Everything You Need to Know About Disposable Pizza Pans Sourcing in 2025

Introduction: Navigating the Global Market for disposable pizza pans

In an increasingly competitive landscape, sourcing disposable pizza pans can pose significant challenges for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe—particularly in key markets like Germany and Saudi Arabia—the need for high-quality, cost-effective solutions is paramount. This guide delves into the intricacies of the global market for disposable pizza pans, providing insights into various types, applications, and materials available. It offers a comprehensive overview of supplier vetting processes, pricing structures, and best practices for making informed purchasing decisions.

By equipping buyers with essential knowledge about the disposable pizza pan landscape, this guide aims to empower stakeholders across the foodservice and catering industries. From evaluating the heat distribution capabilities of aluminum pans to understanding the environmental impacts of disposable options, we cover all critical aspects that affect product selection. Furthermore, we highlight the importance of aligning sourcing strategies with local market demands and regulatory requirements, ensuring that your purchasing decisions are both sustainable and economically sound.

Ultimately, this guide serves as a vital resource, enabling businesses to streamline their procurement processes and enhance operational efficiency while meeting customer expectations for quality and convenience.

Understanding disposable pizza pans Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aluminum Foil Pizza Pans | Lightweight, sturdy, excellent heat distribution | Pizzerias, catering services | Pros: Cost-effective, easy cleanup. Cons: Limited reuse. |

| Heavy-Duty Disposable Pizza Pans | Thicker material, designed for heavier toppings | Commercial kitchens, food trucks | Pros: Better durability, holds larger pizzas. Cons: Higher cost. |

| Individual Pizza Pans | Smaller size for personal pizzas, often deep-dish style | Fast-food restaurants, events | Pros: Perfect for single servings, minimal waste. Cons: May not suit larger orders. |

| Biodegradable Pizza Pans | Made from sustainable materials, eco-friendly | Eco-conscious businesses, events | Pros: Environmentally friendly, aligns with green initiatives. Cons: Generally higher price point. |

| Nested Pizza Pans | Designed to stack for space-saving, various sizes available | Large-scale operations, food prep | Pros: Efficient storage, versatile sizes. Cons: May require additional storage solutions. |

What Are the Key Characteristics of Aluminum Foil Pizza Pans?

Aluminum foil pizza pans are widely recognized for their lightweight yet sturdy construction, making them ideal for quick-service environments. These pans provide excellent heat distribution, ensuring that pizzas cook evenly. They are commonly used in pizzerias and catering services where convenience and cost-effectiveness are paramount. However, their disposable nature means they cannot be reused, which may not appeal to all businesses.

How Do Heavy-Duty Disposable Pizza Pans Differ from Standard Options?

Heavy-duty disposable pizza pans are designed to withstand the rigors of commercial kitchens, accommodating heavier toppings without bending or warping. They are particularly suitable for food trucks and busy restaurants that serve larger pizzas. While they offer enhanced durability, buyers should consider their higher price point compared to standard aluminum pans, which may impact budget-sensitive operations.

What Advantages Do Individual Pizza Pans Offer for B2B Buyers?

Individual pizza pans are specifically designed for personal-sized servings, often in a deep-dish format. These pans are ideal for fast-food restaurants and event catering, where single servings are in demand. The primary advantage is minimal food waste, as each pan is tailored for one pizza. However, businesses should assess whether this format aligns with their customer base, as it may not suit larger orders.

Why Should Businesses Consider Biodegradable Pizza Pans?

Biodegradable pizza pans are an excellent choice for eco-conscious businesses looking to align with sustainability goals. Made from renewable materials, these pans decompose naturally, making them suitable for events and establishments that prioritize environmental impact. While they can be more expensive than traditional options, the long-term benefits in brand reputation and customer loyalty can outweigh the initial costs.

What Are the Benefits of Nested Pizza Pans for Large Operations?

Nested pizza pans are designed for efficient storage and space-saving, allowing multiple pans to stack neatly. They come in various sizes, catering to diverse menu options and customer preferences. These pans are particularly beneficial for large-scale operations, such as food prep facilities and restaurants that require quick access to different sizes. However, businesses should ensure they have adequate storage solutions to accommodate the stacked pans effectively.

Key Industrial Applications of disposable pizza pans

| Industry/Sector | Specific Application of Disposable Pizza Pans | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Catering and Event Management | Streamlined service, reduced cleanup time | Quality of materials, size variety, and bulk purchasing options |

| Retail | Grocery Stores and Convenience Stores | Ready-to-use packaging for fresh or frozen pizzas | Cost-effectiveness, shelf life, and branding options |

| Hospitality | Restaurants and Pizzerias | Efficient cooking and serving solutions | Heat resistance, durability, and compliance with food safety standards |

| Food Production | Frozen Pizza Manufacturers | Cost reduction in production and packaging | Supply chain reliability, material sourcing, and certifications |

| Food Festivals | Outdoor Events and Festivals | Convenient serving solution for large crowds | Portability, size options, and environmental considerations |

How Are Disposable Pizza Pans Utilized in the Food Service Industry?

In the food service sector, disposable pizza pans are invaluable for catering and event management. These pans allow caterers to serve pizzas quickly and efficiently while minimizing cleanup efforts. The lightweight yet sturdy design ensures that pizzas can be transported without risk of breakage. B2B buyers in this sector should prioritize sourcing options that offer a variety of sizes to accommodate different pizza styles and portions, ensuring they can meet diverse client needs.

What Role Do Disposable Pizza Pans Play in Retail Environments?

For grocery stores and convenience stores, disposable pizza pans serve as ready-to-use packaging for fresh or frozen pizzas. This application enhances the shopping experience by providing customers with a convenient way to purchase and prepare meals. Retailers benefit from reduced waste and the ability to offer a variety of pizza options without the need for extensive kitchen facilities. Buyers should consider the cost-effectiveness and shelf life of the pans when sourcing, along with potential branding opportunities.

Why Are Disposable Pizza Pans Essential for the Hospitality Sector?

In restaurants and pizzerias, disposable pizza pans streamline the cooking and serving process, allowing for quick turnaround times during busy service periods. These pans are designed to withstand high temperatures, ensuring that pizzas are cooked evenly and served hot. Buyers in this industry must ensure that the pans comply with food safety regulations and are durable enough to handle the rigors of a commercial kitchen, thus reducing the risk of breakage.

How Do Frozen Pizza Manufacturers Benefit from Disposable Pizza Pans?

Frozen pizza manufacturers leverage disposable pizza pans to reduce production and packaging costs. These pans facilitate efficient baking and freezing processes, allowing manufacturers to streamline operations. For B2B buyers in this sector, reliability in the supply chain and the quality of materials used in the pans are critical factors to consider, as they impact both product quality and overall production efficiency.

What Are the Advantages of Using Disposable Pizza Pans at Food Festivals?

During food festivals and outdoor events, disposable pizza pans provide a convenient serving solution for large crowds. They enable vendors to serve food quickly while minimizing cleanup, allowing them to focus on customer engagement. Sourcing considerations for these applications include portability and size options, as well as environmental factors, such as the recyclability of the pans, which is increasingly important to eco-conscious consumers.

3 Common User Pain Points for ‘disposable pizza pans’ & Their Solutions

Scenario 1: Balancing Cost and Quality in Disposable Pizza Pans

The Problem: B2B buyers often struggle to find disposable pizza pans that offer the right balance between affordability and quality. Many budget options compromise on sturdiness and heat distribution, leading to issues such as warping during baking or insufficient support for heavy toppings. This can result in customer dissatisfaction, potential food waste, and ultimately a loss of repeat business for pizzerias or food service establishments.

The Solution: To address this challenge, buyers should prioritize sourcing disposable pizza pans made from high-quality, food-grade aluminum. When evaluating suppliers, consider conducting a thorough quality audit that includes product samples to test for heat resistance and structural integrity. Establish long-term partnerships with reputable manufacturers who specialize in durable, commercially viable products. Additionally, leverage bulk purchasing options that not only reduce costs but also ensure a consistent supply of high-quality pans tailored to specific pizza styles, whether thin crust or deep dish.

Scenario 2: Managing Environmental Concerns with Disposable Pizza Pans

The Problem: Increasingly, B2B buyers are facing pressure from consumers and regulatory bodies to adopt more environmentally friendly practices. The use of disposable pizza pans, while convenient, raises concerns about waste and sustainability. This dilemma complicates procurement strategies, as businesses want to avoid negative public perception while still meeting operational needs for efficiency and convenience.

The Solution: To tackle this issue, buyers should explore eco-friendly disposable pizza pans made from recyclable or biodegradable materials. Engage with suppliers who provide transparency about their manufacturing processes and materials. Implement a recycling program in your establishment to ensure that used pans are disposed of responsibly. Additionally, educate staff about the benefits of using sustainable products and communicate these practices to customers. This not only enhances your brand image but can also attract environmentally conscious consumers, thus differentiating your business in a competitive market.

Scenario 3: Addressing Size and Versatility Limitations in Disposable Pizza Pans

The Problem: Another common pain point for B2B buyers is the limited size and versatility of disposable pizza pans available in the market. Many suppliers only offer standard sizes, which can restrict menu creativity and limit operational efficiency, especially for businesses that cater to diverse customer preferences, including personal-sized pizzas or larger party pizzas.

The Solution: To overcome this limitation, buyers should seek suppliers that offer a comprehensive range of sizes and designs. Evaluate the possibility of custom orders that can accommodate unique specifications for your menu. Consider investing in a mix of different pan sizes to provide flexibility for various pizza styles and customer orders. Additionally, conducting market research to identify trending pizza styles in your target demographics can inform your purchasing decisions. By stocking a versatile inventory of disposable pans, businesses can better meet customer demands and enhance operational efficiency, ultimately boosting customer satisfaction and loyalty.

Strategic Material Selection Guide for disposable pizza pans

What are the Key Materials Used in Disposable Pizza Pans?

When selecting disposable pizza pans, the choice of material significantly impacts performance, cost, and suitability for various applications. Here, we analyze four common materials used in the manufacturing of disposable pizza pans: aluminum, plastic, paperboard, and compostable materials.

Aluminum: The Industry Standard

Key Properties: Aluminum pans are lightweight yet strong, offering excellent thermal conductivity. They can withstand high temperatures, typically up to 400°F (204°C), without warping or melting.

Pros & Cons: The primary advantage of aluminum is its durability and ability to provide even heat distribution, resulting in a perfectly cooked pizza crust. However, aluminum pans can be more expensive than other options and may not be suitable for acidic foods, which can react with the metal.

Impact on Application: Aluminum pans are compatible with a wide range of cooking methods, including baking and grilling. They are widely accepted in international markets, making them a reliable choice for B2B buyers.

Considerations for International Buyers: Compliance with food safety standards, such as those set by the FDA or EU regulations, is crucial. Buyers in regions like Germany and Saudi Arabia should ensure that their suppliers adhere to local regulations regarding aluminum usage.

Plastic: Lightweight and Versatile

Key Properties: Plastic disposable pizza pans are generally made from polypropylene or polystyrene, which can withstand temperatures up to 200°F (93°C). They are not suitable for high-temperature cooking but are excellent for serving.

Pros & Cons: The lightweight nature of plastic makes it easy to handle and transport. However, its lower heat resistance limits its use in cooking applications. Additionally, plastic pans are often less environmentally friendly, raising concerns in regions with strict waste management policies.

Impact on Application: Plastic pans are ideal for takeout and delivery services where the focus is on convenience rather than cooking. They are commonly used in fast-food chains across various regions.

Considerations for International Buyers: Buyers should be aware of regulations regarding plastic use, especially in Europe, where there is a growing emphasis on reducing single-use plastics. Compliance with local environmental laws is essential.

Paperboard: Eco-Friendly Option

Key Properties: Made from recycled materials, paperboard pans are lightweight and can handle moderate temperatures up to 350°F (177°C). They are often coated to provide moisture resistance.

Pros & Cons: The primary advantage of paperboard is its eco-friendliness, appealing to businesses focused on sustainability. However, they may not be as durable as aluminum or plastic, leading to potential leakage or structural failure under heavy toppings.

Impact on Application: Paperboard pans are suitable for serving pizzas in casual dining settings or for takeout. They are particularly popular in markets with a strong emphasis on environmental responsibility.

Considerations for International Buyers: Compliance with environmental standards is critical, especially in European markets. Buyers should verify certifications related to sustainability and recyclability.

Compostable Materials: The Future of Disposable Pans

Key Properties: Compostable pizza pans are typically made from plant-based materials, such as sugarcane or bamboo, and can withstand temperatures similar to paperboard.

Pros & Cons: These pans offer an excellent eco-friendly alternative, as they break down naturally in composting environments. However, they can be more expensive than traditional materials and may not be as widely available.

Impact on Application: Compostable pans are ideal for businesses looking to enhance their sustainability profile and cater to environmentally conscious consumers. They are increasingly being adopted in various regions, particularly in Europe and North America.

Considerations for International Buyers: Buyers should ensure that compostable products meet local composting standards and certifications. This is especially important in regions like Europe, where regulations around compostable materials are stringent.

Summary Table of Material Selection for Disposable Pizza Pans

| Material | Typical Use Case for Disposable Pizza Pans | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Baking and serving pizzas | Excellent heat distribution | Can react with acidic foods | Medium |

| Plastic | Takeout and delivery | Lightweight and easy to handle | Limited heat resistance | Low |

| Paperboard | Casual dining and takeout | Eco-friendly and recyclable | Less durable, potential leakage | Medium |

| Compostable | Sustainable dining options | Environmentally friendly | Higher cost and limited availability | High |

This strategic material selection guide provides valuable insights for B2B buyers, enabling them to make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for disposable pizza pans

What Are the Key Stages in the Manufacturing Process of Disposable Pizza Pans?

The manufacturing process of disposable pizza pans involves several critical stages that ensure the final product meets quality and performance standards. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation

The first step involves sourcing high-quality materials, predominantly aluminum, known for its lightweight and excellent heat conductivity. Suppliers often use food-grade aluminum to ensure safety and compliance with international food standards. The raw aluminum is then rolled into sheets of specific thicknesses, depending on the desired sturdiness of the pizza pans.

Forming

Once the materials are prepared, the aluminum sheets are cut into required dimensions using precision machinery. This process may involve die-cutting, where a die shapes the aluminum into the pan’s form. Advanced techniques like deep drawing can also be employed to create deeper pans suitable for various pizza styles. Automation in this stage enhances efficiency and consistency in product quality.

Assembly

In the assembly phase, pans may undergo additional processes such as edge curling to enhance structural integrity and prevent sharp edges. This stage is crucial for ensuring that the pans can withstand the rigors of baking without warping or collapsing. For some manufacturers, this phase might also include applying non-stick coatings, although this is less common for disposable pans.

Finishing

The finishing stage involves cleaning and packaging the pans. This step ensures that any residual particles from manufacturing are removed, and the pans are ready for distribution. Quality packaging is vital to prevent damage during transportation. Manufacturers often use recyclable materials for packaging, aligning with sustainability practices increasingly valued by B2B buyers.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing of disposable pizza pans, ensuring that products not only meet but exceed industry standards. Key international standards, such as ISO 9001, are often adopted by manufacturers to establish a quality management system that enhances operational efficiency and customer satisfaction.

International Standards and Certifications

For B2B buyers, understanding the certifications that a manufacturer holds is essential. ISO 9001 focuses on continuous improvement and customer satisfaction, while CE marking indicates compliance with European health, safety, and environmental protection standards. In certain regions, API (American Petroleum Institute) standards might be relevant if the pans are used in specialized cooking environments.

What Are the Critical Quality Control Checkpoints in the Production of Disposable Pizza Pans?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to identify defects early and ensure compliance with specifications.

Incoming Quality Control (IQC)

The first checkpoint occurs at the material reception stage, where incoming aluminum sheets are inspected for defects. Measurements and samples are taken to ensure that they meet the required specifications. This stage is critical, as the quality of raw materials directly affects the final product.

In-Process Quality Control (IPQC)

During the forming and assembly phases, manufacturers implement in-process quality control measures. Operators often conduct visual inspections and utilize gauges to measure dimensions, ensuring that the pans are formed correctly. Statistical process control (SPC) techniques may also be employed to monitor the manufacturing process continuously.

Final Quality Control (FQC)

After the pans are finished, a final quality check is performed. This includes testing for structural integrity, checking for any defects in the coating (if applicable), and ensuring that the pans meet size specifications. Random sampling may be conducted to validate the quality of the entire batch, ensuring that only products that pass all tests reach the market.

What Testing Methods Are Commonly Used to Ensure Quality in Disposable Pizza Pans?

Various testing methods are employed to ensure the quality and safety of disposable pizza pans. These methods include:

- Dimensional Inspection: Measuring the pans to ensure they conform to specified dimensions.

- Weight Testing: Ensuring that the weight of the pan aligns with industry standards for sturdiness.

- Heat Resistance Testing: Assessing how well the pans withstand high temperatures without warping or degrading.

- Non-Toxicity Testing: Ensuring that the materials used in the pans are safe for food contact, complying with relevant health regulations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is essential to mitigate risks associated with subpar products. Here are some actionable steps:

-

Supplier Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes and quality assurance practices. This includes checking for compliance with international standards and certifications.

-

Quality Reports: Requesting detailed quality reports can help buyers understand how a supplier manages their quality control processes. These reports often include data on defect rates, testing results, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s manufacturing and quality assurance processes. These inspections can help ensure that products meet specified standards before they are shipped.

What Nuances Should International Buyers Consider Regarding Quality Control?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of the following nuances:

-

Regional Standards: Different regions may have varying standards for food safety and product quality. Understanding local regulations is crucial for compliance and market acceptance.

-

Cultural Expectations: Expectations regarding quality and safety can differ by region. Engaging with local stakeholders can provide valuable insights into market-specific requirements.

-

Supply Chain Logistics: Quality control does not end at the factory; it extends to transportation and storage. Ensuring that suppliers have robust logistics practices can prevent quality degradation before the product reaches the buyer.

By understanding the manufacturing processes and quality assurance practices for disposable pizza pans, B2B buyers can make informed decisions that enhance their operational efficiency and product quality, ultimately leading to greater customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘disposable pizza pans’

Introduction

This practical sourcing guide serves as a step-by-step checklist for B2B buyers looking to procure disposable pizza pans. With an increasing demand for convenience in food service, understanding the essential criteria for sourcing these products is crucial for ensuring quality and efficiency in your operations. This guide will help you navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that the disposable pizza pans meet your business needs. Consider factors such as size (e.g., 10″, 12″, or 16″ pans), material (aluminum vs. plastic), and design (shallow vs. deep dish). This clarity will help in narrowing down potential suppliers and ensuring that the products align with your menu offerings.

- Size Variability: Different sizes accommodate various pizza styles; for example, personal pizzas may require smaller pans.

- Material Considerations: Aluminum pans are generally preferred for their heat conductivity and sturdiness, while plastic options may be suitable for cold items.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers who specialize in disposable pizza pans. Use industry directories, trade shows, and online marketplaces to compile a list of reputable vendors. It’s essential to focus on suppliers with a strong track record of reliability and quality.

- Supplier Reputation: Look for customer reviews and ratings to gauge reliability.

- Industry Experience: Suppliers with experience in your specific market (e.g., fast food, catering) may better understand your needs.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; direct communication can reveal more about their service levels and product offerings.

- Case Studies: Ask for examples of how they have supported similar businesses.

- References: Contact previous clients to inquire about their experiences regarding quality and service.

Step 4: Request Samples for Quality Assessment

Always request samples of disposable pizza pans before finalizing your order. This step allows you to evaluate the product’s quality, durability, and suitability for your specific needs. Inspect the pans for any defects and ensure they meet your technical specifications.

- Quality Indicators: Check for uniform thickness and absence of sharp edges.

- Durability Testing: Consider how the pans hold up under various cooking conditions.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations regarding pricing and terms. Understanding market rates and being aware of bulk purchase discounts can significantly impact your overall costs. Ensure that payment terms, delivery timelines, and return policies are clearly defined.

- Bulk Discounts: Inquire about pricing tiers based on order volume.

- Contract Clarity: Ensure that all terms are documented to avoid future disputes.

Step 6: Verify Compliance and Certifications

Ensure that the disposable pizza pans comply with international safety and quality standards. Depending on your market, certifications such as FDA approval for food contact materials may be necessary. Compliance with local regulations is essential for maintaining product integrity and consumer safety.

- Documentation Requests: Ask for certificates of compliance and quality assurance.

- Local Regulations: Familiarize yourself with any specific requirements in your region.

Step 7: Establish a Reliable Order Schedule

Once you’ve finalized your supplier, set up a reliable order schedule to maintain consistent inventory levels. Establishing a routine for reordering can help prevent stockouts, ensuring your operations run smoothly.

- Inventory Management: Use forecasting tools to anticipate demand and adjust orders accordingly.

- Supplier Communication: Maintain open lines of communication with your supplier for timely updates on stock availability.

By following this checklist, B2B buyers can streamline their sourcing process for disposable pizza pans, ensuring they make informed decisions that align with their business needs.

Comprehensive Cost and Pricing Analysis for disposable pizza pans Sourcing

What Are the Key Cost Components in Sourcing Disposable Pizza Pans?

When sourcing disposable pizza pans, understanding the cost structure is essential for effective budgeting and financial planning. The primary cost components include:

-

Materials: Disposable pizza pans are typically made from aluminum, which is favored for its lightweight nature and excellent heat conduction. The choice of food-grade aluminum can impact costs, as higher quality materials may yield better performance but come at a premium.

-

Labor: Labor costs encompass the wages of workers involved in the manufacturing process. These can vary significantly based on geographic location, with labor being cheaper in some regions, like parts of Africa and South America, compared to Western Europe.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility management. Efficient production processes can help mitigate these expenses.

-

Tooling: If custom molds are required for specific pan designs or sizes, tooling costs can be significant. Buyers should consider whether standard sizes will suffice or if customization is necessary for their market needs.

-

Quality Control (QC): Ensuring that the pans meet safety and quality standards requires investment in QC processes. This is particularly crucial for international buyers who must comply with varying regulations in their respective countries.

-

Logistics: Shipping costs can heavily influence the total price, especially for international transactions. Factors such as distance, shipping method, and customs duties should be carefully evaluated.

-

Margin: Supplier margins typically range from 10% to 30%, depending on the competitiveness of the market and the value-added services provided.

How Do Price Influencers Affect Disposable Pizza Pan Costs?

Several factors can influence the pricing of disposable pizza pans:

-

Volume/MOQ: Higher order volumes generally lead to lower unit prices due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their purchasing capabilities.

-

Specifications and Customization: Custom designs or specific sizes can increase costs. It’s essential to balance the need for customization with budget constraints.

-

Material Quality and Certifications: Higher quality materials and certifications (like FDA approval) can add to the cost but may be necessary to meet safety standards in certain markets.

-

Supplier Factors: The reputation and reliability of suppliers can also affect pricing. Established suppliers may charge more but offer better quality assurance and customer service.

-

Incoterms: Understanding the terms of shipment is critical. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect overall costs and risk management.

What Negotiation Strategies Can B2B Buyers Use?

For international buyers, particularly in Africa, South America, the Middle East, and Europe, effective negotiation can lead to better pricing:

-

Research and Benchmarking: Conduct thorough market research to understand prevailing prices and negotiate effectively. Use this data to inform your discussions with suppliers.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better terms and pricing. Consider loyalty discounts or exclusive agreements.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes not just the purchase price but also shipping, storage, and disposal costs. This holistic view can help justify higher upfront costs if they result in overall savings.

-

Be Mindful of Pricing Nuances: International buyers should be aware of currency fluctuations and economic conditions in supplier countries, which can impact pricing.

Why Is It Important to Acknowledge Indicative Prices?

While indicative prices are useful for budgeting, they can fluctuate based on market conditions, raw material availability, and geopolitical factors. Therefore, it’s crucial for buyers to maintain flexibility in their procurement strategies and stay updated on market trends to make informed purchasing decisions.

Alternatives Analysis: Comparing disposable pizza pans With Other Solutions

Exploring Alternative Solutions to Disposable Pizza Pans

In the food service industry, selecting the right tools and materials is crucial for operational efficiency and customer satisfaction. While disposable pizza pans offer numerous advantages, it’s important to consider alternative solutions that may align better with specific business needs. This section compares disposable pizza pans against two viable alternatives: reusable pizza pans and pizza stones. Understanding the strengths and weaknesses of each option can help B2B buyers make informed purchasing decisions.

| Comparison Aspect | Disposable Pizza Pans | Reusable Pizza Pans | Pizza Stones |

|---|---|---|---|

| Performance | Excellent heat distribution; ideal for high-volume use | Good heat retention; requires proper seasoning | Exceptional heat retention; great for crispy crusts |

| Cost | Low initial investment; cost-effective for bulk purchases | Higher upfront costs; cost-effective over time with frequent use | Moderate investment; can be costly if not maintained |

| Ease of Implementation | Ready to use; no setup required | Requires cleaning and storage; easy to use | Requires preheating; can be heavy to handle |

| Maintenance | Minimal; dispose after use | Requires regular cleaning and care | Requires careful handling and occasional seasoning |

| Best Use Case | Ideal for pizzerias, catering, or events | Suitable for restaurants focused on quality and consistency | Best for artisanal pizzas and high-end pizza establishments |

What Are the Advantages and Disadvantages of Reusable Pizza Pans?

Reusable pizza pans are made from durable materials like aluminum or steel, allowing them to withstand repeated use. They offer good heat retention and can produce a consistent crust. However, the upfront investment is higher compared to disposable options. Maintenance is also a consideration, as these pans require regular cleaning and proper storage. They are best suited for businesses that prioritize quality and are willing to invest time in maintenance.

How Do Pizza Stones Compare as an Alternative Solution?

Pizza stones are favored for their ability to retain heat and create a crispy crust, making them a popular choice among gourmet pizza makers. However, they require a longer preheating time and can be cumbersome to handle due to their weight. While they provide superior cooking results, their maintenance needs can be more demanding, including careful cleaning and occasional seasoning to maintain their surface. Pizza stones are ideal for high-end pizzerias that focus on artisanal pizza preparation but may not be practical for high-volume operations.

How Can B2B Buyers Choose the Right Pizza Preparation Solution?

Selecting the right pizza preparation solution hinges on understanding your business’s specific needs and operational dynamics. For businesses focused on high-volume service with minimal cleanup, disposable pizza pans are often the best choice. Conversely, if quality and consistency are paramount, investing in reusable pizza pans or pizza stones may yield better long-term results. Evaluate your budget, maintenance capabilities, and the desired quality of your pizza offerings to determine which solution aligns best with your operational goals. Making an informed decision will ultimately enhance your service delivery and customer satisfaction.

Essential Technical Properties and Trade Terminology for disposable pizza pans

What Are the Key Technical Properties of Disposable Pizza Pans?

When selecting disposable pizza pans for commercial use, understanding the technical specifications is crucial for ensuring product quality and operational efficiency. Here are some essential properties to consider:

-

Material Grade

– Disposable pizza pans are typically made from aluminum or other food-grade materials. Aluminum pans are favored for their lightweight yet durable nature, ensuring even heat distribution, which is vital for achieving a crispy crust. Buyers should verify the material’s compliance with food safety standards, which is particularly important in regions with strict regulations. -

Thickness

– The thickness of the pan affects its strength and heat retention. Thicker pans (often referred to as “heavy-duty”) are less likely to warp or bend under high temperatures, making them suitable for commercial kitchens where durability is essential. A thicker pan can also provide better insulation, maintaining food temperature for longer periods. -

Size and Shape Variability

– Disposable pizza pans come in various sizes (e.g., 9″, 12″, 14″) and shapes (round, square). This variability allows businesses to cater to different pizza styles and portion sizes, enhancing menu versatility. When sourcing, buyers should consider their specific needs based on customer preferences and serving methods. -

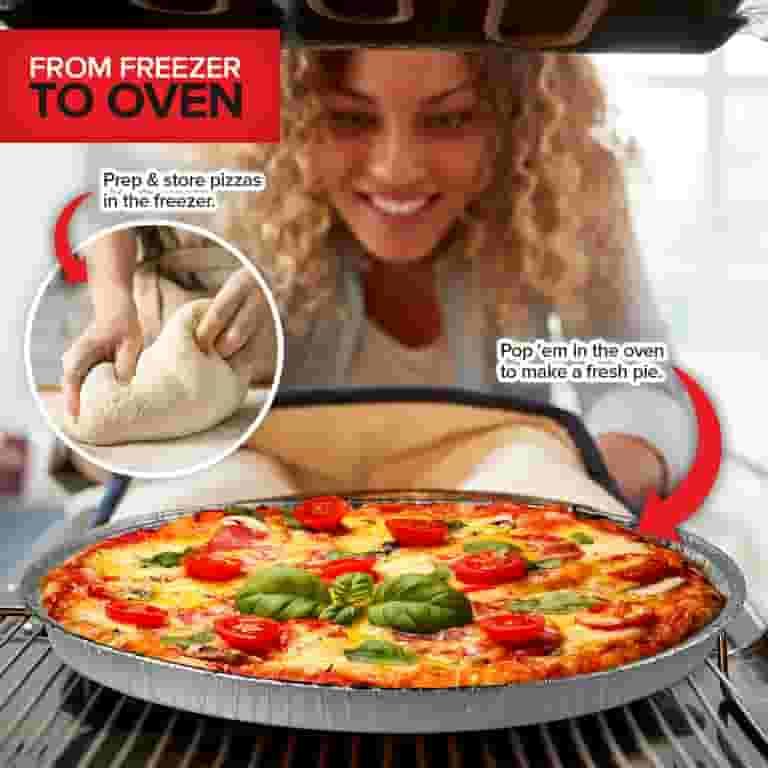

Oven and Freezer Compatibility

– It’s crucial to confirm that the pans can withstand high oven temperatures as well as freezing conditions without compromising structural integrity. This property is particularly relevant for pizzerias that prepare pizzas in advance and store them for later sale. -

Coating and Finish

– Some disposable pizza pans feature non-stick coatings, which facilitate easy food release and simplify cleanup. However, buyers should evaluate whether these coatings are suitable for their cooking methods and if they meet health standards, especially in international markets. -

Recyclability and Environmental Impact

– Increasingly, businesses are considering the environmental impact of their packaging. Sourcing recyclable or biodegradable pizza pans can enhance a company’s sustainability profile, appealing to environmentally conscious consumers.

What Are Common Trade Terms Used in the Disposable Pizza Pan Industry?

Navigating the disposable pizza pan market involves familiarity with specific trade terminology. Here are several key terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce products that are sold under another brand name. Buyers may seek OEM partnerships for customized disposable pizza pans tailored to their brand specifications. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, especially for businesses looking to minimize excess stock. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for specified products. It’s an essential step in the procurement process, allowing buyers to compare offers and negotiate better deals. -

Incoterms (International Commercial Terms)

– These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand shipping costs and logistics, which is critical for managing supply chain operations. -

Lead Time

– Lead time refers to the period between placing an order and receiving the product. Understanding lead times is vital for businesses to manage inventory levels effectively and ensure timely product availability. -

Compliance Standards

– These are regulations that products must meet to be deemed safe for consumer use. Buyers should be aware of local and international compliance standards relevant to disposable pizza pans, especially regarding food safety and environmental regulations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing disposable pizza pans, ensuring they meet operational needs and market expectations.

Navigating Market Dynamics and Sourcing Trends in the disposable pizza pans Sector

What Are the Current Market Dynamics and Key Trends in the Disposable Pizza Pan Sector?

The global market for disposable pizza pans is significantly influenced by evolving consumer preferences, increasing demand for convenience, and the proliferation of food delivery services. Key drivers include the growing popularity of pizza as a quick meal option and the expansion of food service industries across regions, particularly in Africa, South America, the Middle East, and Europe. As urbanization increases, the demand for ready-to-eat meals is propelling the need for disposable packaging solutions, including pizza pans that offer convenience without compromising on quality.

Emerging B2B trends are leaning towards digital transformation in the sourcing process. Buyers are increasingly utilizing online platforms for procurement, allowing for easier comparison of products and prices. Additionally, the introduction of smart inventory management systems is aiding suppliers in optimizing stock levels and reducing waste, which is crucial in a competitive market. B2B buyers are also seeking versatile products that can cater to various pizza styles—ranging from thin crust to deep dish—highlighting the importance of offering a diverse product range.

Furthermore, sustainability is becoming a critical consideration, with companies exploring eco-friendly materials and production processes. This shift not only addresses environmental concerns but also aligns with the values of modern consumers who prefer brands that prioritize sustainability.

How Is Sustainability Impacting the Sourcing of Disposable Pizza Pans?

Sustainability has emerged as a focal point in the disposable pizza pans market, driven by increasing environmental awareness among consumers and businesses alike. The production and disposal of conventional disposable pans often contribute to significant waste, leading to a pressing need for more sustainable alternatives. Manufacturers are responding by introducing products made from biodegradable materials, such as plant-based plastics or recycled aluminum.

Ethical sourcing is equally important, as businesses are now expected to demonstrate transparency in their supply chains. B2B buyers are increasingly prioritizing suppliers who can provide proof of sustainable practices, such as certifications from recognized environmental organizations. These certifications, such as FSC (Forest Stewardship Council) or ISO 14001, indicate a commitment to responsible sourcing and minimal environmental impact.

Investing in ‘green’ materials not only enhances a company’s reputation but also meets the demands of eco-conscious consumers, which can lead to increased sales and customer loyalty. In regions like Europe and the Middle East, where regulatory frameworks around environmental sustainability are stricter, adopting these practices can also help businesses remain compliant and competitive.

What Is the Brief Evolution of Disposable Pizza Pans in the B2B Sector?

The evolution of disposable pizza pans has been marked by significant advancements in materials and manufacturing processes. Initially, these pans were primarily made from basic aluminum, which, while functional, posed challenges in terms of waste management. Over the years, as the food service industry expanded, so did the variety of disposable pans available, with innovations aimed at improving durability and heat retention.

The introduction of eco-friendly materials has transformed the market landscape, appealing to environmentally conscious consumers and businesses. Manufacturers have adapted to changing regulations and consumer expectations by focusing on sustainability, leading to the development of biodegradable and recyclable options. This evolution reflects a broader trend in the food service industry towards convenience, efficiency, and environmental responsibility, establishing disposable pizza pans as a crucial component in modern food preparation and delivery.

Overall, understanding these market dynamics, sustainability considerations, and the historical context can empower B2B buyers to make informed decisions when sourcing disposable pizza pans, ensuring they align with both operational needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of disposable pizza pans

-

How do I choose the right disposable pizza pan for my business?

When selecting a disposable pizza pan, consider factors such as size, material, and intended use. For instance, aluminum pans are lightweight and provide excellent heat conduction, making them ideal for various pizza styles. Evaluate the thickness of the pan; heavier-duty options are preferable for high-heat applications. Additionally, consider your customer base and menu offerings. If you serve a variety of pizza sizes, sourcing a range of pan sizes can enhance your flexibility and efficiency in food preparation. -

What are the benefits of using disposable pizza pans in my restaurant?

Disposable pizza pans offer numerous advantages for restaurants, including reduced cleaning time and labor costs. They eliminate the need for washing and sanitizing, allowing staff to focus on food preparation and customer service. These pans are also lightweight and easy to handle, which can speed up the cooking process. Furthermore, they are often less expensive than traditional pans, contributing to cost savings, especially in high-volume settings. -

What factors should I consider when vetting suppliers for disposable pizza pans?

When vetting suppliers, assess their reliability, product quality, and compliance with international food safety standards. Request samples to evaluate the durability and heat resistance of the pans. Additionally, review their production capabilities to ensure they can meet your demand. Check for certifications and read reviews from other businesses to gauge their reputation. Establishing clear communication regarding pricing, delivery timelines, and after-sales support is also essential. -

Can I customize disposable pizza pans with my branding?

Yes, many suppliers offer customization options for disposable pizza pans, including printing your logo or brand colors. Customization enhances brand visibility and can create a more professional presentation for your customers. However, minimum order quantities (MOQs) may apply, so it’s important to discuss your specific needs with the supplier. Be sure to inquire about lead times for custom orders to ensure they align with your business schedule. -

What are the typical minimum order quantities (MOQs) for disposable pizza pans?

Minimum order quantities for disposable pizza pans vary by supplier and product type. Generally, MOQs can range from a few hundred to several thousand units. Suppliers often set these limits based on production efficiencies and inventory management. It’s advisable to discuss your specific needs with potential suppliers, as some may offer flexibility for first-time buyers or smaller businesses looking to test the market. -

What payment terms should I expect when sourcing disposable pizza pans internationally?

Payment terms for international purchases can vary widely based on the supplier and the nature of the transaction. Common terms include upfront payment, partial payment upon order confirmation, and balance upon shipment. Some suppliers may offer credit terms after establishing a relationship. It’s crucial to negotiate terms that are favorable for your cash flow while ensuring they align with the supplier’s policies. Consider using secure payment methods to protect your transactions. -

How can I ensure the quality of disposable pizza pans I import?

To ensure quality, request samples before placing a large order. Evaluate the material, thickness, and overall construction of the pans. Additionally, inquire about the supplier’s quality assurance processes and any relevant certifications they hold. Consider conducting third-party inspections before shipment, especially for large orders, to verify compliance with your quality standards. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations. -

What logistical considerations should I keep in mind when importing disposable pizza pans?

When importing disposable pizza pans, consider shipping costs, delivery times, and customs regulations in your country. Work with a reliable freight forwarder to navigate international shipping and ensure compliance with local import laws. Be aware of potential tariffs and duties that may apply to your shipment. Additionally, establish a clear timeline for delivery to align with your inventory needs, ensuring you have sufficient stock to meet customer demand.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Disposable Pizza Pans Manufacturers & Suppliers List

1. Target – Durable Disposable Pizza Pans

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Durable Disposable Pizza Pans, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. WebstaurantStore – Commercial Pizza Pans

Domain: webstaurantstore.com

Registered: 2003 (22 years)

Introduction: Commercial Pizza Pans available in various types including Coupe Pans, Cutter / CAR Pans, Deep Dish Pans, Detroit Style Pans, Flatbread Pans, Sicilian Style Pans, and Wide Rim Pans. Materials include Aluminized Steel, Aluminum, Carbon Steel, Galvanized Iron, Hard Anodized Aluminum, Heavy Weight Aluminum, Silver Anodized Aluminum, and Tin Plated Steel. Available shapes: Rectangle, Round, Square. Si…

3. Handi-Foil – 12 Aluminum Foil Pizza Pan

Domain: foil-pans.com

Registered: 2010 (15 years)

Introduction: {‘product_name’: ‘Handi-Foil 12″ Aluminum Foil Pizza Pan’, ‘type’: ‘Disposable Waffle Bottom Baking Sheets’, ‘pack_size’: ’12/PK’, ‘item_number’: ‘319-35-12’, ‘dimensions’: {‘top_out’: ’13″‘, ‘top_in’: ’12 13/32″‘, ‘bottom’: ’12″‘, ‘vertical_depth’: ‘5/8″‘}, ‘capacity_fl_oz’: ‘38.0’, ‘gauge’: ’35’, ‘rim_style’: ‘Full Curl (FC)’, ‘case_cube_ft’: ‘0.5’, ‘ship_weight_lbs’: ‘2.0’, ‘manufacturer’: ‘Han…

4. Reddit – Pizza Crust Tips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: To achieve a good pizza crust in a home oven using an aluminum pan or parchment, consider the following tips: 1. Preheat the pan in the oven before placing the pizza on it. 2. Use a pizza peel to slide the pizza onto the pan for better heat transfer. 3. Consider using a cast iron pan for better results, as it retains heat well. 4. Par-bake the crust before adding toppings to ensure even cooking. 5…

5. D & W Fine Pack – Disposable Aluminum Foil Pizza Pan

Domain: wholesalefoilpans.com

Registered: 2019 (6 years)

Introduction: {“product_name”: “D & W Fine Pack Disposable Aluminum Foil 12″ Pizza Pan”, “case_quantity”: 250, “sku”: “#C81”, “price”: “$75.00”, “original_price”: “$171.00”, “material”: “35 gauge aluminum foil”, “dimensions”: {“top_outside_diameter”: “13””, “top_inside_diameter”: “12⅜””, “bottom_diameter”: “12””, “height”: “⅝””}, “features”: [“Durable construction”, “Versatile use for pizzas, cookies, cinnamon …

6. TVWBB – Disposable Foil Pizza Pans

Domain: tvwbb.com

Registered: 2008 (17 years)

Introduction: Disposable 12″ or 13″ foil pizza pans, used for catching droppings while cooking in a smoker, can be placed on the bottom rack. They are suggested for use alongside a water pan, provided no food is cooked on the bottom rack.

7. GoSolut – Take and Bake Pizza Trays

Domain: gosolut.com

Registered: 2008 (17 years)

Introduction: Take and Bake Pizza Trays:

– Types: Classic black pizza trays and Kraft natural corrugated pizza trays with optional snap-on PET lid.

– Material: Heavy gauge SBS ovenable paperboard with a thin extruded PET layer for black trays; Kraft Eco E-Flute for Kraft trays.

– Features: Ovenable, cut-resistant, leak-proof surface, excellent product visibility, consumer convenience.

– Cooking: Safe for co…

Strategic Sourcing Conclusion and Outlook for disposable pizza pans

As the demand for disposable pizza pans continues to rise globally, strategic sourcing becomes essential for international B2B buyers. Leveraging the convenience of disposable aluminum pans not only enhances operational efficiency but also improves customer satisfaction by simplifying the preparation and cleanup processes. Key considerations in sourcing include evaluating suppliers based on product quality, pricing, and delivery reliability, particularly for markets in Africa, South America, the Middle East, and Europe.

Investing in high-quality disposable pizza pans can lead to significant cost savings and reduced waste, aligning with sustainability goals that are increasingly important to consumers. Moreover, by sourcing from reputable manufacturers, businesses can ensure compliance with food safety standards, which is crucial in maintaining brand reputation in competitive markets.

Looking forward, B2B buyers are encouraged to explore partnerships with manufacturers that offer innovative solutions and customization options. By doing so, they can stay ahead of market trends and meet evolving consumer preferences. Now is the time to act—evaluate your sourcing strategy for disposable pizza pans and position your business for success in the ever-evolving food service landscape.