Everything You Need to Know About Ollies Laminate Flooring Sourcing in 2025

Introduction: Navigating the Global Market for ollies laminate flooring

In an era where quality flooring options are essential for both aesthetic appeal and functionality, sourcing ollies laminate flooring can pose a significant challenge for international B2B buyers. The competitive landscape, marked by fluctuating prices and varying quality standards, makes it crucial for businesses to make informed purchasing decisions. This comprehensive guide serves as a vital resource, addressing key aspects of ollies laminate flooring, including types, applications, supplier vetting processes, and cost considerations.

Buyers from regions such as Africa, South America, the Middle East, and Europe, including Germany and Saudi Arabia, will find tailored insights that cater to their unique market dynamics. By delving into the specifications of ollies laminate flooring—such as durability, ease of installation, and design versatility—this guide empowers stakeholders to navigate the complexities of sourcing effectively.

Whether you’re looking to enhance residential spaces or commercial environments, understanding the nuances of laminate flooring can lead to significant cost savings and improved customer satisfaction. Ultimately, this guide equips B2B buyers with the knowledge to confidently select reliable suppliers and premium products, ensuring that their flooring investments yield lasting value.

Understanding ollies laminate flooring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Laminate | 7MM thickness, glue-free click-in locking system | Residential and light commercial flooring | Pros: Affordable, easy installation. Cons: Less durable than thicker options. |

| Water Resistant Laminate | 8MM thickness, designed to withstand moisture | Areas prone to spills or humidity (e.g., kitchens, bathrooms) | Pros: Enhanced durability, suitable for wet areas. Cons: Slightly higher cost. |

| High-Density Laminate | 12MM thickness, superior impact resistance | Heavy traffic areas, commercial spaces | Pros: Long-lasting, excellent sound insulation. Cons: Higher price point. |

| Aesthetic Variants | Available in various wood finishes and colors | Residential, hospitality, and retail spaces | Pros: Wide design options for aesthetics. Cons: May require more maintenance. |

| Eco-Friendly Laminate | Made from recycled materials, low VOC emissions | Sustainable building projects, eco-conscious businesses | Pros: Environmentally friendly, meets green building standards. Cons: Limited availability. |

What are the characteristics and suitability of Standard Laminate Flooring?

Standard laminate flooring is typically 7MM thick and features a glue-free click-in locking system, making it easy to install. This type is ideal for residential and light commercial applications where budget constraints are significant. It offers an affordable solution while providing a decent aesthetic appeal. However, its durability may not be sufficient for high-traffic areas, which is a critical consideration for B2B buyers looking for longevity in their flooring investments.

How does Water-Resistant Laminate Flooring perform in moisture-prone areas?

Water-resistant laminate flooring usually comes in a thicker 8MM format, engineered specifically to resist moisture. This makes it an excellent choice for areas like kitchens and bathrooms, where spills are common. B2B buyers should consider its enhanced durability and the peace of mind it provides in environments prone to humidity. While it comes at a slightly higher price point, the added longevity in challenging conditions can justify the investment.

What advantages does High-Density Laminate offer for commercial spaces?

High-density laminate flooring, often 12MM thick, excels in high-traffic areas due to its superior impact resistance. This makes it suitable for commercial spaces such as retail stores and office environments where durability is paramount. The sound insulation properties of this type can also enhance the overall ambiance of a space. However, B2B buyers need to weigh its higher cost against the benefits of longevity and reduced maintenance needs.

Why are Aesthetic Variants important for B2B buyers?

Aesthetic variants of laminate flooring provide a wide array of wood finishes and colors, allowing businesses to align their flooring choices with brand identity and design preferences. This type is particularly popular in residential, hospitality, and retail spaces, where visual appeal is crucial. While they enhance the aesthetic value, B2B buyers must consider the potential for increased maintenance depending on the finish selected.

How does Eco-Friendly Laminate Flooring cater to sustainable initiatives?

Eco-friendly laminate flooring is crafted from recycled materials and features low VOC emissions, making it an ideal choice for businesses committed to sustainability. This type is increasingly sought after in green building projects and by eco-conscious companies. While availability may be limited, the environmental benefits and compliance with green building standards can provide a competitive edge for businesses looking to enhance their corporate social responsibility profile.

Key Industrial Applications of ollies laminate flooring

| Industry/Sector | Specific Application of ollies laminate flooring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Flooring for retail stores and showrooms | Enhances aesthetic appeal, attracting more customers | Consider durability, ease of installation, and design options |

| Hospitality | Flooring for hotels and restaurants | Provides a welcoming atmosphere while being easy to maintain | Evaluate water resistance, slip resistance, and warranty terms |

| Education | Flooring for schools and universities | Durable and easy to clean, promoting a safe learning environment | Assess noise reduction properties and resilience to wear |

| Residential Development | Flooring for new housing projects | Cost-effective flooring solution appealing to homebuyers | Focus on pricing, variety in styles, and eco-friendliness |

| Healthcare | Flooring for clinics and hospitals | Easy to clean and maintain, reducing infection risk | Ensure compliance with health standards and slip resistance |

How is Ollies Laminate Flooring Used in Retail Environments?

In the retail sector, ollies laminate flooring is extensively used to enhance the aesthetic appeal of stores and showrooms. Its diverse styles and finishes can create an inviting atmosphere that attracts customers and encourages foot traffic. The flooring’s durability ensures it withstands high foot traffic, minimizing the need for frequent replacements. For international buyers, especially in regions like Europe and the Middle East, sourcing considerations include the flooring’s ability to complement local design trends and its ease of installation, which can reduce labor costs.

What Are the Benefits of Using Ollies Laminate Flooring in Hospitality?

Hotels and restaurants benefit significantly from ollies laminate flooring, which offers an attractive and low-maintenance solution. The flooring can be designed to resemble natural wood, providing a luxurious feel without the associated costs. Its durability is crucial in high-traffic areas, while its water-resistant options are ideal for dining areas and restrooms. For buyers in regions like Africa and South America, understanding local climate conditions and ensuring the flooring meets slip resistance standards are vital for safety and longevity.

Why Choose Ollies Laminate Flooring for Educational Institutions?

In educational settings, ollies laminate flooring is favored for its durability and ease of maintenance. Schools and universities require flooring that can withstand heavy use while providing a safe environment for students. The laminate’s ability to reduce noise and its resistance to stains and spills make it a practical choice for classrooms and communal areas. International buyers should consider sourcing products that comply with local safety regulations and offer warranties that reflect the flooring’s longevity.

How Can Residential Developers Benefit from Ollies Laminate Flooring?

For residential development projects, ollies laminate flooring provides a cost-effective solution that appeals to homebuyers. The flooring’s affordability, combined with its aesthetic versatility, makes it an attractive option for new housing developments. Buyers in Europe or South America may prioritize eco-friendly materials and designs that align with contemporary home trends. Sourcing considerations should also include the availability of various styles and colors to meet diverse consumer preferences.

What Role Does Ollies Laminate Flooring Play in Healthcare Facilities?

In healthcare settings, ollies laminate flooring is utilized for its hygiene and maintenance advantages. The flooring is easy to clean, which is essential for minimizing infection risks in clinics and hospitals. Additionally, its durability ensures it can withstand the rigors of a healthcare environment. Buyers in the Middle East and Africa should focus on sourcing products that comply with health and safety regulations, ensuring features such as slip resistance and long-term durability are prioritized.

3 Common User Pain Points for ‘ollies laminate flooring’ & Their Solutions

Scenario 1: Cost Concerns for Budget-Conscious Buyers

The Problem: International B2B buyers often face budget constraints, especially when sourcing materials like laminate flooring. Ollie’s laminate flooring is priced competitively, but buyers may worry about the quality and durability of lower-cost options. Concerns about hidden costs, such as installation or maintenance, can also lead to hesitation in making bulk purchases.

The Solution: To address these concerns, buyers should focus on the specifications and warranty details of Ollie’s laminate flooring. For instance, the Chestnut Oak Laminate Flooring offers a 10-year limited warranty against defects, providing reassurance of its quality. Buyers should conduct a thorough cost-benefit analysis, considering not just the upfront price but the long-term value, including installation ease and maintenance costs. Additionally, leveraging Ollie’s rewards program can lead to further savings. By purchasing in bulk, buyers can negotiate better terms, ensuring that quality and affordability coexist in their procurement strategy.

Scenario 2: Sourcing Challenges in Diverse Markets

The Problem: Sourcing laminate flooring in international markets can be complicated due to variations in availability, cultural preferences, and logistical challenges. Buyers from regions like Africa or the Middle East might struggle to find the right styles and sizes that appeal to local tastes while also adhering to quality standards.

The Solution: To streamline the sourcing process, buyers should engage directly with Ollie’s supply chain representatives to understand the inventory flow and availability in their regions. They should also consider using Ollie’s store locator tool to identify nearby outlets or distribution centers that carry a diverse range of laminate flooring options. Creating a clear specification sheet that outlines preferred styles, sizes, and technical requirements can facilitate better communication with suppliers. Furthermore, attending trade shows or industry expos can provide insights into trends and preferences, allowing buyers to make informed choices that resonate with their target markets.

Scenario 3: Installation and Maintenance Misunderstandings

The Problem: Many B2B buyers may underestimate the importance of proper installation and maintenance of laminate flooring, which can lead to dissatisfaction with the product. There can be confusion about the installation process of Ollie’s glue-free click-in locking system, leading to potential delays and additional costs if not executed correctly.

The Solution: To mitigate installation issues, buyers should invest time in understanding the installation guidelines provided by Ollie’s. They can also seek professional installers who have experience with laminate flooring to ensure the job is done correctly. Providing training sessions for in-house teams on the specifics of the click-in locking system can empower them to handle installations confidently. Additionally, establishing a clear maintenance plan is crucial; buyers should be educated on the best practices for cleaning and caring for laminate flooring to extend its life. Regular communication with the supplier regarding maintenance support and warranty claims can further enhance the buyer’s experience and satisfaction with the product.

Strategic Material Selection Guide for ollies laminate flooring

What Are the Key Materials Used in Ollie’s Laminate Flooring?

Ollie’s laminate flooring is primarily composed of several key materials that contribute to its performance, durability, and overall appeal. Understanding these materials is crucial for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. Below is an analysis of four common materials used in Ollie’s laminate flooring.

1. High-Density Fiberboard (HDF)

Key Properties: HDF is engineered from wood fibers that are compressed under high pressure, resulting in a dense and stable core. It typically offers a temperature rating suitable for indoor environments and is resistant to warping.

Pros & Cons: HDF is known for its durability, making it suitable for high-traffic areas. It is cost-effective compared to solid wood, but it may be less resistant to moisture, which can be a drawback in humid climates.

Impact on Application: HDF is compatible with various finishes and can mimic the appearance of natural wood, making it a popular choice for residential and commercial spaces.

Considerations for International Buyers: Buyers should ensure that HDF complies with local regulations regarding formaldehyde emissions, especially in regions like Europe where standards are stringent (e.g., E1 or E0 ratings).

2. Melamine Resin

Key Properties: Melamine resin is a thermosetting plastic that provides a hard, durable surface finish. It is resistant to scratches, stains, and fading, making it ideal for flooring applications.

Pros & Cons: The key advantage of melamine resin is its low maintenance and high durability. However, it can be more expensive than other surface finishes and may not be as environmentally friendly.

Impact on Application: Melamine’s resistance to moisture and heat makes it suitable for various environments, but care must be taken in extremely humid conditions.

Considerations for International Buyers: Compliance with environmental standards is essential, particularly in markets like Germany, where buyers may favor eco-friendly products. Certifications such as GREENGUARD can enhance marketability.

3. Decorative Paper

Key Properties: Decorative paper is printed with high-resolution images that replicate the look of wood, stone, or other materials. It is treated with resin to enhance durability and moisture resistance.

Pros & Cons: The primary advantage is the aesthetic appeal and variety of designs available at a low cost. However, decorative paper can be susceptible to wear and tear over time, particularly in high-traffic areas.

Impact on Application: This material allows for a wide range of design options, making it suitable for both residential and commercial applications where aesthetics are a priority.

Considerations for International Buyers: Buyers should consider the longevity of the decorative finish in relation to local climate conditions. In humid regions, additional protective coatings may be necessary.

4. Backing Layer (Foam or Cork)

Key Properties: The backing layer provides cushioning and sound insulation. Foam or cork is commonly used, offering thermal insulation and moisture resistance.

Pros & Cons: The backing layer enhances comfort underfoot and reduces noise, making it a popular choice for multi-story buildings. However, it may add to the overall cost of the flooring.

Impact on Application: A quality backing layer improves the overall performance of laminate flooring, particularly in residential settings where comfort and noise reduction are important.

Considerations for International Buyers: Buyers should ensure that the backing material meets local fire safety standards and is suitable for the intended application, especially in commercial spaces.

Summary Table of Material Selection for Ollie’s Laminate Flooring

| Material | Typical Use Case for ollies laminate flooring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Density Fiberboard (HDF) | Residential and commercial flooring | Durable and cost-effective | Less moisture resistant | Medium |

| Melamine Resin | Surface finish for laminate flooring | Scratch and stain resistant | Higher cost and environmental concerns | High |

| Decorative Paper | Aesthetic designs for laminate flooring | Wide variety of designs | Susceptible to wear in high-traffic areas | Low |

| Backing Layer (Foam/Cork) | Comfort and sound insulation | Enhances comfort and reduces noise | Can increase overall flooring cost | Medium |

This guide provides valuable insights for B2B buyers in diverse international markets, helping them make informed decisions regarding the selection of materials for Ollie’s laminate flooring products.

In-depth Look: Manufacturing Processes and Quality Assurance for ollies laminate flooring

What Are the Main Stages of Manufacturing Ollie’s Laminate Flooring?

Ollie’s laminate flooring is produced through a well-defined manufacturing process that ensures both quality and cost-effectiveness. The primary stages of manufacturing include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality raw materials, primarily made from high-density fiberboard (HDF), which serves as the core of the laminate. This fiberboard is produced from wood fibers that are bonded together using adhesives and pressed under high pressure. The surface layer, often printed with a wood-like design, is made from a melamine resin that is durable and resistant to wear and tear.

-

Forming: After preparation, the HDF is cut into panels of standard sizes, typically 7.6″ x 50.79″ or similar dimensions. The surface layer is then applied, which includes a protective overlay to enhance durability and aesthetics. A glue-free click-in locking system is integrated at this stage, allowing for easier installation without the need for adhesives.

-

Assembly: Once the panels are formed, they are subjected to a series of treatments to ensure they meet quality standards. This includes applying heat and pressure to bond the layers together effectively. The panels are then inspected for any defects or inconsistencies.

-

Finishing: The final stage involves applying a finish that enhances the appearance and durability of the laminate flooring. This includes UV coatings that protect against fading and scratches. The finished panels undergo a final inspection before packaging, ensuring they meet Ollie’s standards.

How Is Quality Assurance Implemented in Ollie’s Laminate Flooring?

Quality assurance is crucial in the laminate flooring manufacturing process to maintain product integrity and customer satisfaction. Ollie’s follows international standards such as ISO 9001, which outlines requirements for a quality management system, ensuring consistent quality across all products.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers must provide documentation that verifies compliance with quality standards.

– In-Process Quality Control (IPQC): During the manufacturing stages, inspectors monitor processes to identify and rectify issues in real-time. This ensures that any defects are caught early, minimizing waste and rework.

– Final Quality Control (FQC): After the finishing stage, each batch of laminate flooring undergoes rigorous testing. This includes checks for physical properties such as thickness, density, and surface quality. -

Common Testing Methods:

– Wear Resistance Testing: Assessing how well the laminate can withstand daily wear and tear.

– Moisture Resistance Testing: Evaluating the product’s ability to resist moisture, which is particularly important for buyers in humid regions.

– Chemical Resistance Testing: Ensuring that the laminate can withstand common household chemicals without damage.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those operating in diverse international markets like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facility’s adherence to quality standards. This includes reviewing processes, equipment, and staff qualifications.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their quality management practices. Reports should include data on IQC, IPQC, and FQC findings, along with corrective actions taken for any identified issues.

-

Third-Party Inspections: Engaging independent inspection agencies to evaluate the manufacturing process and the final product can add an additional layer of assurance. These agencies can provide unbiased evaluations that help buyers feel confident in their purchasing decisions.

What Are the Quality Certification Nuances for International Buyers?

International buyers must navigate various certification requirements based on their regional standards. For example, European markets may require CE marking, which indicates compliance with EU safety, health, and environmental protection standards.

-

Understanding Local Standards: Buyers should familiarize themselves with the specific certifications required in their target markets. This includes ISO certifications for quality management and environmental management.

-

Documentation and Traceability: Ensuring that suppliers provide documentation that supports their compliance with international and local standards is crucial. This includes certificates of conformity and test reports that demonstrate adherence to quality benchmarks.

-

Cultural and Regional Considerations: Buyers from regions like Africa and South America may encounter different expectations regarding product durability and performance. Understanding local customer preferences and regulatory requirements can help buyers select the most suitable products.

Conclusion: Ensuring Quality in Ollie’s Laminate Flooring

Ollie’s laminate flooring manufacturing process emphasizes quality through meticulous attention to material selection, manufacturing techniques, and stringent quality control measures. For international B2B buyers, understanding these processes and implementing thorough verification practices can lead to successful partnerships and high customer satisfaction. By leveraging quality certifications and conducting regular audits, buyers can confidently source laminate flooring that meets their specific needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ollies laminate flooring’

Introduction

This sourcing guide aims to assist B2B buyers in effectively procuring Ollie’s laminate flooring. With a focus on quality, price, and supplier reliability, this checklist provides actionable steps to streamline the procurement process and ensure optimal purchasing decisions.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical specifications for the laminate flooring. Consider factors such as thickness, finish, and water resistance, as these will influence performance and suitability for your projects. For instance, a 7MM thickness is standard for residential use, while commercial applications may require thicker options for durability.

Step 2: Research Market Prices

Conduct thorough market research to understand the pricing landscape of laminate flooring. This will help you identify competitive pricing and ensure that you are making a cost-effective purchase. Pay attention to the pricing per square foot and compare it with other suppliers to gauge value. For example, Ollie’s offers laminate flooring at prices significantly lower than traditional retailers.

Step 3: Evaluate Potential Suppliers

Vetting suppliers is crucial for ensuring product quality and reliability. Request comprehensive company profiles, including their history, client base, and case studies. Additionally, seek references from other B2B buyers in your region to validate their credibility. A supplier with a strong track record can often provide better warranty terms and customer support.

Step 4: Check Product Certifications and Warranties

Ensure that the laminate flooring you are considering has the necessary product certifications. Look for certifications related to quality standards and environmental impact, such as CARB compliance for formaldehyde emissions. Additionally, evaluate the warranty terms, as a robust warranty (e.g., a 10-year limited warranty) indicates the manufacturer’s confidence in their product.

Step 5: Request Samples

Before finalizing your order, request samples of the laminate flooring. This allows you to assess the product’s aesthetic appeal, texture, and quality firsthand. It’s also an opportunity to ensure that the color and finish align with your project requirements. Engaging with samples can prevent costly mistakes and ensure customer satisfaction.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations to secure favorable terms and conditions. Discuss payment terms, delivery schedules, and return policies. A clear understanding of these aspects can help mitigate risks associated with procurement and ensure a smooth transaction.

Step 7: Plan for Logistics and Installation

Finally, consider the logistics of transporting the laminate flooring to your location. Assess the supplier’s shipping capabilities and timelines, and plan for installation logistics as well. Understanding these elements will help you maintain project timelines and avoid delays, ensuring that the flooring is available when needed.

By following this checklist, B2B buyers can enhance their sourcing strategy for Ollie’s laminate flooring, ensuring quality products at competitive prices while establishing solid relationships with reliable suppliers.

Comprehensive Cost and Pricing Analysis for ollies laminate flooring Sourcing

What Are the Key Cost Components in Ollie’s Laminate Flooring Sourcing?

When sourcing Ollie’s laminate flooring, understanding the cost structure is vital for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

- Materials: The type of laminate, such as the Chestnut Oak or Driftwood Gray options, influences material costs. Higher quality materials, such as water-resistant options, typically incur additional costs, impacting the overall pricing.

- Labor: Labor costs can vary based on the region of production. Countries with lower labor costs may offer competitive pricing, while those with higher labor standards may require a premium.

- Manufacturing Overhead: This includes utilities, rent, and indirect labor. Efficient manufacturing processes can reduce these costs, which can be reflected in the final pricing.

- Tooling: Custom tooling for specific laminate designs can add to the initial setup costs. Buyers should consider whether they need customized designs, as this will affect the overall cost.

- Quality Control: Effective QC processes ensure that the flooring meets standards, which can add to the cost but ultimately reduce returns and increase customer satisfaction.

- Logistics: Shipping costs, influenced by distance and shipping methods, play a significant role in the total cost. Buyers must factor in freight and customs duties, especially for international transactions.

- Margin: The supplier’s desired profit margin will also affect pricing. Understanding the supplier’s pricing strategy can help buyers negotiate better deals.

How Do Price Influencers Affect Ollie’s Laminate Flooring Costs?

Several price influencers can significantly impact the sourcing costs of Ollie’s laminate flooring:

- Volume/MOQ: Bulk purchases often come with discounts. Understanding the minimum order quantity (MOQ) can help buyers optimize costs.

- Specifications/Customization: Custom specifications, such as unique colors or sizes, can lead to higher prices. Buyers should assess whether customization is necessary or if standard options suffice.

- Materials: The choice between standard and premium materials can change the cost structure. Water-resistant laminates, for instance, command higher prices due to their added durability.

- Quality and Certifications: Certifications for sustainability or safety can influence costs. Buyers should consider the importance of these certifications in their markets.

- Supplier Factors: Supplier reliability, production capacity, and location can impact pricing. Establishing relationships with suppliers can lead to better terms and pricing.

- Incoterms: The choice of Incoterms affects logistics costs. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for budgeting.

What Are the Best Negotiation Tips for B2B Buyers Sourcing Ollie’s Laminate Flooring?

To maximize value when sourcing Ollie’s laminate flooring, B2B buyers should employ strategic negotiation techniques:

- Do Your Research: Understanding market prices and supplier costs helps in negotiations. Benchmark against competitors to ensure you’re getting a fair deal.

- Leverage Volume: If planning to purchase large quantities, use this to negotiate lower prices or better payment terms. Suppliers are often willing to offer discounts for bulk orders.

- Total Cost of Ownership (TCO): Consider the TCO, which includes purchase price, shipping, installation, and long-term maintenance costs. A higher upfront cost may lead to lower TCO if the product lasts longer or requires less maintenance.

- Be Flexible: If a specific product is not available, be open to alternatives that meet your needs. This flexibility can lead to better pricing or terms.

- Build Relationships: Establishing a good rapport with suppliers can lead to more favorable terms and priority access to new products or deals.

What Pricing Nuances Should International Buyers Consider?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of certain nuances:

- Currency Fluctuations: Keep an eye on exchange rates, as fluctuations can impact the final cost.

- Tariffs and Duties: Understand the import tariffs and duties that may apply to flooring products. These can significantly affect the total landed cost.

- Shipping Times: Consider the lead times for shipping, especially for bulk orders. Longer shipping times can affect project timelines.

- Cultural Considerations: Different regions may have varying expectations regarding quality and service. Tailoring your approach based on local business practices can enhance negotiations.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always verify current pricing and terms directly with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing ollies laminate flooring With Other Solutions

Understanding Alternative Flooring Solutions for B2B Buyers

When evaluating flooring solutions for commercial or residential use, it is essential to consider various alternatives that meet specific requirements. Ollie’s laminate flooring offers a competitive option, but buyers should also be aware of other flooring types that may suit their needs better or provide unique advantages. This analysis compares Ollie’s laminate flooring with two notable alternatives: vinyl plank flooring and hardwood flooring.

| Comparison Aspect | Ollie’s Laminate Flooring | Vinyl Plank Flooring | Hardwood Flooring |

|---|---|---|---|

| Performance | Good durability, 10-year warranty | Excellent water resistance, durable | High durability, timeless aesthetics |

| Cost | Low cost at $25.99 per case | Moderate cost, typically $3-$5 per sq ft | Higher cost, $5-$15+ per sq ft |

| Ease of Implementation | Easy click-in installation | Simple installation with glue or click | More complex installation, requires professional help |

| Maintenance | Low maintenance, easy to clean | Low maintenance, resistant to stains | Moderate maintenance, periodic refinishing required |

| Best Use Case | Budget-friendly projects, moderate traffic | High moisture areas (e.g., kitchens) | High-end residential, long-term investment |

What Are the Pros and Cons of Vinyl Plank Flooring?

Vinyl plank flooring has gained popularity due to its excellent water resistance and durability, making it ideal for high-moisture environments such as kitchens and bathrooms. It is available in a wide range of styles that mimic wood and stone, providing aesthetic flexibility. The cost is moderate, generally ranging from $3 to $5 per square foot, making it accessible for various budgets. However, while vinyl is durable, it may not have the same longevity as hardwood flooring and can be susceptible to scratches if not adequately protected.

How Does Hardwood Flooring Compare to Laminate Flooring?

Hardwood flooring is often regarded as a premium choice, known for its timeless beauty and durability. It can last for decades with proper care and can be refinished multiple times, making it a long-term investment. However, the cost of hardwood flooring is significantly higher, often ranging from $5 to $15 or more per square foot, which may be prohibitive for some buyers. Installation can also be complex, often requiring professional help, which adds to the overall expense. While hardwood offers unparalleled aesthetic appeal, it requires more maintenance, including periodic refinishing to maintain its beauty.

Conclusion: How to Choose the Right Flooring Solution for Your Needs

Choosing the right flooring solution requires careful consideration of various factors, including performance, cost, ease of installation, and maintenance. Ollie’s laminate flooring presents an attractive option for budget-conscious projects, particularly where moderate foot traffic is expected. However, buyers should weigh the benefits of alternatives like vinyl plank and hardwood flooring based on the specific demands of their project. Ultimately, the decision should align with the intended use, budget constraints, and long-term maintenance expectations, ensuring a sound investment in quality flooring.

Essential Technical Properties and Trade Terminology for ollies laminate flooring

What Are the Key Technical Properties of Ollies Laminate Flooring?

When considering Ollies laminate flooring, understanding its technical specifications is crucial for B2B buyers who seek quality and value. Here are some essential properties to evaluate:

-

Material Grade

The material grade of laminate flooring indicates its quality and durability. Ollies typically offers first-quality laminate, which is designed to withstand heavy foot traffic and everyday wear. For B2B buyers, selecting a higher material grade ensures long-term performance and customer satisfaction, reducing the likelihood of returns and complaints. -

Thickness

Laminate flooring thickness is measured in millimeters (MM), with common options being 7MM to 8MM. Thicker planks generally offer better stability, sound insulation, and resistance to wear. For businesses in retail or construction, recommending thicker options can enhance the overall value proposition to end consumers, leading to repeat business. -

Locking System

Ollies laminate flooring features a glue-free click-in locking system that simplifies installation. This technology not only reduces labor costs but also minimizes installation time, making it appealing for contractors and installers. Understanding the benefits of easy installation can help B2B buyers present more efficient solutions to their clients. -

Warranty

A limited warranty, such as the 10-year warranty against defects offered by Ollies, provides assurance regarding the product’s quality and longevity. For B2B buyers, a robust warranty can serve as a competitive advantage in sales discussions, showcasing the manufacturer’s confidence in their product. -

Water Resistance

Some Ollies laminate flooring options are water-resistant, making them suitable for areas prone to moisture, such as kitchens and bathrooms. This feature is increasingly important for buyers operating in regions with high humidity or for projects requiring versatility. Understanding water resistance can help buyers meet diverse customer needs. -

Case Coverage

Each case of Ollies laminate flooring typically covers a specific area (e.g., 26.8 square feet per case). Knowing the coverage allows B2B buyers to calculate the total amount needed for their projects efficiently, helping to manage inventory and costs effectively.

What Are Common Trade Terms Used in the Laminate Flooring Industry?

Familiarity with industry jargon can enhance communication and negotiation in B2B transactions. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of laminate flooring, buyers may deal with OEMs that produce flooring products under different brand names. Understanding OEM relationships can help buyers leverage better pricing and quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For laminate flooring, MOQs can affect purchasing decisions, particularly for smaller businesses or those with limited cash flow. Knowing the MOQ helps buyers plan their inventory and cash management strategies effectively. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. For B2B buyers, issuing an RFQ can streamline the procurement process for laminate flooring, ensuring competitive pricing and better supplier relationships. -

Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms is vital for B2B buyers involved in importing laminate flooring, as they clarify who bears the risk and costs associated with shipping and delivery. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In the flooring industry, knowing the lead time can help businesses manage project timelines and customer expectations. Shorter lead times can be a significant selling point for suppliers. -

Stock Keeping Unit (SKU)

An SKU is a unique identifier for each distinct product and service that can be purchased. For laminate flooring, SKUs are essential for inventory management, pricing, and sales tracking. B2B buyers should ensure that suppliers provide clear SKU information to facilitate efficient procurement processes.

Understanding these properties and terms can significantly enhance the ability of B2B buyers to make informed decisions, negotiate effectively, and ultimately deliver value to their customers.

Navigating Market Dynamics and Sourcing Trends in the ollies laminate flooring Sector

What Are the Key Market Dynamics Affecting Ollies Laminate Flooring?

The global laminate flooring market is experiencing significant growth driven by factors such as urbanization, increased disposable income, and a rising preference for cost-effective, aesthetically pleasing flooring solutions. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the demand for high-quality yet affordable flooring options is becoming increasingly pronounced. In markets like Germany and Saudi Arabia, the push for modern living spaces and commercial developments is bolstering laminate flooring’s appeal due to its durability and ease of installation.

Emerging technologies in sourcing, such as digital platforms for procurement and inventory management systems, are revolutionizing how businesses interact with suppliers. These platforms enhance transparency and efficiency, allowing buyers to compare prices, track shipments, and ensure timely deliveries. Additionally, the growing trend of e-commerce is making it easier for international buyers to access Ollies laminate flooring products, further expanding market reach.

Another notable trend is the increasing emphasis on customization. Suppliers are responding to the demand for unique styles and finishes, enabling buyers to meet specific market needs. For example, Ollies offers diverse laminate flooring options like Chestnut Oak and Driftwood Gray, appealing to various design preferences.

How Is Sustainability Influencing the Sourcing of Ollies Laminate Flooring?

Sustainability is a critical consideration in today’s B2B landscape, particularly in the flooring sector. The environmental impact of production processes and the lifecycle of flooring materials is under scrutiny. Buyers are increasingly seeking laminate flooring solutions that minimize ecological footprints, such as products that utilize recycled materials or are manufactured with lower emissions.

Ethical sourcing is also gaining traction. International buyers are encouraged to partner with suppliers who adhere to responsible labor practices and environmental regulations. For Ollies laminate flooring, showcasing certifications such as FSC (Forest Stewardship Council) or other eco-labels can add significant value, indicating that the products meet specific environmental standards. This transparency not only resonates with environmentally conscious consumers but also enhances brand reputation, making it a crucial factor for B2B buyers.

Moreover, the demand for ‘green’ materials is rising, with businesses seeking products that contribute to sustainable building practices. Laminate flooring options that are free from harmful chemicals and are easy to recycle at the end of their lifespan are becoming increasingly popular.

What Is the Historical Context of Ollies Laminate Flooring in the Market?

Ollies Bargain Outlet has positioned itself as a leader in the discount retail sector, specializing in closeout merchandise and excess inventory. The company’s approach to laminate flooring has evolved significantly since its inception, adapting to changing consumer preferences and market dynamics. Initially focused on traditional retail models, Ollies has leveraged its buying power to offer high-quality laminate flooring at competitive prices, catering to both residential and commercial buyers.

Over the years, the laminate flooring market has seen advancements in technology and design, leading to more durable and aesthetically appealing products. Ollies has embraced these changes, ensuring that its laminate offerings meet the demands of a diverse clientele. This evolution reflects broader trends within the flooring industry, where innovation and consumer preferences continually shape product availability and sourcing strategies. As a result, Ollies remains a relevant player in the global flooring market, appealing to cost-conscious buyers seeking quality and value.

Frequently Asked Questions (FAQs) for B2B Buyers of ollies laminate flooring

-

How do I choose the right laminate flooring for my business needs?

When selecting laminate flooring, consider factors such as durability, moisture resistance, and aesthetic appeal. For high-traffic areas, opt for thicker laminate (8mm or more) that can withstand wear. Additionally, evaluate the warranty offered; a 10 to 30-year warranty can indicate quality. Always request samples to assess color and texture suitability for your projects. Lastly, consider your target market’s preferences, as trends may vary significantly across regions like Europe, Africa, and the Middle East. -

What types of laminate flooring does Ollie’s offer for international buyers?

Ollie’s provides a variety of laminate flooring options, including standard and water-resistant varieties. Their offerings typically include different finishes, such as Chestnut Oak and Driftwood Gray, with specifications like glue-free click-in locking systems for easy installation. International buyers can inquire about bulk purchasing options to meet their specific project requirements. Always check for the latest inventory and availability through their online platform or local outlets. -

What are the minimum order quantities (MOQ) for Ollie’s laminate flooring?

The minimum order quantity for laminate flooring may vary based on the specific product and the buyer’s location. Generally, for bulk purchases, it is advisable to contact Ollie’s customer service or a sales representative directly. They can provide insights on bulk pricing and any available discounts for larger orders, which can be particularly advantageous for B2B buyers looking to maximize cost efficiency. -

What payment terms are available for international B2B purchases?

Ollie’s typically accepts various payment methods, including credit cards and bank transfers. For international buyers, it is crucial to confirm the accepted payment methods and any specific terms related to currency exchange and transaction fees. Establishing a clear understanding of payment timelines and conditions can help avoid complications during the purchasing process, ensuring a smoother transaction. -

How does Ollie’s ensure the quality of its laminate flooring products?

Ollie’s laminate flooring products come with warranties ranging from 10 to 30 years, which indicates their commitment to quality. Additionally, products undergo rigorous quality assurance processes to meet safety and durability standards. Buyers are encouraged to request detailed product specifications and certifications to ensure compliance with their local regulations and standards, particularly when importing goods. -

What logistics options are available for shipping laminate flooring internationally?

Shipping options for international orders can vary based on the destination and the volume of the order. Ollie’s may partner with reliable logistics companies to facilitate efficient shipping. Buyers should inquire about shipping costs, estimated delivery times, and customs clearance processes. It’s essential to ensure that all logistics details are clarified before placing an order to avoid delays. -

Can I customize the laminate flooring options available from Ollie’s?

Customization options for laminate flooring, such as specific colors, patterns, or sizes, may be limited. However, for large-scale B2B orders, it is advisable to discuss potential customization with Ollie’s sales representatives. They may offer tailored solutions or direct you to manufacturers who specialize in custom flooring products, allowing you to meet your unique business needs. -

What are the best practices for vetting suppliers of laminate flooring?

When vetting suppliers, consider their reputation, product quality, and customer service. Request references from other businesses that have purchased from them, and check online reviews for insights into their reliability. It’s also beneficial to visit their facilities, if possible, to inspect their manufacturing processes. Finally, ensure that the supplier complies with international trade regulations and offers warranties and return policies that protect your investment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Ollies Laminate Flooring Manufacturers & Suppliers List

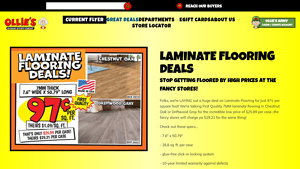

1. Ollie’s – 7MM First Quality Laminate Flooring

Domain: ollies.com

Registered: 2003 (22 years)

Introduction: Laminate Flooring Deals: 7MM First Quality laminate flooring available in Chestnut Oak or Driftwood Gray for 97¢ per square foot. Price: $25.99 per case (compared to $29.21 at fancy stores). Specifications: – Dimensions: 7.6″ x 50.79″ – Coverage: 26.8 sq. ft. per case – Installation: Glue-free click-in locking system – Warranty: 10-year limited warranty against defects.

2. LVP – Residential Quality Concerns

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The flooring in question is a residential rated LVP (Luxury Vinyl Plank) with a 12mil wear layer. It is priced under $2 per square foot, which raises concerns about its quality. The overall thickness is noted to be 5mm, which some users consider inadequate. There are discussions about the quality of the milling, the locking mechanism, and potential brittleness due to high limestone content. The fl…

3. Ollies – Vinyl Planks

4. Instagram – Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact for scraping Instagram services, inquire about the number of pages to scrape per month.

5. Pergo & Mohawk – Laminate Flooring

Domain: city-data.com

Registered: 2003 (22 years)

Introduction: Laminate flooring available at Ollie’s, specifically brands Pergo and Mohawk. The flooring is intended for installation in living rooms and is noted for its good quality.

6. DIY Chatroom – Affordable Laminate Flooring Options

Domain: diychatroom.com

Registered: 2003 (22 years)

Introduction: Laminate flooring available at B.J.’s, Costco, and Ollies for about $1 per square foot. One retailer offers an 8mm layer with a 10-year warranty for 97 cents per foot. Limited color choices. Installation requires underlayment and is suitable for wood subfloor. Some users report issues with planks being out of square or difficulties with the ‘click’ mechanism. Concerns about durability and ease of …

7. Mohawk – Laminate Flooring

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Mohawk Laminate Flooring for Family Room at Ollies Outlet in Lavale

Strategic Sourcing Conclusion and Outlook for ollies laminate flooring

In today’s competitive flooring market, strategic sourcing of Ollie’s laminate flooring offers international B2B buyers a pathway to cost efficiency and quality assurance. With prices significantly lower than traditional retail outlets, buyers from regions such as Africa, South America, the Middle East, and Europe can benefit from exceptional savings while accessing high-quality products like the 7MM Chestnut Oak and water-resistant options.

The glue-free click-in locking system and robust warranty options enhance the appeal of these products, ensuring long-term value for businesses looking to satisfy customer demands for durability and aesthetics. Leveraging Ollie’s extensive inventory and commitment to everyday low pricing allows buyers to diversify their offerings without compromising on quality.

As you consider your sourcing strategies, remember that partnering with Ollie’s not only provides a competitive edge but also supports sustainable business practices by reducing excess inventory waste. Looking ahead, seize the opportunity to explore these flooring solutions and stay ahead of market trends. Engage with Ollie’s today to secure your inventory and position your business for success in the evolving flooring landscape.