Is Your Ego Battery Circuit Board Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for ego battery circuit board

In the rapidly evolving landscape of battery technology, sourcing the right ego battery circuit board can be a daunting challenge for international B2B buyers. As businesses strive for efficiency and reliability, understanding the intricacies of these vital components becomes essential. This guide delves into the multifaceted world of ego battery circuit boards, exploring various types, applications, and the critical factors to consider when selecting suppliers. From the innovative features of EGO Power+ systems to the safety mechanisms inherent in lithium battery protection circuit boards, we aim to provide a comprehensive overview that addresses the unique needs of buyers from Africa, South America, the Middle East, and Europe, including regions like Vietnam and Brazil.

Navigating the global market requires more than just product knowledge; it demands a strategic approach to supplier vetting and cost analysis. This guide empowers B2B buyers by equipping them with the insights necessary to make informed purchasing decisions. By examining industry standards, performance metrics, and compatibility across multiple applications, we aim to streamline your sourcing process, ensuring that you find the best solutions to meet your operational requirements. Whether you’re integrating ego battery circuit boards into power tools or consumer electronics, this resource is designed to help you succeed in an increasingly competitive market.

Understanding ego battery circuit board Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard PCB | Basic protection features, suitable for low-power devices | E-cigarettes, small power tools | Pros: Cost-effective, easy to integrate. Cons: Limited safety features. |

| Advanced Protection PCB | Enhanced safety features including overcharge and over-discharge | High-performance power tools, industrial applications | Pros: High reliability, robust safety. Cons: Higher cost, may require specialized installation. |

| Smart Battery Management PCB | Integrated battery management systems with real-time monitoring | Electric vehicles, renewable energy systems | Pros: Optimizes battery life, versatile. Cons: Complex design may increase failure points. |

| High-Current PCB | Designed for high-drain applications, robust thermal management | Heavy-duty tools, electric machinery | Pros: Handles high loads efficiently. Cons: Bulkier design, higher manufacturing costs. |

| Compact PCB | Miniaturized design for space-constrained applications | Wearable tech, portable devices | Pros: Space-efficient, lightweight. Cons: Limited capacity for additional features. |

What Are the Characteristics of Standard PCB for Ego Batteries?

Standard PCBs are the most basic type of ego battery circuit boards, primarily designed for low-power applications like e-cigarettes and small handheld devices. They offer essential protection features to prevent overcharging and over-discharging, making them suitable for consumers seeking budget-friendly solutions. B2B buyers should consider their specific application needs, as these boards may lack advanced safety features found in higher-end models, which could be a critical factor in safety-sensitive industries.

How Do Advanced Protection PCBs Enhance Safety?

Advanced Protection PCBs incorporate sophisticated safety mechanisms such as enhanced overcharge and over-discharge protection, making them ideal for high-performance power tools and industrial applications. These boards ensure reliable operation and longevity, reducing the risk of battery failure in demanding environments. For B2B buyers, investing in these boards may incur a higher upfront cost, but the long-term benefits in safety and reliability can justify the expense, particularly in industries where equipment downtime is costly.

Why Choose Smart Battery Management PCBs?

Smart Battery Management PCBs are equipped with integrated management systems that monitor battery performance in real-time. This technology is particularly beneficial for electric vehicles and renewable energy applications where efficiency is paramount. B2B buyers should prioritize these boards for applications requiring optimized battery life and performance. However, they may involve a more complex design that could lead to higher failure points, necessitating thorough testing and quality assurance.

What Are the Benefits of High-Current PCBs?

High-Current PCBs are specifically engineered for applications requiring substantial power output, such as heavy-duty tools and electric machinery. They feature robust thermal management systems to handle the increased heat generated during operation. For B2B buyers in industries that rely on high-drain devices, these boards provide the necessary performance and durability. However, their bulkier design and higher manufacturing costs should be weighed against their performance benefits.

When to Consider Compact PCBs?

Compact PCBs are designed for space-constrained applications, making them perfect for wearable technology and portable devices. Their lightweight and miniaturized design allow for integration into smaller products without sacrificing performance. B2B buyers in the consumer electronics sector should consider these boards for innovative product designs. However, the limited capacity for additional features may restrict their applicability in more complex systems, necessitating careful consideration of product requirements.

Key Industrial Applications of ego battery circuit board

| Industry/Sector | Specific Application of ego battery circuit board | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | E-cigarettes and vaping devices | Enhanced safety through built-in protection features | Ensure compliance with international safety standards |

| Power Tools | Cordless power tools like lawnmowers and saws | Improved performance and longevity of tools | Look for compatibility with existing battery systems |

| Renewable Energy | Energy storage systems for solar panels and wind turbines | Efficient energy management and safety during charging/discharging | Evaluate capacity, voltage requirements, and environmental factors |

| Medical Devices | Portable medical equipment requiring reliable power supply | Critical for patient safety and device functionality | Consider certifications for medical-grade components |

| Telecommunications | Backup power systems for communication devices | Ensures uninterrupted service and reliability | Prioritize suppliers with a strong track record in quality control |

How is the ego battery circuit board used in consumer electronics?

In the consumer electronics sector, ego battery circuit boards are pivotal in e-cigarettes and vaping devices. These boards control the current flow, ensuring optimal performance while integrating safety features that prevent overcharging and overheating. For B2B buyers, especially in regions like Africa and South America, sourcing high-quality circuit boards that meet regulatory standards is crucial. Buyers should prioritize manufacturers that offer robust testing and certification processes to guarantee product safety.

What role do ego battery circuit boards play in power tools?

Ego battery circuit boards are essential in cordless power tools, such as lawnmowers and drills. They manage battery performance, enabling tools to operate efficiently and prolonging their lifespan. For international buyers, particularly in Europe and the Middle East, it is vital to consider compatibility with existing tools and the availability of replacement parts. Sourcing from reputable suppliers ensures that businesses can maintain tool performance and reduce downtime.

How do ego battery circuit boards contribute to renewable energy systems?

In renewable energy applications, ego battery circuit boards are integral to energy storage systems associated with solar panels and wind turbines. They facilitate efficient energy management by monitoring voltage and current levels during charging and discharging cycles. For buyers in emerging markets, understanding the specific energy capacity and environmental conditions is essential for selecting the right circuit board. Suppliers should provide detailed specifications and performance data to support informed purchasing decisions.

Why are ego battery circuit boards critical for medical devices?

For portable medical devices, ego battery circuit boards ensure reliable power supply and safety. They monitor battery conditions to prevent failures that could jeopardize patient care. B2B buyers in the healthcare sector must ensure that the circuit boards they source comply with medical device regulations and standards. Suppliers should offer detailed documentation regarding the safety features and certifications of their products to reassure buyers of their reliability.

How do ego battery circuit boards enhance telecommunications?

In telecommunications, ego battery circuit boards are used in backup power systems to ensure uninterrupted service for communication devices. These boards provide essential power management features that protect against overcurrent and short circuits. Buyers in this sector, particularly in regions with unstable power supplies, should focus on sourcing high-quality circuit boards that guarantee reliability and performance. It’s also beneficial to partner with suppliers that offer robust warranty and support services to address any potential issues swiftly.

3 Common User Pain Points for ‘ego battery circuit board’ & Their Solutions

Scenario 1: Difficulty in Ensuring Battery Safety and Longevity

The Problem: B2B buyers sourcing ego battery circuit boards often grapple with the challenge of ensuring the safety and longevity of the batteries they use. Many manufacturers in regions like Africa and South America may not be fully aware of the potential hazards associated with improper battery management, such as overcharging, overheating, and risk of fire. This can lead to significant financial losses, product recalls, and damage to brand reputation.

The Solution: To mitigate these risks, it is crucial for buyers to prioritize sourcing ego battery circuit boards equipped with advanced protection features. Look for suppliers that provide detailed specifications on the circuit boards, emphasizing built-in safety mechanisms such as overcharge, over-discharge, and short circuit protections. Conduct thorough supplier assessments to ensure they adhere to international safety standards. Additionally, consider implementing a robust battery management system (BMS) that continuously monitors voltage, current, and temperature. This proactive approach will not only enhance battery safety but also extend its life cycle, ultimately leading to reduced operational costs.

Scenario 2: Compatibility Issues with Diverse Tools

The Problem: As businesses expand their product offerings, they may encounter compatibility issues with ego battery circuit boards across various tools and equipment. This situation can be particularly prevalent in industries that rely on multiple battery-powered devices, resulting in increased operational complexity and inventory management challenges. Buyers may find themselves investing in different batteries for different tools, leading to inefficiencies and higher costs.

The Solution: To address compatibility concerns, buyers should seek ego battery circuit boards that are part of a universal battery platform. This allows for the use of a single battery type across multiple tools, simplifying inventory management and reducing costs. When engaging with suppliers, ask for comprehensive compatibility charts that outline which circuit boards work with specific models. Additionally, investing in modular designs can provide the flexibility needed to adapt to various tools without the need for multiple battery types. This approach not only streamlines operations but also enhances the overall customer experience by ensuring reliable performance across the board.

Scenario 3: Challenges in Finding Reliable Suppliers

The Problem: In regions such as the Middle East and Europe, finding reliable suppliers for ego battery circuit boards can be a daunting task. Many businesses face difficulties in verifying the authenticity of parts, leading to concerns over product quality and after-sales support. This uncertainty can disrupt production schedules and lead to financial losses, particularly for companies that depend on consistent battery performance.

The Solution: To overcome supplier reliability issues, B2B buyers should establish strong relationships with certified manufacturers known for their quality assurance processes. Conduct due diligence by requesting product samples, checking certifications, and reviewing customer feedback. Building a network of trusted suppliers can provide insights into the best practices for sourcing ego battery circuit boards. Additionally, consider collaborating with local distributors who have a deep understanding of the market dynamics and can offer tailored solutions. Leveraging technology, such as online platforms that provide supplier ratings and reviews, can also enhance the procurement process, ensuring that businesses receive high-quality components that meet their operational needs.

Strategic Material Selection Guide for ego battery circuit board

What Are the Common Materials Used in Ego Battery Circuit Boards?

Selecting the right materials for ego battery circuit boards is crucial for ensuring optimal performance, safety, and longevity. Here, we analyze four common materials used in the manufacturing of these circuit boards, focusing on their key properties, advantages and disadvantages, and considerations for international B2B buyers.

1. FR-4 (Flame Retardant 4)

Key Properties: FR-4 is a composite material made from woven fiberglass cloth and epoxy resin. It has excellent electrical insulation properties, high mechanical strength, and can withstand temperatures up to 130°C.

Pros & Cons: The durability of FR-4 makes it suitable for various applications, including battery management systems. However, it can be relatively expensive compared to other materials, and its manufacturing process can be complex due to the need for precise lamination and curing.

Impact on Application: FR-4 is compatible with a wide range of electronic components and is effective in preventing overheating, a critical factor in battery applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards like UL 94 for flammability and IPC-A-600 for quality assurance. FR-4 is widely accepted in global markets, including Europe and the Middle East.

2. Polyimide (PI)

Key Properties: Polyimide is known for its high thermal stability, operating effectively in temperatures exceeding 200°C. It also exhibits excellent chemical resistance and flexibility.

Pros & Cons: The high temperature and chemical resistance make polyimide ideal for applications in harsh environments. However, it is more expensive than FR-4 and can be challenging to process, which may increase manufacturing costs.

Impact on Application: Polyimide is particularly suitable for applications where heat dissipation is critical, such as in high-performance battery systems. Its flexibility allows for intricate designs that can save space.

Considerations for International Buyers: Compliance with ASTM D-3039 for mechanical properties is essential. Buyers in regions like Africa and South America should also consider the availability of polyimide and its associated costs.

3. Aluminum

Key Properties: Aluminum is lightweight, has good thermal conductivity, and is resistant to corrosion. It can operate effectively in various temperatures and has a high strength-to-weight ratio.

Pros & Cons: The thermal management capabilities of aluminum make it an excellent choice for heat-sensitive applications. However, it may require additional coatings to enhance its corrosion resistance, which can add to the overall cost.

Impact on Application: Aluminum is particularly beneficial in applications where heat dissipation is crucial, such as in battery packs. Its lightweight nature also contributes to the overall efficiency of portable devices.

Considerations for International Buyers: Buyers should be aware of local regulations regarding aluminum use and recycling, particularly in Europe, where sustainability is a significant concern. Compliance with standards like ASTM B209 for aluminum sheet and plate is also essential.

4. Copper

Key Properties: Copper is renowned for its excellent electrical conductivity and thermal properties. It is also relatively easy to work with and can be plated or coated for additional protection.

Pros & Cons: The primary advantage of copper is its superior conductivity, making it ideal for power distribution in battery circuits. However, it is prone to corrosion, which necessitates protective coatings that can complicate manufacturing.

Impact on Application: Copper is often used in traces and pads on circuit boards, ensuring efficient power transfer and minimal energy loss. It is crucial in applications where performance and efficiency are paramount.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as IPC-2221 for printed board design. In regions like the Middle East and Africa, the availability of high-quality copper can vary, impacting sourcing decisions.

Summary Table of Material Selection for Ego Battery Circuit Boards

| Material | Typical Use Case for ego battery circuit board | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| FR-4 | General circuit boards in battery management | Excellent electrical insulation | Higher manufacturing complexity | Medium |

| Polyimide | High-performance battery systems | High thermal stability | Expensive and challenging to process | High |

| Aluminum | Heat-sensitive battery packs | Good thermal conductivity | Requires coatings for corrosion | Medium |

| Copper | Power distribution traces on circuit boards | Superior electrical conductivity | Prone to corrosion | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions when sourcing materials for ego battery circuit boards.

In-depth Look: Manufacturing Processes and Quality Assurance for ego battery circuit board

What Are the Main Stages in Manufacturing Ego Battery Circuit Boards?

The manufacturing of Ego battery circuit boards involves several critical stages that ensure both functionality and safety. The primary stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Ego Battery Circuit Boards?

Material preparation begins with the selection of high-quality raw materials, such as copper-clad laminates and various electronic components. The copper layer serves as the conductive pathway for the circuit. Manufacturers often utilize advanced software for circuit design, ensuring that the layout optimally supports electrical performance and safety features. Once the designs are finalized, materials undergo rigorous inspection to confirm their compliance with international standards, such as ISO 9001, which emphasizes quality management systems.

What Techniques Are Used in the Forming Stage?

In the forming stage, the prepared materials are processed into circuit boards. Techniques like etching, drilling, and lamination are employed. The etching process removes unwanted copper to create the desired circuit pattern, while drilling creates holes for component placement and interconnections. Manufacturers might use laser drilling for precision, especially in high-density applications. After etching and drilling, the boards are laminated, bonding the layers together under heat and pressure to enhance durability.

How Are Ego Battery Circuit Boards Assembled?

The assembly stage involves placing electronic components onto the circuit board. This is typically done using Surface Mount Technology (SMT) and Through-Hole Technology (THT). SMT allows for the mounting of components directly onto the surface of the board, which is beneficial for compact designs, while THT involves inserting components through drilled holes. Automated pick-and-place machines are commonly used to enhance efficiency and accuracy during assembly.

Following component placement, soldering is performed, often through reflow or wave soldering methods. The choice of soldering technique can impact the reliability of the connections, making it essential for manufacturers to select the appropriate method based on the specific requirements of the Ego battery circuit board.

What Finishing Processes Are Involved in Manufacturing?

Finishing processes enhance the performance and longevity of the circuit boards. This stage may include surface treatment, conformal coating, and testing. Surface treatments such as gold plating or immersion tin can improve solderability and corrosion resistance. Conformal coatings protect the circuitry from environmental factors, which is particularly important for devices used in outdoor power tools and e-cigarettes.

What Are the Quality Assurance Measures for Ego Battery Circuit Boards?

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that each Ego battery circuit board meets strict safety and performance standards. Various international standards and industry-specific regulations guide these QA processes.

Which International Standards Are Relevant for Ego Battery Circuit Boards?

One of the most relevant international standards is ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 ensures that manufacturers have established processes for quality control and continuous improvement. Additionally, certifications such as CE mark indicate that products meet European safety standards, while UL certification can assure buyers of product safety in North America.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints typically include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC involves inspecting raw materials before they enter the production process. This step ensures that only compliant materials are used.

- IPQC monitors the manufacturing process in real-time. Regular checks during assembly can catch defects early, minimizing waste and rework.

- FQC is the final inspection stage, where completed circuit boards undergo rigorous testing to ensure they meet design specifications and performance criteria.

What Common Testing Methods Are Used?

Testing methods for Ego battery circuit boards can vary but often include:

- Functional Testing: This assesses whether the circuit board operates as intended within the specified parameters.

- Thermal Cycling Tests: These simulate extreme temperature variations to ensure the board can withstand environmental stresses.

- Electrical Testing: This includes continuity tests and insulation resistance tests to verify the integrity of electrical connections.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

What Auditing Practices Should Be Considered?

Buyers can request audits of the supplier’s manufacturing facility to evaluate their adherence to quality management systems. Third-party audits by recognized organizations can provide an objective assessment of compliance with international standards.

How Important Are Quality Reports?

Suppliers should provide detailed quality reports that outline their testing methodologies, results, and any corrective actions taken for non-conformities. These reports serve as documentation of the supplier’s commitment to quality and transparency.

What Role Does Third-Party Inspection Play?

Engaging third-party inspection services can further enhance trust. These services can perform random inspections at various stages of the production process, ensuring that the products meet the required specifications before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers must be aware of the nuances in quality control that may vary by region. For example, some markets may have stricter safety regulations than others. Understanding local compliance requirements, as well as the certifications that are relevant in specific regions, is essential for successful procurement.

In conclusion, the manufacturing processes and quality assurance measures for Ego battery circuit boards are integral to ensuring safety, performance, and reliability. By understanding these processes and actively engaging in supplier verification, B2B buyers can make informed decisions that lead to successful partnerships and high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ego battery circuit board’

This guide aims to assist international B2B buyers in effectively sourcing EGO battery circuit boards, ensuring a streamlined procurement process that meets both technical and operational needs.

Step 1: Define Your Technical Specifications

Clearly outline the specific technical requirements for the EGO battery circuit board you need. Consider factors such as voltage ratings, current capacity, and compatibility with existing systems. This step is critical to ensure that the product you procure meets your operational needs and complies with local regulations.

Step 2: Research Potential Suppliers

Conduct thorough research on suppliers who specialize in EGO battery circuit boards. Look for manufacturers with a proven track record and positive customer feedback. Utilize online platforms and industry forums to gather insights on their reliability and product quality.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications such as ISO 9001 or other industry-specific standards. Certifications indicate adherence to quality management practices and can significantly reduce the risk of receiving subpar products. Additionally, inquire about their compliance with safety regulations, especially if you plan to use these boards in consumer-facing products.

Step 4: Request Sample Products

Before making a bulk order, request samples of the EGO battery circuit boards. Testing these samples in your applications allows you to assess their performance and compatibility with your devices. This step can save you time and resources by avoiding potential issues post-purchase.

Step 5: Assess Production Capabilities

Understand the supplier’s production capacity and lead times. Ensure they can meet your volume requirements without compromising quality. A reliable supplier should be able to provide clear timelines for production and delivery, which is essential for planning your inventory and operations effectively.

Step 6: Negotiate Terms and Pricing

Engage in discussions regarding pricing, payment terms, and bulk order discounts. Establishing clear agreements can lead to better long-term relationships with suppliers. Ensure that all terms are documented to avoid misunderstandings later.

Step 7: Implement Quality Control Measures

Once you select a supplier and place an order, implement quality control measures to monitor the incoming products. This includes inspecting the boards upon delivery and conducting functionality tests. Maintaining a rigorous quality assurance process is vital to ensure that the EGO battery circuit boards perform as expected in your applications.

By following these steps, B2B buyers can effectively navigate the sourcing process for EGO battery circuit boards, ensuring they select a reliable supplier and high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for ego battery circuit board Sourcing

What Are the Key Cost Components in Sourcing Ego Battery Circuit Boards?

When considering the sourcing of Ego battery circuit boards, understanding the cost structure is crucial for international B2B buyers. The total cost comprises several components:

-

Materials: The primary materials include high-quality printed circuit boards (PCBs), electronic components (such as capacitors, resistors, and ICs), and protective elements. The choice of materials significantly impacts both performance and pricing. For instance, using certified components may increase costs but enhances reliability and safety.

-

Labor: Labor costs vary by region and are influenced by the complexity of assembly and testing processes. Skilled labor is required for tasks such as soldering, quality control, and final assembly. Countries with a strong electronics manufacturing base may offer competitive labor rates, while regions with less experience may incur higher costs.

-

Manufacturing Overhead: This encompasses costs related to utilities, facility maintenance, and equipment depreciation. Manufacturing overhead can fluctuate based on the operational efficiency of the supplier and the scale of production.

-

Tooling: Initial setup costs for tooling can be significant, especially for custom circuit boards. This includes the expenses for molds, jigs, and other specialized tools required for production.

-

Quality Control (QC): Ensuring the circuit boards meet safety and performance standards is vital. Quality control processes may involve testing for electrical performance, durability, and compliance with international safety standards, adding to the overall cost.

-

Logistics: Shipping costs can vary widely depending on the destination, shipping method, and logistics provider. International buyers should consider potential tariffs and import duties that may further impact the final price.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. Understanding market rates for similar products can help buyers negotiate better pricing.

How Do Price Influencers Affect the Sourcing of Ego Battery Circuit Boards?

Several factors can influence the pricing of Ego battery circuit boards:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to significant price reductions due to economies of scale. Buyers should discuss potential discounts for bulk purchases or long-term contracts.

-

Specifications and Customization: Custom designs or specific technical requirements can increase costs. Buyers should clearly communicate their needs to avoid unexpected charges.

-

Materials and Quality Certifications: The choice of materials and the level of certification (e.g., ISO, RoHS compliance) can also affect pricing. Higher quality standards often come at a premium but are essential for safety and reliability, particularly in applications like e-cigarettes and power tools.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role. Established suppliers may charge more due to their proven track record, while newer suppliers may offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can influence logistics costs and risk allocation. Understanding these terms is essential for managing the total cost of ownership.

What Are Essential Buyer Tips for Negotiating Prices on Ego Battery Circuit Boards?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips:

-

Negotiate Effectively: Approach suppliers with a clear understanding of your requirements and budget. Be prepared to negotiate on price, especially for larger orders.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership rather than just the initial purchase price. Consider long-term factors such as warranty, reliability, and maintenance costs.

-

Understand Pricing Nuances for International Purchases: Be aware of currency fluctuations, import duties, and regional market dynamics that could affect pricing. Familiarizing yourself with local regulations and compliance standards can also prevent costly delays.

-

Request Multiple Quotes: Obtaining quotes from several suppliers can provide insights into market pricing and help you identify the best value.

In conclusion, understanding the comprehensive cost structure and pricing dynamics of Ego battery circuit boards is essential for making informed purchasing decisions. By considering the cost components, price influencers, and effective negotiation strategies, international B2B buyers can optimize their sourcing processes and enhance their competitive edge in the market.

Alternatives Analysis: Comparing ego battery circuit board With Other Solutions

Introduction: Understanding Alternative Solutions for Battery Circuit Boards

In the rapidly evolving landscape of battery technology, various solutions exist to meet the demands of performance, safety, and cost-effectiveness. The Ego Battery Circuit Board, designed specifically for Ego-branded batteries, provides a robust option for managing power in devices like e-cigarettes and power tools. However, exploring alternative technologies can help businesses identify the most suitable solution for their specific applications. This analysis compares the Ego Battery Circuit Board with two viable alternatives: Lithium Battery Management Systems (BMS) and Generic Battery Circuit Boards.

Comparison Table

| Comparison Aspect | Ego Battery Circuit Board | Lithium Battery Management System (BMS) | Generic Battery Circuit Board |

|---|---|---|---|

| Performance | High, with intelligent power management | Excellent, supports multiple cell types | Moderate, basic power regulation |

| Cost | Moderate, premium brand pricing | Variable, often higher due to complexity | Low, widely available |

| Ease of Implementation | Moderate, requires specific knowledge | Complex, may need professional installation | Easy, suitable for general applications |

| Maintenance | Low, designed for durability | Low to moderate, depends on configuration | Low, typically requires minimal upkeep |

| Best Use Case | Cordless power tools, e-cigarettes | Electric vehicles, advanced power tools | General electronics, low-cost devices |

Detailed Breakdown of Alternatives

What are Lithium Battery Management Systems (BMS) and Their Advantages?

Lithium Battery Management Systems (BMS) are sophisticated solutions designed to monitor and manage lithium-ion batteries. They provide real-time data on battery health, voltage, and temperature while ensuring safe charging and discharging processes. The primary advantages of a BMS include its ability to support various cell configurations, making it ideal for electric vehicles and high-performance applications. However, the complexity of installation and typically higher costs may deter some buyers, especially those focused on simpler applications.

How Do Generic Battery Circuit Boards Compare?

Generic Battery Circuit Boards serve as a basic solution for power regulation and battery management. They are more affordable and widely available, making them an attractive option for businesses with budget constraints. These boards typically offer basic overcharge and over-discharge protection but lack the advanced features found in specialized solutions like the Ego Battery Circuit Board or BMS. Their ease of implementation makes them suitable for general electronics, but they may not provide the same level of performance or safety for high-demand applications.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a battery circuit board solution, B2B buyers must consider their specific use cases, performance requirements, and budget constraints. The Ego Battery Circuit Board excels in applications where high performance and safety are critical, particularly in cordless tools and e-cigarettes. Conversely, a Lithium BMS offers advanced features for high-performance needs, while Generic Circuit Boards provide a cost-effective solution for standard applications. Ultimately, understanding the unique demands of your business will guide you in choosing the most appropriate battery management technology to enhance operational efficiency and safety.

Essential Technical Properties and Trade Terminology for ego battery circuit board

What Are the Essential Technical Properties of Ego Battery Circuit Boards?

When sourcing ego battery circuit boards, understanding their technical specifications is crucial for ensuring optimal performance and safety in applications such as portable power tools and electronic devices. Here are some critical specifications to consider:

1. Material Grade

The material used in the construction of the circuit board significantly affects its durability and performance. Common materials include FR-4 (a fiberglass epoxy laminate) and polyimide, which offer excellent thermal stability and electrical insulation. For B2B buyers, choosing the right material ensures that the circuit board can withstand the operational stresses of the intended application, thereby extending its lifespan and reliability.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension or property. For ego battery circuit boards, tighter tolerances (e.g., ±0.1 mm) can lead to better performance and compatibility with other components. In B2B transactions, specifying tolerance levels helps in maintaining quality control and ensuring that the circuit board fits precisely within the device, minimizing the risk of malfunctions.

3. Voltage Rating

The voltage rating indicates the maximum voltage the circuit board can handle without failure. Ego battery circuit boards typically operate at voltages around 56V, compatible with EGO Power+ tools. Understanding voltage ratings is essential for B2B buyers to ensure that the circuit boards will operate safely within the electrical parameters of their devices, preventing potential hazards like overheating or short circuits.

4. Current Capacity

This specification refers to the maximum current the circuit board can carry without overheating. For instance, ego battery circuit boards should be designed to handle the specific current requirements of the devices they serve. B2B buyers must evaluate current capacity to avoid performance issues or damage to the circuit board during operation, ensuring that the end product meets customer expectations.

5. Protection Features

Ego battery circuit boards often come equipped with built-in protection features such as overcharge, over-discharge, and short-circuit protection. These features are vital for maintaining battery health and safety. Buyers should prioritize circuit boards with these protections, as they reduce the risk of battery failure and enhance user safety, which can be a significant selling point in competitive markets.

What Are Key Trade Terms Related to Ego Battery Circuit Boards?

Understanding industry terminology is crucial for effective communication and negotiation in B2B transactions. Here are several common terms that buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of ego battery circuit boards, buyers may work with OEMs to ensure they receive components that meet specific quality and performance standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory effectively and avoid overstocking or stockouts, especially when dealing with circuit boards that may require significant investment.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For ego battery circuit boards, submitting an RFQ can help buyers compare costs and features from different suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in a transaction. Familiarity with Incoterms is crucial for B2B buyers to understand shipping responsibilities, costs, and risk transfer when importing circuit boards from global suppliers.

5. PCBA (Printed Circuit Board Assembly)

PCBA refers to a completed circuit board that has been populated with electronic components. This term is vital for B2B buyers who may require fully assembled boards rather than just bare PCBs, impacting lead times and production efficiency.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing ego battery circuit boards, ensuring quality, safety, and compatibility with their applications.

Navigating Market Dynamics and Sourcing Trends in the ego battery circuit board Sector

What Are the Key Trends Shaping the Ego Battery Circuit Board Market?

The ego battery circuit board market is experiencing significant growth, driven by the increasing demand for portable and efficient power solutions across various sectors, including e-cigarettes and power tools. Global trends indicate a rising preference for cordless technology, with manufacturers focusing on creating versatile battery systems that can power multiple devices. The patented 56V ARC Lithium battery technology, known for its intelligent power management, is gaining traction among buyers looking for reliable performance and durability.

Emerging technologies such as smart battery management systems (BMS) are revolutionizing the market, providing real-time monitoring and control features that enhance user safety and device longevity. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe (e.g., Vietnam, Brazil), navigate this landscape, understanding the integration of advanced electronics into battery circuit boards becomes critical. The shift towards modular designs is also notable, allowing users to easily replace or upgrade components, further increasing the appeal of ego battery circuit boards.

How Is Sustainability and Ethical Sourcing Influencing the Ego Battery Circuit Board Sector?

Sustainability has become a pivotal consideration for B2B buyers in the ego battery circuit board sector. The environmental impact of electronic waste and the carbon footprint associated with battery production necessitate a shift towards more sustainable practices. International buyers are increasingly prioritizing suppliers that demonstrate a commitment to ethical sourcing and environmental stewardship.

Certifications such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) are becoming essential for suppliers aiming to establish credibility in the market. Additionally, the use of eco-friendly materials and processes not only reduces environmental impact but also appeals to a growing consumer base that values sustainability. B2B buyers should seek out manufacturers that provide transparent supply chain practices, ensuring that the materials used in ego battery circuit boards are responsibly sourced and compliant with international environmental standards.

What Is the Historical Context Behind the Evolution of Ego Battery Circuit Boards?

The evolution of ego battery circuit boards can be traced back to the growing demand for efficient power solutions in portable devices. Initially designed for simple applications, these circuit boards have undergone significant advancements, integrating complex electronic components that enhance safety and performance. Early models lacked the sophisticated monitoring systems seen in today’s designs, which now feature advanced protection mechanisms against overcharging, over-discharging, and short circuits.

As the market expanded, especially with the rise of e-cigarettes and cordless power tools, manufacturers began investing in research and development to improve battery technology. The introduction of lithium-based batteries marked a turning point, providing higher energy densities and longer lifespans. This historical context underscores the importance of innovation in the ego battery circuit board sector, highlighting the need for B2B buyers to stay informed about technological advancements that can influence their sourcing decisions.

Understanding these dynamics will enable international buyers to make informed choices that align with market trends, sustainability goals, and evolving consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of ego battery circuit board

-

How do I solve performance issues with Ego battery circuit boards?

To address performance issues, first ensure that the circuit board is compatible with your Ego battery model. Check for visible signs of damage or wear, such as burnt components or broken connections. Regular maintenance, including cleaning contacts and ensuring secure connections, can prevent many issues. If problems persist, consider replacing the circuit board with a genuine part from a reputable supplier, as counterfeit components may lead to further complications. -

What is the best supplier for Ego battery circuit boards?

The best suppliers for Ego battery circuit boards are those that offer genuine products, comprehensive warranties, and robust customer support. Look for suppliers with a strong reputation in the industry and positive reviews from other B2B buyers. Ensure they have experience in international shipping and can navigate customs regulations efficiently. A supplier with a wide range of compatible parts for various Ego models will also be beneficial for future sourcing needs. -

What are the minimum order quantities (MOQs) for Ego battery circuit boards?

Minimum order quantities can vary significantly among suppliers. Typically, MOQs for Ego battery circuit boards range from 10 to 100 units, depending on the supplier’s production capabilities and your specific requirements. It’s essential to discuss your needs directly with potential suppliers, as some may offer flexibility for smaller orders or bulk discounts for larger purchases. -

What are the payment terms for purchasing Ego battery circuit boards internationally?

Payment terms often depend on the supplier and the country of transaction. Common terms include upfront payment, net 30, or net 60 days. International buyers should inquire about secure payment methods, such as letters of credit or escrow services, to mitigate risks. Additionally, confirm whether the supplier accepts multiple currencies to simplify the transaction process. -

How do I ensure quality assurance (QA) when sourcing Ego battery circuit boards?

To ensure quality assurance, request detailed product specifications and certifications from your supplier, including ISO standards. A thorough quality control process should include testing for voltage, current regulation, and thermal management features. Consider visiting the supplier’s facility if possible or requesting third-party inspections before shipment. Maintaining open communication about your quality expectations can also help ensure compliance. -

What logistics considerations should I keep in mind when importing Ego battery circuit boards?

Logistics considerations include shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder experienced in handling electronic components to ensure safe and timely delivery. Familiarize yourself with the import regulations in your country, as certain electronic components may require specific certifications. Plan for potential delays in customs clearance and factor these into your inventory management. -

Can I customize Ego battery circuit boards for specific applications?

Yes, many suppliers offer customization options for Ego battery circuit boards to meet specific application requirements. Customization can include altering circuit specifications, integrating additional features, or modifying form factors. When requesting custom boards, provide detailed specifications and examples of your intended use to help suppliers understand your needs. Be aware that customized boards may have longer lead times and higher costs. -

What are the common applications for Ego battery circuit boards?

Ego battery circuit boards are commonly used in portable power tools, outdoor equipment, and e-cigarettes. Their primary function is to manage battery performance and ensure safety through features like overcharge and over-discharge protection. Understanding the intended application can guide your selection process when sourcing these components, as different devices may require specific design considerations and regulatory compliance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Ego Battery Circuit Board Manufacturers & Suppliers List

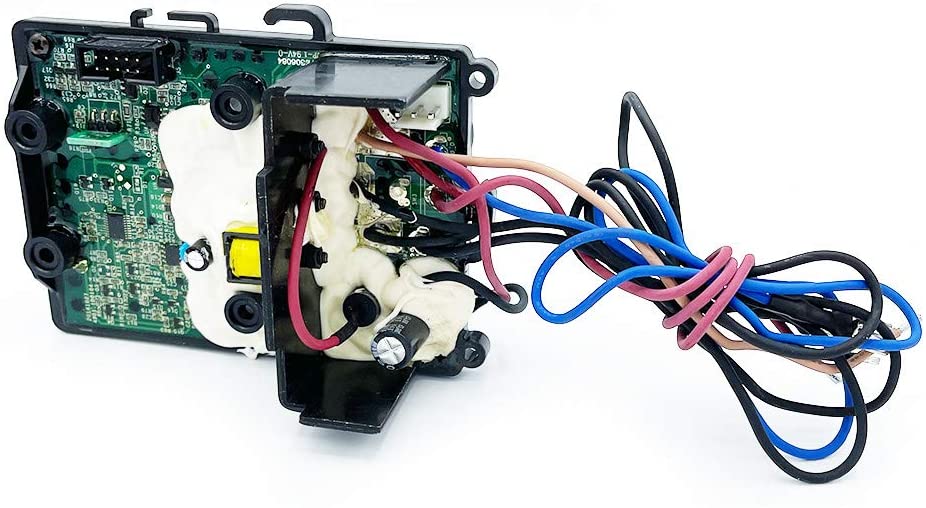

1. EGO – 5AH 56V Battery Issues

Domain: diysolarforum.com

Registered: 2019 (6 years)

Introduction: EGO 5AH 56V battery; issues with Battery Management System (BMS); battery can be charged directly by bypassing BMS; no visible signs of damage; BMS may not function correctly after 3 years; potential internal failure or software issues; used in off-grid solar systems; no known repair service for BMS.

2. Facebook – Key Product

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Key Product, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Planet Eclipse – Ego LV2 MME 9V Battery Circuit Board Assembly

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Planet Eclipse Ego LV2 MME 9V Battery Circuit Board Assembly”, “MPN”: “SPA990104B000”, “Condition”: “New”, “Brand”: “Planet Eclipse”, “Type”: “MME 9V Battery Circuit Board Assembly”, “Suitable For”: “Paintball”, “Quantity Available”: 10, “Price”: “US $14.20”, “Shipping”: “Free Standard Shipping”, “Returns”: “30 days returns, buyer pays for return shipping”, “Seller”: {“Name”: “Ac…

4. EGO Power+ – Outdoor Power Tool Batteries

Domain: endless-sphere.com

Introduction: EGO Power+ Outdoor Power Tool Batteries are 18650 cell based lithium battery packs with 14 series cells, primarily used for outdoor power tools. They come in various sizes with capacities ranging from 2.0 to 7.5 amp hours, using either 2.0 or 2.5 amp hour high current cells. The packs feature a built-in battery management system (BMS) for moisture resistance and cooling, with each cell wrapped in …

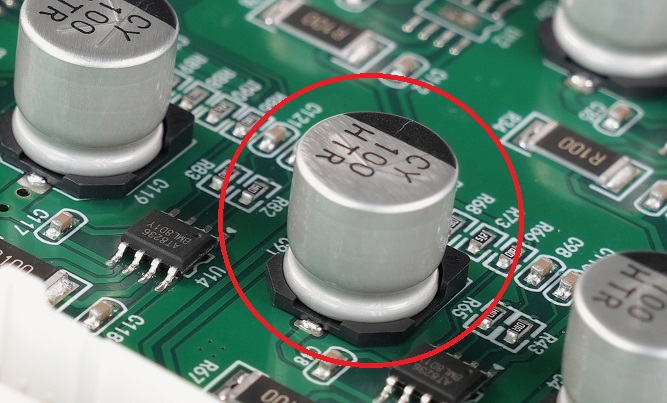

5. Badcaps – BMS Transformer Coil for EGO 56V Batteries

Domain: badcaps.net

Introduction: BMS (Battery Management System) component for EGO 56V power tool batteries; common failure point is a transformer coil on the board; the coil is involved in dropping 56V to lower voltages (12V, 3.3V) for BMS operation; two connectors attach to 14 cell packs (individual cell monitoring) and thermistors; bottom connector connects to battery contacts (negative, positive, T terminal, D terminal); repl…

Strategic Sourcing Conclusion and Outlook for ego battery circuit board

In the rapidly evolving landscape of energy solutions, strategic sourcing of EGO battery circuit boards is pivotal for businesses aiming to enhance their product offerings and operational efficiency. The EGO circuit boards, renowned for their advanced safety features and intelligent power management, present significant advantages for manufacturers and suppliers, particularly in markets across Africa, South America, the Middle East, and Europe.

By partnering with reliable suppliers, companies can ensure the procurement of genuine EGO components that meet stringent quality standards, thereby reducing downtime and maintenance costs. Emphasizing the importance of universal battery compatibility, businesses can leverage this feature to offer versatile solutions across multiple tools, fostering customer loyalty and satisfaction.

Looking ahead, international B2B buyers are encouraged to engage proactively in sourcing discussions, exploring innovative partnerships that will not only streamline their supply chains but also enhance their competitive edge. As the demand for efficient, sustainable power solutions continues to rise, aligning with trusted manufacturers will position businesses favorably in this dynamic market. Take the next step in your strategic sourcing journey and explore the possibilities that EGO battery circuit boards can bring to your operations today.