Everything You Need to Know About U Shape Metal Brackets Sourcing in 2025

Introduction: Navigating the Global Market for u shape metal brackets

In today’s competitive landscape, sourcing reliable u shape metal brackets can pose significant challenges for international B2B buyers. With a multitude of options available, businesses often grapple with ensuring product quality, understanding diverse applications, and navigating supplier vetting processes. This comprehensive guide delves into the critical aspects of the global market for u shape metal brackets, offering insights into various types, applications, and cost considerations.

From structural support in construction projects to equipment mounting in industrial settings, u shape metal brackets play an essential role in ensuring stability and durability. This guide not only outlines the specifications and finishes available—ranging from galvanized steel to anodized aluminum—but also provides actionable strategies for evaluating suppliers, including tips on assessing reliability, certifications, and customer service.

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including Nigeria and Saudi Arabia, making informed purchasing decisions is paramount. This resource empowers you with the knowledge needed to identify quality suppliers and products that meet your specific requirements, ultimately streamlining your procurement process and enhancing operational efficiency. By leveraging this guide, you can confidently navigate the complexities of the market and secure the best solutions for your business needs.

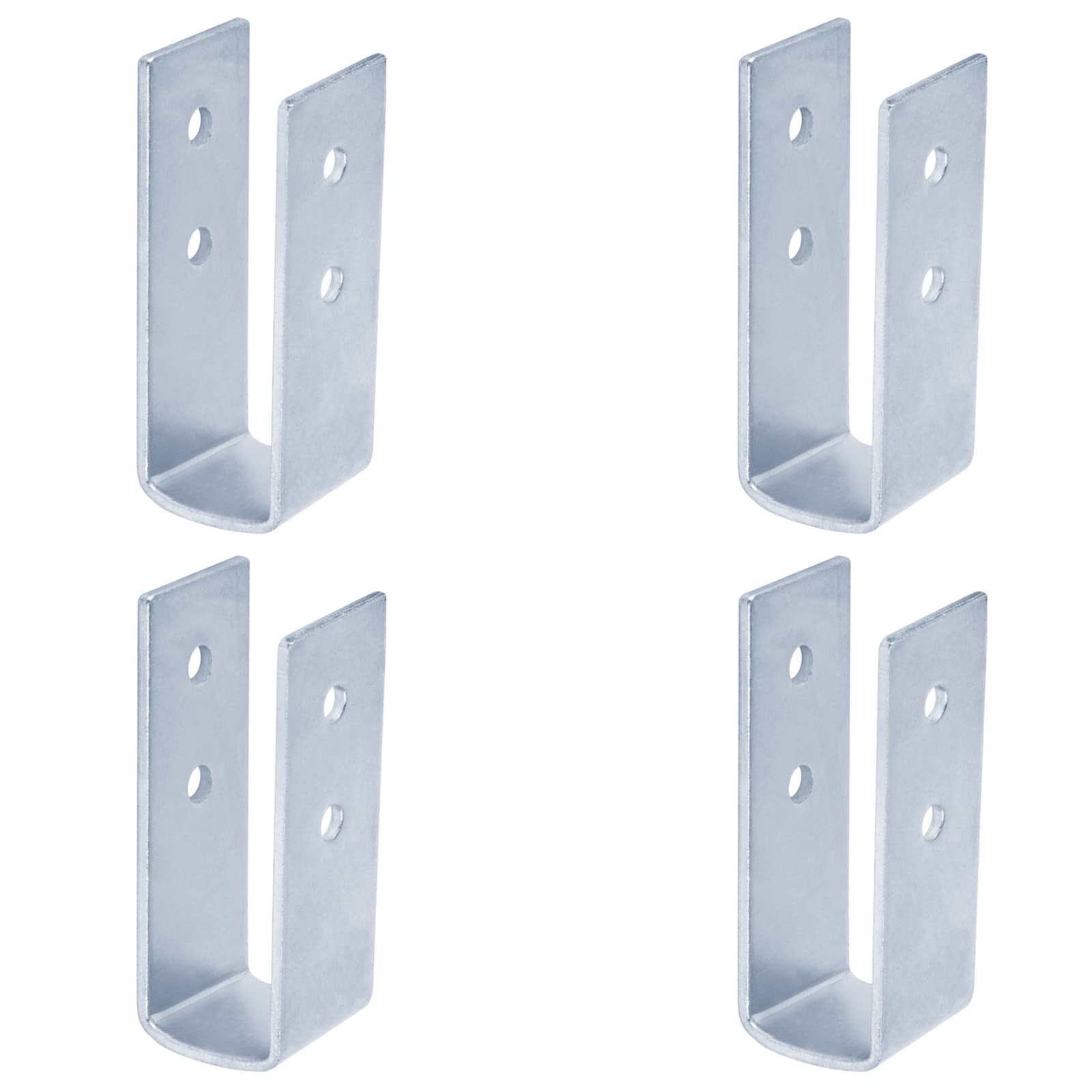

Understanding u shape metal brackets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard U Bracket | Typically made from steel, with multiple holes for mounting. Available in various sizes. | Industrial shelving, structural support. | Pros: Versatile and strong; Cons: May require additional coatings to prevent rust. |

| Heavy-Duty U Bracket | Thicker gauge steel or aluminum, designed for high-load applications. | Construction, heavy machinery support. | Pros: Exceptional load-bearing capacity; Cons: Higher cost than standard options. |

| Adjustable U Bracket | Features slots or movable components for flexible installation. | HVAC systems, adjustable shelving. | Pros: Customizable fit; Cons: More complex installation process. |

| U Shaped Fitting | Designed for connecting multiple pieces of strut channel; often used in conjunction with other fittings. | Modular construction, piping systems. | Pros: Facilitates easy assembly; Cons: Requires compatible strut channels. |

| Aluminum U Bracket | Lightweight, corrosion-resistant, often anodized for durability. | Outdoor applications, signage support. | Pros: Lightweight and resistant to rust; Cons: Lower load capacity compared to steel variants. |

What Are the Key Characteristics of Standard U Brackets?

Standard U brackets are commonly manufactured from steel and come with several holes for mounting purposes. They are available in various sizes, making them adaptable for different applications, particularly in industrial shelving and structural support. When considering a purchase, buyers should assess the environmental conditions, as these brackets may need additional coatings to prevent rust, especially in humid climates.

How Do Heavy-Duty U Brackets Differ from Standard Options?

Heavy-duty U brackets are made from thicker gauge steel or aluminum, allowing them to support significantly higher loads. These brackets are ideal for construction and heavy machinery applications where durability is paramount. Buyers should be prepared for a higher upfront investment; however, the long-term benefits of reliability and reduced maintenance often justify the cost.

What Advantages Do Adjustable U Brackets Offer?

Adjustable U brackets provide flexibility in installation due to their movable components or slots. This feature allows for a customizable fit, making them particularly useful in HVAC systems and adjustable shelving. While they offer significant adaptability, the installation process can be more complex, requiring skilled labor and careful planning.

How Are U Shaped Fittings Utilized in Modular Construction?

U shaped fittings are designed to connect multiple pieces of strut channel, facilitating easy assembly in modular construction and piping systems. They are essential for creating robust structures that can be easily modified or expanded. Buyers should ensure compatibility with their existing strut channels to maximize the effectiveness of these fittings.

Why Choose Aluminum U Brackets for Outdoor Applications?

Aluminum U brackets are lightweight and corrosion-resistant, making them suitable for outdoor applications and signage support. Often anodized for added durability, these brackets are an excellent choice for environments where rust and weight are concerns. However, buyers should consider their lower load-bearing capacity compared to steel options, ensuring that they meet the specific requirements of their projects.

Key Industrial Applications of u shape metal brackets

| Industry/Sector | Specific Application of u shape metal brackets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural support for framing and mounting systems | Enhances structural integrity and safety of installations | Durability, load capacity, and compliance with local standards |

| Renewable Energy | Mounting solar panels and wind turbines | Facilitates efficient energy generation and installation | Weather resistance, material type (e.g., galvanized steel) |

| Manufacturing & Assembly | Supporting conveyor systems and assembly lines | Improves operational efficiency and workflow management | Customization options, size variations, and delivery timelines |

| HVAC Systems | Mounting and securing ductwork and piping | Ensures system reliability and reduces maintenance costs | Corrosion resistance, compatibility with existing systems |

| Telecommunications | Securing antennas and communication equipment | Enhances signal strength and reliability | Material strength, environmental durability, and ease of installation |

How are u shape metal brackets used in construction projects?

In the construction industry, u shape metal brackets play a crucial role in providing structural support for framing and mounting systems. They are utilized to securely join multiple components, ensuring the stability and integrity of the overall structure. This is particularly important in regions prone to extreme weather conditions, where reliable connections can prevent costly damages. Buyers should prioritize sourcing brackets that meet local building codes and standards, focusing on materials that can withstand specific environmental challenges encountered in their geographic areas.

What role do u shape metal brackets play in renewable energy installations?

In the renewable energy sector, u shape metal brackets are essential for mounting solar panels and wind turbines. They provide a strong, secure base that enhances the efficiency and effectiveness of energy generation systems. For international buyers, particularly in emerging markets in Africa and South America, it is vital to consider the durability of these brackets against harsh weather conditions, as well as their compatibility with various mounting systems. Ensuring that brackets are made from corrosion-resistant materials can significantly enhance the lifespan of renewable energy installations.

How do manufacturing and assembly sectors benefit from u shape metal brackets?

Within manufacturing and assembly environments, u shape metal brackets are utilized to support conveyor systems and assembly lines, which are critical for operational efficiency. These brackets help maintain the alignment and stability of equipment, reducing downtime and enhancing productivity. Buyers should seek brackets that offer customization options to fit specific manufacturing setups and ensure quick delivery to minimize disruptions in production schedules. Additionally, evaluating the load capacity of brackets is essential to prevent operational failures.

Why are u shape metal brackets important for HVAC systems?

In HVAC systems, u shape metal brackets are used to mount and secure ductwork and piping, which is vital for ensuring system reliability and efficiency. Properly installed brackets help maintain the structural integrity of HVAC components, reducing the likelihood of leaks and other maintenance issues. Buyers in regions like the Middle East, where high temperatures can affect material performance, should prioritize sourcing brackets that are corrosion-resistant and capable of withstanding thermal expansion.

How do telecommunications companies utilize u shape metal brackets?

Telecommunications companies rely on u shape metal brackets to secure antennas and communication equipment, which are critical for maintaining signal strength and reliability. These brackets must be robust enough to withstand environmental stresses, including wind and rain, particularly in regions with extreme weather patterns. When sourcing these brackets, international buyers should focus on materials that offer high strength and durability, as well as ease of installation to ensure efficient deployment of communication infrastructure.

3 Common User Pain Points for ‘u shape metal brackets’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Size U Shape Metal Bracket

The Problem:

B2B buyers often encounter challenges when selecting the appropriate size of U shape metal brackets for their projects. This issue can stem from a lack of clear specifications or detailed product information. For instance, if a construction company in Nigeria is looking to secure strut channels for a new facility, they may face uncertainty about whether a 4-hole or 6-hole bracket is necessary for their specific load requirements. This indecision can lead to project delays, increased costs from ordering incorrect sizes, and ultimately, project inefficiencies.

The Solution:

To mitigate this challenge, it is crucial for buyers to engage in thorough project planning and consult with suppliers who offer detailed product specifications. When sourcing U shape metal brackets, buyers should consider utilizing engineering consultations provided by manufacturers. This could include reviewing CAD drawings and engineering data sheets available on supplier websites. Additionally, they should assess their load requirements and project specifications to determine the correct size and number of holes needed in the brackets. By doing so, they can ensure compatibility with existing structures and avoid costly mistakes.

Scenario 2: Concerns About Durability and Corrosion Resistance

The Problem:

In regions like the Middle East, where environmental factors such as high humidity and salinity can accelerate material degradation, buyers are often concerned about the durability and corrosion resistance of U shape metal brackets. For example, a construction firm in Saudi Arabia might find that standard metal brackets deteriorate quickly under harsh conditions, leading to structural failures and safety issues. This not only results in financial losses but also affects project timelines and reputations.

The Solution:

To address these concerns, buyers should prioritize sourcing U shape metal brackets made from high-quality materials, such as stainless steel or those treated with protective coatings like hot-dip galvanization. When evaluating suppliers, it’s beneficial to inquire about the specific environmental conditions their products are tested against. Additionally, suppliers that offer extensive warranties on their products can provide an extra layer of assurance. It’s also advisable for buyers to implement a maintenance schedule that includes regular inspections of the brackets to ensure they remain in good condition, thereby prolonging their lifespan and maintaining structural integrity.

Scenario 3: Challenges in Installation and Compatibility with Existing Systems

The Problem:

Another prevalent issue faced by B2B buyers is the challenge of installing U shape metal brackets in a way that is compatible with existing systems. For instance, an engineering firm in South America may find that the brackets they purchased do not fit well with the strut channels they already have, causing significant delays in installation. Misalignment can lead to rework, additional labor costs, and frustration among the installation team.

The Solution:

To overcome installation challenges, buyers should focus on thorough compatibility assessments prior to purchasing U shape metal brackets. This involves measuring the dimensions and specifications of existing systems and consulting with suppliers about the compatibility of their products. Buyers should also consider purchasing brackets that come with installation guides or support from the manufacturer. It may be beneficial to opt for suppliers who provide comprehensive technical support and installation training, ensuring that the installation team is well-equipped to handle the brackets effectively. By fostering a collaborative relationship with suppliers, buyers can enhance their understanding of product applications, leading to smoother installation processes and increased operational efficiency.

Strategic Material Selection Guide for u shape metal brackets

When selecting materials for U-shaped metal brackets, it is essential to consider various factors that influence performance, durability, and suitability for specific applications. Below, we analyze four common materials used in the manufacturing of U-shaped metal brackets, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Steel for U-shaped Metal Brackets?

Steel, particularly carbon steel, is a widely used material for U-shaped brackets due to its strength and versatility. Steel brackets can withstand high loads and are suitable for various structural applications. They typically have a high-temperature rating, making them ideal for environments where heat resistance is necessary. However, steel is prone to corrosion, which can be mitigated through galvanization or powder coating.

Pros: Steel brackets are durable, cost-effective, and can be manufactured in various shapes and sizes. Their high tensile strength makes them suitable for heavy-duty applications.

Cons: The main drawback is their susceptibility to rust if not properly treated, which can lead to structural failure over time. Additionally, the weight of steel may be a concern in applications where lightweight materials are preferred.

Impact on Application: Steel brackets are compatible with various media, including water and chemicals, provided they are adequately coated. However, in corrosive environments, stainless steel may be a better option.

Considerations for International Buyers: Compliance with standards such as ASTM A36 for structural steel is crucial. Buyers in regions like Africa and South America should consider local availability and treatment options to prevent corrosion.

How Does Aluminum Compare for U-shaped Metal Brackets?

Aluminum is another popular choice for U-shaped brackets, particularly in applications where weight is a critical factor. Aluminum is lightweight and offers excellent corrosion resistance, making it suitable for outdoor and marine environments. It also has a moderate temperature rating, which is acceptable for most applications.

Pros: The primary advantage of aluminum is its lightweight nature, which reduces shipping costs and makes installation easier. Additionally, aluminum’s natural corrosion resistance minimizes maintenance needs.

Cons: Aluminum is generally less strong than steel, which may limit its use in heavy-duty applications. It is also more expensive than steel, which can impact overall project budgets.

Impact on Application: Aluminum brackets are compatible with various media, including water and some chemicals. However, they may not be suitable for high-stress applications due to their lower tensile strength.

Considerations for International Buyers: Buyers should ensure that the aluminum used complies with international standards such as ASTM B221. In regions with high humidity, such as parts of the Middle East, the corrosion resistance of aluminum is a significant advantage.

What are the Benefits of Stainless Steel for U-shaped Metal Brackets?

Stainless Steel is an excellent choice for U-shaped brackets, especially in environments prone to corrosion. Stainless steel offers superior strength and durability, making it suitable for heavy-duty applications. It has a high-temperature rating, which adds to its versatility.

Pros: The primary advantage of stainless steel is its exceptional corrosion resistance, which extends the lifespan of the brackets. It also maintains structural integrity under extreme conditions.

Cons: The main limitation is the higher cost compared to carbon steel and aluminum. Additionally, stainless steel can be more challenging to work with during manufacturing, which may increase production times.

Impact on Application: Stainless steel brackets are compatible with a wide range of media, including harsh chemicals. They are ideal for applications in the food and pharmaceutical industries due to their hygienic properties.

Considerations for International Buyers: Compliance with standards such as ASTM A240 is essential. Buyers in Europe and the Middle East should consider the specific grades of stainless steel, such as 304 or 316, based on environmental conditions.

How Does Galvanized Steel Perform for U-shaped Metal Brackets?

Galvanized Steel is carbon steel that has been coated with zinc to enhance its corrosion resistance. This material is particularly useful in applications where exposure to moisture is a concern.

Pros: The galvanization process provides a protective layer that prevents rust, making these brackets suitable for outdoor use. They offer a good balance between strength and cost.

Cons: While galvanized steel is more resistant to corrosion than untreated steel, it is still not as durable as stainless steel in highly corrosive environments. The zinc coating can also wear off over time, especially in abrasive conditions.

Impact on Application: Galvanized steel brackets are suitable for various media, but prolonged exposure to corrosive substances can compromise their integrity.

Considerations for International Buyers: Compliance with standards like ASTM A123 for zinc coatings is vital. Buyers in humid regions, such as parts of Africa, should consider the longevity of the galvanization based on local environmental conditions.

Summary Table

| Material | Typical Use Case for u shape metal brackets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty structural applications | High tensile strength | Susceptible to corrosion | Medium |

| Aluminum | Lightweight applications | Lightweight and corrosion-resistant | Lower strength than steel | High |

| Stainless Steel | Harsh environments (food/pharma) | Exceptional corrosion resistance | Higher cost and manufacturing complexity | High |

| Galvanized Steel | Outdoor applications | Good corrosion resistance | Zinc coating wears off over time | Medium |

This guide provides a comprehensive overview of the materials used for U-shaped metal brackets, aiding international B2B buyers in making informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for u shape metal brackets

What Are the Main Stages of Manufacturing U Shape Metal Brackets?

The manufacturing of U shape metal brackets involves several key stages, each critical to ensuring the final product meets the necessary specifications for durability and functionality. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for U Shape Metal Brackets?

Material preparation is the foundational step in the manufacturing process. High-quality raw materials such as stainless steel, aluminum, or carbon steel are selected based on the intended application of the brackets. The choice of material impacts factors like corrosion resistance, weight capacity, and overall durability.

The raw materials are cut into appropriate sizes using techniques like shearing or laser cutting. This precision ensures that the pieces will fit together correctly during the forming stage. Additionally, the edges are often deburred to eliminate sharp edges that could pose safety risks during assembly or installation.

What Forming Techniques Are Used in U Shape Metal Bracket Production?

Once the materials are prepared, the next step is forming. This involves bending the metal sheets into the desired U shape. Common techniques used include:

- Press Brake Bending: A hydraulic press applies force to bend the metal along a predetermined line, allowing for precise angles and consistent dimensions.

- Roll Bending: For larger brackets, rolling machines can form curves and arcs, providing a smooth finish and reducing the risk of fractures.

These methods ensure that the brackets maintain structural integrity while achieving the required specifications for strength and load-bearing capacity.

How Are U Shape Metal Brackets Assembled?

After forming, the brackets may require assembly, especially if they consist of multiple components. This stage may involve welding, riveting, or using mechanical fasteners, depending on the design and load requirements.

Quality assurance during assembly is crucial, as improper joining can lead to structural failure. Manufacturers often utilize jigs and fixtures to ensure that components are aligned correctly and that the final assembly adheres to design specifications.

What Finishing Processes Are Applied to U Shape Metal Brackets?

Finishing processes enhance the appearance and functionality of the brackets. Common finishing techniques include:

- Powder Coating: This provides a durable, corrosion-resistant layer and can be customized in various colors.

- Galvanization: A protective zinc coating is applied to steel brackets to prevent rust, especially for outdoor applications.

- Anodizing: For aluminum brackets, anodizing increases corrosion resistance and improves surface hardness.

These finishes not only improve the aesthetic appeal but also extend the lifespan of the brackets, making them suitable for various environments.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is vital in ensuring that U shape metal brackets meet international and industry-specific standards. Key standards to consider include ISO 9001, which outlines requirements for a quality management system, and CE marking, which indicates conformity with health, safety, and environmental protection standards within the European Economic Area.

In industries like construction and manufacturing, additional standards such as API (American Petroleum Institute) may apply, particularly for brackets used in oil and gas applications. Understanding these standards helps B2B buyers assess the quality and compliance of the products they intend to purchase.

What Are the Key Quality Control Checkpoints During Manufacturing?

To maintain quality throughout the manufacturing process, several checkpoints are established:

-

Incoming Quality Control (IQC): This involves inspecting raw materials for compliance with specifications before production begins. Materials that do not meet standards are rejected or returned.

-

In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to ensure that processes are being followed correctly. This includes checking dimensions and tolerances at various stages of production.

-

Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection is performed to verify that the finished products meet all specifications and standards. This may involve testing for load capacity, dimensional accuracy, and surface finish.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are several actionable steps:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and overall operational standards of suppliers.

-

Quality Assurance Reports: Requesting documentation such as inspection reports, material certifications, and testing results can provide insights into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control processes and product compliance.

-

Certifications and Compliance Documents: Buyers should verify that suppliers hold relevant certifications and comply with international standards. This includes checking for ISO certifications, CE markings, and any industry-specific certifications.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various quality control nuances that can affect procurement. Different regions may have specific regulatory requirements, and understanding these can help mitigate risks. For instance, buyers from Europe must be particularly aware of CE marking requirements, while those sourcing from the Middle East may need to comply with local standards set by organizations such as the Gulf Standards Organization (GSO).

Additionally, language barriers and cultural differences can affect communication regarding quality expectations. Establishing clear specifications and maintaining open lines of communication with suppliers can help ensure that all parties understand the quality standards required.

In conclusion, the manufacturing processes and quality assurance practices surrounding U shape metal brackets are complex yet crucial for ensuring the delivery of reliable products. By understanding these processes and actively verifying supplier quality control, B2B buyers can make informed decisions that align with their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘u shape metal brackets’

In the competitive landscape of B2B procurement, sourcing U shape metal brackets requires careful consideration and strategic planning. This guide provides a practical checklist to streamline your purchasing process, ensuring that you acquire high-quality products that meet your project’s specifications.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for your U shape metal brackets. This includes dimensions, load capacity, material type (such as stainless steel, aluminum, or galvanized steel), and any specific finishes required for your project. Precise specifications prevent miscommunication with suppliers and ensure that the brackets will meet your structural needs.

- Consider Application: Determine whether the brackets will be used in a heavy-duty industrial setting or a lighter commercial application, as this will influence material choice and design.

- Regulatory Compliance: Verify any local or international standards that the brackets must meet, such as ISO or ASTM specifications.

Step 2: Conduct Market Research

Investigate potential suppliers and manufacturers of U shape metal brackets. Utilize online platforms, industry forums, and trade shows to gather information about various vendors. Understanding the market landscape will help you identify reputable suppliers and compare their offerings.

- Supplier Reviews: Look for feedback from other B2B buyers to gauge reliability and product quality.

- Local vs. International Suppliers: Consider the advantages of sourcing locally (such as reduced shipping costs and lead times) versus the potential cost savings from international suppliers.

Step 3: Evaluate Potential Suppliers

Thoroughly vet each potential supplier to ensure they can meet your specific needs. Request company profiles, case studies, and references from businesses in similar industries or regions. Evaluating suppliers is essential for building a reliable supply chain.

- Certifications and Compliance: Ensure suppliers have the necessary certifications, such as ISO 9001, to guarantee quality management practices.

- Production Capabilities: Assess whether the supplier can handle your order volume and delivery timelines.

Step 4: Request Samples

Before finalizing a supplier, request product samples to assess the quality and suitability of the U shape metal brackets. This step is crucial for verifying that the products meet your technical specifications and quality standards.

- Testing for Durability: Check the sample for strength and durability, especially if the brackets will be subjected to heavy loads or harsh environments.

- Finish and Aesthetics: Ensure the finish aligns with your project’s aesthetic requirements, as this can impact the overall appearance of the installation.

Step 5: Negotiate Pricing and Terms

Once you’ve selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Understanding the total cost of ownership—including shipping and potential tariffs—is vital for budget management.

- Bulk Order Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

- Payment Flexibility: Discuss payment terms that align with your cash flow needs, such as net 30 or net 60 arrangements.

Step 6: Finalize and Place Your Order

After agreeing on terms, finalize the purchase order with your chosen supplier. Ensure that all specifications, pricing, delivery dates, and terms are documented clearly to avoid misunderstandings.

- Confirmation of Order Details: Double-check that all details align with your initial requirements to prevent errors.

- Keep Communication Open: Maintain ongoing communication with the supplier throughout the order process to address any potential issues promptly.

Step 7: Plan for Quality Control

Implement a quality control process upon receiving your U shape metal brackets. Inspect the shipment for any discrepancies or defects before acceptance.

- Document Findings: Keep a record of any quality issues for future reference and potential claims against the supplier.

- Feedback Loop: Provide feedback to the supplier based on your experience, which can help improve future transactions.

By following this checklist, B2B buyers can navigate the procurement process for U shape metal brackets effectively, ensuring that they secure reliable products that meet their project requirements.

Comprehensive Cost and Pricing Analysis for u shape metal brackets Sourcing

When sourcing U-shape metal brackets, understanding the cost structure is crucial for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. This analysis delves into the various cost components and pricing influencers that shape the procurement landscape for these essential hardware components.

What Are the Key Cost Components in U-Shape Metal Bracket Production?

-

Materials: The primary cost driver is the material used in production, which can vary significantly based on specifications. Common materials include stainless steel, aluminum, and coated metals. The choice of material affects not only the cost but also the durability and application of the brackets.

-

Labor: Labor costs depend on the manufacturing location. Regions with lower labor costs, such as parts of Asia and Eastern Europe, can offer competitive pricing. However, skilled labor is necessary for quality assurance in production, which might elevate costs.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize overhead costs, impacting the final pricing of the brackets.

-

Tooling: Tooling costs are significant, especially for custom brackets that require specific molds or dies. Initial investments in tooling can be high but are amortized over larger production runs, making it essential to consider minimum order quantities (MOQs).

-

Quality Control (QC): Ensuring the brackets meet industry standards and specifications incurs additional costs. Rigorous QC processes are critical, particularly for buyers needing certifications for compliance with local regulations.

-

Logistics: Transportation and shipping costs can vary widely based on the distance from the manufacturer to the buyer, the mode of transport, and the chosen Incoterms. For international shipments, customs duties and tariffs can also add to the total cost.

-

Margin: Suppliers typically apply a profit margin to the total cost, which can fluctuate based on competition and market demand. Buyers should be aware of the prevailing market conditions to negotiate better deals.

How Do Pricing Influencers Impact the Cost of U-Shape Metal Brackets?

-

Volume/MOQ: Purchasing in bulk often leads to significant discounts. Suppliers may set MOQs that buyers must meet to enjoy reduced pricing, making it essential to balance inventory needs with cost savings.

-

Specifications and Customization: Custom designs or specific finishes can increase costs. Buyers should weigh the benefits of customization against the potential for higher prices.

-

Material Quality and Certifications: High-quality materials and certifications (e.g., ISO, ASTM) add value but also increase costs. Buyers should assess the necessity of these factors based on their application requirements.

-

Supplier Factors: The reputation, reliability, and location of the supplier can influence pricing. Engaging with established suppliers who have a proven track record may offer better quality assurance, albeit at a potentially higher price.

-

Incoterms: The choice of Incoterms affects logistics and shipping costs. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is critical for budgeting the total landed cost of the brackets.

What Negotiation Strategies Can Help Buyers Secure Better Pricing?

To optimize costs, buyers should consider the following strategies:

- Leverage Volume Discounts: Plan purchases in larger quantities to negotiate better pricing.

- Explore Multiple Suppliers: Request quotes from various suppliers to compare pricing and terms.

- Discuss Long-Term Partnerships: Establishing ongoing relationships can lead to better pricing and terms over time.

- Analyze Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, replacement, and operational costs associated with the brackets.

What Are the Pricing Nuances for International Buyers?

International buyers should be aware of additional factors such as currency fluctuations, import duties, and local market conditions that can affect the final cost. Engaging with suppliers who understand these nuances can streamline procurement and mitigate unexpected expenses.

Disclaimer

Pricing for U-shape metal brackets can vary significantly based on the aforementioned factors. The prices mentioned in this guide are indicative and may not reflect current market conditions. Always consult with suppliers for the most accurate pricing and terms.

Alternatives Analysis: Comparing u shape metal brackets With Other Solutions

When evaluating structural supports, it’s essential to consider various alternatives to U Shape Metal Brackets. Each option presents unique characteristics that may align better with specific project requirements. Below, we compare U Shape Metal Brackets with two viable alternatives: Angle Brackets and Channel Systems.

| Comparison Aspect | U Shape Metal Brackets | Angle Brackets | Channel Systems |

|---|---|---|---|

| Performance | High load-bearing capacity, versatile for various applications. | Moderate load capacity, best for corner support. | Excellent for modular structures, customizable configurations. |

| Cost | Generally low to moderate, varies by material and finish. | Typically low-cost, widely available. | Higher initial investment due to additional components. |

| Ease of Implementation | Simple to install with standard tools. | Easy to install, often requiring fewer fasteners. | Requires more assembly time and additional components. |

| Maintenance | Low maintenance; durable finishes available. | Minimal maintenance; prone to corrosion if not treated. | Low maintenance; easy to modify or expand as needed. |

| Best Use Case | Ideal for joining multiple channels or mounting to surfaces. | Best for reinforcing corners or lightweight structures. | Suitable for complex frameworks and heavy loads in industrial settings. |

What Are the Advantages and Disadvantages of Angle Brackets?

Angle brackets are commonly used for reinforcing corners and providing structural support in various applications. They are typically made from lightweight materials, which makes them cost-effective and easy to handle. While they are suitable for moderate load-bearing tasks, their performance is limited compared to U Shape Metal Brackets. Angle brackets can be susceptible to corrosion if not treated properly, which may require additional maintenance in certain environments. They are best suited for projects where corner reinforcement is needed rather than extensive structural support.

How Do Channel Systems Compare to U Shape Metal Brackets?

Channel systems provide a more flexible and customizable solution for structural support. They allow for a modular design that can be adapted as project requirements change. This adaptability makes channel systems an excellent choice for industrial applications where heavy loads and frequent modifications are common. However, they typically involve a higher initial investment due to the need for additional components and longer assembly times. While they offer low maintenance and excellent long-term performance, the complexity of installation may deter some users.

How Can B2B Buyers Choose the Right Structural Support Solution?

When selecting the right structural support solution, B2B buyers should carefully assess their specific project needs, including load requirements, budget constraints, and the desired level of flexibility. U Shape Metal Brackets are ideal for straightforward applications where strength and reliability are paramount. In contrast, angle brackets may suffice for lighter tasks, while channel systems shine in dynamic, heavy-duty environments. By weighing the pros and cons of each option against project specifications, buyers can make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for u shape metal brackets

What Are the Key Technical Properties of U Shape Metal Brackets?

U shape metal brackets are essential components in various structural and mounting applications. Understanding their technical properties is crucial for making informed purchasing decisions. Here are some of the critical specifications to consider:

-

Material Grade

U shape metal brackets are typically made from various materials, including stainless steel, aluminum, and galvanized steel. Each material has unique properties that affect durability, corrosion resistance, and weight. For instance, stainless steel (Type 304) is known for its excellent corrosion resistance, making it suitable for outdoor or marine applications. Selecting the right material grade ensures that the brackets will perform effectively in their intended environment. -

Load Capacity

This specification refers to the maximum weight the bracket can support without deformation or failure. It is vital for applications where structural integrity is paramount, such as in construction or heavy machinery. Load capacity is often tested based on the bracket’s design, material, and dimensions. When sourcing brackets, understanding the load capacity helps ensure safety and functionality in your projects. -

Hole Configuration

The arrangement and number of holes in a U shape bracket determine how it can be mounted and to what surfaces. Common configurations include 2-hole, 3-hole, and 4-hole designs. Knowing the right configuration for your application can streamline installation and enhance stability. This consideration is particularly important for businesses that require custom mounting solutions. -

Finish Type

The finish of a U shape bracket affects both aesthetics and performance. Common finishes include electro-galvanized, hot-dip galvanized, and powder coating. Each finish offers varying levels of corrosion resistance and visual appeal. For example, a powder-coated finish may provide better protection against environmental elements, making it suitable for outdoor applications. Selecting the appropriate finish can lead to longer-lasting products and reduced maintenance costs. -

Dimensional Tolerance

Tolerance refers to the allowable deviation from specified dimensions. High precision in manufacturing ensures that brackets fit correctly and function as intended. Tolerances are critical in applications requiring tight assembly, such as in machinery or equipment. Understanding tolerance specifications helps buyers ensure compatibility with other components in their projects.

What Are Common Trade Terms Related to U Shape Metal Brackets?

Navigating the purchasing process for U shape metal brackets requires familiarity with industry jargon. Here are some common terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of U shape metal brackets, OEMs often provide custom solutions tailored to specific requirements, ensuring compatibility and quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers, as it can affect inventory costs and overall project budgets. Suppliers often set MOQs to ensure efficient production and shipping processes. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. When sourcing U shape metal brackets, issuing an RFQ allows buyers to compare options from multiple suppliers, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Understanding Incoterms is crucial for international B2B transactions involving U shape metal brackets, as they dictate shipping costs, risks, and responsibilities. -

Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. In the context of U shape metal brackets, knowing the lead time can help businesses plan projects and manage schedules effectively.

By understanding these technical properties and trade terms, international buyers can make informed decisions when sourcing U shape metal brackets, leading to enhanced project success and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the u shape metal brackets Sector

What Are the Key Market Dynamics and Trends Impacting the U Shape Metal Brackets Sector?

The global market for U shape metal brackets is experiencing significant growth, driven by various factors including the expansion of construction and manufacturing sectors. Key trends include the increasing demand for versatile and durable fastening solutions in both commercial and industrial applications. International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly seeking U shape metal brackets that offer not only strength but also customization options. In addition, the rise of modular construction practices has further propelled the demand for adjustable and easy-to-install bracket solutions.

Emerging technologies in the sourcing process, such as digital procurement platforms and supply chain automation, are reshaping how international buyers engage with suppliers. These technologies allow for enhanced visibility and efficiency in sourcing, making it easier for companies in emerging markets to access quality products. Additionally, the trend toward e-commerce has expanded the reach of manufacturers, enabling them to cater to a broader audience and facilitate direct purchasing options for B2B buyers.

Moreover, the market is also witnessing a shift towards improved product finishes and corrosion resistance, with manufacturers offering brackets in various materials including stainless steel and galvanized finishes. This not only enhances durability but also meets the specific needs of different industries, from construction to automotive applications.

How Can Sustainability and Ethical Sourcing Influence B2B Decisions in the U Shape Metal Brackets Sector?

Sustainability has become a cornerstone of purchasing decisions in the B2B landscape, with an increasing number of buyers prioritizing environmentally-friendly products. The U shape metal brackets sector is no exception, as companies are looking to minimize their environmental impact by sourcing brackets made from recycled materials or those that come with certifications such as LEED or ISO 14001. These certifications not only assure buyers of a commitment to sustainability but also enhance the credibility of suppliers in a competitive market.

Furthermore, ethical sourcing practices are gaining traction, particularly among international buyers who are increasingly concerned about labor practices and the overall supply chain integrity. Ensuring that suppliers adhere to fair labor practices and environmental standards is essential for building long-term partnerships and maintaining brand reputation. Companies that transparently communicate their sourcing methods and materials often find favor with buyers looking to align with brands that reflect their values.

In response to these demands, manufacturers are innovating by developing “green” materials and processes for producing U shape metal brackets. For example, the use of eco-friendly coatings or finishes can significantly reduce environmental footprints while maintaining product quality. By adopting these practices, suppliers not only contribute to environmental preservation but also position themselves as leaders in a market that increasingly values sustainability.

What Is the Historical Context Behind the Development of U Shape Metal Brackets?

The evolution of U shape metal brackets can be traced back to the early days of industrialization, where the need for reliable structural connections became paramount in construction and manufacturing. Originally made from basic metals, these brackets were designed to provide simple yet effective solutions for joining structural components. Over the decades, advancements in metallurgy and manufacturing processes have led to the development of more robust and versatile designs.

As industries evolved, so did the applications of U shape metal brackets, expanding from traditional construction to include uses in HVAC systems, electrical installations, and modular furniture. The introduction of new materials, such as aluminum and high-strength steel, has further enhanced their performance and applicability. Today, U shape metal brackets are integral components across various sectors, reflecting a rich history of innovation and adaptation to meet the changing needs of global markets.

This historical context emphasizes the importance of understanding the evolution of products to make informed sourcing decisions, as it highlights the continuous improvement and adaptation that characterize the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of u shape metal brackets

-

How do I select the right U shape metal bracket for my project?

Selecting the right U shape metal bracket involves considering several factors, including the bracket’s size, load capacity, material, and finish. Assess the specific application requirements, such as whether the bracket will be used indoors or outdoors, as this can influence your choice of materials like stainless steel or galvanized steel. Additionally, ensure that the bracket’s dimensions align with your structural components. Consulting with suppliers about load ratings can also help you make an informed decision, ensuring the bracket meets safety and durability standards. -

What is the best material for U shape metal brackets used in outdoor applications?

For outdoor applications, stainless steel or hot-dip galvanized steel are the best materials for U shape metal brackets due to their superior corrosion resistance. Stainless steel, particularly Type 304, is highly durable and can withstand harsh weather conditions, making it ideal for long-term use. Hot-dip galvanized steel, on the other hand, offers a cost-effective solution with a protective zinc coating that prevents rust. When selecting a material, consider the environmental conditions of the installation site to ensure longevity and performance. -

What are the typical minimum order quantities (MOQs) for U shape metal brackets?

Minimum order quantities (MOQs) for U shape metal brackets can vary widely depending on the supplier and the specific product. Generally, MOQs range from 50 to 500 units. However, some manufacturers may offer lower MOQs for standard products or during promotional periods. It’s advisable to communicate directly with suppliers to negotiate terms that align with your project needs, especially if you require custom brackets or specific finishes. -

How can I verify the credibility of a U shape metal bracket supplier?

To verify a supplier’s credibility, start by researching their business history, customer reviews, and industry reputation. Check for certifications relevant to quality assurance, such as ISO standards, which indicate adherence to manufacturing protocols. Request references from previous clients and inquire about their experiences. Additionally, consider visiting the supplier’s facility if possible, or conducting a virtual audit to assess their production capabilities and quality control processes. -

What customization options are available for U shape metal brackets?

Many suppliers offer customization options for U shape metal brackets, including variations in size, material, finish, and hole configuration. Customization can enhance compatibility with specific applications or design requirements. When discussing customization, provide detailed specifications and any relevant drawings to ensure accurate manufacturing. It’s also beneficial to inquire about lead times and any additional costs associated with custom orders. -

What payment terms should I expect when ordering U shape metal brackets internationally?

Payment terms for international orders of U shape metal brackets can vary significantly among suppliers. Common terms include advance payment, letter of credit, or net 30/60 days after delivery. Be sure to discuss and negotiate terms upfront to avoid misunderstandings. Additionally, consider the implications of currency fluctuations and international transaction fees, which may affect the total cost of your order. -

How do I ensure quality assurance for U shape metal brackets?

To ensure quality assurance, request detailed product specifications and certifications from your supplier. Many manufacturers perform quality checks at different stages of production, including material testing and finished product inspections. You can also establish a quality assurance agreement that outlines your expectations for product performance and compliance with industry standards. Consider implementing a third-party inspection service for larger orders to ensure products meet your specifications before shipment. -

What logistics considerations should I keep in mind when importing U shape metal brackets?

When importing U shape metal brackets, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with international shipping practices to streamline the process. Understand the import duties and taxes applicable to your country, as these can significantly impact your total costs. Additionally, ensure that your supplier provides the necessary documentation, such as invoices and certificates of origin, to facilitate smooth customs clearance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 U Shape Metal Brackets Manufacturers & Suppliers List

1. Unistrut – U Brackets

Domain: unistrutstore.com

Registered: 2018 (7 years)

Introduction: U Brackets are designed to securely join multiple pieces of Unistrut Channel or mount channels to walls or other surfaces. They ensure strong, reliable connections for various structural applications. Available in multiple sizes, they offer flexible mounting solutions for both industrial and commercial projects. Free shipping on orders over $35 (some conditions apply). Specific products include: U…

2. Wagner – Steel U-Bracket

Domain: shop.wagnercompanies.com

Registered: 1999 (26 years)

Introduction: This company, Wagner – Steel U-Bracket, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Unistrut – U Shaped Fittings

Domain: unistrutohio.com

Registered: 2002 (23 years)

Introduction: Unistrut U Shaped Fittings (1-5/8″) include various types and finishes. There are 34 products available, categorized by fitting type, including 1-Hole, 2-Hole, 3-Hole, 4-Hole, and 5-Hole options. Finishes include 304 Stainless Steel, Electrogalvanized, Hot-Dipped Galvanized, and Perma-Green® III. Some specific products include: Unistrut P1043A (6 Hole, “U” Shape Fitting), Unistrut P1044 (4 Hole, “…

4. Robert Brooke – U Shape Bracket Aluminum

Domain: robertbrooke.com

Registered: 1998 (27 years)

Introduction: U Shape Bracket Aluminum for 1/2″ Panel

5. Shiffle Equip – U Bracket for Bathroom Partition Hardware

Domain: shifflerequip.com

Registered: 1997 (28 years)

Introduction: U bracket for 1/2 inch thick material, 14 gauge, cold rolled, satin stainless steel. Dimensions: 2 inches long. Designed for use as bathroom partition hardware. Provides additional support and stability for securing objects to walls or surfaces. Ideal for both DIY and professional projects. SKU: JAC-01879, MFG Part #: 1879, Price: $2.34.

6. Cascade Iron Co – Heavy Duty U Shaped Bracket

Domain: cascadeironco.com

Registered: 2018 (7 years)

Introduction: Heavy Duty U Shaped Bracket for Double Shelves\n- Price: $26.00 – $32.00 USD depending on size and finish\n- Sizes available: 5″, 7″, 9″, 11″\n- Weight capacity: Each bracket holds 100 lbs\n- Material: .25″ thick x 2″ wide premium US steel\n- Made in USA\n- Finish options: Clear Coated Raw Steel, Black, Brass, White, Silver\n- Includes: One Double Shelf Bracket, matching lag bolt hardware for wall…

7. Shielden Strut – U Shaped Connector Brackets

Domain: shieldenstrut.com

Introduction: U brackets, also known as U shaped brackets or U shaped connector brackets, are versatile mounting components engineered for strong, stable support between parallel surfaces. They are commonly used in mechanical framing, equipment mounting, and heavy-duty installations. Ideal applications include mounting pipes, conduit, or panels, securing beams, frames, or electrical trays, and providing heavy-d…

8. Partitions and Stalls – Aluminum U Shape Bracket

Domain: partitionsandstalls.com

Registered: 2012 (13 years)

Introduction: {“Product Name”: “Aluminum U Shape Bracket”, “Dimensions”: “1/2\” X 1-3/8\” X 57\””, “Material”: “Extruded Anodized Aluminum”, “Base Width”: “3/4\””, “Length”: “57\””, “Screw Hole Spacing”: “Every 13\””, “Panel Clearance”: “1/2\” for 1/2\” thick panels”, “Alternate Name”: “Bathroom Stall Continuous U Bracket”, “Manufacturer Part Number”: “2664”, “SKU”: “9A2924”, “Availability”: “In stock”, “Lead T…

Strategic Sourcing Conclusion and Outlook for u shape metal brackets

As we wrap up this guide on U shape metal brackets, it’s essential to recognize the pivotal role that strategic sourcing plays in optimizing your procurement processes. By understanding the diverse applications and specifications of U shape metal brackets, international B2B buyers can leverage these insights to make informed purchasing decisions. Sourcing high-quality brackets not only enhances structural integrity but also ensures compatibility with various projects, from industrial installations to commercial applications.

In regions such as Africa, South America, the Middle East, and Europe, establishing strong supplier relationships and negotiating favorable terms can significantly impact your bottom line. With multiple finishes and configurations available, buyers should prioritize suppliers that offer customization and engineering support, ensuring that the brackets meet specific project requirements.

Looking forward, now is the time to engage with trusted suppliers who can provide comprehensive solutions tailored to your needs. By adopting a proactive sourcing strategy, you can enhance operational efficiency and drive growth in your business. Seize the opportunity to strengthen your supply chain and position your company for success in the competitive global market.