Is Your 1 4 Inch Plexiglass 4X8 Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for 1 4 inch plexiglass 4×8

In today’s competitive landscape, sourcing high-quality 1/4 inch plexiglass 4×8 sheets can pose significant challenges for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The need for durable, versatile materials that can withstand various applications—from display cases to protective barriers—makes understanding the global plexiglass market essential. This guide aims to empower procurement professionals by providing a comprehensive overview of the types of plexiglass available, their applications, and crucial factors for supplier vetting.

Throughout this guide, we will explore the various grades of plexiglass, the benefits of choosing cast over extruded options, and the intricacies of pricing, including shipping considerations and potential custom fabrication. Furthermore, we will address how to identify reliable suppliers and negotiate contracts that align with your specific business needs.

By equipping international buyers with actionable insights and strategic approaches, this guide will enable you to make informed purchasing decisions that enhance your operational efficiency and product quality. Whether you are in Brazil seeking innovative display solutions or in Vietnam looking for robust glazing materials, understanding the nuances of the plexiglass market is key to achieving your business objectives.

Understanding 1 4 inch plexiglass 4×8 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clear Cast Acrylic | High optical clarity, superior impact resistance | Glazing, sneeze guards, displays | Pros: Excellent clarity, customizable sizes. Cons: Higher cost than extruded options. |

| Extruded Acrylic | Lightweight, cost-effective, lower clarity | Signage, light fixtures | Pros: Economical, easy to fabricate. Cons: Less durable than cast acrylic. |

| UV-Resistant Acrylic | Coated for UV protection, maintains color integrity | Outdoor applications, signage, displays | Pros: Prevents yellowing, durable. Cons: Typically more expensive than standard options. |

| Frosted Acrylic | Translucent finish, diffuses light | Privacy screens, decorative applications | Pros: Aesthetic appeal, light diffusion. Cons: Reduced clarity compared to clear options. |

| Colored Acrylic | Available in various colors, opaque options | Retail displays, artistic projects, furniture | Pros: Customizable aesthetics, versatile. Cons: Limited light transmission, may be pricier. |

What Are the Characteristics of Clear Cast Acrylic?

Clear cast acrylic sheets are renowned for their high optical clarity and exceptional impact resistance, making them a preferred choice for applications requiring transparency and durability. With a thickness of 1/4 inch and dimensions of 4×8 feet, these sheets are ideal for glazing in commercial settings, such as storm windows or protective barriers in retail environments. B2B buyers should consider the customization options available, as these sheets can be cut to specific dimensions, offering flexibility for various projects. However, the cost is generally higher than that of extruded acrylic, which may impact budget-sensitive projects.

How Does Extruded Acrylic Differ from Other Types?

Extruded acrylic is known for being lightweight and cost-effective, making it a popular choice for signage and light fixtures. It possesses lower optical clarity compared to cast acrylic but is easier to fabricate and handle. This type of acrylic is especially suitable for large-scale projects where budget constraints are a priority. When purchasing, B2B buyers should weigh the benefits of lower costs against the potential need for more frequent replacements due to the material’s lower impact resistance.

What Advantages Does UV-Resistant Acrylic Offer?

UV-resistant acrylic sheets are specially coated to prevent yellowing and maintain color integrity over time, making them ideal for outdoor applications. Businesses in regions with high sun exposure can benefit significantly from this type of acrylic, as it extends the life of signage and displays. While the initial investment may be higher, the long-term savings on replacements and maintenance can justify the cost. B2B buyers should consider their geographical location and exposure levels when evaluating this option.

Why Choose Frosted Acrylic for Privacy Solutions?

Frosted acrylic provides a translucent finish that diffuses light while ensuring privacy, making it an excellent choice for office partitions and decorative applications. This type of acrylic offers aesthetic appeal and can enhance the ambiance of a workspace or retail environment. B2B buyers should consider the visual impact and functionality of frosted acrylic, especially in settings where light diffusion is desired. However, it is essential to note that the clarity is reduced compared to clear options, which may not be suitable for all applications.

What Are the Benefits of Using Colored Acrylic?

Colored acrylic sheets are available in a wide range of hues and can be opaque or translucent, making them versatile for various applications, from retail displays to artistic projects. This type allows businesses to customize their products and branding effectively. When purchasing colored acrylic, B2B buyers should consider factors such as colorfastness and light transmission. While these sheets can be more expensive than clear options, their ability to enhance visual branding can provide significant marketing advantages.

Key Industrial Applications of 1 4 inch plexiglass 4×8

| Industry/Sector | Specific Application of 1/4 inch plexiglass 4×8 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Window Glazing and Facades | Provides a lightweight, durable alternative to glass, enhancing energy efficiency and safety. | Ensure UV resistance and thermal insulation properties; consider local climate conditions. |

| Retail Displays | Point of Purchase (POP) Displays | Enhances product visibility and aesthetics, driving customer engagement and sales. | Look for custom cutting options and ease of fabrication for unique designs. |

| Healthcare | Protective Barriers and Sneeze Guards | Creates a hygienic barrier in reception areas, enhancing safety for both staff and clients. | Ensure clarity and ease of cleaning; verify compliance with health regulations. |

| Transportation | Vehicle Windows and Enclosures | Reduces weight while increasing impact resistance, improving fuel efficiency and safety. | Assess compatibility with existing vehicle designs and local regulations for vehicle modifications. |

| Aquaculture | Aquarium Tanks and Enclosures | Offers superior clarity and strength, providing a safe environment for aquatic life. | Ensure material is non-toxic and suitable for long-term underwater use; consider local sourcing options to reduce costs. |

How is 1/4 Inch Plexiglass 4×8 Used in Construction and Architecture?

In the construction and architecture sectors, 1/4 inch plexiglass 4×8 sheets are frequently utilized for window glazing and building facades. Their lightweight nature and high impact resistance make them an ideal substitute for traditional glass, providing enhanced energy efficiency and safety. Buyers in this sector should focus on sourcing materials that offer UV resistance and thermal insulation properties, particularly in regions with extreme weather conditions.

What Role Does 1/4 Inch Plexiglass 4×8 Play in Retail Displays?

Retailers leverage 1/4 inch plexiglass 4×8 sheets for creating eye-catching point-of-purchase (POP) displays. The clarity and versatility of this acrylic material significantly enhance product visibility, thereby driving customer engagement and sales. Businesses should prioritize suppliers that offer custom cutting and fabrication services to meet unique design requirements and ensure seamless integration into existing store layouts.

Why is 1/4 Inch Plexiglass 4×8 Essential in Healthcare Settings?

In healthcare environments, 1/4 inch plexiglass 4×8 is commonly used to construct protective barriers and sneeze guards. These installations create hygienic separations between staff and patients, helping to mitigate the spread of airborne contaminants. Buyers must ensure that the plexiglass sheets are easy to clean and maintain, while also verifying compliance with local health regulations to safeguard public health.

How is 1/4 Inch Plexiglass 4×8 Beneficial for Transportation?

The transportation industry employs 1/4 inch plexiglass 4×8 for vehicle windows and enclosures, capitalizing on its lightweight and impact-resistant properties. This not only enhances safety but also contributes to improved fuel efficiency. Buyers should evaluate the material’s compatibility with existing vehicle designs and ensure adherence to local regulations governing vehicle modifications.

What Applications Does 1/4 Inch Plexiglass 4×8 Have in Aquaculture?

In aquaculture, 1/4 inch plexiglass 4×8 sheets are essential for constructing aquarium tanks and enclosures. Their superior optical clarity and strength create a safe and visually appealing environment for aquatic life. Buyers in this sector should prioritize sourcing non-toxic materials suitable for long-term underwater use, while also considering local suppliers to minimize logistics costs.

3 Common User Pain Points for ‘1 4 inch plexiglass 4×8’ & Their Solutions

Scenario 1: Overcoming Shipping and Handling Challenges for Large Orders

The Problem: When purchasing 1/4 inch plexiglass sheets in bulk, B2B buyers often encounter significant shipping and handling challenges. The weight and size of the 4×8 sheets can lead to high shipping costs and logistical issues, especially when dealing with international suppliers. This can result in unexpected expenses that impact the overall budget and project timelines, causing frustration and delays in production or installation.

The Solution: To mitigate shipping and handling challenges, B2B buyers should consider sourcing from suppliers that offer competitive shipping rates or free shipping on large orders. Look for vendors who specialize in large quantities and can provide customized shipping solutions, such as palletized deliveries that are more efficient and cost-effective. Additionally, it’s wise to negotiate terms upfront, including shipping costs and delivery timelines, to avoid surprises later on. Utilizing local suppliers whenever possible can also minimize shipping challenges, as well as reduce lead times and costs. Finally, always ensure that the supplier can guarantee the integrity of the sheets during transit, reducing the likelihood of damages that could further delay projects.

Scenario 2: Ensuring Proper Specifications for Project Needs

The Problem: B2B buyers frequently face challenges in specifying the correct thickness and type of plexiglass for their unique applications. For instance, a buyer in the construction industry may require sheets that are not only durable but also lightweight and easy to handle. Without proper specifications, the wrong type of plexiglass may lead to structural failures or aesthetic issues, resulting in costly reworks and project delays.

The Solution: To avoid specification errors, it’s crucial for buyers to thoroughly understand the project requirements before making a purchase. Engaging with technical experts from the supplier can provide insights into the best materials for specific applications. For example, when considering 1/4 inch plexiglass for exterior applications, ask about its UV resistance and impact strength compared to other materials. Creating a checklist of requirements—such as weight limits, transparency needs, and environmental considerations—can streamline the selection process. Furthermore, requesting samples to evaluate in real-world conditions can help ensure that the selected plexiglass meets all functional and aesthetic needs before committing to a large order.

Scenario 3: Addressing Fabrication and Customization Limitations

The Problem: Many B2B buyers find that the standard dimensions of 1/4 inch plexiglass sheets may not align with their specific project needs, leading to complications in fabrication. For instance, a buyer might need custom cuts for a unique display case or a specialized application, but may be unsure how to approach sourcing these custom dimensions without incurring excessive costs or delays.

The Solution: To effectively address customization challenges, buyers should seek suppliers that offer custom fabrication services as part of their core offerings. When engaging with a supplier, clearly communicate the exact dimensions and specifications required for your project. Many vendors provide cut-to-size options that can save time and reduce waste. Additionally, consider suppliers with advanced cutting technologies, such as laser cutting or CNC machining, which can ensure high precision and quality in the finished product. It’s also beneficial to inquire about the lead time for custom orders and any potential cost implications. Building a strong relationship with a supplier that understands your customization needs can streamline future projects and foster a collaborative approach to problem-solving.

Strategic Material Selection Guide for 1 4 inch plexiglass 4×8

What Are the Key Properties of 1/4 Inch Plexiglass?

1/4 inch plexiglass, also known as acrylic or cast acrylic, is a versatile material used across various industries. Its key properties include high optical clarity, lightweight nature, and exceptional impact resistance—up to 17 times stronger than glass. It also offers good temperature resistance, making it suitable for a range of applications, from indoor displays to outdoor installations. However, it is important to note that while plexiglass is resistant to many chemicals, it can be susceptible to certain solvents and should be evaluated for specific media compatibility.

What Are the Advantages and Disadvantages of Using 1/4 Inch Plexiglass?

Pros: The advantages of 1/4 inch plexiglass include its lightweight nature, which simplifies handling and installation, and its ease of fabrication, allowing for straightforward cutting, drilling, and shaping. Additionally, it is often more cost-effective than glass, providing a budget-friendly alternative for businesses. Its high impact strength makes it ideal for applications requiring durability, such as safety barriers, display cases, and protective shields.

Cons: On the downside, while plexiglass is durable, it is not as scratch-resistant as glass, which may necessitate additional protective coatings for certain applications. Furthermore, its thermal expansion properties mean that it can warp if not properly installed or if subjected to extreme temperature changes. This aspect is crucial for international buyers in regions with varying climates.

What Impact Does Material Selection Have on Applications?

The choice of 1/4 inch plexiglass significantly impacts its application. For instance, in environments where clarity and visibility are paramount, such as retail displays or aquariums, the optical properties of plexiglass are highly beneficial. Conversely, in outdoor settings, considerations around UV resistance and temperature fluctuations become critical. Buyers should also evaluate the potential for chemical exposure based on the intended use, as certain chemicals can degrade acrylic over time.

What Should International B2B Buyers Consider When Sourcing 1/4 Inch Plexiglass?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, compliance with local standards is essential. Buyers should be aware of relevant certifications, such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards). These standards ensure that the materials meet specific safety and performance criteria. Additionally, understanding regional preferences and market trends can aid in making informed purchasing decisions. For example, some regions may prioritize eco-friendly materials or specific thicknesses based on common applications.

Summary Table of Material Selection for 1/4 Inch Plexiglass

| Material | Typical Use Case for 1/4 Inch Plexiglass 4×8 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Clear Cast Acrylic | Safety barriers, display cases | High impact resistance | Less scratch-resistant than glass | Medium |

| Extruded Acrylic | Indoor signage, decorative panels | Cost-effective and lightweight | Lower optical clarity than cast | Low |

| Polycarbonate | Security glazing, riot shields | Superior impact resistance | Higher cost compared to acrylic | High |

| Glass | Windows, high-end displays | Excellent scratch resistance | Heavier and more fragile | High |

This strategic material selection guide emphasizes the importance of understanding the properties, advantages, disadvantages, and regional considerations for 1/4 inch plexiglass. By evaluating these factors, international B2B buyers can make informed decisions that align with their specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for 1 4 inch plexiglass 4×8

What Are the Main Stages in the Manufacturing Process of 1/4 Inch Plexiglass 4×8?

The manufacturing process for 1/4 inch plexiglass (acrylic) sheets, particularly in the dimensions of 4×8 feet, involves several critical stages that ensure the final product meets the high standards expected in various applications.

Material Preparation

The process begins with the selection of high-quality raw materials, primarily methyl methacrylate (MMA) monomer. This material is polymerized to create acrylic sheets. The preparation phase includes precise measurement and mixing of MMA with necessary additives to enhance properties such as UV resistance and impact strength. Following this, the mixture is subjected to a polymerization process, often using heat or chemical initiators to facilitate the transformation from liquid to solid.

Forming Techniques

Once the material is prepared, it undergoes forming techniques. The most common methods for producing 1/4 inch plexiglass sheets include casting and extrusion. In casting, the polymerized MMA is poured into molds, allowing it to set and form sheets of specified thickness. This method is preferred for its superior optical clarity and uniform thickness. Extrusion, on the other hand, involves forcing the molten acrylic through a die to create continuous sheets. While extrusion is typically more economical, cast acrylic is favored for applications requiring higher quality and clarity.

Assembly and Finishing Processes

After forming, the sheets are trimmed to size, typically to the standard dimensions of 48 inches by 96 inches. This step involves cutting the sheets accurately to ensure minimal waste and adherence to specifications. Following cutting, finishing techniques such as polishing or coating may be applied. Polishing enhances the surface clarity, while coatings can provide additional protection against scratches or environmental factors.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is integral to the production of 1/4 inch plexiglass sheets, ensuring that the final product meets international standards and customer expectations.

What Are the Relevant International Standards for Plexiglass Manufacturing?

B2B buyers should be aware of the international quality standards applicable to plexiglass manufacturing, such as ISO 9001, which focuses on quality management systems. Compliance with these standards indicates that the manufacturer has established processes to ensure product quality and continuous improvement. Additionally, certifications like CE mark for European markets and API standards for specific industrial applications may apply.

What QC Checkpoints Are Commonly Implemented?

The quality control process is typically structured around several checkpoints:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified criteria before entering production.

- In-Process Quality Control (IPQC): Throughout the manufacturing stages, real-time monitoring is conducted to identify any deviations from quality standards. This may include measuring thickness, clarity, and the absence of defects.

- Final Quality Control (FQC): After production, a thorough inspection of the finished sheets is performed. This includes visual inspections for clarity and defects, as well as dimensional checks to ensure compliance with specifications.

What Common Testing Methods Are Used?

Manufacturers utilize various testing methods to validate the quality of the plexiglass sheets. Common methods include:

- Optical Clarity Tests: Assessing the transparency and clarity of the sheets.

- Impact Resistance Testing: Evaluating the sheets’ durability under stress or impact.

- Thermal Stability Tests: Ensuring the material can withstand varying temperatures without deformation.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability.

What Steps Can Buyers Take to Audit Suppliers?

Buyers should consider conducting audits of potential suppliers. This can involve on-site visits to evaluate manufacturing practices, review quality management systems, and check compliance with international standards. During these audits, buyers can request documentation such as quality control reports, certifications, and evidence of testing methods used.

How Can Reports and Third-Party Inspections Aid in Verification?

Requesting detailed reports on the supplier’s quality assurance processes can provide insights into their operational standards. Additionally, engaging third-party inspection services to evaluate the manufacturing processes and product quality can offer an unbiased assessment. These inspections can include pre-shipment inspections to verify that the products meet agreed specifications before they leave the supplier’s facility.

What Are the Unique QC and Certification Considerations for International Buyers?

Navigating the complexities of quality control and certification can be challenging for international buyers. Different regions may have varying standards and regulations that must be adhered to.

What Are the Certification Nuances for Different Markets?

For example, European buyers may prioritize CE certification, while buyers in the Middle East may look for compliance with local standards. Buyers from Africa and South America should also consider regional certifications that may impact their import processes. Understanding these nuances helps mitigate risks associated with non-compliance and ensures smoother transactions.

How Can Buyers Ensure Compliance with Local Regulations?

B2B buyers should stay informed about local regulations concerning material imports. This includes understanding the necessary documentation and certifications required for customs clearance. Engaging with legal experts or local trade associations can provide additional insights into compliance requirements.

By comprehensively understanding the manufacturing processes and quality assurance measures for 1/4 inch plexiglass sheets, B2B buyers can make informed decisions and establish reliable supply chains that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1 4 inch plexiglass 4×8’

In today’s competitive marketplace, sourcing 1/4 inch plexiglass 4×8 sheets requires a strategic approach to ensure quality, cost-effectiveness, and reliability. This guide provides a comprehensive checklist for B2B buyers looking to procure this versatile material, particularly from international suppliers.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical specifications for the plexiglass. This includes understanding the required thickness, dimensions, optical clarity, and any specific performance attributes (e.g., UV resistance, impact strength). Having precise specifications helps in narrowing down suppliers who can meet your exact needs and ensures that you receive the correct product.

Step 2: Research and Identify Potential Suppliers

Conduct thorough market research to compile a list of potential suppliers. Utilize industry directories, trade shows, and online platforms to find manufacturers and distributors specializing in acrylic products. Pay attention to their reputation, customer reviews, and product offerings to ensure they align with your requirements.

Step 3: Evaluate Supplier Certifications and Compliance

It is essential to verify that suppliers hold relevant certifications and comply with international standards. Check for ISO certifications, quality control measures, and any specific regulatory compliance (such as REACH in Europe or ASTM standards). This step is critical to ensure that the materials you source are safe, reliable, and meet your industry’s standards.

Step 4: Request Samples and Test Quality

Once you have shortlisted suppliers, request samples of their 1/4 inch plexiglass sheets. Testing the samples for clarity, durability, and other specifications will provide insight into the quality of the product. This step minimizes the risk of receiving substandard materials that could impact your projects.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers and compare their pricing structures, including shipping costs and any additional handling fees. Take note of bulk order discounts and payment terms. Understanding the total cost of procurement will help you make an informed decision and optimize your budget.

Step 6: Assess Supplier Communication and Support

Evaluate the responsiveness and communication style of each supplier. A reliable supplier should provide clear, timely responses to your inquiries and demonstrate a willingness to assist with any issues. Good communication is key to a successful partnership, especially for international transactions where time zones and languages may differ.

Step 7: Finalize Your Order and Confirm Logistics

After selecting a supplier, finalize your order by confirming all details, including specifications, pricing, and delivery timelines. Discuss logistics for shipping, including any customs considerations, especially for international orders. Ensure that you have a clear understanding of the return policy and warranty options in case the product does not meet your expectations.

By following these steps, B2B buyers can effectively navigate the sourcing process for 1/4 inch plexiglass 4×8 sheets, ensuring they obtain quality materials that meet their specific needs while establishing strong supplier relationships.

Comprehensive Cost and Pricing Analysis for 1 4 inch plexiglass 4×8 Sourcing

What Are the Key Cost Components for Sourcing 1/4 Inch Plexiglass 4×8?

When sourcing 1/4 inch plexiglass sheets measuring 4×8 feet, understanding the cost structure is essential for effective budget management. The primary cost components include:

-

Materials: The base cost of the plexiglass itself is a significant factor. For instance, prices can range from approximately $114.71 to $279.00 per sheet depending on the supplier and any additional features like UV resistance or custom specifications.

-

Labor: This includes costs associated with handling, cutting, and fabricating the sheets to meet specific requirements. Labor costs can vary widely based on the region and the complexity of the work required.

-

Manufacturing Overhead: This encompasses the indirect costs related to production, such as utilities, rent, and equipment depreciation. Overhead costs can differ based on the supplier’s operational efficiency.

-

Tooling: If custom shapes or sizes are required, tooling costs may be incurred. These costs will depend on the complexity of the design and the machinery needed for fabrication.

-

Quality Control (QC): Ensuring that the plexiglass meets industry standards or specific certifications may involve additional QC costs. This is particularly important for applications in regulated sectors like medical or food services.

-

Logistics: Shipping fees can significantly impact overall costs, especially for international buyers. Costs vary based on weight, dimensions, and delivery methods. Special handling may be required for larger orders, which can further add to logistics expenses.

-

Margin: Suppliers will typically include a profit margin in their pricing. This can vary based on market competition, demand, and supplier relationships.

What Influences the Pricing of 1/4 Inch Plexiglass 4×8?

Several factors can influence the pricing of plexiglass sheets:

-

Volume/MOQ: Purchasing in bulk often leads to cost savings. Suppliers may offer tiered pricing, reducing the unit cost as order volumes increase. For example, buying multiple sheets can result in discounts ranging from 5% to 15%.

-

Specifications and Customization: Custom dimensions, thicknesses, or specialized features (like impact resistance or color) can affect the price. It’s essential to clearly define requirements to avoid unexpected costs.

-

Quality and Certifications: Higher quality materials or those with specific certifications (e.g., UV resistance, fire rating) can command higher prices. Buyers should assess the necessity of these features based on their application.

-

Supplier Factors: The reliability, reputation, and location of the supplier can also influence pricing. Established suppliers may offer better quality assurance but could come at a premium.

-

Incoterms: The terms of shipping (FOB, CIF, DDP) will affect the total landed cost. Understanding these terms is crucial for international buyers to accurately estimate their total expenses.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Plexiglass?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, adopting strategic sourcing practices can lead to significant cost savings:

-

Negotiate Terms: Engage in discussions with suppliers about pricing and payment terms. Building a strong relationship can often lead to better deals and favorable terms.

-

Consider Total Cost of Ownership (TCO): Evaluate all associated costs beyond the initial purchase price. This includes shipping, handling, potential damage during transport, and installation costs.

-

Research Market Prices: Conduct thorough market research to understand average pricing and available suppliers. This knowledge can empower buyers during negotiations.

-

Leverage Local Suppliers: Whenever possible, consider sourcing from local suppliers to reduce shipping costs and lead times. This can also simplify logistics and customs processes.

-

Be Aware of Pricing Nuances: Understand that pricing can vary based on global market conditions, currency fluctuations, and regional demands. Staying informed about these factors can help buyers make more strategic purchasing decisions.

Disclaimer

The prices mentioned in this analysis are indicative and can fluctuate based on market conditions, supplier pricing strategies, and other factors. It is advisable for buyers to request quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing 1 4 inch plexiglass 4×8 With Other Solutions

Exploring Alternatives to 1/4 Inch Plexiglass 4×8: A Comparative Analysis

When considering materials for applications such as glazing, display cases, or protective barriers, it’s essential to evaluate viable alternatives to 1/4 inch plexiglass (acrylic). Each alternative offers distinct characteristics that may better suit specific needs, depending on factors such as performance, cost, and ease of implementation. Below is a comparison of 1/4 inch plexiglass with two alternative solutions: polycarbonate sheets and tempered glass.

| Comparison Aspect | 1/4 Inch Plexiglass 4×8 | Polycarbonate Sheets | Tempered Glass |

|---|---|---|---|

| Performance | High impact resistance, lightweight | Superior impact resistance, shatter-proof | Very strong, scratch-resistant |

| Cost | Approx. $134.95 per sheet | Approx. $180.00 per sheet | Approx. $300.00 per sheet |

| Ease of Implementation | Easy to cut and fabricate | More challenging to cut; requires special tools | Requires professional installation |

| Maintenance | Low maintenance; easy to clean | Low maintenance; easy to clean | Moderate maintenance; can shatter if dropped |

| Best Use Case | Retail displays, sneeze guards | Security applications, safety barriers | Windows, doors, high-end displays |

Understanding the Pros and Cons of Alternatives

Polycarbonate Sheets

Polycarbonate sheets are known for their exceptional impact resistance, making them nearly unbreakable. They are ideal for high-security applications, such as banks or schools, where safety is paramount. While they are generally more expensive than plexiglass, their durability can lead to lower replacement costs over time. However, polycarbonate is more challenging to cut and may require special tools, which can complicate installation. Additionally, while they are resistant to shattering, they can scratch more easily than plexiglass.

Tempered Glass

Tempered glass is a robust option that offers excellent strength and is often used in high-end applications. It is scratch-resistant and provides a premium aesthetic that many businesses seek for their storefronts or interior designs. However, tempered glass comes at a higher cost compared to plexiglass and typically requires professional installation due to its weight and fragility. While it is less prone to damage, if broken, it shatters into small, blunt pieces, which can be a safety concern. Maintenance can also be higher, as glass needs regular cleaning to maintain clarity.

Making the Right Choice for Your Business Needs

In conclusion, selecting the right material depends on the specific requirements of your application. If you need a lightweight, easy-to-handle option for displays or barriers, 1/4 inch plexiglass is a strong candidate. However, for scenarios requiring enhanced security and durability, polycarbonate sheets may be more suitable, despite the higher cost and installation challenges. On the other hand, if the aesthetic appeal and premium feel are paramount, tempered glass could be the best choice, provided that you’re prepared for the associated costs and installation complexities. By carefully assessing your operational needs, budget, and desired outcomes, you can make an informed decision that aligns with your business goals.

Essential Technical Properties and Trade Terminology for 1 4 inch plexiglass 4×8

What Are the Key Technical Properties of 1/4 Inch Plexiglass 4×8?

When evaluating 1/4 inch plexiglass (also known as acrylic) sheets measuring 4×8 feet, several critical technical specifications come into play. Understanding these properties is vital for B2B buyers as they influence the material’s performance, application suitability, and overall cost-effectiveness.

1. Material Grade

Plexiglass comes in different grades, primarily cast and extruded. Cast acrylic offers superior optical clarity and greater impact resistance, making it ideal for applications like display cases and protective barriers. Conversely, extruded acrylic is often more cost-effective but may not provide the same level of quality. Selecting the appropriate grade ensures that the final product meets specific performance requirements.

2. Thickness Tolerance

The standard thickness for these sheets is 1/4 inch, but tolerances can vary, typically +/- 10%. This means the actual thickness may fluctuate slightly, which can affect fit and installation. For applications requiring precise dimensions, such as custom fabrication, understanding these tolerances helps in avoiding costly errors.

3. Impact Resistance

Plexiglass has a high impact strength—17 times greater than glass—making it an excellent choice for environments where safety is a concern, such as in schools or public spaces. This property allows for durability while maintaining clarity, which is crucial for display and visibility applications.

4. Optical Clarity

Acrylic sheets are known for their exceptional clarity, often exceeding that of glass. This property is essential in applications where visibility is paramount, such as in aquariums or retail displays. High optical clarity ensures that the intended aesthetics and functionalities of the product are maintained.

5. Moisture Resistance

Unlike glass, plexiglass is moisture-resistant, making it suitable for use in humid environments or outdoor applications. This property extends the material’s lifespan and reduces the risk of degradation, thus providing better value in long-term applications.

6. UV Resistance

Many acrylic sheets are treated to resist UV rays, preventing yellowing and degradation over time. This is particularly important for outdoor applications where exposure to sunlight is a concern, ensuring that the material retains its transparency and structural integrity.

What Are Common Trade Terms Related to 1/4 Inch Plexiglass 4×8?

Navigating the world of B2B procurement involves understanding specific jargon and terminology. Here are several common terms that are crucial for buyers in the acrylic sheet market.

1. OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of plexiglass, it could relate to companies that fabricate custom acrylic components for larger manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ specifies the smallest number of units a buyer can purchase. Understanding MOQ is essential for B2B buyers as it affects inventory management and cost structure, especially when dealing with custom sizes or configurations.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for a specific quantity of goods. For 1/4 inch plexiglass, an RFQ allows buyers to compare prices and terms from multiple suppliers, aiding in informed purchasing decisions.

4. Incoterms (International Commercial Terms)

These are standardized trade terms used in international shipping that define the responsibilities of buyers and sellers. Familiarity with Incoterms is crucial for B2B transactions involving plexiglass, as they outline shipping costs, risk, and delivery responsibilities.

5. Lead Time

This term refers to the time it takes from placing an order to delivery. For products like 1/4 inch plexiglass, understanding lead times is critical for project planning and scheduling, particularly in industries with tight deadlines.

6. Custom Fabrication

This refers to the process of tailoring the plexiglass sheets to specific dimensions and requirements. Knowing about custom fabrication options is important for buyers who need unique sizes or shapes for their applications, ensuring they get the exact product needed for their projects.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when procuring 1/4 inch plexiglass sheets, ensuring that their applications are met with the highest standards of quality and efficiency.

Navigating Market Dynamics and Sourcing Trends in the 1 4 inch plexiglass 4×8 Sector

What Are the Key Market Dynamics and Trends Influencing the 1/4 Inch Plexiglass 4×8 Sector?

The 1/4 inch plexiglass 4×8 market is experiencing a surge driven by several global factors. Firstly, the increasing demand for lightweight, durable materials across diverse industries, including construction, automotive, and retail, is pushing the market forward. Plexiglass is favored for its high impact resistance and clarity, making it a popular choice for applications ranging from glazing to protective barriers in commercial spaces.

Emerging technologies in manufacturing, particularly advancements in laser cutting and CNC machining, have enabled more precise customization of plexiglass products. This trend is critical for international B2B buyers who seek tailored solutions to meet specific project requirements. Additionally, the rise of e-commerce platforms is transforming how businesses source materials, offering greater access to suppliers worldwide. In regions like Africa, South America, the Middle East, and Europe, companies are increasingly leveraging online platforms to procure materials, ensuring competitive pricing and faster delivery times.

Another significant trend is the growing emphasis on sustainability and eco-friendly practices. As consumers become more environmentally conscious, businesses are aligning their sourcing strategies with sustainable practices, which in turn influences their choice of materials. This shift is not only a response to consumer demand but also a proactive measure to comply with increasingly stringent regulations regarding environmental impact.

How Important Is Sustainability and Ethical Sourcing in the 1/4 Inch Plexiglass 4×8 Market?

Sustainability is becoming a cornerstone of sourcing strategies in the B2B plexiglass sector. The environmental impact of manufacturing processes and materials is under scrutiny, prompting buyers to consider the lifecycle of the products they procure. For instance, 1/4 inch plexiglass can be produced using recycled materials, thereby reducing waste and energy consumption.

Ethical sourcing has gained traction as businesses recognize the importance of transparency in their supply chains. Buyers are increasingly looking for suppliers who adhere to ‘green’ certifications, ensuring that the materials they source are produced responsibly. Certifications such as ISO 14001 for environmental management systems or the Forest Stewardship Council (FSC) certification for sustainable forestry are becoming essential criteria for procurement decisions.

Moreover, the demand for plexiglass as a protective barrier in public spaces, particularly in the wake of the COVID-19 pandemic, has highlighted the importance of sourcing materials that not only meet safety standards but are also environmentally friendly. This shift towards ethical sourcing and sustainable practices is expected to shape the future of the plexiglass market, influencing everything from product design to supplier selection.

How Has the 1/4 Inch Plexiglass 4×8 Sector Evolved Over Time?

The evolution of the 1/4 inch plexiglass 4×8 sector can be traced back to the introduction of acrylic materials in the mid-20th century. Initially developed as a lightweight and shatter-resistant alternative to glass, plexiglass quickly found applications in numerous fields, including signage, display cases, and protective barriers.

Over the years, advancements in manufacturing technologies have enhanced the properties of plexiglass, making it more versatile and accessible. The shift from traditional glass to plexiglass in various applications has been fueled by its superior impact resistance and ease of fabrication. Today, suppliers offer a range of options, including custom sizes and thicknesses, catering to the specific needs of international B2B buyers.

In recent years, the focus on sustainability and environmental responsibility has further transformed the sector. As businesses seek to minimize their carbon footprint, the demand for eco-friendly plexiglass options has surged, leading to innovations in production processes and materials. This ongoing evolution is set to continue, shaping the landscape of the 1/4 inch plexiglass 4×8 market for years to come.

Frequently Asked Questions (FAQs) for B2B Buyers of 1 4 inch plexiglass 4×8

-

1. How do I ensure the quality of 1/4 inch plexiglass before purchasing?

To ensure quality, request samples from potential suppliers to assess optical clarity, thickness consistency, and impact resistance. Look for certifications that indicate compliance with industry standards, such as ASTM or ISO. Furthermore, inquire about the supplier’s manufacturing processes and quality control measures, as well as customer reviews or testimonials. Establishing a clear communication channel with suppliers will help you address any concerns regarding quality before finalizing your order. -

2. What are the most common applications for 1/4 inch plexiglass sheets?

1/4 inch plexiglass sheets are widely used in various applications due to their strength and clarity. Common uses include windows, display cases, and protective barriers in retail environments. They are also ideal for crafting projects, aquariums, and signage. Due to their impact resistance, these sheets serve well as a glass replacement in areas prone to shattering, such as storm windows or garage door windows. -

3. What customization options are available for 1/4 inch plexiglass sheets?

Most suppliers offer customization options such as cut-to-size sheets, drilled holes, and specific edge finishes. You can specify dimensions, shapes, and additional features like UV protection or color tinting. When discussing customization, provide detailed specifications to ensure that the final product meets your exact needs. It’s advisable to confirm lead times for custom orders, as they may differ from standard products. -

4. What is the minimum order quantity (MOQ) for 1/4 inch plexiglass sheets?

The MOQ for 1/4 inch plexiglass sheets can vary significantly between suppliers. Some may offer flexible options for smaller orders, while others might require bulk purchases to ensure cost-effectiveness. When sourcing internationally, it’s essential to clarify the MOQ during initial discussions to avoid unexpected costs and to determine if the supplier can accommodate your specific requirements. -

5. How do I verify the credibility of a plexiglass supplier in international markets?

To verify a supplier’s credibility, conduct thorough research that includes checking their business licenses, certifications, and industry reputation. Utilize platforms like Alibaba or Global Sources to view ratings and reviews from previous customers. Additionally, consider requesting references or connecting with industry contacts who have experience with the supplier. Engaging in a video call can also help assess their operations and build trust. -

6. What payment terms should I expect when purchasing 1/4 inch plexiglass internationally?

Payment terms can vary widely based on the supplier and transaction size. Common options include upfront payment, partial payment upon order confirmation, and balance due upon delivery. For larger orders, you might negotiate net payment terms or letters of credit for added security. Always review payment terms carefully and consider using escrow services for additional protection, especially in international transactions. -

7. What logistics considerations should I keep in mind when importing plexiglass?

Logistics for importing plexiglass involve understanding shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder familiar with handling acrylic materials to ensure safe transport. Confirm the supplier’s ability to provide necessary documentation, such as bills of lading and commercial invoices, to facilitate customs clearance. Additionally, factor in lead times for both production and shipping to align with your project schedules. -

8. How can I handle potential issues during the import process of plexiglass sheets?

To handle potential issues during the import process, maintain open communication with your supplier and logistics provider. Ensure you have a clear understanding of the shipping timeline and be proactive in addressing any delays. Familiarize yourself with your country’s import regulations to mitigate customs-related challenges. In case of discrepancies or damages, document the issue thoroughly and reach out to the supplier promptly to discuss resolutions, such as replacements or refunds.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 1 4 Inch Plexiglass 4X8 Manufacturers & Suppliers List

1. Shapes Plastics – 1/4 Clear Cast Acrylic Sheet

Domain: shapesplastics.com

Registered: 2019 (6 years)

Introduction: {“product_name”: “1/4\” Clear Cast Acrylic Sheet”, “dimensions”: “48\” x 96\””, “price”: “$134.95”, “bulk_pricing”: [{“quantity”: 2, “price”: “$128.20”}, {“quantity”: 5, “price”: “$121.46”}, {“quantity”: 10, “price”: “$114.71”}], “material_type”: “Acrylic/Plexiglass”, “features”: [“lightweight”, “impact-resistant”, “transparent”, “high impact strength”], “applications”: [“storm windows”, “garage d…

2. Acme Plastics – Acrylic Sheets 4’x 8′

Domain: acmeplastics.com

Registered: 1997 (28 years)

Introduction: Acrylic Sheets 4’x 8′ | 48″ x 96″ | Available in various types including Acrylic Cast Clear Sheet, Acrylic Extruded Clear Sheet, Acrylic P95 Sheets, Acrylic Non-Glare Sheet, Lucite L Clear Sheet, Acrylic Bullet Resistant Sheet, Acrylic Mirror Sheet, Acrylic Cast Color Sheet, Acrylic Cast White Sheet, Recycled Acrylic Clear Sheet, and Glowforge®-Compatible Acrylic Sheets. Custom sizes available for…

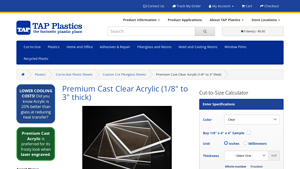

3. Tap Plastics – Acrylic Sheets

Domain: tapplastics.com

Registered: 1999 (26 years)

Introduction: Acrylic Sheets – Cast Clear, available in various sizes, offers high clarity and excellent optical properties. It is lightweight, shatter-resistant, and easy to fabricate. Ideal for a range of applications including displays, signage, and protective barriers.

Strategic Sourcing Conclusion and Outlook for 1 4 inch plexiglass 4×8

In summary, strategic sourcing of 1/4 inch plexiglass 4×8 sheets offers significant advantages for international B2B buyers, including cost-effectiveness, versatility, and enhanced performance compared to traditional glass. The competitive pricing structures provided by suppliers, especially for bulk orders, allow businesses to maximize value while minimizing expenses. Moreover, the lightweight yet durable nature of plexiglass makes it an ideal choice for a variety of applications, ranging from construction and manufacturing to retail and healthcare.

As global markets continue to evolve, staying informed about sourcing strategies will be crucial for businesses aiming to leverage the benefits of acrylic materials. Buyers in regions such as Africa, South America, the Middle East, and Europe should consider building long-term relationships with reliable suppliers who can offer tailored solutions and support.

Looking ahead, the demand for innovative and sustainable materials like plexiglass is set to grow. Companies are encouraged to actively engage with suppliers, explore custom fabrication options, and capitalize on emerging market trends. By doing so, they can position themselves advantageously in a competitive landscape and ensure they meet their operational needs effectively.