Clear Plastic Salad Bowls: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for clear plastic salad bowls

In today’s rapidly evolving food service industry, sourcing clear plastic salad bowls that meet both aesthetic and functional demands poses a significant challenge for international B2B buyers. Whether you’re operating a salad bar in Saudi Arabia or a catering service in Brazil, the right salad bowl can enhance presentation while ensuring durability and sustainability. This comprehensive guide explores various types of clear plastic salad bowls, including traditional PET options and innovative compostable alternatives made from PLA bioplastics.

By delving into applications, supplier vetting processes, and cost considerations, this guide equips buyers with the necessary insights to make informed purchasing decisions. It addresses essential factors such as bowl sizes, lid compatibility, and the environmental benefits of choosing compostable materials, which are increasingly important in regions focused on sustainability. Additionally, we highlight key suppliers and their offerings, ensuring that you can confidently navigate the complexities of sourcing clear plastic salad bowls across diverse markets in Africa, South America, the Middle East, and Europe.

With this guide, you’ll gain actionable strategies to enhance your product offerings, cater to consumer preferences, and ultimately boost your business’s competitive edge in the global market.

Understanding clear plastic salad bowls Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compostable PLA Salad Bowls | Made from plant-based PLA; certified compostable | Salad bars, catering, eco-friendly packaging | Pros: Sustainable, lightweight, strong; Cons: Not microwave-safe, limited to cold foods. |

| PET Clear Salad Bowls | High clarity, durable PET plastic; available with lids | Takeout, delivery, food storage | Pros: Excellent visibility, durable, versatile; Cons: Less eco-friendly than compostable options. |

| Stackable Salad Bowls | Designed for easy stacking; various sizes | Catering events, food service | Pros: Space-saving, efficient for storage; Cons: May lack individual branding options. |

| Reversible Containers | Can function as bowls or plates; dome lids | Catering, buffets, versatile serving | Pros: Multi-functional, cost-effective; Cons: Limited size options may not suit all needs. |

| Large Capacity Bowls | Available in sizes up to 160 oz; heavy-duty design | Large gatherings, events, bulk serving | Pros: Ideal for bulk servings, strong construction; Cons: Bulk purchasing may require higher upfront costs. |

What are the Characteristics of Compostable PLA Salad Bowls?

Compostable PLA salad bowls are made from plant-based polymers, offering a sustainable alternative to traditional plastics. They are lightweight yet strong, making them suitable for grab-and-go salads and catering services. Key B2B purchasing considerations include their certification for industrial composting, aligning with sustainability initiatives, and the ability to meet consumer demand for eco-friendly packaging. However, they are not microwave-safe, limiting their use to cold dishes.

How Do PET Clear Salad Bowls Stand Out?

PET clear salad bowls are renowned for their durability and clarity, making them ideal for showcasing fresh ingredients. These bowls are versatile and can be used for various applications, including takeout and food storage. B2B buyers should consider the quality of the material, which offers better oxygen barriers to keep food fresher longer. While they provide excellent visibility for products, they are less environmentally friendly compared to compostable options.

What Benefits Do Stackable Salad Bowls Provide?

Stackable salad bowls are designed for efficient storage and transportation, making them a popular choice for catering events and food services. These bowls come in various sizes, accommodating different serving needs. B2B buyers should note their space-saving design, which is advantageous for businesses with limited storage. However, they may lack customization options, which could be a drawback for brands looking to enhance their visibility.

Why Choose Reversible Containers for Your Business?

Reversible containers can be utilized as either bowls or plates, offering versatility for catering and buffet-style events. The dome lids enhance their functionality, allowing for a variety of food presentations. For B2B buyers, the cost-effectiveness of these containers is a significant advantage, as they reduce the need for multiple types of packaging. However, limited size options may restrict their use in certain catering scenarios.

What Should Buyers Consider About Large Capacity Bowls?

Large capacity bowls, often available in sizes up to 160 oz, are designed for bulk servings, making them ideal for large gatherings and events. Their heavy-duty construction ensures they can handle substantial amounts of food without compromising integrity. B2B buyers should weigh the benefits of bulk purchasing against the upfront costs, as these bowls can be a more significant investment initially. However, their utility in high-volume situations can justify the expense.

Key Industrial Applications of clear plastic salad bowls

| Industry/Sector | Specific Application of clear plastic salad bowls | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Takeout and Delivery Services | Enhances customer experience with appealing presentation; durable for transport | Ensure compliance with local food safety regulations; consider eco-friendly materials. |

| Catering | Event Catering and Buffets | Provides a visually appealing option for salads and sides; stackable for efficient storage | Assess volume needs and customization options for branding. |

| Retail | Salad Bars and Grocery Store Salad Displays | Promotes fresh, healthy eating; encourages impulse purchases | Evaluate size variety and durability under refrigeration. |

| Hospitality | Hotel and Restaurant Dining | Offers a stylish serving option for salads and desserts; easy to clean | Look for bulk purchasing options to manage costs effectively. |

| Food Manufacturing | Pre-packaged Salad Production | Facilitates efficient packaging; maintains food freshness and visibility | Ensure materials meet food safety standards and consider shelf-life. |

How Are Clear Plastic Salad Bowls Used in Food Service?

In the food service industry, clear plastic salad bowls are essential for takeout and delivery services. Their durability ensures that salads remain intact during transport, while the transparent design enhances visual appeal, encouraging customer purchases. International buyers should consider sourcing bowls that comply with local food safety regulations and explore options made from eco-friendly materials to meet rising consumer demand for sustainable packaging.

What Role Do Clear Plastic Salad Bowls Play in Catering?

Catering businesses utilize clear plastic salad bowls for events such as weddings and corporate functions. These bowls provide an attractive presentation for salads and side dishes, making them ideal for buffets. The stackable design aids in efficient storage and transport. Buyers in this sector should assess their volume needs and explore customization options for branding purposes to enhance their market presence.

How Are Clear Plastic Salad Bowls Beneficial in Retail Settings?

In retail, clear plastic salad bowls are commonly used in salad bars and grocery store displays. They promote fresh, healthy eating by allowing customers to see the vibrant colors and textures of the food. This visibility often leads to increased impulse purchases. Retailers should evaluate the variety of sizes available and the bowls’ durability, particularly under refrigeration, to ensure product longevity and quality.

What Advantages Do Clear Plastic Salad Bowls Offer in Hospitality?

Hotels and restaurants leverage clear plastic salad bowls to serve salads and desserts stylishly. Their lightweight and elegant design allows for easy handling and cleaning, enhancing overall dining experiences. When sourcing for hospitality, businesses should look for bulk purchasing options to manage costs effectively while ensuring the bowls meet high aesthetic standards.

How Do Clear Plastic Salad Bowls Facilitate Food Manufacturing?

In food manufacturing, clear plastic salad bowls are vital for pre-packaged salad production. They facilitate efficient packaging while maintaining food freshness and visibility, which is crucial for retail sales. Buyers in this sector must ensure that the materials used comply with food safety standards and consider the shelf-life of the products to optimize distribution strategies.

3 Common User Pain Points for ‘clear plastic salad bowls’ & Their Solutions

Scenario 1: Sourcing Sustainable Options for Eco-Conscious Customers

The Problem: As a B2B buyer in the food service industry, you are increasingly pressured to meet sustainability standards and consumer demand for eco-friendly products. Many traditional plastic salad bowls contribute to environmental waste and are not biodegradable. Sourcing clear plastic salad bowls that are both functional and sustainable can be a daunting challenge, especially when considering the diverse preferences of international markets like Africa and Europe, where environmental regulations can vary significantly.

The Solution: To address this challenge, consider sourcing clear salad bowls made from compostable materials, such as PLA (polylactic acid) bioplastic. These bowls are derived from renewable resources like corn starch and are designed to break down in industrial composting facilities within 2-4 months. When placing your order, inquire about certifications such as BPI (Biodegradable Products Institute) or CMA (Compost Manufacturing Alliance) to ensure compliance with sustainability standards. Additionally, educate your customers about the environmental benefits of these products to help position your offerings as eco-friendly choices. By focusing on sustainable sourcing, you can align your business with the growing trend of environmentally responsible consumption.

Scenario 2: Ensuring Durability for Takeout and Delivery Services

The Problem: In the competitive landscape of food delivery and takeout services, the durability of packaging is paramount. You may have experienced the frustration of receiving complaints from customers about damaged salad bowls that led to spills, loss of product quality, and ultimately, customer dissatisfaction. This is particularly critical in regions where transportation conditions may not be optimal, such as in remote areas of South America or the Middle East.

The Solution: Opt for clear plastic salad bowls made from high-quality PET (polyethylene terephthalate) that are specifically designed for takeout and delivery. These bowls offer excellent durability and are resistant to cracking and leaking, ensuring that your salads remain intact during transit. When selecting your suppliers, look for those who offer stacking options to save space and prevent damage. Additionally, consider integrating tight-fitting lids that create a secure seal, further protecting the contents. By prioritizing durability in your product selection, you enhance customer satisfaction and reduce return rates, ultimately benefiting your bottom line.

Scenario 3: Navigating Size and Presentation for Different Serving Needs

The Problem: As a supplier catering to diverse food service clients, you may find it challenging to meet varying portion sizes and presentation standards. Clients in catering services may require different bowl sizes for events, while restaurants might need stylish yet functional options for individual servings. Failing to provide the right size can lead to over- or under-serving, impacting food costs and customer experience.

The Solution: To effectively navigate this challenge, offer a versatile range of clear plastic salad bowls in multiple sizes—such as 16 oz, 24 oz, 32 oz, and 48 oz. This flexibility allows your clients to choose the appropriate size based on their specific service style, whether for individual meals, catering events, or salad bars. Additionally, emphasize the aesthetic appeal of the bowls; clear options provide a visually appealing presentation that enhances the overall dining experience. When marketing these products, consider providing usage suggestions or serving guides to help clients understand how to best utilize the different sizes. This approach not only meets diverse needs but also positions your business as a knowledgeable partner in their food service operations.

Strategic Material Selection Guide for clear plastic salad bowls

What Are the Key Materials Used for Clear Plastic Salad Bowls?

When selecting materials for clear plastic salad bowls, it is essential to consider various factors such as durability, cost, environmental impact, and compliance with international standards. Below, we analyze four common materials used in the production of clear plastic salad bowls: PLA (Polylactic Acid), PET (Polyethylene Terephthalate), PS (Polystyrene), and PP (Polypropylene).

How Does PLA (Polylactic Acid) Perform in Salad Bowl Applications?

PLA is a bioplastic derived from renewable resources like corn starch. It is known for its compostability and is suitable for cold food applications.

Key Properties: PLA bowls are lightweight yet strong, with a temperature resistance of up to 50°C. They are not suitable for microwave use but can withstand refrigeration.

Pros & Cons: The primary advantage of PLA is its eco-friendliness, as it is compostable in industrial facilities, making it an attractive option for environmentally conscious businesses. However, its lower heat resistance limits its use for hot foods, and it may not be as durable as traditional plastics.

Impact on Application: PLA is ideal for salad bars and takeout, where cold food is predominant. Its compostable nature aligns with sustainability initiatives, appealing to consumers and businesses looking to reduce their environmental footprint.

International Considerations: Buyers in regions like Europe and parts of South America may favor PLA due to stringent environmental regulations. Compliance with standards such as BPI and CMA certifications is crucial for market acceptance.

What Advantages Does PET (Polyethylene Terephthalate) Offer?

PET is a widely used thermoplastic known for its clarity and strength, making it a popular choice for food packaging, including salad bowls.

Key Properties: PET has excellent temperature resistance, typically up to 70°C, and is highly resistant to impact and moisture.

Pros & Cons: The main advantage of PET is its durability and recyclability, making it suitable for various food types, including salads and desserts. However, it is more expensive than some alternatives, and its production process can be complex due to the need for specialized machinery.

Impact on Application: PET bowls are perfect for takeout and delivery, ensuring that food remains fresh longer due to better oxygen barrier properties compared to other plastics.

International Considerations: Compliance with FDA and EU regulations is critical for PET products. Buyers from regions such as the Middle East and Africa should ensure that their suppliers meet local standards for food safety.

How Does PS (Polystyrene) Compare for Salad Bowls?

Polystyrene is another common plastic used in food packaging, known for its rigid structure.

Key Properties: PS offers good clarity and is lightweight, with a temperature tolerance of around 70°C. It is less resistant to impact compared to PET.

Pros & Cons: The advantage of PS is its low cost and ease of manufacturing, making it a budget-friendly option. However, it is less durable and can break easily, which may not be suitable for high-traffic food service environments.

Impact on Application: PS bowls are often used for single-use applications, such as events and parties, where cost efficiency is prioritized over durability.

International Considerations: Buyers should be aware of the growing regulatory scrutiny on polystyrene in various regions. Compliance with local bans or restrictions is essential, especially in Europe.

What Role Does PP (Polypropylene) Play in Salad Bowl Manufacturing?

Polypropylene is a versatile plastic known for its flexibility and resistance to fatigue.

Key Properties: PP can withstand temperatures up to 120°C, making it suitable for both hot and cold food applications. It is also resistant to many chemicals, enhancing its usability.

Pros & Cons: The main advantage of PP is its high durability and versatility. It can be used for a variety of food types, including salads, hot dishes, and desserts. However, it is generally less transparent than PET and PLA.

Impact on Application: PP bowls are ideal for catering and food service operations that require a mix of hot and cold food options.

International Considerations: Buyers should ensure that PP products comply with local food safety regulations, particularly in regions like South America and Africa, where standards may vary.

Summary Table of Material Properties

| Material | Typical Use Case for clear plastic salad bowls | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PLA | Cold food applications, salad bars | Eco-friendly, compostable | Lower heat resistance | Medium |

| PET | Takeout, delivery | Durable, excellent clarity | Higher production cost | High |

| PS | Single-use events, parties | Low cost, easy to manufacture | Less durable, brittle | Low |

| PP | Catering, mixed food types | High durability, temperature resistant | Less transparency | Medium |

This analysis provides B2B buyers with actionable insights into the material selection process for clear plastic salad bowls, helping them make informed decisions that align with their operational needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for clear plastic salad bowls

What are the Main Stages of Manufacturing Clear Plastic Salad Bowls?

The manufacturing of clear plastic salad bowls involves a series of well-defined stages that ensure quality and efficiency.

Material Preparation

The process begins with material preparation, where raw plastic pellets, typically made from PET (Polyethylene Terephthalate) or PLA (Polylactic Acid), are sourced. For environmentally conscious buyers, PLA, a biodegradable option derived from renewable resources like corn starch, is gaining traction. The material is dried to remove moisture, which can lead to defects during the molding process. This step is crucial, as the quality of the raw material directly influences the final product’s durability and appearance.

Forming Techniques

Once the materials are prepared, the next phase is forming. This usually involves injection molding or thermoforming:

-

Injection Molding: This technique is predominant for creating complex shapes and designs. The raw plastic is heated until it becomes pliable and then injected into a mold under high pressure. This method is favored for its precision and ability to produce large quantities quickly.

-

Thermoforming: This involves heating a sheet of plastic until it is pliable, then draping it over a mold and allowing it to cool. This technique is more cost-effective for lower-volume production runs and is often used for simpler designs.

Both methods ensure that the salad bowls have the desired clarity and strength, making them suitable for a variety of applications, from salad bars to takeout services.

Assembly and Finishing

After forming, the bowls may require assembly, particularly if they come with lids or additional components. This stage may include attaching lids, ensuring a secure fit that prevents spillage during transport.

Finishing touches such as quality checks for clarity, strength, and surface defects are conducted at this stage. Additionally, bowls may be printed with branding or product information using techniques like pad printing or screen printing, adding value for B2B buyers who wish to personalize their products.

How is Quality Assurance Managed Throughout the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing of clear plastic salad bowls, ensuring that products meet both safety and performance standards.

International Standards for Quality Assurance

Manufacturers typically adhere to international quality management standards such as ISO 9001, which sets criteria for a quality management system. Compliance with ISO standards assures buyers that the manufacturer has established processes in place for continuous improvement and customer satisfaction.

In addition to ISO, specific certifications like CE (Conformité Européenne) indicate that products meet EU safety and health requirements. For environmentally friendly products, look for certifications like BPI (Biodegradable Products Institute) and CMA (Compost Manufacturing Alliance) for PLA bowls.

Key Quality Control Checkpoints

Quality control is implemented at various stages of the production process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials before production begins. It ensures that only high-quality materials are used in manufacturing.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, continuous monitoring takes place. Operators check for defects in real-time, allowing for immediate corrections if issues arise.

-

Final Quality Control (FQC): After production, a thorough inspection is conducted to assess the finished products. This includes checking for dimensional accuracy, clarity, strength, and compliance with safety standards.

What Common Testing Methods are Used in Quality Assurance?

Manufacturers employ various testing methods to ensure their products meet required specifications.

-

Mechanical Testing: This includes tensile strength tests to evaluate the bowls’ resistance to stretching and breaking. Impact resistance tests assess how well the bowls can withstand drops or impacts without shattering.

-

Thermal Testing: For products like PLA that are sensitive to temperature, thermal stability tests determine how well the bowls hold up under different temperatures, ensuring they are suitable for their intended uses.

-

Chemical Testing: This ensures that materials are free from harmful substances, especially for food contact products. Compliance with FDA regulations is critical for B2B buyers, particularly in markets with stringent food safety laws.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers.

Conducting Audits

One of the most effective ways to ensure a supplier’s credibility is through audits. Buyers can conduct on-site visits to review manufacturing processes, quality control systems, and compliance with international standards. This firsthand observation provides valuable insights into the supplier’s operational integrity.

Requesting Quality Reports

Buyers should also request quality assurance reports that document the results of quality control checks, testing procedures, and compliance certifications. These documents should outline the methods used and any corrective actions taken in response to identified issues.

Third-Party Inspections

Engaging third-party inspection services can further validate a supplier’s claims regarding product quality. These independent entities can perform audits and testing, providing unbiased assessments that help buyers make informed decisions.

What are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of the unique challenges associated with sourcing clear plastic salad bowls.

Regulatory Compliance

Each region may have specific regulations governing food contact materials. Buyers must ensure that their suppliers are compliant with local laws. For instance, the EU has strict regulations on food safety that differ from those in South America or Africa. Understanding these nuances is essential for avoiding legal complications.

Cultural and Market Considerations

Cultural preferences can influence the choice of materials and design. For example, sustainability is a significant concern in European markets, prompting a preference for compostable materials like PLA. Buyers should communicate their market requirements clearly to suppliers to ensure alignment in product offerings.

Currency and Trade Risks

Finally, international transactions may involve currency fluctuations and trade risks. Establishing clear contracts that outline payment terms, delivery schedules, and quality expectations can mitigate these risks and foster successful long-term partnerships.

By understanding the manufacturing processes and quality assurance mechanisms in place, B2B buyers can make informed decisions and select suppliers that align with their operational standards and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘clear plastic salad bowls’

To effectively source clear plastic salad bowls, it’s essential to follow a systematic approach. This guide provides a step-by-step checklist designed to help international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, make informed purchasing decisions. By adhering to these steps, you can ensure that the products you procure meet your quality, sustainability, and logistical requirements.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the salad bowls you need. This includes material type (e.g., PET or PLA), sizes (e.g., 16 oz, 32 oz), and whether you require lids. Defining these parameters upfront helps streamline your search and ensures that suppliers can meet your specific needs.

- Material Considerations: Decide if you prefer traditional plastics or more sustainable options like compostable PLA.

- Size Variability: Consider the range of sizes you may need based on your target market (e.g., individual servings vs. larger catering portions).

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in clear plastic salad bowls. Utilize online marketplaces, trade directories, and industry reports to compile a list of potential vendors.

- Supplier Reputation: Look for suppliers with positive customer reviews and a solid track record in the industry.

- Geographical Location: Consider suppliers who can efficiently serve your region, as this can affect shipping costs and delivery times.

Step 3: Verify Supplier Certifications

It is critical to confirm that suppliers hold relevant certifications, particularly for food safety and environmental standards. This includes certifications like FDA approval for food contact and BPI or CMA certifications for compostable products.

- Importance of Certifications: Certifications ensure that the products meet legal requirements and align with your sustainability goals.

- Documentation Requests: Don’t hesitate to request copies of these certifications for your records.

Step 4: Request Samples for Quality Assessment

Before placing large orders, request samples from shortlisted suppliers. This allows you to evaluate the quality, durability, and design of the salad bowls first-hand.

- Evaluation Criteria: Assess clarity, strength, and usability, especially if you require lids for delivery purposes.

- Testing for Performance: If applicable, test the bowls under conditions they will be used, such as stacking and holding cold food.

Step 5: Compare Pricing and Terms of Sale

Gather pricing information and compare it across potential suppliers. Pay attention to minimum order quantities, payment terms, and shipping costs.

- Total Cost of Ownership: Consider not only the unit price but also the overall cost, including shipping and any potential customs fees.

- Negotiation Opportunities: Don’t hesitate to negotiate terms, especially if you plan to establish a long-term partnership.

Step 6: Evaluate Customer Support and Communication

Assess the responsiveness and clarity of communication from your suppliers. Good customer support can facilitate smoother transactions and issue resolution.

- Response Times: Take note of how quickly suppliers respond to inquiries and whether they provide detailed information.

- Support Availability: Ensure that they have a reliable support system in place for any post-purchase issues.

Step 7: Finalize Your Order and Review Logistics

Once you’ve selected a supplier, finalize your order details. Review logistics concerning delivery timelines and any necessary customs documentation, especially for international shipments.

- Logistical Planning: Consider your inventory needs and how quickly you need the product to avoid stockouts.

- Customs Compliance: Ensure that all necessary documentation is in order for smooth customs clearance.

By following this checklist, you can confidently navigate the sourcing process for clear plastic salad bowls, ensuring that you choose the right products and suppliers for your business needs.

Comprehensive Cost and Pricing Analysis for clear plastic salad bowls Sourcing

What are the Key Cost Components in Clear Plastic Salad Bowl Manufacturing?

When sourcing clear plastic salad bowls, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice between traditional petroleum-based plastics (like PET and PLA) directly affects the price. PLA, a bioplastic made from renewable resources, is often more expensive due to its eco-friendly attributes. The availability and market demand for these materials can lead to fluctuations in pricing.

-

Labor: Labor costs vary significantly based on geographic location. Suppliers in regions with lower labor costs may offer more competitive pricing. However, labor quality and expertise in manufacturing should not be compromised, as this can affect product quality.

-

Manufacturing Overhead: This encompasses costs related to factory operation, maintenance, and utilities. Efficient manufacturing processes can reduce overhead costs, which is beneficial for pricing.

-

Tooling: Initial tooling costs for molds and production setup can be significant, especially for customized designs. These costs are typically amortized over the production run, meaning larger orders can benefit from lower per-unit costs.

-

Quality Control (QC): Implementing strict QC processes ensures product reliability and compliance with safety standards, which can increase costs. However, it also protects against costly recalls and brand damage.

-

Logistics: Shipping costs, including freight and insurance, can vary widely based on distance and shipping method. Incoterms (International Commercial Terms) play a critical role in determining who bears these costs and risks.

-

Margin: Suppliers typically add a markup to cover their operational costs and profit. Understanding standard margins in the industry can help buyers gauge fair pricing.

How Do Price Influencers Affect Clear Plastic Salad Bowl Costs?

Several factors influence the pricing of clear plastic salad bowls:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced per-unit costs due to economies of scale. Suppliers are usually willing to negotiate better pricing for bulk purchases.

-

Specifications and Customization: Custom sizes, designs, or branding can significantly impact pricing. While customization adds value, it also involves additional costs in tooling and production.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like BPI or CMA for compostability) can lead to increased costs. Buyers should assess whether these attributes align with their market needs.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may charge a premium for their services but often provide better product quality and service.

What Negotiation Tips Can Help B2B Buyers Optimize Costs?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant cost savings:

-

Understand Total Cost of Ownership: Beyond the purchase price, consider logistics, storage, and waste management costs. This holistic approach can reveal the true cost of sourcing.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and service terms. Frequent communication and feedback can foster trust and collaboration.

-

Research Market Prices: Being informed about prevailing market prices and trends allows buyers to negotiate confidently and identify fair pricing.

-

Consider Incoterms Carefully: Understanding the implications of different Incoterms can help buyers manage risks and costs associated with shipping and logistics.

What Should Buyers Keep in Mind Regarding Pricing Nuances?

When sourcing clear plastic salad bowls internationally, buyers should be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rates can impact costs, especially for buyers sourcing from suppliers in different currencies.

-

Import Duties and Taxes: International shipments may incur additional costs, such as tariffs or import taxes. Understanding local regulations can prevent unexpected expenses.

-

Cultural Considerations: Negotiation styles vary across regions. Buyers should adapt their approaches based on cultural norms to enhance negotiation outcomes.

In conclusion, a thorough understanding of cost components, price influencers, and negotiation strategies can empower B2B buyers to make informed decisions when sourcing clear plastic salad bowls. By strategically navigating these factors, buyers can achieve cost efficiency while ensuring quality and compliance.

Alternatives Analysis: Comparing clear plastic salad bowls With Other Solutions

In the competitive landscape of food service packaging, businesses often seek alternatives to clear plastic salad bowls to meet various operational and environmental needs. Understanding the strengths and weaknesses of each option can help B2B buyers make informed decisions that align with their brand values and customer expectations.

| Comparison Aspect | Clear Plastic Salad Bowls | Compostable PLA Salad Bowls | Glass Salad Bowls |

|---|---|---|---|

| Performance | Durable, stackable, and clear visibility | Lightweight, strong, but not microwave safe | Heavy and sturdy, excellent presentation |

| Cost | Moderate price per unit | Generally higher cost due to material | Higher upfront investment but reusable |

| Ease of Implementation | Readily available, easy to source | Requires suppliers with compostable certifications | Requires careful handling and cleaning |

| Maintenance | Disposable, no cleanup required | Disposable, compostable after use | Requires washing and storage |

| Best Use Case | Grab-and-go salads, catering | Eco-conscious businesses, salad bars | Upscale dining, catering events |

What Are the Benefits and Drawbacks of Using Compostable PLA Salad Bowls?

Compostable PLA salad bowls are made from plant-based materials, making them a sustainable choice for eco-conscious businesses. These bowls are lightweight and designed for stackability, which simplifies storage and transport. However, their inability to withstand high temperatures limits their use to cold food applications, such as salads and desserts. The higher cost of PLA bowls compared to traditional plastic can be a disadvantage for businesses operating on tight margins. Nevertheless, they align well with growing consumer demand for environmentally friendly products and can enhance a brand’s image.

How Do Glass Salad Bowls Compare to Clear Plastic Salad Bowls?

Glass salad bowls offer a premium look and feel, making them ideal for upscale dining experiences and catered events. Their durability and aesthetic appeal can enhance food presentation, attracting customers who value quality. However, glass bowls are heavier and more fragile than plastic options, which can lead to increased handling costs and the risk of breakage. Additionally, glass requires thorough cleaning and storage, making it less convenient for high-volume operations. While glass bowls can be reused, the initial investment is significantly higher than that of plastic alternatives.

Conclusion: Which Solution is Right for Your Business?

Choosing the right salad bowl solution involves assessing specific business needs, including budget constraints, operational efficiency, and environmental considerations. Clear plastic salad bowls offer a balance of performance and cost-effectiveness, making them suitable for fast-paced environments. Compostable PLA bowls cater to businesses focused on sustainability, while glass bowls provide an upscale option for premium service. By evaluating these alternatives against your operational requirements and customer expectations, you can make a strategic choice that aligns with your brand identity and market positioning.

Essential Technical Properties and Trade Terminology for clear plastic salad bowls

What Are the Key Technical Properties of Clear Plastic Salad Bowls?

When sourcing clear plastic salad bowls for business needs, understanding the technical specifications is crucial. Here are several key properties to consider:

-

Material Grade

Clear plastic salad bowls are commonly made from materials like PET (Polyethylene Terephthalate) or PLA (Polylactic Acid). PET is known for its durability and clarity, making it ideal for takeout and salad bars. PLA, a bioplastic made from renewable resources, offers an eco-friendly alternative but is generally not microwave safe. Selecting the right material impacts not only the functionality of the bowl but also its sustainability profile, which can be a significant selling point in today’s market. -

Capacity and Size Options

Salad bowls come in various sizes, typically ranging from 16 oz to 64 oz. Understanding capacity is essential for businesses that serve different portions, whether for individual meals or larger catering needs. Choosing the right size can enhance customer satisfaction by providing appropriate serving options. -

Stackability and Design

Many clear plastic salad bowls are designed for stackability, which saves space during storage and transportation. This feature is particularly important for businesses with limited storage capacity or those needing efficient logistics for delivery services. A well-designed bowl should also have a secure lid option to prevent spills during transit. -

Barrier Properties

The oxygen and moisture barrier properties of the material affect food freshness and shelf life. PET bowls typically offer better oxygen barrier characteristics than OPS (Oriented Polystyrene), which helps keep food fresher for longer periods. This is a vital consideration for businesses that prioritize food quality and waste reduction. -

Compliance and Safety Standards

Clear plastic salad bowls must meet certain safety standards, such as FDA approval for food contact. Understanding these regulations is critical for B2B buyers to ensure they are sourcing safe products for their customers. Compliance with environmental standards, particularly for biodegradable options like PLA, can also enhance a company’s sustainability credentials. -

Customization Options

Many manufacturers offer customization for clear plastic salad bowls, including branding and labeling options. Customization can enhance brand visibility and customer loyalty, making it an important factor for businesses looking to differentiate themselves in a competitive market.

What Common Trade Terms Should B2B Buyers Know for Clear Plastic Salad Bowls?

Familiarity with industry jargon can streamline the purchasing process and improve communication with suppliers. Here are essential terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers for clear plastic salad bowls. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, especially for businesses looking to minimize excess stock. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer solicits quotes from suppliers for specific products or services. Utilizing RFQs can help buyers compare prices and terms, ensuring they secure the best deal for their clear plastic salad bowls. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is crucial for international buyers, as they determine costs and risks associated with the transport of goods. -

Lead Time

This term refers to the time it takes from placing an order to receiving the goods. Knowing the lead time is vital for inventory planning and ensuring that businesses can meet customer demand without delays. -

Recyclability

This term indicates whether the materials used in the salad bowls can be recycled after use. As sustainability becomes increasingly important to consumers, sourcing recyclable products can enhance a company’s reputation and align with environmental goals.

By understanding these technical properties and trade terminology, B2B buyers can make informed decisions when sourcing clear plastic salad bowls, ensuring they meet their operational needs while also catering to consumer preferences for sustainability and quality.

Navigating Market Dynamics and Sourcing Trends in the clear plastic salad bowls Sector

What Are the Current Market Dynamics and Key Trends in the Clear Plastic Salad Bowls Sector?

The clear plastic salad bowls market is experiencing significant growth, driven by increasing consumer demand for convenience and sustainability in food packaging. Globally, the rise of health-conscious eating habits, alongside the expansion of food delivery services, is propelling the demand for clear salad bowls, particularly in regions such as Africa, South America, the Middle East, and Europe. B2B buyers in these markets are increasingly seeking versatile packaging solutions that accommodate various food types—from salads and poke bowls to desserts—while ensuring product visibility and freshness.

Emerging technologies such as smart packaging and e-commerce platforms are shaping the sourcing landscape. For instance, advancements in biodegradable materials, like PLA bioplastics, are attracting B2B buyers focused on sustainable practices. Furthermore, the trend toward online ordering and home delivery has led suppliers to innovate in packaging design, ensuring products are stackable, durable, and compatible with various food service models. As international regulations around plastic use tighten, buyers are also prioritizing suppliers that offer compliant and eco-friendly products.

How Is Sustainability and Ethical Sourcing Transforming the Clear Plastic Salad Bowls Industry?

Sustainability is a pivotal concern for B2B buyers in the clear plastic salad bowls sector. The environmental impact of traditional petroleum-based plastics has prompted a shift towards compostable materials, such as PLA bioplastics. These materials not only reduce reliance on fossil fuels but also align with increasing regulatory pressures and consumer preferences for greener alternatives. Buyers are now more inclined to partner with suppliers who demonstrate a commitment to ethical sourcing and environmental stewardship.

Moreover, certifications such as BPI (Biodegradable Products Institute) and CMA (Compost Manufacturing Alliance) are becoming critical in the purchasing decision process. These certifications assure buyers that the products meet stringent compostability standards, thus facilitating compliance with local regulations and enhancing brand reputation. As sustainability becomes intertwined with corporate responsibility, B2B buyers are also looking for transparency in supply chains, pushing suppliers to adopt practices that minimize environmental footprints while delivering high-quality products.

What Is the Evolution of Clear Plastic Salad Bowls and Its Implications for B2B Buyers?

The evolution of clear plastic salad bowls has been marked by significant advancements in material technology and design. Initially dominated by traditional petroleum-based plastics, the sector has witnessed a gradual transition towards more sustainable options, influenced by both consumer demand and regulatory changes. The introduction of innovative materials like PET (polyethylene terephthalate) and PLA bioplastics has expanded the functionality and appeal of salad bowls, making them suitable for a wider array of food applications.

As a result, B2B buyers can now access a diverse range of products, from sturdy, stackable options for takeout to eco-friendly compostable containers for health-conscious consumers. This evolution underscores the importance of staying informed about industry trends and material advancements, enabling buyers to make strategic sourcing decisions that align with their business goals and sustainability initiatives. The shift towards sustainability not only enhances brand image but also positions companies to meet the growing consumer demand for environmentally responsible products.

Frequently Asked Questions (FAQs) for B2B Buyers of clear plastic salad bowls

-

How do I ensure the quality of clear plastic salad bowls from international suppliers?

To ensure quality when sourcing clear plastic salad bowls, conduct thorough supplier vetting. Request samples to assess the material’s durability and clarity. Look for certifications such as FDA approval for food contact and any compostability certifications if relevant. Additionally, check customer reviews and request references from previous clients. Establish clear quality assurance protocols, including regular inspections and testing during production, to ensure the bowls meet your standards. -

What is the best material for clear plastic salad bowls?

The best materials for clear plastic salad bowls include PET (Polyethylene Terephthalate) and PLA (Polylactic Acid). PET is highly durable, clear, and recyclable, making it suitable for a variety of food items. PLA, being compostable and derived from renewable resources, offers a sustainable alternative for environmentally-conscious businesses. When choosing a material, consider your target market’s preferences for sustainability and durability, as well as the intended use of the bowls. -

What customization options are available for clear plastic salad bowls?

Many manufacturers offer customization options for clear plastic salad bowls, including size, design, and branding. You can request custom sizes or shapes to fit specific product offerings, as well as printed logos or labels for branding purposes. Discuss your needs with suppliers to explore available designs and printing techniques. Keep in mind that customization may affect minimum order quantities and lead times, so plan accordingly. -

What are the typical minimum order quantities (MOQs) for clear plastic salad bowls?

Minimum order quantities (MOQs) for clear plastic salad bowls can vary significantly depending on the supplier and customization options. Generally, MOQs range from 500 to 5,000 units. For custom designs or materials, MOQs may be higher. It’s essential to discuss your needs with potential suppliers and negotiate terms that suit your business model while ensuring you can meet demand without excessive inventory. -

What payment terms should I expect when sourcing clear plastic salad bowls?

Payment terms can vary based on the supplier’s policies and your negotiation. Common practices include a 30% deposit upon order confirmation and the balance before shipment or upon delivery. Some suppliers may offer credit terms for established businesses. Ensure you understand the payment structure, including any additional fees for international transactions, and consider using secure payment methods to protect your investment. -

How can I manage logistics when importing clear plastic salad bowls?

Managing logistics for importing clear plastic salad bowls involves selecting reliable freight forwarders and understanding shipping regulations in your country. Ensure that you have all necessary documentation, including invoices, packing lists, and customs declarations. Familiarize yourself with duties and tariffs that may apply. Consider using a third-party logistics provider to streamline the process and handle warehousing, distribution, and customs clearance. -

What are the environmental benefits of using compostable salad bowls?

Choosing compostable salad bowls made from materials like PLA provides significant environmental benefits. These bowls break down in industrial composting facilities, reducing landfill waste and supporting sustainability efforts. By opting for compostable options, you can appeal to environmentally-conscious consumers and align with evolving regulations regarding single-use plastics. This choice can enhance your brand’s reputation and contribute to a more sustainable supply chain. -

How do I handle quality assurance and compliance for food safety?

To handle quality assurance and compliance for food safety, ensure that your suppliers adhere to international food safety standards, such as HACCP (Hazard Analysis Critical Control Point) and ISO certifications. Regular audits and inspections of the production process can help maintain quality. Request documentation that verifies compliance with regulations in your target markets. Establish a clear protocol for handling any quality issues that may arise after the products are received.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Clear Plastic Salad Bowls Manufacturers & Suppliers List

1. Goodstart Packaging – Compostable PLA Salad Bowls

Domain: goodstartpackaging.com

Registered: 2010 (15 years)

Introduction: Clear compostable PLA bioplastic salad bowls and lids are designed for build-your-own salads, salad bars, and grab-and-go. Made from PLA plant-based plastic, these bowls avoid polyethylene toxins. Features include:

– Light and strong, comparable to plastic

– Designed for stackability

– Certified compostable by CMA and/or BPI

– Available sizes: 16 oz, 24 oz, 32 oz, and 48 oz

– Freezer-safe but…

2. Factory Direct Party – Disposable Plastic Bowls

Domain: factorydirectparty.com

Registered: 2009 (16 years)

Introduction: Disposable Plastic Bowls available in various sizes and designs, ideal for parties and gatherings. Clear plastic bowls add a modern touch, while disposable options ensure quick cleanup. Sizes include 12 Oz. and 24 Oz. Package quantities range from 8 to 100 Ct. Colors available: Black, Clear, Gold, Hot Pink, Ivory, Lime, Red, Silver. In stock items: 17 products, out of stock: 3 products.

3. Target – Clear Plastic Salad Bowls

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Clear Plastic Salad Bowls, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

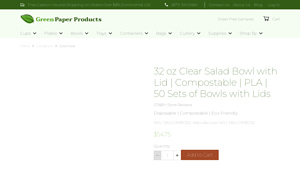

4. Green Paper Products – 32 oz Clear Salad Bowl with Lid

Domain: greenpaperproducts.com

Registered: 2007 (18 years)

Introduction: {“Product Name”: “32 oz Clear Salad Bowl with Lid”, “Material”: “PLA (Polylactic Acid)”, “Quantity”: “50 Sets (50 Bowls & 50 Lids)”, “Features”: [“Compostable”, “Eco-Friendly”, “Heavy Duty”, “Clear Design”, “Freezer-Safe”, “Suitable for Cold Foods”], “Certifications”: [“CMA Certified”, “TUV OK Compost Industrial”, “USDA BioBased”], “Dimensions”: {“Length”: “6.7 inches (170.2mm)”, “Width”: “6.7 inc…

5. EcoQuality – Crystal Clear Plastic Salad Bowls

Domain: ecoqualityinc.com

Registered: 2017 (8 years)

Introduction: {‘product_name’: ‘Crystal Clear Plastic Disposable Salad Bowls with Lids To-Go’, ‘sizes_available’: [’18oz’, ’24oz’, ’32oz’, ’40oz’, ’48oz’, ’64oz’], ‘price_per_pack’: {’25pcs’: ‘$5.95′, ’50pcs’: ‘$11.95’, ‘100pcs’: ‘$23.95’, ‘150pcs’: ‘$35.95’, ‘300pcs’: ‘$71.95’, ‘600pcs’: ‘$143.95’}, ‘sku’: ‘EQ18CRCLPLBOWLS-25’, ‘material’: ‘PET Plastic’, ‘features’: [‘BPA FREE’, ‘100% Recyclable’, ‘Leak Proof …

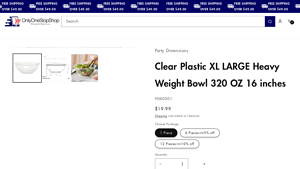

6. Only One Stop Shop – X-Large Clear Plastic Bowl

Domain: onlyonestopshop.com

Registered: 2014 (11 years)

Introduction: {“Product Name”: “X-Large Clear Plastic Bowl”, “Capacity”: “320 oz”, “Diameter”: “16 inches”, “Material”: “Plastic”, “Shape”: “Round”, “SKU”: “HS60301”, “Regular Price”: “$19.99”, “Package Options”: [{“Quantity”: “1 Piece”, “Price”: “$19.99”}, {“Quantity”: “6 Pieces”, “Price”: “$113.94”, “Discount”: “5% off”}, {“Quantity”: “12 Pieces”, “Price”: “$215.90”, “Discount”: “10% off”}], “Shipping Informa…

Strategic Sourcing Conclusion and Outlook for clear plastic salad bowls

In the evolving market for clear plastic salad bowls, strategic sourcing plays a pivotal role in ensuring product quality, sustainability, and cost-effectiveness. Buyers should prioritize suppliers offering innovative materials, such as compostable PLA and recyclable PET, which align with global sustainability trends and consumer preferences. Understanding the specifications—such as durability, size options, and compatibility with lids—can significantly enhance the customer experience and operational efficiency.

B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are encouraged to explore diverse sourcing strategies to optimize their supply chain. Leveraging local suppliers can reduce lead times and shipping costs, while global partnerships can expand product offerings and competitive pricing.

As the demand for eco-friendly packaging continues to rise, staying ahead of market trends will be essential. Investing in clear plastic salad bowls that meet both functional and environmental standards will not only enhance your brand reputation but also cater to a growing segment of environmentally conscious consumers. Engage with suppliers today to secure a sustainable, profitable future in your food service operations.