How to Source Beyond Garmets Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for beyond garmets

In today’s rapidly evolving global marketplace, sourcing beyond garments—apparel that transcends traditional clothing—presents both opportunities and challenges for international B2B buyers. Whether it’s technical outerwear for extreme environments or sustainable fashion solutions, the diverse landscape of beyond garments requires strategic navigation to identify quality suppliers and innovative products. This guide aims to equip buyers from Africa, South America, the Middle East, and Europe, including key markets like Nigeria and Saudi Arabia, with the essential knowledge to make informed purchasing decisions.

Throughout this comprehensive resource, we will delve into various types of beyond garments, explore their applications across different industries, and provide valuable insights on supplier vetting processes. Additionally, we will discuss cost considerations and market trends that can impact sourcing decisions. By empowering B2B buyers with actionable insights and industry best practices, this guide serves as a crucial tool in overcoming the challenges of sourcing high-quality beyond garments.

With the right knowledge and strategies, buyers can not only enhance their product offerings but also establish robust partnerships with reliable suppliers, ensuring a competitive edge in the dynamic global apparel market.

Understanding beyond garmets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Suits | Tailored formal wear, typically made from high-quality fabrics. | Corporate attire, formal events | Pros: Professional appearance, high demand. Cons: Higher cost, requires careful sizing. |

| Jackets | Versatile outerwear, available in various styles and materials. | Casual wear, outdoor activities | Pros: Wide variety, suitable for different climates. Cons: Seasonal demand fluctuations. |

| Uniforms | Customizable attire for specific industries or companies. | Corporate branding, service industries | Pros: Enhances brand visibility, promotes team unity. Cons: Initial investment in customization. |

| Activewear | Functional clothing designed for physical activities, often with moisture-wicking properties. | Sports teams, fitness centers | Pros: Growing market, promotes health and wellness. Cons: Competitive pricing, requires trend awareness. |

| Workwear | Durable clothing designed for labor-intensive jobs, often safety compliant. | Construction, manufacturing sectors | Pros: High durability, essential for safety. Cons: Limited style options, may require bulk purchases. |

What Are the Characteristics and Suitability of Suits in B2B Purchasing?

Suits are integral to corporate attire, characterized by their tailored fit and high-quality fabrics, often made from wool or blends. They are suitable for businesses in sectors requiring formal dress codes, such as finance, law, and high-level corporate events. When purchasing suits, buyers should consider fabric quality, tailoring options, and customization for branding. The investment in suits can yield high returns through enhanced professional appearance and employee confidence.

How Do Jackets Serve Various B2B Applications?

Jackets are a versatile clothing type, ranging from casual to formal styles and available in multiple materials such as denim, leather, and synthetic fabrics. They cater to various applications, including corporate casual wear and outdoor events. B2B buyers should focus on seasonal trends and the specific needs of their target market. While jackets can attract a broad audience, fluctuating demand based on seasons may influence purchasing decisions.

Why Are Uniforms Important for Branding in B2B?

Uniforms provide a unique opportunity for companies to enhance their brand visibility and promote a sense of unity among employees. They are customizable, allowing businesses to incorporate logos and colors that reflect their brand identity. Uniforms find applications in service industries, healthcare, and hospitality. Buyers must weigh the initial investment against long-term branding benefits, ensuring that the uniforms align with the company’s image and employee comfort.

What Makes Activewear a Growing Market in B2B?

Activewear is designed for functionality, incorporating features like moisture-wicking and stretchable fabrics suitable for physical activities. This type of clothing is increasingly popular among sports teams and fitness centers, making it a lucrative market for B2B buyers. When considering activewear, it is crucial to stay updated on trends and consumer preferences. While activewear presents a growing opportunity, buyers must navigate competitive pricing and quality differentiation.

How Does Workwear Ensure Safety in Labor-Intensive Industries?

Workwear is specifically designed for durability and safety in demanding environments, such as construction and manufacturing. These garments often meet safety compliance standards, making them essential for protecting workers. B2B buyers should focus on the material’s resilience and the garment’s compliance with industry regulations. Although workwear may have limited style options, the focus on safety and functionality makes it a necessary investment for businesses in high-risk sectors.

Key Industrial Applications of beyond garmets

| Industry/Sector | Specific Application of Beyond Garments | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Custom Apparel Production | Tailored clothing solutions that enhance brand identity | Quality control, lead times, and compliance with local regulations |

| Defense and Military | Tactical and Operational Clothing | Durable and functional gear that meets extreme conditions | Material specifications, certification standards, and supply chain reliability |

| Corporate Uniforms | Professional Workwear | Improved employee branding and morale through uniformity | Customization options, comfort, and durability of materials |

| Sports and Outdoor Gear | Performance-Enhancing Clothing | Enhanced functionality and comfort for athletes | Technical specifications, moisture-wicking properties, and environmental sustainability |

| Hospitality and Events | Event-Specific Attire | Strengthens brand image through cohesive staff appearance | Design flexibility, fabric quality, and scalability for large orders |

How is Beyond Garments Utilized in the Fashion Retail Sector?

In the fashion retail sector, beyond garments are pivotal for custom apparel production. Brands leverage this capability to create tailored clothing solutions that resonate with their target audience, enhancing brand identity. The key challenges include ensuring high-quality production, maintaining timely delivery, and adhering to local regulations, especially for international buyers in regions like Africa and South America. Buyers must prioritize suppliers who demonstrate robust quality control measures and a proven track record in compliance.

What Role Does Beyond Garments Play in Defense and Military Applications?

Beyond garments serve a critical role in the defense and military sectors by providing tactical and operational clothing designed for durability and functionality in extreme conditions. This application addresses the need for specialized gear that withstands harsh environments while ensuring the safety of personnel. Buyers must consider material specifications and certification standards, as well as the reliability of the supply chain, to ensure that the products meet stringent operational requirements.

Why are Corporate Uniforms Important for Businesses?

In the corporate sector, beyond garments are essential for producing professional workwear that enhances employee branding and morale. Uniforms foster a sense of belonging and professionalism among staff, which can positively impact customer perception. Buyers need to focus on customization options that align with their brand image, as well as the comfort and durability of the materials used, to ensure employee satisfaction and longevity of the uniforms.

How Can Beyond Garments Enhance Sports and Outdoor Gear?

In the sports and outdoor industry, beyond garments are utilized for developing performance-enhancing clothing that maximizes functionality and comfort for athletes. This application addresses specific needs such as moisture-wicking properties and breathability, which are crucial for optimal performance. Buyers should emphasize technical specifications and the environmental sustainability of materials to appeal to a growing market that values eco-friendly practices.

What Benefits Do Beyond Garments Offer for Hospitality and Events?

For the hospitality and events sector, beyond garments are vital for creating event-specific attire that strengthens brand image through cohesive staff appearance. This application solves the challenge of maintaining a professional look across diverse events and settings. Buyers should consider design flexibility and fabric quality, as well as the ability to scale production for large orders, to ensure that their needs are met effectively and efficiently.

3 Common User Pain Points for ‘beyond garmets’ & Their Solutions

Scenario 1: Sourcing High-Quality Fabrics for Diverse Markets

The Problem: B2B buyers often face the challenge of sourcing high-quality fabrics that cater to various regional preferences and climates. For instance, buyers in Africa may require lightweight, breathable fabrics suitable for hot weather, while those in Europe may prioritize durability and warmth for colder seasons. This discrepancy can lead to misunderstandings with suppliers, resulting in delays, increased costs, and dissatisfaction among end customers.

The Solution: To overcome this issue, buyers should conduct thorough market research to understand the specific fabric requirements of their target regions. Establishing clear communication with suppliers about these needs is crucial. When sourcing ‘beyond garments’, buyers should inquire about the range of fabric options available and their suitability for different climates. Additionally, developing a sample approval process can help ensure that the chosen fabrics meet quality standards and regional preferences before placing larger orders. Engaging in collaborative partnerships with fabric suppliers who can provide insights into local trends can further enhance the sourcing strategy.

Scenario 2: Managing Lead Times and Production Schedules

The Problem: One of the most pressing concerns for B2B buyers is the unpredictability of lead times and production schedules, especially when dealing with international suppliers. Buyers may experience extended wait times for garment production, which can disrupt their sales cycles and inventory management. This is particularly problematic for businesses that rely on seasonal trends or promotional events, as delays can lead to lost sales and damaged customer relationships.

The Solution: To mitigate lead time issues, buyers should implement a robust supply chain management system that includes clear timelines and milestones for production and delivery. Setting realistic expectations with suppliers regarding production capacity and scheduling is essential. Buyers should also consider diversifying their supplier base to include local or regional manufacturers who can offer shorter lead times. Regularly reviewing and adjusting orders based on sales forecasts can help maintain an optimal inventory level. Building a strong relationship with suppliers, including open lines of communication, can facilitate quicker responses to any production delays.

Scenario 3: Ensuring Compliance with International Standards

The Problem: B2B buyers often grapple with the complexities of ensuring that their sourced garments comply with various international standards, such as quality certifications, environmental regulations, and ethical labor practices. This is especially critical when entering markets in Europe or North America, where compliance is heavily scrutinized. Failure to meet these standards can lead to financial penalties, damaged reputations, and lost business opportunities.

The Solution: To navigate compliance challenges, buyers should conduct comprehensive due diligence on potential suppliers, verifying their certifications and adherence to international standards such as ISO and BSCI. Establishing a compliance checklist tailored to the specific requirements of target markets can streamline this process. Additionally, buyers can invest in third-party audits or certifications to validate supplier claims. Collaborating with suppliers to implement sustainable practices not only ensures compliance but can also enhance brand value in competitive markets. Regular training and updates on compliance regulations should be part of the buyer’s operational strategy to adapt to any changes in standards effectively.

Strategic Material Selection Guide for beyond garmets

What Are the Key Properties of Common Materials Used in Beyond Garments?

When selecting materials for beyond garments, understanding the key properties of various fabrics is crucial for ensuring product performance. Common materials include polyester, nylon, cotton blends, and wool. Each material has unique characteristics that can affect durability, functionality, and overall cost.

Polyester is a synthetic fabric known for its durability and resistance to shrinking and stretching. It is lightweight, quick-drying, and often used in outdoor garments due to its moisture-wicking properties. However, it can be less breathable than natural fibers, which may affect comfort in hot climates. For international buyers, especially in regions like Africa and the Middle East, compliance with environmental standards and certifications such as Oeko-Tex can be a consideration.

Nylon is another synthetic option that offers excellent strength and elasticity. It is resistant to abrasion and mildew, making it suitable for rugged applications. Nylon garments can withstand high temperatures, but they may not perform well in extreme cold conditions. Buyers from Europe and South America should consider the environmental impact of nylon production and look for suppliers who adhere to sustainable practices.

Cotton blends combine the softness and breathability of cotton with the durability of synthetic fibers. This makes them versatile for various applications, from casual wear to more technical garments. While cotton blends are comfortable, they can be prone to wrinkling and may require more maintenance. Compliance with international standards for organic cotton can be a significant factor for buyers in Europe and North America.

Wool, particularly merino wool, is known for its natural temperature-regulating properties, making it suitable for both warm and cold climates. It is also naturally moisture-wicking and odor-resistant. However, wool can be more expensive and may require special care during washing. Buyers in regions with varying climate conditions, such as Europe and South America, may find wool garments appealing for their versatility.

How Do These Materials Impact Application in Beyond Garments?

The choice of material significantly impacts the application of beyond garments. For instance, polyester and nylon are ideal for activewear and outdoor gear due to their moisture management and durability. Cotton blends can be used for everyday apparel, while wool is excellent for thermal wear. Understanding the specific media compatibility of these materials is essential for ensuring that the final product meets the needs of the target market.

International buyers should also be aware of regional preferences and compliance requirements. For example, buyers in Nigeria may prioritize durability and cost-effectiveness, while those in Saudi Arabia may focus on breathability and comfort due to the hot climate. Adhering to common standards such as ASTM, DIN, or JIS can facilitate smoother transactions and enhance product acceptance in various markets.

Summary Table of Material Selection for Beyond Garments

| Material | Typical Use Case for beyond garments | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Activewear, outdoor clothing | Durable, moisture-wicking | Less breathable than natural fibers | Medium |

| Nylon | Technical outerwear, sports gear | High strength, abrasion-resistant | Poor performance in extreme cold | Medium |

| Cotton Blends | Casual wear, everyday apparel | Soft, breathable | Prone to wrinkling, requires care | Low |

| Wool | Thermal wear, high-end garments | Temperature regulation, moisture-wicking | Higher cost, special care needed | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of common materials used in beyond garments. Understanding these factors will help in making informed decisions that align with market demands and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for beyond garmets

What Are the Key Manufacturing Processes for Beyond Garments?

Manufacturing processes for beyond garments, which encompass a wide range of apparel beyond basic clothing, involve several critical stages. Each stage is designed to ensure that the final product meets both aesthetic and functional standards, particularly for B2B clients. Here’s a breakdown of the main stages:

How Is Material Prepared for Beyond Garments Manufacturing?

Material preparation is the first step in the manufacturing process. This stage involves sourcing high-quality fabrics and materials that align with the intended use of the garment. Suppliers often use a combination of natural and synthetic fibers, which may include cotton, polyester, and specialized performance materials.

Once the materials are sourced, they undergo various treatments such as dyeing, finishing, and pre-shrinking to enhance durability and performance. Suppliers frequently invest in advanced technology, such as automatic cutting machines, to ensure precision in material usage and reduce waste.

What Techniques Are Used in Forming and Assembly?

After material preparation, the next phase is forming, which involves cutting the materials into specific patterns. This is typically done using CAD (Computer-Aided Design) software, which allows for precise measurements and reduces the likelihood of errors.

Following cutting, the assembly stage begins. Key techniques in this phase include sewing, bonding, and welding, depending on the type of garment being produced. For instance, high-performance outerwear may utilize seam-sealing technology to enhance waterproofing. Skilled workers or automated sewing machines are employed to ensure that seams are strong and aesthetically pleasing.

What Are the Finishing Techniques for Beyond Garments?

Finishing is the final manufacturing stage, where the garment undergoes processes that enhance its appearance and performance. Techniques such as ironing, adding labels, and final inspections are performed to ensure that the product meets quality standards. Specialized finishing treatments, such as water-repellent coatings or anti-odor treatments, may also be applied to meet specific market demands.

How Is Quality Assurance Implemented in Beyond Garments Manufacturing?

Quality assurance (QA) is crucial in the manufacturing process for beyond garments. It ensures that products not only comply with industry standards but also meet the specific needs of B2B buyers across different regions.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with international standards such as ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with this standard demonstrates a commitment to quality and customer satisfaction. Additionally, certifications like BSCI (Business Social Compliance Initiative) ensure that the manufacturing process adheres to social responsibility standards, which is particularly important for buyers in Europe and other socially conscious markets.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards. Any non-conforming materials are rejected at this stage.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the quality of the production process. This helps identify issues early and reduces rework.

-

Final Quality Control (FQC): Once the garments are completed, a thorough inspection is conducted. This includes checking for defects, ensuring that all specifications are met, and verifying that the finishing touches have been applied correctly.

What Common Testing Methods Are Used in the Quality Assurance Process?

Various testing methods are employed to ensure that the garments perform as expected. Common tests include:

-

Physical Testing: Assessing fabric strength, durability, and resistance to wear and tear.

-

Chemical Testing: Evaluating the safety of dyes and finishes, including tests for harmful substances in compliance with REACH regulations in Europe.

-

Performance Testing: For specialized garments, such as outdoor or workwear, performance tests may include waterproofing, breathability, and thermal insulation assessments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers need to ensure that their suppliers maintain robust quality control practices. Here are several actionable steps to verify QC:

What Role Do Audits and Reports Play in Supplier Verification?

Conducting audits is an effective way to assess a supplier’s quality management system. Buyers can request documentation of internal audits, quality control reports, and certifications to understand the supplier’s adherence to quality standards.

Why Is Third-Party Inspection Important?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services can verify compliance with international standards and conduct random inspections throughout the production process, offering additional assurance to buyers.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control and certifications. For instance, varying standards of quality and compliance may exist across different markets.

Buyers should familiarize themselves with local regulations and certifications that may impact their purchasing decisions. Additionally, understanding cultural differences in quality expectations can help in negotiating and establishing strong supplier relationships.

Conclusion

In summary, the manufacturing processes and quality assurance for beyond garments involve meticulous attention to detail at every stage. B2B buyers must not only focus on the final product but also understand the underlying processes that ensure quality and compliance with international standards. By actively engaging in supplier verification and staying informed about industry practices, buyers can secure high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘beyond garmets’

To successfully source products beyond garments, it’s essential to follow a structured approach that ensures quality, compliance, and alignment with your business needs. This checklist will guide B2B buyers through the critical steps involved in procuring high-quality products that meet international standards.

Step 1: Identify Your Product Requirements

Begin by clearly defining what you need in terms of product specifications, including materials, styles, and intended use. This step is crucial because it sets the foundation for your sourcing process. Consider factors such as target market, seasonal trends, and specific customer preferences.

- Sub-bullet: Create detailed technical specifications to share with potential suppliers.

- Sub-bullet: Determine your budget constraints and delivery timelines.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a solid reputation in the industry. Look for companies that specialize in the types of products you need and have a history of successful international trade.

- Sub-bullet: Utilize platforms such as trade directories and industry exhibitions to find suppliers.

- Sub-bullet: Pay attention to reviews and testimonials from other buyers, particularly from your target regions.

Step 3: Verify Supplier Certifications

Before proceeding with any supplier, ensure they possess the necessary certifications and compliance with international standards. Certifications such as ISO9001 and BSCI are indicators of quality management and social responsibility.

- Sub-bullet: Request copies of certifications and verify their validity through official channels.

- Sub-bullet: Inquire about their quality control processes and product testing protocols.

Step 4: Request Samples and Conduct Quality Checks

Once you have shortlisted potential suppliers, request samples of the products. This step allows you to assess the quality, craftsmanship, and adherence to your specifications firsthand.

- Sub-bullet: Evaluate the samples against your defined requirements.

- Sub-bullet: Consider conducting a quality inspection at the supplier’s facility if feasible.

Step 5: Negotiate Terms and Conditions

Effective negotiation is key to establishing a mutually beneficial relationship. Discuss pricing, payment terms, lead times, and any other critical conditions before finalizing the agreement.

- Sub-bullet: Be clear about your expectations regarding product quality and delivery schedules.

- Sub-bullet: Ensure all agreed terms are documented in a contract to prevent misunderstandings.

Step 6: Establish Logistics and Shipping Arrangements

Plan your logistics carefully to ensure timely delivery of your products. This includes selecting reliable shipping partners and understanding import regulations in your country.

- Sub-bullet: Discuss shipping options and costs with your supplier.

- Sub-bullet: Familiarize yourself with customs requirements and potential tariffs.

Step 7: Monitor Production and Maintain Communication

Once the order is placed, maintain regular communication with your supplier to monitor production progress and address any issues promptly. This helps ensure that your expectations are met throughout the manufacturing process.

- Sub-bullet: Schedule regular updates and establish a clear point of contact.

- Sub-bullet: Be proactive in addressing any concerns that may arise during production.

By following this comprehensive checklist, B2B buyers can streamline their sourcing process for products beyond garments, ensuring they select the best suppliers to meet their business needs while maintaining high standards of quality and compliance.

Comprehensive Cost and Pricing Analysis for beyond garmets Sourcing

What are the Key Cost Components in Beyond Garments Sourcing?

When sourcing from Beyond Garments, understanding the cost structure is crucial for effective budgeting and negotiations. The primary components include:

-

Materials: The choice of fabrics significantly influences pricing. High-quality or specialty materials (e.g., organic cotton, recycled polyester) may incur higher costs but can enhance product value.

-

Labor: Labor costs vary based on the complexity of the garment and the skill level required. Factories like Beyond Garments invest in skilled labor to ensure quality, which can affect the overall pricing.

-

Manufacturing Overhead: This encompasses utilities, rent, and general factory operations. Given Beyond Garments’ advanced manufacturing capabilities and equipment, overhead costs are generally higher but translate into quality assurance.

-

Tooling: Initial costs for tooling can be substantial, especially for custom designs. Buyers should inquire about these costs upfront, as they can be amortized over larger orders.

-

Quality Control (QC): Rigorous quality control processes are necessary to meet international standards. Costs associated with QC can be significant, especially if multiple inspections are needed throughout the production process.

-

Logistics: Shipping and handling fees vary based on the Incoterms agreed upon. Understanding these terms is essential for accurate cost estimation.

-

Margin: Suppliers like Beyond Garments typically add a margin to cover their costs and profit. This can vary widely depending on the competition and market demand.

How Do Price Influencers Affect Sourcing Decisions?

Several factors can influence the pricing of garments from Beyond Garments:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly impact pricing. Higher volumes often lead to lower per-unit costs due to economies of scale.

-

Specifications and Customization: Custom designs or specifications can lead to increased costs. It’s essential for buyers to clearly define their needs to avoid unexpected charges.

-

Materials Quality and Certifications: Higher quality materials or specific certifications (e.g., ISO, BSCI) may increase costs but can also enhance brand reputation and customer satisfaction.

-

Supplier Factors: The supplier’s reputation and operational efficiency can influence costs. Established suppliers with a track record of reliability may charge a premium for their services.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Familiarizing oneself with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is vital for accurate budgeting.

What Negotiation Strategies Can Enhance Cost-Efficiency?

For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Leverage Volume Discounts: When placing orders, aim for larger quantities to negotiate lower prices. Suppliers are often willing to provide discounts for bulk orders.

-

Clarify Specifications Early: Clearly define product specifications from the outset to avoid additional costs related to changes or customizations later in the process.

-

Consider Total Cost of Ownership: Analyze the long-term costs associated with sourcing, including shipping, tariffs, and potential waste. This holistic view can lead to more informed purchasing decisions.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, favorable terms, and priority service. Trust can often yield better negotiation outcomes.

-

Stay Informed on Market Trends: Being aware of market conditions can give buyers leverage in negotiations. Understanding when demand is low can help in negotiating better prices.

Are There Pricing Nuances for International Buyers?

International buyers should remain mindful of several pricing nuances when sourcing from Beyond Garments:

-

Currency Fluctuations: Exchange rates can affect pricing. It’s prudent to negotiate in a stable currency or agree on a fixed rate to mitigate risks.

-

Tariffs and Duties: Be aware of any import duties or tariffs that may apply. These can significantly impact the final cost of goods.

-

Cultural Sensitivity: Understanding cultural nuances in negotiation styles can facilitate smoother transactions. Building rapport can be as important as negotiating price.

-

Disclaimer on Prices: Prices provided by suppliers are often indicative and subject to change based on market conditions, material costs, and other variables. Always confirm pricing before finalizing any agreements.

By understanding these components and strategies, international B2B buyers can navigate the complexities of sourcing from Beyond Garments effectively, ensuring a balance between quality and cost.

Alternatives Analysis: Comparing beyond garmets With Other Solutions

Understanding Alternatives in the Apparel Industry

In the competitive landscape of the apparel industry, B2B buyers often seek innovative solutions that go beyond traditional garment offerings. The concept of “beyond garments” encompasses a range of advanced textile solutions, including performance apparel and sustainable fashion technologies. As buyers evaluate their options, understanding viable alternatives is crucial for making informed purchasing decisions.

Comparison Table of Beyond Garments and Alternative Solutions

| Comparison Aspect | Beyond Garments | Alternative 1: Performance Fabrics | Alternative 2: Sustainable Apparel Solutions |

|---|---|---|---|

| Performance | High durability and tailored fit | Enhanced moisture-wicking and breathability | Eco-friendly materials with moderate durability |

| Cost | Moderate to high price range | Generally higher due to technology involved | Variable; can be cost-effective or premium |

| Ease of Implementation | Requires skilled labor for production | Requires advanced machinery and training | Easier to implement with existing systems |

| Maintenance | Standard care for garments | Often requires special care (e.g., washing) | Low maintenance; many are machine washable |

| Best Use Case | Formal and semi-formal wear | Activewear and outdoor apparel | Casual and eco-conscious fashion |

Detailed Breakdown of Alternatives

Performance Fabrics

Performance fabrics are engineered textiles designed to enhance comfort and functionality. They often feature advanced moisture-wicking properties, breathability, and thermal regulation. The main advantage of performance fabrics is their ability to cater to active lifestyles, making them ideal for sports and outdoor activities. However, these fabrics can be more expensive due to the technology involved, and they may require specialized care during washing to maintain their properties.

Sustainable Apparel Solutions

Sustainable apparel solutions focus on reducing environmental impact through eco-friendly materials, such as organic cotton, recycled polyester, and innovative biodegradable textiles. These products appeal to consumers seeking to make environmentally conscious choices. The primary benefit of sustainable apparel is its growing market demand, especially among millennials and Gen Z. However, sustainability often comes at a premium price, and the durability of some eco-friendly materials may not match that of traditional textiles.

How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate solution for their needs, B2B buyers should consider their target market, budget constraints, and the specific application of the garments. For those focused on active lifestyles, performance fabrics may be the best fit, providing enhanced functionality. In contrast, brands seeking to align with eco-conscious consumers might prioritize sustainable apparel solutions. Ultimately, the decision should align with the company’s brand values and customer expectations, ensuring that the selected approach not only meets operational needs but also resonates with the intended audience.

Essential Technical Properties and Trade Terminology for beyond garmets

What Are the Key Technical Properties for Beyond Garments?

In the realm of beyond garments, understanding critical technical properties is essential for B2B buyers looking to ensure product quality and compliance with market demands. Here are some of the vital specifications to consider:

-

Material Composition

– This refers to the types of fabrics and blends used in garment production. Common materials include cotton, polyester, and wool, each offering different qualities like breathability, durability, and insulation. For B2B buyers, selecting the right material affects product performance, longevity, and ultimately customer satisfaction. -

Construction Quality

– This encompasses the techniques and standards used in garment assembly, such as stitching methods (e.g., double stitching vs. single stitching) and seam finishes. High-quality construction ensures garments can withstand wear and tear, which is crucial for brands aiming for longevity in the market. Buyers should assess construction quality to avoid returns and enhance brand reputation. -

Size Tolerance

– Size tolerance defines the acceptable range of variation in garment dimensions, critical for ensuring a consistent fit across different sizes. Tighter tolerances typically indicate higher quality and are important for brands that emphasize fit and comfort. Understanding size tolerance is essential for B2B buyers to meet consumer expectations. -

Colorfastness

– This property measures a fabric’s ability to retain its color after exposure to washing, sunlight, and rubbing. High colorfastness ratings prevent color bleeding and fading, which are significant concerns for retailers. For B2B buyers, selecting textiles with excellent colorfastness can enhance product appeal and reduce customer complaints. -

Durability Ratings

– Durability ratings assess how well a garment can withstand physical stress over time, including abrasion resistance and tensile strength. Buyers should prioritize durability ratings to ensure the products they purchase can endure their intended use, particularly in demanding environments.

Which Trade Terminology Should B2B Buyers Know?

Navigating the world of beyond garments also requires familiarity with specific industry jargon. Here are some essential terms to understand:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of beyond garments, an OEM might create specific clothing items for brands under their label. Understanding OEM relationships is crucial for buyers looking to source unique products or customize existing ones. -

MOQ (Minimum Order Quantity)

– MOQ specifies the smallest quantity of products a supplier is willing to sell. This is particularly important for B2B buyers to understand as it can affect inventory management and cash flow. Negotiating MOQs can help businesses optimize their purchasing strategies and reduce excess inventory. -

RFQ (Request for Quotation)

– An RFQ is a document that a buyer sends to suppliers to request pricing for specific products or services. This process helps buyers compare prices and terms from different vendors, ensuring they receive competitive offers. Being adept at crafting RFQs can significantly streamline the procurement process. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers for the delivery of goods. Familiarity with Incoterms is essential for B2B buyers to understand shipping costs, risk management, and logistics arrangements, ensuring smooth transactions across international borders. -

BSCI (Business Social Compliance Initiative)

– This certification indicates that a supplier adheres to social responsibility standards concerning labor practices. For ethical sourcing, B2B buyers should prioritize suppliers with BSCI certification to ensure compliance with international labor laws and enhance their brand’s social responsibility image.

By understanding these technical properties and trade terms, B2B buyers in the beyond garments sector can make informed decisions that enhance product quality, optimize sourcing strategies, and ultimately drive business success.

Navigating Market Dynamics and Sourcing Trends in the beyond garmets Sector

What Are the Key Market Dynamics and Trends Affecting the Beyond Garments Sector?

The beyond garments sector is undergoing significant transformation driven by a convergence of global trends and technological advancements. One of the primary market drivers is the increasing demand for functional and versatile clothing that transcends traditional garment categories. International B2B buyers from Africa, South America, the Middle East, and Europe are particularly focused on sourcing products that meet the evolving needs of consumers who seek comfort, style, and utility in their apparel choices.

Emerging technologies such as AI-driven design tools and digital supply chain management systems are reshaping how manufacturers create and distribute garments. These innovations enhance efficiency, reduce lead times, and enable more personalized products, which are essential in today’s competitive landscape. Furthermore, the rise of e-commerce platforms and virtual showrooms is changing how buyers engage with suppliers, offering greater access to a diverse range of products and suppliers globally.

Additionally, sustainability is becoming a critical factor in sourcing decisions. Buyers are increasingly looking for manufacturers who prioritize eco-friendly practices and materials, reflecting a broader societal push towards responsible consumption. As companies navigate these dynamics, staying informed about market shifts and emerging trends will be vital for making strategic sourcing decisions.

How Is Sustainability and Ethical Sourcing Influencing the Beyond Garments Sector?

Sustainability and ethical sourcing are no longer optional but essential components of the beyond garments sector. The environmental impact of textile production, including water consumption, chemical pollution, and waste generation, has prompted a reevaluation of sourcing strategies among B2B buyers. Companies are increasingly seeking suppliers who demonstrate a commitment to sustainable practices, such as using organic materials, reducing carbon footprints, and implementing waste management systems.

Certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® are gaining traction as benchmarks for eco-friendly and ethical sourcing. These certifications assure buyers that the materials used meet rigorous environmental and social standards, thereby enhancing their brand reputation and consumer trust.

Moreover, the demand for recycled materials is on the rise, with many manufacturers exploring innovative ways to incorporate recycled fabrics into their product lines. This trend not only addresses environmental concerns but also aligns with consumer preferences for sustainable products. B2B buyers should prioritize partnerships with manufacturers who share their commitment to sustainability, as this will be pivotal in maintaining competitive advantage and meeting regulatory requirements in various markets.

What Is the Brief History and Evolution of the Beyond Garments Sector?

The beyond garments sector has evolved significantly since its inception, with roots tracing back to the early 1990s when the demand for functional apparel began to rise. Initially focused on traditional clothing, the sector has expanded to include specialized garments designed for various applications, including outdoor activities, workwear, and tactical use.

As global markets expanded, so did the complexity of supply chains, prompting manufacturers to adopt advanced technologies and innovative practices to meet diverse consumer needs. The integration of sustainability into sourcing strategies has further transformed the sector, aligning with broader societal values and consumer expectations.

Today, the beyond garments sector represents a dynamic intersection of fashion, functionality, and sustainability, making it a focal point for international B2B buyers looking to navigate the complexities of modern apparel sourcing.

Frequently Asked Questions (FAQs) for B2B Buyers of beyond garmets

-

How do I ensure the quality of garments from Beyond Garments?

To ensure the quality of garments, request samples before committing to larger orders. Assess the materials, stitching, and overall craftsmanship. Additionally, verify that the supplier adheres to international standards such as ISO9001 and BSCI, which indicate robust quality management and social responsibility practices. Establishing a clear quality assurance protocol and regular audits can further enhance confidence in product quality. -

What customization options are available for bulk orders?

Beyond Garments offers extensive customization options, including fabric selection, design alterations, and branding elements like logos and labels. Communicate your specific needs early in the negotiation process to align expectations. Ensure to inquire about the minimum order quantities (MOQs) for customized items, as these can vary based on the complexity of the designs and the materials used. -

What are the minimum order quantities (MOQ) for sourcing garments?

The MOQ for sourcing garments from Beyond Garments typically depends on the product type and customization requirements. Generally, MOQs can range from 500 to 1,000 pieces per style. It’s advisable to discuss your requirements directly with the supplier to negotiate terms that suit your business needs, especially if you’re looking to start with a smaller trial order. -

What payment terms should I expect when working with Beyond Garments?

Payment terms can vary, but many suppliers, including Beyond Garments, often require a deposit (usually 30-50%) upon order confirmation, with the balance due before shipment. It’s essential to clarify these terms upfront and consider using secure payment methods such as letters of credit or escrow services to protect your investment. -

How can I verify the credibility of Beyond Garments as a supplier?

To verify the credibility of Beyond Garments, check their certifications (ISO9001, BSCI), request references from existing clients, and review their business history and online presence. Engaging in direct communication to assess their responsiveness and willingness to provide documentation is also crucial. Additionally, consider visiting their facilities if possible, or using third-party inspection services. -

What logistics options are available for shipping garments internationally?

Beyond Garments typically offers various logistics options, including air freight for quicker delivery and sea freight for more cost-effective solutions. Discuss your preferred shipping methods and timelines with the supplier. Ensure that they can provide all necessary documentation for customs clearance and inquire about their experience with shipping to your specific region. -

How do I handle disputes or issues with my order?

In the event of a dispute or issue with your order, it’s essential to address the matter promptly and directly with Beyond Garments. Maintain clear communication, provide documentation of the issue, and refer to your agreement terms regarding quality and delivery. If necessary, involve a third-party mediator or consult legal resources based on the severity of the issue. -

What steps should I take to ensure timely delivery of my orders?

To ensure timely delivery of your orders, establish a clear timeline with Beyond Garments, including production and shipping schedules. Regular follow-ups during the production phase can help identify potential delays early. Consider setting buffer times in your planning to accommodate any unforeseen circumstances, and ensure that all logistics and customs requirements are understood and planned for in advance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Beyond Garmets Manufacturers & Suppliers List

1. Beyond Garments – Men’s and Women’s Clothing

Domain: beyondgarments.86exporter.com

Registered: 2023 (2 years)

Introduction: Beyond Garments CO.,LTD specializes in large-scale production of men’s and women’s clothing, including suits and jackets. The company was founded in 1995 and is located next to Ningbo Beilun Port in China. They have over 1,000 employees and an output value of 500 million yuan. The production equipment is imported from the United States, Japan, Germany, and Italy, featuring brands like Durkopp and …

2. Hengyuan – Suits and Jackets

Domain: cnnbbeyond.com

Registered: 2004 (21 years)

Introduction: Ningbo Hengyuan Garment Co., Ltd. specializes in large-scale production of men’s and women’s clothing, including suits and jackets. The company was founded in 1995 and is located near Ningbo Beilun Port. It employs over 1,500 staff and has an annual production capacity of 100 million units of suits and 1.2 million jackets. The production facility is equipped with world-class machinery, including G…

3. Hangzhou Beyond Garments – Menswear & Athleisure

Domain: paris.premierevision.com

Registered: 2002 (23 years)

Introduction: Hangzhou Beyond Garments Co. Ltd, located in China, specializes in manufacturing menswear, womenswear, athleisure, and casual clothing. They export to Australia, Europe, North America, and Asia.

4. Beyond Garments Co., Ltd. – OEM Apparel

Domain: tradeeasy.com

Registered: 1997 (28 years)

Introduction: {“Company Name”: “Beyond Garments Co.,Ltd.”, “Country”: “China”, “Established Year”: 1995, “Employee Count”: 2000, “Yearly Sales Volume”: “US$50M – US$100M”, “Registered Capital”: “US$1M – US$5M”, “Principal Customers”: [“HM”, “TARGET”, “NAUTICA”, “RV”, “EMIRATES”, “JACK WILLS”, “RM WILLIAMS”], “OEM”: “YES”, “ODM”: “YES”, “Factory Location”: “No.8 Longtanshan Road, Beilun, Ningbo, China”, “Certifi…

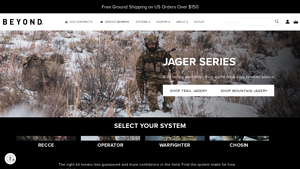

5. Beyond Clothing – Key Products

Domain: beyondclothing.com

Registered: 2004 (21 years)

Introduction: Key Products: 1. L8 | Chosin ECW Parka – Price: $1,849.99, Sizes: S, M, L, XL, 2XL, Color: Alpine Multicam 2. L8 | Chosin ECW Bib – Price: $1,399.99, Sizes: S, M, L, XL, 2XL, Color: Alpine Multicam 3. Chosin ECW Overboot – Price: $549.99, Sizes: XS/S, M/L, XL/2XL, Color: Alpine Multicam 4. Chosin ECW Mitt – Price: $549.99, Sizes: S, M, L, XL, 2XL, Color: Alpine Multicam 5. Mountain Jager Jacket – …

6. Accio – Quality Apparel

Domain: accio.com

Registered: 1997 (28 years)

Introduction: This company, Accio – Quality Apparel, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for beyond garmets

In the evolving landscape of the apparel industry, strategic sourcing emerges as a vital component for international B2B buyers seeking to capitalize on new opportunities beyond traditional garments. The insights gathered from established players like Beyond Garments highlight the importance of leveraging advanced production capabilities and adhering to international quality standards. Buyers are encouraged to consider suppliers who not only offer a diverse range of products but also demonstrate a commitment to sustainability and innovation.

By prioritizing partnerships with manufacturers that embrace cutting-edge technology and efficient production methods, businesses can significantly enhance their supply chain resilience. Additionally, understanding regional market demands—especially in emerging markets across Africa, South America, the Middle East, and Europe—will enable buyers to tailor their sourcing strategies effectively.

Looking ahead, the potential for growth in the beyond garments sector is substantial. International B2B buyers are urged to take proactive steps in identifying and engaging with reliable suppliers that align with their strategic objectives. By doing so, they can secure a competitive edge in a dynamic market while fostering relationships that pave the way for sustainable success. Embrace the future of sourcing and explore the myriad possibilities that lie beyond traditional garments.