How to Source Mg Zn Moulding Prices Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for mg zn moulding prices

In today’s competitive global landscape, sourcing magnesium zinc (Mg Zn) moulding prices can pose significant challenges for international B2B buyers. The complexity of pricing structures, coupled with varying supplier capabilities and regional market fluctuations, makes it essential for companies to navigate these waters with precision. This guide serves as a comprehensive resource for understanding the diverse types of Mg Zn mouldings, their applications across industries, and the critical factors influencing pricing.

From die casting to custom alloy specifications, we delve into the nuances of product attributes that can impact cost-effectiveness and performance. Buyers from Africa, South America, the Middle East, and Europe—particularly Germany and Saudi Arabia—will find actionable insights on how to vet suppliers effectively, ensuring they partner with those who meet stringent quality and reliability standards.

Moreover, this guide provides clarity on bulk discount opportunities, minimum order quantities, and delivery timelines, empowering businesses to make informed purchasing decisions. By leveraging this knowledge, B2B buyers can optimize their procurement strategies, reduce costs, and enhance their competitive advantage in their respective markets. Whether you are a seasoned buyer or new to the Mg Zn moulding sector, this resource is designed to equip you with the essential tools for successful sourcing and strategic partnership development.

Understanding mg zn moulding prices Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Die Casting Moulds | High precision, lightweight, corrosion-resistant | Automotive parts, electronics, consumer goods | Pros: High accuracy; Cons: Higher initial cost |

| Injection Moulding | Customizable shapes and sizes, suitable for mass production | Household items, medical devices, packaging | Pros: Cost-effective for large runs; Cons: Longer setup time |

| Master Alloys | Enhances mechanical properties, available in various forms | Aerospace components, military applications | Pros: Improves material performance; Cons: May require specialized handling |

| CNC Machining Moulds | High precision, complex geometries, rapid prototyping | Industrial machinery, custom tooling | Pros: Versatile; Cons: Slower production rate |

| Custom Moulds | Tailored specifications, flexible designs | Specialized industrial applications, prototypes | Pros: Meets specific needs; Cons: Potentially higher costs |

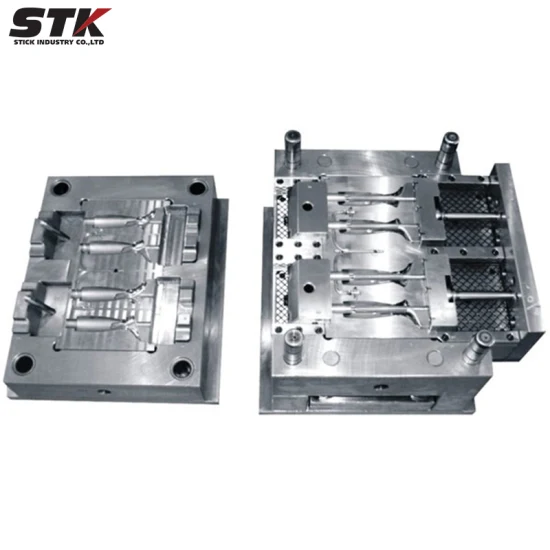

What Are the Key Characteristics of Die Casting Moulds?

Die casting moulds are primarily recognized for their high precision and lightweight nature. These moulds are often made from magnesium-zinc alloys, which provide excellent corrosion resistance. They are widely used in the automotive and electronics sectors, where the need for durable and lightweight components is critical. Buyers should consider the initial investment, as die casting can be more expensive upfront but offers long-term durability and performance.

How Does Injection Moulding Differ from Other Types?

Injection moulding stands out for its ability to produce complex shapes and sizes, making it ideal for mass production. This process allows for a high degree of customization, which is essential for industries such as packaging and medical devices. While it can be cost-effective for large production runs, buyers must account for longer setup times and potential tooling costs, which can impact overall project timelines.

Why Are Master Alloys Important in B2B Applications?

Master alloys, such as magnesium-zinc, play a crucial role in enhancing the mechanical properties of base materials. They are commonly used in aerospace and military applications where strength and durability are paramount. While they improve performance significantly, buyers should be aware of the specialized handling and storage requirements that may add to operational costs.

What Advantages Do CNC Machining Moulds Offer?

CNC machining moulds provide high precision and the ability to create complex geometries, making them suitable for rapid prototyping and production of industrial machinery components. This method allows for flexibility in design, accommodating unique specifications. However, the production rate can be slower compared to other methods, which may affect project timelines and costs.

How Can Custom Moulds Meet Specific Business Needs?

Custom moulds are designed to meet the unique specifications of various industrial applications, making them an excellent choice for companies requiring specialized solutions. Their flexibility in design allows businesses to innovate and create tailored products. While they can be more expensive than standard options, the ability to meet precise requirements often justifies the investment, especially in competitive markets.

Key Industrial Applications of mg zn moulding prices

| Industry/Sector | Specific Application of mg zn moulding prices | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Precision components for lightweight vehicle parts | Reduces vehicle weight, enhancing fuel efficiency and performance | Supplier reliability, certifications, and compliance with automotive standards |

| Aerospace | Structural components for aircraft and spacecraft | High strength-to-weight ratio, critical for safety and efficiency | Quality assurance processes, material traceability, and delivery timelines |

| Electronics | Enclosures and housings for electronic devices | Provides durability and corrosion resistance, extending product life | Customization options, precision machining capabilities, and MOQ flexibility |

| Construction & Infrastructure | Formwork and molds for concrete applications | Enhances structural integrity and reduces overall construction time | Custom designs, compatibility with local building codes, and material sourcing |

| Medical Devices | Components for medical equipment and devices | Ensures compliance with stringent health regulations and reliability | Regulatory compliance, biocompatibility testing, and precision manufacturing capabilities |

How Is ‘mg zn moulding prices’ Used in the Automotive Industry?

In the automotive sector, magnesium-zinc (Mg-Zn) alloys are crucial for manufacturing precision components such as brackets, housings, and structural parts. These alloys offer a lightweight alternative to traditional materials, significantly enhancing fuel efficiency and performance. International buyers, especially from regions like Europe and South America, should prioritize suppliers that meet automotive standards and can provide certifications to ensure product quality and safety.

What Role Do ‘mg zn moulding prices’ Play in Aerospace Applications?

Aerospace manufacturers utilize Mg-Zn alloys for their structural components due to their high strength-to-weight ratio. This is essential for ensuring the safety and efficiency of aircraft and spacecraft. Buyers from the Middle East and Africa must focus on suppliers with stringent quality assurance processes and the ability to provide material traceability, as these factors are critical in the aerospace industry.

How Are ‘mg zn moulding prices’ Applied in Electronics Manufacturing?

In the electronics industry, Mg-Zn alloys are often used for enclosures and housings that require durability and corrosion resistance. This application extends the lifespan of electronic devices, making them more reliable for consumers. B2B buyers should seek suppliers that offer customization options and precision machining capabilities to meet specific design requirements while ensuring competitive pricing.

Why Are ‘mg zn moulding prices’ Important in Construction and Infrastructure?

In construction, Mg-Zn alloys are utilized to create molds and formwork for concrete applications. The use of these alloys enhances the structural integrity of buildings and reduces construction time significantly. Buyers, particularly from Africa and South America, should consider sourcing from manufacturers that can provide custom designs and comply with local building codes to ensure the effectiveness of their applications.

What Benefits Do ‘mg zn moulding prices’ Offer in Medical Devices?

In the medical device sector, Mg-Zn alloys are employed in the production of various components, ensuring compliance with stringent health regulations. The reliability and biocompatibility of these materials are vital for medical applications. International buyers must focus on suppliers that have proven expertise in regulatory compliance and can deliver high-precision manufacturing capabilities to meet the demands of the healthcare industry.

3 Common User Pain Points for ‘mg zn moulding prices’ & Their Solutions

Scenario 1: Navigating Price Variability in Mg Zn Moulding

The Problem: B2B buyers often face challenges with fluctuating prices for magnesium zinc (Mg Zn) moulding products. This variability can stem from several factors, including raw material costs, supplier pricing strategies, and market demand. For buyers in regions like Africa and South America, where budgets may be tight, unexpected price hikes can lead to project delays or reduced profit margins, complicating budget forecasting and planning.

The Solution: To effectively manage price variability, buyers should adopt a multi-supplier sourcing strategy. By engaging with multiple suppliers, buyers can compare prices regularly and establish relationships that offer better terms. Consider leveraging digital platforms that aggregate supplier pricing and allow for real-time comparisons. Establishing long-term contracts with fixed pricing or price caps can also help mitigate the impact of market fluctuations. Additionally, staying informed about global market trends related to magnesium and zinc can aid in anticipating price changes, allowing buyers to make more informed purchasing decisions.

Scenario 2: Ensuring Quality Amidst Competitive Pricing

The Problem: In the pursuit of lower prices, B2B buyers may compromise on the quality of Mg Zn moulding products. This is particularly concerning in industries such as automotive or aerospace, where precision and durability are paramount. Buyers may find themselves receiving subpar products that do not meet their specifications, leading to costly rework, production delays, and potential damage to their business reputation.

The Solution: Buyers should prioritize quality assurance by focusing on verified suppliers with proven track records. Requesting samples before placing bulk orders is crucial; this allows for an evaluation of the material’s performance and adherence to specifications. Implementing a comprehensive quality control process that includes third-party inspections can further ensure that products meet required standards. Additionally, engaging in open communication with suppliers about quality expectations and performance metrics can foster a partnership focused on maintaining high standards, thus balancing cost with quality effectively.

Scenario 3: Customization Challenges in Mg Zn Moulding

The Problem: B2B buyers often encounter difficulties when seeking customized Mg Zn moulding solutions tailored to specific project requirements. Many suppliers may not offer sufficient customization options or may impose high minimum order quantities (MOQs), making it hard for buyers with unique needs to find suitable products without incurring unnecessary costs.

The Solution: To address customization challenges, buyers should clearly outline their specifications and seek suppliers that specialize in custom solutions. Engaging with manufacturers that offer flexible MOQs can provide access to tailored products without the burden of excessive inventory costs. Utilizing platforms that connect buyers with a wide range of manufacturers can simplify the search for customizable options. Additionally, fostering collaborative relationships with suppliers can lead to innovative solutions that meet specific needs while maintaining cost-effectiveness. Buyers should also consider participating in industry trade shows or forums to discover new suppliers and technologies that can accommodate unique requirements.

Strategic Material Selection Guide for mg zn moulding prices

What Are the Key Properties of Common Materials Used in Mg Zn Moulding?

When considering materials for magnesium zinc (Mg Zn) moulding, several options stand out due to their unique properties and suitability for various applications. The most common materials include Mg-Zn alloys, aluminum alloys, zinc alloys, and custom composite materials. Each material presents distinct advantages and disadvantages that can significantly impact both manufacturing processes and end-product performance.

Mg-Zn Alloys: A Strong Choice for High-Performance Applications

Mg-Zn alloys, such as MgZn20, MgZn25, and MgZn30, are known for their high strength-to-weight ratio, excellent corrosion resistance, and good machinability. These alloys perform well under high temperatures and pressures, making them suitable for demanding applications in automotive and aerospace sectors.

Pros: The primary advantage of Mg-Zn alloys is their lightweight nature combined with high strength, which is crucial for applications where weight reduction is a priority. They also exhibit good fatigue resistance, enhancing their longevity in dynamic environments.

Cons: However, Mg-Zn alloys can be more expensive than traditional materials, and their manufacturing complexity may increase costs. Additionally, they may require specific surface treatments to enhance corrosion resistance further.

Impact on Application: These alloys are particularly compatible with environments that involve exposure to moisture and chemicals, making them ideal for automotive components and marine applications.

Considerations for International Buyers: Buyers from regions such as Europe and the Middle East should ensure compliance with relevant standards, such as ASTM or DIN, particularly for aerospace applications where safety is paramount.

Aluminum Alloys: Versatile and Cost-Effective

Aluminum alloys are another popular choice for moulding due to their versatility and relatively low cost. They offer good corrosion resistance and can be easily machined and formed into various shapes.

Pros: The primary advantage of aluminum alloys is their affordability and ease of availability. They also provide excellent thermal and electrical conductivity, making them suitable for electronic components.

Cons: On the downside, aluminum alloys generally have lower strength compared to Mg-Zn alloys. They may also require additional coatings for enhanced corrosion resistance, especially in harsh environments.

Impact on Application: Aluminum alloys are widely used in construction, automotive, and consumer goods, where weight savings and cost efficiency are critical.

Considerations for International Buyers: Buyers should be aware of the specific alloy grades that meet their local standards and regulations, such as JIS in Japan or EN in Europe.

Zinc Alloys: Cost-Effective with Good Casting Properties

Zinc alloys are often used in die casting due to their excellent fluidity and ability to fill intricate moulds. They are particularly effective in producing complex shapes with high dimensional accuracy.

Pros: The key advantage of zinc alloys is their low melting point, which allows for faster production cycles and reduced energy costs during manufacturing. They also provide good corrosion resistance and can be plated for enhanced aesthetics.

Cons: However, zinc alloys may not be suitable for high-temperature applications, as they can lose strength under heat. Their mechanical properties may also be inferior to those of Mg-Zn alloys.

Impact on Application: Zinc alloys are commonly used in automotive parts, household goods, and decorative items, where intricate designs and cost-effectiveness are essential.

Considerations for International Buyers: Buyers should consider the specific casting standards applicable in their regions and ensure that the zinc alloys meet industry requirements.

Custom Composite Materials: Tailored Solutions for Specific Needs

Custom composite materials, which can include various combinations of metals and polymers, offer unique properties tailored to specific applications. They can be engineered to enhance strength, reduce weight, or improve corrosion resistance.

Pros: The main advantage of custom composites is their flexibility in design and performance characteristics. They can be optimized for specific applications, providing a competitive edge in niche markets.

Cons: The complexity of manufacturing custom composites can lead to higher costs and longer lead times. Additionally, ensuring quality control across different batches can be challenging.

Impact on Application: Custom composites are ideal for specialized applications in industries such as aerospace, where performance requirements are stringent.

Considerations for International Buyers: Buyers should verify that custom composites comply with international standards and certifications relevant to their industry.

Summary Table of Material Properties and Considerations

| Material | Typical Use Case for mg zn moulding prices | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mg-Zn Alloys | Automotive and aerospace components | High strength-to-weight ratio | Higher cost and manufacturing complexity | High |

| Aluminum Alloys | Construction and consumer goods | Cost-effective and versatile | Lower strength compared to Mg-Zn alloys | Medium |

| Zinc Alloys | Die casting for automotive and decor items | Good fluidity and fast production | Not suitable for high-temperature applications | Low |

| Custom Composites | Specialized aerospace applications | Tailored performance characteristics | Higher costs and longer lead times | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on performance, cost, and compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for mg zn moulding prices

What Are the Main Stages of Manufacturing Mg Zn Moulding?

Manufacturing magnesium-zinc (Mg-Zn) mouldings involves several crucial stages, each designed to ensure high-quality outcomes that meet industry standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in the manufacturing process is selecting and preparing the raw materials. For Mg-Zn mouldings, high-purity magnesium and zinc are typically used. These metals are sourced from verified suppliers to ensure quality. Before processing, materials undergo a quality check to verify their chemical composition and physical properties. This step is vital, as impurities can lead to defects in the final product.

-

Forming: Forming is where the actual shaping of the moulding occurs. This can be done through various techniques such as die casting, injection moulding, or CNC machining. In die casting, molten Mg-Zn alloy is poured into a mould under high pressure, allowing for high precision and complex geometries. Injection moulding involves injecting the molten alloy into a mould cavity, which is often used for producing larger quantities. The choice of technique depends on the required specifications, including dimensions and tolerances.

-

Assembly: In many cases, the moulded parts require assembly with other components. This may involve processes like welding, fastening, or adhesive bonding. Quality control during assembly is essential to ensure that all parts fit correctly and function as intended.

-

Finishing: The final stage involves surface treatment and finishing. This can include processes such as polishing, anodizing, or applying protective coatings. The finishing stage not only enhances the aesthetic appeal but also improves the corrosion resistance and overall durability of the mouldings. It is important to adhere to specific finishing standards required by different industries, such as automotive or electronics.

What Key Techniques Are Used in Mg Zn Moulding Manufacturing?

Several advanced techniques are employed in the manufacturing of Mg-Zn mouldings to ensure precision and quality.

-

Die Casting: This technique is favored for its ability to produce complex shapes with high dimensional accuracy. The process involves forcing molten metal into a mould cavity at high pressure, which allows for rapid production and excellent surface finish.

-

CNC Machining: CNC (Computer Numerical Control) machining is used for parts that require tight tolerances and intricate designs. This technique uses automated tools to precisely cut and shape the material according to pre-programmed specifications.

-

Injection Moulding: Particularly useful for producing large volumes of smaller parts, injection moulding allows for quick cycle times and consistent quality. The process involves heating the material until it melts and injecting it into a mould.

How Is Quality Assurance Implemented in Mg Zn Moulding Production?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that the final products meet both international and industry-specific standards.

-

International Standards: Many manufacturers adhere to ISO 9001, an international standard that specifies requirements for a quality management system (QMS). Compliance with ISO 9001 demonstrates a commitment to consistent quality and customer satisfaction.

-

Industry-Specific Certifications: Depending on the application, additional certifications may be required. For example, CE marking is crucial for products sold in the European market, while API (American Petroleum Institute) standards may apply for components used in the oil and gas industry.

What Are the Key Quality Control Checkpoints in Mg Zn Moulding?

Quality control involves multiple checkpoints throughout the manufacturing process to identify and rectify potential issues.

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon delivery. Suppliers must provide certificates of analysis to confirm that materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor production parameters. This includes checking temperature, pressure, and timing during forming processes to ensure they remain within specified limits.

-

Final Quality Control (FQC): Once production is complete, the final products undergo rigorous testing. This may include dimensional checks, mechanical property tests, and surface inspections. Any deviations from specifications are addressed before products are shipped.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to mitigate risks.

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s production processes, quality control measures, and compliance with international standards. This firsthand evaluation can uncover potential issues that may not be evident through documentation alone.

-

Quality Control Reports: Suppliers should provide detailed reports on their quality assurance processes, including results from IQC, IPQC, and FQC. These reports should include data on defects, corrective actions taken, and overall quality performance.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspectors can conduct random checks and provide certifications that assure buyers of the supplier’s compliance with relevant standards.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

When sourcing Mg-Zn mouldings, international buyers must be aware of specific nuances that can affect quality control.

-

Regional Regulations: Different regions may have varying regulations regarding materials and manufacturing processes. Buyers should ensure that suppliers are compliant with local regulations in their target market.

-

Cultural Factors: Understanding cultural differences can also impact quality expectations. For example, communication styles and approaches to quality may vary significantly between regions, influencing how quality control is perceived and implemented.

-

Logistical Considerations: The supply chain’s complexity can also affect product quality. Buyers should consider how transportation and storage conditions might impact the integrity of materials and finished products.

In conclusion, the manufacturing processes and quality assurance measures for Mg-Zn mouldings are integral to ensuring high-quality products that meet international standards. By understanding these processes and implementing robust verification strategies, B2B buyers can make informed decisions and establish successful partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mg zn moulding prices’

To assist international B2B buyers in procuring magnesium-zinc (Mg-Zn) moulding products effectively, this guide provides a structured approach for navigating the complexities of sourcing. The following checklist outlines critical steps to ensure a successful procurement process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital before initiating the sourcing process. This includes determining the desired alloy composition (e.g., MgZn20, MgZn25, MgZn30), as well as mechanical properties like strength, corrosion resistance, and heat resistance. Clarity in specifications helps suppliers provide accurate quotes and ensures that the products meet your production requirements.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in Mg-Zn moulding. Utilize online platforms, trade directories, and industry associations to compile a list of potential vendors. Focus on suppliers with a proven track record and extensive experience, particularly those with positive reviews and a history of serving your target market (Africa, South America, the Middle East, and Europe).

Step 3: Evaluate Supplier Certifications and Quality Standards

Before proceeding, verify that suppliers possess the necessary certifications and adhere to quality standards relevant to your industry. Look for ISO certifications or specific industry-related accreditations that demonstrate compliance with international manufacturing practices. This step is crucial to ensuring that the products will meet safety and quality requirements.

Step 4: Request Detailed Quotations

Once potential suppliers are shortlisted, request detailed quotations that include unit prices, minimum order quantities (MOQ), and lead times. Pay attention to bulk discount options and the flexibility of order sizes. A comprehensive quotation will allow for better comparison and negotiation, ensuring you receive the best possible pricing for your order.

Step 5: Assess Customization Capabilities

Depending on your specific needs, assess whether suppliers can accommodate customization in terms of size, shape, and surface finish of the Mg-Zn moulds. Customization capabilities can significantly impact the performance and integration of the moulds into your production processes. Inquire about past projects to gauge their expertise in custom solutions.

Step 6: Conduct Due Diligence on Supplier Reliability

Engage in due diligence by checking supplier references and seeking feedback from other businesses within your industry. This step will provide insights into their reliability, delivery timelines, and customer service. Use platforms like LinkedIn or industry forums to connect with previous customers for honest reviews.

Step 7: Negotiate Terms and Finalize Agreements

Once a suitable supplier is identified, enter negotiations to finalize terms of the agreement, including payment terms, delivery schedules, and warranty conditions. Clear communication at this stage is essential to avoid misunderstandings and ensure that both parties are aligned on expectations. Document all agreements to protect your interests.

By following these steps, B2B buyers can navigate the complexities of sourcing Mg-Zn moulding products effectively, ensuring that they select the right suppliers to meet their production needs.

Comprehensive Cost and Pricing Analysis for mg zn moulding prices Sourcing

What Are the Key Cost Components in Mg Zn Moulding Prices?

When evaluating the cost structure of magnesium zinc (Mg Zn) moulding, several critical components contribute to the final pricing.

-

Materials: The primary materials involved are magnesium and zinc, which are often sourced in bulk. Prices fluctuate based on market demand and availability. For instance, standard alloys like MgZn20, MgZn25, and MgZn30 may have different costs due to their unique compositions and processing requirements.

-

Labor: Labor costs can vary significantly depending on the region and the level of expertise required for skilled labor in die casting and injection moulding processes. Countries with higher labor costs may reflect this in the overall price.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility expenses. Efficient manufacturing processes can help lower these overhead costs, which can be a point of negotiation for buyers.

-

Tooling: Custom tooling can be a substantial initial investment, especially for unique mould designs. The complexity of the mould will directly influence the tooling costs, which are amortized over the volume of production.

-

Quality Control (QC): Rigorous quality checks are essential, especially in industries requiring high precision and durability. The cost of QC can vary based on the certifications and standards the supplier adheres to.

-

Logistics: Shipping costs, including customs duties and freight charges, can significantly impact the final price, especially for international buyers. The choice of Incoterms can influence responsibility for these costs.

-

Margin: Suppliers typically add a profit margin that varies based on their market position, competition, and the perceived value of their products.

How Do Volume and Specifications Impact Mg Zn Moulding Prices?

Volume and specifications play crucial roles in determining pricing.

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQs) that can affect pricing. Larger orders typically yield better unit prices due to economies of scale. For instance, orders exceeding 1,000 units may qualify for significant bulk discounts.

-

Specifications and Customization: Customized products, including specific shapes, sizes, and finishes, usually come at a premium. Buyers should clearly define their specifications to avoid unexpected costs during the manufacturing process.

What Other Factors Influence Mg Zn Moulding Prices for International Buyers?

Several other factors can affect pricing, particularly for international B2B buyers:

-

Quality and Certifications: Products meeting international standards (e.g., ISO certifications) may carry higher costs due to the stringent quality assurance processes involved.

-

Supplier Factors: The supplier’s reputation, experience, and production capacity can influence pricing. Established suppliers with a track record may command higher prices but can offer reliability and consistency.

-

Incoterms: Understanding Incoterms is essential for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost, impacting overall pricing negotiations.

What Are Effective Buyer Tips for Sourcing Mg Zn Moulding?

To maximize cost-efficiency when sourcing Mg Zn mouldings, consider the following strategies:

-

Negotiate Wisely: Engage suppliers in discussions about pricing, especially for larger orders or long-term contracts. Leverage your position as a buyer to negotiate better terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the unit price. Consider logistics, potential tariffs, and the costs associated with quality failures. A lower initial price may lead to higher TCO if the product requires extensive rework or fails to meet performance standards.

-

Research Market Trends: Stay informed about material prices and market trends. Knowledge of the current landscape can provide leverage during negotiations and help in timing your purchases effectively.

Disclaimer on Indicative Prices

Prices for Mg Zn moulding can vary significantly based on the factors outlined above. The figures mentioned in this analysis are indicative and subject to change based on market conditions and supplier negotiations. Always consult multiple suppliers to ensure you receive competitive pricing tailored to your specific needs.

Alternatives Analysis: Comparing mg zn moulding prices With Other Solutions

Exploring Alternative Solutions to Mg Zn Moulding Prices

In the competitive landscape of manufacturing, understanding the various options available for moulding processes is crucial for B2B buyers. While magnesium zinc (Mg Zn) moulding offers unique benefits, other technologies may provide similar or even superior outcomes depending on specific project requirements. This section explores alternatives to Mg Zn moulding prices, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Mg Zn Moulding Prices | Aluminum Moulding | Plastic Injection Moulding |

|---|---|---|---|

| Performance | High strength, lightweight, corrosion-resistant | Good strength, lightweight, moderate corrosion resistance | High versatility, complex shapes, good finish |

| Cost | $0.04 – $550+ per unit | $500 – $3,500 per unit | $1.50 – $5,000 per unit |

| Ease of Implementation | Moderate; requires specific equipment | Moderate; established technology | High; widely available machinery |

| Maintenance | Low; durable finish | Moderate; depends on alloy type | Low; maintenance of machines required |

| Best Use Case | Aerospace, automotive, electronics | Automotive, consumer goods | Consumer products, industrial applications |

In-Depth Analysis of Alternatives

1. Aluminum Moulding

Aluminum moulding is a popular alternative known for its strength-to-weight ratio and good thermal conductivity. While it typically costs between $500 and $3,500 per unit, it offers excellent versatility across various applications, particularly in the automotive and consumer goods sectors. The implementation requires specialized equipment but is generally straightforward. Aluminum’s maintenance needs are moderate, depending on the alloy type used, which can affect corrosion resistance. Buyers seeking a balance between performance and cost may find aluminum moulding a suitable choice.

2. Plastic Injection Moulding

Plastic injection moulding stands out for its ability to produce complex shapes with high precision. The cost varies widely, ranging from $1.50 to $5,000 per unit, influenced by factors such as material choice and complexity. This method is characterized by high ease of implementation due to the availability of equipment and skilled labor, making it a preferred option for mass production. Maintenance is generally low, focused mainly on the machinery. Its best use cases include consumer products and industrial applications, particularly where high-volume production is necessary. However, it may not offer the same strength or heat resistance as Mg Zn moulding.

Conclusion: How to Choose the Right Moulding Solution

Selecting the right moulding solution requires a thorough understanding of specific project needs, including material properties, production volume, and budget constraints. Mg Zn moulding is ideal for applications requiring high strength and lightweight materials, particularly in aerospace and electronics. However, alternatives like aluminum and plastic injection moulding provide viable options that may better suit other applications. By carefully evaluating the performance, cost, and implementation aspects of each solution, B2B buyers can make informed decisions that align with their operational goals and customer demands.

Essential Technical Properties and Trade Terminology for mg zn moulding prices

What Are the Key Technical Properties of Mg Zn Moulding?

When considering magnesium zinc (Mg Zn) moulding, several critical specifications influence pricing, quality, and suitability for applications. Understanding these properties is essential for B2B buyers to make informed purchasing decisions.

-

Material Grade

The grade of Mg Zn alloy, such as MgZn20, MgZn25, or MgZn30, indicates the specific composition and performance characteristics. Higher grades generally offer improved strength and corrosion resistance, making them suitable for demanding applications in automotive, aerospace, and electronics. Selecting the right grade can significantly impact the durability and longevity of the final product. -

Tolerance

Tolerance refers to the permissible limit of variation in dimensions and physical properties of the moulded parts. Tight tolerances are crucial in high-precision industries, as they ensure that components fit and function correctly. A supplier’s ability to meet specified tolerances can affect production efficiency and reduce the need for post-manufacturing adjustments. -

Surface Finish

The surface finish of Mg Zn mouldings can vary from rough to highly polished, influencing both aesthetics and functionality. A smoother finish can enhance corrosion resistance and reduce friction, which is particularly important in mechanical applications. Buyers should specify surface finish requirements to ensure compliance with their product standards. -

Cavity Customization

The ability to customize mould cavities allows for the production of complex shapes and designs tailored to specific applications. This flexibility can reduce material waste and improve production efficiency. Understanding the capabilities of a supplier in this area is vital for meeting unique design specifications. -

Heat Resistance

Mg Zn alloys possess varying degrees of heat resistance, which is a critical factor in applications exposed to high temperatures. Ensuring that the chosen material can withstand operational heat without losing integrity is essential for product reliability and performance. -

Corrosion Resistance

Corrosion resistance is a key property for Mg Zn alloys, especially in harsh environments. Buyers should consider the specific corrosion resistance requirements of their applications to select an appropriate alloy that will maintain performance over time.

What Are Common Trade Terms Used in Mg Zn Moulding Transactions?

Familiarity with industry jargon can streamline communication and negotiations, ensuring clarity in transactions involving Mg Zn moulding.

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products or components that are used in another company’s end products. In the context of Mg Zn moulding, understanding whether a supplier operates as an OEM can help buyers assess the quality and reliability of the components. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity a supplier is willing to sell. This term is crucial for B2B buyers as it affects budgeting and inventory management. Understanding MOQ helps in planning purchases, especially for smaller businesses that may not need large quantities. -

RFQ (Request for Quotation)

An RFQ is a formal document requesting pricing information from suppliers. It typically includes detailed specifications and quantities. Using an RFQ allows buyers to compare offers from multiple suppliers, ensuring they secure the best price and terms. -

Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers. They clarify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand the total cost of procurement and potential liabilities. -

Lead Time

Lead time is the period between placing an order and receiving the goods. Understanding lead times is vital for inventory management and project planning, especially in industries where timely delivery is critical. -

Custom Alloy

A custom alloy refers to a specific formulation of materials designed to meet unique performance characteristics. Buyers may require custom alloys to achieve particular strength, weight, or corrosion resistance in their products, emphasizing the importance of clear communication with suppliers about material specifications.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of Mg Zn moulding prices more effectively, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the mg zn moulding prices Sector

The global market for magnesium zinc (Mg Zn) moulding prices is influenced by several key drivers, including technological advancements, the push for lightweight materials, and increasing demand in various industries such as automotive, aerospace, and consumer goods. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to optimize production costs, they are increasingly turning to magnesium zinc alloys due to their favorable properties, such as high strength-to-weight ratios, corrosion resistance, and versatility in die casting applications.

Emerging trends in sourcing practices highlight the growing importance of digital platforms that facilitate supplier comparisons and bulk discounts. Buyers are leveraging technology to access real-time pricing data, evaluate supplier reliability, and customize orders to meet specific production requirements. Additionally, the rise of Industry 4.0 is reshaping manufacturing processes, with automation and smart manufacturing technologies driving efficiency and reducing lead times. This shift is particularly relevant for B2B buyers looking to enhance their operational agility in an increasingly competitive landscape.

Moreover, the market dynamics are influenced by geopolitical factors and supply chain disruptions. Buyers must remain vigilant regarding fluctuations in raw material prices and the potential impact of trade policies. Strategic partnerships with reliable suppliers who offer customized solutions will be crucial for maintaining a competitive edge in the Mg Zn moulding prices sector.

How Are Sustainability and Ethical Sourcing Affecting B2B Buyers in the Mg Zn Moulding Prices Sector?

Sustainability has emerged as a critical consideration for B2B buyers in the Mg Zn moulding sector. The environmental impact of sourcing practices is under scrutiny, prompting companies to adopt more responsible procurement strategies. Ethical sourcing of materials, including Mg Zn alloys, is becoming a priority, as buyers seek to minimize their carbon footprints and promote sustainable manufacturing processes.

Investing in suppliers who prioritize green certifications and sustainable practices can enhance a company’s reputation and align with consumer demand for environmentally friendly products. Certifications such as ISO 14001 for environmental management and compliance with REACH regulations are increasingly becoming prerequisites for suppliers in this sector. Furthermore, the use of recycled materials in the production of magnesium zinc alloys is gaining traction, as it not only reduces waste but also lowers production costs.

Buyers should actively seek suppliers that demonstrate a commitment to sustainability through transparent supply chains and the use of eco-friendly materials. This not only helps mitigate risks associated with environmental compliance but also fosters long-term relationships with partners who share similar values.

What Is the Historical Context of Mg Zn Moulding Prices and Their Evolution in B2B Markets?

The evolution of magnesium zinc (Mg Zn) moulding prices can be traced back to the early development of lightweight materials in the mid-20th century. Initially, magnesium alloys were primarily used in aerospace applications due to their high strength-to-weight ratio. As industries recognized the benefits of these materials, their application expanded into automotive and consumer products.

Over the decades, advancements in alloying techniques and die casting technologies have significantly improved the performance characteristics of Mg Zn alloys, making them more appealing for a broader range of applications. The introduction of master alloys, such as Mg-Zn, has further optimized the properties of these materials, allowing for enhanced customization based on specific industry needs.

Today, Mg Zn moulding prices reflect a combination of raw material costs, technological advancements, and market demand. This historical context is essential for B2B buyers to understand how sourcing trends have evolved and how they can leverage these developments to secure competitive pricing and superior quality in their production processes.

Frequently Asked Questions (FAQs) for B2B Buyers of mg zn moulding prices

-

How do I determine the right supplier for magnesium zinc moulding?

To find the right supplier for magnesium zinc moulding, assess their experience, certifications, and customer reviews. Look for suppliers with a proven track record in manufacturing high-precision die castings and those who can provide customization options. Additionally, consider their minimum order quantities (MOQ) and delivery timelines. Engaging with suppliers who have been in business for over five years and have a rating of 4.5 stars or higher can further enhance your chances of a successful partnership. -

What factors influence magnesium zinc moulding prices?

Magnesium zinc moulding prices are influenced by several factors, including the alloy composition, production method, and customization requirements. The quantity ordered also plays a significant role, as bulk orders typically attract discounts. Market conditions, such as demand fluctuations and raw material costs, can affect pricing. Lastly, the supplier’s location and shipping logistics can add to the overall cost, especially for international transactions. -

What customization options are available for magnesium zinc moulding?

Most suppliers offer extensive customization options for magnesium zinc moulding, allowing you to specify the size, shape, and surface finish of the moulds. Custom alloy compositions can also be requested to meet specific performance requirements. It’s advisable to communicate your exact needs with potential suppliers early in the negotiation process to ensure they can accommodate your requirements, which may include adjustments to mould materials and cavity designs. -

What are the typical payment terms for magnesium zinc moulding orders?

Payment terms for magnesium zinc moulding orders can vary by supplier but commonly include options such as upfront payment, a deposit followed by balance payment upon delivery, or payment upon receipt of goods. International buyers should confirm whether suppliers accept various payment methods, including letters of credit, PayPal, or bank transfers. It’s also prudent to discuss any potential currency exchange issues, particularly when dealing with suppliers in different regions. -

How can I ensure quality assurance in magnesium zinc moulding?

To ensure quality assurance, request detailed specifications and samples before placing a large order. Look for suppliers who implement strict quality control processes and are willing to provide certifications for their products. Regular audits and inspections can help maintain standards throughout production. Additionally, inquire about the supplier’s return policy and warranty terms, as these can provide further assurance of product quality. -

What are the logistics considerations for importing magnesium zinc moulding?

Logistics considerations include shipping methods, customs regulations, and potential tariffs. International buyers should evaluate the supplier’s experience with export procedures to ensure smooth transactions. It’s important to understand the lead times for production and delivery, as well as the costs associated with shipping, insurance, and handling. Collaborating with a freight forwarder can also help navigate the complexities of international shipping. -

What is the minimum order quantity (MOQ) for magnesium zinc moulding?

The minimum order quantity (MOQ) for magnesium zinc moulding varies among suppliers and can range from as low as one piece to several hundred units. Factors influencing MOQ include the complexity of the mould, production setup costs, and the supplier’s capacity. For first-time buyers or those testing the market, it’s advisable to negotiate with suppliers regarding MOQ to find a balance that meets your needs without incurring excessive costs. -

How do I handle disputes with suppliers regarding magnesium zinc moulding orders?

Handling disputes with suppliers requires clear communication and documentation. Always keep a record of agreements, specifications, and correspondences. If issues arise, initiate a discussion to understand the supplier’s perspective and seek a resolution collaboratively. If the dispute cannot be resolved amicably, consider involving a third-party mediator or referring to the terms outlined in the purchase agreement. Legal advice may be necessary for significant disputes, especially in international transactions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Mg Zn Moulding Prices Manufacturers & Suppliers List

1. Accio – Mg Zn Moulding Prices

Domain: accio.com

Registered: 1997 (28 years)

Introduction: Mg Zn Moulding Prices: Compare Top Suppliers & Bulk Discounts. Key considerations: Unit Price: $0.04 – $550+. Quantity: Product attributes include die casting, high precision, corrosion resistant, lightweight, high strength, heat resistant, non-magnetic, low density, durable finish, and custom alloy options. Select by: Best Selling, MOQ < 5, Verified Supplier, 5+ Years Supplier Exp., Manufacturer …

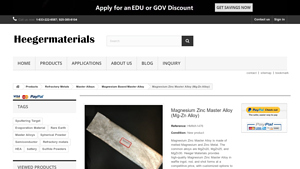

2. Heeger Materials – Magnesium Zinc Master Alloy

Domain: heegermaterials.com

Registered: 2015 (10 years)

Introduction: Product Name: Magnesium Zinc Master Alloy (Mg-Zn Alloy)\nReference: HMMA1476\nCondition: New product\nComposition: Made of melted Magnesium and Zinc Metal\nCommon Alloys: MgZn20, MgZn25, MgZn30\nForms Available: Waffle ingot, rod, shot, and customized options\nMinimum Purchase Order Quantity: 1\nSpecifications: \n- HM-MGZN-1: Balance 20±2% Zn\n- HM-MGZN-2: Balance 25±2% Zn\n- HM-MGZN-3: Balance 30…

3. American Elements – Zinc Magnesium Alloy

Domain: americanelements.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “Zinc Magnesium Alloy”, “Linear Formula”: “Zn/Mg”, “Appearance”: “Gray metallic solid in various forms such as sheets, discs, foils, rods, tubes, ingots”, “Melting Point”: “342 °C”, “Boiling Point”: “N/A”, “Density”: “N/A”, “Solubility in H2O”: “N/A”, “CAS”: “12032-46-1”, “Chemical Identifiers”: {“Pubchem CID”: “11457656”, “IUPAC Name”: “magnesium; zinc”, “SMILES”: “[Mg].[Zn]”, “I…

4. Orange Aluminum – Price Tag Molding

Domain: orangealuminum.com

Registered: 2006 (19 years)

Introduction: {“Product Name”: “Price Tag Molding”, “Width”: “5/32 inch”, “Height”: “11/16 inch”, “Fits”: “5/8 inch Reveal”, “Material”: “6063-T5 Aluminum”, “SKU”: “PTF630625”, “UPC”: “”, “Specification Met”: “ASTM B221-20”, “Yield Strength”: “35k PSI-1”, “Hardness”: “Brinell 55”, “RoHS Compliance”: “RoHS 3 (2015/863/EU)”, “REACH Compliance”: “REACH (EC 1907/2006) (209 SVHC)”, “DFARS Compliance”: “Specialty Met…

5. Advanced Magnesium Technologies – AM-lite Magnesium Alloy

Domain: azom.com

Registered: 1999 (26 years)

Introduction: AM-lite is a new magnesium alloy developed by Advanced Magnesium Technologies as an alternative to zinc, aluminium, AZ91D, and plastic injection mouldings. Key features include: excellent die castability, significant cost advantages, high-quality as-cast surface suitable for decorative finishes, and improved recyclability. Advantages over competitors include: 3x more parts per tonne than zinc, 26%…

6. JSW – Magnesium Injection Molding Machine

Domain: jsw.co.jp

Introduction: Magnesium Injection Molding Machine

– Magnesium is the lightest metal in practical use with atomic number 12.

– Features: rigidity, electromagnetic wave shielding, vibration absorption, dimensional stability.

– Alternatives to: plastic, aluminum, and steel.

– Historical context: Nearly 100 years of production; previously limited use due to corrosion and high costs.

– Recent advancements: Surface t…

7. Bole Machinery – Magnesium Alloy Injection Moulding Equipment

Domain: bolemachinery.com

Registered: 2016 (9 years)

Introduction: Magnesium Alloy Semi-solid Injection Moulding Equipment, 4000T capacity, low density (1.8g/cm3), lightest metal in practical metals, 2/3 the density of aluminum alloy (2.7g/cm3), 1/4 the density of iron, high specific strength and stiffness, good thermal conductivity, electromagnetic shielding.

Strategic Sourcing Conclusion and Outlook for mg zn moulding prices

In navigating the complexities of magnesium zinc (Mg Zn) moulding prices, international B2B buyers must prioritize strategic sourcing to optimize their procurement processes. The diverse range of suppliers, with prices varying from as low as $0.04 to over $5,000 depending on customization and order volume, underscores the importance of thorough market research. Buyers should focus on suppliers with a proven track record, verified ratings, and flexible minimum order quantities to ensure quality and reliability.

Moreover, understanding the intrinsic properties of Mg Zn alloys—such as corrosion resistance, lightweight nature, and high strength—can significantly enhance product offerings and cater to specific industry needs. Engaging with suppliers who offer customizable solutions can yield significant competitive advantages in diverse markets, including those in Africa, South America, the Middle East, and Europe.

Looking ahead, the demand for high-performance materials in various applications is expected to rise. By leveraging strategic sourcing practices, buyers can not only secure favorable pricing but also foster long-term partnerships with suppliers that align with their business objectives. Take action today—explore your options and connect with trusted suppliers to elevate your sourcing strategy and drive innovation in your projects.