Everything You Need to Know About Steel Beam Price Calculator Sourcing in 2025

Introduction: Navigating the Global Market for steel beam price calculator

In today’s competitive construction landscape, accurately determining the cost of materials is paramount for international B2B buyers, especially when it comes to sourcing a reliable steel beam price calculator. With fluctuating market prices and varying supplier capabilities, navigating the complexities of steel procurement can be daunting. This comprehensive guide aims to demystify the process, offering insights into the different types of steel beams, their applications in diverse construction projects, and the intricacies involved in supplier vetting.

Understanding the nuances of steel beam pricing is essential for buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Saudi Arabia. The guide will cover critical aspects such as the factors influencing steel beam prices, how to utilize calculators effectively, and best practices for evaluating suppliers based on quality and reliability. By equipping buyers with actionable insights and a clear framework for decision-making, this guide empowers businesses to make informed purchases that not only meet structural requirements but also align with budgetary constraints.

Whether you are involved in residential construction, commercial projects, or infrastructure development, this guide serves as a vital resource for mastering the art of steel procurement. With the right tools and knowledge, you can streamline your purchasing process, ensuring that your projects are not only successful but also cost-effective.

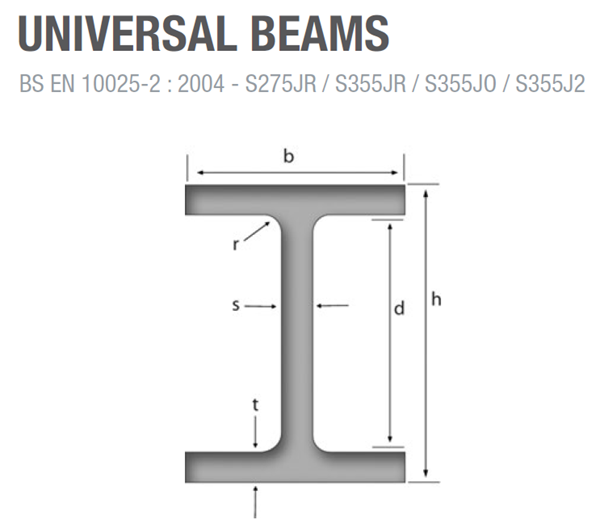

Understanding steel beam price calculator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard I-Beam Calculator | Calculates costs based on standard dimensions and materials. | Construction of commercial buildings, bridges | Pros: Easy to use, quick estimates. Cons: Limited to standard sizes. |

| Custom Steel Beam Calculator | Allows input of custom dimensions, weights, and fabrication needs. | Specialized constructions, custom projects | Pros: Tailored estimates, versatility. Cons: More complex, may require detailed knowledge. |

| Weight and Load Calculator | Focuses on calculating beam weights and load capacities. | Structural engineering, load assessments | Pros: Accurate load predictions. Cons: May not provide cost estimates directly. |

| Integrated Price Calculator | Combines material costs with fabrication and installation. | Comprehensive project budgeting | Pros: All-in-one solution, streamlined process. Cons: Can be overwhelming for simple projects. |

| Online Steel Beam Estimator | Web-based tool providing instant pricing based on market rates. | Quick project quotes and budgeting | Pros: Fast access to pricing, user-friendly. Cons: May lack local supplier data. |

What Are the Characteristics of a Standard I-Beam Calculator?

A Standard I-Beam Calculator is designed for straightforward calculations based on pre-defined dimensions and specifications. It typically includes a database of standard beam sizes and weights, making it ideal for conventional construction projects such as commercial buildings and bridges. When using this tool, buyers benefit from quick estimates, allowing for efficient project planning. However, its limitation lies in the inability to accommodate custom specifications, which may necessitate additional calculations or consultations for unique projects.

How Does a Custom Steel Beam Calculator Enhance Project Flexibility?

Custom Steel Beam Calculators offer significant versatility by allowing users to input specific dimensions, weights, and fabrication details. This tool is particularly useful for specialized construction projects where standard dimensions may not suffice. B2B buyers can obtain tailored estimates that reflect their unique project requirements, which enhances accuracy in budgeting. However, the complexity of these calculators may require users to have a more in-depth understanding of structural specifications and steel grades.

Why Is a Weight and Load Calculator Critical for Structural Engineering?

The Weight and Load Calculator is an essential tool for structural engineers, focusing on the calculation of beam weights and their load-bearing capacities. This tool is critical for ensuring that structures can safely support intended loads, making it indispensable in the design phase of any construction project. While it provides precise load predictions, it may not directly offer cost estimates, necessitating the use of additional calculators or consultations for comprehensive project budgeting.

What Advantages Does an Integrated Price Calculator Offer?

An Integrated Price Calculator provides a holistic approach to project budgeting by combining material costs with fabrication and installation expenses. This all-in-one solution streamlines the procurement process, allowing buyers to see the total cost associated with a project from start to finish. While this tool simplifies budgeting, it can also be overwhelming for simpler projects where detailed cost breakdowns may not be necessary.

How Does an Online Steel Beam Estimator Facilitate Quick Pricing?

Online Steel Beam Estimators are web-based tools that provide instant pricing based on current market rates. This feature is particularly beneficial for B2B buyers looking for quick quotes to inform project decisions. The user-friendly interface allows for rapid input and retrieval of pricing information, which is crucial in competitive bidding situations. However, these estimators may lack localized supplier data, which could affect accuracy in specific markets.

Key Industrial Applications of steel beam price calculator

| Industry/Sector | Specific Application of Steel Beam Price Calculator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Estimating costs for residential and commercial projects | Accurate budgeting and cost control | Availability of local suppliers, compliance with local standards |

| Manufacturing | Calculating beam costs for machinery support structures | Optimized material usage and cost efficiency | Material quality, lead times, and fabrication capabilities |

| Infrastructure | Assessing steel beam requirements for bridges and highways | Enhanced project planning and timely execution | Regulatory compliance, environmental considerations |

| Oil & Gas | Sizing beams for offshore platforms and refineries | Reduced risk of structural failures and delays | Corrosion resistance, weight specifications, and local sourcing |

| Renewable Energy | Determining beam needs for solar and wind energy installations | Improved project feasibility and investment returns | Sustainability certifications, material sourcing, and cost variations |

How is the Steel Beam Price Calculator Used in Construction Projects?

In the construction industry, the steel beam price calculator is essential for estimating costs associated with both residential and commercial projects. By inputting specific dimensions and requirements, contractors can quickly determine the total cost of steel beams needed for structural support. This tool addresses the challenge of fluctuating steel prices and helps ensure accurate budgeting, enabling businesses to avoid unexpected expenses. For international buyers, understanding local market prices and sourcing regulations is crucial to ensure compliance and optimize costs.

What Role Does the Steel Beam Price Calculator Play in Manufacturing?

Manufacturers utilize the steel beam price calculator to determine costs for beams that support machinery and equipment. This application is critical for optimizing material usage and minimizing waste, which directly impacts production costs. By calculating the price based on specific requirements, manufacturers can make informed decisions on sourcing and budgeting. International buyers must consider local fabrication capabilities and material quality to ensure that the beams meet their operational needs and industry standards.

How is the Steel Beam Price Calculator Important for Infrastructure Projects?

In the infrastructure sector, the steel beam price calculator assists engineers and project managers in estimating requirements for bridges and highways. The ability to accurately assess costs and material needs enhances project planning and execution. This tool helps mitigate risks associated with structural integrity by ensuring that the right specifications are met. International buyers should focus on regulatory compliance and environmental factors, especially in regions where infrastructure projects are subject to stringent guidelines.

What Benefits Does the Steel Beam Price Calculator Provide to the Oil & Gas Industry?

For the oil and gas sector, the steel beam price calculator is vital for sizing beams used in offshore platforms and refineries. Accurate calculations reduce the risk of structural failures and project delays, which can be costly in this industry. Buyers must consider factors such as corrosion resistance and weight specifications when sourcing materials. Understanding local sourcing options and regulations can significantly impact project timelines and budgets in various regions, including the Middle East and South America.

How Does the Steel Beam Price Calculator Support Renewable Energy Initiatives?

In the renewable energy sector, the steel beam price calculator helps determine the structural needs for solar and wind energy installations. By accurately estimating costs, project developers can assess the feasibility of their investments and ensure timely project delivery. Buyers in this sector should prioritize sustainability certifications and sourcing practices that align with their environmental goals. Understanding cost variations based on local market conditions is essential for optimizing project budgets and maximizing returns on investment.

3 Common User Pain Points for ‘steel beam price calculator’ & Their Solutions

Scenario 1: Difficulty in Estimating Accurate Costs for Steel Beams

The Problem: B2B buyers often face challenges in obtaining accurate pricing for steel beams due to fluctuating market prices and diverse fabrication costs. This uncertainty can lead to budget overruns and project delays, as buyers may not account for additional costs associated with custom dimensions, specific steel grades, or fabrication processes. Buyers in regions like Nigeria or Saudi Arabia, where local suppliers may have inconsistent pricing structures, find it especially difficult to get reliable estimates, causing frustration and anxiety.

The Solution: To navigate these pricing challenges effectively, B2B buyers should utilize comprehensive steel beam price calculators that allow for customizable inputs such as weight, length, and steel grade. By entering specific project requirements, buyers can receive real-time cost estimates that reflect current market conditions. It’s crucial to stay informed about local steel prices and any additional fabrication costs—considering a percentage markup for cutting or welding. Buyers should regularly consult with local suppliers and adjust their calculator inputs based on the latest quotes, ensuring their budget reflects the most accurate costs. Engaging with local suppliers to negotiate bulk pricing or discounts for larger orders can further optimize costs.

Scenario 2: Complexity in Selecting the Right Beam Specifications

The Problem: Many B2B buyers struggle with selecting the appropriate steel beam specifications for their projects, leading to potential structural issues or compliance failures. The complexity of understanding various beam types, sizes, and their load-bearing capacities can be overwhelming. In regions with less access to engineering expertise, like parts of South America, buyers may find it challenging to determine the correct specifications, which could compromise the safety and integrity of their construction projects.

The Solution: Buyers should leverage advanced steel beam calculators that not only provide pricing but also guide them through the selection process by incorporating necessary engineering principles. These calculators often feature options to input load requirements, beam length, and type, offering tailored recommendations based on structural needs. Additionally, buyers should consult with structural engineers or use online resources to better understand the requirements for their specific applications. By combining these tools with expert insights, buyers can confidently select the correct specifications for their projects, ensuring both safety and compliance with local building codes.

Scenario 3: Time Constraints in Gathering Quotes from Multiple Suppliers

The Problem: In the fast-paced construction industry, B2B buyers frequently face time constraints when gathering quotes for steel beams from multiple suppliers. This process can be tedious and time-consuming, often resulting in delays that affect project timelines. For buyers in Europe, where competition is high, the inability to quickly assess options can lead to missed opportunities and increased costs.

The Solution: To expedite the quotation process, buyers should utilize integrated steel beam price calculators that provide instant pricing while allowing comparisons across different suppliers. Choosing platforms that aggregate multiple suppliers’ pricing enables buyers to view various options in real time, significantly reducing the time spent on individual inquiries. Additionally, establishing ongoing relationships with a select group of trusted suppliers can streamline future transactions, allowing for quicker responses and more efficient negotiations. Utilizing technology, such as automated quote requests, can further enhance efficiency, ensuring buyers can focus on critical project aspects without compromising on cost-effectiveness or quality.

Strategic Material Selection Guide for steel beam price calculator

What Are the Key Properties of Common Materials Used in Steel Beam Price Calculators?

When selecting materials for steel beams, understanding their properties is crucial for ensuring optimal performance in various applications. Here, we analyze four common materials: Carbon Steel, Stainless Steel, Alloy Steel, and Galvanized Steel.

Carbon Steel: The Versatile Choice

Key Properties: Carbon steel is known for its high strength and durability, making it suitable for various structural applications. It has good weldability and can withstand significant loads, although it is not inherently corrosion-resistant.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and availability. However, it is susceptible to rust and corrosion, which can limit its lifespan in harsh environments. Additionally, while it performs well under high stress, it may not be suitable for applications requiring high-temperature resistance.

Impact on Application: Carbon steel beams are widely used in construction, particularly for structural frameworks. However, in regions with high humidity or exposure to corrosive elements, additional protective measures may be necessary.

Considerations for International Buyers: Buyers in Africa and South America should be aware of local climate conditions and consider protective coatings. Compliance with standards such as ASTM A36 is essential for ensuring quality and safety.

Stainless Steel: The Corrosion-Resistant Alternative

Key Properties: Stainless steel offers excellent corrosion resistance due to its chromium content, making it ideal for applications in harsh environments. It also maintains strength at high temperatures.

Pros & Cons: The key advantage of stainless steel is its longevity and aesthetic appeal, making it suitable for both structural and decorative applications. However, it is significantly more expensive than carbon steel and can be more challenging to fabricate.

Impact on Application: Stainless steel beams are preferred in industries such as food processing and pharmaceuticals, where hygiene is critical. Their resistance to corrosive substances allows for extended service life.

Considerations for International Buyers: Buyers in the Middle East and Europe should ensure compliance with standards like ASTM A240. The higher initial cost may be justified by the reduced maintenance needs over time.

Alloy Steel: Enhanced Performance for Specific Applications

Key Properties: Alloy steel is engineered to provide specific properties such as increased strength, toughness, and wear resistance. It can be tailored for various applications by adjusting its composition.

Pros & Cons: The main advantage of alloy steel is its versatility; it can be designed to meet specific performance requirements. However, this customization can lead to higher manufacturing complexity and costs.

Impact on Application: Alloy steel beams are often used in heavy-duty applications, such as bridges and industrial structures, where enhanced strength is necessary.

Considerations for International Buyers: Buyers should be aware of the specific alloy compositions required for their projects and ensure compliance with relevant standards like ASTM A992.

Galvanized Steel: Protection Against Corrosion

Key Properties: Galvanized steel is carbon steel that has been coated with zinc to enhance its corrosion resistance. This makes it suitable for outdoor applications and environments prone to moisture.

Pros & Cons: The primary advantage is its durability and reduced maintenance needs compared to untreated steel. However, the galvanization process can add to the overall cost, and the coating may be compromised if damaged.

Impact on Application: Galvanized steel beams are commonly used in construction projects exposed to the elements, such as roofing and outdoor structures.

Considerations for International Buyers: Buyers in humid regions, such as parts of Africa and South America, should prioritize galvanized steel to ensure longevity. Compliance with standards like ASTM A123 is crucial for quality assurance.

Summary Table of Material Properties

| Material | Typical Use Case for steel beam price calculator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural frameworks in construction | Cost-effective and widely available | Susceptible to corrosion | Low |

| Stainless Steel | Food processing and pharmaceutical applications | Excellent corrosion resistance | High cost and fabrication complexity | High |

| Alloy Steel | Heavy-duty structures like bridges | Tailored for specific performance needs | Higher manufacturing complexity | Medium |

| Galvanized Steel | Outdoor construction projects | Durable with reduced maintenance needs | Coating can be compromised | Medium |

This strategic material selection guide aims to equip international B2B buyers with the necessary insights to make informed decisions when using steel beam price calculators, ensuring that they select the most suitable materials for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for steel beam price calculator

What Are the Main Stages of the Steel Beam Manufacturing Process?

The manufacturing of steel beams is a complex process that involves several key stages, each contributing to the overall quality and performance of the final product. Understanding these stages can help B2B buyers make informed decisions when utilizing a steel beam price calculator.

Material Preparation: How Is Steel Processed for Beam Production?

The first step in manufacturing steel beams is material preparation. This involves sourcing high-quality raw materials, typically steel scrap or direct reduced iron (DRI). The steel is then melted in an electric arc furnace (EAF) or a basic oxygen furnace (BOF). Once melted, the steel is cast into semi-finished shapes such as blooms or billets, which are further processed into beam shapes.

Before proceeding to forming, the steel is analyzed for its chemical composition and mechanical properties. This ensures that the material meets the required specifications for strength and durability. For B2B buyers, it’s crucial to confirm that suppliers adhere to international standards such as ASTM or EN for material quality.

Forming: What Techniques Are Used to Shape Steel Beams?

The forming stage involves shaping the semi-finished steel into the desired beam profile. The most common techniques include:

-

Hot Rolling: This is the primary method for producing I-beams, H-beams, and other structural shapes. The heated steel is passed through rollers to achieve the desired cross-section. Hot rolling enhances the material’s strength and ductility.

-

Cold Forming: In some cases, steel can be cold-formed into specific shapes. This technique is often used for lighter gauges and can improve surface finish and dimensional accuracy.

-

Welding: For custom beam sizes or configurations, sections may be welded together. This requires precise control to ensure that the welds meet structural integrity standards.

During this phase, manufacturers may also employ advanced technologies like Computer Numerical Control (CNC) machining for precision cutting and shaping.

What Quality Assurance Practices Are Essential in Steel Beam Production?

Quality assurance (QA) is critical to ensuring that steel beams meet both safety and performance standards. B2B buyers should be aware of the key QA practices that manufacturers should implement throughout the production process.

International Standards: Which Certifications Should Buyers Look For?

To ensure compliance with global quality standards, steel beam manufacturers often obtain certifications such as ISO 9001 for quality management systems. Additionally, industry-specific certifications like CE marking (for Europe) and API (American Petroleum Institute) may be relevant, particularly for beams used in construction and infrastructure projects.

These certifications signify that the manufacturer adheres to strict quality controls and processes. B2B buyers should request documentation of these certifications during the supplier selection process.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early and ensure compliance with specifications. Common QC checkpoints include:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality and conformity to specifications before they enter the production line.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, operators conduct inspections to monitor key parameters such as dimensions, weight, and weld integrity.

-

Final Quality Control (FQC): Once the beams are manufactured, they undergo a final inspection, which includes non-destructive testing methods such as ultrasonic testing, magnetic particle testing, or radiographic testing to identify any internal flaws.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is paramount to ensuring reliability. Here are some actionable steps:

-

Request Certification Documentation: Always ask for copies of relevant certifications and quality management system documents. This can include ISO certifications, CE markings, and API standards.

-

Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Consider engaging third-party inspection agencies to perform these audits.

-

Review Quality Control Reports: Suppliers should provide detailed QC reports that outline testing methods, results, and any corrective actions taken. This transparency builds trust and ensures accountability.

-

Seek Customer References: Ask for references from other B2B clients who have purchased steel beams from the supplier. Their experiences can provide valuable insights into the supplier’s reliability and quality.

What Common Testing Methods Are Utilized in Steel Beam Quality Control?

To ensure the structural integrity and performance of steel beams, various testing methods are employed. B2B buyers should be aware of these methods to evaluate the quality of their purchases effectively:

-

Tensile Testing: This evaluates the material’s strength and ductility by measuring how much it stretches before breaking.

-

Impact Testing: This assesses the material’s toughness by subjecting it to sudden impacts, simulating real-world conditions.

-

Fatigue Testing: This tests how materials perform under cyclic loading over time, which is crucial for beams subjected to dynamic loads.

-

Dimensional Inspection: Accurate measurements of length, width, and thickness ensure that the beams meet specified tolerances.

Conclusion: How Can B2B Buyers Ensure High-Quality Steel Beams?

Understanding the manufacturing processes and quality assurance practices is essential for B2B buyers looking to procure steel beams. By familiarizing themselves with the stages of production, relevant international standards, and effective verification methods, buyers can make informed decisions and ensure they receive high-quality products that meet their project requirements. Engaging with reputable suppliers who prioritize quality and compliance will ultimately lead to successful construction outcomes and cost savings.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘steel beam price calculator’

Introduction

This practical sourcing guide aims to equip B2B buyers with the essential steps for procuring a steel beam price calculator. Given the complexities involved in steel beam specifications and pricing, a structured approach will help ensure that you select the right tool that meets your project needs effectively and efficiently.

Step 1: Define Your Technical Specifications

Begin by clearly outlining your project requirements. This includes the types of steel beams you need, the dimensions, weight capacities, and any specific fabrication processes. Having these specifications will help you identify calculators that can handle your particular use case, ensuring accuracy in pricing and material selection.

- Key Considerations:

- Types of beams (I-beams, H-beams, etc.)

- Load-bearing requirements

- Environmental factors (e.g., corrosion resistance)

Step 2: Research Available Calculators

Conduct thorough research on various steel beam price calculators available in the market. Look for tools that allow customization of dimensions and materials, and that provide real-time pricing based on current market rates. A comprehensive tool will help streamline the procurement process, saving you time and effort.

- Focus Areas:

- User interface and ease of use

- Integration capabilities with other project management tools

- Availability of customer support and training resources

Step 3: Evaluate Potential Suppliers

Before committing to a particular calculator, it’s crucial to vet potential suppliers. Request detailed company profiles, case studies, and references from other businesses that have used their calculators. This will provide insight into the reliability and accuracy of their tools.

- What to Look For:

- Reviews from similar industries

- Case studies demonstrating successful implementations

- Response times and support availability

Step 4: Check Compliance and Certifications

Ensure that the calculators you are considering comply with local and international standards. Certifications such as CE marking can indicate that the product meets necessary safety and quality standards, which is particularly important in structural applications.

- Important Certifications:

- CE certification for structural steel

- ISO certifications related to quality management systems

Step 5: Request a Demo or Trial Period

Before making a purchase, request a demonstration or trial period for the calculator. This allows you to explore its functionalities and ensure it meets your operational requirements. A hands-on experience can reveal potential issues that may not be apparent through documentation alone.

- What to Test:

- Ease of inputting data and generating results

- Clarity of output reports

- Overall user experience

Step 6: Compare Pricing Models

Finally, compare the pricing structures of the calculators. Some suppliers may offer subscription-based models, while others may charge a one-time fee. Consider your budget and the long-term value of the tool to determine the most cost-effective solution.

- Factors to Consider:

- Hidden costs (e.g., updates, customer support)

- Scalability for future projects

- Value-added features (e.g., advanced analytics, integration with other software)

By following this checklist, B2B buyers can effectively navigate the complexities of procuring a steel beam price calculator, ensuring they select a solution that best fits their project needs and operational requirements.

Comprehensive Cost and Pricing Analysis for steel beam price calculator Sourcing

What Are the Key Cost Components for Steel Beam Pricing?

Understanding the cost structure of steel beams is crucial for B2B buyers looking to optimize their sourcing strategies. The primary cost components include:

-

Materials: The type of steel used directly influences the price. Common grades such as S235, S275, and S355 vary in cost depending on their mechanical properties and market demand. Additionally, prices fluctuate with global steel market trends, currency exchange rates, and local availability.

-

Labor: Labor costs encompass the wages for skilled workers involved in fabrication, cutting, welding, and assembly. Regions with higher labor costs will reflect these expenses in the final price of the steel beams.

-

Manufacturing Overhead: This includes fixed costs such as utilities, rent, and equipment depreciation. Efficient manufacturers with lower overhead can offer more competitive pricing.

-

Tooling: Custom tooling for unique specifications can add significant costs. Standardized sizes typically incur lower tooling expenses, so opting for standard dimensions can be cost-effective.

-

Quality Control (QC): Ensuring that the steel beams meet safety and quality standards involves additional costs. Certifications such as ISO, CE, or ASTM compliance can influence pricing, as manufacturers must invest in testing and quality assurance processes.

-

Logistics: Transportation costs can vary widely based on distance, mode of transport, and the complexity of delivery logistics. International shipping, in particular, can add layers of complexity and cost due to tariffs and customs regulations.

-

Margin: Suppliers apply a margin to cover their costs and ensure profitability. This can vary based on market competition and the supplier’s positioning strategy.

How Do Price Influencers Affect Steel Beam Costs?

Several factors can significantly impact the final pricing of steel beams, including:

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk often leads to cost reductions due to economies of scale. Suppliers may offer better rates for larger orders, making it beneficial for companies with extensive projects.

-

Specifications and Customization: Custom dimensions or specialized fabrication requirements can increase costs. Buyers should carefully evaluate whether customization is necessary for their project to avoid unnecessary expenses.

-

Quality and Certifications: Higher-quality materials and certified products typically come at a premium. However, investing in quality can lead to long-term savings by reducing maintenance and replacement costs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with robust supply chains may offer better pricing stability and service levels.

-

Incoterms: Understanding the terms of delivery (e.g., FOB, CIF) can help buyers manage logistics costs effectively. Clarity on who bears the risk and cost at each stage of transport can prevent unexpected expenses.

What Are Effective Buyer Tips for Sourcing Steel Beams?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, consider the following strategies:

-

Negotiate Wisely: Leverage volume orders and long-term relationships to negotiate better pricing. Suppliers may be willing to offer discounts for repeat business or larger contracts.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not only the purchase price but also installation, maintenance, and potential downtime costs. A slightly higher upfront cost may yield lower long-term expenses.

-

Understand Pricing Nuances: Be aware of the regional market dynamics that can influence pricing, such as local steel production capabilities, demand fluctuations, and economic conditions. This knowledge can empower buyers during negotiations.

-

Consider Currency Risks: International transactions can involve currency fluctuations. Locking in prices or using hedging strategies may mitigate risks associated with currency exchange.

Disclaimer on Indicative Prices

Prices for steel beams are subject to change based on market conditions, availability, and specific buyer requirements. Buyers are encouraged to conduct thorough market research and obtain multiple quotations to ensure they receive the best pricing for their projects.

Alternatives Analysis: Comparing steel beam price calculator With Other Solutions

Introduction: Understanding Alternatives in Steel Beam Cost Estimation

When it comes to estimating the costs associated with steel beams, various solutions exist beyond the traditional steel beam price calculator. These alternatives cater to different operational needs and project requirements, offering unique features and benefits. As B2B buyers from diverse regions consider their options, understanding these alternatives is crucial for making informed decisions that align with their specific construction or fabrication needs.

Comparison Table

| Comparison Aspect | Steel Beam Price Calculator | Alternative 1: Manual Estimation | Alternative 2: Third-Party Software |

|---|---|---|---|

| Performance | High accuracy, real-time calculations | Moderate accuracy, prone to human error | High accuracy, comprehensive features |

| Cost | Generally low (often free) | No direct costs, but time-intensive | Subscription fees or one-time purchase |

| Ease of Implementation | User-friendly, quick setup | Requires expertise and experience | Moderate learning curve, may need training |

| Maintenance | Low, requires minimal updates | None, but knowledge must be current | Regular updates required for software |

| Best Use Case | Quick cost estimates for projects | Small-scale projects or DIY tasks | Large-scale projects requiring detailed analysis |

Detailed Breakdown of Alternatives

Manual Estimation

Manual estimation involves calculating material costs based on weight, dimensions, and local market prices without relying on digital tools. While this method can be cost-effective since it doesn’t incur software fees, it is often time-consuming and prone to human error. Accuracy is contingent on the estimator’s experience and knowledge of structural engineering principles, making it less reliable for complex projects. This approach is best suited for small-scale endeavors where speed is less critical, and the estimator is familiar with the materials and local conditions.

Third-Party Software

Third-party software solutions for structural engineering often provide extensive features, including cost estimation, load analysis, and project management tools. These platforms typically require a subscription or one-time purchase fee, which can be a barrier for smaller businesses. However, they offer high accuracy and comprehensive data analysis capabilities, making them ideal for large-scale projects with complex requirements. A moderate learning curve is associated with these tools, necessitating training for optimal use. This option is best for firms that regularly engage in large-scale construction and need detailed analytical capabilities.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right solution for estimating steel beam costs depends on various factors, including project scale, complexity, and available resources. The steel beam price calculator stands out for its ease of use and efficiency, making it a suitable choice for quick estimates. In contrast, manual estimation may work for simpler projects but lacks reliability for more intricate tasks. Third-party software, while potentially costly, offers comprehensive analysis for larger endeavors. B2B buyers should evaluate their specific needs, budget constraints, and the level of detail required in their estimates to determine the most appropriate solution for their projects.

Essential Technical Properties and Trade Terminology for steel beam price calculator

What Are the Key Technical Properties of Steel Beams in Price Calculations?

Understanding the technical properties of steel beams is essential for B2B buyers, especially when it comes to accurately calculating costs and ensuring the structural integrity of projects. Here are some critical specifications that play a significant role in the pricing and performance of steel beams:

-

Material Grade

The material grade of a steel beam indicates its strength and durability. Common grades include S235, S275, and S355, with higher numbers signifying increased yield strength. For B2B buyers, selecting the appropriate grade is crucial to ensure that the steel can handle expected loads and environmental conditions, thus preventing costly structural failures. -

Weight

The weight of the steel beam is a vital factor in the price calculation. Steel beams are typically priced per kilogram or ton, making weight a direct influence on overall costs. Accurate weight estimations help buyers budget effectively and determine shipping logistics, especially when sourcing materials internationally. -

Dimensions (Height, Width, Length)

The dimensions of the beam—specifically its height, width, and length—are fundamental in defining its load-bearing capacity. Custom dimensions may be necessary for specific applications, and understanding how these measurements affect price is essential for precise cost estimations. Buyers need to communicate their requirements clearly to suppliers to avoid misunderstandings and ensure timely delivery. -

Tolerance

Tolerance refers to the allowable deviation from specified dimensions during the manufacturing process. Tighter tolerances may increase production costs but are necessary for projects requiring high precision. For B2B buyers, knowing the tolerance levels can prevent issues during installation, ensuring that beams fit seamlessly within the overall structure. -

Fabrication Costs

In addition to the base material cost, fabrication processes such as cutting, drilling, and welding add to the total price. Understanding these costs upfront allows buyers to factor them into their budgets and choose suppliers who offer transparent pricing structures.

What Are Common Trade Terminologies Related to Steel Beam Pricing?

Familiarity with industry-specific jargon is essential for B2B buyers to navigate the procurement process effectively. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces components that are used in another company’s end product. In the context of steel beams, buyers often deal with OEMs for custom fabrication and modifications to meet specific project needs. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to manage inventory levels and avoid overstocking or stockouts, especially when dealing with bulk steel orders. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. For steel beam buyers, issuing RFQs helps in comparing prices and services from multiple suppliers, enabling informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and costs associated with transporting steel beams across borders. -

Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. Knowing the lead time for steel beams is critical for project planning and ensuring that construction schedules are met without delays.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when using steel beam price calculators, ensuring that they secure the right products at competitive prices for their projects.

Navigating Market Dynamics and Sourcing Trends in the steel beam price calculator Sector

What Are the Key Market Dynamics Influencing the Steel Beam Price Calculator Sector?

The global steel beam market is witnessing significant transformations driven by various factors. One of the primary drivers is the increasing demand for infrastructure development, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Countries like Nigeria and Saudi Arabia are investing heavily in construction projects, necessitating accurate and efficient cost estimations for materials like steel beams. The rise of advanced B2B technologies, including integrated steel beam price calculators, is reshaping how buyers interact with suppliers. These digital tools provide instant pricing based on customizable parameters, allowing for quicker decision-making and streamlined procurement processes.

Another notable trend is the shift towards data-driven procurement, where buyers leverage analytics to assess market trends and pricing fluctuations. As the steel market is often subject to volatility due to factors like geopolitical tensions and raw material supply constraints, having access to real-time data can empower B2B buyers to make informed purchasing decisions. Moreover, the emergence of cloud-based solutions has facilitated better collaboration between buyers and suppliers, optimizing the supply chain and reducing lead times.

How Are Sustainability and Ethical Sourcing Shaping the Steel Beam Sector?

Sustainability is becoming a crucial consideration for B2B buyers in the steel beam sector. The environmental impact of steel production, including carbon emissions and resource depletion, is prompting many companies to seek eco-friendly alternatives. This trend is particularly relevant in regions like Europe, where regulations are increasingly stringent regarding carbon footprints and sustainability practices.

Ethical sourcing is another critical aspect, as buyers are now prioritizing suppliers who adhere to responsible labor practices and transparent supply chains. Certifications such as LEED (Leadership in Energy and Environmental Design) and ISO 14001 (Environmental Management) are becoming essential for suppliers aiming to attract environmentally conscious buyers. By choosing suppliers with these certifications, businesses not only enhance their reputation but also contribute to global sustainability goals.

Furthermore, the adoption of recycled steel and green building materials is gaining traction. These materials not only reduce the environmental impact but can also be cost-effective in the long run, offering a compelling value proposition for international B2B buyers.

How Has the Steel Beam Price Calculator Sector Evolved Over Time?

The evolution of the steel beam price calculator sector reflects broader technological advancements and changing market demands. Initially, pricing was largely dependent on manual calculations and quotes from suppliers, leading to inefficiencies and delays. As construction projects grew in complexity, the need for accurate and timely pricing became paramount.

The introduction of online calculators has revolutionized this space, enabling instant cost estimations based on user-defined parameters such as dimensions, weight, and fabrication requirements. This shift not only improves operational efficiency but also enhances transparency in pricing, allowing buyers to compare costs more effectively. As the industry continues to embrace digital solutions, the future of steel beam price calculators looks promising, with ongoing innovations aimed at further simplifying the procurement process for B2B buyers globally.

In summary, understanding these market dynamics, sustainability imperatives, and the historical context of pricing tools will empower B2B buyers to navigate the steel beam sector more effectively, ensuring they make informed and responsible purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of steel beam price calculator

-

How do I calculate the cost of steel beams using a price calculator?

To calculate the cost of steel beams using a price calculator, first, determine the specifications of the beam you need, including dimensions (height, width, and length), steel grade, and type (e.g., I-beam). Input these details into the calculator along with the current market price of steel per weight unit. Most calculators also allow you to include fabrication costs, taxes, and quantities. Once all data is entered, the calculator will provide a total cost estimate, helping you budget effectively for your project. -

What is the best steel beam price calculator for international buyers?

The best steel beam price calculator for international buyers is one that is user-friendly and offers real-time pricing based on local market conditions. Look for calculators that allow customization of dimensions and include options for various steel grades. A reliable calculator should also provide transparent breakdowns of costs, including fabrication and shipping fees, ensuring you can accurately assess total expenses. Additionally, consider tools that are compatible with multiple currencies to facilitate transactions across regions. -

Can I customize the dimensions of steel beams in the price calculator?

Yes, most steel beam price calculators allow for customization of dimensions. You can typically input specific measurements for height, width, and length, as well as select the type of beam you need. This flexibility is crucial for meeting unique project specifications and ensuring that the beams fit your structural requirements. Be sure to check if the calculator accommodates various steel grades and fabrication options, as these can significantly impact the overall cost. -

What factors should I consider when selecting a supplier for steel beams?

When selecting a supplier for steel beams, consider their reputation, certifications, and the quality of their products. Verify if they are CE-approved or have other relevant certifications that ensure compliance with international standards. Assess their experience in international trade, particularly in your region, and inquire about their lead times and delivery logistics. Additionally, review customer testimonials and request samples if possible to evaluate the quality before committing to a larger order. -

What are the minimum order quantities (MOQs) for steel beams?

Minimum order quantities (MOQs) for steel beams can vary significantly between suppliers. Some may have a low MOQ for standard sizes, while others may require larger orders for custom dimensions. It’s crucial to discuss MOQs during your supplier negotiations, especially if you’re operating on a limited budget. Understanding the MOQ will help you plan your inventory and budget accordingly, ensuring you don’t overcommit resources. -

What payment terms should I expect when purchasing steel beams internationally?

Payment terms for international purchases of steel beams can vary widely. Common terms include full payment upfront, partial payment with the balance due upon delivery, or net terms that allow for payment within a specified period post-delivery. Be sure to clarify these terms with your supplier before finalizing the order. Additionally, consider discussing options for secure payment methods, such as letters of credit, to protect your investment and ensure that both parties are covered in the transaction. -

How can I ensure the quality of steel beams sourced internationally?

To ensure the quality of steel beams sourced internationally, request certifications from your supplier that demonstrate compliance with industry standards. Look for quality assurance processes in place, such as third-party inspections or audits. Additionally, consider suppliers that offer a warranty or guarantee on their products. Establishing a good line of communication with your supplier can also help address any quality concerns proactively before and after the order is fulfilled. -

What logistics considerations should I keep in mind when ordering steel beams?

When ordering steel beams, logistics considerations are crucial for timely delivery and project success. Evaluate shipping options, costs, and delivery timelines to ensure they align with your project schedule. Consider the supplier’s experience with international shipping regulations and customs clearance processes, as these can affect delivery times. Additionally, ensure that the packaging is adequate to prevent damage during transit. Finally, confirm the terms of delivery, including whether the price includes shipping or if it will be an additional cost.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Steel Beam Price Calculator Manufacturers & Suppliers List

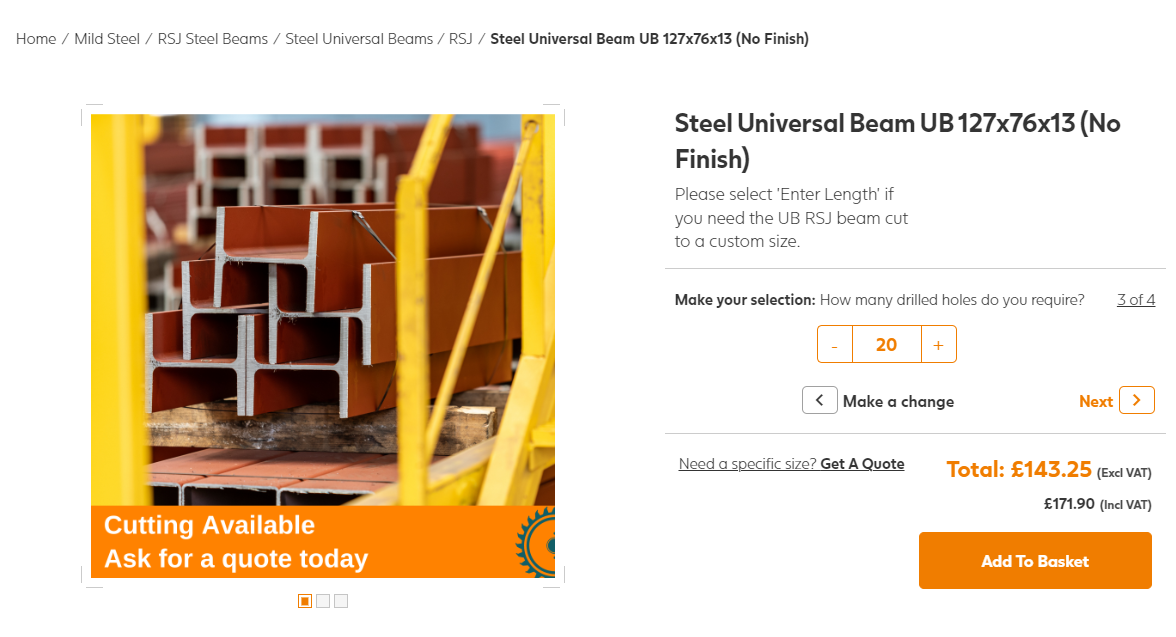

1. Steel Products Direct – RSJ Steel Beam Price Calculator

Domain: steelproductsdirect.com

Registered: 2017 (8 years)

Introduction: RSJ Steel Beam Price Calculator, Excellent service, Quick response times, UK wide deliveries, Call 020 4511 5540 for advice, Steel Beam Cost Calculator, Scenarios for calculating steel beam needs, Universal Beam Sizes: 127 x 76 x 13 (13.0 Kg/m), 152 x 89 x 16 (16.0 Kg/m), 178 x 102 x 19 (19.0 Kg/m), 203 x 102 x 23 (23.1 Kg/m), 203 x 133 x 25 (25.1 Kg/m), 203 x 133 x 30 (30.0 Kg/m), 254 x 102 x 22 …

2. Steel Beam Calculator – Quick & Accurate Steel Beam Calculations

Domain: steelbeamcalculator.com

Registered: 2010 (15 years)

Introduction: Steel Beam Calculator offers detailed calculations for steel beams in just minutes. Key features include: 30-day money-back guarantee, no sign-up necessary for demo, compliance with US Standards to AISC Allowable Stress Design 9th Edition, and trusted by over 5000 professionals worldwide. The calculator provides beautifully detailed calculations including design summary, shear force, bending momen…

3. Midwest Steel Supply – Hot Roll Steel I Beams

Domain: midweststeelsupply.com

Registered: 2005 (20 years)

Introduction: Hot Roll Steel I Beam

– Sizes Available: 4×13, 5×16, 5×19, 6×9, 6×12, 6×15, 6×16, 6×20, 6×25, 8×10, 8×13, 8×15, 8×18, 8×21, 8×24, 8×28, 8×31, 8×35, 8×40, 8×48, 8×67, 8×74, 10×12, 10×15, 10×17, 10×19, 10×22, 10×26, 10×30, 10×33, 10×39, 10×45, 10×49, 10×54, 10×77, 12×14, 12×16, 12×19, 12×22, 12×26, 12×30, 12×35, 12×40, 12×45, 12×50, 12×53, 14×22, 14×26, 14×30, 14×34, 14×38, 14×48, 14×61, 14×74, 16×2…

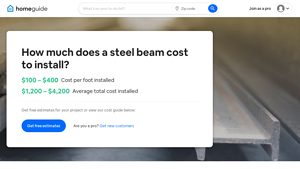

4. HomeGuide – Steel Beam Costs

Domain: homeguide.com

Registered: 1995 (30 years)

Introduction: Steel Beam Costs: $100 – $400 per foot installed; Average total cost: $1,200 – $4,200. Steel I-beam prices: $6 to $18 per foot (materials only). Replacement of load-bearing wall with support beam: $4,000 to $10,000. Installation cost breakdown: Steel I-Beam: $60 – $180, Delivery: $80 – $400+, Installation: $500 – $2,000, Structural Engineer: $300 – $1,000, Permits: $75 – $500. Types of beams: I-Be…

5. Estimator Florida – Steel I-Beam Installation Costs

Domain: estimatorflorida.com

Registered: 2020 (5 years)

Introduction: Steel I-Beam Installation Cost: $130 – $520 per foot; Average total cost: $1,560 – $5,460; Replacing load-bearing wall: $5,200 – $13,000; Material cost: $7.80 – $23.40 per foot. Steel I-beam types and costs: S3 x 5.7 (5.7 lbs, $7.80 – $10.40), S4 x 7.7 (7.7 lbs, $9.10 – $15.60), S6 x 12.5 (12.5 lbs, $15.60 – $23.40). Average installation cost breakdown: Steel I-Beam: $78 – $234, Delivery: $104 – $…

Strategic Sourcing Conclusion and Outlook for steel beam price calculator

In the realm of strategic sourcing, leveraging a steel beam price calculator is essential for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Understanding the intricacies of beam specifications—such as size, weight, and material grade—enables buyers to make informed decisions that optimize both cost and structural integrity. These tools not only streamline the procurement process but also enhance collaboration with trusted suppliers, ensuring timely delivery of high-quality materials.

The integration of advanced calculators simplifies the complex task of estimating costs, allowing businesses to allocate resources more effectively. By reducing the time spent on manual calculations and inquiries, companies can focus on their core operations, driving productivity and profitability.

As the global construction market evolves, staying ahead of pricing trends and supplier capabilities will be crucial. We encourage B2B buyers to adopt these innovative tools, ensuring they remain competitive and responsive to market demands. Embrace the power of strategic sourcing today and position your business for sustained success in the dynamic steel industry.