Good Laptop For Fusion 360: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for good laptop for fusion 360

In today’s fast-paced design environment, sourcing a good laptop for Fusion 360 presents a significant challenge for international B2B buyers. With the increasing demand for efficient design and engineering tools, organizations must navigate a complex landscape of options that align with their specific needs and budgets. This guide offers a comprehensive overview of the essential factors to consider when selecting the right laptop for Fusion 360, including performance specifications, application requirements, supplier vetting processes, and cost considerations.

Whether you are based in Africa, South America, the Middle East, or Europe, understanding the intricacies of the global market for laptops tailored to Fusion 360 can empower you to make informed purchasing decisions. This guide not only highlights the types of laptops that excel in running Fusion 360 but also delves into the practical applications of these machines in various industries. By providing insights into the latest technology trends, performance benchmarks, and supplier recommendations, we aim to equip you with the knowledge necessary to enhance your design workflows and drive productivity.

As you explore the options available, this guide will serve as a valuable resource, ensuring that you select a laptop that meets your operational requirements while staying within your financial parameters. By making informed choices, you can invest in technology that not only supports your current projects but also scales with your future needs.

Understanding good laptop for fusion 360 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-End Workstations | Powerful CPUs (Intel i7/i9, AMD Ryzen 7/9), professional GPUs | Engineering, Product Design | Pros: Exceptional performance, reliability; Cons: High cost, less portable. |

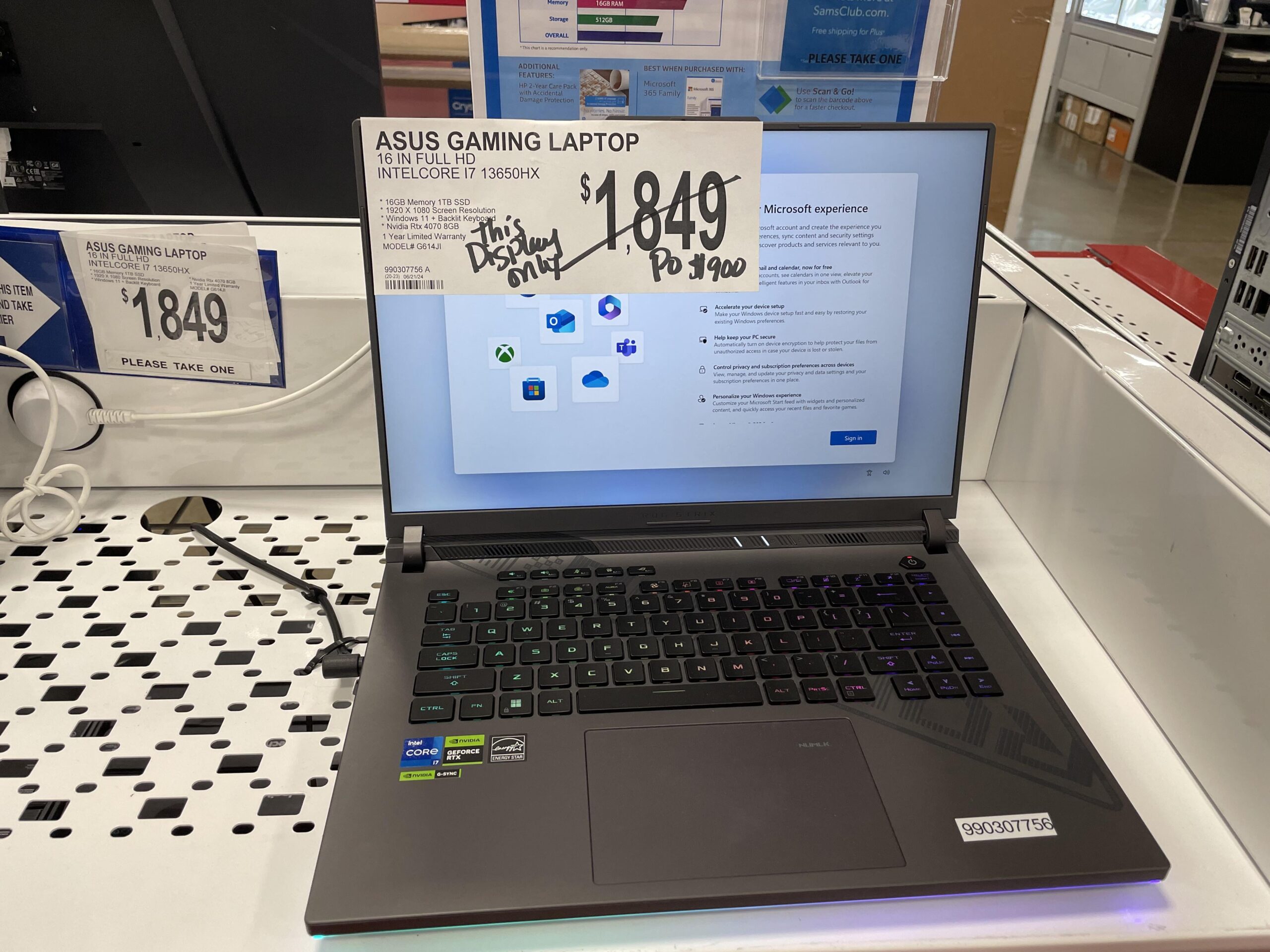

| Gaming Laptops | High-end GPUs (NVIDIA RTX series), fast refresh rates | CAD, 3D modeling, simulation | Pros: Strong graphics performance, often more affordable; Cons: Can be bulkier, less battery-efficient. |

| Budget-Friendly Options | Adequate performance with lower-tier CPUs and GPUs | Small businesses, startups | Pros: Cost-effective, good for basic tasks; Cons: Limited performance for complex designs. |

| MacBook Pro | macOS optimized for creative applications, M2 Max chip | Design firms, freelance designers | Pros: Excellent build quality, seamless software integration; Cons: Higher price, limited upgrade options. |

| Custom-built Laptops | Tailored specifications for specific needs, modular components | Specialized engineering firms, tech startups | Pros: Maximum performance for specific tasks, flexible configurations; Cons: Requires technical knowledge, less portable. |

What Are High-End Workstations and Their B2B Suitability?

High-end workstations are designed for intensive computing tasks, making them ideal for professionals in engineering and product design. Equipped with powerful CPUs like Intel i7/i9 or AMD Ryzen 7/9, and professional GPUs, they deliver unmatched performance for software like Fusion 360. When purchasing, B2B buyers should consider the specific requirements of their applications, such as whether they need enhanced graphics capabilities or multi-core processing for simulations. While these machines are reliable, their high price point may be a consideration for budget-conscious businesses.

How Do Gaming Laptops Meet the Needs of CAD Professionals?

Gaming laptops are increasingly popular among CAD professionals due to their powerful graphics capabilities, often featuring high-end NVIDIA RTX series GPUs. They are suitable for tasks that require fast rendering and 3D modeling, making them a viable option for businesses that need robust performance without the workstation price tag. Buyers should evaluate the balance between performance and portability, as gaming laptops can be bulkier and have shorter battery life. However, their cost-effectiveness and strong performance make them attractive for many businesses.

What Benefits Do Budget-Friendly Options Provide for Startups?

Budget-friendly laptops provide a practical solution for startups and small businesses needing basic performance for CAD applications. These laptops typically feature lower-tier CPUs and GPUs, which are sufficient for less complex designs and tasks. B2B buyers should assess the specific software requirements and consider that while these options are cost-effective, they may struggle with more demanding applications. The trade-off between price and performance is crucial, as these machines may limit future scalability.

Why Are MacBook Pros a Preferred Choice for Design Firms?

MacBook Pros, especially with the M2 Max chip, are favored by design firms for their exceptional performance and seamless integration with design software. The macOS environment is optimized for creative applications, making it a preferred choice among designers and engineers alike. B2B buyers should weigh the benefits of build quality and user experience against the higher price and limited upgradeability. For firms that prioritize design aesthetics and software compatibility, the MacBook Pro is a compelling option.

How Can Custom-Built Laptops Enhance Specialized Engineering Tasks?

Custom-built laptops offer the flexibility to tailor specifications according to specific business needs, making them ideal for specialized engineering firms and tech startups. Buyers can select components that maximize performance for particular tasks, such as high-end CPUs and GPUs for demanding applications. However, the need for technical knowledge in building and maintaining these machines can be a barrier. Despite this, the ability to create a machine that perfectly fits specific requirements can provide significant advantages in performance and efficiency for businesses focused on specialized tasks.

Key Industrial Applications of good laptop for fusion 360

| Industry/Sector | Specific Application of good laptop for fusion 360 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Product Design and Prototyping | Accelerates product development cycles and reduces costs. | Prioritize high-performance CPUs and GPUs for complex designs. |

| Architecture and Construction | Building Information Modeling (BIM) | Enhances collaboration and visualization of designs. | Ensure compatibility with CAD software and high RAM capacity. |

| Automotive | CAD Modeling for Vehicle Design | Improves design accuracy and innovation in vehicle features. | Look for laptops with robust graphics capabilities and cooling systems. |

| Aerospace | Simulation and Analysis of Aerodynamic Structures | Increases efficiency in testing and reduces material waste. | Focus on laptops with high processing power and extensive storage. |

| Education and Training | Teaching CAD and Design Principles | Facilitates hands-on learning experiences for students. | Consider portability and battery life for classroom environments. |

How is a Good Laptop for Fusion 360 Utilized in Manufacturing?

In the manufacturing sector, a good laptop for Fusion 360 is essential for product design and prototyping. Engineers and designers leverage its advanced processing capabilities to create detailed 3D models and simulations, which significantly shorten product development cycles and lower costs. For B2B buyers, especially in regions like Africa and South America, sourcing laptops with powerful CPUs and GPUs is crucial to handle complex designs and ensure smooth operation during intensive tasks.

What Role Does a Good Laptop Play in Architecture and Construction?

In architecture and construction, a good laptop for Fusion 360 is pivotal for Building Information Modeling (BIM). It enables architects to visualize intricate designs and collaborate effectively with project stakeholders. This not only enhances project accuracy but also improves communication across teams. Buyers should prioritize laptops that are compatible with various CAD software and possess ample RAM to manage large files, particularly in the Middle East and Europe, where large-scale projects are common.

How is a Good Laptop Essential for Automotive Design?

The automotive industry relies heavily on CAD modeling for vehicle design, where a good laptop for Fusion 360 becomes indispensable. Designers use these laptops to create and refine vehicle components, ensuring high precision and innovation in features. For international buyers, especially in Brazil, it is critical to select laptops with robust graphics capabilities and efficient cooling systems to support prolonged design sessions without overheating.

What Advantages Does a Good Laptop Provide in Aerospace Applications?

In the aerospace sector, a good laptop for Fusion 360 is utilized for the simulation and analysis of aerodynamic structures. This application aids engineers in testing designs virtually, which not only saves time but also reduces material waste. Buyers in this industry should focus on laptops that offer high processing power and extensive storage capacity to handle large datasets and complex simulations, ensuring effective performance in rigorous testing environments.

How Does a Good Laptop Enhance Education and Training in CAD?

In educational settings, a good laptop for Fusion 360 is utilized to teach CAD and design principles effectively. These laptops facilitate hands-on learning experiences, allowing students to engage with design software actively. For educational institutions, especially in emerging markets, sourcing laptops that are portable and have long battery life is vital to accommodate diverse classroom environments and ensure uninterrupted learning experiences.

3 Common User Pain Points for ‘good laptop for fusion 360’ & Their Solutions

Scenario 1: Limited Budget Constraints for High-Performance Laptops

The Problem:

Many B2B buyers face the challenge of sourcing a laptop that meets the demanding specifications required for running Fusion 360 while adhering to strict budget constraints. This situation is particularly acute for businesses in emerging markets, such as those in Africa and South America, where high-performance laptops can be prohibitively expensive. Buyers often find themselves torn between opting for budget-friendly options that may lack the necessary performance features, or investing heavily in a high-end model that could strain their finances.

The Solution:

To navigate this challenge, buyers should prioritize key specifications that directly impact Fusion 360 performance. Focus on laptops equipped with at least an Intel i7 or AMD Ryzen 7 processor, as these provide the single-core performance essential for CAD software. Opt for models with a minimum of 16GB RAM and a dedicated GPU, such as the NVIDIA RTX series, to ensure smoother graphics rendering. Buyers can also explore refurbished or certified pre-owned laptops that meet these specifications, providing a cost-effective way to acquire powerful hardware without sacrificing performance. Additionally, consider financing options or bulk purchase discounts to ease the financial burden.

Scenario 2: Inadequate Thermal Management Leading to Performance Throttling

The Problem:

Another prevalent issue is inadequate thermal management in laptops, which can lead to performance throttling during intensive tasks in Fusion 360. This is particularly frustrating for teams working on complex designs or simulations, as overheating can cause the laptop to slow down or even shut down unexpectedly, resulting in lost productivity and potential project delays. Buyers may struggle to identify which models offer robust thermal solutions without extensive research.

The Solution:

When selecting a laptop, buyers should look for models specifically designed for high-performance tasks, as these typically feature advanced cooling systems. For instance, laptops from gaming lines like Razer or ASUS TUF often incorporate superior thermal management technologies. Additionally, consider laptops with multiple fans, heat pipes, and ventilation systems that allow for efficient airflow. It’s also beneficial to invest in a cooling pad or external fan system that can further enhance cooling during intensive use. Reading reviews that focus on thermal performance can also guide buyers toward models that maintain optimal temperatures under load.

Scenario 3: Compatibility Issues with Existing Software and Hardware

The Problem:

Compatibility issues can arise when integrating new laptops with existing software and hardware setups, particularly for businesses that rely on a suite of design tools in conjunction with Fusion 360. Buyers may encounter challenges such as outdated operating systems, insufficient connectivity options for peripherals, or lack of support for specific software versions. This can lead to frustrating delays as teams work to troubleshoot and resolve these compatibility issues.

The Solution:

To mitigate compatibility problems, it is crucial for buyers to conduct thorough research on system requirements for both Fusion 360 and any other software they intend to use. Ensure that the selected laptop comes with the latest operating system, such as Windows 11, which offers improved support for modern applications. Additionally, verify that the laptop has adequate ports (USB-C, HDMI, etc.) for connecting external devices, including monitors and printers. Engaging with IT departments or consulting with technology partners can also provide insights into the best hardware choices that will seamlessly integrate into existing workflows. Finally, consider opting for laptops from manufacturers known for strong customer support and software compatibility, which can save time and reduce hassle in the long run.

Strategic Material Selection Guide for good laptop for fusion 360

When selecting a laptop for running Fusion 360, the choice of materials used in the laptop’s construction can significantly impact performance, durability, and overall user experience. Here, we will analyze four common materials used in laptop manufacturing, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Aluminum in Laptop Manufacturing?

Aluminum is a popular material for laptop chassis due to its lightweight nature and excellent thermal conductivity. It typically has a high strength-to-weight ratio, making it durable while keeping the device portable. Aluminum also offers good corrosion resistance, which is crucial for laptops used in various environments, particularly in regions with high humidity or temperature fluctuations.

Pros:

– Lightweight and portable

– Excellent thermal management

– Corrosion-resistant

Cons:

– Can be more expensive than plastic

– Susceptible to scratches and dents

For international buyers, particularly in Africa and South America, aluminum’s durability makes it suitable for varied climates. Compliance with standards like ASTM can assure quality, while its higher cost may require justification in budget-sensitive markets.

How Does Plastic Compare as a Material for Laptops?

Plastic is frequently used in budget-friendly laptops. It is lightweight and can be molded into various shapes, allowing for creative designs. However, plastic typically has lower thermal conductivity compared to metals, which may lead to overheating during intensive tasks like 3D modeling in Fusion 360.

Pros:

– Cost-effective and lightweight

– Versatile in design

Cons:

– Lower durability compared to metals

– Poor thermal management

For B2B buyers in regions like the Middle East, where heat can be a concern, the thermal limitations of plastic laptops may be a significant drawback. Buyers should ensure that any plastic laptop has adequate cooling systems to support software like Fusion 360.

What Role Does Magnesium Alloy Play in Laptop Construction?

Magnesium alloy is another material gaining popularity in high-end laptops. It combines the lightweight properties of aluminum with increased strength and better thermal performance. Magnesium alloys are also less prone to bending, which enhances the laptop’s durability.

Pros:

– Stronger than aluminum

– Lightweight and good thermal properties

Cons:

– More expensive than aluminum

– Can be challenging to manufacture

For international buyers, particularly in Europe, magnesium alloys may meet higher performance standards, but the increased cost may be a barrier. Buyers should weigh the benefits of durability and performance against budget constraints.

Why Is Carbon Fiber Considered an Advanced Material for Laptops?

Carbon fiber is known for its exceptional strength-to-weight ratio and rigidity. It is often used in premium laptops aimed at professionals who require high performance and portability. Carbon fiber also offers excellent thermal stability, making it suitable for intensive applications.

Pros:

– Extremely lightweight and strong

– Superior thermal stability

Cons:

– Very high manufacturing costs

– Limited availability

For B2B buyers in emerging markets, the high cost of carbon fiber laptops may limit their accessibility. However, for businesses that prioritize performance and reliability, investing in carbon fiber laptops could yield long-term benefits.

Summary Table of Material Properties for Laptops

| Material | Typical Use Case for good laptop for fusion 360 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | High-performance laptops | Lightweight and excellent thermal management | Susceptible to scratches and dents | Medium |

| Plastic | Budget-friendly laptops | Cost-effective and versatile in design | Lower durability and poor thermal management | Low |

| Magnesium Alloy | High-end, durable laptops | Stronger than aluminum | More expensive and challenging to manufacture | High |

| Carbon Fiber | Premium professional laptops | Extremely lightweight and strong | Very high manufacturing costs | High |

This analysis provides B2B buyers with a comprehensive understanding of the materials used in laptops suitable for Fusion 360, allowing them to make informed decisions based on performance, cost, and specific regional needs.

In-depth Look: Manufacturing Processes and Quality Assurance for good laptop for fusion 360

What Are the Main Stages of Manufacturing Processes for Laptops Suitable for Fusion 360?

The manufacturing process of laptops designed for demanding applications like Fusion 360 involves several critical stages. These stages include material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring that the final product meets the performance and reliability standards expected by professionals in design and engineering.

-

Material Preparation: This initial stage involves sourcing high-quality materials such as aluminum, magnesium alloys, and plastics. These materials are selected for their strength-to-weight ratio and thermal conductivity, which are crucial for laptops that need to dissipate heat during intensive tasks like 3D modeling and rendering. Quality checks on raw materials are essential to ensure they meet industry standards and specifications.

-

Forming: In this stage, materials are shaped into the components of the laptop. Techniques such as CNC machining, injection molding, and stamping are commonly used. CNC machining is particularly important for precision parts like the chassis and heat sinks, while injection molding is used for plastic components. The forming process requires meticulous attention to detail to achieve the desired tolerances and finishes.

-

Assembly: This phase involves integrating various components, including the motherboard, CPU, GPU, RAM, and storage devices. Automated assembly lines are often employed to enhance efficiency, but skilled technicians are also involved to handle delicate components and ensure that everything is correctly installed. During assembly, critical connections, such as the thermal interface between the CPU and cooling system, are monitored to prevent overheating.

-

Finishing: The final stage involves applying protective coatings, branding, and conducting aesthetic quality checks. Finishing processes may include anodizing metal surfaces for durability and resistance to wear, as well as applying paints or coatings that enhance the laptop’s visual appeal. This stage also involves rigorous functional testing to ensure that all features work as intended.

How Is Quality Assurance Implemented in Laptop Manufacturing for Fusion 360?

Quality assurance (QA) is an integral part of the manufacturing process for laptops, particularly those intended for professional applications like Fusion 360. Implementing rigorous QA protocols ensures that the end product is reliable and performs at a high level.

-

International Standards and Certifications: Adhering to international quality standards such as ISO 9001 is crucial for manufacturers. This standard focuses on quality management systems and helps ensure consistent quality in products and services. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and RoHS (Restriction of Hazardous Substances) ensure compliance with safety and environmental regulations.

-

Quality Control Checkpoints: Quality control (QC) checkpoints are established throughout the manufacturing process. These include:

– Incoming Quality Control (IQC): This involves inspecting materials and components upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, checks are conducted at various stages to identify defects early in the process. This may involve monitoring dimensions, tolerances, and functional tests.

– Final Quality Control (FQC): Before shipping, the completed laptops undergo comprehensive testing, which includes performance benchmarks, thermal management assessments, and battery life evaluations. -

Common Testing Methods: Various testing methods are employed to ensure laptops can handle the demands of applications like Fusion 360. These tests may include:

– Stress Testing: Evaluating the laptop’s performance under extreme conditions, such as high CPU and GPU loads.

– Thermal Testing: Ensuring that the cooling systems are effective and that temperatures remain within safe limits.

– Battery Life Testing: Assessing how long the laptop can operate under various workloads.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is crucial to ensuring the reliability of the products they purchase.

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should look for suppliers who are transparent about their operations and willing to provide access to their facilities for evaluation.

-

Quality Assurance Reports: Requesting documentation related to quality control processes, such as inspection reports and certification of compliance with international standards, can help buyers assess a supplier’s commitment to quality. These reports should detail the methodologies used during testing and the results achieved.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. This can be particularly beneficial for buyers who may not have the resources to conduct their own audits.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, B2B buyers must navigate various quality control nuances that can impact their purchasing decisions.

-

Cultural and Regulatory Differences: Understanding the cultural context and regulatory requirements of the supplier’s country is essential. Different regions may have varying standards for product quality and safety, which can affect the manufacturing process and final product performance.

-

Logistics and Supply Chain Considerations: Buyers should also consider how logistics and supply chain issues may impact product quality. Delays in shipping or improper handling during transit can affect the condition of the laptops upon arrival. Establishing clear communication channels with suppliers can help mitigate these risks.

-

Building Long-term Relationships: Developing long-term relationships with suppliers can enhance quality assurance efforts. By fostering collaboration, buyers can influence their suppliers to adopt higher standards of quality and become more responsive to feedback.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for laptops suitable for Fusion 360 is vital for B2B buyers. By focusing on high-quality materials, rigorous QA protocols, and effective verification methods, buyers can ensure they select laptops that will meet their professional needs and stand the test of time.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘good laptop for fusion 360’

To assist B2B buyers in procuring the right laptop for Autodesk Fusion 360, this guide offers a practical checklist. By following these steps, buyers can ensure they select a device that meets their technical needs and supports their operational efficiency.

Step 1: Define Your Technical Specifications

Start by identifying the specific technical requirements for running Fusion 360 effectively. This includes focusing on CPU performance, GPU capabilities, RAM, and storage.

– CPU: Aim for high single-core performance; Intel Core i7/i9 or AMD Ryzen 7/9 processors are ideal.

– GPU: Look for NVIDIA RTX series or equivalent professional GPUs to handle graphic-intensive tasks efficiently.

Step 2: Establish a Budget

Setting a clear budget is crucial to streamline the sourcing process. Determine how much your organization is willing to invest in a laptop while considering the long-term benefits.

– Cost vs. Performance: Balance between high-performance laptops and budget-friendly options, ensuring you do not compromise on essential specifications.

– Total Cost of Ownership: Consider future upgrades, warranties, and support services when calculating the budget.

Step 3: Research Potential Models

Conduct thorough research on laptops that meet your specifications. Create a shortlist of models known for their performance in CAD applications like Fusion 360.

– Recommendations: Look into high-performance workstations such as Dell XPS, Lenovo ThinkPad, and HP ZBook.

– User Reviews: Evaluate feedback from current users, particularly those in similar industries or geographical regions, to gauge reliability and performance.

Step 4: Evaluate Supplier Certifications

Before finalizing a supplier, ensure they have the necessary certifications and industry standing. This helps to mitigate risks associated with product quality and after-sales support.

– Manufacturer Partnerships: Check if the supplier is an authorized distributor for major brands.

– Service Agreements: Verify the terms of service agreements and warranty offerings for added security.

Step 5: Request Demonstrations or Trials

Whenever possible, request a demonstration or trial period to assess the laptop’s performance with Fusion 360. This hands-on experience is invaluable.

– Performance Testing: Use the software to run typical tasks your team will perform, assessing speed and responsiveness.

– Ergonomics and Usability: Evaluate the laptop’s design, display quality, and keyboard comfort to ensure it meets user preferences.

Step 6: Verify Return and Exchange Policies

Understanding the return and exchange policies of suppliers is essential for minimizing risk. If the laptop does not meet expectations, a flexible return policy can save time and resources.

– Duration and Conditions: Familiarize yourself with the time frame and conditions under which returns are accepted.

– Restocking Fees: Be aware of any potential restocking fees that could affect your overall budget.

Step 7: Finalize the Purchase with Confidence

Once all checks have been completed, and you are satisfied with your chosen model and supplier, proceed to finalize the purchase. Ensure all documentation is in order.

– Invoice and Warranty: Keep a record of the invoice and warranty details for future reference.

– Post-Purchase Support: Establish a point of contact for any post-purchase issues or support needs.

By following this checklist, B2B buyers can confidently navigate the procurement process for laptops suited for Fusion 360, ensuring they select a device that enhances productivity and meets their design requirements.

Comprehensive Cost and Pricing Analysis for good laptop for fusion 360 Sourcing

What Are the Key Cost Components for Sourcing a Good Laptop for Fusion 360?

When sourcing laptops suitable for Fusion 360, a variety of cost components come into play. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The quality of components such as CPUs, GPUs, RAM, and SSDs significantly influences the overall cost. High-performance options, like the latest NVIDIA RTX series graphics cards or Intel i9 processors, come at a premium.

-

Labor: Labor costs can vary based on the region of production. For instance, manufacturing in countries with higher wage standards, such as those in Europe, may lead to increased costs compared to regions in Asia or South America.

-

Manufacturing Overhead: This encompasses operational costs associated with production facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce these overheads, impacting the final pricing.

-

Tooling: This involves the costs associated with the production tools and machinery necessary for assembling the laptops. Custom tooling for specialized configurations may add to the cost.

-

Quality Control: Ensuring the laptops meet performance standards requires investment in QC processes. Certifications such as ISO can further influence costs but also enhance product reliability.

-

Logistics: Shipping costs vary significantly based on distance, mode of transport, and Incoterms. For international buyers, understanding these logistics costs is crucial for total cost assessment.

-

Margin: Suppliers typically add a margin based on market demand, competition, and perceived value. This margin can vary widely, affecting the final price offered to buyers.

How Do Price Influencers Affect Laptop Sourcing for Fusion 360?

Several factors influence the pricing of laptops suitable for Fusion 360, making it essential for buyers to understand these nuances.

-

Volume/MOQ: Purchasing in bulk can lead to significant discounts. Establishing a Minimum Order Quantity (MOQ) with suppliers can further reduce costs.

-

Specs/Customization: Customized laptops tailored to specific needs (e.g., enhanced RAM or specialized GPUs) may incur additional charges. Buyers should weigh the cost against their actual performance requirements.

-

Materials: The choice of materials can significantly impact pricing. For instance, opting for premium components will yield better performance but at a higher cost.

-

Quality/Certifications: Laptops with recognized quality certifications may be priced higher but offer greater reliability, which can be a worthwhile investment for businesses relying on Fusion 360.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their brand value, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is crucial for international buyers. These terms dictate who bears the costs and risks during shipping, affecting the total cost structure.

What Are the Best Negotiation Strategies for International B2B Buyers?

For international buyers, especially those from regions like Africa and South America, effective negotiation strategies can help secure better pricing and terms.

-

Research and Preparation: Understand market prices and suppliers’ costs to negotiate confidently. Having knowledge of local competitors can strengthen your position.

-

Build Relationships: Developing a rapport with suppliers can lead to better terms and pricing. Long-term relationships often yield greater flexibility and concessions.

-

Leverage Total Cost of Ownership (TCO): Presenting a TCO analysis can justify higher initial costs if the chosen laptop offers lower operational costs or longer lifespan. This approach can be persuasive in negotiations.

-

Be Flexible with Specifications: Indicating flexibility in specifications may enable suppliers to offer alternative models that meet budget constraints while still providing adequate performance.

-

Inquire About Volume Discounts: If planning future purchases, discuss potential discounts for bulk orders to establish a mutually beneficial agreement.

What Should International Buyers Keep in Mind Regarding Pricing Nuances?

International buyers should be aware of pricing nuances that can affect their sourcing decisions. Currency fluctuations can impact costs, making it essential to lock in prices when possible. Additionally, understanding import duties and taxes is crucial, as these can significantly raise the final cost of laptops.

Lastly, always ask for indicative prices and ensure clarity on warranty and service agreements, particularly when dealing with international suppliers. This diligence can help avoid unexpected costs and ensure a smoother purchasing process.

Alternatives Analysis: Comparing good laptop for fusion 360 With Other Solutions

Exploring Alternative Solutions for Running Fusion 360

When considering the best technology for running Fusion 360, businesses have various options beyond investing in a high-performance laptop. Evaluating alternatives can lead to cost savings and enhanced productivity. This section compares a good laptop for Fusion 360 against two viable alternatives: a desktop workstation and cloud-based computing solutions.

| Comparison Aspect | Good Laptop For Fusion 360 | Desktop Workstation | Cloud-Based Computing Solutions |

|---|---|---|---|

| Performance | High single-core performance; capable of handling design tasks efficiently. | Exceptional multi-core performance; ideal for rendering and simulations. | Performance depends on internet speed and server capabilities; can scale up as needed. |

| Cost | Higher upfront cost; requires periodic upgrades. | Generally more cost-effective for high performance; however, initial investment can be significant. | Subscription-based pricing; lower upfront costs but ongoing expenses. |

| Ease of Implementation | Easy to set up; portable and user-friendly. | Requires assembly and configuration; less portable. | Requires a stable internet connection and cloud service setup. |

| Maintenance | Moderate; may require hardware upgrades over time. | Higher maintenance due to hardware components and potential for failure. | Minimal; managed by the service provider, but dependent on internet reliability. |

| Best Use Case | Ideal for professionals on the go or in remote locations. | Best for teams requiring high computational power for extensive projects. | Suitable for collaborative teams needing access to powerful resources without hardware constraints. |

What Are the Advantages and Disadvantages of a Desktop Workstation?

Desktop workstations are tailored for intensive tasks, making them an excellent alternative for running Fusion 360. With superior multi-core performance, they excel at rendering and simulations, which can be beneficial for complex designs. The initial cost may be lower compared to high-end laptops when factoring in performance, but they require a significant upfront investment and ongoing maintenance. Their lack of portability can be a drawback for professionals who need to work in different locations or travel frequently.

How Do Cloud-Based Computing Solutions Compare?

Cloud-based computing solutions provide a flexible and scalable alternative to traditional hardware. They allow users to access powerful computing resources without investing in physical hardware, which can be particularly appealing for companies with fluctuating demands. However, performance is contingent on internet speed and service reliability, which can hinder productivity in areas with poor connectivity. Additionally, while the upfront costs are lower, ongoing subscription fees may accumulate over time, potentially leading to higher long-term expenses.

Conclusion: How to Choose the Right Solution for Your Business Needs

When selecting the right technology for running Fusion 360, B2B buyers should consider their specific operational needs, budget constraints, and team dynamics. A high-performance laptop may be best suited for professionals who prioritize portability and ease of use. In contrast, a desktop workstation may serve teams requiring robust performance for rendering and simulations. Alternatively, cloud-based solutions offer flexibility and scalability for collaborative efforts but depend on reliable internet access. Evaluating these aspects will help businesses make an informed decision that aligns with their strategic goals and operational requirements.

Essential Technical Properties and Trade Terminology for good laptop for fusion 360

When selecting a laptop suitable for running Fusion 360, understanding the technical specifications and industry terminology is crucial for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Below are key properties and terms that will aid in making informed purchasing decisions.

What Are the Essential Technical Properties of a Laptop for Fusion 360?

1. Processor (CPU) Performance: Why is it Critical?

The CPU is the heart of any computer, and for Fusion 360, it is essential to prioritize single-core performance. Fusion 360 primarily utilizes single-threaded processes, meaning that a CPU with strong single-core capabilities will yield better performance. Recommended models include Intel Core i7/i9 or AMD Ryzen 7/9, ideally from the latest generations. This is particularly important for tasks such as modeling and design.

2. Graphics Processing Unit (GPU): What Should You Look For?

A dedicated GPU is vital for rendering complex models and simulations in Fusion 360. NVIDIA’s RTX series (e.g., RTX 4060, 4070) or professional GPUs like the NVIDIA RTX A-series are preferred for their superior performance in graphics-intensive applications. A robust GPU enhances visual rendering capabilities and accelerates simulations, which is essential for design professionals.

3. Memory (RAM): How Much Is Necessary?

A minimum of 16GB of RAM is recommended, with 32GB being ideal for more demanding tasks. Sufficient RAM allows for smooth multitasking and handling of larger design files, which is crucial in a professional setting where efficiency and speed can significantly impact productivity.

4. Storage Capacity and Speed: Why Are They Important?

Solid-state drives (SSDs) are preferable due to their fast read/write speeds, which reduce load times and improve overall system responsiveness. A minimum storage capacity of 1TB is recommended, especially when dealing with large design files and projects. This ensures that users have ample space for software, files, and backups, reducing the need for external storage solutions.

5. Display Quality: What Should Be Considered?

A high-resolution display (preferably Full HD or higher) with good color accuracy is important for design work. IPS panels are recommended for their wider viewing angles and better color reproduction, which are critical for visual assessments of designs. A larger screen can also enhance productivity by providing more workspace.

What Are Common Trade Terms Related to Purchasing Laptops for Fusion 360?

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to companies that produce components or products that are used in another company’s end product. In the laptop market, understanding OEM relationships can help buyers ensure they are sourcing high-quality components that meet the necessary performance standards.

2. MOQ (Minimum Order Quantity): Why Is This Important?

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ can help in budgeting and planning inventory. This is particularly important for companies looking to purchase multiple units for teams or departments.

3. RFQ (Request for Quotation): How Does It Work?

An RFQ is a document that a buyer sends to suppliers to solicit price quotes for specific products. This process is essential for B2B transactions, allowing buyers to compare prices and terms from different vendors, ensuring they get the best deal.

4. Incoterms (International Commercial Terms): What Should Buyers Know?

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping costs, risks, and responsibilities, particularly when sourcing laptops from international suppliers.

5. Warranty and Support: Why Do They Matter?

Warranties provide assurances regarding product quality and performance. For laptops used in demanding environments like CAD applications, knowing the warranty terms and available technical support can be vital for minimizing downtime and ensuring business continuity.

In conclusion, a comprehensive understanding of these technical properties and industry terms can empower B2B buyers to make informed decisions when selecting laptops for Fusion 360, ultimately enhancing productivity and performance in design and engineering tasks.

Navigating Market Dynamics and Sourcing Trends in the good laptop for fusion 360 Sector

What Are the Key Market Trends Impacting the Sourcing of Laptops for Fusion 360?

The global market for laptops suitable for Fusion 360 is evolving rapidly, driven by the increasing demand for high-performance computing solutions in design and engineering sectors. Key trends include the growing emphasis on single-core performance due to Fusion 360’s reliance on single-threaded processing for most tasks, alongside the need for robust graphics capabilities for rendering and simulation tasks. This has led to a surge in demand for laptops equipped with Intel’s Core i7/i9 or AMD’s Ryzen 7/9 processors, coupled with powerful GPUs like NVIDIA’s RTX series or AMD’s Radeon Pro series.

Additionally, the shift towards remote work and cloud-based applications is influencing purchasing decisions. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly looking for laptops that combine portability with high performance. The focus on hybrid work environments necessitates versatile devices that can handle intensive tasks while remaining lightweight and durable.

Emerging markets are also seeing a rise in locally assembled or branded laptops, which can offer competitive pricing and features tailored to regional needs. Furthermore, as the technology landscape continues to evolve, there is a growing interest in custom-built solutions, allowing businesses to optimize specifications based on their unique workflow requirements.

How Does Sustainability Influence the Sourcing of Laptops for Fusion 360?

Sustainability is becoming a crucial factor in the B2B purchasing process for laptops designed for Fusion 360. Businesses are increasingly aware of the environmental impact of their sourcing decisions, prompting them to seek out laptops that are manufactured with sustainable practices in mind. This includes the use of recycled materials, energy-efficient manufacturing processes, and adherence to environmental regulations.

Moreover, ethical sourcing has gained traction, with buyers looking for suppliers who can demonstrate commitment to fair labor practices and transparency in their supply chains. Certifications such as Energy Star, EPEAT, and ISO 14001 are becoming essential in the decision-making process, indicating a manufacturer’s adherence to sustainable practices.

The push for ‘green’ technology is not only a compliance measure but also a strategic advantage. Companies that prioritize sustainability can enhance their brand reputation and appeal to environmentally conscious clients. For laptops suited for Fusion 360, this means sourcing from manufacturers that prioritize eco-friendly materials and processes, thus aligning with global sustainability goals while ensuring high performance.

What Is the Historical Context of Laptop Development for Fusion 360?

The evolution of laptops suitable for Fusion 360 has mirrored advancements in technology and user demands over the years. Initially, laptops were primarily designed for general office use, with limited capabilities for handling intensive design software. However, as applications like Fusion 360 gained popularity, the demand for more powerful machines became evident.

In the early 2010s, the introduction of dedicated graphics cards and multi-core processors marked a significant turning point, allowing for more complex simulations and rendering tasks. As Fusion 360 evolved, so did the specifications required to run it effectively, leading to the emergence of high-performance laptops specifically tailored for engineering and design professionals.

Today, laptops for Fusion 360 are characterized by their powerful CPUs, advanced GPUs, ample RAM, and high-speed storage solutions, all while maintaining portability and energy efficiency. This ongoing evolution reflects the dynamic nature of design and engineering, where technological advancements continually reshape the tools professionals rely on.

Frequently Asked Questions (FAQs) for B2B Buyers of good laptop for fusion 360

-

How do I choose the right laptop for Fusion 360?

To select the best laptop for Fusion 360, prioritize a high-performance CPU with strong single-core capabilities, such as the Intel Core i7/i9 or AMD Ryzen 7/9. Ensure the laptop has a dedicated GPU, preferably from the NVIDIA RTX series or AMD Radeon Pro series, to handle graphics-intensive tasks. A minimum of 16GB RAM is recommended, with 32GB being ideal for more complex projects. Additionally, look for at least 1TB of SSD storage for optimal performance and quick load times. Finally, consider the laptop’s build quality and portability based on your operational needs. -

What specifications should I look for in a laptop for CAD software like Fusion 360?

When sourcing a laptop for CAD applications like Fusion 360, focus on the processor, graphics card, RAM, and storage. The ideal specifications include a powerful CPU (Intel i7/i9 or AMD Ryzen 7/9), a dedicated GPU (NVIDIA RTX series or AMD Radeon Pro), and at least 16GB of RAM, preferably expandable to 32GB. Storage should be a minimum of 1TB SSD to accommodate large design files and ensure fast access. Additionally, ensure the laptop runs on the latest operating system for compatibility and security. -

What are the recommended brands for laptops suitable for Fusion 360?

Top brands recognized for providing laptops suitable for Fusion 360 include Dell, HP, Lenovo, and ASUS. Dell’s Precision and XPS series are noted for their robust performance, while HP’s ZBook series offers reliability for professional use. Lenovo’s ThinkPad P series is also a strong contender, known for durability and performance. For budget options, ASUS TUF series and Acer Predator series offer good performance at a competitive price point. Always verify that the specific model meets the required specifications for optimal Fusion 360 performance. -

What are the key factors in vetting suppliers for laptops in international trade?

When vetting suppliers for laptops, consider their reputation, product quality, and customer service. Request references and check online reviews to gauge reliability. Ensure that the supplier adheres to international quality standards and has a clear return policy. Evaluate their ability to provide warranty support and after-sales service. Additionally, assess their logistics capabilities, including shipping times and costs, especially if you’re sourcing from different regions like Africa or South America, where logistics can vary significantly. -

How can I customize a laptop for Fusion 360 according to my business needs?

Customization options for laptops can vary by manufacturer. Most brands allow for RAM upgrades, storage expansion, and sometimes GPU options. When placing an order, specify the required configurations, such as increased RAM (32GB or more) and larger SSD storage (1TB or above). Discuss with your supplier about any available options for pre-installed software or specific hardware configurations that optimize performance for Fusion 360. Always confirm that these customizations do not void the warranty and are feasible for your operational needs. -

What are the typical minimum order quantities (MOQ) for laptops when buying internationally?

Minimum order quantities (MOQ) for laptops can vary widely depending on the supplier and the model. Generally, larger manufacturers may have a lower MOQ, sometimes allowing single-unit purchases, while bulk orders might range from 10 to 100 units. For B2B buyers in regions like Africa and South America, negotiating MOQ with suppliers is often possible, especially if you can demonstrate the potential for future orders. Always clarify MOQ terms before proceeding to ensure they align with your purchasing strategy. -

What payment terms should I expect when sourcing laptops internationally?

Payment terms for international laptop purchases typically vary by supplier but often include options like upfront payment, partial payment upon order confirmation, or payment upon delivery. Many suppliers also accept letters of credit or escrow services to secure transactions. It’s essential to discuss these terms upfront and ensure they are clearly documented in the purchase agreement. Additionally, consider potential currency fluctuations and transaction fees when negotiating payment terms, as these can impact your overall costs. -

How do I ensure quality assurance (QA) for laptops sourced internationally?

To ensure quality assurance for laptops sourced internationally, establish clear specifications and standards in your purchase agreement. Request samples or demo units to evaluate performance before committing to larger orders. Verify that the supplier conducts rigorous QA checks during production and offers warranties or guarantees on their products. Additionally, consider third-party inspection services if purchasing in bulk, as they can provide an unbiased assessment of the laptops’ quality before shipment. Maintaining open communication with the supplier throughout the process is crucial for addressing any potential issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 1 Good Laptop For Fusion 360 Manufacturers & Suppliers List

1. ASUS – ROG Zephyrus G14 (2024)

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: ASUS – ROG Zephyrus G14 (2024) 14″ OLED 3K 120Hz Gaming Laptop – AMD Ryzen 9 8945HS – 32GB LPDDR5X – GeForce RTX 4070 – 1TB SSD – Platinum White

Strategic Sourcing Conclusion and Outlook for good laptop for fusion 360

In the realm of strategic sourcing for laptops that effectively run Fusion 360, prioritizing specific hardware specifications is critical. The ideal laptop should feature a powerful single-core processor, such as Intel Core i7/i9 or AMD Ryzen 7/9, coupled with a robust GPU from the NVIDIA RTX series or AMD Radeon Pro. A minimum of 16GB RAM and 1TB SSD storage are essential for optimal performance, especially when handling complex designs and simulations.

For international B2B buyers, particularly those in emerging markets like Nigeria and Brazil, understanding the importance of these specifications can guide informed purchasing decisions. Investing in high-performance laptops not only enhances productivity but also supports a competitive edge in design and manufacturing sectors. As the demand for advanced design software increases, so does the necessity for strategic sourcing that aligns with these technological requirements.

Looking ahead, businesses must remain agile and proactive in their sourcing strategies. Evaluate suppliers who can provide high-quality, reliable laptops that meet these specifications, ensuring that your team is equipped to tackle the evolving challenges of design and engineering. Embrace this opportunity to elevate your operations and drive innovation in your projects.