Cost Of R32 Refrigerant: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for cost of r32 refrigerant

In today’s competitive HVAC market, understanding the cost of R32 refrigerant is essential for businesses aiming to optimize their operational efficiency and environmental compliance. With its rising popularity as a low global warming potential (GWP) alternative to R410A, R32 offers significant benefits, but navigating the complexities of pricing and sourcing can be a challenge for international B2B buyers. This guide delves into the various aspects of R32 refrigerant, including its applications across different HVAC systems, the factors influencing its cost, and practical tips for supplier vetting.

Our comprehensive resource equips buyers from diverse regions—such as Africa, South America, the Middle East, and Europe (including Germany and Nigeria)—with the necessary insights to make informed purchasing decisions. We will explore the types of R32 refrigerants available in the market, examine cost variations based on geography and supplier, and provide actionable strategies for negotiating favorable terms. Additionally, we will address important compliance and technical considerations to ensure that your HVAC systems operate efficiently and sustainably.

By leveraging the information presented in this guide, businesses can confidently source R32 refrigerant, enhancing their HVAC operations while adhering to environmental regulations. Prepare to navigate the global market with clarity and purpose, ensuring your organization remains at the forefront of sustainable practices in the HVAC industry.

Understanding cost of r32 refrigerant Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| R32 Standard Cylinder | Pure refrigerant, 20 lb capacity, low GWP | HVAC systems, air conditioning units | Pros: Efficient, environmentally friendly. Cons: Handling requires specific safety measures. |

| R32 Blends | Mixtures with other refrigerants for tailored performance | Specialized HVAC applications, commercial units | Pros: Customized performance. Cons: May require additional training for handling. |

| R32 Bulk Purchase | Available in larger quantities, often with volume discounts | Large-scale HVAC contractors, wholesalers | Pros: Cost-effective for bulk buyers. Cons: Higher upfront investment. |

| R32 Reclaimed | Recycled refrigerant, lower cost, suitable for retrofitting | Retrofitting older systems, cost-sensitive projects | Pros: Eco-friendly, budget-friendly. Cons: Potentially lower purity affecting performance. |

| R32 Specialty Products | Includes specific formulations for unique applications | Niche markets, specialized industrial uses | Pros: Tailored solutions. Cons: Limited availability and higher costs. |

What Are the Characteristics of R32 Standard Cylinder Refrigerants?

R32 standard cylinders are a widely used form of refrigerant, known for their efficiency and low global warming potential (GWP). Typically available in 20 lb tanks, they are suitable for a variety of HVAC applications, including air conditioning and heat pumps. Buyers should consider the required safety protocols for handling R32, as it is classified as mildly flammable. This type is ideal for businesses looking for reliable performance and compliance with environmental regulations.

How Do R32 Blends Differ from Pure R32 Refrigerant?

R32 blends are formulated by mixing R32 with other refrigerants to achieve specific performance characteristics tailored to particular applications. These blends are often used in specialized HVAC systems where unique environmental conditions or performance metrics are required. While they offer advantages like enhanced efficiency and reduced environmental impact, companies must ensure that their staff is trained to handle these mixtures safely. The choice of blend can significantly impact system performance and energy consumption.

Why Consider R32 Bulk Purchases for Your Business?

For businesses that frequently use refrigerants, purchasing R32 in bulk can lead to substantial cost savings. Suppliers often provide volume discounts, making it an attractive option for HVAC contractors and wholesalers. Bulk purchases also ensure a steady supply, minimizing downtime for projects. However, companies should be prepared for a higher initial investment and ensure they have adequate storage and handling capabilities to maintain product integrity.

What Are the Benefits of Using Reclaimed R32 Refrigerant?

Reclaimed R32 refrigerant is an eco-friendly option that has been recycled from previous uses. This type is particularly appealing for businesses focused on sustainability and cost savings. It is suitable for retrofitting older HVAC systems, allowing companies to reduce their environmental footprint without significant capital investment. However, buyers should be aware that reclaimed refrigerants may have lower purity levels, which could affect overall system performance.

How Do R32 Specialty Products Serve Niche Markets?

R32 specialty products are designed for specific industrial applications and often come with unique formulations. These products cater to niche markets that require tailored refrigerant solutions, such as high-performance HVAC systems in extreme climates. While they can offer significant benefits in terms of efficiency and effectiveness, availability may be limited, and costs can be higher than standard options. Businesses should assess their specific needs and weigh the advantages against potential costs before opting for specialty products.

Key Industrial Applications of cost of r32 refrigerant

| Industry/Sector | Specific Application of cost of r32 refrigerant | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC Systems | Used in air conditioning units and heat pumps | Higher energy efficiency and lower operational costs | Ensure compliance with local regulations and proper handling protocols |

| Refrigeration | Employed in commercial refrigeration systems | Reduced environmental impact and improved cooling performance | Verify supplier certifications and availability of bulk purchasing options |

| Automotive | Utilized in vehicle air conditioning systems | Enhanced performance and lower greenhouse gas emissions | Consider local environmental regulations and pricing fluctuations |

| Industrial Processes | Integrated into process cooling systems | Improved efficiency and reduced energy consumption | Assess compatibility with existing equipment and serviceability |

| Residential Cooling | Used in residential HVAC applications | Cost-effective solution with better heat transfer capabilities | Look for volume discounts and reliable delivery options |

How is R32 Refrigerant Used in HVAC Systems and What Problems Does It Solve?

R32 refrigerant is increasingly favored in HVAC systems due to its superior energy efficiency, which can lead to significantly lower operational costs. It serves as an effective replacement for R410A, providing up to 12% better efficiency. For international B2B buyers, especially in regions like Africa and Europe, understanding local regulations surrounding refrigerant use is crucial. Buyers must ensure that they source R32 from certified suppliers who comply with environmental standards, particularly as R32 has a lower global warming potential (GWP) compared to older refrigerants.

What Role Does R32 Refrigerant Play in Commercial Refrigeration?

In commercial refrigeration, R32 is utilized in various systems, including supermarket chillers and cold storage facilities. Its lower environmental impact and improved cooling performance make it a suitable choice for businesses aiming to enhance sustainability. International buyers should consider suppliers that offer bulk purchasing options to manage costs effectively. Additionally, understanding the specific requirements for handling and servicing R32 systems is vital to ensure compliance with safety regulations.

How is R32 Refrigerant Beneficial in Automotive Applications?

R32 refrigerant is employed in automotive air conditioning systems, providing enhanced cooling performance while minimizing greenhouse gas emissions. Its efficiency not only contributes to a better driving experience but also aligns with the automotive industry’s push towards sustainability. Buyers in regions like South America and the Middle East should focus on sourcing R32 from reputable suppliers who adhere to local environmental regulations and provide adequate training on handling this refrigerant.

In What Ways is R32 Used in Industrial Processes?

In industrial settings, R32 is integrated into process cooling systems, where it helps maintain optimal temperatures for various manufacturing processes. Its high efficiency translates to reduced energy consumption, directly benefiting the bottom line. For businesses in Europe and Africa, sourcing R32 requires careful consideration of compatibility with existing systems and availability of technical support from suppliers to ensure seamless integration.

How Does R32 Refrigerant Improve Residential Cooling Solutions?

R32 is also used in residential HVAC applications, providing an effective and cost-efficient cooling solution. Its superior heat transfer capabilities make it a preferred choice for homeowners looking to reduce energy bills. For B2B buyers targeting the residential market, sourcing R32 in bulk can lead to significant cost savings. It is essential to partner with suppliers who can guarantee timely delivery and provide support for installation and maintenance to maximize the benefits of using R32 in residential settings.

3 Common User Pain Points for ‘cost of r32 refrigerant’ & Their Solutions

Scenario 1: Budget Overruns Due to Fluctuating R32 Prices

The Problem: Many B2B buyers are grappling with the unpredictable nature of R32 refrigerant pricing. Fluctuations in global supply chains, regulatory changes, and seasonal demand can lead to sudden price increases. This unpredictability can strain budgets, especially for contractors and HVAC companies that rely on tight profit margins. Buyers often find themselves in a position where they have to either absorb higher costs or pass them onto clients, which can jeopardize business relationships.

The Solution: To mitigate the impact of fluctuating prices, businesses should establish long-term contracts with suppliers to lock in prices. Engage in strategic sourcing by collaborating with multiple suppliers to compare rates and terms. Additionally, consider bulk purchasing to take advantage of volume discounts. By forecasting usage based on historical data and current market trends, companies can better manage their inventory and reduce the risk of last-minute purchases at inflated prices. Regularly reviewing supplier performance and market conditions will also allow businesses to pivot quickly when prices start to rise.

Scenario 2: Compliance Challenges with R32 Refrigerant Regulations

The Problem: Compliance with environmental regulations is a significant concern for international B2B buyers of R32 refrigerant, especially in regions like Europe and North America. The introduction of stricter laws regarding the use of refrigerants, including the phasedown of high-GWP substances, complicates procurement. Buyers may find themselves caught off-guard by regulatory changes, leading to potential fines or disruptions in service if they cannot source compliant products.

The Solution: To stay ahead of compliance issues, companies should invest in a comprehensive understanding of local and international refrigerant regulations. Regular training for procurement teams on the latest legal requirements will ensure that they are well-informed. Partnering with suppliers who provide transparent documentation and compliance certifications for R32 refrigerant is crucial. Furthermore, utilizing refrigerants with lower global warming potential (GWP) and transitioning to alternative options as they become available can help future-proof operations against regulatory changes.

Scenario 3: Technical Challenges in Handling R32 Refrigerant

The Problem: R32 refrigerant requires specific handling and installation techniques, which can be daunting for HVAC professionals, especially in regions where training resources are limited. Improper handling can lead to system inefficiencies or safety hazards, resulting in additional costs for repairs and replacements. B2B buyers may struggle to find qualified technicians who are knowledgeable about the unique properties and installation requirements of R32.

The Solution: To overcome these technical challenges, companies should prioritize training programs for their technicians. Investing in certifications that focus on the safe handling and application of R32 refrigerant will enhance workforce competency. Collaborating with suppliers who offer training resources and technical support can also be beneficial. Creating a comprehensive technical manual that outlines best practices for installation, maintenance, and troubleshooting of R32 systems will empower technicians and minimize errors. Additionally, leveraging technology such as VR or AR training modules can provide immersive learning experiences for employees, ensuring they are well-prepared to handle R32 refrigerant effectively.

Strategic Material Selection Guide for cost of r32 refrigerant

What Are the Key Materials Used in R32 Refrigerant Systems?

When selecting materials for R32 refrigerant systems, it is essential to consider properties that influence performance, durability, and compliance with international standards. Here, we analyze four common materials used in R32 applications: copper, aluminum, stainless steel, and thermoplastic.

How Does Copper Perform in R32 Refrigerant Applications?

Copper is a widely used material in HVAC systems, including those utilizing R32 refrigerant. Its excellent thermal conductivity allows for efficient heat transfer, which is crucial in cooling applications. Copper also has good corrosion resistance, particularly when properly treated, making it suitable for various environments.

Pros: Copper’s durability and thermal efficiency make it a preferred choice for piping and heat exchangers. It is relatively easy to work with, allowing for straightforward installation and maintenance.

Cons: However, copper can be more expensive than alternatives like aluminum. It is also susceptible to corrosion in certain environments, which may require additional protective measures.

Impact on Application: Copper’s compatibility with R32 ensures optimal performance in heat transfer applications, but buyers must consider the environmental conditions to mitigate corrosion risks.

Considerations for International Buyers: Compliance with standards such as ASTM B280 for copper tubing is crucial. Buyers from regions like Europe and Africa should also be aware of local regulations regarding refrigerant handling and materials.

What Role Does Aluminum Play in R32 Refrigerant Systems?

Aluminum is another popular choice for R32 applications, especially in components like evaporators and condensers. It is lightweight and has good thermal conductivity, making it effective for heat exchange.

Pros: The primary advantage of aluminum is its lower cost compared to copper, along with its resistance to corrosion, particularly in humid environments.

Cons: While aluminum is lightweight, it is not as durable as copper and can be more prone to mechanical damage. Additionally, its thermal conductivity is lower than that of copper.

Impact on Application: Aluminum’s compatibility with R32 makes it suitable for lightweight and cost-effective solutions, but its mechanical properties may limit its use in high-stress applications.

Considerations for International Buyers: Compliance with standards like ASTM B221 for aluminum extrusions is essential. Buyers should also consider the availability of aluminum components in their region, as supply chains can vary significantly.

How Does Stainless Steel Compare in R32 Refrigerant Systems?

Stainless steel is known for its exceptional corrosion resistance and strength, making it suitable for high-pressure applications. It is often used in valves and fittings in R32 systems.

Pros: The durability of stainless steel ensures a long service life, reducing maintenance costs. Its resistance to corrosion makes it suitable for various environments.

Cons: However, stainless steel is more expensive than both copper and aluminum. Its manufacturing process can also be more complex, leading to higher initial costs.

Impact on Application: Stainless steel’s compatibility with R32 and its ability to withstand high pressures make it an excellent choice for critical system components.

Considerations for International Buyers: Compliance with standards like ASTM A312 for stainless steel pipes is vital. Buyers in regions with stringent environmental regulations should also consider the recyclability of stainless steel.

What Advantages Do Thermoplastics Offer in R32 Refrigerant Applications?

Thermoplastics, such as polyamide and polyethylene, are increasingly being used in R32 refrigerant systems due to their lightweight nature and flexibility. They are often found in insulation and non-structural components.

Pros: The main advantage of thermoplastics is their resistance to corrosion and low weight, which can lead to reduced shipping costs and easier installation.

Cons: However, thermoplastics may not withstand high temperatures and pressures as well as metals, limiting their application scope. They can also be less durable in harsh environmental conditions.

Impact on Application: Thermoplastics can be effective in specific applications, but their limitations in temperature and pressure ratings must be considered.

Considerations for International Buyers: Buyers should ensure that thermoplastics meet relevant standards, such as ISO 9001 for quality management. Understanding local regulations regarding plastic use in refrigerant systems is also crucial.

Summary Table of Material Selection for R32 Refrigerant

| Material | Typical Use Case for cost of r32 refrigerant | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Piping and heat exchangers | Excellent thermal conductivity | Higher cost, corrosion risk | High |

| Aluminum | Evaporators and condensers | Lightweight and cost-effective | Less durable, lower thermal conductivity | Medium |

| Stainless Steel | Valves and fittings | Exceptional corrosion resistance | Higher cost, complex manufacturing | High |

| Thermoplastics | Insulation and non-structural components | Corrosion resistance and flexibility | Limited temperature/pressure tolerance | Low |

This analysis provides a comprehensive overview of material selection for R32 refrigerant systems, highlighting the importance of understanding the properties and implications of each material in various international contexts.

In-depth Look: Manufacturing Processes and Quality Assurance for cost of r32 refrigerant

What Are the Key Stages in the Manufacturing Process of R32 Refrigerant?

The manufacturing process of R32 refrigerant, also known as difluoromethane, involves several critical stages that ensure its purity, efficiency, and compliance with international standards. Understanding these stages can help B2B buyers make informed decisions when sourcing R32 refrigerant.

Material Preparation: What Raw Materials Are Used in R32 Production?

The production of R32 begins with the careful selection of raw materials, primarily hydrogen fluoride and chloroform. These materials undergo rigorous quality checks to ensure they meet the necessary specifications. The purity of these inputs is crucial, as impurities can affect the refrigerant’s performance and environmental impact.

Forming: How Is R32 Refrigerant Synthesized?

Once the raw materials are prepared, the next stage involves chemical synthesis. R32 is produced through a fluorination reaction, where hydrogen fluoride reacts with chloroform in a controlled environment. This process typically occurs in specialized reactors that maintain specific temperatures and pressures to optimize yield and minimize by-products. The result is a gaseous form of R32 that requires further purification.

Assembly: What Are the Key Techniques for Purification?

Following synthesis, the refrigerant undergoes several purification steps to remove any residual impurities. Techniques such as distillation and adsorption are commonly used. Distillation separates components based on boiling points, while adsorption utilizes materials that selectively bind to unwanted substances. These processes are essential to ensure that the final product meets the high standards required for HVAC applications.

Finishing: How Is R32 Refrigerant Packaged for Distribution?

After purification, R32 is compressed and stored in high-pressure cylinders. This stage involves precise filling techniques to ensure that each cylinder contains the correct amount of refrigerant. Proper labeling and documentation are also critical at this stage, as B2B buyers must have access to safety data sheets and product specifications.

What Quality Assurance Measures Are Implemented in R32 Refrigerant Production?

Quality assurance is a cornerstone of the manufacturing process for R32 refrigerant. Adhering to international and industry-specific standards is essential for ensuring product quality and safety.

What International Standards Are Relevant for R32 Refrigerant?

One of the most recognized quality management standards is ISO 9001, which outlines the criteria for a quality management system. Manufacturers of R32 refrigerant often seek ISO certification to demonstrate their commitment to quality control and continuous improvement. Other relevant standards may include CE marking, which indicates compliance with European safety requirements, and API standards for specific applications.

What Are the Key Quality Control Checkpoints in R32 Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line. Rigorous testing ensures that only high-quality inputs are used.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC involves continuous monitoring of parameters like temperature and pressure. This real-time data helps in identifying deviations that could compromise product quality.

-

Final Quality Control (FQC): After packaging, the final product undergoes comprehensive testing. This may include checking for leaks, assessing pressure levels, and verifying purity through gas chromatography.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing R32 refrigerant, B2B buyers should take proactive steps to ensure that suppliers adhere to stringent QC measures. Here are some effective strategies:

What Audits and Reports Should Buyers Request?

Buyers should request detailed quality assurance reports from potential suppliers. These documents should outline the manufacturing process, quality control measures, and compliance with relevant standards. Additionally, conducting regular audits can help verify that suppliers consistently meet quality expectations. This can be done through third-party inspection agencies that specialize in manufacturing audits.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspectors can evaluate the manufacturing facility, review quality control procedures, and test product samples. This independent verification is particularly valuable for international buyers, who may face challenges in assessing supplier practices from afar.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, especially those from regions like Africa, South America, the Middle East, and Europe, must navigate various complexities in quality assurance.

How Do Regional Regulations Impact Quality Standards?

Different regions may have specific regulations governing the use and production of refrigerants. For instance, buyers in Europe must comply with F-Gas regulations that aim to reduce greenhouse gas emissions. Understanding these regulations is crucial for ensuring compliance and avoiding potential legal issues.

What Additional Considerations Should Buyers Keep in Mind?

Cultural differences and varying business practices can also affect quality assurance. Buyers should invest time in understanding the local market dynamics and establishing clear communication channels with suppliers. This approach fosters transparency and builds trust, which are vital for long-term partnerships.

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Important for B2B Buyers?

In the competitive landscape of refrigerant procurement, understanding the manufacturing processes and quality assurance measures for R32 refrigerant is essential. By comprehensively evaluating suppliers and their practices, B2B buyers can ensure that they receive high-quality products that meet both performance and environmental standards. This diligence not only enhances operational efficiency but also contributes to sustainable business practices in the HVAC industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cost of r32 refrigerant’

Introduction

In the ever-evolving landscape of HVAC solutions, R32 refrigerant is gaining popularity due to its efficiency and lower environmental impact. This guide offers a structured checklist for B2B buyers looking to procure R32 refrigerant, ensuring a smooth purchasing process that aligns with technical and regulatory requirements.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clarify your technical requirements for R32 refrigerant. This includes determining the quantity needed, purity levels (e.g., virgin versus reclaimed), and specific applications (e.g., air conditioning systems, heat pumps). Understanding these specifications will enable you to communicate effectively with potential suppliers and ensure you procure the right product.

Step 2: Research Market Pricing Trends

Conduct thorough market research to understand the current pricing landscape for R32 refrigerant. Prices can vary significantly based on factors such as supplier location, shipping costs, and volume discounts. Knowing the average market price will help you identify competitive offers and negotiate better terms with suppliers.

- Sub-bullet: Monitor fluctuations in prices based on seasonal demand or regulatory changes that may impact availability.

Step 3: Evaluate Potential Suppliers

Selecting the right supplier is crucial for ensuring product quality and reliability. Look for suppliers with a proven track record in the HVAC industry, and request documentation such as company profiles, certifications, and customer references. This vetting process helps mitigate risks associated with product performance and delivery.

- Sub-bullet: Verify if the supplier adheres to local regulations regarding the sale of refrigerants, which can vary by region.

Step 4: Assess Regulatory Compliance

Ensure that your selected suppliers comply with international and local regulations governing refrigerant sales. This includes confirming that they provide the necessary documentation, such as EPA certifications and safety data sheets. Compliance is critical not only for legal reasons but also for ensuring the safety and efficacy of the refrigerant in your systems.

- Sub-bullet: Be aware of specific regulations in your region, such as restrictions on certain refrigerants in areas like California.

Step 5: Request Samples for Quality Assurance

Before placing a bulk order, request samples of R32 refrigerant to assess quality and compatibility with your systems. Testing samples can prevent potential issues that may arise from using subpar products, which could lead to system inefficiencies or failures.

- Sub-bullet: Use standardized testing methods to evaluate the refrigerant’s performance against your technical specifications.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations to establish favorable terms. Discuss pricing, payment options, delivery schedules, and return policies. A well-structured agreement can protect your interests and ensure clarity in the supplier relationship.

- Sub-bullet: Consider including clauses for volume discounts or future orders to enhance your procurement strategy.

Step 7: Plan for Logistics and Delivery

Finally, develop a logistics plan that addresses the transportation and storage of R32 refrigerant. Consider factors such as delivery timelines, shipping methods, and storage conditions to maintain the integrity of the refrigerant. Effective logistics management ensures timely availability and reduces operational disruptions.

- Sub-bullet: Evaluate options for local suppliers to minimize shipping times and costs, especially in regions with strict refrigerant handling regulations.

By following this checklist, B2B buyers can confidently navigate the procurement process for R32 refrigerant, ensuring they meet both technical and regulatory requirements while optimizing costs.

Comprehensive Cost and Pricing Analysis for cost of r32 refrigerant Sourcing

What Are the Key Cost Components of R32 Refrigerant Sourcing?

When evaluating the costs associated with sourcing R32 refrigerant, several key components come into play. Materials represent the primary cost factor, as R32 is a specialized hydrofluorocarbon that requires precise manufacturing standards. Labor costs are also significant, particularly in the production and filling processes, which necessitate trained personnel familiar with safety protocols and equipment handling.

Manufacturing overhead includes expenses related to the facilities, utilities, and maintenance of the production equipment. Additionally, tooling costs can influence the price, especially for manufacturers investing in specialized machinery for R32 production. Quality control (QC) is crucial given the environmental regulations surrounding refrigerants, which necessitate rigorous testing and compliance checks, adding to the overall cost structure.

Finally, logistics plays a vital role in determining the final price. This includes transportation, storage, and distribution costs, which can vary significantly based on geographical location and shipping methods.

How Do Price Influencers Affect R32 Refrigerant Costs?

Several factors can influence the pricing of R32 refrigerant in the B2B marketplace. Volume and minimum order quantities (MOQ) are crucial; larger orders often come with significant discounts, making it more cost-effective for buyers to purchase in bulk. Additionally, specifications and customization requirements can affect pricing, as tailored formulations may necessitate additional production processes.

The quality of materials used and any certifications required also play a role in price determination. Suppliers that offer certified products may charge a premium, but this can also lead to long-term savings through enhanced efficiency and reduced environmental impact.

Supplier factors, including reputation and reliability, can influence costs as well. Established suppliers with a track record of quality and service may command higher prices but can offer better assurance of product performance. Furthermore, Incoterms dictate shipping responsibilities and costs, which can significantly impact the total cost of acquisition depending on the terms negotiated.

What Buyer Tips Can Enhance Cost-Efficiency in R32 Refrigerant Procurement?

For B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to substantial savings. Understanding the total cost of ownership (TCO) is essential; this includes not just the purchase price but also installation, maintenance, and operational efficiency over the refrigerant’s lifecycle.

Buyers should also be aware of pricing nuances in different markets. For example, while prices may be lower in bulk purchases, international shipping costs and import duties can quickly offset these savings. Therefore, sourcing from regional suppliers may offer a more competitive total cost.

Additionally, building strong relationships with suppliers can lead to better pricing and terms. Regular communication and feedback can enhance collaboration and may provide opportunities for exclusive discounts or early access to new products.

Conclusion: Understanding R32 Refrigerant Pricing Dynamics

In summary, the cost of R32 refrigerant sourcing is influenced by a combination of material, labor, overhead, tooling, quality control, and logistics costs. Buyers should be cognizant of how volume, specifications, quality, supplier reliability, and Incoterms can affect pricing. By leveraging strategic negotiation and focusing on the total cost of ownership, international B2B buyers can enhance their procurement processes and achieve better financial outcomes.

Disclaimer: The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and regional factors. Always consult with multiple suppliers to ensure competitive pricing and optimal procurement strategies.

Alternatives Analysis: Comparing cost of r32 refrigerant With Other Solutions

Exploring Alternative Refrigerant Solutions: A Comparative Analysis

In the evolving HVAC landscape, businesses are often tasked with selecting the most effective refrigerant solution that balances performance, cost, and environmental considerations. R-32 refrigerant has emerged as a leading choice, primarily due to its efficiency and lower global warming potential (GWP). However, several alternatives also exist that may better suit specific applications or business needs. This analysis will compare R-32 refrigerant against two viable alternatives: R-410A and R-454B.

| Comparison Aspect | Cost Of R32 Refrigerant | R-410A | R-454B |

|---|---|---|---|

| Performance | Up to 12% more efficient than R-410A | Good efficiency, but higher GWP | Similar performance to R-32 with lower GWP |

| Cost | Approx. $319 for 20 lbs | Approx. $420 for 20 lbs | Approx. $999 for 25 lbs |

| Ease of Implementation | Requires specific fittings and tools | Widely used, minimal adjustment needed | Requires new system design for optimal use |

| Maintenance | Low maintenance, but specific procedures required | Standard maintenance practices apply | Requires training for technicians on new protocols |

| Best Use Case | Modern HVAC systems seeking efficiency | Established systems and retrofits | New installations aiming for environmental compliance |

In-Depth Look at Alternatives

What are the Pros and Cons of R-410A?

R-410A has been a staple in the HVAC industry for many years due to its reliability and effectiveness. Its performance is well-documented, making it a safe choice for businesses with existing systems designed for this refrigerant. However, it comes with a higher GWP, which is a significant drawback in an era increasingly focused on sustainability. Additionally, the cost of R-410A is higher than R-32, which may impact the bottom line for businesses looking to optimize operational costs.

How Does R-454B Compare to R-32?

R-454B is a newer refrigerant that offers performance comparable to R-32 while boasting a lower GWP, making it an attractive alternative for businesses prioritizing environmental responsibility. However, its cost is considerably higher, which may deter some buyers. Moreover, implementing R-454B might necessitate new equipment or system designs, potentially leading to higher upfront investments. Businesses must weigh the long-term benefits of reduced environmental impact against initial costs and compatibility issues.

Conclusion: Making the Right Choice for Your Business

When selecting a refrigerant solution, B2B buyers should consider a variety of factors, including cost, performance, and environmental impact. R-32 offers a compelling balance of efficiency and affordability, particularly for modern HVAC applications. However, alternatives like R-410A and R-454B may be better suited for specific operational contexts or compliance with environmental regulations. Ultimately, the decision should align with the company’s goals regarding sustainability, budget constraints, and system compatibility. By carefully analyzing these factors, businesses can make an informed choice that supports both their operational needs and environmental commitments.

Essential Technical Properties and Trade Terminology for cost of r32 refrigerant

What Are the Key Technical Properties of R32 Refrigerant?

Understanding the technical properties of R32 refrigerant is crucial for B2B buyers in the HVAC industry. Here are some of the essential specifications that impact purchasing decisions:

-

GWP (Global Warming Potential)

R32 has a GWP of 675, significantly lower than many traditional refrigerants like R410A, which has a GWP of 2088. This property is critical for companies aiming to comply with environmental regulations and reduce their carbon footprint. Lower GWP refrigerants are increasingly preferred in markets across Europe, Africa, and South America, as they align with global sustainability goals. -

Energy Efficiency

R32 is known for its superior energy efficiency, being up to 12% more efficient than R410A systems. This efficiency translates to lower operational costs for end-users, making it an attractive option for HVAC contractors and businesses looking to reduce energy consumption. Understanding the energy performance of refrigerants can help buyers justify the cost based on long-term savings. -

Flammability Classification

Classified as A2L, R32 is considered mildly flammable. This classification influences safety protocols and equipment design. B2B buyers must ensure that their systems are compatible with A2L refrigerants and that their teams are trained in handling such materials. Knowledge of flammability properties is essential for compliance with safety standards and regulations. -

Single-Component Refrigerant

R32 is a single-component refrigerant, which simplifies the charging and servicing process. Unlike blends that require precise ratios, R32 can be recharged with a single refrigerant type, reducing the complexity and potential for errors during installation and maintenance. This property is particularly important for contractors and service providers who prioritize efficiency and ease of use. -

Refrigerant Type

As a hydrofluorocarbon (HFC), R32 is designed specifically for modern HVAC applications, including heat pumps and air conditioning systems. Understanding the refrigerant type is vital for selecting the right product for specific applications, ensuring that the system operates at optimal performance levels. -

Tank Size and Shipping Considerations

R32 is commonly available in 20-pound cylinders, which are a standard size for HVAC applications. Knowing the tank size and associated shipping weight (approximately 33 lbs) is essential for logistics planning and inventory management. B2B buyers should consider shipping costs and storage capabilities when purchasing in bulk.

What Are Common Trade Terms Relevant to Purchasing R32 Refrigerant?

Familiarity with industry terminology can enhance the purchasing experience for B2B buyers. Here are some key terms to understand:

-

OEM (Original Equipment Manufacturer)

An OEM produces components or systems that are used in another company’s end products. In the context of refrigerants, knowing whether the supplier is an OEM can assure buyers of the quality and compatibility of the refrigerant with specific HVAC systems. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier requires for an order. Understanding MOQs helps buyers evaluate their purchasing strategy, ensuring they meet supplier requirements while optimizing inventory levels. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specified products or services. B2B buyers should utilize RFQs to obtain competitive pricing for R32 refrigerant, ensuring they secure the best deal based on their volume needs. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with Incoterms helps B2B buyers understand their obligations concerning transport costs, insurance, and liability during the shipping process. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is crucial for effective project planning and inventory management, particularly for businesses operating in regions with fluctuating supply chains. -

Hazmat (Hazardous Materials)

R32 is classified as a hazmat due to its flammability. Buyers must be aware of the regulations surrounding the storage and transport of hazardous materials, ensuring compliance with local and international safety standards.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing R32 refrigerant, ensuring they meet operational needs while adhering to environmental and safety regulations.

Navigating Market Dynamics and Sourcing Trends in the cost of r32 refrigerant Sector

Understanding the Market Dynamics and Key Trends in the Cost of R32 Refrigerant

The global market for R32 refrigerant is influenced by several key drivers, including the transition towards low-GWP (Global Warming Potential) refrigerants mandated by international climate agreements. As countries strive to meet their environmental targets, R32 is gaining traction due to its efficiency and reduced environmental impact compared to traditional refrigerants like R410A. In particular, markets in Africa, South America, the Middle East, and Europe are experiencing a surge in demand as HVAC systems are upgraded to meet stricter regulations and efficiency standards.

Emerging B2B technologies are reshaping the sourcing landscape. The adoption of digital procurement platforms allows international buyers to streamline their purchasing processes, enabling them to compare prices and suppliers more effectively. Furthermore, advancements in logistics technology are facilitating faster and more reliable delivery of R32, which is crucial for contractors and HVAC professionals who require timely access to refrigerants.

Market dynamics are also characterized by fluctuating prices due to supply chain disruptions, geopolitical tensions, and changing regulatory landscapes. For instance, the availability of R32 can be affected by regional restrictions, such as those imposed in California and New York on certain refrigerants. B2B buyers must stay informed about these dynamics to make strategic sourcing decisions that align with their operational needs and compliance requirements.

How Does Sustainability Influence the Cost of R32 Refrigerant and Ethical Sourcing?

Sustainability is increasingly becoming a cornerstone of business strategy, particularly in the HVAC sector. The environmental impact of refrigerants, including their contribution to greenhouse gas emissions, has led to a heightened focus on ethical sourcing practices. For B2B buyers, choosing R32 not only aligns with environmental regulations but also reflects a commitment to sustainability, which can enhance brand reputation and customer loyalty.

Ethical supply chains are essential for ensuring that the procurement of R32 is not only environmentally responsible but also socially equitable. Buyers should seek suppliers who prioritize transparency and sustainability in their operations. Certifications, such as ISO 14001 for environmental management, can serve as indicators of a supplier’s commitment to sustainable practices. Additionally, the use of green refrigerants like R32, which is designed to minimize environmental impact, is crucial for companies aiming to achieve sustainability goals.

As the demand for environmentally friendly products grows, companies that invest in ethical sourcing can differentiate themselves in a competitive market. This not only improves their market positioning but can also lead to cost savings through energy-efficient operations and reduced regulatory risks.

What is the Evolution of R32 Refrigerant in the B2B Market?

R32 refrigerant, introduced as a replacement for R410A, represents a significant evolution in the HVAC sector. Initially developed in the early 2000s, R32 gained recognition for its lower GWP and higher energy efficiency, making it an attractive option for modern HVAC systems. As international regulations began to tighten around the use of high-GWP refrigerants, R32 emerged as a compliant alternative that meets the needs of both consumers and regulatory bodies.

The growing adoption of R32 reflects a broader trend towards more sustainable and efficient cooling solutions in the HVAC industry. As more countries phase out harmful refrigerants, the shift towards R32 not only represents a technological advancement but also a commitment to environmental stewardship. This evolution continues to shape sourcing strategies for B2B buyers, emphasizing the importance of selecting refrigerants that align with future regulatory frameworks and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of cost of r32 refrigerant

-

How do I determine the cost of R32 refrigerant for bulk purchases?

To accurately assess the cost of R32 refrigerant for bulk purchases, consider several factors, including supplier pricing, shipping costs, and any applicable tariffs or taxes. Many suppliers offer volume discounts, so inquire about pricing tiers based on quantity. Additionally, it’s important to compare prices from multiple suppliers, as costs can vary significantly across regions. Always factor in the cost of compliance with local regulations, which may influence pricing, especially for international shipments. -

What is the best supplier for R32 refrigerant in my region?

Identifying the best supplier for R32 refrigerant involves evaluating several criteria: reliability, pricing, availability, and customer service. Look for suppliers with a strong reputation in your region, especially those with experience in international trade. Reading customer reviews and requesting references can provide insights into their reliability. Additionally, check if they offer technical support and compliance with local regulations, which is crucial for smooth operations in the HVAC industry. -

What are the minimum order quantities (MOQ) for R32 refrigerant?

Minimum order quantities for R32 refrigerant can vary by supplier and region. Many suppliers set MOQs to ensure cost-effectiveness in shipping and handling. Generally, MOQs can range from a single cylinder to several pallets. When negotiating with suppliers, clarify the MOQ and discuss potential flexibility, especially if you are looking to establish a long-term partnership or if you require custom solutions for your business. -

What payment terms should I expect when purchasing R32 refrigerant internationally?

Payment terms for international purchases of R32 refrigerant often depend on the supplier and the specifics of the transaction. Common terms include advance payment, letters of credit, or net payment options (e.g., net 30 or net 60 days). It’s essential to confirm these terms upfront and assess the risks associated with each option. Additionally, consider currency fluctuations and transaction fees, as these can impact the final cost of your purchase. -

How do I ensure the quality of R32 refrigerant before purchasing?

To ensure the quality of R32 refrigerant, request documentation such as safety data sheets (SDS) and certificates of analysis (CoA) from potential suppliers. These documents should confirm the refrigerant’s purity and compliance with industry standards. Additionally, consider sourcing from suppliers with recognized certifications (e.g., ISO) and a solid track record in the HVAC industry. Conducting a supplier audit or visiting their facility, if feasible, can further guarantee the quality of the product. -

What are the logistics considerations for importing R32 refrigerant?

Logistics for importing R32 refrigerant involve multiple factors, including compliance with international shipping regulations, proper packaging, and transportation methods. Ensure that the supplier adheres to all relevant safety and environmental standards. Additionally, verify that the refrigerant is transported under appropriate conditions to maintain its integrity. Working with a logistics partner experienced in hazardous materials can streamline the process and help navigate customs clearance efficiently. -

What regulations should I be aware of when sourcing R32 refrigerant?

Sourcing R32 refrigerant requires awareness of various regulations that govern its use, transportation, and disposal. These regulations may differ by country and region, especially concerning greenhouse gas emissions and safety standards. Familiarize yourself with local laws and international agreements such as the Montreal Protocol. Engaging with suppliers who understand these regulations can help ensure compliance and mitigate risks associated with penalties or product recalls. -

Can I customize my order of R32 refrigerant?

Many suppliers offer customization options for R32 refrigerant orders, including packaging sizes and labeling requirements. If your business has specific needs, such as bulk quantities or specialized delivery schedules, discuss these with potential suppliers during the negotiation phase. Customization may also extend to the inclusion of additional services, such as training for handling and usage, which can enhance your team’s operational efficiency and safety standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cost Of R32 Refrigerant Manufacturers & Suppliers List

1. Refrigerant Depot – R-32 20lb. Cylinder

Domain: refrigerantdepot.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “R-32 20lb. Cylinder”, “price”: “$500.00”, “original_price”: “$600.00”, “description”: “R32 refrigerant, also known as difluoromethane, is an hydrofluorocarbon (HFC) used in heating, ventilation, and air conditioning (HVAC) systems. It has higher energy efficiency and lower environmental impact compared to other refrigerants.”, “category”: “HVAC Refrigerants”, “requirements”: “You…

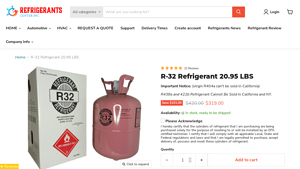

2. Refrigerants Center – R-32 Refrigerant 20LB

Domain: refrigerantscenter.com

Registered: 2019 (6 years)

Introduction: {“name”: “R-32 Refrigerant 20LB”, “weight”: “20.95 lbs”, “original_price”: “$420.00”, “current_price”: “$319.00”, “availability”: “in stock, ready to be shipped”, “efficiency”: “up to 12% more efficient than R410A systems”, “environmental_impact”: “Low GWP approved replacement of R410A refrigerant”, “usage”: “suitable for modern HVAC applications, can be added or recharged in liquid and gas states…

3. Forane – R32 Refrigerant

Domain: johnstonesupply.com

Registered: 1996 (29 years)

Introduction: {“Refrigerant”:”R32″,”Refrigerant Type”:”HFO”,”Tank Size”:”20 Lbs.”,”Order Number”:”B64-386″,”Internal Product ID”:””,”Catalog Page”:”1158″,”Manufacturer Number”:”R32-20″,”Brand”:”Forane”,”Shipping Weight”:”33.00 lbs”,”Shipping Width”:”9.50 in”,”Shipping Length”:”9.50 in”,”Shipping Height”:”16.50 in”,”Hazmat”:”Yes”,”Country of Origin”:”United States”,”Description”:”Forane® 32 A2L refrigerant is cl…

4. Ability Refrigerants – R-32 Refrigerant Gas

Domain: abilityrefrigerants.com

Introduction: {“name”: “R-32 Refrigerant Gas”, “weight”: “5 lbs (2.2 kg)”, “price”: {“original”: “$249.00”, “current”: “$195.00”}, “features”: {“energy_efficiency”: “Lower Global Warming Potential (GWP) compared to R-410A”, “cooling_capacity”: “Highly efficient for peak performance and rapid cooling”, “compatibility”: “Compatible with many modern air conditioning systems”, “environmental_impact”: “Contributes t…

5. Refrigerant – R-32 Low GWP Approved Refrigerant 20.9lb Jug

Domain: budgetheating.com

Registered: 2005 (20 years)

Introduction: {“Product Name”: “R-32 Low GWP Approved Refrigerant 20.9lb Jug”, “Product Code”: “26019”, “Manufacturer”: “Refrigerant”, “List Price”: “$756.00”, “Sale Price”: “$350.00”, “Savings”: “$406.00”, “SKU”: “26019”, “Availability”: “In Stock”, “Shipping”: “Calculated at Checkout”, “Refrigerant Type”: “R-32”, “Efficiency”: “Up to 12% more efficient than R410A systems”, “Global Acceptance”: “Used in over 2…

6. Sanford – R32 Refrigerant

Domain: choosesanford.com

Registered: 2013 (12 years)

Introduction: R32 Refrigerant: Eco-friendly refrigerant with a Global Warming Potential (GWP) of 675, significantly lower than R-410A’s GWP of 2088. It has an Ozone Depletion Potential (ODP) of 0, meaning it does not harm the ozone layer. R32 is approximately 40% more efficient than R-410A, leading to lower energy bills and consistent cooling performance. Pricing for R32 refrigerant is approximately $11.02 per …

7. eRefrigerants – R-32 Refrigerant 20 lb

Domain: erefrigerants.com

Registered: 2024 (1 years)

Introduction: R-32 Refrigerant 20 lb. Regular price: $429.00, Sale price: $429.00. Free shipping within the continental US. 100% virgin factory sealed. Satisfaction guaranteed. R-32 is an HFC refrigerant, used as a replacement for R410A in low temperature refrigeration and air-conditioning applications. Not for retrofit use. Left hand threads due to mildly flammable nature. Product meets or exceeds ARI-700 stan…

Strategic Sourcing Conclusion and Outlook for cost of r32 refrigerant

In the evolving landscape of refrigerants, R32 stands out for its efficiency and lower environmental impact, making it a strategic choice for HVAC applications. With pricing currently ranging from approximately $319 to $600 per 20 lb cylinder, buyers can leverage competitive sourcing strategies to optimize costs. The growing adoption of R32 in over 230 countries underscores its reliability and performance, offering businesses a sustainable option that aligns with global environmental standards.

Strategic sourcing plays a crucial role in securing the best pricing and availability, particularly for international buyers in regions such as Africa, South America, the Middle East, and Europe. By establishing strong supplier relationships and exploring bulk purchase options, organizations can significantly reduce costs while ensuring compliance with local regulations.

Looking ahead, the demand for R32 is expected to rise as businesses prioritize energy efficiency and sustainability. Now is the time for B2B buyers to evaluate their refrigerant sourcing strategies, ensuring they are not only cost-effective but also environmentally responsible. Engage with trusted suppliers to stay ahead of market trends and secure your supply of R32 refrigerant for future growth and compliance.