mistakes and ensure a reliable supply chain.

In summary, understanding the comprehensive cost structure and pricing influences when sourcing plastic letter openers can empower international B2B buyers to make informed decisions and optimize their procurement strategies.

Alternatives Analysis: Comparing plastic letter opener With Other Solutions

When evaluating office supplies for handling correspondence, the plastic letter opener stands out as a popular choice. However, understanding alternatives is essential for B2B buyers looking to optimize their operations. This section provides a detailed comparison of plastic letter openers against other viable solutions, helping businesses make informed decisions.

| Comparison Aspect | Plastic Letter Opener | Electric Letter Opener | Letter Slitter |

|---|---|---|---|

| Performance | Efficient for opening letters quickly and safely. | Fast and can handle multiple letters at once. | Cuts through envelopes with precision. |

| Cost | Low cost, typically ranging from $0.50 to $1.00 per unit. | Higher initial investment, approximately $50 to $200. | Moderate cost, usually $5 to $15 each. |

| Ease of Implementation | Simple to use; no setup required. | Requires electrical outlet and setup. | Easy to use; just position the envelope. |

| Maintenance | Minimal; occasional cleaning required. | Higher maintenance due to electrical components. | Low maintenance; blade replacement may be needed. |

| Best Use Case | Ideal for individual use in offices with moderate correspondence. | Suitable for high-volume offices needing speed. | Best for mailrooms handling bulk mail. |

What Are the Advantages and Disadvantages of Electric Letter Openers?

Electric letter openers offer a compelling alternative for organizations that process large volumes of mail. They are designed for speed, allowing users to open multiple letters quickly. However, the higher cost and the need for electrical outlets can be a barrier for smaller businesses. Maintenance is also a consideration, as electrical components may require more attention than a simple plastic opener.

How Do Letter Slitters Compare in Functionality?

Letter slitters are another alternative that provides a precise way to open envelopes. They typically feature a blade that slices through the paper, making them an efficient option for mailrooms handling bulk correspondence. While they are relatively low-cost and easy to use, they may not be as user-friendly as plastic letter openers for individual users. Additionally, they may require occasional blade replacements, adding to long-term maintenance considerations.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate solution for handling correspondence, B2B buyers should assess their specific needs. For low-volume correspondence, plastic letter openers offer an affordable and efficient choice. In contrast, businesses with high mail volumes may benefit from the speed and efficiency of electric letter openers, despite the higher initial investment. Meanwhile, letter slitters provide a middle ground, catering to bulk mail scenarios with precision. By evaluating performance, cost, ease of use, and maintenance, buyers can make informed decisions that align with their operational requirements.

Essential Technical Properties and Trade Terminology for plastic letter opener

What Are the Key Technical Properties of Plastic Letter Openers?

When evaluating plastic letter openers for B2B procurement, understanding their technical properties is essential for making informed purchasing decisions. Here are some critical specifications that buyers should consider:

-

Material Grade

– The most common materials for plastic letter openers are ABS (Acrylonitrile Butadiene Styrene) and polypropylene. ABS is known for its strength and impact resistance, while polypropylene offers flexibility and chemical resistance. Selecting the right material grade ensures durability and longevity, which is crucial for maintaining a professional image in any business setting. -

Dimensions and Weight

– Typical dimensions for plastic letter openers range from 6.5 inches in length to about 2 inches in width. Weight varies but is generally light, making them easy to handle. Understanding dimensions is vital for ensuring that the product fits within your workspace and meets your ergonomic needs. -

Tolerances

– Tolerance levels dictate how much variation is acceptable in the dimensions of the letter openers. For precision tools like letter openers, tighter tolerances ensure consistent performance and reliability. This is particularly important for bulk orders where uniformity is expected across large quantities. -

Imprint Area

– The imprint area refers to the space available for branding or customization. For many B2B buyers, branding is a key consideration, so understanding the maximum logo size that can be applied is crucial. Typical imprint areas can range from 1 inch to 2 inches, allowing for effective brand visibility. -

Production Time

– This property indicates how quickly a manufacturer can produce and deliver the letter openers. Production times can vary from a few days to several weeks, depending on factors like order volume and customization. Knowing the production timeline helps in planning inventory and aligning with marketing campaigns. -

Recycled Materials

– Increasingly, buyers are interested in sustainability. Letter openers made from recycled plastics not only meet environmental standards but can also enhance a brand’s reputation. Understanding the availability of eco-friendly options can inform purchasing decisions that align with corporate social responsibility goals.

What Are Common Trade Terms in the Plastic Letter Opener Industry?

Navigating the B2B landscape involves familiarizing oneself with industry terminology. Here are some essential trade terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or products that are used in another company’s end products. Understanding OEM relationships can help buyers source quality letter openers that meet their specifications without compromising on standards. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is critical for budget planning and inventory management, especially for companies looking to purchase promotional items in bulk. -

RFQ (Request for Quotation)

– An RFQ is a document that buyers send to suppliers requesting pricing and terms for a specific quantity of goods. This is a vital step in the procurement process, as it helps buyers compare costs and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for managing shipping costs and responsibilities, which can significantly impact the total cost of goods. -

Lead Time

– Lead time refers to the time it takes from placing an order to receiving the goods. This is an important metric for businesses that need to manage their inventory efficiently and ensure timely delivery to their customers. -

Custom Imprinting

– This term refers to the process of adding logos or branding to the plastic letter openers. Custom imprinting is a key feature for many businesses as it enhances brand visibility and provides a personalized touch to promotional items.

By understanding these technical properties and trade terms, B2B buyers can make more strategic decisions when sourcing plastic letter openers, ensuring they meet their operational needs and branding objectives effectively.

Navigating Market Dynamics and Sourcing Trends in the plastic letter opener Sector

What Are the Current Market Dynamics and Key Trends in the Plastic Letter Opener Sector?

The global plastic letter opener market is witnessing significant growth driven by several key factors. The rise of e-commerce and remote work has increased the volume of correspondence, leading to a greater demand for efficient office tools. Buyers in regions like Africa, South America, the Middle East, and Europe are particularly interested in products that enhance productivity and streamline operations. Additionally, customization trends are gaining traction, with businesses seeking personalized products that reflect their brand identity. This trend is exemplified by the popularity of custom-imprinted letter openers, which serve as functional tools and promotional items.

Emerging technologies, such as 3D printing, are revolutionizing the manufacturing process, allowing for rapid prototyping and customization at lower costs. This innovation is particularly beneficial for international buyers who require unique designs or bulk orders. Furthermore, the use of e-commerce platforms for sourcing plastic letter openers is on the rise, providing buyers with access to a broader range of suppliers and competitive pricing. B2B buyers should also pay attention to market dynamics such as fluctuating raw material prices and supply chain disruptions, which can impact sourcing strategies.

How Important Is Sustainability and Ethical Sourcing for B2B Buyers of Plastic Letter Openers?

Sustainability is becoming a crucial consideration for B2B buyers in the plastic letter opener sector. Environmental impacts associated with plastic production and waste have prompted businesses to seek out eco-friendly alternatives. Many suppliers are now offering letter openers made from recycled materials or bio-based plastics, catering to the growing demand for sustainable office supplies.

Additionally, ethical sourcing practices are gaining prominence, with companies increasingly prioritizing suppliers that adhere to fair labor practices and responsible manufacturing processes. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) can serve as indicators of a supplier’s commitment to sustainability. By choosing products that meet these standards, international buyers can not only minimize their environmental footprint but also enhance their corporate social responsibility image, which is particularly valued in markets like Europe and North America.

What Is the Brief Evolution and History of Plastic Letter Openers?

The history of letter openers dates back to the 19th century when they were primarily crafted from metals like brass and silver, symbolizing status and refinement. As office environments evolved, so did the materials used in their production. The introduction of plastics in the mid-20th century marked a significant shift, making letter openers more accessible and affordable to the average consumer and business.

Today, plastic letter openers are favored for their lightweight, durable, and customizable properties. The evolution of design has also led to multifunctional products, such as letter openers that double as rulers or magnifiers, catering to the diverse needs of modern businesses. This shift reflects broader trends in office supply markets, where functionality and cost-effectiveness are paramount for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic letter opener

-

How do I choose the right plastic letter opener for my business needs?

When selecting a plastic letter opener, consider factors such as size, design, and functionality. Evaluate whether you need a basic model or one with added features, such as a built-in magnet or multiple cutting edges. Additionally, assess the opener’s material quality for durability, especially if it will be used frequently. Customization options, like adding your logo or branding, can enhance visibility and promotional value. Compare different suppliers and their offerings to ensure you find a product that meets your specific business requirements. -

What customization options are available for plastic letter openers?

Customization options for plastic letter openers typically include imprinting your company logo, choosing colors, and selecting different styles or shapes. Some suppliers offer the ability to customize the size and design to align with your branding. When inquiring, ask about the maximum imprint area and the types of printing techniques available, such as screen printing or digital printing. This personalization not only promotes brand awareness but also enhances the value of the product as a corporate gift or promotional item. -

What are the minimum order quantities (MOQ) for plastic letter openers?

Minimum order quantities for plastic letter openers can vary significantly by supplier and product type. Typically, MOQs can range from as low as 250 to over 1000 units. When sourcing, it’s essential to confirm the MOQ with your supplier to ensure it aligns with your needs and budget. If your order volume is lower than the MOQ, some suppliers may offer alternatives, such as a higher price per unit or the option to combine orders with other products. -

What payment terms should I expect when sourcing plastic letter openers?

Payment terms can vary by supplier and region, but common practices include a deposit upfront, followed by the balance upon completion or delivery of the order. Some suppliers may offer net terms, allowing payment within a specified period after delivery. It’s crucial to clarify these terms before finalizing the order to avoid misunderstandings. Additionally, consider using secure payment methods to protect your investment, especially when dealing with international suppliers. -

How can I vet suppliers for plastic letter openers effectively?

To vet suppliers, start by researching their reputation online through reviews and testimonials from previous clients. Check for industry certifications and compliance with international quality standards. Request samples to evaluate product quality firsthand and inquire about their production capabilities and lead times. Establishing communication with suppliers is also vital; assess their responsiveness and willingness to address your inquiries as it reflects their overall customer service approach. -

What quality assurance measures should I consider for plastic letter openers?

Quality assurance measures are critical to ensuring the products meet your standards. Inquire if the supplier conducts regular quality checks during production and before shipment. Request documentation on their quality control processes, such as inspection reports or third-party testing results. Additionally, consider whether they offer guarantees or return policies for defective items, which can provide peace of mind for your investment. -

What are the shipping and logistics considerations for importing plastic letter openers?

Shipping and logistics are essential components of the purchasing process. Discuss with your supplier the shipping methods available, estimated delivery times, and costs associated with international shipping. Additionally, understand the customs regulations in your country, including any import duties or taxes that may apply. Collaborating with a reliable freight forwarder can facilitate smoother logistics and help navigate any potential issues related to customs clearance. -

How do I ensure compliance with international trade regulations when sourcing plastic letter openers?

Ensuring compliance with international trade regulations involves understanding both local and exporting country laws regarding imports. Research regulations related to product safety, labeling, and material standards. It’s also advisable to confirm that your supplier adheres to these regulations and can provide necessary documentation, such as certificates of compliance. Engaging a trade compliance specialist can further assist in navigating the complexities of international sourcing and help mitigate risks.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Plastic Letter Opener Manufacturers & Suppliers List

1. Penco – Letter Openers

Domain: shoppennypost.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Letter Openers”, “price”: “$6.00”, “colors_available”: [“Green”, “Light Blue”, “Black”, “Ivory”, “Red”], “dimensions”: {“width”: “6.5 inches”, “height”: “0.8 inches”}, “material”: “Lightweight plastic”, “brand”: “Penco”, “description”: “Handy size to keep at the desk.”}

2. 4imprint – Custom Letter Openers

Domain: 4imprint.com

Registered: 1998 (27 years)

Introduction: Custom-imprinted letter openers, available in various colors including Black, Blue, Gray, Green, Orange, Purple, Red, White, Yellow, Burgundy, Crimson, Dark Green, Lime Green, Navy, Royal Blue, and Light Green. A total of 26 products found under the Letter Openers category. Prices start from $0.50. Options for production time include 24 hours, 2 days or less, and 3 days or less. Imprint color opti…

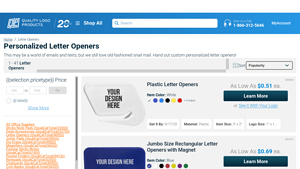

3. Quality Logo Products – Personalized Letter Openers

Domain: qualitylogoproducts.com

Registered: 2003 (22 years)

Introduction: Personalized Letter Openers available in various styles and materials. Key products include: 1. Plastic Letter Openers – As low as $0.51 each, size 3″ x 2″, max logo 1″ x 1.7″, available in white and 4 colors. 2. Jumbo Size Rectangular Letter Openers with Magnet – As low as $0.69 each, size 3.5″ x 2.25″, max logo 1″ x 2.25″, available in blue and 1 more color. 3. Present A Card Letter Openers – As…

4. Choate – CIA Letter Opener

Domain: countryknives.com

Registered: 2000 (25 years)

Introduction: Choate CIA Letter Opener, made from fiberglass reinforced nylon, designed for tactical training and outdoor use.

5. Office Depot – Letter Openers

Domain: officedepot.com

Registered: 1995 (30 years)

Introduction: This company, Office Depot – Letter Openers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Fuller Brush – Vintage Letter Opener

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Fuller Brush Letter Opener, Material: Plastic, Vintage: Yes, Condition: Pre-Owned, Various colors and styles available including Red-Brown, Light Blue, Beige, Clear, Purple Marble, and more. Sizes around 7 to 7.25 inches long. Prices range from ZAR 35.18 to ZAR 617.41. Free international shipping options available.

7. Target – Letter Openers

Domain: target.com

Registered: 1997 (28 years)

Introduction: Letter Openers are categorized under Office Supplies at Target. They are essential tools for creating an efficient and organized workspace, which is crucial for productivity. The product selection includes various styles and designs to suit different preferences. Letter openers help streamline the process of opening mail, making them a practical addition to any office setup.

8. Staples – Concealed Blade Letter Opener

Domain: staples.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “Staples Concealed Blade Letter Opener”, “color”: “Black”, “pack_size”: “2/Pack”, “item_number”: “815014”, “model”: “ST18006/18006”, “price”: “$7.99”, “price_per_unit”: “$4.00/Letter Opener”}

9. JCK Cutter – Wholesale Plastic Letter Opener

Domain: jckcutter.com

Registered: 2022 (3 years)

Introduction: Product Name: Plastic Letter Opener

Type: Wholesale Plastic Letter Opener

Customization: Available (colors, text, logo)

Material: High-quality plastic with concealed stainless steel razor blades

Design: Sleek, stylish, lightweight, portable, keychain hole design

Variety: Multiple models and colors available (e.g., gray, blue, black, green, red)

Applications: Suitable for office use, personal use, …

Strategic Sourcing Conclusion and Outlook for plastic letter opener

In the current global market, strategic sourcing of plastic letter openers presents a unique opportunity for international B2B buyers. These functional desk accessories not only enhance office efficiency but also serve as effective branding tools. With a wide range of customizable options available, businesses can choose products that reflect their brand identity while providing utility to their clients and employees.

Buyers should consider factors such as material quality, design, and the potential for personalization when selecting letter openers. The lightweight and durable nature of plastic makes it an ideal choice, especially for markets in Africa, South America, the Middle East, and Europe, where cost-effectiveness and functionality are paramount. Additionally, sourcing from suppliers that prioritize sustainable practices can enhance brand reputation and appeal to environmentally-conscious consumers.

Looking ahead, businesses are encouraged to leverage the benefits of strategic sourcing to stay competitive. By choosing the right suppliers and products, companies can not only streamline their operations but also foster stronger client relationships through thoughtful branding. Engage with trusted suppliers today to explore innovative designs and secure your market position with high-quality plastic letter openers that resonate with your audience.