Flat Spring Clips Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for flat spring clips

Navigating the complexities of sourcing flat spring clips can be a formidable challenge for B2B buyers in diverse industries. With varying specifications, applications, and quality standards, understanding how to procure these essential components effectively is crucial for operational efficiency. This comprehensive guide delves into the myriad types of flat spring clips available in the global market, from standard designs to custom solutions tailored to unique applications. It covers critical aspects such as material selection, manufacturing processes, supplier vetting, and cost considerations, ensuring you have the knowledge needed to make informed purchasing decisions.

International buyers from regions like Africa, South America, the Middle East, and Europe, including markets like Brazil and Nigeria, will find this guide particularly beneficial. It aims to empower you with actionable insights that address common sourcing challenges, such as identifying reliable suppliers, ensuring product quality, and optimizing procurement costs. By equipping you with the necessary information and resources, this guide positions you to confidently navigate the flat spring clip market, ultimately enhancing your supply chain efficiency and product reliability. Whether you’re in the automotive, aerospace, or electronics sector, understanding the nuances of flat spring clips is essential for your business’s success.

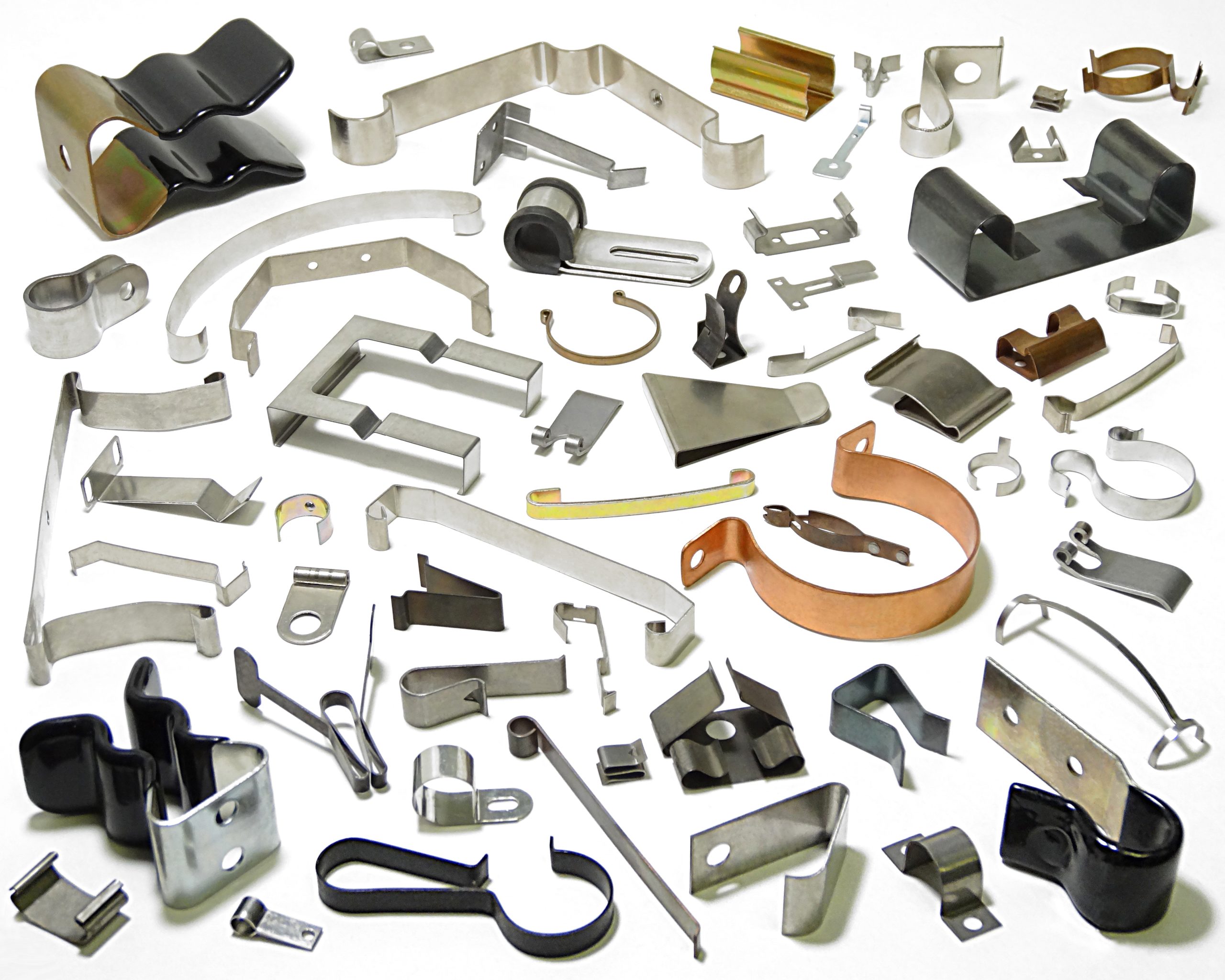

Understanding flat spring clips Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heat Sink Clips | Designed to attach heat sinks to electronic components; provides efficient thermal transfer. | Electronics, Automotive, Aerospace | Pros: Effective heat management; Cons: Requires precise fit for optimal performance. |

| Clamps | Versatile fasteners that hold components together; available in various sizes and materials. | Construction, Manufacturing, Automotive | Pros: Strong holding capacity; Cons: May require additional tools for installation. |

| Clasps | Simple one-piece designs that secure items without the need for additional fasteners. | Consumer Products, Medical Devices, Automotive | Pros: Easy to install; Cons: Limited load-bearing capacity. |

| Closures | Often used for securing lids or doors; designed to withstand repetitive use. | Packaging, Automotive, Appliances | Pros: Durable and reliable; Cons: May be less flexible in design options. |

| Custom Flat Springs | Tailored to specific applications; can be engineered for unique shapes and sizes. | Aerospace, Medical Devices, Custom Equipment | Pros: Highly adaptable; Cons: Typically higher initial costs due to custom manufacturing. |

What Are the Key Characteristics of Heat Sink Clips?

Heat sink clips are essential in electronic applications where thermal management is critical. They securely attach heat sinks to components, ensuring efficient heat dissipation. For B2B buyers, selecting the right heat sink clip involves considering material compatibility, thermal conductivity, and the specific dimensions required for the application. Precision in fit is crucial as it directly impacts performance; thus, sourcing from reputable manufacturers who can provide customized solutions is advisable.

How Do Clamps Function in Various Industries?

Clamps are highly versatile fasteners used across diverse industries, from construction to automotive. Their ability to hold components securely makes them invaluable in assembly processes. Buyers should consider the specific load requirements and environmental conditions when selecting clamps, as different materials (like stainless steel or plastic) offer varying degrees of strength and resistance to corrosion. Additionally, ease of installation can influence the choice, particularly in high-volume production environments.

Why Choose Clasps for Secure Fastening?

Clasps are designed for straightforward fastening, often found in consumer products and medical devices. Their one-piece structure simplifies installation, making them user-friendly. However, B2B buyers should be aware of their limitations in load-bearing capacity, particularly in heavy-duty applications. When sourcing clasps, it’s important to evaluate the intended use and ensure the material chosen can withstand the necessary conditions, such as exposure to chemicals or extreme temperatures.

What Are the Benefits of Using Closures?

Closures are typically employed to secure lids or doors in various applications, including packaging and automotive. Their design allows for repeated use while maintaining a secure hold. Buyers should assess durability and reliability, especially for products that will undergo frequent opening and closing. Material selection is crucial as it affects the closure’s lifespan and performance under stress. Investing in high-quality closures can significantly reduce maintenance costs over time.

How Do Custom Flat Springs Meet Unique Industry Needs?

Custom flat springs are engineered to meet specific application requirements, making them ideal for industries such as aerospace and medical devices. Their adaptability allows for unique shapes and sizes, providing tailored solutions for complex needs. When purchasing custom flat springs, B2B buyers should engage with manufacturers that have expertise in material selection and design. While the initial costs may be higher, the long-term benefits of optimized performance and reliability often justify the investment.

Key Industrial Applications of flat spring clips

| Industry/Sector | Specific Application of flat spring clips | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Securing components in engine assemblies | Enhances reliability and performance of vehicle systems | Material durability, resistance to vibration, and cost |

| Electronics | Mounting circuit boards and securing wiring | Improves device longevity and ease of assembly | Precision manufacturing, thermal conductivity, and size |

| Aerospace | Holding instrumentation and components in aircraft | Ensures safety and compliance with strict regulations | Lightweight materials, fatigue resistance, and certification |

| Medical Devices | Fastening parts in surgical instruments | Critical for patient safety and device functionality | Biocompatibility, sterilization capability, and precision |

| Construction | Supporting fixtures and securing tools on-site | Increases efficiency and organization at job sites | Corrosion resistance, load capacity, and custom designs |

How Are Flat Spring Clips Used in the Automotive Industry?

In the automotive sector, flat spring clips are essential for securing various components within engine assemblies. They provide a reliable fastening solution that can withstand the high vibrations and temperatures typical in automotive environments. The primary requirement for buyers in this sector is to ensure that the clips are made from durable materials that can endure rigorous conditions without failure. International buyers, particularly in regions like Africa and South America, should consider sourcing from manufacturers that understand local automotive standards and can deliver quality parts that enhance vehicle performance.

What Role Do Flat Spring Clips Play in Electronics?

In electronics, flat spring clips are commonly used to mount circuit boards and secure wiring. They help in organizing components, ensuring that devices operate efficiently and have a longer lifespan. Buyers in this industry must prioritize precision manufacturing to accommodate intricate designs and small sizes. Additionally, sourcing clips with good thermal conductivity is crucial for applications involving heat dissipation. International buyers should seek suppliers with a track record in the electronics sector to ensure compliance with international quality standards.

Why Are Flat Spring Clips Important in Aerospace Applications?

Flat spring clips are critical in the aerospace industry for holding instrumentation and various components securely in aircraft. Their role is vital in ensuring safety and compliance with stringent aviation regulations. Buyers in this sector must focus on sourcing lightweight yet robust materials that can withstand extreme conditions. It is essential for international buyers to partner with certified manufacturers who can guarantee high-quality production processes and materials that meet aerospace industry standards.

How Are Flat Spring Clips Utilized in Medical Devices?

In medical devices, flat spring clips are used to fasten parts in surgical instruments, contributing to the overall functionality and safety of these critical tools. The requirements for buyers in this sector include ensuring that the clips are made from biocompatible materials and can withstand sterilization processes. International buyers should also consider the precision of the clips, as any failure could have serious implications for patient safety. Sourcing from suppliers experienced in the medical device industry can enhance the reliability of the products.

What Benefits Do Flat Spring Clips Offer in Construction?

In the construction industry, flat spring clips are utilized to support fixtures and secure tools, improving efficiency and organization at job sites. They help in managing the workspace by keeping tools easily accessible and securely fastened. Buyers should focus on sourcing clips that are corrosion-resistant and can bear significant loads. For international buyers, understanding local construction regulations and material standards is crucial to ensure compliance and reliability in their projects. Custom designs may also be necessary to meet specific project needs.

3 Common User Pain Points for ‘flat spring clips’ & Their Solutions

Scenario 1: Inconsistent Performance Across Applications

The Problem: Many B2B buyers experience frustration when flat spring clips do not perform consistently across different applications. For instance, a manufacturer might use the same type of clip for both automotive and electronic components, only to find that the clips do not maintain adequate force or fatigue life in all environments. Variations in temperature, humidity, or mechanical stress can lead to premature failure, resulting in costly downtimes and potential damage to the components they secure.

The Solution: To address this challenge, it’s crucial for buyers to thoroughly assess the specific requirements of each application before selecting spring clips. This involves evaluating the material properties, such as tensile strength, corrosion resistance, and fatigue limits, in relation to the operational environment. Engaging with manufacturers who specialize in custom solutions can be beneficial. Buyers should request samples or prototypes of clips designed for specific conditions and conduct rigorous testing before full-scale deployment. This proactive approach ensures that the chosen clips will provide reliable performance, thus minimizing the risk of failure and associated costs.

Scenario 2: Sourcing Quality Materials for Durability

The Problem: Sourcing flat spring clips made from high-quality materials can be a significant hurdle for B2B buyers, especially in regions with less stringent manufacturing standards. Poor-quality materials can lead to clips that deform, corrode, or break under stress, jeopardizing the integrity of the entire assembly. Buyers often struggle to verify the quality of materials used in the clips, which can lead to unexpected failures and increased replacement costs.

The Solution: To mitigate this issue, buyers should prioritize suppliers who provide comprehensive material certifications and transparency in their manufacturing processes. It is advisable to establish partnerships with manufacturers who can demonstrate their compliance with international quality standards, such as ISO certifications. Furthermore, engaging in open communication with suppliers about the intended application and environmental conditions can guide them in recommending the most suitable materials—be it high-carbon steel, stainless steel, or specialized alloys. Buyers should also consider investing in a quality assurance program that includes regular audits and material testing to ensure ongoing compliance with their specifications.

Scenario 3: Complexity in Customization and Design

The Problem: B2B buyers often encounter challenges when trying to customize flat spring clips for specific applications. Many suppliers may offer standard sizes and shapes, but when unique designs are required, the process can become complicated and lengthy. This complexity can lead to delays in production and increased costs, as well as frustration over the inability to find a suitable off-the-shelf solution.

The Solution: To streamline the customization process, buyers should work with manufacturers who specialize in engineering and prototyping. Providing detailed drawings, specifications, or even part samples can facilitate a smoother design phase. Additionally, buyers should inquire about the manufacturer’s capabilities in terms of material selection, production techniques, and lead times for prototypes. By leveraging advanced manufacturing methods, such as four-slide machines or laser cutting, suppliers can efficiently produce custom clips that meet specific design requirements without excessive delays. Establishing a collaborative relationship with the manufacturer early in the design process can also lead to valuable insights and recommendations that enhance the final product’s performance.

Strategic Material Selection Guide for flat spring clips

What Are the Key Properties of Common Materials for Flat Spring Clips?

When selecting materials for flat spring clips, it is crucial to understand the properties that will affect performance in various applications. Here, we analyze four commonly used materials: high carbon steel, stainless steel, beryllium copper, and phosphor bronze. Each material has distinct characteristics that can significantly influence the clip’s functionality and suitability for specific environments.

How Does High Carbon Steel Perform in Flat Spring Clip Applications?

High carbon steel, such as grades 1074, 1075, and 1095, is known for its excellent strength and hardness. It typically offers high fatigue resistance, making it suitable for applications requiring repeated stress. However, high carbon steel is prone to corrosion, which can limit its use in humid or corrosive environments unless adequately coated.

Pros: High strength and fatigue resistance, cost-effective, readily available.

Cons: Susceptible to rust without protective coatings, less suitable for high-corrosion environments.

Impact on Application: Ideal for automotive and industrial applications where strength is critical but may require additional surface treatments in corrosive settings.

Considerations for International Buyers: Compliance with ASTM standards is common; however, buyers in regions like Africa and South America should ensure proper coatings are available to mitigate corrosion risks.

Why Is Stainless Steel a Preferred Choice for Flat Spring Clips?

Stainless steel, particularly the 300 series and 17-4PH, is favored for its excellent corrosion resistance and strength. It performs well in a wide range of temperatures and is suitable for various applications, including medical devices and outdoor equipment. Its durability makes it a long-term investment, although it comes at a higher cost than carbon steel.

Pros: Exceptional corrosion resistance, high strength, and durability.

Cons: Higher cost compared to carbon steel, may be more challenging to machine.

Impact on Application: Ideal for applications exposed to moisture or chemicals, such as in the medical and food processing industries.

Considerations for International Buyers: Compliance with DIN and JIS standards is essential, especially in Europe and the Middle East, where quality assurance is critical.

What Advantages Does Beryllium Copper Offer for Flat Spring Clips?

Beryllium copper is known for its excellent electrical conductivity and high fatigue strength. It is often used in applications requiring both mechanical performance and electrical properties, such as in connectors and electrical components. However, it is more expensive and can be challenging to source due to its specialized nature.

Pros: High electrical conductivity, excellent fatigue resistance, good corrosion resistance.

Cons: Higher cost, potential sourcing challenges.

Impact on Application: Suitable for electrical applications where conductivity and strength are critical, such as in aerospace and defense.

Considerations for International Buyers: Buyers should be aware of regulations surrounding beryllium due to its toxicity in dust form, which may affect sourcing in certain regions.

How Does Phosphor Bronze Compare in Flat Spring Clip Manufacturing?

Phosphor bronze is another excellent choice for flat spring clips, offering good strength, corrosion resistance, and excellent fatigue properties. It is often used in marine and electrical applications due to its resistance to seawater and electrical conductivity. However, it can be more expensive than other materials.

Pros: Good corrosion resistance, excellent fatigue life, and electrical conductivity.

Cons: Higher cost, less strength compared to high carbon steel.

Impact on Application: Ideal for marine applications and electrical connectors where corrosion resistance is essential.

Considerations for International Buyers: Compliance with ASTM standards is necessary, and buyers should consider the specific environmental conditions of their applications.

Summary Table of Material Selections for Flat Spring Clips

| Material | Typical Use Case for flat spring clips | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High Carbon Steel | Automotive and industrial applications | High strength and fatigue resistance | Susceptible to corrosion without coatings | Low |

| Stainless Steel | Medical devices and outdoor equipment | Exceptional corrosion resistance | Higher cost compared to carbon steel | High |

| Beryllium Copper | Electrical components and connectors | High electrical conductivity | Higher cost and sourcing challenges | High |

| Phosphor Bronze | Marine and electrical applications | Good corrosion resistance | Higher cost and less strength | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of materials used in flat spring clips, aiding in informed decision-making for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for flat spring clips

What Are the Main Stages in the Manufacturing Process of Flat Spring Clips?

The manufacturing of flat spring clips involves a series of well-defined stages, ensuring that the end product meets industry standards and customer specifications. Each stage contributes to the overall quality, performance, and reliability of the final product.

1. Material Preparation: What Materials Are Commonly Used?

The first step in the manufacturing process is material preparation. Flat spring clips can be made from various materials, including high carbon steels, stainless steels, beryllium copper, and exotic alloys like Inconel. The choice of material is critical as it affects the clip’s strength, flexibility, and fatigue life. Manufacturers typically source raw materials that meet specific industry standards, ensuring they possess the necessary mechanical properties for the intended application.

Once the material is selected, it undergoes cutting or stamping to create blanks. This initial shaping is essential, as the thickness and surface finish of these blanks directly impact the forming process and the final quality of the clips.

2. Forming: What Techniques Are Used to Shape Flat Spring Clips?

The forming stage involves shaping the prepared blanks into the desired clip configuration. Various techniques can be employed, including:

- Stamping: This method uses a die to cut and shape the material into the specified design. It is efficient for producing large quantities of clips with consistent quality.

- Laser Cutting: For complex designs or smaller production runs, laser cutting offers precision and flexibility. It allows for intricate shapes that might be challenging to achieve with traditional stamping methods.

- Four-Slide Technology: This specialized machine enables simultaneous bending and forming of the metal, ideal for producing multiple clips quickly and accurately.

Each technique has its advantages, and the choice depends on factors such as order volume, design complexity, and material type.

3. Assembly: How Are Flat Spring Clips Assembled?

In many cases, flat spring clips are standalone components; however, they can also be part of larger assemblies. If assembly is required, it typically involves the integration of various parts, such as attaching clips to brackets or other components. This process is often automated to enhance efficiency and ensure consistent quality.

The assembly stage may also include the application of additional features, such as coatings or treatments that improve corrosion resistance or enhance performance in specific environments.

4. Finishing: What Are the Common Finishing Techniques for Spring Clips?

Finishing processes enhance the aesthetic and functional characteristics of flat spring clips. Common techniques include:

- Heat Treatment: This process alters the material’s mechanical properties, improving strength and fatigue resistance.

- Coating: Clips may be coated with materials such as zinc or powder coating to provide protection against environmental factors.

- Deburring and Polishing: These processes remove sharp edges and improve surface finish, which is crucial for applications in sensitive environments like medical devices.

Finishing not only impacts the performance of the clips but also their appearance, which can be essential for consumer-facing products.

What Quality Assurance Measures Are Typically Implemented?

Quality assurance (QA) is a vital aspect of the manufacturing process for flat spring clips, ensuring that products meet stringent industry standards and customer expectations. Various international and industry-specific standards guide QA practices.

Relevant International Standards: How Do They Impact Quality Assurance?

ISO 9001 is one of the most recognized quality management standards globally. It provides a framework for organizations to ensure consistent quality in their products and services. Adherence to this standard helps manufacturers establish robust processes and continuous improvement practices.

In addition to ISO 9001, other industry-specific certifications may be relevant, such as:

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Standards: Relevant for manufacturers supplying the oil and gas sector, ensuring that products meet the industry’s rigorous safety and quality requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated throughout the manufacturing process. Key checkpoints typically include:

- Incoming Quality Control (IQC): Materials are inspected upon receipt to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Ongoing checks during manufacturing to monitor critical parameters and ensure adherence to specifications.

- Final Quality Control (FQC): The final inspection of finished products before they are shipped to customers, verifying that they meet all quality standards.

Common testing methods used during these checkpoints include dimensional inspections, tensile strength tests, and fatigue testing, ensuring that the clips perform as expected under real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential for ensuring product reliability.

What Are the Best Practices for Supplier Audits?

Buyers should conduct thorough supplier audits before engaging in long-term contracts. This involves visiting the manufacturing facility to evaluate processes, equipment, and quality management systems. Key areas to assess during an audit include:

- Compliance with international standards (e.g., ISO 9001).

- Documentation of quality control procedures and test results.

- Evidence of continuous improvement initiatives.

How Can Buyers Use Third-Party Inspections?

Engaging third-party inspection services is another effective way to verify supplier quality. These independent organizations can conduct audits and inspections at various stages of the manufacturing process, providing unbiased assessments of quality and compliance.

Additionally, buyers should request regular QC reports from suppliers, detailing inspection results, testing methods, and any corrective actions taken. This transparency builds trust and ensures that products consistently meet quality standards.

What Are the Quality Control Nuances for International Buyers?

B2B buyers from diverse regions must navigate various quality control nuances. For instance, understanding the specific regulatory requirements and standards in their target markets is crucial. Buyers should be aware of local certifications and compliance requirements that may differ from international norms.

Establishing clear communication with suppliers about quality expectations and compliance can mitigate risks. Contracts should include detailed specifications regarding quality standards, testing methods, and responsibilities for non-conformance.

By paying close attention to manufacturing processes and quality assurance measures, B2B buyers can make informed decisions, ensuring they procure high-quality flat spring clips that meet their operational needs and industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flat spring clips’

In this practical sourcing guide, we aim to assist B2B buyers in effectively procuring flat spring clips. This checklist will help you navigate the complexities of sourcing, ensuring you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for your flat spring clips. Consider the application, material, dimensions, and load capacity. For instance, whether you need stainless steel for corrosion resistance or high carbon steel for enhanced strength can significantly affect the performance and longevity of the clips.

Step 2: Research Material Options

Understanding the various materials available for flat spring clips is crucial. Different materials offer unique benefits; for example, beryllium copper provides excellent electrical conductivity, while Inconel is suitable for high-temperature environments. Knowing the right material for your application helps ensure that the clips will perform optimally under expected conditions.

Step 3: Evaluate Manufacturing Capabilities

Assess potential suppliers based on their manufacturing processes. Look for companies that utilize advanced techniques such as stamping, laser cutting, or four-slide forming, which can enhance precision and reduce production time. A supplier’s ability to customize designs according to your specifications is also vital, as it can lead to better fit and functionality.

Step 4: Verify Supplier Certifications

Ensure that your suppliers hold relevant certifications such as ISO 9001:2015, which indicates a commitment to quality management. Certifications can provide assurance that the supplier adheres to industry standards, improving the likelihood of receiving high-quality products. Additionally, inquire about their compliance with international regulations, especially if you are sourcing from different regions.

Step 5: Request Samples and Prototypes

Before finalizing any orders, request samples or prototypes of the flat spring clips. This step allows you to assess the quality, fit, and functionality of the clips in a real-world application. Testing samples can help identify any potential issues early on and ensure that the final product meets your expectations.

Step 6: Establish Clear Communication Channels

Maintain open lines of communication with your suppliers throughout the sourcing process. Discuss lead times, pricing, and any potential challenges that may arise. Clear communication can facilitate smoother transactions and foster a better working relationship, ultimately leading to more efficient sourcing.

Step 7: Negotiate Terms and Finalize Contracts

Once you’ve selected a supplier, negotiate terms that align with your business needs, including pricing, delivery schedules, and payment terms. Be sure to review the contract carefully to ensure all specifications, quality assurances, and compliance requirements are documented. A well-defined agreement can help prevent misunderstandings and protect both parties throughout the procurement process.

By following these steps, you can streamline your sourcing process for flat spring clips, ensuring that you select the right products from reputable suppliers that meet your specific requirements.

Comprehensive Cost and Pricing Analysis for flat spring clips Sourcing

What Are the Key Cost Components for Sourcing Flat Spring Clips?

When evaluating the cost structure for sourcing flat spring clips, several components come into play. The primary cost drivers include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly affects the overall cost. Common materials for flat spring clips include high carbon steels, stainless steels, and exotic alloys. Each material has a different price point based on its properties, availability, and the complexity of sourcing. For instance, while high carbon steels are generally more affordable, specialized materials like Inconel or beryllium copper can substantially increase costs.

-

Labor: Labor costs vary depending on the manufacturing location and the complexity of the production process. Regions with lower labor costs may offer competitive pricing, but this must be balanced against quality and compliance considerations.

-

Manufacturing Overhead: Overhead encompasses the indirect costs of production, such as utilities, rent, and equipment maintenance. Efficient manufacturing practices and advanced technology can help minimize these costs.

-

Tooling: The initial investment in tooling can be significant, especially for custom designs. Tooling costs are typically amortized over production volume, meaning that larger orders can result in lower per-unit costs.

-

Quality Control: Ensuring the quality of flat spring clips through rigorous testing and certification processes can add to the cost. Quality certifications, such as ISO, are essential for suppliers, particularly in industries like aerospace and medical devices.

-

Logistics: Shipping and handling costs are crucial, especially for international buyers. Factors such as shipping distance, weight, and packaging can influence logistics costs. Understanding Incoterms can also help buyers navigate these expenses effectively.

-

Supplier Margin: Supplier markup varies significantly based on their operational costs, market demand, and the level of service provided. This margin can be negotiable, especially for larger volumes.

How Do Price Influencers Impact the Cost of Flat Spring Clips?

Several factors can influence the pricing of flat spring clips, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases typically reduce the unit price. Buyers should consider their inventory needs and negotiate MOQs to achieve better pricing.

-

Specifications and Customization: Custom designs will generally incur higher costs due to the additional engineering and tooling required. Buyers should evaluate the necessity of customization against potential cost savings from standard products.

-

Material Selection: The choice of material has a direct correlation to pricing. Buyers should assess the performance requirements of their applications to choose the most cost-effective material without compromising quality.

-

Quality and Certifications: Higher quality standards and certifications may lead to increased costs. However, investing in quality can reduce long-term expenses related to replacements and failures.

-

Supplier Factors: The supplier’s reputation, reliability, and location can affect pricing. Established suppliers with a proven track record may charge higher prices but offer better quality and service.

-

Incoterms: Understanding shipping terms can help buyers manage costs effectively. Different Incoterms can lead to variations in who bears the shipping costs, insurance, and risks.

What Tips Should International Buyers Consider for Cost-Efficiency in Sourcing Flat Spring Clips?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiation: Engage suppliers in discussions about pricing, especially for large orders. Many suppliers are open to negotiation, particularly if they see a long-term relationship potential.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the entire lifecycle cost of the clips. This includes installation, maintenance, and potential failure costs. Opting for slightly higher-priced quality clips may save money in the long run.

-

Research and Compare Suppliers: Conduct thorough research on multiple suppliers. Comparing quotes and capabilities can reveal significant pricing differences and help identify the best value.

-

Leverage Local Knowledge: Work with local agents or consultants who understand the regional market and can provide insights into the best suppliers and negotiation tactics.

-

Stay Informed on Market Trends: Keep abreast of changes in material costs and global supply chain dynamics that could impact pricing. This knowledge can provide leverage during negotiations.

Disclaimer for Indicative Prices

Pricing for flat spring clips can vary widely based on the factors mentioned above. It is crucial for buyers to request specific quotes from suppliers to obtain accurate pricing tailored to their unique requirements.

Alternatives Analysis: Comparing flat spring clips With Other Solutions

Exploring Alternatives to Flat Spring Clips for B2B Buyers

In the competitive landscape of manufacturing and assembly, selecting the right fastening solution is crucial for efficiency and cost-effectiveness. While flat spring clips are a popular choice due to their reliability and versatility, there are alternative methods and technologies that may better suit specific applications or operational needs. This section examines flat spring clips alongside two viable alternatives: Plastic Snap-Fit Fasteners and Bolted Connections.

Comparison Table

| Comparison Aspect | Flat Spring Clips | Plastic Snap-Fit Fasteners | Bolted Connections |

|---|---|---|---|

| Performance | High load-bearing capacity; excellent vibration dampening | Moderate strength; suitable for lightweight applications | High strength; very secure under high loads |

| Cost | Generally low-cost; bulk manufacturing reduces price | Cost-effective for large volumes; lower material costs | Higher initial costs due to hardware and labor |

| Ease of Implementation | Simple installation; requires no additional tools | Easy to assemble; can be pre-assembled | Requires tools; installation time can vary |

| Maintenance | Low maintenance; durable under stress | Limited lifespan; may degrade under UV exposure | Low maintenance; durable but requires periodic checks |

| Best Use Case | Automotive, electronics, and medical devices | Consumer products, toys, and lightweight assemblies | Heavy machinery, structural components, and automotive applications |

In-Depth Look at Alternatives

What Are the Advantages and Disadvantages of Plastic Snap-Fit Fasteners?

Plastic snap-fit fasteners offer a lightweight and cost-effective alternative to flat spring clips, particularly in applications where weight reduction is essential. They are easy to install, as they simply snap into place, eliminating the need for additional tools. However, their performance is limited to lighter loads, and they may not provide the same level of durability or vibration dampening as metal clips. Additionally, exposure to environmental factors such as UV light can lead to degradation over time, which is a significant consideration for outdoor applications.

How Do Bolted Connections Compare to Flat Spring Clips?

Bolted connections provide a robust fastening solution, ideal for high-strength applications where security is paramount. They excel in heavy machinery and structural components, ensuring that parts remain tightly secured under significant stress. However, bolted connections come with higher costs due to the need for additional hardware and labor for installation. Moreover, they require periodic maintenance checks to ensure that bolts remain tight and secure, making them less appealing for applications where maintenance frequency is a concern.

Making the Right Choice for Your Needs

When deciding between flat spring clips and their alternatives, B2B buyers should carefully assess their specific application requirements. Considerations such as load-bearing needs, environmental factors, and installation constraints play a vital role in this decision-making process. Flat spring clips are generally the best option for applications demanding high load capacity and low maintenance. In contrast, if cost is a significant factor and the application involves lighter components, plastic snap-fit fasteners could be a better choice. For high-security applications, bolted connections offer unparalleled strength but at a higher cost and maintenance requirement. Ultimately, the right solution will depend on the unique demands of each project and the operational priorities of your organization.

Essential Technical Properties and Trade Terminology for flat spring clips

What Are the Key Technical Properties of Flat Spring Clips?

When selecting flat spring clips for various applications, understanding their critical technical properties is vital for ensuring performance and longevity. Here are several key specifications that B2B buyers should consider:

Material Grade

The material grade of a spring clip significantly affects its strength, durability, and resistance to corrosion. Common materials include high carbon steels, stainless steels (e.g., 300 series), and specialty alloys such as Inconel and Elgiloy. Each material has unique properties suitable for specific environments and applications, such as automotive, aerospace, or medical devices. Selecting the right material ensures that the clip can withstand operational stresses and environmental factors.

Thickness and Dimensions

The thickness of a flat spring clip directly influences its force and deflection capabilities. Thicker clips generally provide higher load-bearing capacity but may be less flexible. Precise dimensional specifications are critical; manufacturers often adhere to tight tolerances to ensure compatibility with mating components. Buyers should specify their dimensional requirements to avoid performance issues.

Fatigue Life

Fatigue life refers to the number of cycles a spring clip can endure before failure due to repeated stress. This property is crucial in applications where the clip will undergo constant movement or loading. Understanding fatigue life helps buyers choose clips that will last longer, reducing replacement costs and downtime.

Tolerance

Tolerance defines the allowable deviation from specified dimensions. In the manufacturing of flat spring clips, tight tolerances are essential for ensuring proper fit and function in assembly. A small tolerance can prevent issues such as misalignment, which may lead to failure in critical applications. Buyers should communicate their tolerance requirements clearly to manufacturers to ensure high-quality production.

Force and Deflection Capabilities

Force capability indicates how much load a clip can support, while deflection capability describes how much the clip can flex under load without permanent deformation. These properties are critical in applications requiring precise force application, such as in electronic devices or automotive components. Understanding these capabilities helps buyers select clips that meet their operational demands.

Which Trade Terms Should B2B Buyers Know in the Flat Spring Clip Industry?

Familiarity with industry terminology can streamline the purchasing process and enhance communication with suppliers. Here are several essential trade terms relevant to flat spring clips:

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of flat spring clips, an OEM may require custom clips designed for specific machinery or devices. Understanding this term helps buyers identify potential suppliers who can meet their unique specifications.

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of products that a supplier is willing to sell. Knowing the MOQ is crucial for buyers as it can impact inventory costs and financial planning. Different manufacturers may have varying MOQs based on production capabilities and materials.

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to potential suppliers inviting them to submit price offers for specific products. This is a common practice in B2B transactions for flat spring clips, allowing buyers to compare prices and terms from multiple suppliers efficiently.

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Understanding Incoterms is vital for international transactions, as they clarify who is responsible for shipping costs, insurance, and customs clearance, thereby minimizing potential disputes.

Lead Time

Lead time refers to the duration between placing an order and receiving the products. This is a critical factor for B2B buyers, especially in industries where time-sensitive production schedules are necessary. Knowing the lead times of different suppliers can help in planning and inventory management.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing flat spring clips, ensuring that they select the right components for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the flat spring clips Sector

What Are the Current Market Dynamics for Flat Spring Clips?

The flat spring clips sector is witnessing significant growth driven by the increasing demand for durable, efficient fastening solutions across various industries. Key markets, including automotive, aerospace, electronics, and medical devices, are pushing the need for high-quality, customized spring clips. In regions such as Africa, South America, the Middle East, and Europe, buyers are increasingly focused on sourcing products that not only meet technical specifications but also adhere to local and international quality standards.

Emerging technologies in manufacturing processes, such as automated stamping and laser cutting, are enhancing production efficiency and allowing for the customization of designs tailored to specific applications. The trend toward digital procurement methods is also gaining momentum, with B2B buyers leveraging online platforms for sourcing, facilitating quicker decision-making and streamlined communication with suppliers. Additionally, the rise of Industry 4.0 technologies is influencing sourcing strategies, with manufacturers adopting IoT devices to monitor production and ensure quality control in real-time.

International buyers must navigate varying regulatory environments and standards across regions. For instance, the European market places strong emphasis on compliance with environmental regulations and product safety, necessitating thorough due diligence when selecting suppliers. Understanding these dynamics is crucial for B2B buyers to ensure a reliable supply chain that meets both current and future market demands.

How Is Sustainability Shaping the Sourcing of Flat Spring Clips?

Sustainability and ethical sourcing have become paramount in the flat spring clips sector, influenced by global environmental concerns and consumer preferences for responsible manufacturing practices. The environmental impact of metal sourcing and processing is significant, prompting buyers to seek suppliers that prioritize eco-friendly practices. This includes the use of recycled materials and energy-efficient manufacturing processes, which can reduce the carbon footprint of production.

B2B buyers are increasingly interested in suppliers that can provide certifications for sustainable practices, such as ISO 14001 for environmental management or the use of green materials. These certifications not only demonstrate a commitment to sustainability but also enhance a company’s reputation in the market. Furthermore, sourcing from suppliers that engage in ethical labor practices ensures compliance with international labor laws and contributes to a more equitable global economy.

As the demand for sustainable products grows, manufacturers are innovating with alternative materials, such as biodegradable composites and advanced alloys that require less energy to produce. This shift not only meets regulatory requirements but also aligns with the values of modern consumers who prioritize sustainability in their purchasing decisions. B2B buyers should actively seek out partnerships with suppliers who can demonstrate their commitment to sustainability and ethical sourcing.

What Is the Historical Context of Flat Spring Clips in B2B Markets?

The evolution of flat spring clips dates back to the industrial revolution when the need for efficient fastening mechanisms became prominent. Initially used in simple machinery, these components quickly found applications in a wide range of industries, from automotive to aerospace. Over the decades, advancements in materials science and manufacturing technology have significantly enhanced the performance and versatility of flat spring clips.

In the late 20th century, the rise of automation and precision engineering transformed the production processes for spring clips, allowing for greater customization and efficiency. Today, with the integration of digital technologies and a focus on sustainability, the flat spring clips sector is poised for continued growth. Understanding this historical context helps B2B buyers appreciate the innovations that have shaped the market and the potential future developments that could influence their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of flat spring clips

-

How do I choose the right flat spring clip for my application?

Choosing the right flat spring clip involves understanding the specific requirements of your application, such as load capacity, environmental factors, and material compatibility. Consider the material type—common options include stainless steel, carbon steel, and various alloys—based on strength, corrosion resistance, and flexibility. Additionally, evaluate the design and dimensions of the clip to ensure it fits securely with the components it will hold. Collaborating with manufacturers to discuss your specifications can lead to tailored solutions that meet your needs effectively. -

What is the best material for flat spring clips in harsh environments?

For applications in harsh environments, stainless steel is often the best material choice due to its excellent corrosion resistance and durability. Grades like 300 series stainless steel are particularly effective in resisting oxidation and rust, making them suitable for marine or chemical applications. If extreme temperatures or specific chemical exposures are a concern, consider specialized alloys such as Inconel or Elgiloy, which offer enhanced performance under severe conditions. Always consult with suppliers to select the best material based on your operational needs. -

How can I ensure the quality of flat spring clips from suppliers?

To ensure quality, start by vetting suppliers through their certifications, such as ISO 9001, which indicates a commitment to quality management systems. Request samples of their products to assess material quality and manufacturing standards. Additionally, inquire about their quality assurance processes, including inspections and testing methods. Building a strong relationship with suppliers and maintaining open communication can help address any quality concerns and ensure that the clips meet your specifications consistently. -

What are the typical minimum order quantities (MOQ) for flat spring clips?

Minimum order quantities for flat spring clips can vary significantly among suppliers and depend on the complexity of the design and materials used. Common MOQs range from a few hundred to several thousand units. For custom designs, MOQs may be higher due to setup costs. It’s beneficial to discuss your needs with potential suppliers to negotiate quantities that align with your production schedules while also considering pricing advantages for larger orders. -

What customization options are available for flat spring clips?

Many manufacturers offer extensive customization options for flat spring clips, including alterations in dimensions, shapes, and materials. You can specify unique designs tailored to your application, whether for size adjustments, load requirements, or specific environmental considerations. Some suppliers also provide finishing options, such as coatings for enhanced corrosion resistance or aesthetic appeal. Collaborating closely with the manufacturer during the design phase ensures that the final product meets your exact specifications. -

What payment terms are typically offered by international suppliers?

Payment terms can vary based on the supplier’s policies and your negotiation. Common arrangements include upfront payments, a percentage upfront with the balance upon delivery, or net terms (e.g., net 30 days). For international transactions, consider using secure payment methods like letters of credit or escrow services to protect both parties. Always clarify payment terms before finalizing orders to avoid any misunderstandings. -

How does international shipping affect the procurement of flat spring clips?

International shipping can significantly impact procurement timelines and costs. Factors such as shipping methods, customs clearance, and potential tariffs should be considered when sourcing from overseas suppliers. It’s crucial to work with suppliers who have experience in international logistics to streamline the process. Additionally, understanding the import regulations in your country can help avoid delays and additional fees. Clear communication about shipping timelines and responsibilities is essential to ensure timely delivery. -

What are the best practices for handling and storing flat spring clips?

Proper handling and storage of flat spring clips are vital to maintain their integrity and functionality. Store clips in a dry, clean environment to prevent corrosion, especially for metal components. Use labeled containers to organize different sizes and types, reducing the risk of damage during retrieval. When handling, wear gloves to avoid oil contamination from your hands, which can lead to rust. Regular inspections of stored clips can help identify any issues before they affect production.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Flat Spring Clips Manufacturers & Suppliers List

1. McMaster – Flat Spring Clips

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Flat Spring Clips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Peninsula Spring – Sheet Metal Spring Clips

Domain: peninsulaspring.com

Introduction: Sheet Metal Spring Clips are used to hold components by applying consistent force. Their force, deflection capabilities, and fatigue life depend on material type, thickness, and design. They are in high demand across various industries, including machinery, medical devices, and aerospace. Types of spring clips manufactured include Heat Sink Clips, Clamps, Clasps, and Closures. They are made from m…

3. Fourslide – Metal Spring Clips

Domain: fourslide.com

Registered: 1996 (29 years)

Introduction: Metal spring clips come in various shapes and sizes, used for applications such as attaching penlights to keychains, securing distributor caps, and keeping glove boxes closed. Fourslide Spring and Stamping specializes in manufacturing a wide variety of metal clips, clasps, catches, latches, and clamps.

4. Valco Cleve – Custom Spring Clips

Domain: valcocleve.com

Registered: 1996 (29 years)

Introduction: Custom Spring Steel Clip Manufacturer based in the USA. Offers a variety of spring clip types including double-end, single-end, dual-type, flat-type, loop springs, latch-type, and plastic. Provides prototyping services for custom spring clips. Fast shipping available, often same-day. Over 1,200 variations of custom spring clips. Industries served include construction, healthcare, automotive, minin…

Strategic Sourcing Conclusion and Outlook for flat spring clips

In today’s competitive landscape, the strategic sourcing of flat spring clips is crucial for businesses across various sectors. By understanding the diverse applications and material options available, buyers can make informed decisions that enhance product reliability and performance. Leveraging custom manufacturing capabilities allows companies to secure tailored solutions that meet specific operational demands, ultimately driving efficiency and cost savings.

As industries in Africa, South America, the Middle East, and Europe continue to expand, the demand for high-quality flat spring clips will only grow. Sourcing from reputable manufacturers who prioritize quality, compliance, and innovation can provide a significant competitive edge. By fostering relationships with suppliers that specialize in advanced materials and production techniques, businesses can ensure they are equipped to meet future challenges.

Looking ahead, now is the time for international B2B buyers to evaluate their sourcing strategies. Emphasizing quality and customization will not only enhance product offerings but also solidify market positioning. Engage with suppliers today to explore how strategic sourcing of flat spring clips can drive your business forward and prepare for the evolving demands of tomorrow’s marketplace.