Everything You Need to Know About Heaviest Ankle Weights Sourcing in 2025

Introduction: Navigating the Global Market for heaviest ankle weights

In the increasingly competitive landscape of fitness equipment, sourcing the heaviest ankle weights presents a unique challenge for international B2B buyers. As demand for effective strength training solutions grows across diverse markets—including Africa, South America, the Middle East, and Europe—businesses must navigate a complex array of products that meet varying consumer needs. This guide aims to equip you with the knowledge needed to make informed purchasing decisions by exploring the types of ankle weights available, their applications in various training regimens, and the nuances of supplier vetting.

Understanding the key features that differentiate ankle weights, such as adjustability, material quality, and comfort, is crucial for selecting products that will enhance customer satisfaction and drive sales. Moreover, the guide delves into cost considerations, helping you strike a balance between quality and affordability. By addressing these critical aspects, we empower B2B buyers to streamline their sourcing processes and ultimately improve their competitive edge in the global market.

This comprehensive resource not only highlights the latest trends in ankle weights but also provides actionable insights tailored to the specific needs of buyers from regions like Germany and Vietnam. With a focus on quality and performance, this guide serves as your go-to reference for making strategic purchasing decisions that resonate with your target audience.

Understanding heaviest ankle weights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Adjustable Ankle Weights | Removable weights, adjustable up to 10lbs | Gyms, personal training studios, home fitness | Pros: Versatile for various fitness levels. Cons: May not support heavy lifting needs. |

| Neoprene Ankle Weights | Soft, comfortable fabric, moisture-wicking properties | Rehabilitation centers, group classes | Pros: Comfortable for extended wear. Cons: Limited weight options. |

| Heavy Duty Ankle Weights | High weight capacity (up to 20lbs), durable materials | Strength training, athletic training | Pros: Suitable for advanced users. Cons: Bulkier and may be less comfortable. |

| Compact Ankle Weights | Lightweight design, easy to store and transport | Travel fitness, outdoor workouts | Pros: Convenient for portability. Cons: Limited weight capacity. |

| Multi-Functional Ankle Weights | Can be used as wrist weights, adjustable weight options | Versatile training programs, group fitness | Pros: Multi-use increases value. Cons: May compromise fit for specific uses. |

What Are the Characteristics of Adjustable Ankle Weights?

Adjustable ankle weights are designed with removable weights, allowing users to customize the resistance level from 2 to 10 pounds. This flexibility makes them suitable for a wide range of users, from beginners to more experienced athletes. B2B buyers should consider the ease of adjustment and comfort, as these factors can significantly impact user experience in commercial settings, such as gyms and personal training studios.

How Do Neoprene Ankle Weights Benefit Users?

Neoprene ankle weights are known for their soft, comfortable fabric, making them ideal for extended wear. They often come with moisture-wicking properties, which can enhance user comfort during workouts. These weights are particularly suitable for rehabilitation centers and group fitness classes, where comfort is essential. B2B buyers should prioritize quality stitching and adjustable straps to ensure durability and a secure fit for various users.

What Makes Heavy Duty Ankle Weights Different?

Heavy-duty ankle weights cater to advanced users, with capacities reaching up to 20 pounds. Made from durable materials, they are designed for rigorous strength training and athletic programs. Buyers in the B2B space should assess the weight distribution and comfort level, as these factors can affect performance and user satisfaction. While they are excellent for serious training, their bulkiness may deter some users.

Why Choose Compact Ankle Weights?

Compact ankle weights are lightweight and designed for easy storage and transportation, making them ideal for travel fitness or outdoor workouts. Their portability is a significant advantage for personal trainers who conduct sessions in various locations. However, B2B buyers should be aware that these weights typically have a limited capacity, so they may not meet the needs of all users.

What Are the Advantages of Multi-Functional Ankle Weights?

Multi-functional ankle weights can double as wrist weights and offer adjustable weight options. This versatility makes them an attractive choice for B2B buyers looking to provide value in group fitness settings. While they can accommodate various workouts, it’s essential to ensure that the fit remains snug during different exercises to avoid slippage. This adaptability can enhance the overall appeal of a fitness program, making it more engaging for participants.

Key Industrial Applications of heaviest ankle weights

| Industry/Sector | Specific Application of heaviest ankle weights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fitness and Rehabilitation | Strength training programs for rehabilitation | Enhances muscle recovery and strength in injured patients | Quality materials for durability and comfort; adjustable weights |

| Sports Performance | Athletic training for competitive sports | Improves strength and endurance, aiding performance | Sourcing from reputable suppliers with proven track records |

| Health and Wellness Centers | Group fitness classes and personal training sessions | Increases workout intensity, attracting more clients | Versatility and ease of use; bulk purchasing options |

| Home Fitness Equipment Retailers | Retailing for home workout enthusiasts | Expands product offerings for consumers seeking convenience | Competitive pricing; customer reviews and product testing |

| Military and Tactical Training | Physical training for soldiers and tactical units | Builds strength and endurance under load for operational readiness | Durability and resistance to wear; compliance with military standards |

How Are Heaviest Ankle Weights Used in Fitness and Rehabilitation?

In fitness and rehabilitation settings, heaviest ankle weights are utilized to enhance strength training programs aimed at recovering patients. By incorporating these weights into exercises, therapists can facilitate gradual muscle recovery and strength building, which is crucial for individuals rehabilitating from injuries. Buyers in this sector should prioritize high-quality materials that ensure comfort and durability, as well as adjustable weights to cater to varying recovery stages.

What Role Do Heaviest Ankle Weights Play in Sports Performance?

Athletic training programs leverage heaviest ankle weights to improve both strength and endurance among competitive athletes. By adding resistance during training, athletes can enhance their performance in sports that require explosive movements. International buyers, particularly from regions with a focus on sports development, should seek suppliers that offer reliable products with proven effectiveness, ensuring that the weights can withstand rigorous training sessions.

How Do Health and Wellness Centers Benefit from Using Heaviest Ankle Weights?

Health and wellness centers incorporate heaviest ankle weights into group fitness classes and personal training sessions to increase workout intensity. This not only helps clients achieve better results but also attracts a broader clientele seeking effective fitness solutions. When sourcing these weights, businesses should consider versatility in design and ease of use, as well as options for bulk purchasing to meet the demands of larger classes.

Why Are Heaviest Ankle Weights Important for Home Fitness Equipment Retailers?

Home fitness equipment retailers can expand their product offerings by including heaviest ankle weights, catering to consumers looking for convenient workout solutions. These weights are particularly appealing to those seeking to enhance their home workout routines without requiring extensive equipment. Retailers should focus on competitive pricing and ensuring that products come with positive customer reviews and testing to build trust with their clientele.

How Are Heaviest Ankle Weights Utilized in Military and Tactical Training?

In military and tactical training environments, heaviest ankle weights are used to build strength and endurance among soldiers and tactical units. This training prepares personnel for the physical demands of their roles, enhancing operational readiness. Buyers in this sector must ensure that the ankle weights are durable and resistant to wear, and that they comply with military standards to guarantee reliability during rigorous training exercises.

3 Common User Pain Points for ‘heaviest ankle weights’ & Their Solutions

Scenario 1: Inconsistent Quality in Sourcing Heaviest Ankle Weights

The Problem: B2B buyers, especially those operating fitness centers or retailers, often face challenges with inconsistent quality when sourcing the heaviest ankle weights. This inconsistency can stem from various suppliers offering different materials, stitching quality, and weight adjustability features. Such variability can lead to customer dissatisfaction, increased returns, and ultimately damage to the brand’s reputation. For example, a gym owner may find that certain weights fall apart after minimal use, leading to safety concerns for clients during workouts.

The Solution: To combat this issue, B2B buyers should implement a stringent supplier vetting process. This includes requesting samples of the ankle weights to assess their durability and functionality firsthand. Buyers should also prioritize suppliers with a proven track record of quality control and positive customer reviews. By establishing clear specifications—such as the desired weight range, material standards (like neoprene or nylon), and adjustable weight mechanisms—buyers can better communicate their needs and expectations to suppliers. Regular quality audits and feedback loops can also help maintain standards over time, ensuring that the products delivered consistently meet the required quality benchmarks.

Scenario 2: Complicated Adjustability Mechanisms

The Problem: Many ankle weights come with complex adjustability features that can frustrate users, particularly beginners or those unfamiliar with fitness equipment. Complications in adjusting weights can lead to improper usage, which not only diminishes the effectiveness of workouts but may also cause injuries. For instance, a new gym member might struggle to adjust the weights correctly, resulting in a poor workout experience and possible abandonment of the equipment altogether.

The Solution: When selecting heaviest ankle weights, B2B buyers should focus on products with user-friendly adjustability features. Look for weights that utilize simple Velcro straps or easy-to-use weight pouches that allow users to make adjustments quickly. Providing instructional materials, such as clear usage guides or demonstration videos, can also enhance user experience. Furthermore, consider offering training sessions or workshops at fitness facilities to educate users on the proper use of the equipment. Such initiatives can increase customer satisfaction, encourage consistent use, and ultimately drive sales for the business.

Scenario 3: Discomfort Leading to Low Usage Rates

The Problem: Discomfort caused by poorly designed ankle weights can significantly reduce their usage rates among clients. Issues such as chafing, excessive bulkiness, or inadequate fit can deter users from incorporating ankle weights into their workout routines. For example, a fitness studio may find that their clients avoid using ankle weights during sessions, opting for bodyweight exercises instead, which can limit the effectiveness of their training programs.

The Solution: To address discomfort issues, B2B buyers should prioritize sourcing ankle weights designed with comfort in mind. This includes selecting products made from soft, breathable materials that minimize skin irritation, and ensuring they have adjustable features that cater to various ankle sizes. Conducting user trials to gather feedback on comfort can provide valuable insights before making bulk purchases. Additionally, offering a range of weight options can cater to different fitness levels and preferences, allowing users to choose weights that feel comfortable and effective for their training goals. Providing a comfortable experience can lead to increased adoption of the equipment and enhance overall workout satisfaction among clients.

Strategic Material Selection Guide for heaviest ankle weights

What Materials Are Commonly Used in the Production of Heaviest Ankle Weights?

When selecting materials for heaviest ankle weights, several options stand out due to their unique properties and performance characteristics. Understanding these materials is crucial for B2B buyers looking to optimize product quality, cost, and compliance with international standards.

How Does Neoprene Perform in Ankle Weights?

Neoprene is a synthetic rubber widely used in the production of ankle weights. It offers excellent flexibility, durability, and resistance to abrasion, making it suitable for high-intensity workouts. Neoprene can withstand a range of temperatures, ensuring that the weights maintain their integrity even in varied climates.

Pros: Neoprene is lightweight, water-resistant, and provides a snug fit, which is essential for comfort during workouts. Its durability means it can endure repeated use without significant wear.

Cons: The primary drawback of neoprene is its cost, which can be higher than alternatives like cotton or nylon. Additionally, it may not be as breathable, leading to discomfort in hot climates.

Impact on Application: Neoprene’s resistance to moisture makes it ideal for use in humid environments, common in regions like Africa and South America.

Considerations for International Buyers: Buyers should ensure that the neoprene used complies with environmental regulations, such as REACH in Europe. Understanding local preferences for material softness and flexibility can also guide purchasing decisions.

What Role Does Nylon Play in Ankle Weights?

Nylon is another popular material for ankle weights, known for its strength and versatility. It offers good resistance to wear and tear, making it suitable for both casual and professional training environments.

Pros: Nylon is lightweight, easy to clean, and often more affordable than neoprene. Its ability to dry quickly makes it a practical choice for users who may sweat during workouts.

Cons: While durable, nylon may not provide the same level of comfort as neoprene, especially if not lined properly. It can also be less resistant to UV light, which may affect longevity if exposed to sunlight frequently.

Impact on Application: Nylon is particularly well-suited for regions with high humidity, as it can wick moisture away from the skin, enhancing user comfort.

Considerations for International Buyers: Buyers should verify that the nylon used meets local textile standards, such as Oeko-Tex certification, to ensure safety and environmental compliance.

How Does Cotton Compare for Heaviest Ankle Weights?

Cotton is occasionally used in ankle weights, especially in lower-cost options. While it is soft and comfortable against the skin, its performance characteristics differ significantly from synthetic materials.

Pros: Cotton is breathable and hypoallergenic, making it a comfortable choice for users with sensitive skin. It is also generally less expensive than synthetic alternatives.

Cons: Cotton lacks durability, particularly in wet conditions, where it can absorb moisture and become heavy. It is also prone to wear and tear, which can lead to a shorter product lifespan.

Impact on Application: Cotton may be suitable for light-use scenarios, such as home workouts, but may not withstand the rigors of professional training.

Considerations for International Buyers: Buyers should be aware of the varying quality of cotton and ensure that it meets international standards for safety and performance.

What Advantages Does Steel Offer in Ankle Weights?

Steel is often used as a filler material in adjustable ankle weights, providing the necessary weight without significantly increasing the bulk.

Pros: Steel offers excellent durability and density, allowing for a compact design. It is also corrosion-resistant when properly treated, making it suitable for various environments.

Cons: The main limitation is that steel can add to the overall cost of the product. Additionally, it may require careful handling to avoid rusting if exposed to moisture.

Impact on Application: Steel’s density allows for precise weight adjustments, which is particularly beneficial for serious athletes looking for specific resistance levels.

Considerations for International Buyers: Compliance with international standards for metal safety, such as ASTM or DIN, is crucial. Buyers should also consider local preferences for weight increments and adjustability.

Summary Table of Material Selection for Heaviest Ankle Weights

| Material | Typical Use Case for heaviest ankle weights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Neoprene | High-intensity workouts | Flexible and durable | Higher cost, less breathable | High |

| Nylon | Casual and professional training | Lightweight and easy to clean | Less comfortable, UV sensitivity | Medium |

| Cotton | Light-use scenarios, home workouts | Soft and breathable | Less durable, moisture absorption | Low |

| Steel | Filler for adjustable weights | Compact and durable | Higher cost, rust potential | Medium |

This strategic material selection guide provides essential insights for B2B buyers in the global market, helping them make informed decisions based on material properties, performance, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for heaviest ankle weights

What Are the Key Stages in Manufacturing Heaviest Ankle Weights?

The manufacturing of heavy ankle weights involves several critical stages that ensure the final product meets quality standards and fulfills the requirements of international B2B buyers. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing ankle weights is selecting high-quality materials. Common materials include neoprene, nylon, and fillers such as sand and steel. Suppliers often conduct rigorous assessments to ensure that these materials are durable, comfortable, and resistant to wear. The materials are then cut and prepped according to the specifications of the ankle weights, ensuring they meet the desired weight and size.

Forming

This stage involves creating the individual components of the ankle weights. For neoprene weights, the material is cut into appropriate shapes and sizes. Various forming techniques such as stitching, welding, or molding may be employed, depending on the design requirements. For instance, neoprene components are often stitched to create pockets for the weight fillers, ensuring that they remain securely enclosed during use.

Assembly

Once the components are formed, they are assembled into the final product. This involves stitching the outer casing and inserting the weight fillers. Velcro straps are attached to ensure a secure fit around the ankle. The assembly process is crucial as it directly impacts the product’s usability and comfort. Automated machinery may be used for precision, but skilled labor is often required for quality assurance during this stage.

Finishing

The finishing stage encompasses quality checks, branding, and packaging. Quality checks ensure that each pair of ankle weights meets the required specifications. Products are often branded with labels or tags, and finally, they are packaged for distribution. The packaging must also be durable to protect the weights during transportation.

How Is Quality Assurance Implemented in the Manufacturing of Heaviest Ankle Weights?

Quality assurance (QA) is a critical aspect of manufacturing ankle weights, ensuring that the end products are safe, effective, and meet customer expectations. Various international and industry-specific standards guide this process.

Relevant International Standards

Manufacturers often adhere to international standards such as ISO 9001, which specifies requirements for a quality management system (QMS). Compliance with ISO 9001 helps ensure consistent quality in production and improves operational efficiency. Additionally, products sold in Europe may need to comply with CE marking requirements, indicating conformity with health and safety standards.

Industry-Specific Standards

In the fitness equipment industry, certifications such as the American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM) may also apply. These certifications focus on the safety and performance of fitness products, ensuring they can withstand rigorous use without compromising user safety.

What Are the Key Quality Control Checkpoints in Manufacturing Heaviest Ankle Weights?

Quality control (QC) is integral to the manufacturing process and typically includes several checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

Incoming Quality Control (IQC)

Before production begins, IQC ensures that all incoming materials meet specified standards. This includes checking the quality of neoprene, nylon, and weight fillers. Suppliers may use sampling techniques to assess material quality and consistency, ensuring that only compliant materials proceed to the next stage.

In-Process Quality Control (IPQC)

During the assembly process, IPQC involves monitoring production activities to detect any deviations from established standards. This may include visual inspections and functional tests to ensure that components are correctly formed and assembled. Regular checks help identify issues early, reducing the risk of defects in the final product.

Final Quality Control (FQC)

FQC is the last line of defense before products are shipped to clients. This stage involves comprehensive testing of completed ankle weights to ensure they meet all performance and safety standards. Common tests include weight accuracy, durability under stress, and comfort during use. Products that fail to meet the required standards are either reworked or discarded.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are some strategies to ensure compliance and quality:

Conducting Supplier Audits

One effective method for verifying supplier quality control is through on-site audits. These audits allow buyers to assess the manufacturing processes and QC checkpoints firsthand. Auditors can evaluate the supplier’s adherence to international standards and their internal quality management systems.

Requesting Quality Reports

Buyers should request detailed quality reports from suppliers. These reports should outline the QC processes, including IQC, IPQC, and FQC results. Transparency in reporting can provide insights into the supplier’s commitment to quality.

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services can conduct random checks during production and after completion, ensuring that the products meet international standards before shipment.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various certification and quality control nuances, particularly when sourcing from different regions. Here are some key considerations:

Understanding Regional Compliance Requirements

Different regions may have varying compliance requirements. For example, products sold in the European market must meet CE marking standards, while those in the U.S. may require compliance with ANSI and ASTM standards. Buyers should familiarize themselves with these requirements to ensure that the products they import are compliant.

Assessing Supplier Capabilities

Not all suppliers may have the capacity or expertise to meet international standards. Buyers should assess the supplier’s experience in manufacturing heavy ankle weights and their familiarity with the relevant certifications. This can often be gauged through previous customer reviews and case studies.

Building Long-Term Relationships

Establishing long-term relationships with trusted suppliers can enhance quality assurance. Suppliers who understand the specific needs and expectations of their clients are more likely to prioritize quality in their production processes. Regular communication and feedback can foster such relationships, leading to improved product quality and reliability.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing heavy ankle weights, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heaviest ankle weights’

In the competitive landscape of fitness equipment, sourcing high-quality heaviest ankle weights requires a strategic approach. This checklist serves as a practical guide for B2B buyers to ensure they procure the best products that meet their business needs and customer expectations.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for the ankle weights you intend to purchase. Consider factors such as weight range, material composition, and adjustability features. For example, weights that can be adjusted from 2 lbs to 10 lbs per ankle offer versatility for various fitness levels, making them appealing to a broader customer base.

Step 2: Research Market Trends and Customer Needs

Understanding current market trends is vital for making informed purchasing decisions. Review industry reports, customer reviews, and competitor offerings to identify what features are in demand. This could include preferences for materials such as neoprene for comfort, or specific weights favored by target demographics, such as beginners versus experienced athletes.

Step 3: Evaluate Potential Suppliers

Before making commitments, thoroughly vet potential suppliers. Request comprehensive company profiles, product catalogs, and references from other B2B clients in similar markets. Look for suppliers that have a proven track record in delivering quality products consistently and can provide testimonials or case studies to back their claims.

Step 4: Verify Quality Assurance and Compliance Standards

It is essential to ensure that the ankle weights meet international safety and quality standards. Ask suppliers for certifications such as ISO or other relevant industry-specific standards. This step not only safeguards your business but also builds trust with your customers, as they are increasingly aware of product quality.

Step 5: Request Samples for Testing

Before placing a bulk order, request samples of the ankle weights to assess their quality firsthand. Evaluate the materials, weight adjustability, and comfort level during use. This hands-on experience will help you make an informed decision and avoid potential issues related to product quality after purchase.

Step 6: Assess Pricing and Payment Terms

Consider the pricing structure and payment terms offered by suppliers. Compare quotes from multiple vendors to ensure you are getting competitive pricing without compromising on quality. Additionally, inquire about bulk purchase discounts and payment flexibility, which can significantly impact your overall budget.

Step 7: Establish a Clear Communication Channel

Maintain open lines of communication with your chosen supplier throughout the procurement process. This is crucial for addressing any concerns or modifications needed in real-time. Clear communication can lead to better service and support, ensuring a smoother transaction and fostering a long-term business relationship.

By following this checklist, B2B buyers can make informed decisions when sourcing heaviest ankle weights, ultimately enhancing their product offerings and customer satisfaction.

Comprehensive Cost and Pricing Analysis for heaviest ankle weights Sourcing

What Are the Key Cost Components in Sourcing Heaviest Ankle Weights?

When sourcing heaviest ankle weights, a thorough understanding of the cost structure is essential. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts costs. High-quality neoprene, sand, and steel are commonly used for durability and comfort. The cost of these raw materials fluctuates based on market conditions and availability, which can affect overall pricing.

-

Labor: Labor costs vary by region. For instance, manufacturers in Asia may offer lower labor rates compared to those in Europe. However, the skill level required for quality assembly can justify higher labor costs if it results in superior products.

-

Manufacturing Overhead: This encompasses utilities, rent, and administrative costs associated with production. Efficient production processes can help reduce overhead costs, which is crucial for maintaining competitive pricing.

-

Tooling: Initial setup costs for molds and machinery can be significant, particularly for custom designs. Manufacturers may pass these costs onto buyers, especially if the minimum order quantity (MOQ) is not met.

-

Quality Control (QC): Implementing stringent QC processes is vital to ensure product consistency and safety. Additional costs incurred for quality inspections and certifications can impact the final price.

-

Logistics: Shipping costs vary widely depending on the destination and Incoterms. Buyers need to consider freight, insurance, and customs duties, which can add considerable expense to international orders.

-

Margin: Suppliers typically add a margin to cover their costs and desired profit. Understanding the typical margins in your supplier’s region can aid in negotiation.

How Do Price Influencers Affect the Cost of Heaviest Ankle Weights?

Several factors influence the pricing of heaviest ankle weights, particularly for international B2B buyers:

-

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Suppliers may offer discounts for larger orders, making it advantageous for buyers to consolidate their purchases.

-

Specifications/Customization: Custom designs or specifications can increase costs due to the need for specialized tooling and materials. Buyers should assess whether customization is necessary for their market.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO, CE) can lead to increased costs. Buyers should evaluate the trade-off between price and product quality, especially when sourcing for a discerning clientele.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record of quality may command higher prices but can also offer peace of mind regarding product consistency.

-

Incoterms: Understanding the Incoterms agreed upon in the contract is crucial. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, Freight) can significantly affect the total landed cost of the products.

What Buyer Tips Can Help in Negotiating Costs for Heaviest Ankle Weights?

B2B buyers should employ strategic approaches to optimize their purchasing of heaviest ankle weights:

-

Negotiation: Building a good relationship with suppliers can lead to better pricing. Engaging in open discussions about costs, especially regarding bulk orders or long-term contracts, can yield favorable terms.

-

Cost-Efficiency: Conduct a thorough analysis of the Total Cost of Ownership (TCO). This includes not only the purchase price but also shipping, duties, and potential return costs. A lower initial price may not always translate to overall savings.

-

Pricing Nuances for International Buyers: International buyers should be aware of currency fluctuations and geopolitical factors that may impact pricing. Additionally, understanding local market conditions and competitor pricing can provide leverage during negotiations.

-

Evaluate Supplier Options: Diversifying suppliers can lead to more competitive pricing. Consider sourcing from multiple regions to mitigate risks associated with supply chain disruptions.

By considering these factors, international B2B buyers can make informed decisions when sourcing heaviest ankle weights, ensuring they achieve cost-effective and high-quality outcomes.

Alternatives Analysis: Comparing heaviest ankle weights With Other Solutions

Exploring Alternatives to Heaviest Ankle Weights

When considering the best solutions for enhancing lower body strength and conditioning, heaviest ankle weights are a popular choice among fitness enthusiasts. However, various alternatives can also achieve similar goals, each with distinct advantages and disadvantages. This analysis compares heaviest ankle weights with two viable alternatives: resistance bands and weighted vests.

| Comparison Aspect | Heaviest Ankle Weights | Resistance Bands | Weighted Vests |

|---|---|---|---|

| Performance | Excellent for targeted lower body workouts, promoting muscle hypertrophy. | Versatile for full-body workouts; suitable for various fitness levels. | Great for increasing overall body resistance during workouts. |

| Cost | Moderate ($54-$60 per pair) | Affordable ($10-$50 depending on brand and type) | Higher range ($40-$100) based on weight and design. |

| Ease of Implementation | Simple to use; just strap on and start exercising. | Requires some knowledge of exercises; can be less intuitive. | Easy to wear, but can be cumbersome for certain movements. |

| Maintenance | Minimal; just clean and store properly. | Durable but may wear over time; requires careful storage. | Requires regular cleaning and checking for wear and tear. |

| Best Use Case | Ideal for targeted lower body workouts and rehabilitation. | Best for dynamic workouts and progressive resistance training. | Suitable for high-intensity training and endurance workouts. |

Detailed Breakdown of Alternatives

Resistance Bands

Resistance bands are elastic bands used in strength training and rehabilitation. They come in various resistance levels, making them versatile for users of different fitness levels. Pros include their affordability and ability to facilitate a wide range of exercises, from strength training to flexibility routines. However, they may require more space and knowledge to maximize their potential effectively. Additionally, bands can be less effective for very heavy resistance training compared to heaviest ankle weights, which directly target muscle groups.

Weighted Vests

Weighted vests distribute weight evenly across the torso and can increase the intensity of bodyweight exercises. They are particularly effective for strength training, cardio, and endurance workouts. The main advantage is their versatility; users can perform a wide variety of exercises without altering their movement patterns significantly. However, weighted vests can be more expensive and may cause discomfort during extended use if not properly fitted. Additionally, they may restrict movement for certain exercises, making them less ideal for rehabilitation purposes compared to ankle weights.

Making the Right Choice for Your Needs

When choosing between heaviest ankle weights and their alternatives, B2B buyers should consider their specific fitness goals, budget constraints, and the intended user demographic. Heaviest ankle weights are perfect for targeted strength training and rehabilitation, offering a straightforward solution for lower body workouts. In contrast, resistance bands and weighted vests provide more versatility for broader exercise applications but may require more expertise to use effectively.

Ultimately, the right choice hinges on understanding the unique needs of the end-users, whether they are athletes, rehabilitation patients, or general fitness enthusiasts. By aligning the product features with user requirements, buyers can ensure they invest in solutions that deliver optimal performance and user satisfaction.

Essential Technical Properties and Trade Terminology for heaviest ankle weights

What Are the Key Technical Properties of Heaviest Ankle Weights?

When sourcing the heaviest ankle weights for your business, understanding their technical properties is crucial for making informed purchasing decisions. Here are some critical specifications to consider:

1. Material Composition

The most common materials used in ankle weights include neoprene, nylon, and cotton. Neoprene is favored for its durability, flexibility, and moisture-wicking properties, making it comfortable for prolonged use. Nylon is often used for its lightweight nature and resistance to wear and tear. Understanding the material composition helps buyers assess product longevity and suitability for their target market.

2. Weight Adjustability

Many ankle weights offer adjustable weights, typically ranging from 2 to 10 pounds per cuff, allowing users to customize their workout intensity. This feature is particularly appealing to businesses targeting diverse customer segments, from beginners to advanced fitness enthusiasts. The ability to adjust weight in increments (e.g., 2-pound increments) can enhance user experience and satisfaction.

3. Closure Mechanism

The closure mechanism, often Velcro or fabric fasteners, is essential for ensuring a secure fit during workouts. A high-quality closure not only prevents slipping but also enhances user comfort. When selecting products, consider those with reinforced stitching and robust fasteners, which can contribute to longer product life and reduced returns.

4. Size and Fit

Ankle weights typically come in a one-size-fits-all design, but dimensions can vary. A standard size might measure approximately 14″ x 5.5″ for lighter weights, while heavier options may reach 18.5″ x 7″. Understanding sizing is important for ensuring compatibility with various users, reducing the likelihood of product dissatisfaction.

5. Weight Distribution

Proper weight distribution is vital for balance and comfort during use. Ankle weights should be designed to ensure that the weight is evenly distributed around the ankle to prevent strain or injury. Buyers should inquire about the design specifics, as this can impact user safety and overall effectiveness.

6. Durability and Warranty

Durability is a key concern, particularly for products intended for commercial use in gyms or fitness studios. Many manufacturers provide warranties to guarantee quality. A robust warranty can indicate confidence in the product’s lifespan and may influence purchasing decisions for B2B buyers.

What Are Common Trade Terms in the Ankle Weights Industry?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are some common terms you may encounter:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then branded and sold by another company. Understanding OEM relationships is crucial for businesses looking to source ankle weights that can be customized with their branding.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. This is a critical consideration for businesses, as it affects inventory management and cash flow. Knowing the MOQ helps buyers plan their purchases according to demand.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. Crafting a well-defined RFQ can streamline the procurement process and ensure that you receive competitive offers from multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for navigating shipping logistics and costs.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is critical for inventory planning and meeting customer demands, particularly in markets with fluctuating demand cycles.

6. Customs Duties

Customs duties are tariffs imposed on imported goods. Knowing the applicable customs duties for ankle weights can impact pricing strategies and profit margins for B2B buyers, particularly in regions with stringent import regulations.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing the heaviest ankle weights, ensuring they meet the needs of their customers and maintain a competitive edge in the market.

Navigating Market Dynamics and Sourcing Trends in the heaviest ankle weights Sector

What Are the Current Market Dynamics and Key Trends for Heaviest Ankle Weights?

The global market for ankle weights, particularly the heaviest varieties, is witnessing significant growth driven by an increasing focus on fitness and rehabilitation. As consumers prioritize health, the demand for versatile workout equipment that enhances lower body strength is on the rise. Key trends include the integration of adjustable weights, catering to various fitness levels, and the use of high-quality materials, such as neoprene and nylon, which enhance durability and comfort. Furthermore, the rise of home fitness solutions has led to a surge in direct-to-consumer models, allowing manufacturers to reach international markets effectively.

In regions like Africa, South America, the Middle East, and Europe, B2B buyers are increasingly leveraging e-commerce platforms for sourcing. This shift is supported by advancements in logistics technology that facilitate faster delivery and lower shipping costs. Emerging markets are particularly interested in budget-friendly options that do not compromise on quality, prompting manufacturers to innovate in their product offerings. For instance, adjustable ankle weights that allow for incremental increases in resistance are appealing to both beginners and seasoned athletes, thus broadening the market base.

How Can Sustainability and Ethical Sourcing Impact the Heaviest Ankle Weights Sector?

As sustainability becomes a critical concern for businesses globally, the heaviest ankle weights sector is no exception. The environmental impact of production processes is under scrutiny, with buyers increasingly favoring suppliers who demonstrate commitment to sustainable practices. This includes the use of eco-friendly materials, such as recycled fabrics and non-toxic fillers, which not only reduce waste but also appeal to environmentally conscious consumers.

Ethical sourcing is paramount, particularly in regions where labor practices may vary significantly. B2B buyers are advised to seek suppliers that provide transparency in their supply chains, ensuring fair labor practices and compliance with international labor standards. Certifications such as Fair Trade or Global Organic Textile Standard (GOTS) can serve as indicators of a company’s commitment to ethical sourcing. By prioritizing suppliers who adhere to sustainable and ethical practices, businesses can enhance their brand reputation and meet the growing consumer demand for responsible products.

What Is the Historical Context Behind the Heaviest Ankle Weights Market?

The use of ankle weights can be traced back to ancient civilizations, where they were employed to enhance physical performance in various sports. In the modern fitness landscape, the evolution of ankle weights has been significant, transitioning from simple, heavy designs to sophisticated, adjustable models that cater to a diverse range of users. The introduction of materials like neoprene and innovations in design have transformed ankle weights into a staple in both personal and commercial fitness settings. As the focus on fitness and wellness continues to expand globally, the heaviest ankle weights are positioned to remain an integral part of workout regimens across different demographics.

In summary, the heaviest ankle weights market is evolving rapidly, influenced by consumer trends, sustainability imperatives, and a rich historical context. For B2B buyers, understanding these dynamics is essential for making informed sourcing decisions that align with market demands and ethical considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of heaviest ankle weights

-

How do I select the best heavy ankle weights for my business needs?

When sourcing heavy ankle weights, consider factors such as weight range, material quality, and adjustability. Look for products made from durable materials like neoprene, which provide comfort and longevity. Also, evaluate the weight increments available, as this allows users to tailor their workouts. Supplier reviews and certifications can provide insights into product quality and supplier reliability. Additionally, consider the specific fitness goals of your target market to ensure the weights meet their needs. -

What are the most common weight increments for ankle weights?

Most heavy ankle weights typically offer increments ranging from 2 to 10 pounds per ankle, with adjustable options available. Common configurations include weights that can be adjusted in 2-pound increments, allowing users to customize their resistance. This flexibility is particularly beneficial for businesses targeting a diverse clientele, from beginners to advanced athletes. Ensure that the products you source offer a variety of options to cater to different fitness levels and preferences. -

What are the key features to look for in heavy ankle weights?

When evaluating heavy ankle weights, prioritize features such as adjustable Velcro straps for a secure fit, durable materials to withstand frequent use, and the ability to add or remove weights easily. Comfort is crucial, so look for designs that minimize chafing and irritation during workouts. Additionally, consider whether the weights can be used for both ankle and wrist exercises, enhancing their versatility and appeal to potential buyers. -

What is the minimum order quantity (MOQ) for heavy ankle weights?

Minimum order quantities can vary significantly by supplier and region. Typically, MOQs for heavy ankle weights range from 50 to 500 pairs. It’s essential to discuss your requirements with potential suppliers to negotiate favorable terms. Lower MOQs may be available for established brands or during promotional periods, so exploring multiple suppliers can help you find the best deal. Always factor in your storage capacity and market demand when determining your order size. -

How can I ensure the quality of the heavy ankle weights I purchase?

To ensure quality, request samples from suppliers before placing a bulk order. This allows you to assess the product’s material, construction, and overall performance firsthand. Additionally, inquire about the supplier’s quality assurance processes, such as certifications and testing protocols. Reviews and testimonials from other businesses can also provide valuable insights into the reliability of the products. Consider visiting manufacturing facilities if possible, especially for significant investments. -

What payment terms are typically offered by suppliers of heavy ankle weights?

Payment terms can vary widely among suppliers, but common options include upfront payment, partial payment upon order confirmation, and balance payment prior to shipping. Some suppliers may offer credit terms based on your purchasing history. Always clarify payment terms upfront to avoid misunderstandings. Consider using secure payment methods, such as letters of credit or escrow services, for larger transactions to protect your investment. -

How should I approach logistics and shipping for my heavy ankle weights orders?

When organizing logistics, choose a shipping method that balances cost and delivery time. Sea freight is often more economical for larger orders, while air freight is faster but more expensive. Ensure your supplier is experienced in international shipping and can handle customs clearance. Additionally, discuss packaging options to minimize damage during transit. Establishing a reliable logistics partner can streamline the process and enhance your supply chain efficiency. -

What are the customs regulations for importing heavy ankle weights into my region?

Customs regulations vary by country, so it’s crucial to research the specific import requirements for heavy ankle weights in your target market. This includes understanding tariff classifications, documentation needed for clearance, and any applicable duties. Collaborating with a customs broker can facilitate the import process, ensuring compliance with local regulations. Stay informed about changes in trade policies that may affect costs and delivery timelines, particularly in regions with fluctuating regulations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 2 Heaviest Ankle Weights Manufacturers & Suppliers List

1. Bala – Adjustable Ankle Weights

Domain: verywellfit.com

Registered: 2017 (8 years)

Introduction: Best Overall: Bala Bangles at Amazon $55

– Weight per Ankle: 1, 2, or 3 pounds (adjustable)

– Material: Steel, silicone

– Closure: Velcro

– Dimensions: 13 x 3 inches

– Overall Rating: 4.8/5

– Pros: Sleek appearance, water-resistant, comfortable and high-quality

– Cons: Pricier than other options

– Who They’re For: Best for beginner to intermediate exercisers who want a high-quality, adjustable, an…

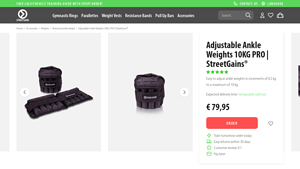

2. StreetGains® – Adjustable Ankle Weights 10KG PRO

Domain: streetgains.eu

Introduction: {“product_name”: “StreetGains® Adjustable Ankle Weights 10KG PRO”, “weight”: “10 kg (2 x 5 kg)”, “adjustable_weight”: “1 to 10 kg”, “material”: “heavy-duty nylon”, “features”: [“two ankle weights”, “compact size due to steel bar weights”, “removable weights”, “wide velcro closure”, “strong steel locking clips”, “one size fits all”], “dimensions”: “36 x 16 x 3 cm”, “color”: “black”, “product_number…

Strategic Sourcing Conclusion and Outlook for heaviest ankle weights

In summary, strategic sourcing of the heaviest ankle weights presents a significant opportunity for international B2B buyers to enhance their product offerings in the fitness market. Key takeaways emphasize the importance of quality, adjustability, and comfort in ankle weights, which cater to various fitness levels and preferences. The growing trend towards home fitness solutions, particularly in regions such as Africa, South America, the Middle East, and Europe, underscores the demand for durable and versatile products.

Investing in high-quality ankle weights can lead to greater customer satisfaction and retention, as evidenced by positive user reviews highlighting their effectiveness in enhancing workout routines. Buyers should consider sourcing from reputable manufacturers who prioritize innovative design and material quality, ensuring that their products meet diverse market needs.

As the fitness industry continues to evolve, staying ahead of consumer trends and preferences is crucial. We encourage international B2B buyers to explore partnerships with suppliers who can deliver the latest advancements in ankle weight technology. By doing so, you will not only meet market demands but also position your business for sustained growth and success in an increasingly competitive landscape.