Is Your Electric Shock Gloves Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for electric shock gloves

In today’s evolving security landscape, sourcing effective electric shock gloves poses a significant challenge for international B2B buyers. These innovative tools not only enhance the capabilities of law enforcement and security personnel but also ensure non-lethal intervention in potentially volatile situations. As the demand for reliable protective gear rises across regions—especially in Africa, South America, the Middle East, and Europe—understanding the nuances of electric shock gloves becomes essential for making informed purchasing decisions.

This comprehensive guide delves into various types of electric shock gloves, their applications across diverse sectors, and critical considerations for supplier vetting. It addresses factors such as product specifications, safety standards, and cost implications, providing buyers with a holistic view of the market. By equipping decision-makers with actionable insights, this guide empowers organizations to enhance their operational effectiveness while ensuring safety and compliance in their respective regions.

Whether you are a security firm in Nigeria seeking advanced protective gear or a law enforcement agency in Germany looking to upgrade your tactical equipment, this guide is tailored to meet your needs. Dive into the world of electric shock gloves and discover how to navigate this complex market with confidence, ensuring your organization is equipped with the best tools for the job.

Understanding electric shock gloves Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conductive Distraction Device (CD3) | Transforms into a device for law enforcement with low output voltage. | Law enforcement, corrections, security, military | Pros: Enhances existing tactics; non-lethal. Cons: May require training for effective use. |

| Electric Taser Gloves | Integrates stun gun technology with ergonomic design. | Riot control, personal protection, animal control | Pros: Instant immobilization; safe voltage levels. Cons: Limited operational duration. |

| Police Stun Gloves | Features unique activation for issuing warnings during interventions. | Security personnel, law enforcement, event security | Pros: Innovative warning system; effective for crowd control. Cons: Restricted to certified personnel. |

| Neuro-Muscular Disruption Gloves | Delivers high-frequency pulses for immediate muscle disruption. | Suspect apprehension, mental health interventions | Pros: Quick incapacitation; versatile applications. Cons: Requires precise targeting for effectiveness. |

| Carbon Fiber Reinforced Gloves | Provides protection against blunt force while delivering electric shock. | VIP protection, security training, event security | Pros: Enhanced safety for users; dual functionality. Cons: Heavier than standard gloves; may be costly. |

What Are the Characteristics of Conductive Distraction Devices (CD3)?

Conductive Distraction Devices (CD3) are designed primarily for law enforcement and security professionals. These gloves transform into a low-output voltage emitter, allowing users to apply non-lethal force while adhering to existing operational protocols. The gloves are lightweight and come in various sizes, making them suitable for diverse users. Buyers should consider the need for training and integration with current tactics to maximize effectiveness.

How Do Electric Taser Gloves Function?

Electric Taser Gloves utilize advanced technology that combines the immobilizing effects of stun guns with the convenience of wearable gloves. They are effective in high-stress situations, delivering low-voltage pulses that incapacitate an assailant for a brief period. These gloves are ideal for riot control, personal defense, and animal control. B2B buyers should evaluate their operational needs and training requirements, as these gloves are designed for immediate, non-lethal intervention.

What Makes Police Stun Gloves Unique?

Police Stun Gloves stand out due to their unique activation feature that allows users to issue warnings during interventions. This capability is particularly beneficial in maintaining order without resorting to force. They are exclusively available to certified professionals, which ensures that users are trained in their proper application. When considering these gloves, buyers should assess the certification requirements and the potential for enhancing crowd control strategies.

What Are Neuro-Muscular Disruption Gloves?

Neuro-Muscular Disruption Gloves are engineered to deliver high-frequency electric pulses that cause immediate muscle spasms upon contact. This technology is particularly effective for suspect apprehension and mental health interventions, providing a safe method to subdue individuals. Buyers should consider the specific target areas for application and the need for precise training to ensure effective use in critical situations.

Why Choose Carbon Fiber Reinforced Gloves?

Carbon Fiber Reinforced Gloves offer a unique combination of impact protection and electric shock capabilities. The gloves are designed for use in high-risk environments, providing safety against blunt force while also delivering electric shocks for self-defense. They are ideal for VIP protection and security training. Buyers should weigh the benefits of enhanced safety against the potential for increased costs and weight compared to standard gloves.

Key Industrial Applications of electric shock gloves

| Industry/Sector | Specific Application of Electric Shock Gloves | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Law Enforcement | Suspect apprehension during arrests | Enhances officer safety while subduing suspects | Compliance with local regulations and training needs |

| Security Services | Event security and crowd control | Provides a non-lethal option for managing aggressive behavior | Durability and effectiveness in various environments |

| Corrections Facilities | Riot control and inmate management | Reduces the risk of injury to staff and inmates | Reliable power source and ease of use in high-stress situations |

| Animal Control | Subduing aggressive animals during rescue operations | Ensures safety for handlers and effectiveness in animal capture | Range of voltage settings and comfort for prolonged use |

| Personal Defense | Civilian self-defense | Offers a portable and discreet self-defense tool | Weight, battery life, and ease of activation |

How Are Electric Shock Gloves Used in Law Enforcement?

Electric shock gloves are increasingly utilized by law enforcement agencies for suspect apprehension. When officers encounter aggressive individuals, these gloves deliver a non-lethal electric shock, immobilizing the suspect temporarily. This capability not only ensures the safety of officers but also minimizes the risk of permanent injury to suspects. For international buyers, particularly in regions like Africa and Europe, it is crucial to ensure that these gloves comply with local use-of-force regulations and that personnel receive proper training for effective deployment.

What Role Do Electric Shock Gloves Play in Security Services?

In the security sector, electric shock gloves serve as vital tools for event security and crowd management. Security personnel can use these gloves to quickly diffuse potentially dangerous situations without resorting to lethal force. The gloves allow for immediate immobilization of aggressive individuals, which is essential in high-density environments like concerts or sports events. Buyers should prioritize sourcing gloves that are durable, reliable, and effective in various weather conditions to maintain operational integrity.

How Are Electric Shock Gloves Beneficial in Corrections Facilities?

In corrections facilities, electric shock gloves are employed for riot control and inmate management. These gloves provide correctional officers with a non-lethal means to subdue inmates during violent outbreaks, thereby reducing the likelihood of injuries to both staff and inmates. When sourcing these gloves, it is important for facilities to consider the reliability of the power source and the gloves’ usability in high-stress situations, ensuring they can be deployed effectively when needed most.

What Is the Application of Electric Shock Gloves in Animal Control?

Electric shock gloves are also valuable in the field of animal control, particularly for subduing aggressive animals during rescue operations. Handlers can use the gloves to safely immobilize animals, ensuring both their safety and that of the personnel involved. International buyers, especially those operating in regions with diverse wildlife, should look for gloves that offer adjustable voltage settings and ergonomic designs to facilitate prolonged use without discomfort.

How Can Electric Shock Gloves Enhance Personal Defense?

For personal defense, electric shock gloves provide individuals with a discreet yet effective means of self-protection. These gloves can incapacitate an assailant quickly, providing the wearer with a crucial window to escape. When sourcing electric shock gloves for personal use, buyers should consider factors such as weight, battery life, and ease of activation, ensuring that the gloves can be relied upon in critical situations.

3 Common User Pain Points for ‘electric shock gloves’ & Their Solutions

Scenario 1: Ensuring Compliance with Safety Regulations

The Problem: As law enforcement agencies and security firms operate under strict regulations, ensuring that electric shock gloves comply with local and international safety standards can be a significant challenge. In regions such as Africa and the Middle East, the lack of clarity around compliance can lead to operational delays, legal liabilities, and financial penalties. Buyers are often unsure which manufacturers provide products that meet the necessary certifications, resulting in wasted time and resources.

The Solution: B2B buyers should prioritize sourcing electric shock gloves from manufacturers with a proven track record of compliance. Request detailed documentation regarding safety certifications and compliance with relevant standards (such as ISO certifications or local regulations). Conduct thorough due diligence by reviewing product specifications and requesting samples to ensure they meet operational requirements. Additionally, partnering with suppliers who offer ongoing support and updates about compliance changes can help buyers stay ahead of regulatory challenges. Establishing a relationship with a trusted manufacturer can also provide insights into best practices and innovations in safety technology.

Scenario 2: Addressing Operational Training Needs

The Problem: Many organizations face the dilemma of how to effectively train personnel in the proper use of electric shock gloves. Without adequate training, there’s a risk of misuse, which can lead to unintended injuries, legal consequences, and diminished effectiveness in high-stress situations. This concern is particularly pressing in regions with varying levels of training resources and support for security personnel.

The Solution: Implementing a structured training program is essential for maximizing the effectiveness of electric shock gloves. Buyers should work with manufacturers who provide comprehensive training modules, including hands-on demonstrations and scenario-based exercises. Consider developing a partnership with local training organizations or security consultants who specialize in non-lethal defense tactics. This collaboration can enhance understanding and confidence in using the gloves correctly. Furthermore, creating a feedback loop where operators can share experiences and best practices can foster a culture of safety and proficiency.

Scenario 3: Balancing Functionality and Comfort

The Problem: Security personnel often struggle to find electric shock gloves that balance functionality with comfort and mobility. Heavy or poorly designed gloves can hinder performance during critical moments, leading to frustration and reduced operational effectiveness. This issue is especially relevant in diverse climates, from the heat of South America to the cooler temperatures of Europe, where glove materials can affect usability.

The Solution: When selecting electric shock gloves, B2B buyers should focus on ergonomics and material composition. Engage with suppliers who offer a variety of models tailored for different environments and operational needs. For instance, gloves made from lightweight, breathable materials can enhance comfort in warmer climates, while reinforced designs can provide better protection in more hazardous situations. Conducting field tests with personnel to assess glove performance in real-world scenarios can provide invaluable insights. Additionally, consider gloves that feature adjustable fits and customizable options to ensure that each user can maintain dexterity and comfort while effectively utilizing the gloves in various operational contexts.

Strategic Material Selection Guide for electric shock gloves

What Are the Key Materials Used in Electric Shock Gloves?

When selecting electric shock gloves for various applications, the choice of materials plays a crucial role in determining the gloves’ performance, durability, and suitability for specific environments. Below is an analysis of four common materials used in the manufacturing of electric shock gloves, focusing on their properties, advantages and disadvantages, and considerations for international B2B buyers.

How Does Leather Contribute to Electric Shock Gloves?

Leather, particularly goat skin or cowhide, is often used as the outer layer for electric shock gloves. It offers excellent flexibility and tactile sensitivity, which are essential for handling tasks. Leather is naturally resistant to abrasion, making it durable in high-wear environments. However, it has limited resistance to extreme temperatures and moisture, which can affect its longevity and performance.

Pros: Durable, good grip, high tactile sensitivity.

Cons: Limited temperature resistance, can absorb moisture, higher maintenance required.

Impact on Application: Suitable for environments where dexterity is crucial, but may not perform well in wet or extreme temperature conditions.

Considerations for International Buyers: Compliance with local standards for leather quality is essential, particularly in regions like Europe where regulations may be stricter.

What Role Does Carbon Fiber Play in Electric Shock Gloves?

Carbon fiber is increasingly being integrated into electric shock gloves due to its lightweight and high-strength properties. It provides excellent impact resistance, making it ideal for gloves used in law enforcement and security. Additionally, carbon fiber can withstand a range of temperatures, enhancing the glove’s versatility.

Pros: Lightweight, strong, resistant to impact.

Cons: Higher manufacturing costs, potential brittleness under extreme conditions.

Impact on Application: Ideal for high-risk environments where both protection and mobility are necessary.

Considerations for International Buyers: Buyers should ensure that the carbon fiber used meets relevant safety standards, such as ASTM or DIN.

How Does Synthetic Rubber Enhance Electric Shock Gloves?

Synthetic rubber, often used in the inner layers of electric shock gloves, provides excellent insulation properties. It can effectively withstand electrical currents while offering a good grip. Synthetic rubber is also resistant to various chemicals, making it suitable for diverse applications.

Pros: Excellent insulation, chemical resistance, good grip.

Cons: May degrade over time with exposure to UV light, can be less breathable than natural materials.

Impact on Application: Suitable for environments where electrical hazards are present, but may require careful storage to prevent degradation.

Considerations for International Buyers: Ensure compliance with international electrical safety standards and consider local climate impacts on material longevity.

What Advantages Does Kevlar Offer in Electric Shock Gloves?

Kevlar is renowned for its high tensile strength and cut resistance, making it an excellent choice for gloves intended for high-risk applications. It can provide an additional layer of protection against cuts and abrasions while maintaining flexibility.

Pros: High cut resistance, lightweight, durable.

Cons: Higher cost, may not provide as much electrical insulation as other materials.

Impact on Application: Ideal for environments where both electrical and physical hazards are present.

Considerations for International Buyers: Buyers should verify that Kevlar meets the required safety standards for their specific region, particularly in Europe and North America.

Summary Table of Material Selection for Electric Shock Gloves

| Material | Typical Use Case for electric shock gloves | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | General law enforcement and security | Durable and flexible | Limited temperature resistance | Medium |

| Carbon Fiber | High-risk security applications | Lightweight and impact-resistant | Higher manufacturing costs | High |

| Synthetic Rubber | Environments with electrical hazards | Excellent insulation | UV degradation over time | Medium |

| Kevlar | High-risk environments (cuts & shocks) | High cut resistance | Higher cost, less electrical insulation | High |

This comprehensive analysis of materials used in electric shock gloves will assist international B2B buyers in making informed decisions based on their specific operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for electric shock gloves

What Are the Key Stages in the Manufacturing Process of Electric Shock Gloves?

The manufacturing process for electric shock gloves involves several critical stages, each designed to ensure the final product meets stringent safety and performance standards. Understanding these stages can help B2B buyers assess the quality and reliability of potential suppliers.

1. Material Preparation: What Materials Are Used in Electric Shock Gloves?

The first stage of manufacturing involves selecting and preparing the appropriate materials. Electric shock gloves typically incorporate:

- Conductive Materials: These are crucial for delivering the electrical pulse. Commonly used materials include conductive fabrics or coatings, often made from silver or copper-infused textiles.

- Protective Fabrics: High-durability materials like Kevlar or carbon fiber are often integrated to provide protection against blunt force and abrasions.

- Insulation Materials: To prevent accidental shocks to the user, insulating materials such as rubber or specialized polymers are used.

Once materials are sourced, they undergo a quality check to ensure they meet industry standards before proceeding to the next phase.

2. Forming: How Are Electric Shock Gloves Shaped and Designed?

During the forming stage, the prepared materials are cut and shaped into the glove’s components. This process often involves:

- Cutting: Precision cutting machines are used to ensure each piece is uniform and fits the design specifications.

- Sewing and Bonding: The glove components are stitched or bonded together using high-strength threads and adhesives, ensuring durability and flexibility. Advanced manufacturing techniques such as ultrasonic welding may also be employed to enhance the bond between layers.

This stage is critical for ensuring that the glove not only fits comfortably but also provides the necessary protection and functionality.

3. Assembly: What Techniques Are Used to Assemble Electric Shock Gloves?

The assembly process integrates all components into a finished glove. Key techniques include:

- Integration of Electrical Components: Conductive threads and electrodes are strategically placed to ensure effective electrical discharge upon activation. The assembly must ensure that all electrical components are securely attached to prevent malfunctions.

- Incorporation of Safety Features: Additional features such as quick-release mechanisms and ergonomic designs are added during this stage. This enhances the glove’s usability and safety for the wearer.

Quality control checkpoints are critical during assembly to identify any defects before the gloves proceed to the finishing stage.

4. Finishing: How Is the Final Product Prepared for Market?

The final stage involves finishing touches that prepare the glove for market release. This includes:

- Quality Inspection: A thorough inspection is performed to check for defects in stitching, functionality of electrical components, and overall aesthetics.

- Testing: Each glove undergoes rigorous testing to ensure it meets specified safety standards, including electrical safety and performance tests.

- Packaging: The gloves are then packaged with necessary documentation, including user manuals and safety certifications.

What Quality Assurance Measures Are Implemented in the Production of Electric Shock Gloves?

Quality assurance is paramount in the production of electric shock gloves to ensure safety and compliance with international standards. Here are some essential elements of the QA process:

Relevant International Standards: Which Standards Are Critical for Electric Shock Gloves?

Compliance with international standards is crucial for B2B buyers looking to ensure product safety and reliability. Key standards include:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). Manufacturers must demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For gloves used in specific industries, adherence to American Petroleum Institute (API) standards may be necessary, particularly in environments where electrical hazards are prevalent.

Quality Control Checkpoints: What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integrated at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early, allowing for immediate corrections.

- Final Quality Control (FQC): A comprehensive inspection of the finished product ensures that all specifications and quality standards are met before shipping.

Common Testing Methods: How Are Electric Shock Gloves Tested for Safety and Performance?

Electric shock gloves undergo several testing methods to ensure their safety and effectiveness:

- Electrical Testing: This includes checking the voltage output and ensuring the glove operates within safe limits.

- Durability Testing: Gloves are subjected to stress tests to evaluate their resistance to wear and tear, ensuring they can withstand various operational conditions.

- Performance Testing: Assessing the gloves’ effectiveness in immobilizing targets as intended, typically simulating real-world scenarios.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is vital. Here are some actionable steps:

Conducting Supplier Audits: What Should Buyers Look for in Supplier Audits?

Buyers should consider conducting on-site audits of potential suppliers. Key aspects to evaluate include:

- Manufacturing Facilities: Assess the cleanliness, organization, and technological capabilities of the manufacturing site.

- Quality Management Systems: Review the supplier’s adherence to ISO 9001 or similar standards and their internal quality control measures.

Requesting Quality Reports and Certifications: What Documentation Should Buyers Demand?

Buyers should request comprehensive quality reports and certifications from suppliers, including:

- Testing Certifications: Documents proving that the gloves have undergone necessary safety and performance tests.

- Audit Reports: Records from third-party audits that verify the supplier’s compliance with industry standards.

Engaging Third-Party Inspection Services: How Can Third-Party Inspections Provide Assurance?

Employing third-party inspection services can provide an additional layer of assurance. These services can:

- Conduct Independent Testing: Verify that the gloves meet all necessary safety and performance standards.

- Offer Objective Reviews: Provide unbiased evaluations of the manufacturing processes and quality control measures in place.

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Critical for B2B Buyers?

For B2B buyers in the electric shock glove market, understanding the manufacturing processes and quality assurance measures is essential. This knowledge not only helps in selecting reliable suppliers but also ensures that the products meet safety standards and performance expectations. By being proactive in verifying these processes, buyers can mitigate risks and enhance their operational effectiveness in their respective industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric shock gloves’

Electric shock gloves are becoming essential tools for various industries, including law enforcement, security, and emergency services. This guide provides a structured checklist to help B2B buyers navigate the procurement process effectively, ensuring they select high-quality gloves that meet their specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial as it determines the effectiveness and suitability of the electric shock gloves for your intended application. Consider factors such as voltage output, duration of use, and safety features. It’s important to align these specifications with the operational needs of your organization and any applicable regulations in your region.

- Voltage and Current: Look for gloves that operate within safe voltage levels (typically below 380V) to ensure user safety.

- Battery Life and Charge Time: Ensure the gloves have sufficient battery life for your operations, with a reasonable charge time.

Step 2: Research Compliance and Safety Standards

Before proceeding with a purchase, verify that the electric shock gloves meet relevant safety and compliance standards. Compliance with international standards ensures that the gloves are tested for safety and effectiveness.

- ISO and IEC Standards: Check for certifications that indicate adherence to international safety standards.

- Local Regulations: Familiarize yourself with any regional regulations regarding the use of electric shock devices, particularly in sectors such as law enforcement.

Step 3: Evaluate Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in electric shock gloves. Evaluating suppliers helps ensure you choose a reputable company that can deliver quality products.

- Supplier Background: Request information about their experience, market presence, and client testimonials.

- Product Range: Assess whether they offer a variety of models that cater to different operational needs.

Step 4: Request Product Samples

Before making a bulk purchase, request samples of the gloves you are considering. Testing the product firsthand allows you to evaluate their comfort, fit, and functionality.

- Comfort and Fit: Ensure the gloves provide an ergonomic fit for the user, allowing for full mobility.

- Performance Testing: Test the gloves under simulated operational conditions to assess their performance and durability.

Step 5: Compare Pricing and Warranty Options

Price comparison is essential to ensure you are getting the best value for your investment. However, consider the overall value, including warranty and service agreements.

- Warranty Coverage: Look for suppliers that offer comprehensive warranties, indicating confidence in their product quality.

- Bulk Pricing Discounts: Inquire about discounts for bulk purchases, which can significantly reduce costs.

Step 6: Verify Supplier Certifications

Ensure that your chosen supplier has the necessary certifications and quality control processes in place. This step is vital for maintaining product reliability and safety.

- Quality Assurance: Check if the supplier follows strict quality control measures during manufacturing.

- Product Testing: Confirm that the gloves undergo rigorous testing to meet safety and performance standards.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier and product, ensure that all terms are clearly outlined in a purchase agreement. This contract should include payment terms, delivery schedules, and after-sales support.

- Clear Terms: Ensure the agreement specifies all technical specifications and compliance requirements.

- After-Sales Support: Confirm the availability of support services, including maintenance and repair options.

By following this checklist, B2B buyers can make informed decisions when sourcing electric shock gloves, ensuring they meet operational needs while adhering to safety standards.

Comprehensive Cost and Pricing Analysis for electric shock gloves Sourcing

What Are the Key Cost Components in Electric Shock Gloves Manufacturing?

When sourcing electric shock gloves, understanding the cost structure is vital for effective budgeting and negotiation. The primary cost components include:

-

Materials: The selection of materials significantly impacts the overall cost. Common materials include high-quality leather or synthetic fabrics for the glove shell, conductive materials for the electrodes, and durable components like carbon fiber for structural integrity. High-performance materials often come at a premium but can enhance safety and usability.

-

Labor: Labor costs vary depending on the manufacturing location. Regions with skilled labor and advanced manufacturing capabilities, such as Europe, may have higher labor costs compared to emerging markets in Africa or South America. Labor costs also include expenses related to skilled technicians for assembly and quality control.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, making it essential to choose suppliers with optimized operations.

-

Tooling: Initial tooling costs can be significant, particularly for custom designs. These costs should be amortized over the expected production volume to understand their impact on unit pricing.

-

Quality Control (QC): Rigorous QC processes are essential to ensure compliance with international safety standards. The costs associated with testing and certification can add to the overall price but are crucial for maintaining product integrity and marketability.

-

Logistics: Shipping and handling costs vary based on the supplier’s location and the delivery terms. Incoterms will influence who bears the costs and risks during transportation, impacting the final price.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market competition and perceived value of the product. Higher margins may be justified for gloves with advanced technology or certifications.

How Do Price Influencers Affect Electric Shock Gloves Costs?

Several factors influence the pricing of electric shock gloves, including:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can affect pricing; larger orders typically result in lower per-unit costs. Buyers should assess their needs and negotiate for better pricing based on volume.

-

Specifications and Customization: Tailored designs or specific features (like enhanced insulation or advanced battery technology) can increase costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Materials and Quality Certifications: The quality of materials used and certifications (such as CE or ISO) can influence pricing. Higher-quality materials may incur greater initial costs but can reduce long-term maintenance and replacement expenses.

-

Supplier Factors: Supplier reputation, production capabilities, and geographic location play a role in pricing. Established suppliers with a proven track record may charge more but often provide better reliability and support.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for accurate cost assessment.

What Negotiation Strategies Can Help Buyers Secure Better Pricing?

International B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Conduct Thorough Research: Understanding market prices and competitor offerings can empower buyers during negotiations. Utilize online platforms and industry reports for insights.

-

Engage Multiple Suppliers: Requesting quotes from various suppliers can create competitive pressure, potentially leading to better pricing.

-

Leverage Total Cost of Ownership (TCO): Highlighting the long-term value and cost savings associated with higher-quality products can justify a higher initial investment.

-

Be Clear on Specifications: Clearly defined product requirements can reduce misunderstandings and ensure quotes are based on the same specifications, leading to more accurate comparisons.

-

Negotiate Payment Terms: Flexible payment options can ease cash flow concerns, making it easier to commit to larger orders.

What Are the Pricing Nuances for International Buyers?

International buyers must navigate additional complexities in pricing, including currency fluctuations, import tariffs, and varying shipping costs. It is crucial to account for these factors in the overall budget.

Buyers should also be aware of local regulations regarding the importation of electric shock devices, which may affect cost and availability. Engaging with local distributors who understand these nuances can facilitate smoother transactions and compliance with legal requirements.

While indicative pricing can provide a ballpark figure, it is essential to obtain tailored quotes to reflect specific needs and conditions accurately.

Alternatives Analysis: Comparing electric shock gloves With Other Solutions

Understanding Alternatives to Electric Shock Gloves in Law Enforcement

In the realm of non-lethal defense technology, electric shock gloves have emerged as a notable solution for law enforcement and security personnel. However, various alternatives exist that can also fulfill similar roles in immobilizing or controlling aggressive individuals. This section compares electric shock gloves with two prominent alternatives: Tasers and Pepper Spray. By examining these options, B2B buyers can make informed decisions tailored to their specific operational needs.

Comparison Table

| Comparison Aspect | Electric Shock Gloves | Tasers | Pepper Spray |

|---|---|---|---|

| Performance | Instant immobilization for 2-3 sec | Effective range of up to 15 ft | Disables for 30-45 minutes |

| Cost | Moderate, varies by brand/model | Higher initial investment | Low-cost and widely available |

| Ease of Implementation | Requires basic training | Requires specific training | Minimal training needed |

| Maintenance | Regular checks for battery and wear | Battery replacement and testing | Minimal maintenance required |

| Best Use Case | Close combat situations | Crowd control, suspect apprehension | Personal defense, crowd control |

Detailed Breakdown of Alternatives

What are the Pros and Cons of Tasers?

Tasers are highly effective for law enforcement due to their ability to incapacitate a target from a distance, typically up to 15 feet. They deliver a high-voltage shock that can render a suspect immobile for several seconds, allowing officers to apprehend them safely. However, the initial cost of a Taser can be significantly higher compared to electric shock gloves, which may deter budget-conscious agencies. Additionally, Tasers require specialized training to ensure proper use, which can add to operational costs and time.

How Does Pepper Spray Compare?

Pepper spray is a low-cost alternative that is easy to use and requires minimal training, making it highly accessible for law enforcement and security personnel. It can incapacitate an aggressor for a considerable duration, often 30 to 45 minutes, providing enough time to diffuse a situation. However, its effectiveness can be compromised by environmental factors such as wind or rain, and it may not be suitable for all scenarios, particularly in close quarters where the risk of collateral damage is higher.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate non-lethal defense solution, B2B buyers must evaluate their specific operational requirements, budget constraints, and the environments in which they operate. Electric shock gloves offer close-combat advantages and immediate immobilization, making them suitable for tactical units. In contrast, Tasers provide range and incapacitation, while pepper spray offers a cost-effective, easy-to-deploy solution for various situations. By considering these factors, buyers can effectively match their choice of technology to the demands of their operational context.

Essential Technical Properties and Trade Terminology for electric shock gloves

What Are the Key Technical Properties of Electric Shock Gloves?

When evaluating electric shock gloves for procurement, understanding the critical specifications is vital for informed decision-making. Here are some essential technical properties that B2B buyers should consider:

1. Voltage and Current Ratings

Electric shock gloves typically operate at specific voltage and current levels, which are crucial for their effectiveness and safety. For instance, gloves may have voltage ratings ranging from 210V to 362V and current ratings between 0.7A to 1.5A. Understanding these ratings helps buyers assess the gloves’ immobilization capabilities while ensuring they comply with safety regulations. A glove with higher voltage may provide more immediate incapacitation but could also increase the risk of injury if misused.

2. Material Composition

The materials used in electric shock gloves, such as carbon fiber, leather, and synthetic fibers, determine their durability, comfort, and protective capabilities. For example, carbon fiber reinforcement can protect the wearer from blunt force while maintaining flexibility. Buyers should evaluate material properties to ensure they meet the demands of specific applications, whether in law enforcement, security, or personal defense.

3. Battery Life and Charge Time

Most electric shock gloves are powered by rechargeable lithium-ion batteries, with specifications detailing charge time and operational duration. Typical charge times range from 2 to 6 hours, with usage durations varying from 90 minutes to several hours. Buyers must consider battery life in relation to operational needs, especially in high-demand scenarios where prolonged use is necessary.

4. Pulse Duration and Frequency

Pulse duration, measured in microseconds (μs), and pulse frequency, expressed in pulses per second (pps), are critical for the gloves’ effectiveness. Shorter pulse durations (e.g., 105-116 μs) combined with higher frequencies (e.g., 300 pulses per minute) can lead to effective neuro-muscular disruption. Understanding these metrics allows buyers to assess the gloves’ incapacitating efficiency and their suitability for specific applications.

5. Weight and Ergonomics

The weight of the gloves can significantly impact usability. Typical weights range from 260g to 650g. Ergonomically designed gloves enhance user comfort and mobility, which is crucial for law enforcement and security personnel during extended use. Buyers should prioritize gloves that offer a balance of protection and usability to ensure effectiveness in the field.

What Trade Terminology Should B2B Buyers Know Regarding Electric Shock Gloves?

Familiarity with industry-specific jargon is essential for navigating the procurement process effectively. Here are some common terms you should be aware of:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the context of electric shock gloves, understanding OEM partnerships can help buyers identify reputable manufacturers and ensure they are sourcing high-quality products.

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest number of units that a supplier is willing to sell in a single order. Buyers should be aware of the MOQ when budgeting for procurement, as it can affect overall costs and inventory management.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to obtain price quotes and terms for specific products or services. Creating a detailed RFQ for electric shock gloves can help buyers gather competitive pricing and better understand product specifications.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in global trade. Familiarity with terms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) is crucial for B2B buyers to manage shipping logistics and costs effectively.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for inventory planning, especially for organizations that require electric shock gloves for immediate operational needs.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed purchasing decisions, ultimately enhancing their operational effectiveness and safety in the field.

Navigating Market Dynamics and Sourcing Trends in the electric shock gloves Sector

What Are the Key Trends Driving the Electric Shock Gloves Market?

The electric shock gloves market is witnessing significant growth, driven by the increasing demand for non-lethal defense tools across various sectors, including law enforcement, security, and personal protection. As urban crime rates rise, the need for effective yet humane options for subduing threats has become paramount. Additionally, advancements in technology are leading to the development of more sophisticated gloves that not only immobilize assailants but also ensure the safety of the users. Features such as smart activation, event recording, and ergonomic designs are becoming standard, enhancing both functionality and user experience.

Emerging markets in Africa, South America, and the Middle East are increasingly adopting these technologies. Buyers in these regions are particularly interested in products that cater to local security challenges while adhering to global standards. In Europe, countries like Germany are focusing on regulatory compliance and the integration of electric shock gloves into existing law enforcement protocols. Notably, international buyers are also prioritizing suppliers who can provide comprehensive training and support for their personnel.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing for Electric Shock Gloves?

Sustainability is becoming a crucial consideration for B2B buyers in the electric shock gloves sector. Companies are increasingly aware of the environmental impact of their sourcing decisions, particularly concerning the materials used in manufacturing these gloves. Buyers should seek suppliers who utilize eco-friendly materials, such as organic textiles or recycled components, and who have transparent supply chains that minimize environmental degradation.

Moreover, the importance of ethical sourcing cannot be overstated. Buyers should prioritize manufacturers who adhere to fair labor practices and provide certifications to validate their claims. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as benchmarks. By aligning with suppliers committed to sustainable practices, international buyers not only mitigate risk but also enhance their brand reputation, which is increasingly important in today’s conscientious market.

What Is the Historical Context of Electric Shock Gloves in the B2B Sector?

The evolution of electric shock gloves can be traced back to the broader development of non-lethal weapons aimed at law enforcement and security personnel. Initially, traditional stun guns and tasers dominated the market, but the need for more versatile and user-friendly options led to the innovation of gloves that integrate electrical incapacitation capabilities.

Over the years, manufacturers have refined their designs to incorporate advanced materials and technologies, such as carbon fiber for strength and lightweight mobility, as well as improved battery life and safety features. This evolution reflects a broader trend toward multifunctional tools in security applications, allowing professionals to respond effectively to various situations while minimizing the risk of permanent harm. Today, electric shock gloves are seen as essential gear in the toolkit of security forces worldwide, with continuous advancements promising even greater functionality and safety in the future.

Frequently Asked Questions (FAQs) for B2B Buyers of electric shock gloves

-

How do I choose the right electric shock gloves for my needs?

Selecting the right electric shock gloves depends on the specific requirements of your operation. Consider factors such as the intended use (e.g., law enforcement, personal protection, or security), the voltage level required, and the duration of use. Additionally, check for features like ergonomic design, weight, and battery life. Ensure that the gloves meet safety standards applicable in your region, and consult with suppliers about their compliance with international regulations. -

What are the key features to look for in electric shock gloves?

When sourcing electric shock gloves, prioritize features such as voltage and current specifications, activation mechanisms, and pulse duration. Look for gloves that offer a combination of protective materials and electrical functionality, such as carbon fiber reinforcements for impact resistance. Dual functionality—providing both shock capability and physical protection—is essential for versatile applications. Additionally, consider gloves with user-friendly designs, such as quick-release mechanisms and waterproof materials for enhanced durability. -

What are the typical lead times for electric shock gloves from suppliers?

Lead times can vary significantly based on the supplier’s location, manufacturing capabilities, and the complexity of your order. Generally, expect lead times of 4-12 weeks for standard orders. For customized products, such as those requiring specific branding or features, lead times may extend to 12-16 weeks. Always confirm these timelines with your supplier and consider potential delays in international shipping, particularly in regions with logistic challenges. -

What is the minimum order quantity (MOQ) for electric shock gloves?

Minimum order quantities (MOQ) for electric shock gloves typically range from 50 to 500 pairs, depending on the manufacturer and product specifications. Smaller manufacturers may offer lower MOQs, while established brands might require larger orders to optimize production costs. When negotiating with suppliers, discuss your needs and see if they offer flexibility in MOQs, especially for first-time orders or pilot programs. -

How can I ensure the quality of electric shock gloves from suppliers?

To ensure quality, request samples before placing a bulk order. Evaluate the gloves based on material durability, electrical functionality, and user comfort. Ask suppliers for certifications and compliance with international safety standards, such as ISO or CE markings. Consider conducting third-party inspections or quality assurance checks, particularly for larger orders, to mitigate risks associated with product defects or non-compliance. -

What payment terms are common for international orders of electric shock gloves?

Payment terms for international orders can vary widely but commonly include options such as advance payment, letter of credit, or net 30/60 days after shipment. It’s essential to clarify these terms upfront to avoid misunderstandings. Be aware of currency fluctuations and consider using secure payment methods like PayPal or escrow services for added protection. Always discuss the implications of payment terms on production timelines and shipping schedules. -

What are the logistics considerations for importing electric shock gloves?

When importing electric shock gloves, consider shipping methods, customs regulations, and import duties. Evaluate logistics providers that specialize in international shipping to ensure timely and compliant delivery. Familiarize yourself with your country’s import regulations regarding non-lethal defense equipment, as these can vary significantly. Collaborate with your supplier to prepare all necessary documentation to facilitate a smooth customs clearance process. -

Are electric shock gloves customizable for branding or functionality?

Yes, many manufacturers offer customization options for electric shock gloves, allowing you to incorporate branding elements like logos or specific color schemes. You can also request modifications in features, such as different voltage levels or ergonomic adjustments. Discuss your requirements with potential suppliers early in the conversation to ensure they can accommodate your needs. Keep in mind that customization may affect lead times and minimum order quantities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Electric Shock Gloves Manufacturers & Suppliers List

1. GlovePro – ShockGuard Class 0 Gloves

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The user is looking for gloves that prevent electrical shock while allowing adequate finger movement for handling electronic components. They mention considering Class 0 or 00 gloves for protection against voltages under 50mA. The user expresses concern about the thickness of gloves available on Amazon, which may hinder their ability to work with components.

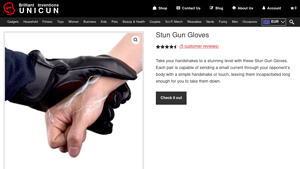

2. Unicun – Stun Gun Gloves

Domain: unicun.com

Registered: 2018 (7 years)

Introduction: Stun Gun Gloves are designed for self-defense, featuring built-in stun technology that delivers a powerful electric shock to deter attackers. The gloves are made from durable materials, ensuring protection and comfort. They are lightweight and easy to use, making them suitable for various situations. The product is rechargeable and includes safety features to prevent accidental discharge. Ideal fo…

3. This Is Why I’m Broke – Revolutionary Tactile Feedback Gloves

Domain: thisiswhyimbroke.com

Registered: 2011 (14 years)

Introduction: This company, This Is Why I’m Broke – Revolutionary Tactile Feedback Gloves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Nexstun – E-Stunglove

Domain: nexstun.com

Registered: 2018 (7 years)

Introduction: Nexstun’s E-Stunglove is the first electric impulse glove designed for law enforcement and personal protection. It features an electric impulse mechanism that deters assailants and neutralizes threats without causing irreversible damage. The glove is classified in the AC-3 zone, with a maximum discharge of 25 mA for 2 seconds, allowing for temporary immobilization of a person. It has 100 hours of …

Strategic Sourcing Conclusion and Outlook for electric shock gloves

In the dynamic landscape of personal safety and security equipment, electric shock gloves are emerging as a pivotal tool for law enforcement and security professionals. The strategic sourcing of these innovative devices allows organizations to enhance their operational effectiveness while ensuring the safety of personnel and civilians alike. With features such as immediate immobilization and non-lethal voltage levels, these gloves represent a significant advancement in non-lethal defense technology.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe assess their procurement strategies, it’s crucial to focus on reliable suppliers who can provide high-quality products tailored to specific operational needs. Understanding the unique demands of various markets can foster successful partnerships that prioritize safety and compliance.

Looking ahead, the demand for electric shock gloves is likely to grow as security challenges evolve globally. By investing in these advanced tools, organizations not only enhance their response capabilities but also set a standard for safety and effectiveness in the field. We encourage buyers to explore the latest innovations in electric shock gloves and consider how these solutions can integrate into their existing safety protocols.