Everything You Need to Know About Wiper For Cleaning Sourcing in 2025

Introduction: Navigating the Global Market for wiper for cleaning

In today’s competitive global market, sourcing the right wiper for cleaning can present significant challenges for B2B buyers. Whether it’s for commercial use in hotels, restaurants, or industrial settings, the demand for effective cleaning solutions is ever-increasing. This comprehensive guide is designed to equip international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, with the insights necessary to make informed purchasing decisions.

Throughout this guide, we will explore various types of wipers, including replaceable head floor wipers and heavy-duty options, along with their diverse applications across different industries. We will also provide actionable strategies for vetting suppliers, understanding pricing structures, and assessing the quality and durability of products. By addressing key considerations such as material specifications and compatibility with cleaning systems, this guide aims to simplify the procurement process.

By leveraging the insights contained within, buyers can enhance their operational efficiency and ensure they are investing in reliable cleaning solutions that meet their specific needs. As the demand for high-quality cleaning products continues to rise, informed decision-making is crucial in navigating the complexities of the global market for wipers.

Understanding wiper for cleaning Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Microfiber Floor Wipers | Highly absorbent, reusable, and effective on various surfaces | Hospitality, healthcare, and commercial cleaning | Pros: Eco-friendly, cost-effective over time. Cons: Requires regular washing, may wear out faster than traditional options. |

| Replaceable Head Wipers | Lightweight with interchangeable heads for different surfaces | Retail, residential, and institutional use | Pros: Versatile, easy to use. Cons: Ongoing cost for replacement heads. |

| Heavy-Duty Scrub Wipers | Robust construction with dual-action scrubbing capability | Automotive, industrial, and construction sectors | Pros: Exceptional durability, effective for tough jobs. Cons: Heavier, may be overkill for light cleaning tasks. |

| Squeegee Wipers | Smooth rubber blade for streak-free finishes | Food service, healthcare, and janitorial services | Pros: Excellent for windows and smooth surfaces. Cons: Limited to flat surfaces, not suitable for textured floors. |

| Specialty Vehicle Wipers | Designed for specific vehicle types with unique features | Automotive maintenance and fleet services | Pros: Tailored performance for specific applications. Cons: Limited compatibility, can be more expensive. |

What Are the Key Characteristics of Microfiber Floor Wipers?

Microfiber floor wipers are designed for high absorbency and effective cleaning across various surfaces. Their fabric captures dirt and moisture, making them ideal for environments like hotels and hospitals where cleanliness is paramount. B2B buyers should consider the long-term cost savings associated with their reusability, although they require regular washing and may degrade faster than traditional options.

How Do Replaceable Head Wipers Enhance Cleaning Efficiency?

Replaceable head wipers feature a lightweight handle and interchangeable heads, allowing users to adapt to different cleaning tasks with ease. These are particularly useful in retail and residential settings where diverse cleaning needs arise. While they offer versatility and ease of use, buyers must account for the recurring costs of replacement heads, which can add to long-term expenses.

Why Choose Heavy-Duty Scrub Wipers for Industrial Applications?

Heavy-duty scrub wipers are built with robust materials and a dual-action scrubbing design, making them perfect for industrial and automotive applications. Their ability to tackle stubborn dirt and debris is a significant advantage in construction or maintenance settings. However, their weight may be a drawback for lighter tasks, so buyers should assess their specific cleaning needs before investing.

In What Situations Are Squeegee Wipers Most Effective?

Squeegee wipers are equipped with smooth rubber blades that provide streak-free finishes, making them ideal for use in food service or healthcare environments where hygiene is crucial. They excel on flat surfaces such as windows and countertops but are not suitable for textured flooring. Buyers should consider their specific cleaning environments to ensure optimal performance.

What Advantages Do Specialty Vehicle Wipers Offer to Fleet Services?

Specialty vehicle wipers are engineered for specific vehicle types, ensuring optimal performance and compatibility. They are essential for fleet services that require reliable and efficient cleaning solutions. While they can be more expensive and limited in compatibility, their tailored features can significantly enhance the cleaning process, making them a worthwhile investment for B2B buyers in automotive maintenance.

Key Industrial Applications of wiper for cleaning

| Industry/Sector | Specific Application of wiper for cleaning | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Cleaning production floors and machinery | Enhances safety and efficiency by maintaining a clean environment | Durability, compatibility with various surfaces, and ease of use |

| Hospitality | Maintaining cleanliness in hotels and restaurants | Improves guest experience and ensures compliance with health standards | Quick-drying materials, ergonomic designs, and eco-friendliness |

| Automotive | Cleaning vehicle interiors and exteriors | Enhances customer satisfaction and vehicle presentation | Versatility, effectiveness on different surfaces, and ease of maintenance |

| Healthcare | Sanitizing medical facilities | Critical for infection control and patient safety | Non-toxic materials, high absorbency, and easy disposal options |

| Retail | Cleaning display areas and customer spaces | Creates a welcoming environment that encourages customer engagement | Lightweight design, effectiveness on various surfaces, and cost-effectiveness |

How is ‘wiper for cleaning’ utilized in the manufacturing sector?

In manufacturing, wipers are essential for cleaning production floors and machinery. They help prevent accidents caused by slippery surfaces and ensure that equipment functions optimally. Buyers from this sector, especially in regions like Africa and South America, should prioritize wipers that are durable and compatible with various surfaces, as well as easy to use. This is crucial for maintaining productivity and workplace safety.

What role does ‘wiper for cleaning’ play in the hospitality industry?

In the hospitality sector, wipers are used to maintain cleanliness in hotels and restaurants, significantly impacting guest experience. Clean floors and surfaces contribute to a positive impression and compliance with health regulations. International buyers, particularly from the Middle East and Europe, should consider quick-drying and ergonomic wipers that are also eco-friendly. These features not only enhance efficiency but also align with growing sustainability initiatives.

Why is ‘wiper for cleaning’ important in the automotive industry?

Wipers are vital for cleaning vehicle interiors and exteriors, playing a key role in enhancing customer satisfaction and vehicle presentation. For automotive businesses, especially in regions like Nigeria and Saudi Arabia, sourcing versatile wipers that are effective on a variety of surfaces is essential. Additionally, ease of maintenance and durability are critical factors, as they directly affect the overall customer experience and brand reputation.

How does ‘wiper for cleaning’ contribute to healthcare environments?

In healthcare settings, wipers are crucial for sanitizing medical facilities, where cleanliness is paramount for infection control and patient safety. Buyers from healthcare sectors in Africa and South America should prioritize wipers made from non-toxic materials with high absorbency and easy disposal options. This ensures compliance with health standards and promotes a safe environment for both patients and staff.

What benefits do ‘wipers for cleaning’ offer in retail spaces?

In retail environments, wipers are used to clean display areas and customer spaces, creating a welcoming atmosphere that encourages engagement. Buyers from Europe and the Middle East should focus on lightweight designs that are effective on various surfaces and cost-effective. This ensures that cleaning staff can maintain high standards of cleanliness without incurring significant operational costs, ultimately enhancing the shopping experience.

3 Common User Pain Points for ‘wiper for cleaning’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Wiper for Specific Surfaces

The Problem: Many B2B buyers face challenges when trying to identify the appropriate wiper for diverse surfaces in their facilities. For instance, a cleaning service provider may have to manage various environments—from industrial floors to delicate wooden surfaces. Using a one-size-fits-all wiper can lead to subpar cleaning results, potential damage to surfaces, and increased costs due to the need for replacements or repairs. Moreover, suppliers often fail to provide adequate product specifications, leaving buyers unsure about compatibility and effectiveness.

The Solution: To effectively address this issue, buyers should conduct thorough research on wiper materials and designs that suit specific cleaning tasks. They should prioritize sourcing wipers made from various materials, such as thermoplastic elastomer for gentle surfaces and durable synthetic fibers for heavy-duty cleaning. When communicating with suppliers, buyers should request detailed product specifications, including surface compatibility, intended use, and care instructions. Additionally, consider establishing a relationship with a supplier that offers customizable wiper options tailored to your unique cleaning needs, ensuring optimal performance across different surfaces.

Scenario 2: Short Product Lifespan Leading to Increased Costs

The Problem: Another prevalent issue is the short lifespan of cleaning wipers, which can be a significant cost concern for B2B buyers. For example, a commercial cleaning company may find that its wipers wear out quickly when used in high-traffic areas, leading to frequent replacements and escalating operational costs. This not only strains the budget but also disrupts cleaning schedules, affecting overall service quality and client satisfaction.

The Solution: To mitigate this problem, buyers should invest in high-quality, heavy-duty wipers designed for longevity. Look for products with reinforced structures and materials that resist wear and tear, such as those featuring a steel frame or advanced polymer blends. Additionally, buyers should implement a proactive maintenance program that includes regular inspections and cleaning of the wipers to extend their lifespan. Educating staff on proper usage and storage techniques can also prevent premature wear. Lastly, consider negotiating bulk purchasing agreements with suppliers to reduce costs per unit and ensure that you always have a sufficient supply of durable wipers on hand.

Scenario 3: Inefficient Use of Cleaning Supplies Resulting in Waste

The Problem: Inefficient use of cleaning supplies, including wipers, can lead to waste and increased operational costs. B2B buyers often struggle with overusing disposable cleaning sheets or wipers, leading to unnecessary expenses and environmental concerns. For instance, a facility manager might notice that staff frequently discard wipers after minimal use due to unclear guidelines on when to replace or wash them, resulting in excess waste and costs.

The Solution: To combat this inefficiency, establish clear guidelines and training programs for employees regarding the proper usage and care of cleaning wipers. Implement a standardized process for tracking the lifespan of each wiper and educating staff on indicators that signal when a wiper should be replaced. Additionally, consider transitioning to replaceable head wipers that allow for the use of washable and reusable cleaning sheets, reducing waste and long-term costs. Encourage a culture of sustainability by tracking waste reduction and sharing results with the team, fostering awareness of the impact of their cleaning practices on the environment and the company’s bottom line.

Strategic Material Selection Guide for wiper for cleaning

What are the Common Materials Used in Wipers for Cleaning?

When selecting materials for wipers used in cleaning applications, it is essential to understand the specific properties, advantages, and limitations of each material. This knowledge aids international B2B buyers in making informed decisions based on performance, cost, and compliance with regional standards.

How Does ABS Resin Perform in Wiper Manufacturing?

ABS (Acrylonitrile Butadiene Styrene) resin is a popular choice for wiper handles and frames due to its excellent impact resistance and rigidity. It can withstand a temperature range of -20°C to 80°C, making it suitable for various cleaning environments. ABS is also resistant to many chemicals, which enhances its durability in industrial cleaning applications.

Pros: ABS is lightweight, cost-effective, and easy to mold, allowing for complex designs. Its impact resistance ensures longevity even in demanding conditions.

Cons: While it is durable, ABS can become brittle over time when exposed to UV light, which may limit its outdoor applications. Additionally, it may not perform well in extreme heat conditions.

Impact on Application: ABS is compatible with various cleaning agents, making it versatile for different cleaning media. However, it is not suitable for high-temperature environments.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM for material safety. Given its affordability, ABS is a preferred choice in cost-sensitive markets like Nigeria and Brazil.

What Role Does EVA Resin Play in Wiper Design?

EVA (Ethylene Vinyl Acetate) resin is commonly used in the top layer of wiper pads due to its flexibility and resistance to cracking. It can operate effectively at temperatures ranging from -30°C to 60°C, making it suitable for diverse climates.

Pros: EVA provides excellent cushioning and grip, enhancing the user experience. Its resistance to degradation from UV light and moisture makes it ideal for outdoor cleaning applications.

Cons: EVA is generally more expensive than ABS and may not be as rigid, which can affect the overall stability of the wiper.

Impact on Application: EVA’s compatibility with various cleaning solutions allows it to be used in multiple settings, including automotive and industrial cleaning.

Considerations for International Buyers: Buyers in regions with high UV exposure, like the Middle East, should prioritize EVA-based wipers for their durability. Compliance with local regulations regarding chemical resistance is also essential.

Why Choose Thermoplastic Elastomer (TPE) for Wiper Bottoms?

Thermoplastic elastomer (TPE) is often used for the bottom of wipers due to its rubber-like properties. It offers excellent temperature resistance, typically between -40°C and 100°C, and is highly resistant to wear and tear.

Pros: TPE provides superior grip and flexibility, making it ideal for various surfaces. Its durability ensures a longer lifespan for the wiper.

Cons: TPE can be more expensive than traditional rubber, which may impact overall product pricing. Additionally, its manufacturing process can be complex, potentially leading to higher production costs.

Impact on Application: TPE is compatible with a wide range of cleaning solutions, making it suitable for both indoor and outdoor applications.

Considerations for International Buyers: Buyers should look for TPE products that meet international standards like DIN for material quality. In regions like South America, where cost is a significant factor, the higher price of TPE may be a consideration.

Summary Table of Material Properties for Wipers

| Material | Typical Use Case for wiper for cleaning | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| ABS Resin | Handles and frames | Lightweight and cost-effective | Brittle under UV exposure | Low |

| EVA Resin | Wiper pads top layer | Excellent cushioning and grip | More expensive, less rigid | Medium |

| Thermoplastic Elastomer (TPE) | Wiper bottoms | Superior grip and flexibility | Higher cost and complex manufacturing | High |

By understanding these materials, B2B buyers can make informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for wiper for cleaning

What Are the Key Stages in the Manufacturing Process of Wipers for Cleaning?

The manufacturing of wipers for cleaning involves several critical stages that ensure the final product is effective, durable, and meets market demands. Here’s an overview of the main stages involved:

Material Preparation

The first stage in the manufacturing process is the selection and preparation of raw materials. Common materials used include various types of plastics (such as ABS and thermoplastic elastomer), fabrics for the wiping surfaces (like microfiber or other absorbent materials), and metal components for structural integrity. Suppliers often source these materials based on their quality, sustainability, and cost-effectiveness.

Once the materials are selected, they undergo treatment processes, such as drying and cutting, to prepare them for the next stages. This preparation is critical as it influences the overall quality and performance of the wipers.

Forming: How Are Wipers Shaped and Molded?

In the forming stage, manufacturers utilize techniques such as injection molding and extrusion to shape the components of the wipers. Injection molding is commonly used for producing plastic parts, allowing for high precision and the ability to create complex shapes. For example, the wiper’s body and frame may be molded to ensure they fit perfectly with the cleaning surface.

Extrusion is often used for creating the wiping edges, where a continuous profile of the material is formed and cut to the desired length. This stage requires careful monitoring to maintain dimensional accuracy and surface quality, ensuring the wipers can effectively clean surfaces without damaging them.

Assembly: What Are the Steps in the Assembly of Wipers?

After forming, the various components are assembled. This stage may involve manual assembly or automated processes, depending on the scale of production. Key elements of assembly include attaching the handle to the wiping head, integrating any mechanical parts (like swivel joints), and ensuring that all components fit securely together.

Manufacturers often implement jigs and fixtures during assembly to enhance efficiency and maintain consistency. Quality checks at this stage are essential to ensure that the assembled product meets design specifications and performance standards.

Finishing: What Processes Ensure the Wipers Are Ready for Market?

Finishing processes add the final touches to the wipers, including surface treatments, packaging, and labeling. Surface treatments may include coating to enhance durability or aesthetics, such as applying a non-slip finish to the handle.

Packaging is another crucial step, as it not only protects the product during transit but also provides essential information to the buyer, including usage instructions and care guidelines. Effective packaging design can enhance market appeal, especially in competitive international markets.

How Is Quality Assurance Implemented in Wiper Manufacturing?

Quality assurance is an integral part of the manufacturing process, ensuring that wipers meet both industry standards and customer expectations. Here’s how it is typically structured:

What International Standards Should B2B Buyers Be Aware Of?

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. This certification ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

Additionally, industry-specific certifications, such as CE marking in Europe, signify compliance with safety and health regulations. For automotive wipers, standards set by the American Petroleum Institute (API) may also apply, especially for products used in harsh environments.

What Are the Key Quality Control Checkpoints?

Quality control in wiper manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial phase assesses the quality of raw materials before they enter the production process. Materials are tested against specifications to prevent defects in the final product.

-

In-Process Quality Control (IPQC): Continuous monitoring during production ensures that processes remain within set parameters. This might involve regular measurements and inspections of the molded components and assembly quality.

-

Final Quality Control (FQC): After assembly, finished products undergo a comprehensive inspection. This includes functional testing to ensure that wipers perform as intended, checking for durability, and verifying that the packaging meets quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to ensure the quality assurance processes of their suppliers:

-

Audits: Regularly auditing suppliers can provide insight into their quality management practices. Buyers should look for audits conducted by independent third parties for an unbiased assessment.

-

Quality Reports: Suppliers should provide detailed quality reports, including data on defect rates and compliance with international standards. These reports can help buyers assess the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of assurance. These firms can conduct inspections at various stages of the manufacturing process, providing buyers with confidence in the quality of the products.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regulatory Compliance: Different regions have varying regulatory requirements. For instance, products sold in the European Union must comply with CE marking requirements, while products in the U.S. may need to meet specific safety standards.

-

Cultural Considerations: Understanding cultural differences in business practices can also impact quality expectations. Buyers should communicate clearly and establish expectations upfront to avoid misunderstandings.

-

Logistics and Supply Chain Challenges: International shipping can introduce risks such as damage during transit. Suppliers should have robust packaging and handling procedures to minimize these risks and ensure that products arrive in perfect condition.

In summary, understanding the manufacturing processes and quality assurance protocols for wipers for cleaning is crucial for B2B buyers. By focusing on these areas, buyers can ensure they source high-quality products that meet their needs and standards, leading to successful business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wiper for cleaning’

Introduction

In the competitive landscape of B2B procurement, sourcing the right cleaning wipers can significantly impact operational efficiency and product quality. This guide provides a step-by-step checklist designed for international buyers looking to procure effective cleaning wipers, ensuring that you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before engaging suppliers, it is essential to clearly outline the technical specifications for the wipers you need. Consider factors such as size, material, and intended use (e.g., floor cleaning, window cleaning, etc.). This clarity will help you communicate effectively with suppliers and ensure that you receive products that meet your operational requirements.

- Material Considerations: Look for durable materials that can withstand frequent use, such as thermoplastic elastomer or ABS resin.

- Compatibility: Ensure the wipers are compatible with your existing cleaning systems or equipment.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who can meet your specifications. Utilize online platforms, trade shows, and industry networks to compile a list of reputable suppliers.

- Supplier Reputation: Investigate their market presence, years in business, and client testimonials.

- Location: Consider suppliers based in regions that offer logistical advantages, especially if you are sourcing from Africa, South America, the Middle East, or Europe.

Step 3: Evaluate Supplier Certifications

Verify the certifications and compliance of potential suppliers with international quality standards. This step is crucial to ensure that the products meet safety and quality benchmarks.

- ISO Certifications: Look for suppliers with ISO 9001 certification or equivalent.

- Sustainability Standards: Check if suppliers adhere to environmental standards, which is increasingly important for many businesses.

Step 4: Request Samples for Testing

Before finalizing any order, request samples of the cleaning wipers. This allows you to assess the quality, usability, and performance of the products in your specific environment.

- Testing for Effectiveness: Evaluate how well the wipers perform in real-world conditions relevant to your operations.

- Durability Assessment: Check how the wipers hold up after multiple uses, ensuring they meet your longevity requirements.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations to establish favorable terms. Pricing, payment terms, and delivery schedules should be clearly discussed.

- Bulk Purchase Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

- Shipping and Handling: Understand the logistics involved, including shipping costs and timelines, especially for international orders.

Step 6: Establish a Trial Period

Before committing to a long-term contract, consider implementing a trial period with the selected supplier. This allows you to monitor product performance and supplier reliability over time.

- Feedback Loop: Create a system for gathering feedback from your team on the wipers’ performance.

- Adjustment Opportunities: Use the trial period to make any necessary adjustments to the order quantities or specifications based on real-world usage.

Step 7: Build a Long-Term Relationship

After successful procurement, focus on building a long-term relationship with your supplier. Regular communication can help you stay updated on new products and innovations in cleaning technology.

- Regular Reviews: Schedule periodic reviews to discuss performance and any evolving needs.

- Loyalty Benefits: Explore loyalty programs or partnerships that can offer additional savings or benefits over time.

By following this checklist, B2B buyers can streamline the procurement process for cleaning wipers, ensuring they make informed decisions that enhance their operational effectiveness.

Comprehensive Cost and Pricing Analysis for wiper for cleaning Sourcing

What Are the Key Cost Components of Wiper for Cleaning Products?

When analyzing the cost structure of wipers for cleaning, several key components must be considered. These include:

-

Materials: The primary materials used in manufacturing cleaning wipers, such as ABS resin, EVA resin, and thermoplastic elastomer, significantly influence the overall cost. The choice of high-quality materials can enhance durability and performance, but they may also increase the price.

-

Labor: Labor costs vary based on the manufacturing location and the skill level of the workforce. Countries with lower labor costs may offer competitive pricing, while regions with higher wages may see increased costs passed on to buyers.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, such as utilities, rent, and equipment maintenance. Efficient production processes can help keep these costs low.

-

Tooling: The initial investment in molds and machinery necessary for production can be substantial. Tooling costs are often amortized over large production runs, affecting the pricing of smaller orders.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but can add to overall costs. Certifications for quality standards can also influence pricing.

-

Logistics: The cost of shipping and handling, especially for international transactions, can significantly impact the final price. Factors such as distance, shipping method, and customs duties must be taken into account.

-

Margin: Suppliers will typically include a profit margin that reflects their business model and market positioning. Understanding the typical margin in your specific market can provide insights into fair pricing.

How Do Price Influencers Affect Wiper for Cleaning Pricing?

Several factors can influence the pricing of wipers for cleaning:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for larger orders. Understanding the MOQ can help buyers negotiate better rates and optimize their procurement strategy.

-

Specifications and Customization: Custom designs or specific features can increase production costs. Buyers should assess whether the additional investment aligns with their operational needs.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO standards) typically command a premium price. Buyers should weigh the long-term benefits of investing in quality against upfront costs.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality and service may charge more, but they often provide peace of mind and lower risks.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect total costs.

What Tips Can Help Buyers Negotiate Better Prices for Wipers?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance negotiation outcomes:

-

Leverage Total Cost of Ownership (TCO): Focus on the long-term value of the product rather than just the initial price. Highlighting the durability and efficiency of a higher-priced wiper can justify the investment.

-

Negotiate Volume Discounts: If your business model supports it, consider negotiating bulk purchase agreements. Suppliers are often willing to provide discounts for larger orders, which can significantly reduce costs.

-

Research Market Prices: Conduct thorough market research to understand the pricing landscape for wipers in your region. This knowledge can empower you during negotiations.

-

Assess Supplier Flexibility: Engage with multiple suppliers to gauge their willingness to customize products or offer flexible payment terms. A supplier who values your business may provide better pricing or terms.

-

Consider Local Suppliers: Whenever possible, sourcing from local suppliers can reduce shipping costs and lead times. This can be a significant advantage in maintaining inventory and managing cash flow.

Disclaimer on Pricing

It is essential to note that prices for wipers for cleaning can vary significantly based on the factors outlined above. Buyers should always request quotes tailored to their specific needs and circumstances to ensure they receive accurate and relevant pricing information.

Alternatives Analysis: Comparing wiper for cleaning With Other Solutions

Understanding Alternatives to Wipers for Cleaning

In the quest for efficient cleaning solutions, businesses often explore various tools and methods to enhance their operational effectiveness. While wipers for cleaning are widely recognized for their effectiveness, it’s crucial to evaluate alternative solutions that may offer unique benefits or address specific cleaning needs. This analysis will compare wipers with two viable alternatives: microfiber mops and steam cleaners.

Comparison Table

| Comparison Aspect | Wiper For Cleaning | Microfiber Mop | Steam Cleaner |

|---|---|---|---|

| Performance | Effective on flat surfaces; quick dirt capture | Highly absorbent; good for dust and spills | Deep cleaning; sanitizes surfaces |

| Cost | Generally low-cost (around $8.90) | Moderate cost (around $20-$30) | Higher initial investment (around $100+) |

| Ease of Implementation | Simple to use; requires minimal setup | User-friendly; requires some assembly | Requires training for effective use |

| Maintenance | Low maintenance; replaceable heads available | Machine washable; needs periodic replacement | Requires regular descaling and maintenance |

| Best Use Case | Quick clean-ups in commercial spaces | Regular cleaning in offices or homes | Deep cleaning in healthcare or food service environments |

Pros and Cons of Alternatives

Microfiber Mops

Microfiber mops are an excellent alternative for businesses that require regular cleaning of floors and surfaces. They are designed with fine fibers that trap dirt and dust effectively, making them suitable for both wet and dry cleaning. The absorbency of microfiber also allows for efficient spill management. However, while they are generally affordable, they may require more frequent replacements than traditional wipers, especially in high-traffic areas. Additionally, they can be less effective on rough surfaces compared to wipers.

Steam Cleaners

Steam cleaners provide a powerful cleaning method that utilizes high-temperature steam to sanitize surfaces. They are particularly beneficial for deep cleaning and disinfecting areas in healthcare, food service, and hospitality industries. The ability to kill bacteria and viruses without the use of harsh chemicals is a significant advantage. However, the higher cost of steam cleaners and the need for training to operate them effectively can be barriers for some businesses. Additionally, they require regular maintenance to prevent mineral buildup and ensure optimal performance.

Choosing the Right Solution for Your Business Needs

When selecting the appropriate cleaning solution, businesses must consider their specific cleaning requirements, budget constraints, and operational environment. Wipers for cleaning are excellent for quick, efficient clean-ups, particularly in commercial settings where time is of the essence. Microfiber mops offer a versatile option for routine maintenance, while steam cleaners deliver a deep clean that is ideal for industries requiring high sanitation standards. Ultimately, the decision should align with the cleaning frequency, surface type, and desired outcomes to ensure operational efficiency and cleanliness.

Essential Technical Properties and Trade Terminology for wiper for cleaning

What Are the Key Technical Properties of Wipers for Cleaning?

When considering wipers for cleaning in a B2B context, understanding their technical properties is vital for making informed purchasing decisions. Here are several critical specifications to keep in mind:

-

Material Composition

The materials used in wiper construction significantly influence their effectiveness and longevity. Common materials include ABS (Acrylonitrile Butadiene Styrene), EVA (Ethylene Vinyl Acetate), and thermoplastic elastomers. Each material offers unique benefits such as durability, flexibility, and resistance to wear. For instance, ABS is known for its strength and toughness, making it ideal for heavy-duty applications. -

Wiper Width and Design

The dimensions of the wiper, including its width, can impact its cleaning efficiency. Wider wipers cover more surface area, reducing cleaning time, while narrower options are better suited for tight spaces. The design can also include features like textured bottoms or replaceable heads, which enhance dirt capture and ease of use. -

Durability and Lifespan

The expected lifespan of a wiper is crucial for B2B buyers looking to minimize replacement costs. Durability is often indicated by the thickness of the material and the construction quality. Heavy-duty wipers made from reinforced materials tend to last longer, especially in commercial settings where intensive use is common. -

Compatibility with Other Tools

Understanding compatibility is essential, particularly for businesses that use various cleaning systems. Wipers should be compatible with different poles or attachments to allow for versatility in cleaning applications. This can prevent the need for multiple purchases and streamline cleaning processes. -

Maintenance Requirements

Wipers may have specific maintenance needs that can affect their performance. For example, some materials may require special cleaning agents, while others are resistant to harsh chemicals. Knowing these requirements helps businesses maintain the wipers effectively, ensuring optimal performance and longevity. -

Environmental Considerations

Sustainable material choices are increasingly important in today’s market. Buyers should consider whether the wipers are made from recyclable materials or have eco-friendly certifications. This aspect can enhance a company’s sustainability profile and appeal to environmentally conscious customers.

What Are Common Trade Terms in the Wiper Industry?

Familiarity with industry jargon is crucial for effective communication and negotiation in the wiper cleaning market. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of cleaning wipers, this means understanding whether the wiper is made by the original manufacturer or a third party. OEM products are often associated with higher quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ represents the minimum number of units a supplier is willing to sell in a single order. This term is essential for B2B buyers as it affects purchasing strategies and inventory management. Understanding MOQ can help businesses optimize their supply chain and reduce excess inventory. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific quantities of products. This process is vital for comparing costs and negotiating favorable terms. Being clear and precise in an RFQ can lead to better pricing and service agreements. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms is crucial for international transactions, especially for buyers in regions like Africa or South America, as they clarify who bears the risk and costs associated with shipping. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. This term is critical for inventory planning and ensuring that cleaning operations can continue without interruption. Knowing the lead time helps businesses plan their purchases effectively. -

TCO (Total Cost of Ownership)

TCO encompasses all costs associated with purchasing, using, and maintaining a product over its entire lifecycle. For cleaning wipers, understanding TCO can help buyers evaluate the long-term value of their investments, beyond just the initial purchase price.

By mastering these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that their cleaning operations are efficient, cost-effective, and aligned with their overall business strategies.

Navigating Market Dynamics and Sourcing Trends in the wiper for cleaning Sector

What Are the Key Market Dynamics and Trends Affecting the Wiper for Cleaning Sector?

The wiper for cleaning sector is experiencing transformative changes driven by a combination of technological advancements, shifting consumer preferences, and economic factors. Global demand for efficient cleaning solutions is on the rise, influenced by heightened awareness of hygiene standards, especially post-pandemic. In regions such as Africa and South America, where urbanization is accelerating, there is a growing market for high-quality, durable cleaning tools that can withstand diverse environmental conditions. Buyers from the Middle East and Europe are increasingly seeking multifunctional products that combine ease of use with high-performance cleaning capabilities.

Emerging trends in B2B sourcing include a focus on automation and smart technologies, such as IoT-enabled cleaning devices that offer real-time monitoring and maintenance alerts. These innovations not only enhance operational efficiency but also reduce labor costs for businesses. Additionally, online platforms are transforming procurement processes, enabling international buyers to access a broader range of suppliers and products. As a result, businesses must remain agile and responsive to these changes, ensuring they are equipped to meet evolving market demands.

How Are Sustainability and Ethical Sourcing Influencing the Wiper for Cleaning Market?

Sustainability is no longer a trend; it has become a business imperative. B2B buyers are increasingly prioritizing eco-friendly products, including wipers made from sustainable materials such as recycled plastics and biodegradable fibers. The environmental impact of cleaning products is under scrutiny, prompting companies to adopt greener practices across their supply chains. This shift not only appeals to environmentally conscious consumers but also aligns with regulatory pressures in various regions, particularly in Europe, where strict environmental standards are enforced.

Ethical sourcing practices are gaining traction as buyers seek transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and Fair Trade are becoming essential for suppliers looking to establish credibility in the market. By choosing suppliers that adhere to these standards, businesses can mitigate risks associated with labor practices and environmental degradation. Ultimately, investing in sustainable and ethically sourced products not only enhances brand reputation but also drives customer loyalty in an increasingly competitive landscape.

What Is the Brief Evolution of the Wiper for Cleaning Sector?

The wiper for cleaning sector has evolved significantly over the decades, transitioning from basic cloths and mops to advanced cleaning systems. Initially, cleaning tools were primarily manual and made from simple materials, limiting their effectiveness and durability. The introduction of synthetic materials in the late 20th century revolutionized the industry, allowing for the production of more efficient and long-lasting cleaning products.

In recent years, the focus has shifted toward multifunctionality and ease of use, with innovations such as replaceable heads and ergonomic designs becoming standard features. The integration of technology, including smart sensors and automated cleaning systems, is poised to further reshape the sector, offering enhanced performance and convenience for B2B buyers. This evolution reflects the growing demand for high-quality cleaning solutions that not only meet functional needs but also align with sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of wiper for cleaning

-

How do I choose the right wiper for cleaning surfaces in my business?

Choosing the right wiper involves understanding the surfaces you need to clean and the type of dirt or debris you encounter. For instance, microfiber wipers are excellent for capturing fine dust and can be used on sensitive surfaces. In contrast, heavy-duty wipers are suitable for industrial settings where grease and heavy dirt are common. Consider factors like the material of the wiper, its durability, and whether it is compatible with your cleaning equipment. It’s advisable to request samples to test performance before making a bulk purchase. -

What is the best wiper for cleaning in commercial settings?

The best wiper for commercial cleaning often combines durability, effectiveness, and ease of use. Microfiber wipers are highly recommended for their superior dirt-holding capacity and ability to clean without scratching surfaces. For larger areas, consider a floor wiper with a replaceable head, which allows for efficient cleaning while minimizing waste. Ensure the wiper is designed for the specific type of flooring in your facility to avoid damage and enhance cleaning effectiveness. -

What should I consider when vetting suppliers for cleaning wipers?

When vetting suppliers, assess their reputation, quality certifications, and production capabilities. Look for suppliers with experience in exporting to your region, as they will understand logistics and compliance requirements. Request references or case studies from similar businesses to gauge reliability and performance. Additionally, consider their ability to customize products based on your specific needs, such as size, material, or branding. -

What are typical minimum order quantities (MOQ) for cleaning wipers?

Minimum order quantities (MOQ) for cleaning wipers can vary significantly by supplier and product type. Generally, MOQs range from 100 to 1,000 units for bulk orders. Suppliers may offer lower MOQs for customized products or first-time orders to build a relationship. Always clarify MOQs during negotiations, as they can affect your initial investment and inventory management strategy. -

What payment terms should I expect when sourcing cleaning wipers internationally?

Payment terms for international orders typically include options such as advance payment, letters of credit, or payment upon delivery. Many suppliers prefer a partial upfront payment (e.g., 30-50%) with the balance due upon shipment or delivery. It’s crucial to discuss and agree upon payment terms before finalizing your order to avoid misunderstandings. Additionally, consider the impact of exchange rates and transaction fees when budgeting for your purchase. -

How can I ensure quality assurance (QA) for my cleaning wipers?

To ensure quality assurance for cleaning wipers, establish clear specifications and performance standards with your supplier. Request samples and conduct thorough inspections upon delivery to confirm they meet your requirements. You may also consider third-party quality inspections during production or before shipment, especially for larger orders. Maintaining open communication with your supplier throughout the process can help address any issues promptly. -

What logistics considerations should I keep in mind when importing cleaning wipers?

When importing cleaning wipers, consider shipping methods, lead times, and customs regulations in your country. Choose between air freight for faster delivery or sea freight for cost savings, depending on urgency and budget. Familiarize yourself with import duties and taxes that may apply to your shipment to avoid unexpected costs. Collaborating with a reliable logistics partner can streamline the process and mitigate risks associated with international shipping. -

Can I customize cleaning wipers for my brand?

Yes, many suppliers offer customization options for cleaning wipers, including branding, color, and packaging. Customization can enhance brand visibility and create a unique product offering in your market. Discuss your specific requirements with potential suppliers and request samples of customized products to evaluate quality. Keep in mind that custom orders may have higher MOQs and longer lead times, so plan accordingly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Wiper For Cleaning Manufacturers & Suppliers List

1. MUJI – Replaceable Head Floor Wiper

Domain: muji.us

Registered: 2002 (23 years)

Introduction: Replaceable Head Floor Wiper | Cleaning Tool | MUJI USA

2. Reddit – Windshield Wiper Maintenance

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Windshield wipers; maintenance advice: wipe down every month to extend lifespan and improve performance.

3. Scrubblade – 15 Heavy-Duty Wiper Blade

Domain: scrubblade.com

Registered: 2011 (14 years)

Introduction: 15″ Scrubblade Wiper Blade; Regular price: $17.99; Rated 5.0 out of 5 stars based on 12 reviews; Sold individually; Best performance for commercial vehicles, Toyota (Tacoma/4Runner), Jeep, and pre-2011 Ford F-Series applications; Features a heavy-duty design with a robust steel frame, reinforced rivets, and graphite-coated blades; Provides silent, seamless wipes and exceptional durability; Unique …

4. Lucid – Air Windshield Wipers

Domain: lucidowners.com

Registered: 2017 (8 years)

Introduction: Lucid Air windshield wipers, cleaning methods include lifting wipers to clean underneath, using microfiber towels, and cleaning with rubbing alcohol to remove carbon deposits. Users discuss issues with wipers tucking under black trim, and suggest opening the frunk for easier access.

5. eBay – Floor Wiper

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Floor Wiper available on eBay with various options. Popular categories include Mops, Brooms & Scrubbers, and Household Cleaning Products. Prices range from $9.99 to $47.21, with free delivery options available. Products include silicone rubber broom mop, multifunction magic broom mop, and floor squeegee for concrete and tile cleaning. Items are brand new and located in various regions including Ca…

6. Bosch – ICON Wiper Blades

Domain: g05.bimmerpost.com

Registered: 2006 (19 years)

Introduction: Bosch ICON wiper blades recommended for BMW X5, part numbers 26OE and 20OE. Users suggest replacing wipers annually or every 6 months in hot climates. The blades are noted for their flexibility (‘floppy’) which helps them conform to the windshield better. Cleaning methods discussed include using water and avoiding substances that can dry out the rubber. Some users report issues with wiper chatter,…

7. 303 – Wiper Blade Conditioner

Domain: autogeekonline.net

Registered: 2006 (19 years)

Introduction: 303 (used for conditioning wiper blades), Glass Cleaner, Mothers CMX, Boch Icons, Rainx Latitude, MOPAR blades.

8. Kia – Niro 2022+

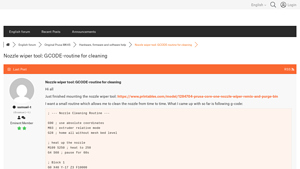

9. Prusa – Nozzle Wiper Tool GCODE Routine

Domain: forum.prusa3d.com

Registered: 2013 (12 years)

Introduction: Nozzle wiper tool; GCODE routine for cleaning; heats nozzle to 250°C; includes multiple blocks of G-code for cleaning; uses absolute coordinates; features pauses for cooling; designed for use with Prusa 3D printers.

Strategic Sourcing Conclusion and Outlook for wiper for cleaning

In today’s dynamic market, effective strategic sourcing of cleaning wipers is paramount for businesses aiming to optimize operations and enhance cleanliness standards. Key takeaways include the importance of selecting high-quality materials, such as durable ABS and thermoplastic elastomers, which ensure longevity and performance. Buyers should prioritize suppliers that offer customizable options, such as replaceable heads and compatibility with various poles, to meet diverse cleaning needs across different environments.

The value of strategic sourcing extends beyond cost savings; it fosters supplier relationships that can lead to innovation and improved product offerings. As international buyers from Africa, South America, the Middle East, and Europe seek to elevate their cleaning standards, the focus should be on sourcing products that not only perform effectively but also align with local market demands and sustainability practices.

Looking ahead, the cleaning industry is poised for growth, driven by increasing hygiene awareness and technological advancements. Now is the time for B2B buyers to engage with suppliers who can provide not just products, but strategic solutions tailored to their specific operational challenges. Embrace this opportunity to enhance your cleaning processes and drive your business forward.