Cvc Camouflage Printed Fabric: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for cvc camouflage printed fabric

In the complex landscape of global textile sourcing, finding high-quality CVC camouflage printed fabric presents a unique challenge for B2B buyers. As industries increasingly demand functional and aesthetically appealing materials, understanding the nuances of CVC (chiefly a blend of 50% cotton and 50% polyester) is crucial. This guide serves as an essential resource for international buyers from regions such as Africa, South America, the Middle East, and Europe, including emerging markets like Nigeria and Vietnam.

Within these pages, we delve into various types of CVC camouflage fabrics, exploring their diverse applications in military uniforms, workwear, and outdoor apparel. Additionally, we provide insights into supplier vetting processes, ensuring that buyers can identify reliable manufacturers who meet their quality standards and ethical sourcing requirements. Cost considerations are thoroughly examined, empowering businesses to make informed decisions that align with their budget constraints and market expectations.

By equipping B2B buyers with the knowledge needed to navigate the intricacies of sourcing CVC camouflage printed fabric, this guide aims to facilitate successful partnerships and enhance product offerings. Whether you are looking to expand your inventory or seeking innovative materials for specific applications, this comprehensive resource will support your strategic sourcing efforts in the global marketplace.

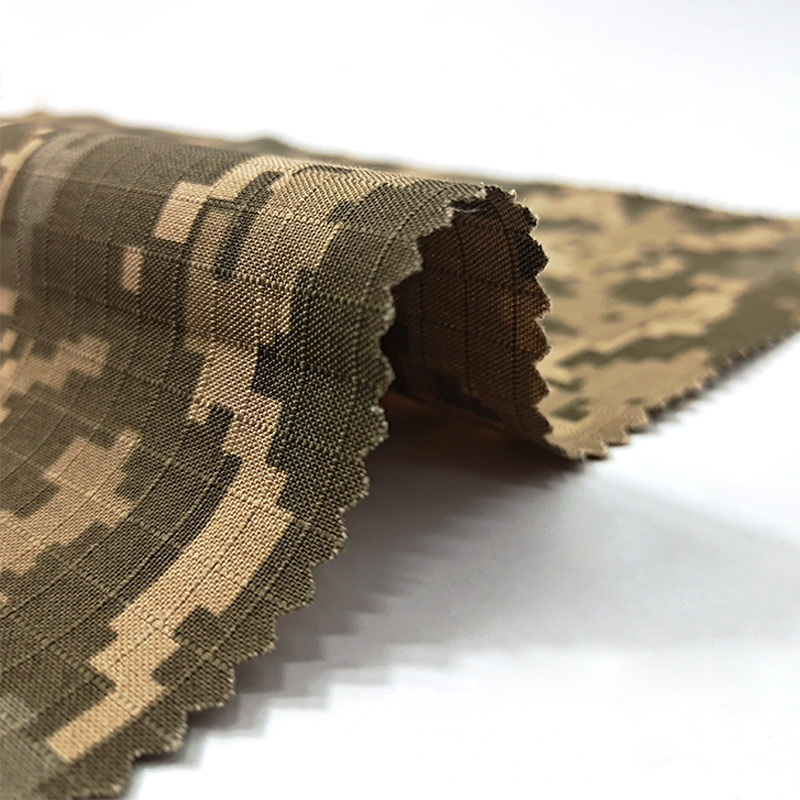

Understanding cvc camouflage printed fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CVC 50/50 Twill Camouflage | Balanced cotton-polyester blend, twill weave | Workwear, military uniforms, outdoor apparel | Pros: Durable, breathable, cost-effective. Cons: May lack advanced moisture-wicking features. |

| CVC Ripstop Camouflage | Ripstop fabric construction, tear-resistant | Tactical gear, outdoor gear, military uniforms | Pros: Highly durable, lightweight. Cons: Limited color options compared to traditional fabrics. |

| CVC Waterproof Camouflage | Water-resistant treatment, blended fabric | Outdoor apparel, military, and tactical gear | Pros: Versatile for wet conditions. Cons: Can be more expensive due to treatment costs. |

| CVC Anti-bacterial Camouflage | Anti-bacterial finish, blended fabric | Medical uniforms, tactical wear | Pros: Reduces odor, suitable for close-contact wear. Cons: May require special care in washing. |

| CVC Digital Camouflage | Digital print patterns, vibrant colors | Military, tactical training, outdoor apparel | Pros: Modern aesthetics, customizable patterns. Cons: Printing process can increase production time. |

What are the Key Characteristics of CVC 50/50 Twill Camouflage Fabric?

CVC 50/50 twill camouflage fabric is composed of 50% cotton and 50% polyester, providing a balance of comfort and durability. The twill weave enhances the fabric’s strength and flexibility, making it ideal for workwear and military uniforms. When purchasing, buyers should consider factors like weight, which typically ranges around 245 GSM, and the potential for customization in patterns and colors.

How Does CVC Ripstop Camouflage Fabric Stand Out?

CVC ripstop camouflage fabric features a unique grid pattern that enhances tear resistance, making it an excellent choice for tactical and outdoor applications. Its lightweight nature allows for ease of movement while maintaining durability. B2B buyers should evaluate the fabric’s weight and thickness, as these can influence its performance in various environments, particularly in military operations.

What Advantages Does CVC Waterproof Camouflage Offer?

CVC waterproof camouflage fabric is treated to repel water, making it suitable for outdoor apparel and military gear. This fabric combines the comfort of cotton with the resilience of polyester, ensuring that it remains functional even in adverse weather conditions. Buyers should assess the fabric’s water resistance level and durability, as well as its suitability for their specific applications.

Why Choose CVC Anti-bacterial Camouflage Fabric?

CVC anti-bacterial camouflage fabric is treated to inhibit bacterial growth, making it ideal for medical uniforms and tactical wear where hygiene is crucial. This fabric provides comfort while reducing odor, which is particularly beneficial for close-contact wear. Buyers should consider the care requirements for maintaining the anti-bacterial properties, as well as the potential for higher costs associated with specialized treatments.

What Makes CVC Digital Camouflage Fabric Unique?

CVC digital camouflage fabric employs advanced printing techniques to create vibrant, pixelated patterns that are popular in military and tactical apparel. This fabric allows for a degree of customization, enabling brands to create unique designs. B2B buyers should factor in the printing process’s impact on lead times and costs, as well as the fabric’s overall durability and usability in various conditions.

Key Industrial Applications of cvc camouflage printed fabric

| Industry/Sector | Specific Application of cvc camouflage printed fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Military & Defense | Uniforms and tactical gear for soldiers | Enhanced concealment and durability in diverse environments | Compliance with military standards and specifications |

| Outdoor & Adventure Gear | Clothing and equipment for outdoor activities | Weather resistance and comfort for prolonged use | Custom patterns and colors suitable for various terrains |

| Fashion & Apparel | Streetwear and fashion lines incorporating camouflage styles | Trendy designs appealing to urban consumers | Flexibility in fabric customization and design options |

| Medical & Safety Gear | Protective uniforms and apparel for medical personnel | Antibacterial properties enhancing hygiene and safety | Certifications for health and safety compliance |

| Sportswear | Activewear for outdoor sports and tactical training | Breathability and movement flexibility | Weight and GSM specifications tailored for performance |

How is CVC Camouflage Printed Fabric Used in Military and Defense Applications?

CVC camouflage printed fabric is primarily utilized in the production of military uniforms and tactical gear. This fabric offers superior durability and weather resistance, which are essential for soldiers operating in diverse environments. For international buyers, particularly those in Africa and the Middle East, it is crucial to ensure that the fabric meets military specifications and standards. Buyers should prioritize sourcing from manufacturers who provide certifications and have a proven track record in military supply.

What are the Benefits of CVC Camouflage Printed Fabric in Outdoor and Adventure Gear?

In the outdoor and adventure gear sector, CVC camouflage printed fabric is used in clothing and equipment designed for hiking, camping, and other outdoor activities. The fabric’s water-resistant and tear-resistant properties make it ideal for rugged use. For B2B buyers, especially in South America and Africa, sourcing fabrics that can be customized with specific patterns and colors for different terrains can enhance product appeal and functionality. Additionally, buyers should consider the weight and GSM of the fabric to ensure comfort during prolonged wear.

How is CVC Camouflage Printed Fabric Transforming Fashion and Apparel?

The fashion industry has embraced CVC camouflage printed fabric for its trendy aesthetic, particularly in streetwear collections. Brands are utilizing this fabric to create unique designs that resonate with urban consumers. B2B buyers in Europe should look for suppliers who can offer a wide range of customization options, including color variations and pattern designs. Understanding market trends and consumer preferences in different regions can aid buyers in selecting the right fabric that aligns with their brand identity.

Why is CVC Camouflage Printed Fabric Important for Medical and Safety Gear?

CVC camouflage printed fabric is increasingly being used in protective uniforms and apparel for medical personnel. Its antibacterial properties enhance hygiene, making it suitable for environments where safety is paramount. B2B buyers, particularly in the Middle East and Europe, need to ensure that the fabric complies with health and safety regulations. Sourcing from manufacturers who can provide the necessary certifications is vital for maintaining quality and safety standards in medical applications.

How Does CVC Camouflage Printed Fabric Benefit the Sportswear Industry?

In the sportswear sector, CVC camouflage printed fabric is favored for creating activewear that is both functional and stylish. The fabric’s breathability and flexibility allow for ease of movement during physical activities. For B2B buyers in Africa and South America, it is important to consider the specific weight and GSM of the fabric to optimize performance for various sports. Additionally, sourcing fabrics that can withstand rigorous use while maintaining aesthetic appeal is crucial for market competitiveness.

3 Common User Pain Points for ‘cvc camouflage printed fabric’ & Their Solutions

Scenario 1: Difficulty in Finding Reliable Suppliers for CVC Camouflage Printed Fabric

The Problem: Many B2B buyers, especially those operating in regions like Africa and South America, face challenges in sourcing reliable suppliers for CVC camouflage printed fabric. With the increasing demand for specialized fabrics in military and workwear applications, buyers often encounter issues such as inconsistent quality, delayed deliveries, and lack of customization options. This can lead to production delays and ultimately affect their ability to meet customer demands and deadlines.

The Solution: To mitigate these challenges, buyers should invest time in researching and vetting suppliers thoroughly. Start by seeking manufacturers with a proven track record in producing CVC camouflage fabric, preferably with certifications like ISO or OEKO-TEX that assure quality standards. Engage with suppliers through platforms like Alibaba or trade shows to assess their capabilities and reliability. Request samples to evaluate the fabric quality and ensure it meets specific requirements such as weight, pattern accuracy, and durability. Establish clear communication channels and set expectations regarding lead times and customization options upfront. Building long-term relationships with trustworthy suppliers can result in more favorable terms and reliable supply chains.

Scenario 2: Challenges in Customization of Patterns and Colors

The Problem: B2B buyers often struggle with the customization of camouflage patterns and colors to meet their specific market needs. For example, companies targeting military contracts may require unique patterns that are not readily available in the market. Additionally, buyers may find that some suppliers have limited capabilities when it comes to accommodating custom requests, which can hinder their ability to compete effectively.

The Solution: Buyers should prioritize suppliers that offer extensive customization options and have the technical capability to produce unique designs. When reaching out to manufacturers, clearly outline your customization needs, including specific color codes and pattern designs. It is beneficial to work with suppliers who utilize digital printing technology, as this allows for greater flexibility in design modifications. Additionally, consider leveraging the expertise of textile designers to create bespoke patterns that align with current trends and market demands. Establishing a collaborative approach with suppliers can ensure that your customization requests are met promptly and to your satisfaction.

Scenario 3: Concerns About Fabric Durability and Performance

The Problem: A critical concern for B2B buyers in industries such as military and outdoor apparel is the durability and performance of CVC camouflage printed fabric. Buyers often encounter fabrics that do not withstand harsh conditions, leading to complaints and returns. Issues such as fading, tearing, and poor water resistance can significantly impact the reputation of a buyer’s brand and their ability to retain customers.

The Solution: To address durability concerns, buyers should request detailed specifications from suppliers about the fabric’s performance characteristics. Look for fabrics that are treated for specific functionalities such as water resistance, UV protection, and tear resistance. Conducting thorough quality control checks upon receiving shipments can help identify any issues before the fabric reaches the end customer. It’s also advisable to seek suppliers who offer warranties or guarantees on their products, providing additional assurance of quality. Regularly gathering feedback from end-users can help refine product offerings and address any performance issues proactively. By focusing on sourcing high-quality, performance-tested fabrics, buyers can enhance their product lines and build a strong reputation in the market.

Strategic Material Selection Guide for cvc camouflage printed fabric

What Are the Key Materials Used in CVC Camouflage Printed Fabric?

CVC (Chief Value Cotton) camouflage printed fabric typically combines cotton and polyester to leverage the benefits of both materials. Below, we analyze four common materials used in CVC camouflage fabrics, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. CVC 50/50 Cotton-Polyester Blend

Key Properties: This blend offers a balanced combination of breathability from cotton and durability from polyester. It typically weighs around 245 GSM, making it suitable for various applications including uniforms and outdoor gear.

Pros & Cons: The CVC 50/50 blend is highly durable and resistant to wear and tear, making it ideal for workwear. However, it may not perform as well in extreme temperatures compared to pure cotton or specialized synthetic fabrics. The manufacturing complexity is moderate, as it requires careful blending to maintain fabric integrity.

Impact on Application: This material is compatible with various printing techniques, allowing for vibrant camouflage patterns. It is suitable for military, outdoor, and tactical apparel.

Considerations for International Buyers: Compliance with international standards such as ISO and OEKO-TEX is essential for buyers in regions like Africa and Europe. Buyers should also consider the fabric’s moisture-wicking properties, especially in humid climates.

2. CVC 60/40 Cotton-Polyester Blend

Key Properties: This variation leans more towards cotton, providing enhanced comfort and breathability while still maintaining the durability of polyester. It is often used in military uniforms and workwear.

Pros & Cons: The increased cotton content improves comfort, making it suitable for extended wear. However, it may be less resistant to fading and wear compared to higher polyester blends. The cost is generally moderate, making it accessible for bulk purchases.

Impact on Application: This blend is particularly effective for applications requiring comfort without sacrificing durability. It is ideal for uniforms and casual outdoor apparel.

Considerations for International Buyers: Buyers should ensure that the fabric meets local regulations regarding fire safety and environmental impact, especially in regions with strict compliance standards.

3. Ripstop CVC Fabric

Key Properties: Ripstop fabric incorporates a special reinforcing technique that makes it resistant to tearing and ripping. This is particularly beneficial in rugged environments.

Pros & Cons: The key advantage of ripstop is its durability and resistance to damage, which is essential for tactical applications. However, the manufacturing process can be more complex and costly, which may affect pricing.

Impact on Application: This material is widely used in military and outdoor gear, where durability is critical. It is also suitable for bags and other equipment that may experience heavy use.

Considerations for International Buyers: Buyers should look for certifications that ensure the fabric’s performance under various environmental conditions, particularly in regions with extreme weather.

4. Anti-Bacterial CVC Fabric

Key Properties: This fabric is treated with anti-bacterial agents, making it suitable for applications where hygiene is paramount, such as medical uniforms or outdoor gear.

Pros & Cons: The primary advantage is the added protection against bacteria, which is essential in healthcare settings. However, the treatment may add to the cost and could affect the fabric’s breathability.

Impact on Application: This fabric is particularly useful for uniforms in medical and military applications, where hygiene is critical.

Considerations for International Buyers: Compliance with health and safety regulations is crucial, especially in regions with stringent healthcare standards. Buyers should verify the effectiveness of the anti-bacterial treatment to ensure it meets their needs.

Summary Table of Material Properties

| Material | Typical Use Case for cvc camouflage printed fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| CVC 50/50 Cotton-Polyester | Workwear, tactical apparel | Durable and resistant to wear | Less effective in extreme temperatures | Medium |

| CVC 60/40 Cotton-Polyester | Military uniforms, casual outdoor wear | Enhanced comfort | Less resistant to fading and wear | Medium |

| Ripstop CVC Fabric | Military gear, rugged outdoor equipment | Excellent durability | Higher manufacturing complexity and cost | High |

| Anti-Bacterial CVC Fabric | Medical uniforms, hygiene-sensitive applications | Bacterial protection | May compromise breathability | Medium to High |

This guide provides a comprehensive overview of the key materials used in CVC camouflage printed fabric, helping international B2B buyers make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cvc camouflage printed fabric

What Are the Key Manufacturing Processes for CVC Camouflage Printed Fabric?

The manufacturing of CVC (Chief Value Cotton) camouflage printed fabric involves several critical stages, each designed to ensure high quality and adherence to specifications demanded by B2B buyers. Understanding these processes can help international buyers make informed decisions about their sourcing.

1. Material Preparation: What Raw Materials Are Used?

The primary materials for CVC camouflage fabric are cotton and polyester, typically blended in ratios such as 50/50 or 60/40. The quality of these fibers directly impacts the final product’s durability and performance. The preparation stage includes:

- Fiber Selection: High-quality cotton and polyester are selected based on criteria such as strength, colorfastness, and texture.

- Yarn Spinning: The chosen fibers are spun into yarn using techniques like ring or rotor spinning. This process determines the yarn count, which affects the fabric’s weight and feel.

2. Forming: How Is the Fabric Constructed?

The forming stage involves weaving or knitting the yarn into fabric. The most common techniques for camouflage fabric include:

- Woven Structures: Techniques like twill or ripstop weaving create durable fabrics ideal for military and workwear applications. Ripstop weaving, in particular, enhances tear resistance.

- Printing Techniques: After weaving, the fabric undergoes a printing process to apply camouflage patterns. Digital printing offers flexibility in design and color application, enabling customization to meet specific client needs.

3. Assembly: Are There Additional Treatments or Features?

Post-weaving, the fabric may undergo several finishing processes to enhance its functionality:

- Waterproofing: Treatments are applied to make the fabric water-resistant, which is crucial for outdoor applications.

- Anti-Bacterial Treatments: Some CVC camouflage fabrics include anti-bacterial finishes, making them suitable for military and healthcare settings.

- Color and Pattern Customization: Buyers can request specific colors and patterns, allowing for tailored products that meet regional or operational needs.

What Quality Assurance Practices Are Essential for CVC Camouflage Fabric?

Quality assurance (QA) is paramount in the textile industry, particularly for camouflage fabrics used in demanding applications. Ensuring that products meet international standards and customer expectations requires a robust QA framework.

1. Which International Standards Should B2B Buyers Consider?

B2B buyers should be aware of various international standards that govern textile manufacturing and quality:

- ISO 9001: This standard focuses on quality management systems and ensures that manufacturers maintain consistent quality across their processes.

- OEKO-TEX® Standard 100: This certification indicates that the fabric has been tested for harmful substances, making it safe for human use.

2. What Are the Key QC Checkpoints During Production?

Quality control involves several critical checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Regular inspections are conducted during production to catch defects early. This includes monitoring weaving and printing processes.

- Final Quality Control (FQC): Finished products undergo thorough inspections to verify that they meet specifications, including color consistency, pattern accuracy, and overall fabric integrity.

3. What Testing Methods Are Commonly Used for Quality Assurance?

Manufacturers utilize various testing methods to ensure compliance with quality standards:

- Physical Testing: This includes tests for tensile strength, tear resistance, and abrasion resistance.

- Chemical Testing: Fabrics are tested for colorfastness, pH levels, and the presence of harmful substances.

- Performance Testing: Evaluating the fabric’s performance under different environmental conditions (e.g., water resistance, UV protection).

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability.

1. What Steps Can Buyers Take to Audit Suppliers?

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities, quality control processes, and adherence to standards.

- Requesting Quality Reports: Buyers should ask for detailed quality reports that outline testing methods, results, and compliance with standards.

2. Are Third-Party Inspections Beneficial?

Engaging third-party inspection services can add an additional layer of assurance. These independent organizations can conduct inspections at various production stages and provide unbiased reports on quality compliance.

3. What Nuances Should International Buyers Be Aware Of?

International buyers should consider cultural and regulatory differences that may impact quality assurance:

- Regulatory Compliance: Different regions may have specific regulations regarding textile safety and quality. Understanding these regulations can prevent compliance issues.

- Communication Barriers: Language and cultural differences can affect clarity in specifications and quality expectations. Establishing clear communication channels is crucial.

Conclusion

The manufacturing processes and quality assurance practices for CVC camouflage printed fabric are intricate and vital for ensuring that the final product meets the stringent demands of various industries. By understanding these processes, B2B buyers can make informed decisions, ensuring they partner with suppliers who uphold the highest quality standards, ultimately leading to successful procurement and satisfaction in their respective markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cvc camouflage printed fabric’

Introduction

This guide provides a comprehensive checklist for B2B buyers interested in sourcing CVC camouflage printed fabric. The aim is to streamline the procurement process by outlining essential steps to ensure quality, compliance, and suitability for your specific applications. By following this checklist, you can make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, establish clear technical specifications for the camouflage fabric you need. This includes the fabric composition (e.g., CVC 50/50 or CVC 60/40), weight (measured in GSM), and any specific features such as water resistance or anti-bacterial properties.

– Why It Matters: Clearly defined specifications help avoid misunderstandings and ensure that the fabric meets your end-use requirements, whether for military, workwear, or outdoor apparel.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in CVC camouflage printed fabric. Look for companies with a solid reputation in the industry, positive customer reviews, and experience in exporting to your region.

– What to Look For: Supplier certifications (like ISO and OEKO-TEX), production capacity, and previous export experience, particularly in markets similar to yours, can indicate reliability and quality.

Step 3: Evaluate Supplier Certifications

Verify the certifications and compliance of your shortlisted suppliers. Ensure they adhere to international quality standards and environmental regulations, such as ISO certifications and OEKO-TEX standards.

– Importance of Certification: Certifications not only demonstrate a commitment to quality but also ensure that the materials are safe and environmentally friendly, which can be a significant selling point in your market.

Step 4: Request Samples

Always request samples before placing a bulk order. This allows you to assess the fabric’s quality, feel, and print accuracy firsthand. Make sure the samples reflect the exact specifications you require.

– Sample Evaluation: Examine the fabric for durability, colorfastness, and overall appearance. This step is crucial to avoid costly mistakes and ensure the fabric meets your expectations.

Step 5: Inquire About Customization Options

Discuss customization options with potential suppliers, including color variations, patterns, and finishing treatments. Many suppliers offer tailored solutions to meet specific needs, which can enhance the uniqueness of your product line.

– Customization Benefits: Tailoring your fabric can give your products a competitive edge in the market, making them more appealing to your target audience.

Step 6: Clarify Minimum Order Quantities (MOQs)

Understand the minimum order quantities required by suppliers. Many manufacturers have MOQs that can vary based on the type of fabric and customization options.

– Why This Matters: Knowing the MOQ helps you plan your budget and inventory effectively, ensuring you can meet demand without overcommitting to excess stock.

Step 7: Negotiate Terms and Conditions

Before finalizing your order, negotiate payment terms, delivery timelines, and return policies with the supplier. Clear agreements help prevent misunderstandings and ensure a smooth procurement process.

– Key Negotiation Points: Discuss payment options (such as L/C or T/T), lead times for production, and logistics to ensure that you can meet your business deadlines without issues.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing CVC camouflage printed fabric, ensuring they secure high-quality products that align with their business objectives.

Comprehensive Cost and Pricing Analysis for cvc camouflage printed fabric Sourcing

What Are the Key Cost Components in Sourcing CVC Camouflage Printed Fabric?

When sourcing CVC (Chief Value Cotton) camouflage printed fabric, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. CVC fabrics typically blend cotton with polyester, with common ratios being 50/50 or 60/40. The quality of cotton and polyester used, as well as any special treatments (e.g., waterproofing or anti-bacterial finishes), can raise or lower material costs.

-

Labor: Labor costs vary by region and manufacturing practices. Countries with lower labor costs may offer more competitive pricing, but it’s essential to consider the skill level of the workforce, which affects quality and production speed.

-

Manufacturing Overhead: This includes the costs associated with running the manufacturing facility, such as utilities, equipment maintenance, and administrative expenses. Factories with more advanced technology may have higher overhead but can provide better quality and consistency.

-

Tooling: Custom patterns or specialized printing techniques require investment in tooling, which can increase initial costs but may be amortized over larger production runs.

-

Quality Control (QC): Ensuring the fabric meets specified standards incurs additional costs. Certifications like OEKO-TEX or ISO can enhance credibility but may add to overall expenses.

-

Logistics: Transportation and shipping costs are significant, especially for international buyers. Factors such as distance, mode of transport, and Incoterms (International Commercial Terms) play a vital role in determining these costs.

-

Margin: Suppliers typically add a margin to cover risks and ensure profitability. This margin can vary based on competition, market demand, and the supplier’s overall business strategy.

How Do Price Influencers Affect CVC Camouflage Printed Fabric Pricing?

Several factors influence the pricing of CVC camouflage printed fabric:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide better pricing for larger orders due to economies of scale. Understanding the MOQ can help buyers negotiate better terms.

-

Specifications and Customization: Customized fabrics (e.g., unique patterns or specific performance characteristics) may come at a premium. Buyers should clearly define their requirements to avoid unexpected costs.

-

Material Quality and Certifications: Higher quality materials and additional certifications typically lead to increased costs. Buyers should weigh the benefits of these features against their budget.

-

Supplier Factors: The supplier’s reputation, production capacity, and location can all impact pricing. Established suppliers may charge more but offer reliability and quality assurance.

-

Incoterms: Understanding the agreed-upon Incoterms is crucial, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can influence total costs.

What Tips Can Help Buyers Optimize Costs When Sourcing CVC Camouflage Printed Fabric?

-

Negotiation: Leverage volume orders to negotiate better pricing. Establishing a long-term relationship with suppliers can also lead to favorable terms.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but the entire lifecycle costs, including maintenance, durability, and potential waste. This approach ensures that buyers invest in quality products that will deliver better value over time.

-

Research and Comparison: Conduct thorough market research to compare prices and offerings from various suppliers. This enables buyers to identify competitive pricing and potential cost-saving opportunities.

-

Understand Local Market Dynamics: Each region may have unique pricing structures influenced by local demand, competition, and economic conditions. Tailoring sourcing strategies to regional insights can lead to better deals.

-

Be Aware of Pricing Nuances for International Transactions: Currency fluctuations, tariffs, and shipping costs can significantly affect pricing. Buyers should factor these elements into their overall budget to avoid surprises.

Disclaimer on Indicative Prices

While this analysis provides a framework for understanding costs and pricing for CVC camouflage printed fabric, actual prices may vary based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable to request quotes from multiple suppliers to obtain the most accurate pricing information.

Alternatives Analysis: Comparing cvc camouflage printed fabric With Other Solutions

Introduction: Exploring Alternatives to CVC Camouflage Printed Fabric

When selecting materials for military, outdoor, or tactical apparel, businesses must consider various options that can meet specific performance and aesthetic requirements. CVC (Chief Value Cotton) camouflage printed fabric is a popular choice due to its blend of cotton and polyester, offering durability and comfort. However, alternatives exist that may better suit particular applications or budget constraints. This analysis compares CVC camouflage printed fabric with two viable alternatives: ripstop nylon and traditional cotton camouflage fabric.

Comparison Table

| Comparison Aspect | CVC Camouflage Printed Fabric | Ripstop Nylon | Traditional Cotton Camouflage Fabric |

|---|---|---|---|

| Performance | Good breathability, moderate durability | High tear resistance, lightweight | Good comfort, moderate durability |

| Cost | Moderate | Higher initial cost | Generally lower than CVC |

| Ease of Implementation | Easy to sew and customize | Requires special handling for sewing | Easy to work with |

| Maintenance | Moderate; machine washable | Quick-drying, low maintenance | High maintenance; prone to shrinking |

| Best Use Case | Workwear, uniforms, casual wear | Military uniforms, outdoor gear | Casual apparel, lightweight outdoor use |

Detailed Breakdown of Alternatives

1. Ripstop Nylon

Ripstop nylon is known for its high durability and tear resistance, making it an excellent choice for military applications and outdoor gear. Its lightweight nature allows for comfortable wear during extended use. However, the initial cost can be higher compared to CVC fabric, which may impact budget-conscious buyers. Additionally, while ripstop nylon is quick-drying and low maintenance, it can be challenging to sew and may require specialized equipment.

2. Traditional Cotton Camouflage Fabric

Traditional cotton camouflage fabric is favored for its breathability and comfort, making it ideal for casual wear and lightweight outdoor clothing. It generally comes at a lower cost than CVC options, making it an attractive choice for bulk purchases. However, traditional cotton fabrics tend to be less durable and more prone to shrinking and wrinkling during washing. This can lead to higher maintenance needs over time, which is a consideration for businesses focused on long-term use.

Conclusion: Making the Right Choice for Your Needs

Choosing the right camouflage fabric depends on various factors, including the intended application, budget, and maintenance preferences. CVC camouflage printed fabric offers a balanced solution for durability and comfort, making it suitable for workwear and uniforms. Alternatively, ripstop nylon may be the best choice for high-performance needs, especially in military settings, despite its higher cost. Traditional cotton camouflage fabric can serve well for casual applications but may require more upkeep. Buyers should carefully assess their specific requirements and long-term usage to select the fabric that aligns best with their operational goals.

Essential Technical Properties and Trade Terminology for cvc camouflage printed fabric

What are the Key Technical Properties of CVC Camouflage Printed Fabric?

Material Composition

CVC (Chief Value Cotton) camouflage printed fabric typically consists of a blend of cotton and polyester, commonly in ratios like 50/50 or 60/40. This combination provides the fabric with the softness and breathability of cotton while enhancing durability and wrinkle resistance with polyester. For B2B buyers, understanding the material composition is crucial for determining the fabric’s suitability for various applications, such as military uniforms, outdoor gear, or fashion apparel.

Weight (GSM)

The weight of camouflage fabric is often expressed in grams per square meter (GSM). Common weights for CVC camouflage fabrics range from 195 to 245 GSM. Heavier fabrics are generally more durable and suitable for workwear, while lighter weights may be preferred for casual clothing. B2B buyers must consider the end-use of the fabric when evaluating GSM, as it directly affects the comfort and performance of the final product.

Width

CVC camouflage fabrics are usually available in widths of 57/58 inches or 58/60 inches. The width is an essential specification for manufacturers, as it determines how much fabric is required for production runs. Knowing the width helps buyers calculate fabric yields and ultimately affects cost efficiency in garment production.

Fabric Construction and Weave Type

The weave type, such as twill or ripstop, plays a significant role in the fabric’s strength and appearance. Ripstop fabrics, characterized by their crosshatch pattern, offer enhanced tear resistance, making them ideal for rugged applications. Understanding the weave type allows B2B buyers to select fabrics that meet specific performance requirements, such as abrasion resistance for workwear or breathability for outdoor clothing.

Finishing Treatments

Many CVC camouflage fabrics undergo additional treatments, such as water resistance, anti-static properties, or antimicrobial finishes. These treatments enhance the fabric’s performance characteristics, making them suitable for specialized applications. Buyers should inquire about available finishes to ensure the fabric meets their specific needs, particularly in markets where durability and functionality are paramount.

What are Common Trade Terms Related to CVC Camouflage Printed Fabric?

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces products that are then marketed by another company under its own brand. In the context of CVC camouflage fabric, buyers often work with OEM manufacturers to produce custom designs or specifications. Understanding OEM relationships is vital for buyers seeking tailored products that meet their brand standards.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For camouflage fabric, MOQs can vary significantly based on the manufacturer and the specific fabric type. Familiarity with MOQ is essential for B2B buyers to ensure they can meet their production needs without incurring excess inventory costs.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specified products or services. When purchasing CVC camouflage fabric, an RFQ allows buyers to compare prices, lead times, and terms from different suppliers. Understanding how to effectively create and send RFQs can streamline the procurement process and enhance cost management.

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, particularly concerning shipping and delivery. For CVC camouflage fabric, common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify the terms of shipping costs and risk transfer. Familiarity with these terms is crucial for B2B buyers to mitigate risks and understand total landed costs.

Lead Time

Lead time is the period between placing an order and receiving the goods. In the textile industry, lead times can vary depending on the complexity of the order and the manufacturer’s production capacity. B2B buyers should consider lead times when planning their supply chains to ensure timely delivery of products to meet market demands.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing CVC camouflage printed fabric, ensuring they select the right materials and suppliers for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the cvc camouflage printed fabric Sector

What Are the Current Market Dynamics and Key Trends in CVC Camouflage Printed Fabric?

The global market for CVC (Chief Value Cotton) camouflage printed fabric is witnessing significant growth, driven by a surge in demand across various sectors, including military, outdoor apparel, and workwear. Key trends influencing this market include the increasing preference for durable and functional fabrics, which are essential for military uniforms and tactical gear, particularly in regions like Africa and the Middle East. Furthermore, the rise of outdoor recreational activities has propelled the demand for camouflage patterns in casual wear, particularly among younger demographics in South America and Europe.

Emerging technologies in textile manufacturing, such as digital printing and sustainable production methods, are reshaping the sourcing landscape. International B2B buyers are increasingly leveraging online platforms for procurement, allowing for greater access to diverse suppliers and fabrics from different regions, including China and Vietnam. This shift not only enhances price competitiveness but also facilitates customization, enabling buyers to meet specific market needs.

Additionally, the adoption of advanced materials that offer properties like moisture-wicking, UV protection, and tear resistance is becoming a standard expectation. These innovations are particularly appealing to buyers looking for high-performance textiles that can withstand harsh environmental conditions, further driving the demand for CVC camouflage printed fabrics.

How Important Is Sustainability and Ethical Sourcing for CVC Camouflage Printed Fabric?

Sustainability and ethical sourcing are critical considerations in the CVC camouflage printed fabric sector. With increasing awareness of environmental issues and consumer preferences shifting toward eco-friendly products, B2B buyers are now prioritizing suppliers that demonstrate a commitment to sustainable practices. The environmental impact of textile production, including water usage and chemical runoff, necessitates a focus on sourcing from manufacturers who employ responsible methods.

Buyers should look for certifications such as OEKO-TEX Standard 100 and GRS (Global Recycle Standard), which ensure that fabrics meet stringent environmental and safety criteria. The use of organic cotton and recycled polyester in CVC blends not only reduces ecological footprints but also aligns with global sustainability goals. Moreover, transparent supply chains that uphold labor rights and fair wages are becoming increasingly important for buyers who want to ensure that their procurement practices support ethical labor conditions.

Investing in sustainable fabrics can also open new market opportunities, as environmentally conscious consumers are often willing to pay a premium for products that reflect their values. Thus, integrating sustainability into sourcing strategies is not just a compliance measure; it is a strategic advantage in an increasingly competitive marketplace.

What Is the Brief Evolution and History of CVC Camouflage Printed Fabric in the B2B Context?

The evolution of CVC camouflage printed fabric can be traced back to the growing need for durable, versatile textiles that meet the rigorous demands of military and outdoor applications. The introduction of CVC blends, combining cotton’s comfort with polyester’s durability, marked a significant advancement in fabric technology. This blend offers enhanced breathability, moisture management, and resistance to wear and tear, making it ideal for uniforms and outdoor gear.

Historically, camouflage fabrics were primarily used in military contexts, but the rise of tactical fashion and outdoor sports has broadened their applications. In recent years, the global textile industry has seen a shift toward customization, with buyers seeking unique patterns and functionalities tailored to specific markets. This evolution reflects not only changes in consumer preferences but also advancements in printing technology, allowing for intricate designs and sustainable production methods.

As the market continues to evolve, CVC camouflage printed fabrics are becoming synonymous with performance, sustainability, and style, catering to an expanding array of applications beyond traditional military use. This historical perspective provides B2B buyers with a context for understanding current trends and future opportunities in the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of cvc camouflage printed fabric

-

How do I ensure quality when sourcing CVC camouflage printed fabric?

To ensure quality, it’s essential to vet potential suppliers by checking their certifications, such as ISO and OEKO-TEX Standard 100. Request samples to evaluate the fabric’s feel, durability, and print quality. Additionally, inquire about their production processes, quality control measures, and past client reviews. Establishing clear quality expectations in the contract can also safeguard against discrepancies. -

What are the typical minimum order quantities (MOQs) for CVC camouflage printed fabric?

Minimum order quantities can vary significantly between suppliers, but they typically range from 3,000 to 5,000 meters for bulk orders. Some manufacturers may offer smaller quantities for sample orders or initial tests. It’s advisable to discuss MOQs upfront to ensure they align with your project requirements and budget, especially for international shipping. -

What customization options are available for CVC camouflage printed fabric?

Most suppliers offer extensive customization options, including color, pattern, weight, and fabric composition. You can request specific camouflage designs tailored to your needs, whether for military uniforms or casual wear. Ensure to provide clear specifications and artwork to avoid miscommunication. Discuss potential additional costs for custom designs as they may vary. -

What payment terms are commonly accepted for international purchases of CVC camouflage printed fabric?

Payment terms can differ among suppliers, but common practices include a 30% deposit upon order confirmation with the balance due before shipment. Some suppliers may accept letters of credit (L/C) or other financing options. Clarifying payment terms early in negotiations will help manage cash flow and mitigate risks associated with international transactions. -

How long does it typically take to receive an order of CVC camouflage printed fabric?

Lead times for orders can range from 30 to 45 days, depending on factors like production capacity, customization requirements, and shipping logistics. It’s advisable to confirm the timeline with your supplier before placing an order. Planning ahead can help accommodate any unforeseen delays and ensure that your supply chain remains uninterrupted. -

What logistics considerations should I be aware of when importing CVC camouflage printed fabric?

When importing, consider shipping methods, customs regulations, and tariffs that may apply. It’s essential to work with a reliable freight forwarder who understands international shipping laws. Ensure all documentation is complete to prevent delays at customs. Additionally, factor in shipping costs and delivery timelines when budgeting for your fabric purchase. -

How can I assess a supplier’s reliability for CVC camouflage printed fabric?

Assessing a supplier’s reliability involves researching their business history, client testimonials, and production capabilities. Request references from other B2B clients, and consider conducting a factory visit if feasible. Look for suppliers with a proven track record in quality assurance and timely delivery. Engaging in thorough communication can also help gauge their responsiveness and professionalism. -

What are the common applications for CVC camouflage printed fabric?

CVC camouflage printed fabric is versatile and commonly used in military uniforms, workwear, and outdoor apparel. It is also suitable for accessories like bags and hats. The fabric’s durability and water-resistant features make it ideal for various industries, including fashion, outdoor sports, and tactical gear. Understanding the specific requirements of your target market can help you select the appropriate fabric type.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Cvc Camouflage Printed Fabric Manufacturers & Suppliers List

1. Sichuan Ronghong Textile – CVC 50 Cotton 50 Polyester Camo Waterproof Fabric

Domain: ronghongtextile.com

Registered: 2022 (3 years)

Introduction: {“Product Name”: “CVC 50 Cotton 50 Polyester Camo Waterproof Fabric”, “Manufacturer”: “Sichuan Ronghong Textile Co., Ltd”, “Founded”: “2006”, “Category”: “Camouflage Fabric”, “Keywords”: [“digital camouflage fabric”, “camo waterproof fabric”, “50% polyester 50% cotton fabric”, “CVC camouflage fabric”], “Thickness”: “Heavy Weight”, “Supply Type”: “Make-to-Order”, “Style”: [“Twill”, “Customized”], “…

2. China Texnet – Polyester Blended Camouflage Fabric

Domain: chinatexnet.com

Registered: 1999 (26 years)

Introduction: {“Product Type”:”Fabric >> Blend & Interweave >> Polyester blended fabric”,”Keywords”:”camouflage, printed, CVC, ripstop, uniform”,”Uses”:”Military Uniform”,”Origin”:”China”,”MOQ”:”5000 Meter”,”Port”:”Shanghai”,”Payment Terms”:”L/C”,”Production Capacity”:”500,000 Meter per month”,”Packing”:”rolled on tube in plastic bag”,”Delivery Time”:”30-45 Days”,”Yarn Count”:”21X21″,”Density”:”108X58″,”Composi…

3. Yilong Textiles – CVC Desert Camouflage Fabric

Domain: yilongtextiles.com

Registered: 2024 (1 years)

Introduction: {“name”:”CVC 60% cotton 40% polyester 3/1 twill anti-static military uniform printing Middle East desert digital camouflage fabric”,”material”:”60% cotton, 40% polyester”,”technics”:”woven”,”style”:”3/1 Twill”,”thickness”:”Medium Weight”,”weight”:”230±5 GSM”,”width”:”58/60 inch”,”color”:”Desert camouflage”,”suitable_for”:”Soldier uniforms, outdoor sportswear, Apparel-Workwear, Apparel-Uniform”,”pr…

4. Workwear Fabric – Ripstop Cotton Polyester CVC Blue Camouflage

Domain: workwear-fabric.com

Registered: 2023 (2 years)

Introduction: {“Product Name”:”Ripstop Cotton Polyester CVC Blue Camouflage Fabric”,”Material”:”Cotton-Polyester Blended Fabric”,”Technics”:”Woven”,”Pattern”:”Plain Dyed”,”Color”:”Customer Request or Pantone Color Code”,”Hand Feeling”:”Soft or Hard as Customer Request”,”Width”:”58/59 inches”,”Feature”:”Can Do Normal Finish or Functional Treatment as Customer Request”,”Craft”:”Continuous Dyeing”,”Dyestuff”:”Vat/…

5. FRPPE – CVC Polyester Cotton Camouflage Fabric

Domain: frppe.com

Registered: 2016 (9 years)

Introduction: CVC Polyester Cotton Camouflage Disruptive Pattern Printing Fabric for Outdoor Tent; 280gsm 100% cotton FR camouflage; Suitable for army/forest fire fighting uniform; Features: flame resistant, comfortable, sweat absorption; Meets standards: EN ISO 11611, EN ISO 11612, GB 8965.1-2009; Minimum Order Quantity: 500 PCS; Application: fire fighting, army, daily training, factory, forest protection, mac…

6. Quality Fabric – CVC Camouflage Printed Fabric

Domain: quality-fabric.com

Registered: 2012 (13 years)

Introduction: Cotton 65%, Polyester 35%, CVC camouflage printed fabric

7. GoldSupplier – Cotton Camouflage Fabric

Domain: goldsupplier.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “Cotton Camouflage Fabric CVC Army Printed Fabric Water-Resistant”, “FOB Price”: “US$ 1.9 – 2.3 / Meter”, “Minimum Order”: “2000 Meters”, “Port”: “Ningbo/Shanghai”, “Payment Terms”: “T/T”, “Supply Type”: “Make-to-Order”, “Type”: “Camouflage Fabric”, “Yarn Type”: “Carded, Combed”, “Pattern”: “Printed”, “Style”: “Twill”, “Width”: “57/58″”, “Technics”: “Woven”, “Features”: [“Anti-Sta…

8. BTCAMO – CVC 50/50 Ripstop Green Digital Camouflage Fabric

Domain: btcamo.com

Registered: 2017 (8 years)

Introduction: {“Product Type”:”CVC 50/50 Ripstop Printed Green Digital Camouflage cloth for Russia Army”,”Product Number”:”BT-224″,”Materials”:”50% Polyester, 50% Cotton”,”Yarn Count”:”30/2*21″,”Density”:”76*53″,”Weight”:”234 GSM”,”Width”:”58″/60″”,”Technics”:”Woven”,”Pattern”:”Camouflage fabric”,”Texture”:”Ripstop”,”Color Fastness”:”4-5 grade”,”Breaking Strength”:”Warp: 600-1200N; Weft: 400-800N”,”MOQ”:”5000 M…

9. Corhunter – Camouflage Fabrics

Domain: corhunter-garment.com

Registered: 2022 (3 years)

Introduction: Camouflage Fabric Categories: Military Combat Uniform, ACU uniform, BDU uniform, Frog Suit, Military Jacket, Tactical Uniform, Tactical Suit, Tactical Shirt, Military Tactical Pants, Camouflage Clothing, Security Uniform, Security Officer Uniform, Security Tactical jacket, Reflective Clothing, Military Beret, Beret Cap Hat, Military Bags, Backpack, Tactical Boots, Bulletproof Equipment, Bulletproo…

Strategic Sourcing Conclusion and Outlook for cvc camouflage printed fabric

In conclusion, strategic sourcing of CVC camouflage printed fabric presents a wealth of opportunities for international B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. Understanding the unique characteristics of CVC fabrics—such as their blend of cotton and polyester, durability, and customizable features—enables buyers to make informed decisions that align with their specific needs, whether for military applications, workwear, or outdoor apparel.

The ability to source from established manufacturers who offer customization, quality certifications, and competitive pricing is essential for businesses aiming to stay ahead in the market. As demand for high-performance fabrics grows, particularly in regions experiencing economic development and increased military spending, buyers should leverage strategic partnerships with suppliers to ensure reliable sourcing and innovation.

Looking ahead, the landscape for CVC camouflage printed fabric is poised for growth. Buyers are encouraged to engage with reputable suppliers, explore new trends in fabric technology, and prioritize sustainable practices. By doing so, they can not only enhance their product offerings but also contribute to a more responsible and resilient textile industry. Connect with trusted manufacturers today to secure your supply chain and capitalize on emerging market opportunities.