Is Your Bundle Of 2X4 Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for bundle of 2×4

Sourcing a bundle of 2×4 lumber can present significant challenges for international B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. Understanding the intricacies of this global marketplace is crucial for making informed purchasing decisions. This guide delves into the various types of 2×4 lumber available, their applications in construction and other industries, and essential criteria for vetting suppliers. Additionally, we will explore pricing structures and logistics considerations that can impact your procurement strategy.

As a B2B buyer, the ability to navigate these complexities not only ensures that you acquire quality materials but also enhances your supply chain efficiency. This comprehensive guide aims to empower you with actionable insights and practical tips tailored to the unique demands of your market. By addressing factors such as product specifications, sourcing strategies, and supplier reliability, you will be better equipped to make decisions that align with your business objectives. Whether you are looking for premium-grade lumber for construction projects or cost-effective options for bulk purchasing, this resource will serve as your roadmap in the global lumber market, ultimately facilitating successful transactions and fostering long-term partnerships.

Understanding bundle of 2×4 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Premium Grade KD-HT Stud | High-grade, kiln-dried, heat-treated for stability | Framing, structural supports | Pros: Excellent durability; meets high grading standards. Cons: Higher cost compared to lower grades. |

| Standard Grade Dimensional Lumber | Basic quality, untreated, suitable for general use | General construction, DIY projects | Pros: Cost-effective; widely available. Cons: Less durable, prone to warping. |

| Southern Yellow Pine | Known for strength, versatility, and cost-effectiveness | Framing, cabinetry, furniture | Pros: Strong and lightweight; good for various applications. Cons: Susceptible to moisture damage if untreated. |

| Cedar Lumber | Naturally resistant to decay, aromatic, and aesthetically pleasing | Outdoor projects, landscaping, furniture | Pros: Long-lasting, attractive finish. Cons: More expensive; limited to specific applications. |

| Composite Lumber | Made from recycled materials; resistant to rot and insects | Decking, outdoor structures | Pros: Eco-friendly; low maintenance. Cons: Heavier; can be more expensive than wood. |

What are the Characteristics of Premium Grade KD-HT Studs?

Premium Grade KD-HT (Kiln-Dried Heat Treated) studs are engineered for superior strength and stability. They are dried to reduce moisture content, which minimizes warping and splitting. These studs meet rigorous grading standards, making them ideal for structural applications such as framing and load-bearing walls. B2B buyers should consider their long-term investment value, as the durability of these studs can lead to lower maintenance costs over time despite their higher initial price.

How Does Standard Grade Dimensional Lumber Compare?

Standard Grade Dimensional Lumber is typically untreated and serves as a cost-effective solution for various construction needs. It is commonly used in non-structural applications or where budget constraints are critical. While it provides adequate strength for general construction, buyers should be aware of its susceptibility to warping and decay if exposed to moisture. This type of lumber is ideal for projects where aesthetics are less of a concern, allowing businesses to save on material costs.

Why Choose Southern Yellow Pine for Your Projects?

Southern Yellow Pine is favored for its strength and versatility, making it a popular choice among builders and manufacturers. It has a high strength-to-weight ratio, which allows for lighter structures without compromising stability. This wood is often treated to enhance its resistance to decay and insects, but untreated versions are also available for interior use. Buyers should evaluate their project requirements, as untreated pine is more affordable but may require additional treatment for outdoor applications.

What Advantages Does Cedar Lumber Offer?

Cedar Lumber is renowned for its natural resistance to decay and its appealing aesthetic qualities. It is an excellent choice for outdoor applications, such as decking and garden furniture, due to its durability and low maintenance requirements. However, cedar is generally more expensive than other types of lumber, making it a premium option. B2B buyers should weigh the benefits of longevity and visual appeal against the higher cost when considering cedar for their projects.

What Makes Composite Lumber a Sustainable Choice?

Composite Lumber is composed of recycled materials, making it an eco-friendly alternative to traditional wood. Its resistance to rot, insects, and warping makes it suitable for outdoor applications like decking and landscaping. While it typically comes at a higher price point than natural wood, its low maintenance requirements and durability can offset initial costs over time. B2B buyers focused on sustainability and long-term performance may find composite lumber to be a worthwhile investment.

Key Industrial Applications of bundle of 2×4

| Industry/Sector | Specific Application of bundle of 2×4 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Framing for Residential and Commercial Buildings | Provides structural integrity, ensuring safety and durability | Quality grading, treatment options, and compliance with local building codes |

| Furniture Manufacturing | Production of Wooden Frames and Supports | Cost-effective material for creating durable furniture | Availability of specific wood types and dimensions, sourcing from sustainable suppliers |

| Agriculture | Greenhouse and Barn Construction | Supports agricultural operations through sturdy structures | Weather-resistant treatments, regional availability, and transportation logistics |

| DIY and Home Improvement | Shelving and Storage Solutions | Allows for versatile and customizable home projects | Sizing options, ease of handling, and local market preferences |

| Export and Logistics | Shipping and Packaging Materials | Reduces shipping costs by providing lightweight yet strong support | Compliance with international shipping standards and local regulations |

How is ‘bundle of 2×4’ used in the construction industry?

In the construction sector, bundles of 2×4 are predominantly used for framing both residential and commercial buildings. They serve as the backbone of structures, providing essential support for walls, roofs, and floors. Buyers must ensure that the lumber meets local building codes and is graded appropriately for structural integrity. Additionally, the treatment of the wood (e.g., pressure-treated for outdoor use) is crucial for durability, especially in regions with extreme weather conditions. B2B buyers in Africa, South America, the Middle East, and Europe should prioritize suppliers who can guarantee quality and compliance with regional standards.

What role does ‘bundle of 2×4’ play in furniture manufacturing?

In the furniture manufacturing industry, bundles of 2×4 are often utilized for creating frames and supports for various furniture pieces, such as tables, chairs, and shelving units. The use of this dimensional lumber allows manufacturers to produce durable and cost-effective products that can withstand regular use. Buyers should consider the specific wood types available, as different species offer varying aesthetics and strength properties. Additionally, sourcing from suppliers committed to sustainable practices can enhance the brand’s reputation and appeal in international markets.

How does ‘bundle of 2×4’ support agricultural operations?

Agricultural applications for bundles of 2×4 include the construction of greenhouses, barns, and other farming structures. These lumber pieces provide the necessary support for roofs and walls, ensuring that agricultural operations are protected from environmental factors. Buyers need to consider the weather-resistant treatments available, especially in regions prone to high humidity or heavy rainfall. Furthermore, logistical aspects such as transportation and availability in rural areas can significantly impact sourcing decisions for agricultural businesses.

In what ways can ‘bundle of 2×4’ enhance DIY projects?

For DIY enthusiasts and home improvement projects, bundles of 2×4 are a versatile solution for building shelving, storage units, and even outdoor structures like decks and fences. Their adaptability allows homeowners to customize solutions to fit their specific needs. When sourcing, buyers should look for options that are easy to handle and cut, as well as those that meet personal project specifications. Understanding local market preferences regarding wood types and finishes can further assist buyers in selecting the right products.

Why is ‘bundle of 2×4’ important in export and logistics?

In the export and logistics sector, bundles of 2×4 are often used as shipping and packaging materials, providing lightweight yet sturdy support for goods during transit. This can significantly reduce shipping costs while ensuring that products remain secure. Buyers must be aware of compliance with international shipping standards and local regulations regarding packaging materials. Additionally, sourcing from suppliers who understand the complexities of logistics can streamline the procurement process and enhance efficiency in global trade.

3 Common User Pain Points for ‘bundle of 2×4’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem:

B2B buyers often encounter significant variability in the quality of ‘bundle of 2×4’ products when sourcing from different suppliers. This inconsistency can lead to project delays, increased costs, and potential safety issues if inferior quality materials are used in construction. Buyers may find themselves receiving a shipment that does not meet their specifications or industry standards, making it difficult to trust the reliability of their suppliers.

The Solution:

To mitigate quality inconsistency, buyers should establish a rigorous supplier evaluation process before placing orders. This includes requesting product samples and certifications that verify compliance with industry standards, such as the American Lumber Standards Committee (ALSC) or equivalent local standards in their region. Additionally, implementing a quality assurance protocol upon receiving shipments can help catch any discrepancies early on. Regular communication with suppliers regarding quality expectations and feedback on received materials will also foster stronger relationships and encourage suppliers to maintain high standards. Consider leveraging technology such as inventory management systems that track supplier performance metrics, helping to make data-driven decisions for future purchases.

Scenario 2: Difficulty in Managing Inventory Levels

The Problem:

B2B buyers often struggle with managing inventory levels of ‘bundle of 2×4’ lumber, especially when dealing with fluctuating project demands. Over-purchasing can lead to increased holding costs, while under-purchasing can delay projects due to insufficient materials. This challenge is exacerbated in regions with unpredictable supply chains, leading to further complications in timely project execution.

The Solution:

To effectively manage inventory levels, buyers should adopt a just-in-time (JIT) inventory strategy. This approach involves closely monitoring project timelines and demand forecasts to order materials only as needed. Utilizing inventory management software can enhance visibility into stock levels and automate reorder alerts when supplies fall below a predetermined threshold. Additionally, buyers should maintain relationships with multiple suppliers to ensure flexibility in sourcing and the ability to adjust orders quickly in response to changing project demands. Collaborating with project managers to align material orders with project schedules will help optimize inventory usage and minimize waste.

Scenario 3: Cost Fluctuations and Budget Management

The Problem:

Cost fluctuations in lumber prices can create budgetary challenges for B2B buyers, particularly in regions affected by supply chain disruptions or seasonal demand spikes. Buyers may find themselves facing unexpected price increases that jeopardize project budgets, leading to difficult conversations with stakeholders about potential cost overruns.

The Solution:

To combat cost fluctuations, buyers should consider establishing long-term contracts with suppliers that lock in prices for a set period. This approach provides price stability and helps with accurate budgeting. Additionally, buyers can explore bulk purchasing options to take advantage of volume discounts, thereby reducing per-unit costs. Another effective strategy is to diversify sourcing options by identifying alternative suppliers and materials, which can provide leverage in negotiations. Engaging in market research and staying informed about lumber market trends will enable buyers to make timely purchasing decisions, ultimately allowing them to allocate resources more effectively and maintain project budgets.

Strategic Material Selection Guide for bundle of 2×4

What Are the Key Materials for Bundles of 2×4 and Their Properties?

When selecting materials for bundles of 2×4, several options stand out based on performance, durability, and cost-effectiveness. Here, we analyze four common materials: Southern Yellow Pine, Douglas Fir, Cedar, and Engineered Wood. Each material has unique properties that can significantly influence application suitability and buyer considerations.

How Does Southern Yellow Pine Perform as a 2×4 Material?

Southern Yellow Pine (SYP) is a popular choice for construction due to its strength and versatility. It is known for its high density, which provides excellent load-bearing capabilities. SYP is treated to resist decay and insect damage, making it suitable for both indoor and outdoor applications. However, it can be susceptible to warping and splitting if not properly dried.

Pros: High strength-to-weight ratio, cost-effective, readily available.

Cons: Requires treatment for outdoor use, potential for warping.

Impact on Application: Ideal for framing, flooring, and structural supports.

International Considerations: Buyers should ensure compliance with local building codes and treatment standards, particularly in regions with high humidity.

What Are the Advantages of Using Douglas Fir for 2×4 Bundles?

Douglas Fir is another strong contender for 2×4 lumber. It boasts a high strength-to-weight ratio and excellent dimensional stability, making it less prone to warping. Its natural resistance to decay, especially when treated, enhances its longevity in construction applications.

Pros: Excellent strength, good dimensional stability, and aesthetic appeal.

Cons: Higher cost compared to SYP, limited availability in some regions.

Impact on Application: Commonly used in heavy framing, beams, and high-load applications.

International Considerations: Ensure compliance with ASTM standards and check for local availability, especially in Europe.

Why Choose Cedar for 2×4 Applications?

Cedar is renowned for its natural resistance to moisture, decay, and insects, making it an excellent choice for outdoor applications. It has a distinctive aroma and beautiful grain, which can enhance aesthetic appeal in visible structures. However, cedar is generally more expensive than other softwoods.

Pros: Natural resistance to decay, attractive appearance, lightweight.

Cons: Higher cost, softer than other woods, making it less suitable for heavy load-bearing applications.

Impact on Application: Ideal for outdoor furniture, decks, and siding.

International Considerations: Buyers should confirm compliance with local environmental regulations regarding sourcing and treatment.

How Does Engineered Wood Compare for Bundles of 2×4?

Engineered wood products, such as laminated veneer lumber (LVL) or glulam, offer superior strength and stability compared to traditional lumber. They are manufactured to specific dimensions, reducing waste and improving consistency. However, they may be more expensive and require specialized handling during installation.

Pros: High strength, consistent quality, and reduced waste.

Cons: Generally more expensive, potential for moisture sensitivity.

Impact on Application: Suitable for structural applications where high load-bearing capacity is required.

International Considerations: Ensure compliance with local building codes and standards, particularly in regions with stringent regulations.

Summary Table of Material Properties

| Material | Typical Use Case for bundle of 2×4 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Southern Yellow Pine | Framing, flooring, structural supports | High strength-to-weight ratio | Requires treatment for outdoor use | Low |

| Douglas Fir | Heavy framing, beams, high-load applications | Excellent dimensional stability | Higher cost compared to SYP | Med |

| Cedar | Outdoor furniture, decks, siding | Natural resistance to decay | Higher cost, softer than other woods | High |

| Engineered Wood | Structural applications | High strength, consistent quality | More expensive, moisture sensitivity | High |

This analysis provides B2B buyers with critical insights into material selection for bundles of 2×4, enabling informed decisions based on performance, cost, and compliance considerations across different international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for bundle of 2×4

What Are the Key Manufacturing Processes for Producing Bundles of 2×4 Lumber?

The manufacturing of 2×4 lumber involves several critical stages that ensure the final product meets industry standards and buyer expectations. Understanding these stages will help B2B buyers make informed decisions when sourcing lumber products.

Material Preparation: How Is Raw Lumber Processed?

The first step in the manufacturing process is the selection and preparation of raw lumber. Typically, softwood species like Southern Yellow Pine or Douglas Fir are used for 2×4 lumber. Logs are debarked and cut into manageable lengths, usually ranging from 8 to 20 feet.

Once the logs are cut, they are sent to a sawmill where they undergo the primary breakdown process. This involves sawing the logs into rough lumber dimensions. At this stage, moisture content is measured, as it affects the drying process. Logs with higher moisture content are typically subjected to drying techniques.

Forming: What Techniques Are Used to Shape the Lumber?

After material preparation, the lumber enters the forming stage. Here, the rough-cut lumber is planed to achieve the desired dimensions of 2 inches by 4 inches. This process not only shapes the wood but also enhances its surface finish, making it smoother and more visually appealing.

Techniques such as CNC machining may be employed to ensure precision in dimensions and to create features like grooves or notches if required for specific applications. Additionally, any defects such as knots or splits are identified and addressed during this stage, either by cutting around them or by applying fillers.

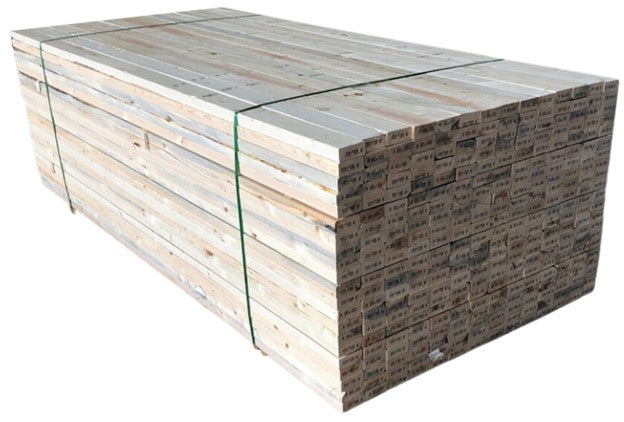

Assembly and Finishing: How Are 2×4 Bundles Prepared for Market?

Once shaped, the lumber is sorted based on quality grades, typically ranging from #1 to #3, according to established grading standards. Higher grades are suitable for structural applications, while lower grades may be used for non-structural purposes.

The assembly involves bundling the lumber into packs, usually secured with metal strapping or bands for stability during transportation. Finishing processes may include treatments to enhance durability, such as pressure treatment with preservatives or kiln-drying to reduce moisture content. The final product is then labeled, and documentation is prepared for shipping.

What Quality Assurance Practices Are Essential in Lumber Production?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that the lumber produced meets international and industry-specific standards. For B2B buyers, understanding these QA practices is crucial for ensuring product reliability.

Which International Standards Apply to 2×4 Lumber Production?

Many manufacturers adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with this standard indicates that a company consistently provides products that meet customer and regulatory requirements.

In addition, European buyers may encounter CE marking, which signifies that a product meets EU safety, health, and environmental protection standards. Similarly, the American National Standards Institute (ANSI) provides guidelines for grading and quality assurance in lumber.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to maintaining product quality throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the facility to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing stages, continuous monitoring is conducted to catch defects early. This may involve measuring dimensions, moisture content, and visual inspections.

- Final Quality Control (FQC): Before shipping, the finished bundles of 2×4 lumber undergo a final inspection to verify that they meet all specifications and standards.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those sourcing from different regions, verifying the quality control processes of suppliers is essential. Buyers can take several steps to ensure that their suppliers maintain high-quality standards:

-

Conduct Supplier Audits: Regular audits can help assess the supplier’s adherence to quality standards and identify areas for improvement. This can include reviewing their quality management systems and processes.

-

Request Quality Reports: Suppliers should provide documentation, including inspection reports and certifications, which can help buyers verify compliance with international standards.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the product quality, ensuring that the lumber meets the required standards before shipment.

What Testing Methods Are Commonly Used in Lumber Quality Assurance?

Various testing methods are employed to ensure the quality and performance of 2×4 lumber. Common tests include:

- Moisture Content Testing: This is critical for determining the lumber’s suitability for specific applications and its longevity.

- Strength Testing: This may involve bending tests to assess the lumber’s load-bearing capacity, which is essential for structural applications.

- Durability Testing: Particularly for treated lumber, tests are conducted to evaluate resistance to decay, insects, and environmental factors.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

When sourcing lumber internationally, particularly from regions like Africa, South America, the Middle East, and Europe, buyers should be aware of potential quality control nuances.

- Cultural Differences in Standards: Different regions may have varying expectations regarding quality and compliance. Buyers should familiarize themselves with the local standards and practices.

- Logistical Challenges: International shipping can introduce risks, such as damage during transit. Ensuring that suppliers have robust packaging and handling processes can mitigate these risks.

- Regulatory Compliance: Buyers must ensure that their suppliers comply with both their home country’s import regulations and the exporting country’s manufacturing standards.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when purchasing bundles of 2×4 lumber, ensuring they receive products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bundle of 2×4’

This practical sourcing guide serves as a step-by-step checklist for B2B buyers looking to procure bundles of 2×4 lumber. By following these guidelines, you can ensure that you make informed decisions that meet your project requirements and maintain quality standards.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the 2×4 lumber you need. Consider factors such as grade, length, wood type (e.g., Southern Yellow Pine, Cedar), and treatment (e.g., heat-treated, pressure-treated). Defining these parameters helps streamline your sourcing process and ensures you receive products that meet your project needs.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers. Look for companies with a strong reputation in the lumber market, particularly those with experience in international shipping and compliance with local regulations. Utilize industry directories, trade shows, and online platforms to compile a list of potential suppliers.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their product quality, delivery capabilities, and customer service track record to ensure they align with your expectations.

Step 4: Verify Certifications and Standards

Check for relevant certifications that indicate compliance with industry standards, such as the Forest Stewardship Council (FSC) certification or other sustainability credentials. Certifications ensure that the lumber is sourced responsibly, which is increasingly important for projects focused on sustainability and ethical practices.

Step 5: Request Samples

Before finalizing your order, request samples of the 2×4 lumber. This step is vital for assessing the quality and suitability of the product for your specific applications. Inspect the samples for dimensional accuracy, surface finish, and any visible defects to ensure they meet your quality standards.

Step 6: Negotiate Terms and Pricing

Engage in discussions with your selected supplier to negotiate pricing and terms. Consider factors such as bulk discounts, payment terms, and shipping costs. A clear understanding of these aspects will help you manage your budget effectively and establish a mutually beneficial relationship with your supplier.

Step 7: Confirm Logistics and Delivery Details

Finally, ensure that you have a clear logistics plan in place. Confirm shipping methods, estimated delivery times, and any customs requirements for your region. Effective logistics management is critical to maintaining your project timeline and avoiding delays.

By following this checklist, you can navigate the complexities of sourcing bundles of 2×4 lumber effectively, ensuring that you choose the right products from reliable suppliers while maintaining quality and cost efficiency.

Comprehensive Cost and Pricing Analysis for bundle of 2×4 Sourcing

Understanding the cost structure and pricing dynamics of a bundle of 2×4 lumber is crucial for international B2B buyers aiming to make informed purchasing decisions. This analysis provides insights into the various cost components, price influencers, and practical tips to enhance procurement efficiency.

What Are the Key Cost Components for 2×4 Lumber Bundles?

The cost of sourcing 2×4 lumber bundles encompasses several critical components:

-

Materials: The type of wood significantly influences material costs. Common species include Southern Yellow Pine and Cedar, with prices varying based on availability and quality grades (e.g., #1, #2). Premium grades command higher prices due to superior characteristics such as durability and aesthetic appeal.

-

Labor: Labor costs are incurred during the milling and processing stages. Skilled labor is essential for ensuring high-quality cuts and finishes. In regions with higher labor costs, such as parts of Europe, this can affect overall pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient production processes can help minimize these costs.

-

Tooling: Specialized equipment for cutting and treating lumber contributes to the cost. Higher-quality tooling can enhance precision and reduce waste.

-

Quality Control (QC): Investing in quality assurance processes helps ensure that lumber meets industry standards and buyer specifications. This can add to costs but is essential for maintaining supplier reliability.

-

Logistics: Transportation and shipping costs vary based on distance and mode of transport. Incoterms (International Commercial Terms) play a vital role in determining who bears these costs. For instance, Delivered Duty Paid (DDP) means the seller covers all costs up to the buyer’s location.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market conditions and competition.

How Do Price Influencers Impact Sourcing Decisions?

Several factors can significantly influence the pricing of 2×4 bundles:

-

Volume/MOQ: Ordering in larger quantities often leads to better pricing due to economies of scale. Establishing a Minimum Order Quantity (MOQ) can help negotiate favorable terms.

-

Specifications and Customization: Custom cuts or treated wood may incur additional costs. Buyers should be clear about their specifications to avoid unexpected charges.

-

Quality and Certifications: Lumber with specific certifications (e.g., FSC, PEFC) often costs more due to the assurance of sustainable sourcing and quality. Buyers in regions with stringent regulations may prioritize certified products.

-

Supplier Factors: The supplier’s reputation, reliability, and location can impact pricing. Established suppliers with a track record may command higher prices but offer better service and quality assurance.

-

Incoterms: Understanding the implications of Incoterms can affect total costs. For instance, choosing a shipping option that includes insurance and customs clearance can mitigate risks but may increase upfront costs.

What Are Effective Buyer Tips for Negotiating 2×4 Lumber Prices?

-

Negotiation: Engaging in open discussions with suppliers about pricing, especially if purchasing in bulk, can yield discounts. Leverage your purchasing power to negotiate better terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes all costs associated with the product throughout its lifecycle, not just the purchase price. This perspective can lead to better long-term investment decisions.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa and South America should be aware of currency fluctuations and international shipping costs. Understanding local market conditions and establishing relationships with regional suppliers can lead to more favorable pricing.

-

Stay Informed: Regularly monitor market trends and pricing changes in the lumber industry. This knowledge can provide leverage during negotiations and help identify the best times to purchase.

Disclaimer on Pricing

Prices for 2×4 lumber bundles can fluctuate based on market demand, availability, and regional factors. The information provided here serves as a general guideline and should be verified with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing bundle of 2×4 With Other Solutions

Introduction to Alternative Solutions for 2×4 Bundles

In the competitive landscape of construction and building materials, the choice of lumber is critical for achieving project objectives efficiently. While the bundle of 2×4 lumber is a staple in the industry, there are alternative solutions that may offer unique advantages depending on specific project requirements. This analysis compares the traditional bundle of 2×4 lumber with engineered wood products and steel framing systems to provide B2B buyers with actionable insights.

Comparison Table

| Comparison Aspect | Bundle Of 2X4 | Engineered Wood Products | Steel Framing Systems |

|---|---|---|---|

| Performance | High strength for various uses | Superior load-bearing capacity | Excellent durability and fire resistance |

| Cost | Generally lower initial cost | Higher upfront cost | Higher initial investment but lower lifecycle costs |

| Ease of Implementation | Simple to work with and cut | Requires specialized tools | Requires skilled labor for installation |

| Maintenance | Minimal maintenance | Low maintenance, resistant to warping | Requires minimal upkeep, resistant to pests |

| Best Use Case | Residential framing, DIY projects | Large commercial projects, high-load applications | High-rise buildings, industrial applications |

Detailed Breakdown of Alternatives

Engineered Wood Products

Engineered wood products, such as laminated veneer lumber (LVL) and glulam beams, are created by bonding together layers of wood. These products offer superior strength and stability, making them ideal for applications requiring high load-bearing capacities, such as in commercial construction. The main advantage of engineered wood is its ability to span longer distances without support, reducing the need for additional structural elements. However, the initial cost is typically higher than traditional lumber, and specialized tools may be needed for cutting and installation.

Steel Framing Systems

Steel framing systems represent a modern approach to construction that utilizes steel components instead of wood. These systems provide excellent durability, fire resistance, and pest control, making them a reliable choice for high-rise buildings and industrial applications. While the initial investment in steel framing can be significant, its long-term benefits include lower maintenance costs and extended lifespan. However, the installation process is more complex and typically requires skilled labor, which can increase project timelines and costs.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate framing solution for a construction project, B2B buyers should consider multiple factors including performance, cost, ease of implementation, and maintenance. While the bundle of 2×4 lumber remains a versatile and cost-effective choice for many applications, engineered wood products and steel framing systems offer distinct advantages for specialized projects. Assessing the specific requirements of each project, such as load demands and environmental conditions, will enable buyers to make informed decisions that align with their budget and performance expectations. By carefully weighing these alternatives, businesses can optimize their construction processes and achieve superior outcomes.

Essential Technical Properties and Trade Terminology for bundle of 2×4

What Are the Essential Technical Properties of a Bundle of 2×4?

When sourcing bundles of 2×4 lumber, understanding key technical properties is crucial for making informed purchasing decisions. Here are several critical specifications to consider:

-

Material Grade

The material grade of a 2×4 indicates its quality and suitability for specific applications. Common grades include #1, #2, and premium grades. Higher-grade lumber is typically stronger and more visually appealing, making it ideal for visible structures. For B2B buyers, selecting the right grade is essential to ensure product longevity and structural integrity. -

Moisture Content

The moisture content of lumber is a key factor affecting its performance. Kiln-dried lumber (KD) typically has a moisture content of 19% or less, which minimizes warping and splitting. For international buyers, understanding local climate conditions can guide the choice between KD and green lumber, impacting the wood’s performance in construction. -

Dimensional Tolerance

Dimensional tolerance refers to the allowable deviation from specified dimensions. For 2×4 lumber, standard tolerances are often within 1/8 inch. This specification is vital for framing and construction projects, ensuring that lumber fits together properly and meets engineering standards. -

Length

Bundles of 2×4 lumber are available in various lengths, typically ranging from 8 to 20 feet. The choice of length can affect shipping costs and usability on-site. B2B buyers should consider their project requirements and the potential for waste when selecting lengths. -

Treatment Type

Treatment types such as pressure-treated or untreated lumber can significantly influence durability and resistance to pests and decay. Pressure-treated lumber is essential for outdoor applications, while untreated wood may suffice for indoor use. Understanding treatment options helps buyers select the appropriate product for their specific environmental conditions. -

Species of Wood

Common species for 2×4 lumber include Southern Yellow Pine, Douglas Fir, and Cedar. Each species has unique characteristics, such as weight, strength, and resistance to decay. Buyers should evaluate species based on their project needs and local availability to ensure optimal performance and cost-effectiveness.

What Are Common Trade Terms Related to 2×4 Lumber Bundles?

Familiarity with industry terminology can enhance communication and negotiation in B2B transactions. Here are several essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are sold under another brand’s name. For lumber suppliers, understanding OEM relationships can help buyers identify quality assurance practices and product sourcing. -

MOQ (Minimum Order Quantity)

MOQ is the minimum quantity that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and overall project costs. Understanding MOQ can lead to better negotiation and purchasing strategies. -

RFQ (Request for Quotation)

An RFQ is a document that solicits pricing and terms from suppliers. This term is essential for buyers looking to compare offers from multiple suppliers and ensure they receive competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. Understanding these terms is vital for B2B buyers to navigate shipping, insurance, and risk management effectively. -

Sourcing

Sourcing refers to the process of identifying and selecting suppliers for goods and services. For lumber buyers, efficient sourcing strategies can lead to cost savings and improved supply chain reliability. -

Lead Time

Lead time is the time taken from placing an order to receiving the goods. For construction projects, understanding lead times is critical for scheduling and project management, allowing buyers to plan accordingly and minimize delays.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, optimize procurement strategies, and enhance their overall purchasing experience for bundles of 2×4 lumber.

Navigating Market Dynamics and Sourcing Trends in the bundle of 2×4 Sector

What Are the Current Market Dynamics and Key Trends in the 2×4 Sector?

The global demand for dimensional lumber, particularly the 2×4 sector, is influenced by various factors, including construction growth, urbanization, and the rising trend of sustainable building practices. Countries in Africa, South America, the Middle East, and Europe are witnessing an uptick in construction projects, fueled by infrastructure development and housing demands. For international B2B buyers, understanding these market dynamics is crucial. Emerging technologies such as online sourcing platforms and digital supply chain management tools are facilitating easier access to suppliers and better inventory management. Additionally, trends toward modular construction and prefabrication are increasing the demand for standardized lumber products like the 2×4, as they offer efficiency and cost savings.

Buyers should also be aware of regional differences in lumber sourcing, particularly with respect to species and treatment methods. For instance, Southern Yellow Pine remains a popular choice in North America, while European markets may favor spruce or fir. Furthermore, the ongoing impact of climate change on forestry practices necessitates a keen awareness of sourcing stability and availability. This changing landscape requires B2B buyers to adopt agile sourcing strategies, leveraging real-time data to make informed procurement decisions.

How Are Sustainability and Ethical Sourcing Influencing the 2×4 Sector?

Sustainability and ethical sourcing are becoming increasingly important in the lumber industry, particularly in the context of the 2×4 market. B2B buyers are not only looking for quality but are also prioritizing suppliers who adhere to environmentally friendly practices. The negative environmental impact of deforestation has led to heightened scrutiny of supply chains. Buyers are encouraged to seek out suppliers who offer certified sustainable products, such as those endorsed by the Forest Stewardship Council (FSC) or other recognized green certifications.

Moreover, the push for ‘green’ building materials is reshaping buyer preferences. Eco-friendly treatments and finishes, along with sourcing from responsibly managed forests, are becoming non-negotiable factors in the purchasing decision. B2B buyers should consider engaging with suppliers who provide transparency in their sourcing practices, including chain-of-custody documentation that verifies sustainable origins. This not only aligns with corporate social responsibility goals but also meets the growing consumer demand for sustainable construction materials.

What Is the Historical Evolution of the 2×4 Sector and Its Relevance Today?

The 2×4 has a rich history that traces back to early American colonization when timber was a primary building material. Over the decades, it evolved from being primarily a local resource to a global commodity, influenced by advancements in milling technology and transportation. The introduction of standardized dimensions revolutionized construction practices, allowing for more efficient building methods.

Today, the relevance of the 2×4 remains strong, particularly in framing residential and commercial structures. Its versatility and availability make it a staple in the construction industry. As international markets continue to grow, the evolution of the 2×4 sector reflects broader trends in global sourcing, sustainability, and technological advancements. Understanding this historical context equips B2B buyers with a deeper appreciation of the product’s significance in contemporary construction, guiding more strategic purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of bundle of 2×4

-

How do I ensure the quality of 2×4 bundles before purchasing?

To ensure quality, request samples from suppliers to assess the lumber’s grade and condition. Look for certifications like the American Lumber Standard Committee (ALSC) or equivalent standards in your region. It’s also advisable to conduct a visual inspection for defects such as warping, knots, or splits. Establishing a relationship with a reliable supplier who can provide a history of quality control practices is crucial. Utilize third-party inspection services if necessary to verify compliance with your specific requirements. -

What are the most important factors to consider when sourcing 2×4 bundles internationally?

Key factors include supplier reliability, product quality, compliance with international standards, and shipping logistics. Verify the supplier’s reputation through reviews and trade references. Consider the total landed cost, which includes shipping, tariffs, and potential customs fees. Additionally, ensure that the lumber meets your country’s import regulations and quality standards to avoid delays. Understanding the supplier’s production capabilities and lead times is also essential for effective project planning. -

What is the typical minimum order quantity (MOQ) for 2×4 bundles?

The MOQ for 2×4 bundles can vary significantly depending on the supplier and the region. Generally, it ranges from a few hundred to several thousand units. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are a small or first-time buyer. Some suppliers may offer smaller trial orders to establish a relationship before committing to larger purchases. Consider your storage capabilities and project timelines when determining the appropriate order size. -

What payment terms should I expect when purchasing 2×4 bundles?

Payment terms can vary widely between suppliers. Common arrangements include full payment upfront, a percentage deposit with the balance due upon shipment, or net terms (e.g., 30 or 60 days post-delivery). It’s essential to clarify terms before finalizing the order to avoid misunderstandings. Consider utilizing secure payment methods such as letters of credit or escrow services for large transactions to mitigate risk. Always ensure that the terms are documented in the purchase agreement. -

How can I customize my 2×4 orders to fit specific project needs?

Customization options for 2×4 bundles may include varying lengths, grades, and treatments (such as pressure treatment for outdoor use). Communicate your specifications clearly to the supplier during the initial discussions. Some suppliers may also offer custom cutting or finishing services. Be prepared to discuss additional costs or minimum order requirements for customized products, and ensure that all specifications are documented in your contract to avoid any discrepancies. -

What logistics considerations should I keep in mind when importing 2×4 bundles?

Logistics considerations include selecting the right shipping method (sea, air, or land), understanding customs clearance processes, and coordinating delivery timelines. Evaluate the total shipping costs and transit times, as these can significantly impact project schedules. Work with a freight forwarder who has experience in lumber shipments to navigate international regulations and ensure compliance. Additionally, consider the implications of potential delays in shipping and customs clearance on your overall project timeline. -

What quality assurance measures should I implement when sourcing 2×4 bundles?

Implementing quality assurance measures involves defining clear specifications for the lumber and establishing criteria for acceptance. Consider conducting pre-shipment inspections to verify that the product meets your standards. Utilize quality control checklists that include factors like moisture content, dimensions, and grading. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations and lead to improved outcomes in future orders. -

How do I handle disputes or issues with my 2×4 supplier?

In case of disputes or issues with your supplier, the first step is to communicate directly and clearly outline your concerns. Keep a record of all correspondence and agreements to support your case. If informal negotiations do not resolve the issue, consult the terms of your contract regarding dispute resolution procedures, which may include mediation or arbitration. In some cases, involving a third-party mediator can facilitate a fair resolution. Always prioritize maintaining a professional relationship, as this can help in future dealings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Bundle Of 2X4 Manufacturers & Suppliers List

1. Martin Metal – Discounted Lumber Bundles

Domain: martinmetal.com

Registered: 2004 (21 years)

Introduction: Discounted Lumber Bundles are available at Martin Metal LLC. These bundles are deeply discounted due to returns, miscuts, or defects. They are sold together and cannot be split up. The inventory is updated daily, but items may sell out before being removed from the site. All discount items are sold as-is and are not returnable. Customers are encouraged to call ahead to reserve items before visitin…

2. Forest Products – SPF Studs

Domain: fp-supply.com

Registered: 2010 (15 years)

Introduction: SPF Studs offered by Forest Products include a variety of options such as premiums, finger jointed, #2 grade, and 10′ pre-cuts. Available sizes include 2×4 and 2×6 in 8′ and 9′ pre-cuts. Key product types include Canfor Select Studs, which allow wane up to 1/3rd the height and 1/8th the width for the full length, and Nechako/Apollo Studs, which have very limited wane and are end painted for easy i…

3. Tandem Drums – Drops 2×4 Bundle

Domain: tandemdrums.com

Registered: 2022 (3 years)

Introduction: {“product_name”: “Drops 2×4 bundle”, “regular_price”: “99.99 USD”, “sale_price”: “99.99 USD”, “original_price”: “119.98 USD”, “quantity_in_cart”: 0, “included_items”: “Two sets of all four Drops® (8 pcs total), two of each weight: 40g / 60g / 120g / 200g.”, “recommended_uses”: “Great for larger drum kits, as well as keeping an extra set at the studio. Use smaller weights (40g / 60g) on rack toms 8…

Strategic Sourcing Conclusion and Outlook for bundle of 2×4

In the realm of strategic sourcing for bundles of 2×4 lumber, international B2B buyers must navigate a landscape defined by quality, pricing, and supplier reliability. The diverse applications of 2×4 lumber in construction and manufacturing underscore its importance, making it essential for buyers to prioritize sourcing from reputable suppliers who adhere to stringent quality standards. By leveraging bulk purchasing options and long-term supplier relationships, businesses can enhance their operational efficiency and reduce costs.

Furthermore, understanding regional market dynamics is crucial for buyers from Africa, South America, the Middle East, and Europe. Factors such as local demand trends, currency fluctuations, and logistical challenges can significantly influence procurement strategies. Engaging with suppliers who offer transparent pricing and flexible shipping solutions will empower buyers to make informed decisions.

Looking ahead, the global lumber market is poised for growth, driven by an increasing demand for sustainable building materials. As sustainability becomes a focal point, sourcing from eco-friendly suppliers can not only enhance brand reputation but also align with international environmental standards. International buyers are encouraged to explore strategic partnerships and remain adaptable to market shifts to capitalize on emerging opportunities in the 2×4 lumber sector.