Is Your Hospital Sand Bed Price Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for hospital sand bed price

In the competitive landscape of healthcare equipment procurement, sourcing hospital sand beds—integral for effective wound care management—poses significant challenges for international B2B buyers. With rising global demand for advanced air fluidized therapy solutions, understanding the nuances of hospital sand bed pricing is crucial for making informed purchasing decisions. This comprehensive guide delves into various types of air fluidized therapy beds, their applications in clinical settings, and the factors influencing pricing structures across different markets.

Buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam, face unique challenges when navigating supplier options and cost considerations. This guide empowers these stakeholders by offering insights into effective supplier vetting processes, key product specifications, and the overall market landscape. By equipping buyers with actionable information, we aim to facilitate strategic purchasing decisions that enhance patient care while optimizing budget allocations.

Whether you are looking to enhance your hospital’s wound care capabilities or seeking cost-effective solutions, this guide serves as a vital resource. It not only clarifies the complexities of hospital sand bed pricing but also addresses the broader implications of product selection on healthcare outcomes, thereby ensuring that you can confidently navigate this essential aspect of medical equipment procurement.

Understanding hospital sand bed price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Air Fluidized Therapy Beds | Uses silicone-coated microspheres to create a fluid-like environment for pressure relief. | Wound care and rehabilitation facilities | Pros: Excellent pressure redistribution, accelerates healing. Cons: Higher initial investment. |

| HydroAire Air Fluidized Therapy | Combines fluidized therapy with advanced temperature control and patient monitoring systems. | Acute care hospitals, long-term care | Pros: Enhanced patient comfort, advanced diagnostics. Cons: Maintenance can be complex. |

| Rental Air Fluidized Therapy Beds | Typically offered on a rental basis, reducing upfront costs for healthcare facilities. | Short-term care settings, transitional care | Pros: Cost-effective for temporary needs. Cons: Long-term rental can accumulate costs. |

| Standard Hospital Sand Beds | Basic sand-filled beds providing pressure relief without advanced features. | General wards, outpatient facilities | Pros: Lower cost, simple design. Cons: Limited therapeutic benefits compared to advanced models. |

| Specialty Air Fluidized Systems | Customizable beds tailored to specific patient needs, including pediatric or bariatric options. | Specialized clinics, pediatric units | Pros: Tailored solutions for unique cases. Cons: Potentially longer lead times for delivery. |

What Are the Characteristics of Air Fluidized Therapy Beds?

Air Fluidized Therapy Beds utilize a unique technology where warm air is forced through silicone-coated microspheres, creating a fluid-like support system. This design allows for excellent immersion and envelopment, reducing pressure points and minimizing friction. These beds are particularly suitable for patients with complex wounds or those at high risk for pressure injuries. When considering a purchase, B2B buyers should evaluate the bed’s specifications, including weight capacity and features that support patient comfort and healing.

How Do HydroAire Air Fluidized Therapy Beds Differ?

HydroAire Air Fluidized Therapy Beds stand out due to their integration of advanced temperature control and real-time patient monitoring systems. This technology not only enhances patient comfort but also provides caregivers with critical data to manage wound care effectively. These beds are ideal for acute care hospitals and long-term care facilities. Buyers should consider the complexity of maintenance and operational training, as these advanced features may require additional staff education.

Why Consider Rental Air Fluidized Therapy Beds?

Rental Air Fluidized Therapy Beds are an economical choice for healthcare facilities that require temporary solutions, such as during peak patient inflow or transitional care scenarios. By renting, facilities can access high-quality therapeutic beds without the burden of significant upfront costs. However, buyers must weigh the potential long-term rental expenses against outright purchases, especially if prolonged use is anticipated.

What Are the Benefits of Standard Hospital Sand Beds?

Standard Hospital Sand Beds provide a basic level of pressure relief using traditional sand filling. They are cost-effective and straightforward, making them suitable for general wards and outpatient facilities where advanced features are unnecessary. B2B buyers should consider their budget and the specific therapeutic needs of their patient population, as these beds may lack the advanced capabilities of more specialized models.

How Do Specialty Air Fluidized Systems Cater to Unique Needs?

Specialty Air Fluidized Systems are customizable beds designed to meet specific patient requirements, such as bariatric or pediatric care. These beds offer tailored solutions that can significantly enhance patient outcomes in specialized clinics. However, buyers should be aware of potential longer lead times for delivery and the necessity for a detailed understanding of patient needs to ensure the right configuration is chosen.

Key Industrial Applications of hospital sand bed price

| Industry/Sector | Specific Application of hospital sand bed price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare Facilities | Wound care treatment for patients with chronic wounds | Accelerates healing, reduces pressure injuries, enhances patient comfort | Compliance with local health regulations and certifications |

| Rehabilitation Centers | Post-operative recovery support | Provides optimal pressure redistribution, improving recovery times | Rental vs. purchase options, maintenance, and service support |

| Home Healthcare Services | At-home care for patients with mobility issues | Enables effective wound management in a familiar environment | Insurance coverage, ease of use for caregivers |

| Long-term Care Facilities | Management of pressure injuries in elderly patients | Enhances quality of care, reduces hospital readmissions | Training for staff on bed operation and patient handling |

| Medical Equipment Suppliers | Resale of air fluidized therapy beds to healthcare providers | Expands product offerings, meets increasing demand for advanced wound care | Reliable suppliers, warranty and support services |

How is ‘hospital sand bed price’ utilized in healthcare facilities for wound care treatment?

In healthcare facilities, hospital sand beds, often referred to as air fluidized therapy beds, play a crucial role in managing patients with chronic wounds. These beds utilize a fluid-like environment created by silicone-coated microspheres, allowing for optimal immersion and pressure redistribution. This technology is essential for treating stage III and IV pressure injuries, significantly accelerating the healing process. For international buyers, especially from regions like Africa and South America, understanding the local regulations and ensuring compliance with health standards is vital for successful procurement.

What benefits do rehabilitation centers gain from using hospital sand beds for post-operative recovery?

Rehabilitation centers leverage hospital sand beds to support post-operative recovery, particularly for patients with complex surgical wounds. The beds provide superior pressure redistribution, minimizing the risk of pressure injuries and enhancing patient comfort. This results in faster recovery times and improved patient outcomes. B2B buyers should consider rental versus purchase options, as well as ongoing maintenance and service support, to ensure they can deliver the best care while managing costs effectively.

How do home healthcare services implement hospital sand beds for at-home care?

Home healthcare services utilize hospital sand beds to facilitate effective wound management for patients with mobility challenges. These beds create a comfortable and healing environment, enabling caregivers to manage complex wounds in the patient’s home. This approach not only enhances the quality of care but also reduces the need for hospital visits. Buyers in this sector must prioritize insurance coverage options and the ease of use for caregivers, ensuring that the beds can be operated safely and effectively in a home setting.

What role do hospital sand beds play in long-term care facilities for managing pressure injuries?

In long-term care facilities, hospital sand beds are essential for managing pressure injuries among elderly patients who are often at higher risk. These beds help maintain skin integrity and comfort, which is crucial for enhancing the quality of care and reducing hospital readmissions. For B2B buyers, training staff on the operation and patient handling techniques is a key consideration to maximize the benefits of these beds and ensure patient safety.

How do medical equipment suppliers benefit from offering hospital sand beds to healthcare providers?

Medical equipment suppliers can expand their product offerings by including hospital sand beds, catering to the increasing demand for advanced wound care solutions. By reselling these beds, suppliers can meet the needs of healthcare providers looking to enhance patient care. Key sourcing considerations include establishing relationships with reliable manufacturers, ensuring warranty and support services are in place, and staying updated on market trends to provide competitive pricing.

3 Common User Pain Points for ‘hospital sand bed price’ & Their Solutions

Scenario 1: Budget Constraints Impacting Purchase Decisions

The Problem: For many healthcare facilities, especially in developing regions like Africa and South America, budget constraints are a significant barrier when considering the acquisition of hospital sand beds. B2B buyers often find themselves struggling to justify the high upfront costs associated with advanced therapy beds, which can exceed $30,000. This financial strain can lead to tough decisions, including delaying necessary upgrades to patient care infrastructure or opting for less effective alternatives that may not provide optimal patient outcomes.

The Solution: To navigate these financial challenges, B2B buyers should explore various financing options, including leasing agreements or rental programs that allow for the use of high-quality sand beds without the immediate financial burden of a full purchase. Companies such as Hillrom and Aurora MFG offer rental programs specifically designed for their air fluidized therapy beds, enabling facilities to access cutting-edge technology while managing cash flow effectively. Additionally, buyers should consider bulk purchasing agreements or establishing partnerships with distributors to secure better pricing and terms. Engaging in discussions with manufacturers about potential discounts for non-profit organizations or government-funded facilities can also yield favorable pricing structures.

Scenario 2: Uncertainty About Product Specifications and Efficacy

The Problem: B2B buyers often face confusion regarding the specifications and clinical efficacy of different hospital sand beds. With numerous brands and models available, understanding which features are critical for patient care can be overwhelming. Buyers may worry about investing in a product that does not meet the specific needs of their patient population, particularly for those with complex wounds requiring specialized care.

The Solution: To mitigate uncertainty, buyers should conduct thorough market research and engage in conversations with healthcare professionals who have experience using various sand bed models. Requesting product demonstrations and case studies can provide valuable insights into how specific beds perform in real-world scenarios. It is also advisable to consult with clinical experts who can guide buyers in understanding the importance of features such as pressure redistribution, moisture management, and ease of use. Additionally, forming a selection committee that includes clinicians, nursing staff, and procurement officers can help ensure that all perspectives are considered in the purchasing decision, leading to a more informed choice.

Scenario 3: Maintenance and Operational Costs Over Time

The Problem: After acquiring a hospital sand bed, many B2B buyers discover that the ongoing maintenance and operational costs can be unexpectedly high. These costs include regular servicing, the need for specialized staff training, and potential repair expenses. Such financial implications can strain operational budgets, particularly for smaller healthcare facilities or those in regions with limited resources.

The Solution: To effectively manage maintenance and operational costs, buyers should prioritize selecting beds that offer comprehensive warranties and support services. Engaging with manufacturers that provide training and resources for staff can reduce the learning curve and minimize costly errors. Additionally, buyers should consider the total cost of ownership when evaluating different models—this includes assessing energy efficiency and the expected lifespan of the equipment. Developing a proactive maintenance schedule based on manufacturer recommendations can also prevent unexpected breakdowns and prolong the life of the bed. Finally, establishing a relationship with a local service provider can ensure timely repairs and support, further reducing downtime and associated costs.

Strategic Material Selection Guide for hospital sand bed price

What Are the Key Materials Used in Hospital Sand Beds?

When selecting materials for hospital sand beds, understanding their properties, advantages, disadvantages, and implications for international buyers is crucial. Here, we analyze common materials used in the construction of these beds, focusing on their performance characteristics and suitability for various applications.

1. Silicone-Coated Microspheres

Key Properties:

Silicone-coated microspheres are lightweight and provide excellent pressure redistribution. They can withstand high temperatures and are resistant to moisture, which helps in maintaining a controlled microclimate for wound healing.

Pros & Cons:

These microspheres are durable and provide a high level of comfort for patients, reducing the risk of pressure injuries. However, they can be more expensive than traditional materials, and manufacturing processes may be complex due to the need for precise coating techniques.

Impact on Application:

The fluid-like environment created by these microspheres is particularly effective for patients with complex wounds, as it minimizes friction and shear forces. This makes them suitable for high-acuity care settings.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local health regulations and standards, such as ASTM or ISO certifications, to guarantee quality and safety.

2. Polyurethane Foam

Key Properties:

Polyurethane foam is known for its flexibility and resilience, offering good pressure distribution. It typically has a moderate temperature rating and is resistant to corrosion and degradation.

Pros & Cons:

While polyurethane foam is relatively cost-effective and widely available, it may not offer the same level of pressure redistribution as silicone microspheres. Additionally, its durability can be compromised over time, especially in high-use environments.

Impact on Application:

This material is commonly used in lower-acuity settings where cost is a significant factor. It is suitable for general patient care but may not be ideal for patients with severe wound conditions.

Considerations for International Buyers:

International buyers should verify that the foam meets local safety standards and consider the availability of replacement parts, which can vary by region.

3. Air Fluidization Systems

Key Properties:

Air fluidization systems utilize air to create a dynamic support surface, enhancing immersion and envelopment. These systems can manage temperature and moisture effectively, which is critical for wound healing.

Pros & Cons:

The primary advantage of air fluidization is its ability to significantly reduce pressure points, making it ideal for high-risk patients. However, these systems can be costly to install and maintain, requiring specialized knowledge for operation.

Impact on Application:

These systems are particularly beneficial in acute care settings, where patients are at risk for pressure injuries. Their effectiveness in managing complex wounds makes them a preferred choice for hospitals.

Considerations for International Buyers:

Buyers should consider the availability of technical support and maintenance services in their region, as well as the compliance with international standards for medical devices.

4. High-Density Polyethylene (HDPE)

Key Properties:

HDPE is a robust thermoplastic known for its high strength-to-density ratio. It is resistant to impact, moisture, and chemicals, making it suitable for healthcare environments.

Pros & Cons:

HDPE is durable and easy to clean, which is essential for infection control. However, it may not provide the same level of comfort as softer materials, potentially impacting patient satisfaction.

Impact on Application:

This material is often used in the structural components of hospital beds, providing a long-lasting solution for general use.

Considerations for International Buyers:

Buyers should ensure that HDPE products meet local regulatory requirements and consider the environmental impact of plastic materials in their regions.

Summary Table of Material Selection for Hospital Sand Beds

| Material | Typical Use Case for hospital sand bed price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone-Coated Microspheres | High-acuity wound care beds | Excellent pressure redistribution | Higher cost and complex manufacturing | High |

| Polyurethane Foam | General patient care beds | Cost-effective and widely available | Durability issues over time | Medium |

| Air Fluidization Systems | Acute care settings | Significant pressure point reduction | High installation and maintenance costs | High |

| High-Density Polyethylene (HDPE) | Structural components of hospital beds | Durable and easy to clean | Less comfort compared to softer materials | Medium |

This analysis should assist international B2B buyers in making informed decisions regarding material selection for hospital sand beds, ensuring both patient care quality and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for hospital sand bed price

What Are the Key Stages in the Manufacturing Process of Hospital Sand Beds?

The manufacturing of hospital sand beds, particularly those utilizing air fluidized therapy, involves several critical stages. Understanding these stages is essential for B2B buyers to ensure product quality and reliability.

Material Preparation: Sourcing and Quality Control

The first stage begins with sourcing high-quality materials, primarily silicone-coated microspheres that mimic sand. These microspheres are crucial for achieving the desired fluid-like state when air is introduced. Manufacturers often engage in rigorous supplier evaluations to ensure that materials meet specific standards. This includes assessing the chemical composition and physical properties of the microspheres, which can affect the bed’s performance in terms of pressure redistribution and moisture management.

Forming: Precision Engineering Techniques

During the forming stage, manufacturers utilize advanced engineering techniques to create the bed’s structure. This includes molding the outer casing that houses the microspheres and air circulation system. Precision engineering is vital here, as any defects can lead to performance issues. Techniques such as computer numerical control (CNC) machining and injection molding are commonly employed to ensure high accuracy in the dimensions and fit of components.

Assembly: Integration of Components

The assembly phase integrates various components, including the air distribution system, control electronics, and safety features such as side rails and patient positioning systems. Each component must be meticulously assembled to ensure proper functionality. Automated assembly lines may be used to enhance efficiency, but manual checks are often implemented to maintain quality control. This step is critical, as the interplay between components directly impacts the bed’s performance in patient care.

Finishing: Quality Checks and Surface Treatment

The finishing stage involves applying protective coatings and conducting final inspections. Surface treatments are essential to ensure the beds are hygienic and resistant to wear. Quality checks at this stage include verifying the functionality of the air distribution system and ensuring that safety features meet regulatory standards. Manufacturers often employ automated testing equipment to streamline this process and enhance accuracy.

How Is Quality Assurance Implemented in Hospital Sand Bed Production?

Quality assurance (QA) in the production of hospital sand beds is paramount, especially when catering to international markets. Buyers need to be aware of the standards and practices that ensure product reliability and safety.

What International Standards Should B2B Buyers Look For?

Manufacturers of hospital sand beds typically comply with international quality management standards such as ISO 9001, which focuses on consistent product quality and customer satisfaction. Additionally, specific industry standards like CE marking in Europe or API certifications may be relevant, depending on the market. These certifications indicate that the products have passed rigorous assessments and meet safety and efficacy requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to maintaining product integrity throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitoring production processes to identify and rectify defects in real-time.

- Final Quality Control (FQC): Conducting comprehensive tests on finished products to verify functionality, safety, and compliance with regulations.

These checkpoints help manufacturers catch potential issues early, reducing the risk of non-compliant products reaching the market.

What Testing Methods Are Commonly Used in Quality Assurance?

B2B buyers should be aware of the various testing methods employed to ensure the quality of hospital sand beds. These methods often include:

- Pressure Redistribution Testing: Evaluating how well the bed distributes pressure across its surface, which is critical for preventing pressure ulcers.

- Durability Testing: Assessing the bed’s longevity under simulated use conditions to ensure it can withstand everyday wear and tear.

- Safety Testing: Verifying the functionality of safety features such as emergency release systems and patient transfer capabilities.

By understanding these testing methods, buyers can better assess the reliability of the products they intend to purchase.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to stringent quality control practices, B2B buyers can take several proactive steps:

- Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This includes reviewing their certifications, production facilities, and compliance with international standards.

- Request Quality Assurance Reports: Suppliers should be able to provide detailed QA reports that outline their testing processes, results, and any corrective actions taken for non-compliance issues.

- Engage Third-Party Inspections: Utilizing third-party inspection services can offer an unbiased assessment of the products and manufacturing practices, ensuring they meet the required standards.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers, particularly from regions like Africa, South America, and the Middle East, face unique challenges in ensuring quality control. These can include:

- Regulatory Variations: Different countries have varying regulations regarding medical devices, which can affect compliance. Buyers must be aware of the specific requirements in their regions and ensure that their suppliers can meet these standards.

- Logistical Challenges: Shipping and logistics can impact product integrity. Buyers should consider how products are packaged and transported to prevent damage during transit.

- Cultural and Language Barriers: Effective communication is crucial for understanding quality expectations. Buyers may need to work with translators or local representatives to ensure clarity in specifications and requirements.

By navigating these complexities and focusing on robust quality assurance processes, B2B buyers can secure reliable hospital sand beds that meet their needs and enhance patient care.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hospital sand bed price’

Introduction

This guide is designed to assist B2B buyers in navigating the procurement process for hospital sand beds, also known as air fluidized therapy beds. Understanding the nuances of pricing, specifications, and supplier evaluations is crucial for making informed purchasing decisions. The following checklist outlines essential steps to ensure you secure the best value and quality for your healthcare facility’s needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the hospital sand bed you intend to purchase. Consider factors such as patient weight capacity, size, and specific features like pressure redistribution capabilities and temperature control. This clarity will help you communicate effectively with suppliers and narrow down options that meet your facility’s needs.

Step 2: Research Market Pricing Trends

Conduct thorough market research to understand the price range for hospital sand beds. Prices can vary significantly based on features, brand reputation, and geographical location. Utilize resources such as industry reports, supplier websites, and peer recommendations to establish a baseline for what you should expect to pay.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request company profiles, case studies, and references from other healthcare facilities that have purchased similar products. Look for suppliers with a proven track record in your region, as they may have insights into local regulations and service expectations.

- Check for certifications: Ensure that suppliers comply with international healthcare standards and have the necessary certifications for their products.

- Assess customer support: Evaluate their ability to provide ongoing support, including installation, maintenance, and training.

Step 4: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that break down costs. Look for transparency in pricing, including shipping, installation, and any additional fees. This will help you compare offers more effectively and identify any hidden costs.

Step 5: Consider Rental Options

Evaluate if renting a hospital sand bed is a more viable option for your facility. Renting can be particularly beneficial for temporary needs or budget constraints. Analyze rental terms, including maintenance responsibilities and any conditions for extending the rental period.

Step 6: Inspect Products Before Purchase

If possible, arrange to inspect the hospital sand beds in person or request a demonstration. This allows you to assess the quality and functionality of the bed firsthand. Ensure that the bed meets your comfort and usability standards, as this directly impacts patient care.

Step 7: Review Warranty and After-Sales Service

Finally, examine the warranty offered by the supplier and the terms of after-sales service. A comprehensive warranty can protect your investment, while good after-sales support ensures that you can address any issues promptly. Look for suppliers that offer robust training and resources for healthcare staff to maximize the bed’s effectiveness in patient care.

By following these steps, you can confidently navigate the procurement process for hospital sand beds, ensuring that you make a well-informed investment that enhances patient care in your facility.

Comprehensive Cost and Pricing Analysis for hospital sand bed price Sourcing

What Are the Key Cost Components in Sourcing Hospital Sand Beds?

When sourcing hospital sand beds, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The most significant cost driver is the specialized materials used in the construction of sand beds, such as silicone-coated microspheres, which are integral to the air fluidization technology. These materials not only enhance patient comfort but also ensure effective pressure redistribution.

-

Labor: Labor costs encompass both the skilled workforce required for manufacturing and the technical staff involved in product development and quality control. Skilled labor is necessary for assembling high-tech beds that meet rigorous medical standards.

-

Manufacturing Overhead: This includes costs related to factory operation, utilities, equipment maintenance, and depreciation. Efficient manufacturing processes can reduce these costs, which is crucial for maintaining competitive pricing.

-

Tooling: Investments in specialized tooling and machinery for producing sand beds can be substantial. This upfront cost is amortized over production volume, affecting the unit price.

-

Quality Control (QC): Ensuring that each sand bed meets health regulations and quality standards involves additional costs related to testing and compliance. This can include certifications from medical device regulatory bodies, which may vary by region.

-

Logistics: Transportation and warehousing costs play a vital role, especially for international buyers. Import duties, shipping rates, and storage fees can significantly impact the final price.

-

Margin: Suppliers will typically add a markup to cover their costs and profit margins. Understanding this can aid buyers in negotiating better terms.

How Do Price Influencers Affect Hospital Sand Bed Pricing?

Several factors influence the pricing of hospital sand beds:

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly affect pricing. Larger orders often lead to lower per-unit costs due to economies of scale.

-

Specifications/Customization: Custom features or specifications tailored to specific healthcare needs can increase costs. Buyers should weigh the necessity of customization against budget constraints.

-

Materials: The choice of materials directly impacts price. Higher-quality materials may lead to higher costs but can improve performance and longevity, thus enhancing the Total Cost of Ownership (TCO).

-

Quality/Certifications: Beds that meet international quality standards or have specific certifications may command a premium price. Buyers must verify these credentials to ensure they are investing in a reliable product.

-

Supplier Factors: The supplier’s reputation, reliability, and service offerings can influence pricing. Established suppliers may charge more due to their perceived value and service quality.

-

Incoterms: Understanding Incoterms is crucial for international buyers. These terms define the responsibilities of buyers and sellers in shipping and logistics, impacting overall costs.

What Tips Can Buyers Use to Negotiate Better Prices for Hospital Sand Beds?

B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, can leverage several strategies:

-

Negotiate Effectively: Engage suppliers in discussions about pricing flexibility. Highlighting your volume commitments or exploring long-term contracts can lead to better pricing.

-

Focus on Cost-Efficiency: Assess the Total Cost of Ownership, which includes initial purchase price, maintenance, and operational costs. Sometimes a higher upfront investment can lead to lower long-term costs.

-

Understand Pricing Nuances: Be aware that prices may vary significantly based on local market conditions, currency fluctuations, and regional demand. Conduct thorough market research to inform negotiations.

-

Explore Financing Options: Some suppliers offer financing plans that can ease the burden of upfront costs. Look for options that suit your financial strategy.

-

Request Multiple Quotes: Obtaining quotes from various suppliers provides leverage in negotiations. It also helps to compare specifications and ensure you’re receiving fair pricing.

Conclusion

In summary, a comprehensive understanding of the cost components and pricing influencers associated with hospital sand beds is essential for B2B buyers. By applying strategic negotiation techniques and focusing on the Total Cost of Ownership, buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that prices may vary and it’s prudent to request indicative pricing from multiple suppliers to ensure competitive offers.

Alternatives Analysis: Comparing hospital sand bed price With Other Solutions

Understanding Alternatives to Hospital Sand Beds

In the realm of advanced wound care and pressure injury prevention, hospital sand beds—also known as air fluidized therapy beds—are a prominent solution. However, various alternatives exist that may provide similar benefits, depending on the specific requirements of healthcare facilities. This analysis will compare hospital sand beds with other viable alternatives, enabling B2B buyers to make informed decisions tailored to their operational needs.

Comparison Table

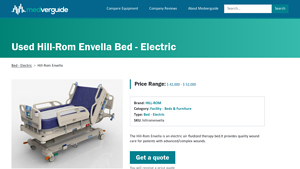

| Comparison Aspect | Hospital Sand Bed Price | Alternative 1: HydroAire Air Fluidized Therapy Bed | Alternative 2: Envella Air Fluidized Therapy Bed |

|---|---|---|---|

| Performance | Excellent pressure redistribution and skin protection | High immersion and envelopment; effective for complex wounds | Superior shear stress performance and comfort |

| Cost | Approx. $40,000 – $60,000 | Approx. $39,974 (discounted from $55,564) | Rental only; pricing varies by provider |

| Ease of Implementation | Requires training and set-up | Moderate; training needed for optimal use | Simple touchscreen controls for ease of use |

| Maintenance | Regular maintenance required | Requires periodic checks for air flow and function | Integrated diagnostics for continuous monitoring |

| Best Use Case | Long-term care in hospitals | Ideal for acute care settings with complex wounds | Best for ongoing patient monitoring and recovery |

Detailed Breakdown of Alternatives

Alternative 1: HydroAire Air Fluidized Therapy Bed

The HydroAire bed offers a compelling solution for healthcare facilities focusing on wound care. With a price point of approximately $39,974, it provides significant savings compared to traditional hospital sand beds. The HydroAire excels in immersion and envelopment, critical for effective wound treatment. However, it requires moderate implementation efforts, including staff training to ensure proper use. Regular maintenance is necessary to ensure optimal performance, making it essential for healthcare providers to allocate resources for ongoing upkeep.

Alternative 2: Envella Air Fluidized Therapy Bed

The Envella bed stands out for its advanced features, particularly in terms of patient comfort and shear stress performance. While this bed is available primarily through rental agreements, its pricing varies significantly based on the provider, making it essential for B2B buyers to evaluate their long-term needs. The Envella bed simplifies operation with its user-friendly touchscreen controls, which can enhance care team productivity. Its integrated diagnostics provide continuous monitoring of airflow and pressure, ensuring consistent performance. However, being rental-based may limit its accessibility for some facilities.

How Can B2B Buyers Choose the Right Solution?

When selecting a wound care solution, B2B buyers should consider several factors, including the specific needs of their patient population, budget constraints, and operational capabilities. Hospital sand beds remain a robust option for long-term care, but alternatives like the HydroAire and Envella beds can offer cost savings and specialized features. Buyers should assess their requirements for performance, ease of implementation, and maintenance to determine the best fit for their facility. Engaging in discussions with suppliers and evaluating trial periods can further aid in making a well-informed decision tailored to their healthcare environment.

Essential Technical Properties and Trade Terminology for hospital sand bed price

What Are the Key Technical Properties of Hospital Sand Beds?

When considering the purchase of hospital sand beds, particularly air fluidized therapy beds, several technical properties are essential for ensuring optimal performance and patient care. Understanding these specifications helps B2B buyers make informed decisions.

-

Material Grade

The bed’s construction materials, often silicone-coated microspheres, are crucial for their durability and effectiveness. High-quality materials ensure long-term usage and resistance to wear and tear, which is vital for hospitals aiming to reduce replacement costs. -

Weight Capacity

Hospital sand beds typically have a defined weight capacity, ranging from 70 to 350 lbs (32 to 160 kg). This specification is critical for ensuring that the bed can safely accommodate a variety of patient sizes, particularly in diverse regions where patient demographics may vary significantly. -

Pressure Redistribution Performance

This property measures how effectively the bed redistributes pressure across its surface. Advanced beds can demonstrate up to 45% better pressure redistribution compared to traditional surfaces. This feature is essential for preventing pressure injuries, a significant concern in healthcare settings. -

Evaporative Capacity

The ability of a bed to manage moisture levels directly influences patient comfort and healing. Some beds can have evaporative capacities up to 58 times greater than standard surfaces, thus promoting a conducive microclimate for skin health. -

Temperature Control Mechanism

Effective temperature regulation is crucial for patient comfort and healing. Beds equipped with variable temperature air flow systems help maintain an optimal thermal environment, reducing the risk of skin breakdown and improving overall patient outcomes. -

Ease of Maintenance

The design of hospital sand beds should facilitate easy cleaning and maintenance. Features such as removable covers and antimicrobial materials can significantly enhance hygiene, making these beds suitable for various healthcare settings.

What Are Common Trade Terms Related to Hospital Sand Beds?

Navigating the purchasing landscape for hospital sand beds involves understanding specific trade terminology that can influence procurement processes.

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand. In the context of hospital sand beds, understanding the OEM can help buyers assess product quality and reliability. -

MOQ (Minimum Order Quantity)

This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers as it can affect budget planning and inventory management. -

RFQ (Request for Quotation)

An RFQ is a formal document requesting prices and terms from suppliers. Issuing an RFQ for hospital sand beds allows buyers to compare options and negotiate better pricing or terms based on their needs. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers, especially when importing products like hospital sand beds from overseas suppliers. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. Understanding lead times helps buyers plan for inventory needs and avoid disruptions in patient care. -

Warranty Period

The warranty period indicates the duration a manufacturer guarantees the product against defects. This is a critical consideration for B2B buyers, as a longer warranty can signify greater confidence in product durability and quality.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can enhance their procurement strategies, ensuring they select the right hospital sand beds to meet their organizational needs.

Navigating Market Dynamics and Sourcing Trends in the hospital sand bed price Sector

What Are the Key Market Dynamics Influencing the Hospital Sand Bed Price Sector?

The hospital sand bed price sector is experiencing a notable transformation driven by several global factors. The increasing prevalence of chronic wounds, particularly in aging populations, is propelling demand for advanced therapeutic solutions like air fluidized therapy beds. These beds, which utilize a unique sand-like material for pressure redistribution, are becoming the gold standard in wound care, leading to a surge in their adoption. Additionally, the growing focus on patient comfort and recovery speed is prompting healthcare facilities to invest in high-quality therapeutic beds, thereby influencing pricing dynamics.

Emerging technologies such as telemedicine and smart bed integration are also shaping the market landscape. These innovations not only enhance patient care but also streamline operational efficiency in hospitals, driving B2B buyers to seek out suppliers that can provide cutting-edge solutions. Furthermore, as global supply chains adapt to post-pandemic realities, there is an increased emphasis on local sourcing to mitigate risks associated with logistics disruptions. For international B2B buyers, particularly those in regions like Africa, South America, and the Middle East, understanding these trends is crucial for making informed purchasing decisions.

How Are Sustainability and Ethical Sourcing Impacting Hospital Sand Bed Pricing?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the hospital sand bed price sector. The environmental impact of manufacturing and transporting hospital beds is under scrutiny, prompting manufacturers to adopt more sustainable practices. This includes using eco-friendly materials and reducing waste in production processes. Buyers are increasingly looking for suppliers that can demonstrate a commitment to sustainability, as this not only aligns with corporate social responsibility goals but can also enhance brand reputation.

Moreover, the demand for “green” certifications is on the rise. Products that meet recognized sustainability standards can command higher prices due to their perceived value and ethical appeal. B2B buyers should prioritize suppliers that offer transparency in their sourcing processes and can provide documentation of sustainable practices. By investing in environmentally friendly products, organizations can not only contribute to global sustainability efforts but also potentially benefit from cost savings through energy-efficient technologies and reduced disposal costs over the product lifecycle.

What Is the Historical Context of Hospital Sand Beds and Their Pricing Trends?

The evolution of hospital sand beds, particularly those utilizing air fluidized therapy, has roots in the early 20th century when medical professionals began exploring ways to improve patient comfort and healing outcomes. Initially, the focus was primarily on basic pressure-relief solutions; however, as technology advanced, the introduction of air fluidized therapy beds revolutionized wound care. These beds effectively distribute pressure, reduce friction, and enhance moisture management, making them essential in modern healthcare settings.

Over the years, the pricing trends for these beds have fluctuated based on technological advancements, manufacturing costs, and market demand. As healthcare systems worldwide increasingly recognize the importance of effective wound management, the investment in high-quality sand beds is seen as a strategic move to improve patient outcomes. This historical context provides B2B buyers with a framework for understanding current pricing dynamics and the value proposition of investing in advanced therapeutic solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of hospital sand bed price

-

How do I determine the right hospital sand bed for my facility?

To select the appropriate hospital sand bed, consider patient needs, bed specifications, and treatment goals. Evaluate the types of wounds commonly treated in your facility, as some beds specialize in pressure injury prevention and wound healing. Review technical specifications such as weight capacity, pressure redistribution efficiency, and ease of use. Engaging with manufacturers for product demonstrations and consultations can also provide insights into the most suitable options for your healthcare setting. -

What factors influence the price of hospital sand beds?

The price of hospital sand beds is influenced by several factors, including the technology used (e.g., air fluidized therapy), brand reputation, features (such as adjustable height and integrated scales), and warranty offerings. Additionally, geographic location, shipping costs, and import duties can affect the final pricing for international buyers. It’s advisable to compare prices across multiple suppliers while considering the total cost of ownership, including maintenance and potential rental options. -

What are the common payment terms for purchasing hospital sand beds internationally?

Payment terms vary by supplier and region but commonly include options like upfront payment, net 30/60/90 days, or letters of credit for larger orders. Some suppliers may also offer financing options or payment plans to accommodate budget constraints. It’s essential to clarify payment terms upfront and ensure they align with your financial capabilities and procurement policies, especially when dealing with international transactions. -

How can I vet suppliers of hospital sand beds?

To vet suppliers, start by researching their reputation through online reviews and industry references. Check for certifications that ensure compliance with medical equipment standards, such as ISO and CE marks. Request product samples or demonstrations to assess quality firsthand, and inquire about their customer service and support systems. Additionally, consider visiting their facilities or attending trade shows to build relationships and gain deeper insights into their operations. -

What is the minimum order quantity (MOQ) for hospital sand beds?

The MOQ for hospital sand beds can vary significantly by manufacturer, ranging from single units for smaller suppliers to larger quantities for established brands. When sourcing internationally, it’s crucial to discuss MOQ with suppliers, as they may offer flexibility based on your specific needs or long-term purchasing agreements. Understanding MOQ will help in planning your budget and inventory management effectively. -

Can hospital sand beds be customized for specific healthcare needs?

Yes, many manufacturers offer customization options for hospital sand beds to cater to specific healthcare requirements. Customizations may include adjustments in size, weight capacity, or additional features like integrated monitoring systems. When discussing customization, communicate your facility’s needs clearly and ask for prototypes or mock-ups if available. This ensures that the final product aligns with your operational standards and patient care protocols. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should have robust quality assurance (QA) measures in place, including regular inspections, compliance with international standards, and a clear warranty policy. Inquire about their QA processes, such as testing protocols for durability and performance. Additionally, ask for documentation that outlines the product’s lifecycle and maintenance requirements, which is critical for ensuring ongoing compliance and reliability in patient care. -

How do logistics and shipping affect the procurement of hospital sand beds?

Logistics and shipping play a significant role in the procurement process, especially for international buyers. Factors such as shipping methods, lead times, and customs clearance can impact delivery schedules and overall costs. It’s advisable to work closely with suppliers and freight forwarders to understand shipping options and associated fees. Additionally, ensure that the supplier has experience in handling medical equipment shipments to avoid potential regulatory issues and delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Hospital Sand Bed Price Manufacturers & Suppliers List

1. Ethos Outcomes – Air Fluidized Therapy

Domain: ethosoutcomes.com

Registered: 2017 (8 years)

Introduction: Air Fluidized Therapy (AFT) is designed for in-home wound healing and recovery, utilizing Clinitron beds. Key features include:

– Fluidization technology with silicone coated microspheres that create a dynamic fluid-like state for optimal immersion and envelopment.

– Reduces mechanical stress from friction and shear, minimizing skin breakdown.

– Variable temperature air flow for heat and moisture …

2. Hillrom – Envella Bed

Domain: hillrom.com

Registered: 1997 (28 years)

Introduction: Envella Bed: Air Fluidized Therapy Hospital Bed designed for wound care with pressure distribution technology. Rental only.

3. Aurora MFG – HydroAire Air Fluidized Therapy Bed

Domain: medmartonline.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “Aurora MFG HydroAire Air Fluidized Therapy Bed”, “SKU”: “AUR-HYDROAIRE”, “Item ID”: “39358”, “Price”: “$39,974”, “Old Price”: “$55,564”, “Savings”: “$15,590”, “Max Weight Capacity”: “300 lbs”, “Bed Height”: [“30 inches”, “26 inches”], “Bed Width”: {“Overall”: “36 inches”, “Inside Tank”: “33 3/4 inches”}, “Bed Length”: {“Overall”: “84 inches”, “Inside Tank”: “81 3/4 inches”}, “Bed…

4. WoundSource – Powered and Air-Fluidized Beds

Domain: woundsource.com

Registered: 1998 (27 years)

Introduction: Powered and air-fluidized beds are semi-electric or completely electric hospital support surfaces with a fully integrated powered mattress that has a total height of 3 inches or greater and a surface designed to reduce friction and shear. An air-fluidized support surface employs the circulation of filtered air through silicone-coated ceramic beads, creating the characteristics of fluid. Indicated …

5. BlueChip Medical – Airus™ Air Fluidized Therapy Bed System

Domain: bluechipmedical.com

Registered: 1999 (26 years)

Introduction: Airus™ Air Fluidized Therapy Bed System (AFT) is the first portable Group 3 AFT bed designed for the prevention and treatment of pressure ulcers. Key features include:

– Full length air fluidized therapy

– Sleep surface dimensions: 32″ x 84″

– Sleep surface height: 29.5″

– Portable system with user-friendly controls

– Easy setup for providers

– Convenient hand-held control

– Battery backup mode

– …

6. HILL-ROM – Hill-Rom Envella Bed

Domain: medverguide.com

Registered: 2020 (5 years)

Introduction: {“Product Name”: “Hill-Rom Envella Bed”, “Type”: “Electric Bed”, “Price Range”: “$42,000 – $52,000”, “Brand”: “HILL-ROM”, “Category”: “Facility – Beds & Furniture”, “SKU”: “hillromenvella”, “Features”: [“Electric air fluidized therapy bed”, “Quality wound care for patients with advanced/complex wounds”, “Weight based pressure redistribution”, “Side transfer”, “Auto leveling bead bath”, “Head-of-be…

7. Agiliti – Adapt Air Pro™

Domain: agilitihealth.com

Registered: 2018 (7 years)

Introduction: Agiliti provides a diverse range of hospital beds and therapeutic support surfaces, including Agiliti-manufactured air and foam surfaces. Featured Product: Adapt Air Pro™ – designed for optimal pressure injury treatment and prevention with 8-inch air cells that deliver 30% more immersion and targeted airflow for microclimate management. Agiliti adheres to quality standards exceeding OEM regulation…

Strategic Sourcing Conclusion and Outlook for hospital sand bed price

How Can Strategic Sourcing Enhance Your Hospital Sand Bed Procurement?

In summary, strategic sourcing for hospital sand beds, particularly air fluidized therapy beds, is critical for enhancing patient care while managing costs effectively. As we have explored, the integration of advanced technologies in these beds significantly improves patient comfort, accelerates wound healing, and reduces the risk of pressure injuries. This not only benefits the patients but also positions healthcare providers to optimize resource allocation and improve overall operational efficiency.

For international B2B buyers from Africa, South America, the Middle East, and Europe, adopting a strategic sourcing approach will enable you to identify reliable suppliers, negotiate favorable terms, and ensure compliance with local healthcare regulations. By leveraging partnerships with manufacturers and distributors, you can secure high-quality products at competitive prices, enhancing your institution’s service delivery capabilities.

Looking ahead, the demand for effective wound care solutions is expected to grow, driven by an increasing patient population and the need for advanced healthcare solutions. Engage with trusted suppliers and consider innovative procurement strategies to stay ahead in this evolving market. Your commitment to strategic sourcing today will lay the foundation for improved patient outcomes and operational success tomorrow.