Is Your Camouflage Sheet Metal Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for camouflage sheet metal

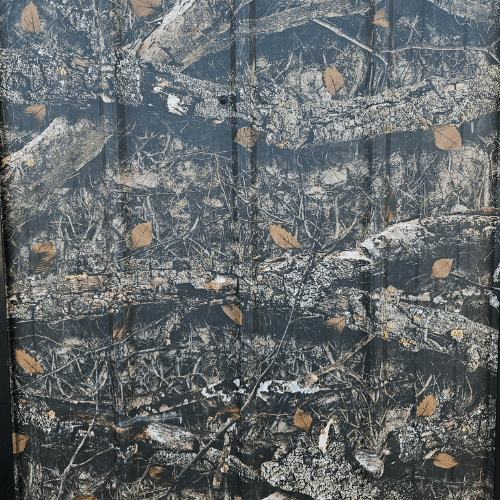

In the competitive landscape of international trade, sourcing camouflage sheet metal presents unique challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, including Germany and Saudi Arabia. The need for durable, aesthetically appealing materials that can withstand diverse environmental conditions while meeting specific application requirements is paramount. This guide aims to equip buyers with the knowledge necessary to navigate this intricate market, exploring various types of camouflage sheet metal, their applications, and the latest innovations in the field.

Throughout this comprehensive resource, we delve into the different grades and finishes of camouflage sheet metal, from digitally printed options to traditional patterns, ensuring that you understand the best fit for your projects. We also provide insights into effective supplier vetting processes, cost considerations, and the logistical aspects of importing these materials across borders. By synthesizing market trends and supplier capabilities, this guide empowers international B2B buyers to make informed purchasing decisions, optimizing both product selection and budget allocation. Whether you’re involved in construction, design, or specialized applications, you’ll find actionable insights tailored to your business needs, enabling you to confidently source camouflage sheet metal that aligns with your operational goals.

Understanding camouflage sheet metal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Realtree Camo Coils | Digitally printed with high-resolution Realtree patterns | Roofing, siding, hunting blinds, and outdoor structures | Pros: Customizable lengths, durable; Cons: Higher initial cost due to printing technology. |

| Hardy Rib Camo Panels | 29-gauge Galvalume steel, available in various lengths | Agricultural buildings, storage facilities, outdoor decor | Pros: Cost-effective, lightweight; Cons: Limited design options compared to digital prints. |

| Pro-Rib Steel Panels | Ribbed design for strength and durability | Barns, sheds, and industrial applications | Pros: Strong structural integrity; Cons: May require additional framing for certain applications. |

| Specialty Camo Finishes | Custom finishes with various camouflage patterns | Military applications, hunting equipment, and outdoor gear | Pros: Unique aesthetics; Cons: Potentially longer lead times for custom orders. |

| AZ-50 Galvalume Coated Steel | Enhanced corrosion resistance with a camouflage finish | Construction, roofing, and outdoor structures | Pros: Excellent longevity; Cons: Higher price point compared to standard finishes. |

What Are the Key Features of Realtree Camo Coils for B2B Buyers?

Realtree Camo Coils are notable for their high-resolution digitally printed camouflage patterns, which provide aesthetic appeal and functional benefits. These coils are versatile and suitable for various applications, including roofing, siding, and hunting blinds. B2B buyers should consider the customization options available, as well as the durability offered by the advanced printing technology. While the initial cost may be higher, the long-term benefits of durability and aesthetic versatility can justify the investment.

Why Choose Hardy Rib Camo Panels for Agricultural Applications?

Hardy Rib Camo Panels are made from 29-gauge Galvalume steel, making them a robust and cost-effective choice for agricultural buildings and outdoor structures. Their lightweight nature facilitates easy installation, while the camouflage design helps blend structures into natural surroundings. Buyers should keep in mind the limited design options compared to digitally printed variants; however, the affordability and functionality of Hardy Rib Panels make them a popular choice for budget-conscious projects.

How Do Pro-Rib Steel Panels Stand Out in Industrial Applications?

Pro-Rib Steel Panels feature a ribbed design that enhances their structural integrity, making them ideal for barns and industrial applications. Their strength and durability ensure they withstand harsh weather conditions, providing long-lasting solutions for construction needs. Buyers should consider the added framing that may be required for certain applications, but the overall performance and reliability of Pro-Rib Panels often outweigh this consideration.

What Advantages Do Specialty Camo Finishes Offer for Military and Outdoor Gear?

Specialty Camo Finishes are tailored for specific applications, particularly in military and outdoor gear. These custom finishes can feature a variety of camouflage patterns, allowing for unique aesthetics that meet tactical requirements. While the appeal lies in their distinctive designs, B2B buyers should be aware of potential longer lead times for custom orders. However, the unique look and functionality can be advantageous for brands seeking to differentiate their products in competitive markets.

Why Consider AZ-50 Galvalume Coated Steel for Long-Term Projects?

AZ-50 Galvalume Coated Steel combines enhanced corrosion resistance with camouflage finishes, making it a superior option for construction and outdoor structures. This type of steel is designed to last, reducing maintenance costs over time. While the price point may be higher than standard finishes, the investment is justified by the longevity and durability it offers. B2B buyers focused on long-term projects will find that this material meets both functional and aesthetic needs effectively.

Key Industrial Applications of camouflage sheet metal

| Industry/Sector | Specific Application of camouflage sheet metal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Camouflage roofing panels for residential and commercial buildings | Enhances aesthetic appeal while providing functional roofing | Durability standards, weather resistance, and local regulations |

| Agriculture | Animal feeders and storage units | Blends with natural surroundings, reducing stress in animals | Material quality, ease of cleaning, and customization options |

| Military & Defense | Tactical shelters and equipment covers | Provides concealment and protection for sensitive operations | Compliance with military specifications and rapid availability |

| Outdoor Recreation | Hunting blinds and outdoor structures | Offers camouflage for hunters, improving success rates | Weight, portability, and ease of assembly for field applications |

| Retail Displays | Custom signage and promotional materials | Unique branding opportunities that attract customer attention | Print quality, durability, and adaptability to various environments |

How is Camouflage Sheet Metal Used in Construction Projects?

In the construction industry, camouflage sheet metal is increasingly utilized for roofing panels on both residential and commercial buildings. These panels not only provide a distinctive aesthetic appeal but also serve practical purposes, such as durability and weather resistance. International buyers, particularly from regions with diverse climates like Europe and the Middle East, should consider local building codes and material specifications to ensure compliance and longevity. The ability to source cut-to-length panels also allows for customized solutions that fit specific architectural designs.

What Role Does Camouflage Sheet Metal Play in Agriculture?

In agriculture, camouflage sheet metal is commonly employed in the manufacturing of animal feeders and storage units. By blending seamlessly with the natural landscape, these products help reduce stress levels in livestock, promoting better health and productivity. Buyers in Africa and South America should focus on sourcing materials that are easy to clean and maintain, as hygiene is crucial in agricultural settings. Additionally, the ability to customize sizes and designs can meet specific operational needs.

How is Camouflage Sheet Metal Essential for Military and Defense Applications?

The military and defense sectors utilize camouflage sheet metal for tactical shelters and equipment covers, providing essential concealment during operations. This application is vital for protecting sensitive equipment and personnel from detection. Buyers from the Middle East and Europe must ensure that their suppliers comply with stringent military specifications and can deliver products within required timelines, especially for urgent deployments.

Why is Camouflage Sheet Metal Important for Outdoor Recreation?

In outdoor recreation, camouflage sheet metal finds applications in hunting blinds and various outdoor structures. These products enhance the hunter’s ability to remain undetected by wildlife, significantly improving success rates. When sourcing these materials, buyers should prioritize factors such as weight and portability, ensuring that products can be easily transported and assembled in the field. Additionally, durability against the elements is crucial for long-term use.

How Can Retailers Benefit from Camouflage Sheet Metal in Their Displays?

Retail environments benefit from camouflage sheet metal through custom signage and promotional materials that stand out in a competitive marketplace. These unique branding opportunities can attract customer attention and enhance the overall shopping experience. For international B2B buyers, considerations around print quality and adaptability to different retail environments are essential. Ensuring the materials can withstand varying weather conditions is also critical for outdoor retail settings.

3 Common User Pain Points for ‘camouflage sheet metal’ & Their Solutions

Scenario 1: Navigating Supply Chain Delays for Camouflage Sheet Metal

The Problem: B2B buyers often encounter significant delays in receiving camouflage sheet metal due to unpredictable supply chain issues. This is particularly prevalent in regions like Africa and South America, where logistical challenges, such as transportation strikes or customs delays, can hinder timely delivery. Such delays can disrupt project timelines, leading to increased costs and client dissatisfaction, particularly for businesses relying on timely installations for roofing or outdoor structures.

The Solution: To mitigate these supply chain delays, buyers should establish relationships with multiple suppliers across different regions. Diversifying suppliers not only provides alternatives in case one source fails to deliver but also allows buyers to negotiate better terms and prices. Implementing a just-in-time inventory system can also be beneficial, ensuring that only necessary materials are ordered and reducing storage costs. Additionally, investing in logistics management software can provide real-time tracking of shipments, allowing buyers to anticipate delays and adjust their project timelines accordingly.

Scenario 2: Ensuring Product Quality and Compliance

The Problem: Another common pain point for B2B buyers of camouflage sheet metal is the inconsistency in product quality and compliance with local building codes. In regions with strict regulations, such as parts of Europe, the failure to meet these standards can result in costly fines or the need for rework. Buyers may struggle to determine whether a supplier’s camouflage sheet metal is durable and suitable for the intended application, such as roofing or decorative elements.

The Solution: To ensure product quality and compliance, buyers should conduct thorough due diligence when selecting suppliers. This includes requesting certification documents that verify adherence to international standards (like ISO) and local building codes. It is also advisable to ask for samples before making a bulk purchase to evaluate the material’s durability and finish. Establishing a clear communication channel with suppliers can facilitate discussions about specifications and standards, ensuring that the products delivered meet the required criteria. Regular audits and inspections of suppliers can further help in maintaining quality control.

Scenario 3: Overcoming Customization Challenges

The Problem: B2B buyers often face challenges when it comes to customizing camouflage sheet metal to meet specific project requirements. Many suppliers offer limited design options or standard sizes, which can be a significant drawback for projects that demand unique specifications or patterns. This limitation can hinder creativity in design or lead to increased costs when attempting to modify existing products.

The Solution: To address customization challenges, buyers should seek suppliers that offer advanced printing technologies, such as digitally printed camouflage patterns. This allows for a wider range of designs and the ability to create custom patterns that align with the buyer’s vision. When discussing projects with suppliers, be clear about your customization needs and explore options for bespoke manufacturing. Additionally, consider collaborating with design teams that specialize in camouflage applications to ensure that your vision is effectively translated into the finished product. Building a strong partnership with a supplier that understands your specific needs will lead to better outcomes and a more satisfying procurement experience.

Strategic Material Selection Guide for camouflage sheet metal

What Are the Key Materials for Camouflage Sheet Metal?

When selecting camouflage sheet metal for various applications, understanding the properties and suitability of different materials is crucial. Here, we analyze four common materials used in camouflage sheet metal, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Galvalume Steel

Key Properties:

Galvalume steel is coated with a mixture of aluminum and zinc, providing excellent corrosion resistance and thermal performance. It typically withstands temperatures up to 600°F and has a pressure rating suitable for most roofing and siding applications.

Pros & Cons:

The primary advantage of galvalume steel is its durability and resistance to rust, making it ideal for outdoor applications. However, its cost can be higher than traditional galvanized steel, and the manufacturing process may be more complex due to the coating.

Impact on Application:

Galvalume is compatible with various media, including paints and adhesives, allowing for versatile camouflage patterns. However, it may require special surface preparation for optimal adhesion.

International Considerations:

Buyers should ensure compliance with ASTM standards for corrosion resistance, particularly in regions with high humidity, such as parts of Africa and South America. The material is widely accepted in Europe, including Germany, where DIN standards apply.

2. Aluminum

Key Properties:

Aluminum is lightweight and has excellent corrosion resistance, with a melting point of approximately 1,220°F. It is also non-magnetic, making it suitable for applications where magnetic interference is a concern.

Pros & Cons:

Aluminum’s lightweight nature makes it easier to handle and install, which can reduce labor costs. However, it is generally more expensive than steel and may not provide the same strength under heavy loads.

Impact on Application:

Due to its lightweight properties, aluminum is ideal for mobile applications, such as temporary structures or vehicles requiring camouflage. Its compatibility with digital printing allows for high-resolution camouflage designs.

International Considerations:

B2B buyers should consider compliance with JIS standards in Japan and similar regulations in Europe. In the Middle East, aluminum is often preferred for its aesthetic qualities and lightweight nature.

3. Stainless Steel

Key Properties:

Stainless steel is known for its exceptional strength and corrosion resistance, with a temperature rating exceeding 1,500°F. It is also highly durable and resistant to wear and tear.

Pros & Cons:

The key advantage of stainless steel is its long lifespan and ability to withstand harsh environments. However, it is significantly more expensive than other materials, and its weight can pose challenges during installation.

Impact on Application:

Stainless steel is suitable for permanent structures where longevity is critical. Its surface can be treated for camouflage applications, but the cost may limit its use in budget-sensitive projects.

International Considerations:

Buyers should ensure compliance with ASTM and ISO standards for quality assurance. In regions like Saudi Arabia, where environmental conditions are extreme, stainless steel’s durability is particularly valued.

4. Digitally Printed Coated Steel

Key Properties:

This material features a base of steel coated with a digitally printed camouflage design, often using high-resolution inks that provide excellent weather resistance and UV protection.

Pros & Cons:

The primary advantage is the aesthetic appeal of high-definition camouflage patterns, which can be customized for specific applications. However, the printing process can increase costs and may require careful handling to avoid damage.

Impact on Application:

Digitally printed coated steel is ideal for applications requiring visually appealing designs, such as hunting blinds and decorative structures. Its compatibility with various coatings enhances its utility.

International Considerations:

Buyers should verify compliance with local standards for printed materials, especially in Europe, where regulations may dictate the types of inks and coatings used.

Summary Table of Material Selection

| Material | Typical Use Case for camouflage sheet metal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvalume Steel | Roofing and siding | Excellent corrosion resistance | Higher cost than galvanized steel | Medium |

| Aluminum | Mobile applications | Lightweight and easy to handle | More expensive than steel | High |

| Stainless Steel | Permanent structures | Exceptional strength and durability | Significantly higher cost | High |

| Digitally Printed Coated Steel | Decorative and aesthetic applications | Customizable high-definition designs | Increased cost and careful handling needed | Medium |

This strategic material selection guide provides valuable insights for B2B buyers, enabling informed decisions when sourcing camouflage sheet metal for diverse applications.

In-depth Look: Manufacturing Processes and Quality Assurance for camouflage sheet metal

The manufacturing process of camouflage sheet metal involves several key stages, each critical for ensuring the final product meets the specific needs of B2B buyers. Understanding these processes can help international buyers, particularly from Africa, South America, the Middle East, and Europe, make informed decisions when sourcing camouflage sheet metal.

What are the Main Stages of Manufacturing Camouflage Sheet Metal?

1. Material Preparation

The first stage in manufacturing camouflage sheet metal involves selecting the appropriate base material. Most camouflage sheet metal products are made from galvanized steel or galvalume steel, which provide excellent corrosion resistance. The raw material is often treated to meet specific thickness requirements, commonly 29-gauge (approximately 0.0142 inches before paint), which balances durability and weight.

Once the base material is selected, it undergoes surface preparation. This step may involve cleaning to remove any contaminants, rust, or oils that could affect adhesion during the finishing process. Advanced techniques, such as chemical treatment or sandblasting, are employed to ensure a clean surface ready for printing or coating.

2. Forming

The next stage is the forming process, where the prepared metal sheets are shaped into the desired profiles. Techniques such as roll forming or stamping are common, allowing manufacturers to create specific designs and dimensions. For camouflage sheet metal, ensuring that the finished product can maintain its integrity during bending and shaping is crucial, particularly for applications like roofing or siding.

3. Assembly

For products requiring multiple components, assembly becomes essential. This may involve joining various metal pieces through welding, riveting, or using adhesives. In the case of camouflage metal roofing panels, each panel must align perfectly for both functional and aesthetic purposes. Attention to detail during this stage is crucial, as misalignment can lead to structural weaknesses or aesthetic inconsistencies.

4. Finishing

Finishing is where camouflage sheet metal truly differentiates itself. The application of camouflage patterns is typically accomplished through high-resolution digital printing or advanced coating techniques. Partnering with established brands like Realtree can enhance the product’s appeal through unique designs.

After printing, a protective coating is often applied to enhance durability, especially for outdoor applications. This may include a polyester or polyurethane topcoat that offers UV protection and weather resistance. The finishing process is critical, as it directly influences the product’s longevity and performance in various environments.

What Quality Assurance Measures Are Essential for Camouflage Sheet Metal?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that the final product meets international standards and customer expectations. Various measures are implemented throughout the manufacturing process to maintain high quality.

Relevant International Standards

International buyers should be aware of standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards indicates that the manufacturer has established a systematic approach to managing quality, ensuring consistent production processes and customer satisfaction.

Additionally, industry-specific certifications may apply, such as CE marking in Europe, which confirms that products meet safety and environmental requirements. For certain applications, API (American Petroleum Institute) certifications may also be relevant, particularly for products used in the oil and gas sector.

Key Quality Control Checkpoints

To maintain high quality, manufacturers typically implement multiple quality control (QC) checkpoints during the production process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications. Any materials that do not pass inspection are rejected or returned.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to monitor production processes. This helps identify issues early, preventing defects from progressing to later stages.

-

Final Quality Control (FQC): Before shipping, finished products undergo thorough inspections. This may include dimensional checks, visual inspections, and testing for adherence to specifications.

Common Testing Methods

Various testing methods are employed to validate the quality of camouflage sheet metal. These may include:

-

Adhesion Testing: Ensures that printed patterns adhere properly to the metal surface, crucial for long-term durability.

-

Corrosion Resistance Testing: Evaluates the metal’s ability to withstand environmental factors, a critical consideration for outdoor applications.

-

Dimensional and Visual Inspections: Confirm that products meet specified dimensions and aesthetic requirements.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are several strategies to consider:

Conducting Audits

Performing on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality management systems. During an audit, buyers can assess compliance with international standards and the effectiveness of the supplier’s QC measures.

Requesting Quality Reports

Buyers should ask for detailed quality reports, including results from IQC, IPQC, and FQC. These documents should provide transparency regarding the manufacturing process and highlight any quality issues encountered and how they were resolved.

Utilizing Third-Party Inspections

Engaging third-party inspection services can add an extra layer of assurance. These independent organizations can conduct audits and inspections, providing unbiased assessments of the supplier’s quality control practices.

What Are the QC and Certification Nuances for International Buyers?

Navigating quality control and certification can be complex for international buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe. Buyers should consider the following:

-

Regional Standards: Familiarize yourself with regional standards and regulations that may apply to camouflage sheet metal in your specific market. For example, certain countries may have unique environmental regulations that affect material sourcing or product specifications.

-

Documentation Requirements: Ensure that suppliers can provide the necessary documentation to prove compliance with relevant standards. This includes certifications, test reports, and compliance statements.

-

Cultural and Language Considerations: Communication can be a barrier, especially when dealing with suppliers from different cultural backgrounds. Clear and concise specifications, along with effective communication strategies, can help mitigate misunderstandings and ensure quality expectations are met.

In conclusion, understanding the manufacturing processes and quality assurance measures for camouflage sheet metal is crucial for international B2B buyers. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control, buyers can make informed decisions that align with their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘camouflage sheet metal’

Introduction

This guide serves as a comprehensive checklist for B2B buyers interested in sourcing camouflage sheet metal. Understanding the nuances of this specialized material is essential to making informed purchasing decisions that align with your business needs. From defining specifications to evaluating suppliers, this checklist will help streamline the procurement process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of any successful procurement process. Consider factors such as gauge thickness, coating type, and dimensions. For example, camouflage sheet metal typically comes in various gauges, with 29 gauge being common for roofing applications.

- Gauge Thickness: Ensure it meets your structural requirements.

- Coating Type: Look for options like AZ-50 Galvalume for enhanced durability.

Step 2: Research Market Trends and Applications

Understanding the market landscape is crucial for identifying potential uses and demand for camouflage sheet metal. Research applications relevant to your industry, such as construction, hunting blinds, or outdoor structures.

- Market Needs: Identify if there’s a growing demand for camouflage patterns in your region.

- Innovative Uses: Consider how businesses are creatively employing camouflage sheet metal beyond traditional applications.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s vital to thoroughly vet suppliers. Request detailed company profiles, case studies, and references from similar industries or regions to gauge their reliability.

- Certifications: Verify if the supplier holds relevant industry certifications, which can indicate quality and compliance.

- Product Range: Assess whether the supplier can offer custom lengths or designs that fit your needs.

Step 4: Request Samples and Specifications

Obtaining samples is critical for assessing the quality and appearance of camouflage sheet metal. Request samples that reflect the specifications you intend to order, allowing you to evaluate the material firsthand.

- Visual Inspection: Check for color consistency and pattern quality.

- Material Properties: Ensure the samples meet your durability and performance expectations.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing and terms. Pay attention not only to the unit price but also to shipping costs, lead times, and payment terms.

- Total Cost of Ownership: Evaluate the long-term value, including potential maintenance and replacement costs.

- Negotiation Leverage: Use competing offers to negotiate better terms or discounts.

Step 6: Verify Delivery and Lead Times

Confirm the supplier’s ability to meet your timeline. Understanding lead times is crucial for planning your projects effectively and avoiding delays.

- Stock Availability: Inquire about stock levels and how quickly they can produce additional quantities.

- Delivery Options: Explore logistics solutions, especially if you require delivery to remote locations.

Step 7: Finalize Contracts and Agreements

Once you have selected a supplier, ensure that all agreements are documented clearly. Contracts should outline specifications, pricing, delivery schedules, and warranty information.

- Review Terms: Make sure you understand the return policies, especially for non-returnable items.

- Legal Compliance: Ensure that the contract complies with international trade regulations applicable to your region.

By following these steps, B2B buyers can navigate the complexities of sourcing camouflage sheet metal effectively, ensuring a successful procurement process that meets their business requirements.

Comprehensive Cost and Pricing Analysis for camouflage sheet metal Sourcing

What Are the Key Cost Components for Camouflage Sheet Metal Sourcing?

When sourcing camouflage sheet metal, understanding the cost structure is vital for effective budgeting and negotiation. The primary cost components include:

-

Materials: The base material for camouflage sheet metal is typically galvalume steel or aluminum, which influences the overall cost. Specialty coatings and digital printing processes, such as those used by Titan Steel for high-resolution camouflage patterns, can also add to material costs.

-

Labor: Labor costs encompass the wages of workers involved in production, from cutting and shaping to printing and finishing. Skilled labor is often required for high-quality applications, which can drive up costs.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment maintenance, and facility expenses. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Initial tooling costs for custom designs can be significant, particularly for unique camouflage patterns. These costs are often amortized over larger production runs.

-

Quality Control (QC): Ensuring that the camouflage sheet metal meets specified quality standards is critical. This involves inspection processes that can add to the overall cost but are essential for customer satisfaction and compliance with industry standards.

-

Logistics: Transportation and handling fees are crucial, especially for international buyers. The complexity of logistics can increase costs, particularly if customs and import duties are involved.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This margin can vary significantly based on market demand and competition.

What Price Influencers Should Buyers Consider?

Several factors can influence the pricing of camouflage sheet metal:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs due to economies of scale. Understanding the supplier’s MOQ can aid in negotiating better pricing.

-

Specifications and Customization: Customized products generally come with higher costs due to the additional labor and material requirements. Clearly defining specifications can help avoid unexpected costs.

-

Materials and Quality Certifications: The choice of materials directly impacts pricing. Higher-quality materials or those with specific certifications (e.g., for outdoor durability) can increase costs but offer better long-term performance.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with proven track records may charge more but offer better quality assurance.

-

Incoterms: Understanding the Incoterms used in the transaction is crucial. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) determine who bears the shipping costs and risks, impacting the total landed cost.

How Can Buyers Negotiate for Better Pricing?

To maximize value when sourcing camouflage sheet metal, consider the following negotiation tips:

-

Understand Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the product, including maintenance, durability, and potential reordering needs. A lower upfront price may not always be the best deal if quality is compromised.

-

Leverage Volume Discounts: If your business anticipates ongoing needs, negotiate for discounts based on projected volumes over time.

-

Be Clear About Requirements: Clearly communicate your specifications and needs to avoid misunderstandings that could lead to additional costs later.

-

Research Market Prices: Conduct market research to understand typical pricing in different regions, especially if sourcing from international suppliers. This knowledge can bolster your negotiating position.

-

Evaluate Multiple Suppliers: Don’t settle for the first quote. Compare offers from several suppliers to find the best combination of price, quality, and service.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider specific pricing nuances:

-

Currency Fluctuations: Be aware of exchange rates when negotiating prices with international suppliers. Fluctuations can significantly impact final costs.

-

Customs Duties and Taxes: Understand the import duties and taxes applicable in your country. These can add substantially to the total cost and should be factored into your budget.

-

Local Regulations: Different countries may have varying regulations regarding materials and quality standards. Ensure that the camouflage sheet metal complies with local laws to avoid penalties or additional costs.

Disclaimer on Pricing

The prices referenced in this analysis are indicative and can vary based on market conditions, supplier negotiations, and regional factors. Always seek quotes from multiple suppliers to get the most accurate and current pricing tailored to your specific needs.

Alternatives Analysis: Comparing camouflage sheet metal With Other Solutions

Understanding Alternatives for Camouflage Sheet Metal Solutions

In the realm of metal solutions, camouflage sheet metal stands out for its aesthetic and functional applications, particularly in industries such as construction, agriculture, and outdoor recreation. However, businesses often seek alternatives that can meet similar objectives, whether due to cost considerations, application-specific requirements, or availability. This section evaluates camouflage sheet metal against two viable alternatives: vinyl-coated metal and painted aluminum sheets.

Comparison Table

| Comparison Aspect | Camouflage Sheet Metal | Vinyl-Coated Metal | Painted Aluminum Sheets |

|---|---|---|---|

| Performance | Durable, weather-resistant, aesthetic | Durable, weather-resistant, varied colors | Lightweight, good weather resistance |

| Cost | Moderate ($4.99 per foot) | Moderate to high (varies by color) | High (typically $5.50 – $7.00 per foot) |

| Ease of Implementation | Requires specialized cutting and installation | Relatively easy to install | Easy to install, lightweight |

| Maintenance | Low maintenance, long-lasting | Moderate maintenance, check for wear | Low maintenance, easy to clean |

| Best Use Case | Hunting blinds, decorative structures | Industrial applications, fencing | Residential siding, decorative finishes |

Detailed Breakdown of Alternatives

What are the Benefits and Drawbacks of Vinyl-Coated Metal?

Vinyl-coated metal is a robust alternative that offers excellent durability and a variety of color options. Its coating provides an extra layer of protection against the elements, making it suitable for outdoor applications. However, while it is relatively easy to install, the cost can escalate depending on the color and finish selected. Additionally, vinyl coatings may fade over time, necessitating periodic inspections and potential re-coating.

How Does Painted Aluminum Sheets Compare?

Painted aluminum sheets are another alternative, known for their lightweight nature and aesthetic appeal. They are available in a wide range of colors and finishes, which makes them suitable for various applications, including residential siding and decorative accents. While they are easy to install due to their lightweight characteristics, the cost is generally higher than camouflage sheet metal. Furthermore, while painted aluminum is low-maintenance, it may not have the same level of durability as steel options, particularly in harsh environments.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When evaluating the best solution for their specific needs, B2B buyers should consider factors such as application, budget, and the environment in which the materials will be used. Camouflage sheet metal excels in durability and aesthetic appeal, making it ideal for applications where visual integration is essential, such as hunting blinds or decorative structures. In contrast, vinyl-coated metal offers versatility in color and ease of installation, while painted aluminum sheets provide a lightweight option with a premium finish. By carefully assessing these alternatives, buyers can select the option that aligns best with their operational requirements and financial constraints.

Essential Technical Properties and Trade Terminology for camouflage sheet metal

Understanding the essential technical properties and terminology associated with camouflage sheet metal is crucial for B2B buyers looking to make informed purchasing decisions. This guide outlines key specifications and common industry terms that are integral to the procurement process.

What Are the Key Technical Properties of Camouflage Sheet Metal?

-

Material Grade

The most common materials used in camouflage sheet metal include Galvalume steel and aluminum. Galvalume, for instance, is coated with a mixture of aluminum and zinc, offering superior corrosion resistance and longevity. Understanding the material grade is vital for buyers as it directly impacts durability, application suitability, and maintenance requirements. -

Gauge Thickness

Gauge thickness, such as 29 gauge (approximately 0.0142 inches), refers to the metal’s thickness. Thicker gauges generally offer better durability and resistance to damage, making them suitable for more demanding applications. For buyers, selecting the appropriate gauge is essential to ensure the product meets the structural and aesthetic needs of their projects. -

Coating and Finish

The coating on camouflage sheet metal not only provides camouflage patterns but also contributes to its durability and resistance to environmental factors. Common finishes include polyester and acrylic coatings, which enhance UV protection and weather resistance. Buyers should consider these coatings to ensure the longevity of their investment, particularly in outdoor applications. -

Panel Dimensions

Camouflage sheet metal is available in various sizes, commonly 36 inches in width and lengths that can be customized. Understanding panel dimensions is crucial for buyers to ensure compatibility with their project specifications and to minimize waste during installation. -

Coverage Area

The coverage area, often specified in square feet or linear feet, indicates how much surface area a panel will cover. For instance, a panel with 36-inch coverage can significantly influence the overall project costs and material needs. Buyers should calculate coverage to optimize inventory and reduce costs. -

Lead Time and Availability

Lead times can vary based on stock levels and custom orders. Understanding lead times is essential for project planning and scheduling. Buyers should inquire about stock availability and potential delays to ensure timely delivery of materials.

What Are Common Trade Terms Used in the Camouflage Sheet Metal Industry?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for buyers who want to ensure they are sourcing high-quality, reliable materials from trusted manufacturers. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers assess their purchasing power and align their orders with their project needs while avoiding excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products. Buyers should utilize RFQs to gather competitive pricing and ensure they are getting the best value for their camouflage sheet metal purchases. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and negotiate better shipping arrangements. -

Custom Length

This term indicates that panels can be cut to specified lengths based on customer requirements. Understanding the option for custom lengths is vital for buyers looking to optimize material usage and ensure a perfect fit for their projects. -

Galvalume Steel

A type of steel coated with aluminum and zinc, known for its corrosion resistance. Buyers should be aware of the advantages of Galvalume steel in applications where durability is essential.

By comprehending these technical properties and industry terms, B2B buyers can navigate the complexities of sourcing camouflage sheet metal more effectively, ensuring they make informed decisions that align with their project requirements and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the camouflage sheet metal Sector

What Are the Key Trends Influencing the Camouflage Sheet Metal Market?

The camouflage sheet metal sector is experiencing a notable transformation driven by several global factors. One significant driver is the increasing demand for innovative building materials that cater to diverse applications, including construction, hunting, and outdoor recreational industries. The rise of digital printing technology, particularly through partnerships with brands like Realtree, has enabled manufacturers to offer high-resolution camouflage patterns on various metal substrates. This has expanded the utility of camouflage sheet metal beyond traditional uses, appealing to sectors such as agriculture, automotive, and consumer products.

Emerging trends in B2B sourcing include a shift toward customization and on-demand production. Buyers increasingly prefer suppliers who can offer tailored solutions that meet specific project requirements. For instance, companies providing cut-to-length panels or custom designs are gaining traction, particularly among international buyers in regions like Africa, South America, and the Middle East. Additionally, the integration of e-commerce platforms for sourcing has streamlined procurement processes, making it easier for businesses to obtain materials quickly and efficiently.

Market dynamics are also influenced by geopolitical factors and supply chain disruptions, which have highlighted the need for resilient sourcing strategies. Buyers are encouraged to engage with multiple suppliers and consider local sourcing options to mitigate risks associated with global logistics.

How Important Is Sustainability and Ethical Sourcing in the Camouflage Sheet Metal Sector?

Sustainability and ethical sourcing have become paramount in the camouflage sheet metal market, reflecting broader trends across industries. The environmental impact of manufacturing processes, particularly in terms of energy consumption and waste generation, is under scrutiny. B2B buyers are increasingly seeking suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or implementing energy-efficient production methods.

Certifications like ISO 14001 for environmental management systems and the use of green materials can serve as indicators of a supplier’s dedication to sustainability. Additionally, the popularity of products made from Galvalume steel, known for its durability and resistance to corrosion, aligns with eco-friendly initiatives. These materials not only enhance the lifespan of products but also reduce the frequency of replacements, contributing to lower overall environmental impact.

Ethical supply chains are also crucial, especially for international buyers. Ensuring that suppliers adhere to fair labor practices and responsible sourcing can enhance a company’s brand reputation and appeal to environmentally-conscious consumers. As sustainability continues to shape purchasing decisions, B2B buyers must prioritize partnerships with suppliers that align with their values and operational goals.

How Has the Camouflage Sheet Metal Sector Evolved Over Time?

The camouflage sheet metal sector has evolved significantly from its early roots in military applications to a broader range of uses in various industries. Initially, camouflage patterns were primarily utilized for defense and tactical purposes, but advancements in technology have paved the way for innovative designs and applications. The introduction of digital printing technologies has allowed for intricate and customizable camouflage patterns that cater to consumer preferences and specific market needs.

In recent years, the collaboration between steel manufacturers and established brands like Realtree has further revolutionized the market. This partnership has made high-quality, visually appealing camouflage designs accessible for a variety of applications, including roofing, siding, and decorative elements in residential and commercial buildings. As the market continues to expand, the focus on sustainability and ethical sourcing will likely dictate future developments, ensuring that the camouflage sheet metal sector remains relevant in an increasingly eco-conscious global economy.

Frequently Asked Questions (FAQs) for B2B Buyers of camouflage sheet metal

-

How do I select the right camouflage sheet metal for my project?

Selecting the appropriate camouflage sheet metal involves assessing several factors, including the intended application, environmental conditions, and required specifications. Consider the gauge, finish, and type of camouflage pattern that will best suit your needs. For outdoor applications, look for materials with UV protection and weather-resistant coatings. Additionally, consult with suppliers about customization options to ensure the product meets your specific requirements, whether for roofing, siding, or other uses. -

What types of camouflage patterns are available in sheet metal?

Camouflage sheet metal comes in various patterns designed for different applications. Popular options include Realtree EDGE, MAX-5, and Timber patterns, which are suitable for outdoor use, such as hunting blinds and cabins. Suppliers may also offer custom digital printing to create unique designs. When sourcing, inquire about the availability of specific patterns and their compatibility with your intended application to ensure optimal camouflage effectiveness. -

What are the minimum order quantities (MOQs) for camouflage sheet metal?

Minimum order quantities can vary significantly between suppliers. Generally, MOQs for camouflage sheet metal range from a few hundred to several thousand square feet, depending on the supplier’s production capabilities and inventory. When negotiating with suppliers, clarify the MOQ and explore potential options for smaller orders, especially if you are testing a new product or entering a new market. Bulk orders may also qualify for discounts, so consider your long-term needs. -

How can I ensure the quality of camouflage sheet metal products?

To ensure quality, vet potential suppliers thoroughly by reviewing their certifications, manufacturing processes, and customer reviews. Request samples to assess the material’s durability, finish, and camouflage effectiveness. Additionally, inquire about their quality assurance protocols, such as inspections during production and testing for weather resistance. Establishing clear quality standards in your contracts can also help mitigate issues down the line. -

What payment terms should I expect when ordering camouflage sheet metal internationally?

Payment terms can vary widely among suppliers, particularly for international transactions. Common terms include a deposit upfront, with the balance due upon delivery or a letter of credit. It’s crucial to establish clear payment terms during negotiations to avoid misunderstandings. Additionally, be aware of any currency fluctuations that may affect pricing and consider using secure payment methods to protect your investment. -

What logistics considerations should I keep in mind when importing camouflage sheet metal?

When importing camouflage sheet metal, consider shipping options, lead times, and customs regulations. Work closely with your supplier to determine the best shipping method, whether by air or sea, based on your timeline and budget. Ensure that all necessary documentation is prepared for customs clearance, including invoices, packing lists, and certificates of origin. Engaging a freight forwarder can streamline the process and help navigate complex logistics. -

How do I customize camouflage sheet metal for my specific needs?

Customization options for camouflage sheet metal can include variations in gauge, length, width, and pattern design. Many suppliers offer digitally printed options that allow for high-resolution images tailored to your requirements. Discuss your specific needs with potential suppliers to explore available customization services. Be sure to clarify any associated costs and lead times for custom orders to align with your project timeline. -

What are the best practices for maintaining camouflage sheet metal?

To maintain the appearance and integrity of camouflage sheet metal, regular inspections and cleaning are essential. Remove dirt, debris, and any corrosive materials promptly to prevent damage. Use mild cleaning solutions and soft brushes to avoid scratching the surface. Additionally, consider applying protective coatings periodically to enhance durability and maintain color vibrancy, especially in harsh environmental conditions. Always follow manufacturer recommendations for maintenance to ensure longevity.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 2 Camouflage Sheet Metal Manufacturers & Suppliers List

1. Titan Steel – Digitally Printed Realtree Camouflage Coils

Domain: business.realtree.com

Registered: 1997 (28 years)

Introduction: Titan Steel offers digitally printed Realtree camouflage coils and sheets for various indoor and outdoor applications. They are the largest vendor of camouflage metal coils and sheets in North America and the first to introduce digitally printed Realtree camo designs to the flat rolled metal coil market. The coils and sheets are suitable for uses such as hunting blinds, roofing, siding, post build…

2. Realtree® Camouflage – 29 Gauge Metal Panels

Domain: allsteelmetal.com

Registered: 2009 (16 years)

Introduction: {‘name’: ‘Realtree® Camouflage’, ‘gauge’: ’29 Gauge’, ‘available_panel_profiles’: [‘Tuff Rib’, ‘Apex’], ‘warranty’: ’20 Year Warranty’, ‘description’: ‘Realtree® Camouflage features an artful mix of fall leaves, evergreens, lichen dappled bark, exposed wood grain, and overlapping branches, creating a color-rich scene ideal for various applications.’}

Strategic Sourcing Conclusion and Outlook for camouflage sheet metal

What Are the Key Insights for Sourcing Camouflage Sheet Metal?

The strategic sourcing of camouflage sheet metal presents significant opportunities for international B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe. As demand for customized, aesthetically appealing, and durable building materials continues to rise, the versatility of camouflage sheet metal becomes increasingly valuable. Its applications range from roofing and siding to specialized installations in hunting and outdoor industries, making it a unique product that meets various market needs.

Buyers should focus on suppliers that offer high-quality materials, such as AZ-50 Galvalume steel, and consider innovative options like digitally printed patterns from reputable brands. Establishing strong supplier relationships can facilitate better pricing, lead times, and product availability, essential factors in maintaining competitive advantage.

How Can Buyers Prepare for Future Trends in Camouflage Sheet Metal?

Looking ahead, the market for camouflage sheet metal is poised for growth, driven by evolving consumer preferences and technological advancements in manufacturing. Buyers are encouraged to stay informed about emerging trends, such as environmentally friendly coatings and enhanced design options. Engaging with suppliers who prioritize sustainability and innovation will be crucial in adapting to these trends.

In conclusion, leveraging strategic sourcing for camouflage sheet metal not only enhances product offerings but also positions businesses favorably in a competitive landscape. International buyers should seize the opportunity to collaborate with leading manufacturers to explore new applications and expand their market reach.