Everything You Need to Know About Vissani Refrigerator Parts Sourcing in 2025

Introduction: Navigating the Global Market for vissani refrigerator parts

In today’s rapidly evolving global market, sourcing Vissani refrigerator parts poses unique challenges for international B2B buyers. With the increasing demand for reliable refrigeration solutions across diverse regions—including Africa, South America, the Middle East, and Europe—finding high-quality, OEM parts can be daunting. Buyers face obstacles such as fluctuating supply chains, varying product specifications, and the need for prompt delivery to minimize downtime in operations. This comprehensive guide aims to navigate these complexities by providing detailed insights into the types of Vissani parts available, their applications, and strategies for effective supplier vetting.

The guide encompasses critical information on the most common replacement parts, including thermostats, door gaskets, and compressors, ensuring that buyers understand not only what they need but also why these components are vital for optimal appliance performance. Moreover, it addresses cost considerations, helping businesses budget effectively while maintaining quality standards. By equipping B2B buyers with actionable knowledge, this resource empowers them to make informed purchasing decisions that enhance operational efficiency and ultimately drive profitability. Whether you are in Germany, Brazil, or any other key market, understanding the landscape of Vissani refrigerator parts is essential for maintaining your competitive edge in the industry.

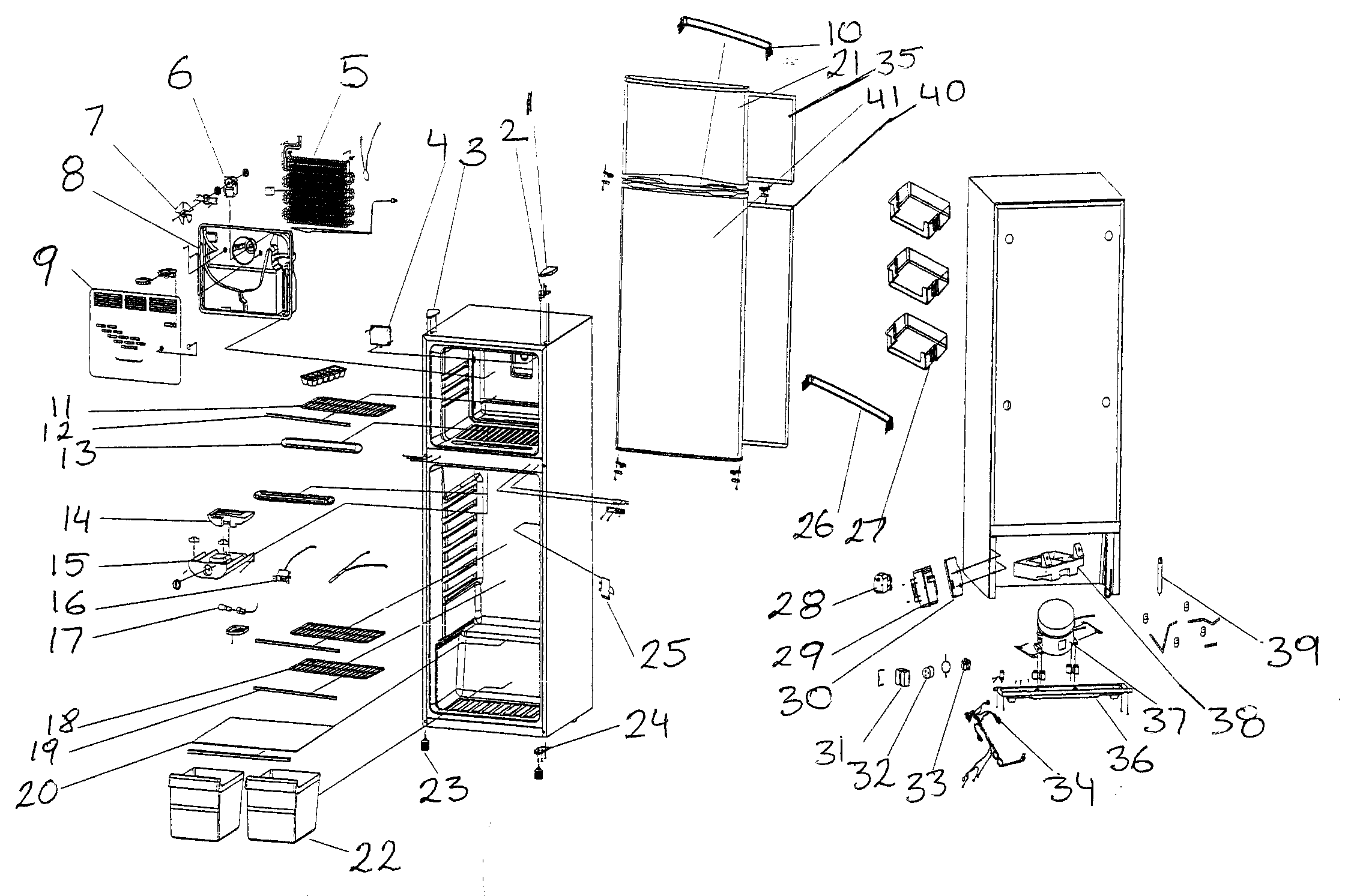

Understanding vissani refrigerator parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compressor & Sealed System | Core component for refrigeration; includes compressor and refrigerant lines. | Commercial kitchens, food storage facilities | Pros: Essential for cooling efficiency; typically durable. Cons: High replacement cost; requires skilled labor for installation. |

| Thermostat | Regulates temperature settings; varies in design (manual, digital). | Restaurants, supermarkets, appliance retailers | Pros: Critical for maintaining food safety; easy to replace. Cons: Limited lifespan; digital models can be more expensive. |

| Gasket & Seal | Rubber or silicone materials that ensure airtight door closure. | Grocery stores, warehouses, appliance repair | Pros: Prevents energy loss; improves efficiency. Cons: Subject to wear and tear; may require frequent replacement. |

| Lighting & Light Bulb | LED or incandescent bulbs providing internal illumination. | Retailers, restaurants, appliance manufacturers | Pros: Enhances visibility of products; energy-efficient options available. Cons: Bulbs can burn out; installation can be cumbersome. |

| Drawer & Shelf Components | Various configurations for food storage; includes crisper drawers and wire shelves. | Grocery stores, restaurants, home appliance retailers | Pros: Optimizes storage space; customizable options available. Cons: Can be specific to model; may need periodic replacement. |

What Are the Key Features of Vissani Compressors and Sealed Systems?

The compressor and sealed system are vital for the refrigeration process in Vissani refrigerators. These components work together to circulate refrigerant, ensuring consistent cooling. For B2B buyers, investing in high-quality compressors can lead to long-term energy savings and reduced operational costs. However, buyers should consider the installation complexity and potential downtime during replacement, which may impact business operations.

How Do Vissani Thermostats Function in Commercial Settings?

Thermostats in Vissani refrigerators are designed to maintain optimal temperature levels for food preservation. They can be manual or digital, with digital options offering more precise control. B2B buyers in the food service industry should prioritize thermostats for their reliability and ease of replacement. However, it’s essential to account for their lifespan and potential failure, which could compromise food safety.

What Role Do Gaskets and Seals Play in Refrigerator Efficiency?

Gaskets and seals are crucial for maintaining energy efficiency by preventing cold air from escaping. In commercial environments, where refrigeration units run continuously, high-quality gaskets can significantly reduce energy costs. B2B buyers should monitor these components for wear and tear, as frequent replacements may be necessary to ensure optimal performance.

Why Are Lighting and Light Bulbs Important in Vissani Refrigerators?

Proper lighting in refrigerators enhances visibility, making it easier for staff to locate products quickly. Vissani offers both LED and incandescent options, with LEDs being more energy-efficient and longer-lasting. For B2B buyers, investing in quality lighting is essential for improving customer experience in retail settings, although the initial installation may require additional effort.

How Do Drawer and Shelf Components Impact Storage Solutions?

Drawer and shelf components in Vissani refrigerators are designed to maximize storage efficiency and organization. These components can vary in style and functionality, catering to different storage needs. B2B buyers should consider the specific requirements of their operations when selecting these parts, as compatibility and customization can greatly enhance usability. Regular replacement of these components ensures optimal performance and customer satisfaction.

Key Industrial Applications of vissani refrigerator parts

| Industry/Sector | Specific Application of Vissani Refrigerator Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Replacement parts for commercial refrigeration units | Ensures food safety and compliance with health standards | OEM parts availability, fast shipping, and warranty options |

| Retail | Maintenance of display refrigerators | Enhances product visibility and reduces spoilage | Compatibility with existing models, bulk order discounts |

| Hospitality | Repair of in-room refrigerators | Improves guest satisfaction and operational efficiency | Reliability of parts, quick turnaround for repairs |

| Healthcare | Parts for medical refrigerators | Critical for maintaining temperature-sensitive medications | Certification for medical use, compliance with regulations |

| Agriculture | Refrigeration for produce storage | Extends shelf life and reduces waste | Durability in harsh environments, energy efficiency ratings |

How Are Vissani Refrigerator Parts Utilized in the Food Service Industry?

In the food service industry, Vissani refrigerator parts play a crucial role in maintaining the functionality of commercial refrigeration units. These parts, such as thermostats, compressors, and door gaskets, are essential for ensuring that food is stored at safe temperatures, preventing spoilage and foodborne illnesses. Businesses in this sector must prioritize sourcing OEM parts to guarantee compatibility and reliability, as any downtime can lead to significant financial losses. Fast shipping options are vital, especially in regions like Africa and South America, where supply chain disruptions can impact service continuity.

What Are the Benefits of Vissani Parts in Retail Applications?

Retailers often utilize Vissani refrigerator parts to maintain their display refrigerators, which are critical for showcasing perishable goods. Regular maintenance and timely replacement of parts, such as LED boards and door seals, enhance product visibility and reduce spoilage. This is particularly important in competitive markets across Europe and the Middle East, where consumer preferences can shift rapidly. When sourcing, retailers should consider bulk order discounts and ensure that parts are compatible with existing refrigeration models to streamline their operations.

How Do Vissani Parts Improve Hospitality Operations?

In the hospitality sector, Vissani refrigerator parts are essential for the repair and maintenance of in-room refrigerators. These units are crucial for guest satisfaction, providing convenience for storing personal items and snacks. Efficient operation of these appliances can significantly enhance the guest experience. For international buyers, especially in regions with high tourist traffic, sourcing reliable parts with quick turnaround times is critical to minimize operational downtime and maintain service quality.

Why Are Vissani Parts Important for Healthcare Refrigeration?

Healthcare facilities rely on Vissani refrigerator parts to maintain the integrity of medical refrigerators used for storing temperature-sensitive medications and vaccines. The reliability of these parts is paramount, as any failure could jeopardize patient safety. Buyers in this sector must ensure that the parts are certified for medical use and comply with stringent health regulations. Sourcing considerations should include the durability of components and the availability of replacement parts to ensure uninterrupted service.

How Do Vissani Parts Support Agricultural Refrigeration Needs?

In agriculture, Vissani refrigerator parts are vital for the refrigeration systems used in produce storage. These parts help maintain optimal temperatures, extending the shelf life of fruits and vegetables, which is essential for minimizing waste and maximizing profits. Buyers in this sector should focus on the durability of parts, particularly in challenging environments, and consider energy efficiency ratings to reduce operational costs. Fast sourcing options are also crucial, especially in regions where agricultural cycles are time-sensitive.

3 Common User Pain Points for ‘vissani refrigerator parts’ & Their Solutions

Scenario 1: Difficulty in Identifying the Right Vissani Parts for Repairs

The Problem: Many B2B buyers face the challenge of accurately identifying the correct parts needed for repairs or replacements in Vissani refrigerators. This issue often arises due to a lack of clear documentation, ambiguous model numbers, or the overwhelming variety of parts available. When a part fails, the urgency to resolve the issue can lead to hasty decisions, resulting in ordering incorrect parts that do not fit or function properly, thereby prolonging downtime and increasing operational costs.

The Solution: To effectively source the right Vissani parts, buyers should begin by carefully locating and documenting the model number of their appliance. This information is typically found on a label inside the refrigerator or on the back panel. Once the model number is confirmed, buyers can consult reputable parts suppliers, such as Parts Town or Home Depot, which offer detailed catalogs and diagrams for Vissani appliances. These resources can help buyers cross-reference parts and ensure compatibility. Additionally, leveraging online forums or support from the suppliers can provide insights from other professionals who have faced similar challenges, further enhancing the accuracy of the order.

Scenario 2: Long Lead Times for Critical Parts

The Problem: Another common issue for B2B buyers of Vissani refrigerator parts is the extended lead times for critical components. When essential parts such as compressors or control boards are out of stock, it can halt operations, especially in food service or retail environments where refrigeration is crucial. The unpredictability of supply chains can lead to frustration and potential loss of revenue, impacting the overall service delivery.

The Solution: To mitigate this issue, B2B buyers should establish relationships with multiple suppliers to diversify their sourcing options. This strategy not only helps in finding parts that may be available from one supplier but also allows for quicker access to alternative parts if a primary supplier cannot meet demand. Additionally, maintaining an inventory of high-demand or frequently replaced parts can reduce lead time during emergencies. Buyers should also consider investing in predictive analytics tools that assess past usage and forecast future needs, enabling proactive ordering and minimizing downtime.

Scenario 3: Poor Quality and Compatibility of Aftermarket Parts

The Problem: B2B buyers often struggle with the quality and compatibility of aftermarket parts for Vissani refrigerators. While these parts may offer a lower upfront cost, they frequently come with risks such as poor performance, shorter lifespans, and compatibility issues. Using subpar parts can lead to further complications, including repeated repairs and increased maintenance costs, ultimately affecting customer satisfaction and trust.

The Solution: To ensure the reliability and longevity of repairs, buyers should prioritize sourcing OEM (Original Equipment Manufacturer) parts from established distributors. OEM parts are specifically designed for Vissani appliances, guaranteeing compatibility and adherence to quality standards. When purchasing, buyers should look for certifications or warranties that verify the authenticity of the parts. Furthermore, establishing a long-term partnership with trusted suppliers can provide access to bulk purchasing discounts, which can help offset the higher cost of OEM parts while ensuring that the equipment remains operational and efficient. Regular training for maintenance staff on identifying quality parts can also empower teams to make better purchasing decisions.

Strategic Material Selection Guide for vissani refrigerator parts

What Are the Key Materials Used in Vissani Refrigerator Parts?

When selecting materials for Vissani refrigerator parts, it is crucial to consider their properties, advantages, and limitations. The right choice can significantly impact the performance, durability, and overall cost-effectiveness of the refrigerator components. Below, we analyze four common materials used in Vissani refrigerator parts.

How Do Plastics Perform in Vissani Refrigerator Parts?

Key Properties: Plastics, such as ABS (Acrylonitrile Butadiene Styrene) and polypropylene, are lightweight and have good thermal resistance, making them suitable for various components like shelves, drawers, and gaskets. They typically withstand temperatures ranging from -20°C to 80°C.

Pros & Cons: Plastics are cost-effective and easy to mold into complex shapes, which simplifies manufacturing processes. However, they may not be as durable as metals and can degrade over time when exposed to UV light or extreme temperatures. Additionally, their mechanical strength is lower than that of metals, which may limit their use in load-bearing applications.

Impact on Application: Plastics are compatible with food storage and do not corrode, making them ideal for refrigerator interiors. However, they may not perform well in high-stress areas, such as door hinges.

Considerations for International Buyers: Compliance with food safety regulations is paramount. Buyers from regions like Europe must ensure that plastics meet EU regulations regarding food contact materials, while buyers in Africa and South America should consider local standards.

What Role Do Metals Play in Vissani Refrigerator Parts?

Key Properties: Metals such as stainless steel and aluminum are commonly used in components that require high strength and durability, such as compressor housings and structural supports. Stainless steel offers excellent corrosion resistance and can withstand high temperatures and pressures.

Pros & Cons: Metals provide superior durability and longevity, making them suitable for high-stress applications. However, they are typically more expensive than plastics and can complicate manufacturing due to their weight and the need for specialized tooling.

Impact on Application: Metals are essential for components exposed to mechanical stress or high temperatures. Their robustness ensures reliable performance, particularly in critical areas like the compressor and cooling systems.

Considerations for International Buyers: Buyers should ensure that metals comply with international standards such as ASTM or DIN. The corrosion resistance of stainless steel is particularly important in humid climates, common in regions like South America and the Middle East.

How Do Glass Components Enhance Vissani Refrigerator Parts?

Key Properties: Glass is often used for shelves and display cases due to its transparency and aesthetic appeal. Tempered glass can withstand significant weight and is resistant to thermal stress, making it ideal for refrigerator applications.

Pros & Cons: Glass provides a premium look and is easy to clean. However, it is heavier than plastic and can be more expensive to manufacture. Additionally, glass is susceptible to breakage, which may pose safety concerns.

Impact on Application: Glass shelves allow for visibility of stored items, enhancing user experience. However, their weight must be considered in the design to ensure structural integrity.

Considerations for International Buyers: Buyers should ensure that glass components meet safety standards, especially in regions with strict regulations on consumer products. In Europe, for example, compliance with EN standards is essential.

What Is the Importance of Rubber in Vissani Refrigerator Parts?

Key Properties: Rubber is primarily used for gaskets and seals, providing excellent flexibility and resilience. It can withstand a range of temperatures and is resistant to moisture, making it ideal for refrigerator applications.

Pros & Cons: Rubber gaskets ensure airtight seals, which are crucial for energy efficiency. However, rubber can degrade over time due to exposure to oils and certain chemicals, necessitating regular replacement.

Impact on Application: Effective sealing is vital for maintaining temperature and preventing energy loss. The right rubber material can enhance the efficiency and longevity of the refrigerator.

Considerations for International Buyers: Compliance with international standards for materials in contact with food is crucial. Buyers should verify that rubber components meet relevant safety standards in their respective regions.

Summary Table of Material Properties for Vissani Refrigerator Parts

| Material | Typical Use Case for Vissani Refrigerator Parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastics | Shelves, drawers, gaskets | Cost-effective, easy to mold | Lower durability, UV degradation | Low |

| Metals | Compressor housings, structural supports | High durability, corrosion resistant | Higher cost, manufacturing complexity | High |

| Glass | Shelves, display cases | Aesthetic appeal, easy to clean | Heavier, risk of breakage | Medium |

| Rubber | Gaskets, seals | Excellent sealing properties | Degrades over time, requires replacement | Medium |

This strategic material selection guide provides insights into the materials used in Vissani refrigerator parts, helping international B2B buyers make informed decisions that align with their operational needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for vissani refrigerator parts

What Are the Key Stages in the Manufacturing Process for Vissani Refrigerator Parts?

Manufacturing Vissani refrigerator parts involves several critical stages, ensuring that each component meets the high standards expected by international B2B buyers. The typical stages include:

-

Material Preparation: This initial stage involves sourcing high-quality raw materials, such as stainless steel, plastics, and insulation materials. Suppliers often rely on certified vendors to ensure that materials meet industry specifications. The materials are then inspected for quality before moving to the next stage.

-

Forming: During the forming stage, raw materials are shaped into specific components using various techniques. Common methods include stamping for metal parts, injection molding for plastic components, and extrusion for insulation materials. Advanced machinery and technology are employed to ensure precision and consistency in the forming process.

-

Assembly: The assembly stage combines the formed parts into a complete component. This process can be manual or automated, depending on the complexity of the part. For instance, refrigerator doors may require intricate assembly of hinges, gaskets, and insulation layers. Efficient assembly lines are designed to minimize errors and enhance productivity.

-

Finishing: The final stage involves applying finishing touches to the components, which may include painting, coating, or polishing. This not only enhances the aesthetic appeal but also protects against corrosion and wear. Quality checks during this stage ensure that the finished products meet both functional and cosmetic standards.

How Does Quality Assurance Ensure High Standards for Vissani Parts?

Quality assurance (QA) is a critical aspect of the manufacturing process for Vissani refrigerator parts, encompassing various international and industry-specific standards to ensure product reliability and safety.

Which International Standards Are Relevant for Quality Control?

Internationally recognized standards, such as ISO 9001, provide a framework for quality management systems. Compliance with these standards demonstrates a manufacturer’s commitment to quality and customer satisfaction. Additionally, Vissani parts may also need to meet specific certifications like CE marking for compliance with European safety standards, ensuring they are safe for consumer use.

What Quality Control Checkpoints Are Implemented?

Quality control checkpoints are established throughout the manufacturing process to identify and rectify defects early. These checkpoints typically include:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to monitor quality and prevent defects from progressing to the next stage.

- Final Quality Control (FQC): A comprehensive inspection of the finished products before they are shipped to customers. This may involve functional testing, dimensional checks, and visual inspections.

What Common Testing Methods Are Used to Validate Product Quality?

Various testing methods are employed to validate the quality of Vissani refrigerator parts. These may include:

- Functional Testing: Ensures that parts operate as intended. For example, thermostats are tested for accuracy in temperature control.

- Durability Testing: Evaluates how well components withstand wear and tear, particularly for moving parts like hinges and motors.

- Safety Testing: Ensures that parts comply with safety regulations, such as electrical safety tests for components involving electricity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential. Here are key strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This evaluation can provide insights into the supplier’s commitment to quality.

-

Quality Assurance Reports: Requesting detailed quality assurance reports can help buyers understand the methodologies and standards followed by the supplier. These reports should outline testing results, compliance with industry standards, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can be particularly valuable for international buyers who may not have the resources to conduct on-site evaluations.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances when sourcing Vissani refrigerator parts. Key considerations include:

-

Regional Compliance Standards: Different regions may have specific compliance requirements. For instance, products sold in Europe must meet CE marking requirements, while buyers in the Middle East may need to adhere to local regulations.

-

Cultural and Language Barriers: Communication can pose challenges in verifying quality control practices. Buyers should ensure that suppliers can provide documentation in a language that is easily understood to avoid misinterpretations.

-

Logistical Considerations: The logistics of shipping parts internationally can impact quality. Buyers should inquire about the packaging methods used to protect parts during transit and whether the supplier has a return policy for defective items.

Conclusion: Ensuring Quality in Vissani Refrigerator Parts Manufacturing

For international B2B buyers, understanding the manufacturing processes and quality assurance practices of Vissani refrigerator parts is crucial for making informed purchasing decisions. By familiarizing themselves with the key stages of manufacturing, relevant quality standards, and effective verification methods, buyers can ensure that they source reliable, high-quality components that meet their operational needs. This proactive approach not only mitigates risks but also fosters long-term partnerships with reputable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vissani refrigerator parts’

Introduction

This guide aims to equip B2B buyers with a structured approach to sourcing Vissani refrigerator parts effectively. By following these steps, you can ensure that your procurement process is efficient, reliable, and aligned with your operational needs. This checklist will help you identify and engage with the right suppliers while minimizing risks associated with sourcing.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to outline the specific parts you need. This includes identifying the model numbers, part types, and any unique features necessary for compatibility. Clear specifications will help avoid miscommunications with suppliers and ensure you receive the correct components.

- Consider using a parts catalog or a service manual to reference the exact specifications.

- Document any common issues associated with your existing Vissani refrigerators to communicate effectively with suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in Vissani refrigerator parts. This step is critical as the right supplier can provide not only the necessary parts but also valuable insights into product quality and reliability.

- Look for suppliers with a strong reputation in the industry, particularly those that have experience in your geographical region.

- Utilize online platforms, industry forums, and trade shows to gather information about potential suppliers.

Step 3: Verify Supplier Certifications

Once you’ve identified potential suppliers, verify their certifications and compliance with international standards. This step is crucial for ensuring the quality and safety of the parts you are sourcing.

- Check for certifications such as ISO 9001, which indicates a commitment to quality management systems.

- Inquire about their sourcing practices to ensure that they provide OEM (Original Equipment Manufacturer) parts.

Step 4: Request Quotes and Compare Pricing

After narrowing down your list of suppliers, request detailed quotes for the specified parts. Comparing pricing is essential to ensure you are getting a fair deal without compromising quality.

- Ensure that quotes include shipping costs, lead times, and any potential discounts for bulk purchases.

- Look for transparency in pricing; avoid suppliers that provide vague quotes without itemized costs.

Step 5: Evaluate Supplier Reliability and Customer Support

Assess the reliability of your shortlisted suppliers by checking customer reviews and testimonials. Strong customer support is vital, especially when dealing with technical parts that may require post-purchase assistance.

- Reach out to previous clients or current users of the supplier’s products to gather insights about their experiences.

- Consider suppliers that offer warranties or guarantees on their parts, as this indicates confidence in their product quality.

Step 6: Establish Clear Payment and Delivery Terms

Before finalizing any agreements, clarify payment and delivery terms with your chosen supplier. Clear terms will help avoid misunderstandings and ensure that both parties are aligned on expectations.

- Discuss payment methods, whether upfront, net terms, or a combination.

- Confirm delivery schedules and logistics arrangements to prevent delays in receiving parts.

Step 7: Place Your Order and Monitor Progress

Once all terms are agreed upon, proceed to place your order. It’s essential to maintain communication with the supplier throughout the order process to monitor progress and address any potential issues.

- Set up a tracking system for your orders to ensure timely delivery.

- Keep records of all communications and transactions for future reference and potential disputes.

By following this checklist, you can streamline your sourcing process for Vissani refrigerator parts, ensuring that you secure quality products from reliable suppliers while minimizing risks.

Comprehensive Cost and Pricing Analysis for vissani refrigerator parts Sourcing

What Are the Key Cost Components in Sourcing Vissani Refrigerator Parts?

When evaluating the cost structure of Vissani refrigerator parts, several components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The cost of raw materials significantly impacts the overall price of refrigerator parts. For instance, components such as compressors, thermostats, and gaskets require high-quality materials to ensure durability and compliance with safety standards.

-

Labor: Labor costs can vary significantly depending on the manufacturing location. Regions with lower labor costs may offer more competitive pricing; however, it is essential to consider the expertise and skill level of the workforce, as this can affect the quality of the parts produced.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, allowing suppliers to offer better pricing.

-

Tooling: The initial investment in tooling can be substantial, especially for custom parts. This cost must be amortized over the production volume, influencing unit pricing.

-

Quality Control: Implementing rigorous QC measures is crucial for ensuring that parts meet industry standards. While this adds to the overall cost, it is vital for maintaining reliability and reducing returns due to defects.

-

Logistics: Transportation and shipping costs can vary based on distance, shipping method, and volume. International buyers should factor in customs duties and potential delays in their logistics planning.

-

Margin: Finally, the supplier’s profit margin will influence the final price. Buyers should consider the balance between price and quality when evaluating supplier options.

How Do Price Influencers Affect the Cost of Vissani Parts?

Several factors can influence pricing, particularly for international B2B buyers:

-

Volume/MOQ: Purchasing in larger quantities often leads to bulk discounts. Negotiating minimum order quantities (MOQ) with suppliers can significantly reduce per-unit costs.

-

Specifications and Customization: Customized parts or specific specifications may incur additional costs. Buyers should weigh the need for customization against budget constraints.

-

Materials and Quality Certifications: Higher quality materials and certifications (such as ISO or CE) can raise prices but ensure compliance with international standards. Investing in certified parts may lead to lower long-term costs due to reduced failure rates.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge a premium for their products due to proven quality and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international transactions, as they define responsibilities regarding shipping, insurance, and tariffs. This knowledge can help buyers negotiate better terms and manage costs effectively.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, terms, and conditions. Leverage volume commitments or long-term contracts to secure better rates.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Assess potential maintenance, warranty, and replacement costs to determine the true cost of ownership over the product’s lifecycle.

-

Understand Pricing Nuances: Be aware of seasonal price fluctuations and market demand, which can impact pricing. Staying informed about market trends can help in timing purchases effectively.

-

Research Suppliers Thoroughly: Conduct due diligence on potential suppliers. Evaluate their manufacturing capabilities, quality control processes, and past performance to ensure reliability.

-

Utilize Local Resources: When sourcing internationally, consider working with local agents or distributors who understand the regional market dynamics and can facilitate smoother transactions.

Disclaimer on Indicative Prices

Prices for Vissani refrigerator parts can vary widely based on the factors mentioned above. The prices provided in the reference materials are indicative and may not reflect current market conditions or specific supplier pricing. Always obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing vissani refrigerator parts With Other Solutions

Introduction: Why Consider Alternatives to Vissani Refrigerator Parts?

In the competitive landscape of appliance parts, businesses often seek alternatives to optimize performance, reduce costs, and enhance reliability. While Vissani refrigerator parts are known for their compatibility and OEM quality, it’s crucial to explore other solutions that may offer better overall value or specific advantages tailored to unique business needs. This analysis compares Vissani refrigerator parts against two viable alternatives: Universal Refrigerator Parts and Aftermarket Replacement Parts.

Comparison Table

| Comparison Aspect | Vissani Refrigerator Parts | Universal Refrigerator Parts | Aftermarket Replacement Parts |

|---|---|---|---|

| Performance | OEM quality, reliable | Variable quality, generally compatible | Variable quality, performance may vary |

| Cost | Moderate pricing | Generally lower cost | Often the lowest cost |

| Ease of Implementation | Model-specific fit, easy installation | Requires verification for fit | May need modifications for fit |

| Maintenance | Minimal, OEM recommended | Varies by manufacturer | Can be higher due to quality variance |

| Best Use Case | Businesses needing guaranteed quality | Cost-sensitive operations needing general compatibility | Budget-conscious companies with flexibility |

Detailed Breakdown of Alternatives

Universal Refrigerator Parts

Universal refrigerator parts are designed to fit a wide range of models and brands, making them a flexible option for businesses that handle multiple refrigerator types. The primary advantage of universal parts is cost; they are generally cheaper than OEM parts, allowing for significant savings, especially in bulk purchases. However, the trade-off may be in the quality and performance of these parts, as they may not always deliver the same reliability as Vissani parts. Businesses should ensure compatibility and assess the quality of the manufacturer before purchasing.

Aftermarket Replacement Parts

Aftermarket replacement parts are often the most budget-friendly option available in the market. These parts can be sourced from various manufacturers and typically come at a lower price point than both Vissani and universal parts. However, the quality can vary significantly, which may lead to inconsistent performance and durability. For companies that prioritize cost over brand loyalty and can accommodate potential modifications for fit, aftermarket parts may serve as a viable solution. It is essential to conduct thorough research on the specific aftermarket parts being considered to ensure they meet operational standards.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate parts for your refrigeration needs involves careful consideration of several factors, including performance requirements, budget constraints, and installation capabilities. Vissani refrigerator parts offer reliable OEM quality, making them ideal for businesses that prioritize performance and warranty support. Conversely, universal and aftermarket parts provide cost-effective alternatives that may suit businesses with less stringent performance requirements or those operating on tighter budgets. Ultimately, B2B buyers should evaluate their specific operational needs, assess the quality and compatibility of alternative parts, and make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for vissani refrigerator parts

What Are the Essential Technical Properties of Vissani Refrigerator Parts?

Understanding the technical specifications of Vissani refrigerator parts is crucial for B2B buyers, particularly when sourcing parts for repair, maintenance, or manufacturing. Here are some key technical properties to consider:

1. Material Grade

The material grade of refrigerator parts, such as stainless steel or plastic, affects durability, corrosion resistance, and thermal conductivity. For instance, stainless steel components are often preferred for their strength and resistance to rust, making them ideal for long-lasting applications in varying climates. B2B buyers should prioritize parts made from high-quality materials to ensure the longevity and reliability of their refrigeration systems.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension of a part. For example, the door gasket must fit within a specific tolerance range to ensure a proper seal and prevent energy loss. Understanding tolerance is vital for manufacturers and repairers to ensure that parts fit correctly, minimizing the risk of malfunction and the costs associated with replacements.

3. Operational Temperature Range

This specification outlines the temperature limits within which the refrigerator parts can operate effectively. For example, thermostats and compressors must be able to function within a defined range to ensure optimal cooling performance. Buyers must consider the operational temperature range when selecting parts for environments with extreme temperatures, which is particularly relevant for regions in Africa and South America.

4. Electrical Ratings

Electrical ratings, including voltage and amperage, are essential for components like motors and circuit boards. Knowing the electrical specifications helps buyers ensure compatibility with existing systems. Proper electrical ratings can prevent overheating and electrical failures, which can lead to costly downtime and repairs.

5. OEM vs. Aftermarket

Original Equipment Manufacturer (OEM) parts are made by the same company that produced the original components, ensuring compatibility and quality. In contrast, aftermarket parts may offer cost savings but can vary in quality and performance. B2B buyers should carefully evaluate the benefits of OEM parts, especially for critical components, to avoid potential long-term issues.

What Are Common Trade Terms in the Vissani Refrigerator Parts Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM parts are components made by the original manufacturer of the appliance. These parts guarantee compatibility and quality, which is critical for maintaining warranty coverage and ensuring the longevity of the appliance.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers, as understanding MOQ can help manage inventory costs and ensure they are not overcommitting to purchases that may not be needed.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. It is a critical step in the procurement process, enabling buyers to compare options and negotiate better deals.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in global trade. Understanding these terms is crucial for B2B buyers when negotiating shipping and delivery conditions, as they dictate who is responsible for costs and risks during transportation.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. This term is important for inventory planning and ensuring that businesses have the necessary parts on hand to avoid disruptions in operations.

In summary, grasping the essential technical properties and trade terminology associated with Vissani refrigerator parts enables B2B buyers to make informed decisions, ensuring that they procure the right components for their needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the vissani refrigerator parts Sector

What Are the Key Market Dynamics and Trends Influencing the Vissani Refrigerator Parts Sector?

The Vissani refrigerator parts market is influenced by several global drivers, including the growing demand for cost-effective and reliable refrigeration solutions across various regions. In emerging markets like Africa and South America, increasing urbanization and disposable incomes are elevating the demand for household appliances, including refrigerators. This trend is mirrored in the Middle East and Europe, where energy efficiency and smart technology integration in appliances are becoming crucial. As a result, international B2B buyers are seeking suppliers who offer not only quality parts but also innovative solutions that enhance operational efficiency.

Current technology trends in sourcing include the adoption of digital platforms for procurement, allowing for faster and more transparent transactions. E-commerce platforms specializing in appliance parts are gaining traction, enabling buyers to access a wide range of components efficiently. Additionally, predictive analytics and IoT applications are being utilized to manage inventory and forecast demand accurately, ensuring that suppliers can meet the needs of international buyers promptly.

Emerging B2B sourcing trends also highlight the shift towards just-in-time (JIT) inventory systems, which minimize holding costs and reduce waste. Buyers are increasingly prioritizing partnerships with suppliers who can provide real-time data on part availability and shipping timelines, enhancing supply chain responsiveness.

How Is Sustainability and Ethical Sourcing Reshaping the Vissani Refrigerator Parts Market?

Sustainability is becoming a critical factor for B2B buyers in the Vissani refrigerator parts sector. The environmental impact of manufacturing processes and the lifecycle of appliance parts are under scrutiny, prompting buyers to consider the sustainability practices of their suppliers. A focus on ethical sourcing is essential, as companies seek to align with suppliers who prioritize reduced carbon footprints, waste management, and resource conservation.

The demand for ‘green’ certifications and materials is rising, as buyers increasingly recognize the importance of environmentally friendly practices. Certifications like ISO 14001 and Energy Star are becoming benchmarks for suppliers aiming to demonstrate their commitment to sustainability. Additionally, the use of recyclable materials in the production of refrigerator parts not only appeals to environmentally conscious buyers but also complies with regulations aimed at reducing plastic waste.

As international markets grapple with climate change, buyers are encouraged to engage with suppliers that are transparent about their sourcing practices and can provide verifiable data on their environmental impact. This shift towards sustainable procurement can enhance brand reputation and customer loyalty, making it a key consideration in the sourcing process.

What Is the Historical Context of the Vissani Refrigerator Parts Sector?

The Vissani brand has evolved significantly since its inception, initially focusing on providing affordable refrigeration solutions primarily for the North American market. Over time, as global demand for refrigeration grew, Vissani expanded its product offerings to include a wider range of refrigerator parts, catering to both residential and commercial needs. This evolution has been driven by technological advancements and changing consumer preferences, including the increasing importance of energy efficiency and smart features.

Today, Vissani parts are recognized for their reliability and affordability, making them a preferred choice among international B2B buyers. The brand’s commitment to quality and innovation continues to shape its market presence, ensuring that it meets the evolving demands of a diverse global customer base. As the market dynamics shift towards sustainability and efficiency, Vissani remains poised to adapt, offering solutions that align with the values of modern consumers and businesses alike.

Frequently Asked Questions (FAQs) for B2B Buyers of vissani refrigerator parts

-

How do I solve issues with my Vissani refrigerator not cooling?

If your Vissani refrigerator is not cooling properly, first check the thermostat settings to ensure they are set correctly. Inspect the door seals for any gaps or damage that may allow warm air to enter. Additionally, ensure that the condenser coils are clean and free of dust, which can hinder cooling efficiency. If these steps do not resolve the issue, consider replacing faulty components such as the compressor or evaporator fan. For parts sourcing, consult reliable suppliers for genuine Vissani parts to ensure compatibility and performance. -

What is the best way to find genuine Vissani refrigerator parts?

To find genuine Vissani refrigerator parts, start by sourcing from authorized distributors or reputable online platforms that specialize in appliance parts. Check for OEM (Original Equipment Manufacturer) parts, as these are designed specifically for Vissani appliances. It’s also beneficial to review customer feedback and verify the supplier’s credentials to ensure reliability. If sourcing internationally, confirm that the supplier can ship to your location and check for any import regulations that may apply. -

What are the common problems associated with Vissani refrigerators?

Common issues with Vissani refrigerators include inconsistent cooling, ice buildup in the freezer, faulty ice makers, and leaking water. Other problems may involve malfunctioning door seals, which can lead to temperature fluctuations, or noisy operation due to worn-out components. Identifying the specific issue can help in sourcing the right replacement parts quickly, ensuring minimal downtime for your operations. -

How can I ensure the quality of Vissani parts when sourcing internationally?

To ensure quality when sourcing Vissani parts internationally, request certifications or quality assurance documentation from suppliers. Conduct a thorough vetting process, including checking references and past customer reviews. Consider ordering sample parts to evaluate their quality firsthand. Additionally, inquire about the supplier’s return policy and warranty terms, which can provide added assurance regarding the reliability of the parts. -

What is the minimum order quantity (MOQ) for Vissani refrigerator parts?

Minimum order quantities (MOQ) for Vissani refrigerator parts can vary significantly depending on the supplier and the specific parts required. Some suppliers may offer flexible MOQs for first-time buyers, while others may have strict policies. It’s advisable to discuss your purchasing needs directly with potential suppliers to negotiate favorable terms, especially if you are looking to establish a long-term business relationship. -

What payment terms should I expect when sourcing Vissani parts?

Payment terms for sourcing Vissani parts can differ based on the supplier’s policies and your negotiation. Common terms include upfront payments, net 30 or net 60 days, and letters of credit for larger orders. Always clarify payment methods accepted, such as wire transfers, credit cards, or PayPal. Additionally, consider discussing bulk order discounts, which could be beneficial for your purchasing strategy. -

How do I handle logistics and shipping for Vissani parts from suppliers?

When handling logistics and shipping for Vissani parts, consider the shipping methods offered by your supplier, including air freight for quicker delivery or sea freight for cost-effectiveness on larger orders. Verify shipping costs, estimated delivery times, and any customs duties or taxes that may apply to your location. Establishing a good relationship with your supplier can also facilitate smoother logistics, ensuring timely deliveries and reducing the risk of delays. -

Are there customization options available for Vissani refrigerator parts?

Customization options for Vissani refrigerator parts may be limited, as most parts are produced according to specific OEM standards. However, some suppliers may offer customization services for bulk orders, such as specific packaging or branding options. It’s advisable to inquire with your supplier about potential customization capabilities, particularly if you have unique requirements or are looking to enhance your product offerings in your local market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Vissani Refrigerator Parts Manufacturers & Suppliers List

1. Vissani – Key Parts for Refrigerators

Domain: appliancerepair.homedepot.com

Registered: 1992 (33 years)

Introduction: Vissani Parts available for various refrigerator models. Key products include: 1. Vissani Defrost Timer – Item #2683068, OEM Part #502412010003, Price: $79.55, In Stock. 2. Vissani Center Hinge – Item #2683044, OEM Part #500717010015, Price: $35.13, On Order. 3. Vissani Wire Shelf – Item #2683050, OEM Part #502901010064, Price: $47.93, On Order. 4. Vissani Door – Item #2683054, OEM Part #503700114…

2. Midea – Vissani Refrigerator Parts

Domain: midea.encompass.com

Registered: 1998 (27 years)

Introduction: This company, Midea – Vissani Refrigerator Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Vissani – Key Products

Domain: searspartsdirect.com

Registered: 1998 (27 years)

Introduction: Official Vissani parts available at Sears PartsDirect. Key product categories include Vissani microwave/hood combos, refrigerators, wine & beverage coolers, and freestanding freezers. Notable models include Vissani MCCF7WBX and MCCF5WBX chest freezers, HMDR1030WE refrigerator, and various over-the-range microwaves (MCO160UQ, MCO160UB, MCO160UW). Each model has a specific number of parts available …

4. Vissani – VISSANI20HVDR1030BE Parts

Domain: appliancepartspros.com

Registered: 1999 (26 years)

Introduction: Parts for VISSANI20HVDR1030BE available at AppliancePartsPros.com. Features include 2 Day Quick Delivery, 365 Day Return Policy, and Free Tech Support. Over 2.1 Million Parts In Stock. Customer service contact via call or text at 1-877-477-7278.

5. Vissani – Refrigerator Door Rack HVDR45

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”:”VISSANI Refrigerator Door Rack Lower Bottom HVDR45″,”Brand”:”Vissani”,”Type”:”Shelf”,”Condition”:”New”,”Quantity Available”:”1″,”Quantity Sold”:”5″,”Item Number”:”156456743106″,”Compatible Models”:”HVDR45 series models and many other manufacturers and models that match part number”,”Seller Name”:”CreekBank Inc”,”Seller Feedback Rating”:”100% positive feedback”,”Price”:”$30.97 (App…

Strategic Sourcing Conclusion and Outlook for vissani refrigerator parts

In today’s competitive landscape, the strategic sourcing of Vissani refrigerator parts is essential for international B2B buyers aiming to enhance operational efficiency and service quality. By prioritizing genuine OEM parts, businesses can ensure optimal performance and longevity of their refrigeration units, minimizing downtime and reducing maintenance costs. Understanding common issues, such as faulty ice makers or defrosting problems, allows buyers to make informed purchasing decisions, ultimately improving customer satisfaction.

Investing in reliable suppliers is crucial for maintaining a steady flow of essential components. With a focus on markets in Africa, South America, the Middle East, and Europe, businesses can leverage local partnerships to streamline logistics and reduce lead times. As demand for reliable refrigeration solutions continues to grow, embracing strategic sourcing will position companies to capitalize on emerging opportunities.

Looking ahead, we encourage B2B buyers to actively seek partnerships that prioritize quality and speed. By aligning with trusted suppliers of Vissani refrigerator parts, organizations can not only meet current demands but also adapt to future challenges in the appliance repair market. The time to act is now—secure your supply chain and elevate your business’s operational capabilities.