Everything You Need to Know About Auto Spring Stick Sourcing in 2025

Introduction: Navigating the Global Market for auto spring stick

In today’s dynamic global market, sourcing reliable and high-quality auto spring sticks presents a significant challenge for B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. Whether you’re looking to equip law enforcement agencies, security personnel, or even personal defense enthusiasts, understanding the diverse types of auto spring sticks, their applications, and the nuances of supplier vetting is crucial. This guide is designed to demystify the complexities of the auto spring stick market, providing actionable insights into product specifications, compliance standards, and pricing structures.

As you navigate through this comprehensive resource, you will discover detailed evaluations of various auto spring stick types, including automatic expandable batons and retractable self-defense sticks, along with their specific use cases. We will delve into supplier vetting processes to ensure you partner with reputable manufacturers that meet your quality and safety requirements. Additionally, this guide will provide an overview of cost considerations, helping you make informed purchasing decisions that align with your budget and operational needs.

By equipping yourself with the knowledge contained in this guide, you empower your organization to make strategic procurement choices, ensuring you acquire the best products available on the market. Ultimately, this resource aims to enhance your confidence in sourcing auto spring sticks, facilitating smoother transactions and fostering long-term supplier relationships.

Understanding auto spring stick Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automatic Expandable Baton | Steel construction, one-push deployment, various lengths (16″ – 28″) | Law enforcement, security personnel, self-defense | Pros: Quick deployment, durable; Cons: May require training for effective use. |

| Tactical Spring Baton | Ergonomic design, safety locking mechanism, compact size | Military, personal protection, outdoor activities | Pros: Easy to carry, versatile; Cons: Limited length options. |

| Self-Defense Retractable Stick | Multi-functional (can break glass, defend), lightweight | Emergency services, personal safety, outdoor use | Pros: Versatile, portable; Cons: May not be as intimidating as larger batons. |

| Heavy-Duty Expandable Baton | Increased diameter, designed for impact resistance | Security firms, crowd control, tactical training | Pros: High durability, effective deterrent; Cons: Heavier and bulkier to carry. |

| Compact Tactical Baton | Shorter length (under 20″), designed for discreet carry | Urban law enforcement, personal defense, travel | Pros: Easy to conceal, quick access; Cons: Limited reach and striking power. |

What Are the Key Characteristics of Automatic Expandable Batons?

Automatic expandable batons are primarily made of high-grade steel and feature a one-push deployment mechanism. Their various lengths (commonly ranging from 16 to 28 inches) cater to different user preferences and scenarios, making them popular among law enforcement and security personnel. When purchasing, consider the baton’s weight and construction quality, as these factors influence both usability and effectiveness in self-defense situations.

How Do Tactical Spring Batons Differ from Other Variants?

Tactical spring batons are characterized by their ergonomic design and safety locking mechanism, allowing for secure handling. They are compact, making them suitable for military applications and personal protection. Buyers should evaluate the baton’s ease of use, safety features, and overall versatility for outdoor activities, as these attributes significantly impact their effectiveness in real-world scenarios.

What Makes Self-Defense Retractable Sticks a Versatile Option?

Self-defense retractable sticks are designed for multifunctionality, often capable of breaking glass in emergencies while providing a means for self-defense. Their lightweight and portable nature make them ideal for emergency services and personal safety. When considering a purchase, buyers should assess their intended use and the stick’s durability, ensuring it meets the demands of various outdoor activities.

What Are the Benefits of Heavy-Duty Expandable Batons?

Heavy-duty expandable batons are built with an increased diameter and designed for maximum impact resistance, making them suitable for security firms and crowd control operations. Their high durability provides an effective deterrent in tense situations. Buyers should weigh the baton’s weight and bulkiness against its striking power, as these factors can influence ease of carry and deployment.

Why Choose Compact Tactical Batons for Urban Environments?

Compact tactical batons, typically under 20 inches, are designed for discreet carry, making them ideal for urban law enforcement and personal defense. Their short length allows for quick access and deployment in tight situations. Buyers should consider the baton’s concealability and striking effectiveness, as these elements are crucial for self-defense in densely populated areas.

Key Industrial Applications of auto spring stick

| Industry/Sector | Specific Application of auto spring stick | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Law Enforcement | Tactical self-defense tool for officers | Enhances officer safety and quick response capabilities | Compliance with local laws and regulations |

| Security Services | Personal protection for security personnel | Provides an effective means of self-defense in critical situations | Durability and reliability under various conditions |

| Outdoor Recreation | Personal safety tool for hikers and outdoor enthusiasts | Increases safety during outdoor activities, deterring potential threats | Lightweight design for easy transport |

| Emergency Services | Multi-functional tool for emergency responders | Versatile use in emergencies, including self-defense and rescue operations | Fast deployment and ease of use under pressure |

| Retail and Distribution | Self-defense tool for store employees | Enhances employee safety, deterring theft and aggression | Cost-effectiveness and ease of training for staff |

How is the auto spring stick used in law enforcement, and what benefits does it provide?

In law enforcement, the auto spring stick serves as a tactical self-defense tool for officers. Its quick deployment mechanism allows officers to respond to threats effectively, enhancing their safety during confrontational situations. Given the increasing security concerns globally, especially in regions like Africa and the Middle East, law enforcement agencies prioritize sourcing reliable, durable auto spring sticks that comply with local regulations. Buyers should consider the baton’s construction material and ease of handling to ensure it meets operational requirements.

What role does the auto spring stick play in security services?

Security personnel frequently use auto spring sticks for personal protection, particularly in high-risk environments such as events or vulnerable locations. This tool provides an immediate means of self-defense, helping security staff manage aggressive individuals or potential threats. For international buyers, especially in South America and Europe, it is crucial to evaluate the baton’s effectiveness in various scenarios and ensure that it meets the necessary safety certifications. Sourcing considerations should include the baton’s weight and ease of concealment for discreet carrying.

How does the auto spring stick enhance safety in outdoor recreation?

Outdoor enthusiasts, including hikers and campers, utilize auto spring sticks as personal safety tools. These sticks can deter wildlife encounters or potential human threats, providing a sense of security during outdoor activities. Buyers from regions with diverse terrains, such as Africa and Brazil, should seek lightweight and compact designs that are easy to carry yet robust enough for self-defense. It’s essential to assess the product’s build quality and user-friendliness, particularly for individuals who may not have prior self-defense training.

Why is the auto spring stick essential for emergency services?

In emergency services, the auto spring stick serves multiple functions, including self-defense and aiding in rescue operations. Its robust construction allows responders to use it to break glass or create leverage in challenging situations. For international buyers, particularly in the Middle East where emergencies can vary significantly, the baton’s reliability and quick deployment feature are critical. Sourcing decisions should focus on the baton’s versatility and the ability to withstand harsh conditions often encountered in emergency scenarios.

What advantages does the auto spring stick offer in retail and distribution environments?

In retail environments, the auto spring stick provides employees with a self-defense option against theft or aggression. This tool not only enhances employee safety but also serves as a deterrent to would-be offenders. Retailers, especially in high-crime areas, should prioritize sourcing auto spring sticks that are cost-effective and easy to train employees on. The balance between affordability and effectiveness is crucial, ensuring that staff can respond confidently to potential threats while maintaining a safe shopping environment.

3 Common User Pain Points for ‘auto spring stick’ & Their Solutions

Scenario 1: Difficulty in Product Sourcing and Quality Assurance

The Problem: For international B2B buyers, particularly in regions like Africa and South America, sourcing reliable suppliers for auto spring sticks can be challenging. Many suppliers may offer products that appear similar but vary significantly in quality, durability, and compliance with safety regulations. Buyers often face the dilemma of balancing cost with quality assurance, which can lead to potential safety risks and financial losses.

The Solution: To navigate this challenge, B2B buyers should prioritize establishing relationships with reputable manufacturers or distributors known for their quality standards. Conducting thorough market research is essential; utilize platforms like Alibaba or ThomasNet to compare suppliers and check their ratings and reviews. Additionally, consider requesting samples before making bulk purchases to evaluate the product firsthand. It’s also advisable to verify that the suppliers comply with international safety standards, such as ISO certifications, to ensure that the auto spring sticks meet the necessary quality benchmarks. Creating a checklist of must-have features, such as material specifications and safety locking mechanisms, can further streamline the sourcing process.

Scenario 2: Concerns Over Deployment Reliability and User Training

The Problem: A frequent concern among organizations purchasing auto spring sticks—especially for self-defense applications—is the reliability of deployment in high-stress situations. Many users, including security personnel and law enforcement, may be unfamiliar with the operation of these tools, leading to hesitation and improper usage when it matters most. This can result in ineffective defense strategies, compromising safety.

The Solution: To address deployment reliability, organizations should invest in comprehensive training programs that educate users on the proper handling and operation of auto spring sticks. This includes practical demonstrations on how to activate the spring mechanism quickly and safely. Regular training sessions and simulations can build confidence and ensure that users are well-prepared for real-life scenarios. Additionally, manufacturers should provide detailed user manuals and instructional videos that outline operational procedures and safety tips. Consider also integrating the auto spring stick into broader self-defense training modules to reinforce its role as an effective tool in emergency situations.

Scenario 3: Ensuring Product Maintenance and Longevity

The Problem: B2B buyers may struggle with the maintenance of auto spring sticks, particularly in harsh environments or when used frequently. Issues such as rusting, failure of the spring mechanism, and wear and tear can significantly reduce the lifespan of these tools, leading to unexpected replacement costs and potential liability issues if a device fails during use.

The Solution: To enhance the longevity of auto spring sticks, buyers should implement a routine maintenance schedule that includes regular inspections and cleaning. Establish protocols for checking the functionality of the spring mechanism and ensuring that the locking mechanisms are working correctly. Using appropriate lubricants can help prevent rust and maintain smooth operation, especially in humid or corrosive environments. Additionally, buyers should educate users on proper storage practices to protect the sticks from environmental damage. Investing in durable carrying cases that shield the tools from impact and moisture can also prolong their lifespan. By proactively addressing maintenance, organizations can minimize downtime and enhance the reliability of their self-defense resources.

Strategic Material Selection Guide for auto spring stick

What Are the Key Materials Used in Auto Spring Sticks?

When selecting materials for auto spring sticks, it’s essential to consider factors such as performance, durability, cost, and compliance with international standards. Here, we analyze four common materials used in the manufacturing of auto spring sticks: stainless steel, aluminum, carbon fiber, and reinforced plastic. Each material has distinct properties that influence its suitability for various applications, especially in the context of international B2B markets.

How Does Stainless Steel Perform in Auto Spring Stick Applications?

Stainless steel is a popular choice for auto spring sticks due to its excellent strength and corrosion resistance. Key properties include a high tensile strength and the ability to withstand extreme temperatures, making it suitable for various environments. The pros of stainless steel include its durability and resistance to rust, which is crucial for outdoor applications. However, it can be heavier than other materials, potentially affecting portability.

From a B2B perspective, stainless steel is often compliant with international standards like ASTM A240, ensuring quality and reliability. Buyers in regions like Europe and the Middle East may prefer stainless steel for its proven performance in harsh conditions. However, the higher cost of stainless steel compared to alternatives may be a consideration for budget-conscious buyers.

What Are the Advantages of Aluminum in Auto Spring Sticks?

Aluminum is another common material used in auto spring sticks, known for its lightweight nature and good corrosion resistance. Key properties include a lower density than stainless steel, which enhances portability without significantly sacrificing strength. The advantages of aluminum include its cost-effectiveness and ease of manufacturing, allowing for complex designs and rapid production.

However, aluminum may not offer the same level of durability as stainless steel, particularly under high-impact conditions. For international buyers, compliance with standards such as ASTM B221 is crucial. In regions like Africa and South America, where weight and cost are significant factors, aluminum may be the preferred choice despite its limitations in extreme durability.

How Does Carbon Fiber Compare in Auto Spring Stick Manufacturing?

Carbon fiber is increasingly being used in high-performance applications, including auto spring sticks, due to its exceptional strength-to-weight ratio. This material is lightweight, rigid, and offers excellent resistance to corrosion and fatigue. The primary advantage of carbon fiber is its ability to provide a high level of performance while remaining lightweight, making it ideal for applications requiring agility.

However, carbon fiber tends to be more expensive than both stainless steel and aluminum, which may limit its use in budget-sensitive markets. Additionally, the manufacturing process can be more complex, requiring specialized equipment and techniques. For international buyers, especially in Europe, adherence to standards like ISO 13019 for composite materials is essential, and the higher cost may necessitate justification through enhanced performance.

What Role Does Reinforced Plastic Play in Auto Spring Sticks?

Reinforced plastic, often a composite material, is gaining traction in the auto spring stick market due to its lightweight and corrosion-resistant properties. Key advantages include lower manufacturing costs and the ability to mold complex shapes easily. Reinforced plastic is also non-conductive, making it safer in certain environments.

On the downside, reinforced plastic may not provide the same level of impact resistance as metals, which could be a concern in high-stress applications. Compliance with standards such as ASTM D638 for plastics is important for international buyers. In regions like South America and Africa, where cost and weight are critical, reinforced plastic can be an attractive option, provided that performance requirements are met.

Summary of Material Selection for Auto Spring Sticks

| Material | Typical Use Case for auto spring stick | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Tactical and law enforcement applications | Excellent strength and corrosion resistance | Heavier, higher cost | High |

| Aluminum | Everyday carry and recreational use | Lightweight and cost-effective | Less durable under impact | Medium |

| Carbon Fiber | High-performance tactical applications | Exceptional strength-to-weight ratio | High cost and complex manufacturing | High |

| Reinforced Plastic | General use and non-tactical applications | Lightweight and easy to mold | Lower impact resistance | Low |

This guide provides a comprehensive overview of materials used in auto spring sticks, helping international B2B buyers make informed decisions based on performance, cost, and compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for auto spring stick

What Are the Key Stages in the Manufacturing Process of Auto Spring Sticks?

The manufacturing of auto spring sticks involves several critical stages, each designed to ensure the final product meets high-quality standards. Understanding these stages can help B2B buyers make informed purchasing decisions.

1. Material Preparation

The first step in manufacturing auto spring sticks is the selection and preparation of raw materials. Typically, high-grade steel or aluminum alloys are used for their strength, durability, and lightweight properties. The materials undergo processes such as cutting and shaping to prepare them for further processing. Quality control begins here, with initial inspections to verify material integrity and compliance with international standards.

2. Forming Techniques

Once the materials are prepared, the next phase involves forming the components of the auto spring stick. This may include:

- Stamping and Forging: These techniques shape the metal into the required forms, ensuring that each piece maintains the necessary specifications for strength and durability.

- Machining: Precision machining is utilized to create the internal mechanisms that allow for the automatic expansion and retraction of the stick. This process often involves CNC (Computer Numerical Control) machines for high accuracy.

3. Assembly Process

The assembly stage is crucial as it brings together all individual components. Skilled technicians perform this task to ensure that each auto spring stick operates flawlessly. Key steps include:

- Integrating the Spring Mechanism: The spring-loaded mechanism is carefully installed, requiring precise alignment to ensure smooth operation.

- Ergonomic Assembly: Handles are attached, often designed with a focus on user comfort and ease of use. This stage may also involve the integration of safety features to prevent accidental deployment.

4. Finishing Touches

Finishing processes enhance both the appearance and functionality of the auto spring sticks. Common finishing techniques include:

- Surface Treatment: Processes such as anodizing or powder coating are applied to prevent corrosion and enhance aesthetic appeal. These treatments also add an extra layer of durability.

- Final Inspection: Each unit undergoes a thorough inspection to identify any defects or inconsistencies before packaging.

What Quality Assurance Measures Are Essential for Auto Spring Sticks?

Quality assurance is a vital aspect of the manufacturing process, ensuring that the final products meet the required standards of safety and performance. Here are the key elements of quality control for auto spring sticks.

Relevant International Standards to Consider

B2B buyers should be aware of the international standards that govern the quality of auto spring sticks. Some of the most relevant include:

- ISO 9001: This standard focuses on quality management systems and is critical for manufacturers aiming to demonstrate their commitment to quality.

- CE Marking: Particularly important for products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For products used in specific industries, such as oil and gas, compliance with API (American Petroleum Institute) standards may also be necessary.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are essential throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify issues as they arise.

- Final Quality Control (FQC): A comprehensive inspection of the finished products ensures they are free of defects and function as intended.

Common Testing Methods for Quality Assurance

Testing methods play a crucial role in quality assurance. Typical tests for auto spring sticks may include:

- Mechanical Testing: This includes tensile strength tests to ensure the materials can withstand the forces they will encounter in use.

- Functional Testing: Each auto spring stick should be tested for its expanding and retracting mechanism to confirm reliable performance.

- Durability Testing: Products may undergo tests simulating real-world conditions to evaluate their longevity and resilience.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying the quality control practices of suppliers is essential to mitigate risks associated with product quality. Here are some actionable steps:

Conducting Supplier Audits

Performing on-site audits can provide insights into a supplier’s manufacturing processes and quality assurance measures. This involves reviewing their production lines, quality control checkpoints, and compliance with international standards.

Requesting Quality Control Reports

B2B buyers should request detailed QC reports from suppliers, which should include results from various testing methods and inspections. These reports provide transparency and help buyers assess the reliability of the supplier.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can further enhance confidence in the supplier’s quality control processes. These independent entities can conduct thorough inspections and audits to ensure compliance with agreed-upon standards.

What Are the Quality Control Nuances for International Buyers?

When purchasing auto spring sticks from international suppliers, buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances that may affect quality control:

- Cultural Differences in Quality Expectations: Different regions may have varying standards for quality and performance. Buyers should establish clear expectations upfront.

- Understanding Local Regulations: Buyers should familiarize themselves with local regulations that may affect product compliance, especially when importing goods.

- Logistical Considerations: The shipping process can impact product quality. Buyers should verify that suppliers have robust systems in place to protect products during transport.

In conclusion, understanding the manufacturing processes and quality assurance measures for auto spring sticks can empower B2B buyers to make informed decisions. By focusing on the key stages of production, relevant standards, and effective verification methods, buyers can enhance their procurement strategies and ensure they receive high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘auto spring stick’

When sourcing auto spring sticks, also known as expandable batons, it is essential to follow a structured approach to ensure that you select high-quality products that meet your needs. This guide provides a step-by-step checklist to help you navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for the auto spring sticks you intend to procure. Consider factors such as length, weight, material composition, and mechanism type.

– Length Options: Different lengths (e.g., 16”, 21”, 26”) serve various purposes, from personal defense to law enforcement use.

– Material: Look for high-grade steel or durable alloys that offer strength and reliability.

Step 2: Research Market Trends and Compliance Standards

Understanding the current market trends is vital to making informed purchasing decisions. Research regulations and compliance standards relevant to your region, as these can vary significantly.

– Legal Compliance: Ensure that the products meet local laws regarding self-defense weapons to avoid legal issues.

– Market Demand: Knowing what features are trending can help you choose products that will appeal to your target audience.

Step 3: Identify and Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specifications and provide reliable products.

– Company Background: Request information about the supplier’s history, customer base, and reputation in the industry.

– Certifications: Verify that suppliers hold relevant certifications, such as ISO standards, which indicate adherence to quality management systems.

Step 4: Request Samples for Quality Assessment

Before placing a large order, it’s prudent to request samples of the auto spring sticks. This step allows you to evaluate the quality and functionality firsthand.

– Testing: Assess the ease of deployment, durability, and overall feel of the product to ensure it meets your expectations.

– Feedback: If possible, involve a focus group of potential users to gather feedback on the samples.

Step 5: Negotiate Pricing and Terms

Once you have identified suitable suppliers and assessed product quality, engage in negotiations to secure favorable pricing and terms.

– Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

– Payment Terms: Discuss payment options and terms to ensure they align with your budget and cash flow requirements.

Step 6: Assess Logistics and Shipping Options

Consider the logistics involved in transporting the auto spring sticks to your location. Efficient logistics can impact your overall cost and delivery time.

– Shipping Times: Understand the estimated shipping times and how they align with your inventory needs.

– Customs Regulations: Be aware of any import regulations or tariffs that may apply, especially when sourcing from international suppliers.

Step 7: Establish a Quality Control Process

Implement a quality control process to ensure that all products received meet your specifications and standards.

– Inspection Protocols: Develop a checklist for inspecting products upon arrival, focusing on dimensions, material quality, and functionality.

– Feedback Loop: Create a system for ongoing feedback from users to continuously improve your procurement strategy.

By following this checklist, you can streamline the sourcing process for auto spring sticks, ensuring that you select products that meet your business needs while adhering to quality and compliance standards.

Comprehensive Cost and Pricing Analysis for auto spring stick Sourcing

What Are the Key Cost Components for Sourcing Auto Spring Sticks?

When considering the cost structure for sourcing auto spring sticks, several components come into play. Materials are a significant part of the cost, with high-grade steel often being used for durability and reliability. The choice of material can significantly influence both the initial cost and the performance of the final product.

Labor costs also contribute to the overall expense, particularly in regions where skilled labor is required for manufacturing processes. This includes assembly, quality control, and any specialized tasks involved in production.

Manufacturing overhead encompasses all indirect costs associated with production, such as utilities, factory rent, and administrative expenses. Tooling costs, which involve the equipment used to manufacture the auto spring sticks, can also be substantial, especially for custom designs.

Quality control (QC) is another critical cost component. Ensuring that each batch meets safety and performance standards involves rigorous testing and inspection, adding to the overall expense.

Finally, logistics costs related to transportation, warehousing, and distribution must be factored in, particularly for international shipments. These costs can vary widely based on the shipping method and distance.

What Influences the Pricing of Auto Spring Sticks in the B2B Market?

Several factors play a crucial role in determining the pricing of auto spring sticks. Volume and minimum order quantities (MOQ) significantly impact unit costs. Suppliers often provide discounts for larger orders, making it essential for buyers to evaluate their needs accurately.

Specifications and customization are other price influencers. Tailoring the product to meet specific requirements, such as size, finish, or additional features, can increase the cost. Buyers should weigh the benefits of customization against the additional expense.

The quality and certifications of the materials used also affect pricing. Products that meet international safety standards or have certifications are likely to command a higher price due to the assurance of reliability and safety.

Supplier factors, including reputation, experience, and location, can also influence costs. Established suppliers may charge a premium for their expertise and reliability. Understanding the supplier landscape in different regions, such as Africa, South America, the Middle East, and Europe, can provide insights into potential pricing variations.

Lastly, Incoterms dictate the responsibilities of buyers and sellers in international transactions, impacting the total cost. Familiarity with these terms can help buyers avoid unexpected charges.

How Can Buyers Negotiate Cost-Effective Pricing for Auto Spring Sticks?

Negotiation is a key strategy for achieving cost-effective pricing. Buyers should approach negotiations with a clear understanding of their desired specifications and the market price range. Gathering multiple quotes can provide leverage in discussions with suppliers.

Consider the Total Cost of Ownership (TCO) rather than just the purchase price. This includes costs associated with shipping, handling, and potential maintenance over time. Evaluating the TCO can lead to more informed purchasing decisions that consider long-term value.

When sourcing internationally, buyers should be aware of pricing nuances specific to their region. For instance, tariffs, taxes, and exchange rates can significantly impact the final cost. Engaging with local experts or consultants can provide valuable insights into these regional factors.

It’s also beneficial to establish long-term relationships with suppliers. Building rapport can lead to better pricing, more flexible terms, and improved service. Suppliers often value loyalty and may be willing to negotiate terms for repeat business.

Disclaimer on Indicative Prices for Auto Spring Sticks

While the pricing information discussed provides a comprehensive overview, it is essential to note that prices for auto spring sticks can vary significantly based on the factors mentioned above. Buyers are encouraged to conduct thorough market research and engage with suppliers directly to obtain accurate and current pricing tailored to their specific needs.

Alternatives Analysis: Comparing auto spring stick With Other Solutions

Understanding Alternative Solutions to Auto Spring Sticks

In the realm of self-defense tools, the auto spring stick has carved out a niche for its reliability and ease of use. However, it is essential for B2B buyers to consider other available options that may better suit specific needs or preferences. This analysis will compare the auto spring stick against two viable alternatives: traditional expandable batons and retractable self-defense sticks.

Comparison Table

| Comparison Aspect | Auto Spring Stick | Traditional Expandable Baton | Retractable Self-Defense Stick |

|---|---|---|---|

| Performance | Quick deployment; effective for self-defense | Reliable with manual extension; effective in various scenarios | Versatile; suitable for both defense and outdoor activities |

| Cost | Moderate ($24.95 – $69.95) | Moderate ($31.95 – $49.95) | Affordable ($24.95 – $69.95) |

| Ease of Implementation | User-friendly; simple button mechanism | Requires practice for effective use | Easy to use; quick deployment with a button |

| Maintenance | Minimal; durable materials | Low; requires occasional checks | Low; designed for rugged use |

| Best Use Case | Personal self-defense; compact for everyday carry | Law enforcement; security personnel | Outdoor activities; emergency preparedness |

Pros and Cons of Each Alternative

Traditional Expandable Baton

Traditional expandable batons, often used by law enforcement, are reliable self-defense tools that require a flick of the wrist for extension. Their construction typically involves strong steel, providing durability and effectiveness in various situations. However, the manual deployment may require practice to master, which could be a downside for less experienced users. Additionally, while they are effective for defense, their bulkiness may limit everyday carry options.

Retractable Self-Defense Stick

Retractable self-defense sticks serve dual purposes, functioning as both a walking aid and a self-defense tool. With automatic spring-loaded mechanisms, they are designed for rapid deployment, making them user-friendly. This versatility appeals to a broader market, especially among outdoor enthusiasts. However, their dual nature may dilute their effectiveness specifically for self-defense compared to dedicated options like the auto spring stick or traditional batons. Furthermore, while they are often affordable, the quality may vary significantly across brands.

Making the Right Choice for Your Needs

When selecting the appropriate self-defense solution, B2B buyers must assess their unique requirements. Consider the context in which the tool will be used—whether for personal safety, law enforcement, or outdoor activities. The auto spring stick offers quick deployment and ease of use, making it an excellent choice for personal self-defense. Traditional expandable batons are ideal for professionals in security roles who require a robust tool for various scenarios. Meanwhile, retractable self-defense sticks can serve multiple functions, appealing to those who value versatility.

Ultimately, understanding the strengths and limitations of each option will empower buyers to make informed decisions that best align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for auto spring stick

What Are the Key Technical Properties of Auto Spring Sticks?

When considering the purchase of auto spring sticks, understanding their technical specifications is crucial for making informed decisions. Here are some essential properties to keep in mind:

1. Material Grade

Auto spring sticks are typically constructed from high-grade materials such as steel or aluminum. Steel offers superior strength and durability, making it ideal for self-defense applications. Aluminum, on the other hand, is lightweight and resistant to corrosion, which is beneficial for portability. Choosing the right material impacts both performance and longevity, making it a critical factor in B2B negotiations.

2. Length and Expandability

The length of an auto spring stick can vary, commonly ranging from 16 to 28 inches when fully extended. The expandability mechanism should allow for rapid deployment, often achieved through a spring-loaded design. This feature is essential for users requiring immediate access to the stick for self-defense or tactical situations. Buyers should evaluate the length options based on intended use cases and storage capabilities.

3. Weight

The weight of an auto spring stick is another vital specification, typically under 1.5 pounds. A lightweight design enhances maneuverability and ease of carry, making it suitable for everyday use. For B2B buyers, understanding weight specifications is important, especially for law enforcement or security personnel who may need to carry multiple units for extended periods.

4. Safety Features

Safety mechanisms, such as locking systems that prevent accidental discharge, are crucial in the design of auto spring sticks. These features ensure that the baton remains secure when not in use and prevents unintended deployment. B2B buyers should prioritize products with robust safety features to minimize liability and enhance user confidence.

5. Durability and Impact Resistance

Durability is often measured by the baton’s ability to withstand impacts and wear over time. Products made from impact-resistant materials are preferable, as they ensure reliability during critical situations. Understanding the durability specifications can help businesses choose products that offer long-term value and reduce replacement costs.

6. Finish and Coating

The finish of the auto spring stick, whether anodized, powder-coated, or chrome-plated, plays a role in corrosion resistance and aesthetic appeal. A well-finished product not only looks professional but also contributes to the longevity of the equipment. B2B buyers should assess the finish options based on their market preferences and operational environments.

What Are Common Trade Terms Associated with Auto Spring Sticks?

Familiarizing oneself with industry terminology can facilitate smoother transactions and negotiations. Here are several key terms relevant to the auto spring stick market:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce products or components that are then marketed by another company under its brand. In the context of auto spring sticks, knowing the OEM can help buyers assess quality and reliability. It’s essential for B2B buyers to evaluate OEM partnerships to ensure they are sourcing from reputable manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for budget management and inventory planning. B2B buyers should negotiate MOQs to align with their operational needs while ensuring they receive competitive pricing.

3. RFQ (Request for Quotation)

An RFQ is a formal document requesting price quotes from suppliers. This process allows buyers to compare prices and terms from various manufacturers. B2B buyers should prepare comprehensive RFQs that include specifications and quantities to receive accurate quotes.

4. Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms is essential for B2B buyers to understand shipping responsibilities, costs, and risks involved in transporting auto spring sticks.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the goods. This term is critical for planning inventory and ensuring timely delivery to customers. B2B buyers should inquire about lead times during negotiations to manage expectations effectively.

6. Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and performance of the product. Understanding warranty terms can help B2B buyers mitigate risks associated with product defects and ensure long-term satisfaction with their purchases.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that align with their operational requirements and market expectations.

Navigating Market Dynamics and Sourcing Trends in the auto spring stick Sector

What Are the Current Trends Shaping the Global Auto Spring Stick Market?

The auto spring stick market is experiencing significant growth driven by various global factors. Increased urbanization and rising safety concerns have led to a surge in demand for self-defense tools, particularly in regions such as Africa, South America, the Middle East, and Europe. In these markets, the growing awareness of personal safety and security has motivated both individuals and law enforcement agencies to seek reliable self-defense products.

Emerging technologies are also reshaping the sourcing landscape. The adoption of e-commerce platforms has made it easier for international B2B buyers to access a diverse range of products quickly and efficiently. Additionally, advancements in manufacturing techniques, such as automated production lines and quality control systems, ensure that products meet stringent safety and durability standards. As consumers become more discerning, suppliers are increasingly focused on providing detailed product specifications, certifications, and customer reviews to build trust and credibility.

Another notable trend is the emphasis on customization. International buyers are looking for suppliers who can provide tailored solutions that meet specific regional needs, whether it involves varying sizes, materials, or functionalities. This trend is particularly pronounced in markets like Germany and Brazil, where consumer preferences can differ significantly.

How Is Sustainability Influencing Sourcing Practices for Auto Spring Sticks?

Sustainability is becoming a critical concern for B2B buyers in the auto spring stick sector. The environmental impact of manufacturing processes and materials used in these products is under scrutiny. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, such as using recycled materials and minimizing carbon footprints in their operations.

Ethical sourcing is another vital consideration. Companies are more likely to engage with suppliers who adhere to fair labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and Fair Trade can enhance a supplier’s appeal, providing assurance that products are sourced responsibly.

Moreover, the demand for “green” certifications is on the rise. Buyers are looking for products made from sustainable materials, such as biodegradable plastics or responsibly sourced metals. This not only aligns with corporate social responsibility goals but also appeals to consumers who are increasingly making purchasing decisions based on environmental considerations.

How Has the Auto Spring Stick Market Evolved Over Time?

The auto spring stick has evolved significantly since its inception. Initially designed for law enforcement and military use, it has transitioned into a mainstream self-defense tool for civilians. The introduction of automatic expansion mechanisms has enhanced usability, allowing for quick deployment in emergency situations.

As safety concerns have escalated globally, particularly in urban environments, the auto spring stick has gained traction as a practical self-defense solution. This shift has prompted manufacturers to innovate continuously, focusing on ergonomic designs, lightweight materials, and multifunctional capabilities. Today, these tools are not only seen as weapons but also as essential safety devices for outdoor activities and everyday situations, reflecting broader trends in personal security and public safety.

In conclusion, understanding these dynamics—market trends, sustainability, and historical evolution—will empower international B2B buyers to make informed sourcing decisions in the auto spring stick sector, aligning with both consumer expectations and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of auto spring stick

-

How do I choose the right auto spring stick for my business needs?

Selecting the right auto spring stick involves evaluating the intended use, required durability, and size specifications. Consider factors such as whether the baton will be used for personal defense, law enforcement, or security purposes. Assess the materials used in the construction—high-grade steel is often preferred for its durability. Additionally, check if the baton offers features like an ergonomic design for better grip and quick deployment mechanisms. It’s advisable to request samples from suppliers to ensure the product meets your expectations before placing a bulk order. -

What are the key features to look for in an auto spring stick?

Key features to consider include the material quality, length options, weight, and deployment mechanism. High-quality steel construction ensures strength and longevity, while various lengths (typically ranging from 16 to 28 inches) cater to different user preferences. A reliable spring mechanism for rapid expansion and a safety locking feature to prevent accidental discharge are essential. Additionally, consider ergonomic design elements for comfort during use, as well as any additional functionalities, such as integrated flashlights or tactical grips. -

What are the minimum order quantities (MOQ) for auto spring sticks?

Minimum order quantities can vary significantly between suppliers, often ranging from 50 to 500 units. It’s crucial to inquire about MOQs directly with potential suppliers, as they may offer flexibility based on your business needs or future purchasing potential. Some manufacturers may also provide tiered pricing based on order size, so understanding the MOQ can help you negotiate better terms and optimize your inventory investment. -

How do I vet suppliers for auto spring sticks in international trade?

To vet suppliers effectively, start by researching their business history, customer reviews, and industry reputation. Verify certifications and compliance with international safety standards, particularly if you are sourcing from regions with less stringent regulations. Request references from other businesses that have sourced similar products. Engaging in direct communication to discuss your specific needs and assessing their responsiveness can also provide insights into their reliability and professionalism. -

What payment terms should I expect when sourcing auto spring sticks internationally?

Payment terms can vary based on the supplier’s policies and your negotiation. Common terms include a deposit upfront (typically 30-50%) with the balance payable upon shipment or delivery. Some suppliers might offer letters of credit or escrow services for added security. It’s essential to clarify these terms before finalizing orders to ensure smooth transactions. Be aware of any additional costs related to currency exchange rates, tariffs, or international shipping fees. -

What quality assurance measures should I consider when sourcing auto spring sticks?

Implementing quality assurance measures involves several steps, including specifying quality standards in your purchase agreement and requesting samples for inspection. Suppliers should provide certificates of compliance or test reports that demonstrate adherence to safety and performance standards. Regular communication during the manufacturing process and an agreed-upon inspection phase before shipment can help ensure that the products meet your specifications and reduce the risk of receiving defective items. -

How can I handle logistics for importing auto spring sticks into my region?

Efficient logistics management starts with understanding the shipping regulations of your destination country, including customs clearance processes and import duties. Collaborate with freight forwarders who specialize in international shipping to ensure compliance and streamline the shipping process. It’s also advisable to consider shipping insurance to protect your investment during transit. Regularly tracking shipments and maintaining communication with your supplier can help mitigate delays and ensure timely delivery. -

What are the best practices for marketing auto spring sticks in my region?

Effective marketing of auto spring sticks involves understanding your target audience’s needs, such as security concerns and preferences for self-defense products. Utilize digital marketing strategies, including SEO-optimized content, social media campaigns, and targeted ads to reach potential buyers. Establish partnerships with local distributors or retailers to expand your reach. Highlight unique selling points like product quality, safety features, and compliance with local regulations to differentiate your offerings in a competitive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Auto Spring Stick Manufacturers & Suppliers List

1. Police Force – Tactical Automatic Expandable Batons

Domain: thehomesecuritysuperstore.com

Registered: 2010 (15 years)

Introduction: Automatic Expandable Batons are designed for easy use and reliability. They extend automatically with a push of a handle-mounted button. Available products include:

1. Police Force Tactical Automatic Expandable Steel Baton 21″ – $35.99

2. Police Force Tactical Automatic Expandable Steel Baton 26″ – $39.95

3. Police Force Tactical Automatic Expandable Steel Baton 16″ – $31.95

4. Streetwise Auto…

2. Stealth Angel – Self Defense Stick Pro

Domain: stealthangelsurvival.com

Registered: 2017 (8 years)

Introduction: Product Name: Self Defense Stick Pro Retractable for Walking Hiking Stealth Angel Survival

Price: $24.95 (originally $69.95, save $45.00)

Availability: In Stock (2 Sizes available)

Sizes: 16 Inches – $24.95, 21 Inches – $29.95, 26 Inches – Sold Out

Shipping: Typically ships within 24 hours, free shipping on orders over $99

Features:

– Versatile tool for safety during outdoor activities

– Automati…

3. TBO Tech – Spring Baton

Domain: tbotech.com

Registered: 2000 (25 years)

Introduction: Product Name: Spring Baton

Item Code: PF21NGAB

Price: $49.95

Sizes Available: 16 Inch (PF16NGAB – $39.95), 21 Inch (PF21NGAB – $49.95)

In Stock: Yes

Automatic Extension: Yes, expands with a simple press

16 Inch Size: 7.5 inches (closed) to 16 inches (fully extended)

21 Inch Size: 9.25 inches (closed) to 20.75 inches (fully extended)

Weight: 21 Inch – 18.9 oz (19.7 oz with holster and lanyard)

Hand…

4. Karatemart – Spring-Loaded Expandable Baton

Domain: karatemart.com

Registered: 1996 (29 years)

Introduction: Product Name: Spring-Loaded Expandable Baton (20.5″)

Price: $44.95

Dimensions: Expands from 9 1/2″ to 20 1/2″

Weight: Under 1 1/4 pounds

Features:

– Automatic tactical baton with spring-loaded trigger for quick deployment.

– Compact and lightweight for easy concealment and carry.

– Safety locking mechanism to prevent accidental discharge.

– Durable steel construction for impact resistance.

– Rubbe…

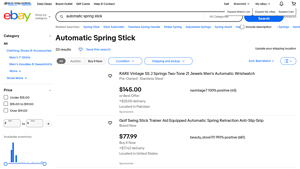

5. Automatic Spring Stick – Various Conditions Available

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Automatic Spring Stick available in various conditions (New: 1,976 items, Used: 31 items). Price range varies, with listings starting around $13.99. Free shipping options available. Items located in the United States and China. Some listings include features like automatic spring retraction and anti-slip grip. Multiple sellers with positive ratings.

Strategic Sourcing Conclusion and Outlook for auto spring stick

What Are the Key Takeaways for B2B Buyers of Auto Spring Sticks?

In summary, the strategic sourcing of auto spring sticks presents a myriad of opportunities for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. These self-defense tools are not only practical but also versatile, catering to various markets such as law enforcement, personal safety, and outdoor activities. As demand for reliable and efficient self-defense products continues to rise, understanding the nuances of product quality, material durability, and ergonomic design becomes crucial for informed purchasing decisions.

How Can Strategic Sourcing Enhance Your Procurement Process?

Investing in strategic sourcing enables businesses to streamline their procurement processes, ensuring access to high-quality auto spring sticks at competitive prices. Establishing relationships with reputable suppliers can lead to better pricing structures, improved product availability, and enhanced customer support. This strategic approach not only mitigates risk but also positions companies to respond swiftly to market changes.

What Should International Buyers Consider for Future Purchases?

As you look ahead, consider the evolving landscape of self-defense products and the potential for innovation within the auto spring stick market. Engage with suppliers who prioritize quality and sustainability, and remain vigilant about market trends that may influence your sourcing strategies. By doing so, you can ensure that your business remains competitive and well-equipped to meet customer demands in an ever-changing environment.