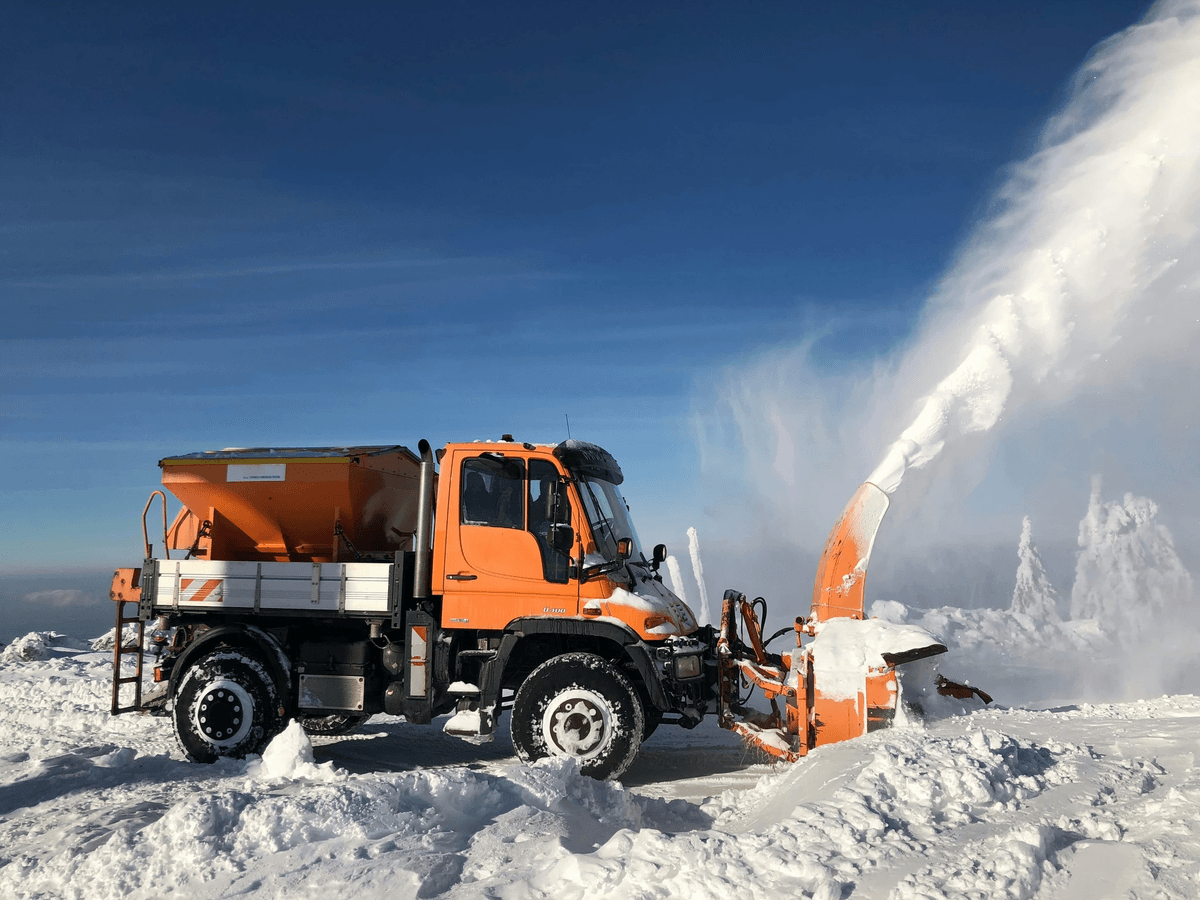

Choosing Your Truck Mounted Snow Blower: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for truck mounted snow blower

In the face of increasingly severe winter weather, businesses and municipalities worldwide grapple with the challenge of efficient snow removal. For B2B buyers seeking to enhance their snow management capabilities, sourcing a truck-mounted snow blower emerges as a crucial solution. These powerful machines offer the versatility to tackle substantial snowfall, ensuring safe and accessible environments for operations across various sectors. However, navigating the complexities of the global market for truck-mounted snow blowers can be daunting, with factors such as specifications, maintenance, and supplier reliability at play.

This comprehensive guide aims to demystify the landscape of truck-mounted snow blowers, addressing key considerations such as types of models available, their diverse applications, and essential supplier vetting processes. By exploring cost factors and operational efficiencies, this guide equips international B2B buyers from regions like Africa, South America, the Middle East, and Europe—including key markets like Germany and Saudi Arabia—with the insights needed to make informed purchasing decisions. With a focus on actionable strategies and best practices, buyers will be empowered to select the right equipment that meets their unique needs while maximizing return on investment. Prepare to streamline your snow removal operations and elevate your service capabilities with the right truck-mounted snow blower.

Understanding truck mounted snow blower Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 1. Standard Truck-Mounted | 84-inch clearing width, hydraulic power, front-mounted design | Municipalities, commercial properties | Pros: High efficiency, powerful. Cons: Heavier, requires larger trucks. |

| 2. Compact Truck-Mounted | 66-inch clearing width, lightweight, versatile mounting options | Residential areas, small business properties | Pros: Easier to maneuver, suitable for smaller spaces. Cons: Lower capacity. |

| 3. Custom Fabricated Units | Tailored specifications, unique features based on client needs | Specialized industries, niche applications | Pros: Meets specific needs, high adaptability. Cons: Longer lead times, potentially higher costs. |

| 4. Heavy-Duty Truck-Mounted | Designed for extreme conditions, larger engines, enhanced durability | Industrial sites, large-scale operations | Pros: Handles heavy snowfall, robust construction. Cons: Higher upfront investment, maintenance costs. |

| 5. Multi-Functional Attachments | Additional features like de-icing capabilities, dual-purpose use | Facilities management, snow removal services | Pros: Versatility, multi-use capabilities. Cons: Complexity can lead to more maintenance. |

What Are the Characteristics of Standard Truck-Mounted Snow Blowers?

Standard truck-mounted snow blowers are typically characterized by their 84-inch clearing width and hydraulic power systems. These machines are designed for municipalities and commercial properties that require efficient snow removal over large areas. The B2B purchasing decision should consider the truck’s compatibility and the snow blower’s weight, as these models generally require heavier-duty vehicles to operate effectively.

How Do Compact Truck-Mounted Snow Blowers Differ?

Compact truck-mounted snow blowers, with a clearing width of around 66 inches, are ideal for residential areas and small business properties. Their lightweight design allows for easier maneuverability, making them suitable for tight spaces. Buyers should evaluate the snow blower’s capacity and the type of snow typically encountered, as these models may not handle heavy snowfall as effectively as their larger counterparts.

Why Consider Custom Fabricated Units?

Custom fabricated truck-mounted snow blowers offer tailored specifications that meet unique client needs. These units are particularly beneficial for specialized industries or niche applications where standard models may fall short. While they provide a perfect fit for specific requirements, B2B buyers should be aware of the longer lead times and potentially higher costs associated with custom solutions.

What Are the Advantages of Heavy-Duty Truck-Mounted Snow Blowers?

Heavy-duty truck-mounted snow blowers are built for extreme conditions and feature larger engines for enhanced durability. They are ideal for industrial sites and large-scale operations that face heavy snowfall. B2B buyers must consider the upfront investment and ongoing maintenance costs, as these units can be more expensive but offer superior performance in challenging weather.

How Do Multi-Functional Attachments Enhance Snow Removal?

Multi-functional attachments for truck-mounted snow blowers can include features like de-icing capabilities, making them versatile for various snow removal tasks. These attachments are particularly useful for facilities management and snow removal services that require flexibility. However, the complexity of these systems can lead to increased maintenance needs, which buyers should factor into their purchasing considerations.

Key Industrial Applications of truck mounted snow blower

| Industry/Sector | Specific Application of truck mounted snow blower | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Municipal Services | Road and highway snow removal | Ensures safe transportation and accessibility | Durability, maintenance requirements, and performance in extreme conditions |

| Construction | Site clearing for construction projects | Reduces downtime and enhances project efficiency | Equipment compatibility with existing vehicles, ease of operation, and weight considerations |

| Airport Operations | Runway and taxiway snow clearance | Maintains airport operations and safety standards | Speed of snow removal, discharge distance, and fuel efficiency |

| Logistics and Warehousing | Clearing access roads and loading docks | Facilitates uninterrupted supply chain operations | Size and power of the blower, adaptability to different terrains, and ease of storage |

| Event Management | Snow removal for outdoor events and venues | Enhances guest experience and safety | Portability, quick attachment to trucks, and operational control features |

How are Truck Mounted Snow Blowers Used in Municipal Services?

Municipal services utilize truck mounted snow blowers primarily for efficient road and highway snow removal. These machines are capable of handling large volumes of snow, ensuring safe transportation during harsh winter conditions. By minimizing road closures and improving accessibility, municipalities can uphold public safety and maintain essential services. International buyers should consider the durability of the equipment and its maintenance requirements to ensure long-term performance in varying climates.

In What Ways Do Construction Companies Benefit from Truck Mounted Snow Blowers?

In the construction sector, truck mounted snow blowers are essential for clearing snow from job sites, allowing projects to continue without significant delays. These blowers quickly remove snow, reducing downtime and enhancing overall project efficiency. Buyers in this sector should focus on compatibility with existing vehicles and the ease of operation, especially in remote or rugged locations where quick mobilization is crucial.

What Role Do Truck Mounted Snow Blowers Play in Airport Operations?

Airports require reliable snow removal solutions to keep runways and taxiways clear, thus ensuring operational safety. Truck mounted snow blowers are instrumental in meeting strict safety standards and maintaining timely flight schedules during winter storms. When sourcing this equipment, airports should prioritize the speed of snow removal and the discharge distance, as these factors directly impact operational efficiency.

How Do Truck Mounted Snow Blowers Enhance Logistics and Warehousing Operations?

In logistics and warehousing, truck mounted snow blowers are used to clear access roads and loading docks, enabling seamless supply chain operations. By ensuring that delivery routes remain unobstructed, businesses can avoid delays and maintain productivity. Buyers should evaluate the size and power of the blower, as well as its adaptability to different terrains, to ensure it meets their specific operational needs.

Why are Truck Mounted Snow Blowers Important for Event Management?

Event management companies rely on truck mounted snow blowers to maintain safe and accessible outdoor venues during winter events. These machines help to quickly clear snow, enhancing guest experience and safety. When sourcing snow blowers, event planners should consider the portability of the equipment and the operational control features that allow for efficient use in dynamic environments.

3 Common User Pain Points for ‘truck mounted snow blower’ & Their Solutions

Scenario 1: Navigating Compatibility Issues with Truck Models

The Problem: A common challenge for B2B buyers is ensuring that a truck-mounted snow blower is compatible with their specific truck model. Many businesses operate a fleet of vehicles that may differ in size and specifications. Buyers may find themselves investing in equipment that is either too heavy for their trucks or incompatible with the mounting system, leading to operational delays and unexpected costs. This can be particularly frustrating when the equipment does not function as intended or requires modifications that increase the total investment.

The Solution: To mitigate compatibility issues, B2B buyers should conduct thorough research on their truck specifications before purchasing a snow blower. This includes knowing the truck’s weight capacity, engine power, and mounting system. When sourcing a truck-mounted snow blower, prioritize models that offer flexibility in mounting options, such as universal mounts or those specifically designed for a range of truck sizes. Furthermore, consulting with suppliers about the compatibility of their products with your truck fleet can provide clarity. For example, companies like Haan Tech offer models tailored for specific truck sizes, ensuring that the blower operates efficiently without the need for additional modifications.

Scenario 2: Dealing with Maintenance and Downtime Concerns

The Problem: Maintenance and downtime are significant pain points for businesses that rely on truck-mounted snow blowers during the winter season. Snow removal is often time-sensitive, and any machinery breakdown can lead to delays in service delivery, resulting in dissatisfied clients and potential revenue loss. B2B buyers may struggle to find reliable maintenance support or may not have a clear understanding of the maintenance requirements for different models.

The Solution: To address maintenance concerns, B2B buyers should select snow blowers that are designed for ease of maintenance. Look for models with fewer moving parts and those that utilize hydraulic systems, which typically require less upkeep. Establish a proactive maintenance schedule that includes regular inspections and servicing, particularly before the snow season begins. Partnering with manufacturers that offer comprehensive service packages or training for your maintenance staff can also be beneficial. Additionally, creating a network with local service providers who specialize in snow removal equipment can ensure that you have quick access to repairs and parts when needed.

Scenario 3: Overcoming Performance Limitations in Heavy Snow Conditions

The Problem: In regions prone to heavy snowfall, a frequent issue is the performance limitations of truck-mounted snow blowers. Some models may struggle to handle dense, wet snow, which can clog the chute and reduce efficiency. B2B buyers often face the dilemma of choosing equipment that can manage such challenging conditions without causing delays or requiring excessive manual labor.

The Solution: To overcome performance limitations, buyers should focus on selecting high-capacity snow blowers with robust features tailored for heavy-duty use. Models equipped with high horsepower engines and efficient auger designs can significantly improve performance in challenging snow conditions. Look for features like adjustable chute controls and side drop chutes, which can help direct wet snow more effectively. Furthermore, investing in a snow blower with a proven track record in harsh climates will pay off in the long run. Consider consulting with industry peers or reading case studies to identify reliable brands and models that perform well under similar conditions.

Strategic Material Selection Guide for truck mounted snow blower

What Materials Are Commonly Used in Truck Mounted Snow Blowers?

When selecting materials for truck mounted snow blowers, it is crucial to consider their properties, performance, and suitability for various applications. The following analysis examines four common materials used in the construction of these machines: steel, aluminum, high-density polyethylene (HDPE), and composite materials.

How Does Steel Perform in Truck Mounted Snow Blowers?

Steel is a widely used material in the manufacturing of truck mounted snow blowers due to its high strength and durability. Key properties include excellent tensile strength, temperature resistance, and the ability to withstand high pressure. Steel components can endure the harsh conditions encountered during snow removal operations, making them suitable for heavy-duty applications.

Pros: Steel offers superior durability and resistance to wear and tear, which is essential for equipment exposed to abrasive snow and ice. It is also relatively cost-effective compared to other materials, making it a popular choice for manufacturers.

Cons: However, steel is prone to corrosion, especially in regions with high moisture or salt exposure. This necessitates protective coatings or treatments, which can increase manufacturing complexity and costs.

Impact on Application: Steel’s compatibility with various media, including abrasive snow and ice, ensures effective performance in diverse environments, from urban settings to rural areas.

International Considerations: Buyers from regions like Europe and the Middle East should ensure compliance with relevant standards such as ASTM and DIN for steel quality and corrosion resistance.

What Advantages Does Aluminum Offer for Snow Blower Construction?

Aluminum is another popular material, known for its lightweight and corrosion-resistant properties. It has a lower density than steel, which translates to reduced overall weight, enhancing fuel efficiency during operation.

Pros: The primary advantage of aluminum is its resistance to rust and corrosion, making it ideal for use in wet or salty environments. This property extends the lifespan of the equipment and reduces maintenance costs.

Cons: On the downside, aluminum is generally more expensive than steel and may not offer the same level of strength under extreme conditions. It is also more susceptible to deformation under high-stress applications.

Impact on Application: Aluminum is well-suited for applications requiring mobility and efficiency, particularly in regions with frequent snowfalls.

International Considerations: Buyers should verify that aluminum components meet international standards for structural integrity and performance, especially in colder climates.

Why Choose High-Density Polyethylene (HDPE) for Snow Blowers?

High-density polyethylene (HDPE) is increasingly used in truck mounted snow blowers, particularly for components like augers and chutes. Its key properties include excellent impact resistance and low moisture absorption.

Pros: HDPE is lightweight, resistant to corrosion, and has a low coefficient of friction, which enhances the efficiency of snow removal. It is also less prone to cracking in cold temperatures compared to other plastics.

Cons: However, HDPE may not withstand high temperatures or heavy loads as effectively as metals, limiting its use in certain structural applications.

Impact on Application: HDPE is particularly effective in environments where snow and ice management is critical, as its properties allow for smooth operation and reduced wear.

International Considerations: Buyers should ensure that HDPE materials comply with local environmental regulations and standards, particularly in regions with strict waste management policies.

What Are the Benefits of Composite Materials in Snow Blowers?

Composite materials, such as fiberglass or carbon fiber, are becoming popular in high-performance truck mounted snow blowers. These materials offer unique properties, including high strength-to-weight ratios and excellent resistance to corrosion.

Pros: Composites are lightweight yet strong, providing enhanced performance and fuel efficiency. They are also highly resistant to environmental factors, making them suitable for various climates.

Cons: The primary disadvantage is the higher cost associated with composite materials and the complexity of manufacturing processes, which can deter some buyers.

Impact on Application: Composites are ideal for specialized applications where performance is paramount, such as in municipalities or businesses that require rapid snow removal.

International Considerations: Buyers should consider the availability of composite materials and ensure compliance with applicable standards and certifications in their regions.

Summary Table of Material Selection for Truck Mounted Snow Blowers

| Material | Typical Use Case for truck mounted snow blower | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components and blades | High durability and strength | Prone to corrosion, requires coatings | Medium |

| Aluminum | Lightweight frames and non-structural parts | Corrosion resistance | Higher cost, less strength than steel | High |

| High-Density Polyethylene | Augers and chutes | Lightweight and low friction | Limited load-bearing capacity | Medium |

| Composite Materials | High-performance applications | Excellent strength-to-weight ratio | Higher manufacturing complexity and cost | High |

This strategic material selection guide provides essential insights for international B2B buyers, enabling them to make informed decisions when procuring truck mounted snow blowers tailored to their specific operational needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for truck mounted snow blower

What Are the Key Stages in the Manufacturing Process of Truck Mounted Snow Blowers?

The manufacturing of truck-mounted snow blowers involves a series of precise stages designed to ensure that each unit meets high performance and durability standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting high-quality raw materials, primarily heavy-duty steel and aluminum, to ensure durability and resistance to harsh winter conditions. The materials are subjected to rigorous quality assessments to confirm their suitability for snow blower construction.

-

Forming: In this phase, the prepared materials undergo various forming techniques. Common processes include cutting, bending, and welding. Advanced CNC (Computer Numerical Control) machines are often employed to ensure precision in shaping components like the auger, chassis, and blower housing. The use of robotic welding technology enhances the structural integrity of the assemblies.

-

Assembly: Once the individual components are formed, they are brought together in an assembly line. This stage typically involves the installation of the engine, drive mechanisms, and control systems. Manufacturers often use modular assembly techniques, allowing for efficient production and easier maintenance. Each assembly is tested for alignment and functionality before proceeding to the next step.

-

Finishing: The final stage includes surface treatment processes such as powder coating or galvanizing to protect against corrosion and enhance aesthetic appeal. Quality checks are conducted at this stage to ensure that the finishing meets environmental and durability standards.

Which International Standards Guide the Quality Assurance of Truck Mounted Snow Blowers?

Quality assurance in the manufacturing of truck-mounted snow blowers is critical for ensuring reliability and safety. International standards like ISO 9001 provide a framework for quality management systems, helping manufacturers maintain consistency in their processes. Other relevant standards include:

- CE Marking: This certification indicates that the product meets European health, safety, and environmental protection standards, making it essential for buyers in the European market.

- API Standards: Particularly relevant for manufacturers who produce equipment for harsh environments, these standards ensure that products can withstand severe operational conditions.

What Are the Key Quality Control Checkpoints in Snow Blower Manufacturing?

Quality control (QC) is integral to the manufacturing process and involves several checkpoints:

-

Incoming Quality Control (IQC): This is the first checkpoint, where raw materials are inspected upon delivery. Suppliers must provide certifications and test reports for materials used.

-

In-Process Quality Control (IPQC): During manufacturing, inspections are performed at various stages to ensure that components are being produced according to specifications. This includes checking dimensional accuracy and functional tests on sub-assemblies.

-

Final Quality Control (FQC): Once assembly is complete, the finished product undergoes comprehensive testing to verify its performance. This includes functional tests of the snow blower’s engine, drive system, and control mechanisms. Any unit failing to meet specified criteria is reworked or discarded.

What Common Testing Methods Are Used to Ensure Product Quality?

To verify the durability and reliability of truck-mounted snow blowers, manufacturers employ various testing methods, including:

- Performance Testing: This evaluates the snow blower’s ability to operate under simulated conditions, including the volume of snow it can effectively clear and its discharge distance.

- Durability Testing: Units are subjected to extended operational cycles to assess wear and tear, ensuring they can withstand harsh conditions over time.

- Safety Testing: All safety features, such as emergency shut-off mechanisms and operational controls, are rigorously tested to ensure compliance with industry standards.

How Can B2B Buyers Verify the Quality Control Processes of Their Suppliers?

When sourcing truck-mounted snow blowers, B2B buyers must ensure their suppliers maintain rigorous quality control processes. Here are some methods to verify these standards:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality assurance measures firsthand. This helps establish the credibility of the supplier.

-

Quality Reports: Requesting detailed quality control reports can provide insights into the supplier’s testing protocols, pass rates, and any corrective actions taken for non-conforming products.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturer’s quality control processes and product quality.

What Are the Nuances of Quality Control for International Buyers?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regulatory Compliance: Understanding local regulations and standards in the buyer’s region is essential. For instance, products sold in Europe must comply with CE marking, while certain Middle Eastern countries may have their own specific certifications.

-

Cultural Differences in Quality Expectations: Different regions may have varying expectations regarding product quality and performance. Engaging local representatives can help bridge these gaps.

-

Logistical Considerations: Shipping products internationally can impact quality if not managed correctly. Buyers should ensure that suppliers have robust packaging and handling processes to prevent damage during transit.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting suppliers for truck-mounted snow blowers, ensuring they invest in reliable and high-quality equipment suitable for their specific operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘truck mounted snow blower’

Introduction

This practical sourcing guide aims to assist B2B buyers in navigating the procurement process for truck-mounted snow blowers. As winter demands efficient snow removal solutions, understanding the key steps in sourcing these powerful machines can ensure that your investment meets operational needs while maximizing performance and safety.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial to ensure the snow blower meets your specific requirements. Consider factors such as the type of truck it will be mounted on (e.g., ¾ ton, 1 ton), clearing width, and engine power. Additionally, evaluate features like discharge distance and capacity to handle the volume of snow typical in your region.

- Key specifications to consider:

- Engine horsepower and type (e.g., gas vs. diesel)

- Dimensions and weight, ensuring compatibility with your vehicle

Step 2: Research Applicable Regulations and Standards

Understanding local regulations regarding equipment operation is vital. Many regions have specific requirements for snow removal equipment, including noise restrictions and emissions standards. Ensure that the models you consider comply with these regulations to avoid potential fines or operational delays.

- Action items:

- Consult local government websites for guidelines

- Check for any industry-specific standards that may apply

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess the supplier’s reputation in terms of product reliability, customer service, and after-sales support.

- What to look for:

- Supplier certifications and industry awards

- Customer reviews and testimonials, focusing on long-term performance

Step 4: Request Demonstrations or Trials

Whenever possible, request a demonstration or trial period for the snow blower models you are considering. This hands-on experience will allow you to evaluate the equipment’s performance in real-world conditions and ensure it meets your operational needs.

- Considerations during trials:

- Test the blower’s ease of use, controls, and maintenance needs

- Observe its performance in various snow conditions

Step 5: Compare Total Cost of Ownership

Analyze not just the initial purchase price but the total cost of ownership, which includes maintenance, fuel consumption, and potential repairs over time. A lower upfront cost may lead to higher long-term expenses, so ensure that your financial assessment includes all relevant factors.

- Cost components to consider:

- Warranty coverage and service agreements

- Availability and pricing of replacement parts

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate the terms of the sale, including price, delivery timelines, and warranty conditions. Ensure that you have a clear understanding of the service levels expected from the supplier, especially regarding maintenance and support.

- Key negotiation points:

- Payment terms and financing options

- Post-sale support and training for your operators

Step 7: Finalize the Purchase and Plan for Training

After securing the best deal, finalize your purchase and prepare for the integration of the snow blower into your operations. Arrange training sessions for your staff to ensure they are familiar with the equipment and its maintenance requirements.

- Training considerations:

- Schedule sessions with the supplier or a qualified trainer

- Provide hands-on training and safety protocols for operators

Comprehensive Cost and Pricing Analysis for truck mounted snow blower Sourcing

What Are the Key Cost Components for Truck Mounted Snow Blowers?

When sourcing truck mounted snow blowers, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used directly impact the overall cost. High-grade steel and components, necessary for durability and efficiency in harsh winter conditions, can increase initial costs but provide long-term savings through reduced maintenance and downtime.

-

Labor: Labor costs can vary significantly depending on the region of production. Skilled labor in countries with high wage standards, such as Germany, may lead to higher manufacturing costs compared to regions with lower labor costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and indirect labor. Efficient manufacturing processes can help reduce these costs, benefiting the final pricing structure.

-

Tooling: Investment in specialized tooling for production can be substantial. This upfront cost is often amortized over larger production runs, making it essential to consider volume when evaluating pricing.

-

Quality Control (QC): Implementing robust QC processes ensures that each unit meets the required standards. While this can add to costs, it is critical for maintaining quality and reducing warranty claims.

-

Logistics: Shipping costs can vary widely based on the geographical location of the supplier and the destination market. International shipping, especially for large machinery, can add significant costs that must be factored into the total price.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market demand and competition. Understanding the typical margin in the industry helps in evaluating fair pricing.

How Do Price Influencers Affect Truck Mounted Snow Blower Costs?

Several factors can influence the pricing of truck mounted snow blowers:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Larger orders often result in lower per-unit costs due to economies of scale, making it advantageous for buyers to consolidate purchases.

-

Specifications and Customization: Custom features or specifications can significantly increase costs. Buyers should be clear about their requirements upfront to avoid unexpected expenses.

-

Materials and Quality Certifications: Premium materials and certifications (like ISO standards) can enhance the product’s reliability but will also increase costs. Buyers should weigh the benefits against their budget constraints.

-

Supplier Factors: The reputation and experience of the supplier can impact pricing. Established suppliers may charge more due to their proven track record and reliability.

-

Incoterms: Understanding shipping terms is essential for cost management. Different Incoterms (such as FOB, CIF) can shift costs and risks between buyers and sellers, influencing the overall price.

What Are Effective Buyer Tips for Sourcing Truck Mounted Snow Blowers?

B2B buyers should consider the following tips to optimize their sourcing of truck mounted snow blowers:

-

Negotiate Wisely: Engage in negotiations with suppliers to explore volume discounts or bundled pricing. Building a relationship can lead to better deals over time.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the purchase price. Consider maintenance, fuel consumption, and potential downtime in your analysis.

-

Understand Pricing Nuances for International Purchases: When sourcing from different regions, be aware of currency fluctuations, local taxes, and tariffs that may affect the final cost.

-

Request Detailed Quotes: Always ask for itemized quotes that break down costs by component. This transparency will help identify areas for negotiation and ensure you are getting a fair deal.

Conclusion

In summary, a comprehensive understanding of the cost structure and pricing influencers is essential for B2B buyers looking to source truck mounted snow blowers. By considering these factors and applying strategic sourcing tips, buyers can make informed decisions that align with their operational needs and budget constraints. Always seek to validate prices with multiple suppliers and be aware of the market trends to ensure competitive pricing.

Alternatives Analysis: Comparing truck mounted snow blower With Other Solutions

Exploring Alternative Solutions for Snow Removal

In the realm of snow removal, the choice of equipment can significantly impact efficiency, cost, and operational effectiveness. While truck-mounted snow blowers are a robust solution, there are alternative methods available that may suit specific operational needs or budget constraints. Understanding these alternatives is crucial for B2B buyers looking to invest in snow management technologies.

| Comparison Aspect | Truck Mounted Snow Blower | Skid Steer Snow Blower | Tractor-Mounted Snow Blower |

|---|---|---|---|

| Performance | High capacity (up to 350 tons/hour), efficient for large areas | Moderate capacity, versatile for various terrains | High capacity, ideal for farms and large properties |

| Cost | Higher initial investment, but efficient for large operations | Moderate cost, lower than truck-mounted options | Varies widely; can be economical depending on tractor ownership |

| Ease of Implementation | Requires specific truck type and installation | Quick attach/detach, flexible for different jobs | Requires compatible tractor, setup may take time |

| Maintenance | Moderate, with regular checks needed | Low, generally robust and easy to service | Moderate to high, depending on tractor model and usage |

| Best Use Case | Urban and industrial settings, large parking lots | Construction sites, residential areas with varied terrain | Agricultural settings, large open areas |

Analyzing Alternatives for Snow Removal

Skid Steer Snow Blower

Skid steer snow blowers are compact and versatile, making them an excellent alternative for operations that require flexibility in various environments. These blowers can be attached to skid steer loaders, which are widely used in construction and landscaping. Their moderate capacity and ability to maneuver in tight spaces make them ideal for residential areas and smaller commercial properties. However, they may not match the high capacity of truck-mounted blowers, making them less suitable for large-scale operations.

Tractor-Mounted Snow Blower

Tractor-mounted snow blowers can be a cost-effective solution, especially for businesses that already own tractors. These blowers leverage the tractor’s power and can handle significant snow volumes, making them suitable for agricultural settings or large properties. However, their performance is highly dependent on the tractor’s specifications, and they may require more maintenance. Additionally, setting up a tractor for snow removal can take time, which may be a drawback for urgent snow management needs.

Making the Right Choice for Snow Removal Equipment

When deciding on the right snow removal solution, B2B buyers should evaluate their specific operational requirements, including the size of the area to be cleared, budget constraints, and existing equipment. Truck-mounted snow blowers offer unmatched performance for large-scale snow management, while skid steer and tractor-mounted blowers provide flexibility and cost savings for smaller or varied job sites. By aligning the choice of equipment with operational needs, buyers can enhance efficiency and ensure effective snow management throughout the winter months.

Essential Technical Properties and Trade Terminology for truck mounted snow blower

What Are the Key Technical Properties of Truck Mounted Snow Blowers?

When considering a truck mounted snow blower for your business, understanding its technical specifications is crucial. Here are some essential properties to keep in mind:

-

Engine Power (HP)

The horsepower (HP) of the engine directly influences the snow blower’s performance. A higher HP rating means more power to move heavy snow quickly and efficiently. For instance, models like the MT 8424 feature a 35 HP engine, which allows for a maximum discharge capacity of up to 350 tons per hour. This capability is vital for municipalities or businesses that require rapid snow removal to maintain safety and accessibility. -

Clearing Width and Height

The clearing width (e.g., 84 inches) and height (e.g., 24 inches) determine how much snow can be cleared in one pass. Wider and taller blowers can handle larger volumes of snow, making them suitable for commercial and industrial applications. Selecting the right dimensions based on your operational needs can significantly reduce the time and effort required for snow removal. -

Discharge Distance

The maximum discharge distance (e.g., 60 feet) indicates how far the snow can be thrown from the blower. A longer discharge distance allows for better control over where the snow is deposited, minimizing the risk of obstructing pathways or roadways. This feature is particularly important in urban environments where space is limited. -

Drive Mechanism

Understanding the drive mechanism, whether it’s a belt-to-chain drive or hydraulic, is essential for maintenance and efficiency. Hydraulic systems often require less maintenance and provide smoother operation, which can be a significant advantage during prolonged use in harsh conditions. -

Weight and Mounting Compatibility

The weight of the snow blower, often around 900 lbs or more, impacts the choice of the truck it can be mounted on. Ensuring the truck can handle the additional weight is critical for safe operation. Additionally, compatibility with mounting systems (like the Boss™ mount) can simplify installation and removal, enhancing operational flexibility.

What Are Common Trade Terms in the Truck Mounted Snow Blower Industry?

Navigating the world of truck mounted snow blowers involves familiarizing oneself with industry jargon. Here are some key terms you should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of snow blowers, purchasing OEM parts can ensure compatibility and reliability, which is essential for maintaining equipment performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for businesses looking to purchase snow blowers or parts in bulk, as it can affect inventory management and cost-effectiveness. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotations for specific products or services. In the snow blower industry, submitting an RFQ can help businesses compare prices and features from different manufacturers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms is vital for international buyers, particularly those in regions like Africa and South America, to avoid unexpected costs during the procurement process. -

Aftermarket Parts

Aftermarket parts are replacements made by manufacturers other than the original producer. While often more affordable, the quality and compatibility can vary, so it’s essential to assess their reliability against OEM parts. -

Payload Capacity

This term refers to the maximum weight a truck can safely carry, including the snow blower and any additional equipment. Understanding payload capacity ensures compliance with safety regulations and prevents damage to the vehicle.

By comprehending these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and ensure the successful procurement of truck mounted snow blowers.

Navigating Market Dynamics and Sourcing Trends in the truck mounted snow blower Sector

What Are the Key Market Dynamics and Trends in the Truck Mounted Snow Blower Sector?

The truck-mounted snow blower market is experiencing robust growth driven by increasing winter weather events and a growing need for efficient snow removal solutions. Key trends influencing this sector include advancements in technology, such as electric start systems, radio control functionalities, and enhanced engine efficiency. These innovations allow operators to manage snow removal tasks more efficiently, reducing labor costs and increasing operational effectiveness. Additionally, as urbanization continues, municipalities and businesses are investing in snow management to ensure safety and accessibility, which propels demand for truck-mounted systems.

In terms of sourcing trends, international B2B buyers are increasingly looking for suppliers that offer customizable solutions tailored to specific regional requirements. Buyers from Africa, South America, the Middle East, and Europe are particularly focused on models that can handle diverse terrains and snowfall conditions. Furthermore, the rise of e-commerce platforms has made it easier for buyers to access a wider range of products and suppliers globally, fostering competitive pricing and innovation.

Buyers should also consider the reliability of supply chains, particularly in the context of fluctuating global trade conditions. Establishing relationships with manufacturers who can offer timely delivery and consistent quality is crucial for maintaining operational readiness during peak snowfall periods.

How Important Is Sustainability and Ethical Sourcing in the Truck Mounted Snow Blower Industry?

Sustainability is becoming a critical factor in the purchasing decisions of B2B buyers in the truck-mounted snow blower sector. The environmental impact of snow removal equipment is significant, particularly concerning fuel consumption and emissions. As such, many companies are prioritizing the adoption of eco-friendly practices and technologies. This includes sourcing materials that are recyclable or produced through sustainable methods.

Buyers are increasingly seeking suppliers that can provide ‘green’ certifications, which demonstrate a commitment to environmental stewardship. Features like fuel-efficient engines and the use of biodegradable hydraulic fluids are becoming standard expectations. Additionally, manufacturers that engage in ethical sourcing practices, such as ensuring fair labor conditions and minimizing waste in their production processes, are more likely to gain the trust and loyalty of international buyers.

As regulatory frameworks around environmental standards become stricter, companies that invest in sustainable practices will not only enhance their brand reputation but also mitigate risks associated with non-compliance, ultimately leading to long-term cost savings.

What Is the Evolution of Truck Mounted Snow Blowers and Its Relevance to B2B Buyers?

The evolution of truck-mounted snow blowers can be traced back to the need for more efficient snow removal methods in urban environments. Initially, snow removal was primarily managed by plows; however, the limitations of plows in certain contexts—such as in residential areas with strict HOA regulations—led to the development of snow blowers that could be mounted on trucks.

Over the years, technological advancements have significantly improved the performance and versatility of these machines. Modern truck-mounted snow blowers now feature powerful engines, enhanced hydraulic systems, and user-friendly controls, making them indispensable for municipalities and businesses that face heavy snowfall.

For B2B buyers, understanding the historical context of these machines can inform purchasing decisions, as it highlights the importance of investing in reliable and efficient snow removal equipment that has stood the test of time. With continued innovations on the horizon, buyers are encouraged to stay abreast of market developments that can impact their operational efficiency and service delivery.

Frequently Asked Questions (FAQs) for B2B Buyers of truck mounted snow blower

-

How do I choose the right truck mounted snow blower for my business needs?

Selecting the right truck mounted snow blower involves assessing several factors, including your vehicle’s compatibility, the typical snow volume in your region, and the type of surfaces you’ll be clearing. Look for blowers with the appropriate clearing width and height to match your operational requirements. Additionally, consider features like hydraulic power, ease of use, and maintenance needs. It’s beneficial to consult with manufacturers or suppliers who can guide you based on your specific applications and provide insights into the best models suited for your business. -

What are the key features to look for in a truck mounted snow blower?

When evaluating truck mounted snow blowers, focus on features such as engine power, clearing width, and discharge capacity. Models with a dedicated engine are often more efficient than those powered by the truck’s engine. Look for advanced controls, like remote operation and adjustable chute deflection, which enhance usability. Additionally, durability features, such as shear bolt protection and weather-resistant components, are crucial for long-term performance in harsh conditions. Lastly, consider any additional features that enhance visibility or safety, such as integrated work lights. -

What is the typical lead time for ordering a truck mounted snow blower?

The lead time for ordering a truck mounted snow blower can vary significantly based on the manufacturer and the customization level required. Generally, you can expect a lead time of 4 to 12 weeks. If you require customization or specific features, this may extend the timeline. It’s advisable to communicate your needs clearly and confirm the estimated delivery time with the supplier before placing an order to avoid any disruptions in your snow removal operations. -

What are the minimum order quantities (MOQ) for truck mounted snow blowers?

Minimum order quantities for truck mounted snow blowers can differ based on the manufacturer and your location. Some suppliers may allow single-unit purchases, while others might require a minimum of 5 to 10 units for bulk orders. If you are considering international purchases, be sure to inquire about MOQs upfront, as they can influence your overall investment and inventory management strategy. Additionally, consider the potential benefits of bulk purchasing, such as reduced pricing per unit and lower shipping costs. -

How can I vet suppliers of truck mounted snow blowers?

Vetting suppliers involves several steps to ensure reliability and product quality. Start by researching their reputation through online reviews and industry forums. Request references from previous clients and check their response times and customer service quality. Ensure the supplier adheres to international quality standards and certifications relevant to your region. Additionally, inquire about their warranty and after-sales support policies, as these are crucial for long-term operational success. A site visit or virtual meeting can also help assess their capabilities and professionalism. -

What payment terms should I expect when purchasing truck mounted snow blowers?

Payment terms for truck mounted snow blowers can vary significantly among suppliers. Common arrangements include a deposit (typically 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer flexible payment options, such as installment plans, especially for larger orders. Be sure to clarify terms related to foreign exchange rates and any potential fees associated with international transactions. It’s also wise to review the supplier’s policies on refunds and cancellations to protect your investment. -

What logistics considerations should I keep in mind when importing truck mounted snow blowers?

Importing truck mounted snow blowers requires careful planning around logistics. Consider shipping methods (air vs. sea) based on your budget and urgency. Ensure compliance with local customs regulations and import duties, which can significantly impact overall costs. It’s also important to coordinate with logistics partners who specialize in heavy equipment transport to manage loading, unloading, and delivery. Lastly, factor in storage needs upon arrival, especially during peak snow seasons, to avoid delays in deployment. -

How can I ensure quality assurance for truck mounted snow blowers?

Ensuring quality assurance involves selecting suppliers who implement rigorous testing and quality control processes. Request detailed specifications and certifications for the snow blowers you plan to purchase. It’s beneficial to conduct pre-shipment inspections, either independently or through third-party services, to verify product conditions and compliance with agreed standards. Additionally, establish clear communication channels with the supplier for any post-purchase support and service agreements to address potential issues effectively after delivery.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Truck Mounted Snow Blower Manufacturers & Suppliers List

1. Haantech – MT 8424 Blower

Domain: haantechsnowblowers.ca

Registered: 2018 (7 years)

Introduction: {“product_name”: “MT 8424 Blower”, “target_truck_types”: “3/4-ton, 1-ton, 5/4-ton trucks”, “engine”: {“type”: “999cc 35 HP efi Loncin”, “features”: [“low oil cut-out”, “error code indication”]}, “starting_system”: “Electric start (radio)”, “fuel_capacity”: “3 Gallons”, “drive_mechanism”: “Twin B belt to Chain Drive”, “clutch_type”: “Centrifugal”, “auger_protection”: “Shear Bolt”, “gearbox”: “Wet s…

2. Ninja Deicer – SnowVac & Hanson Snow Blowers

Domain: ninjadeicer.com

Registered: 2019 (6 years)

Introduction: SnowVac 84: Weight: 1250 pounds, Width: 84 inches, Engine: 38 hp v-twin-cylinder, air-cooled, hydraulic valve train. SnowVac Junior 66: Weight: 825 pounds, Width: 66 inches. Hanson 84 Snow Blower: Weight: 1200-1500 pounds, Width: 84 inches, discontinued but available at lower prices. B.E.A.R. Fabrication Snow Blower: Weight: 750-800 pounds, Width: 80 inches, universal mount, fully hydraulic power …

3. SnowVac – 3/4 Ton Truck Mounted Snowblowers

Domain: plowsite.com

Registered: 2001 (24 years)

Introduction: 3/4 Ton Truck Mounted Snowblowers; Manufacturer: SnowVac; 8′ option starting price: $12,500; Engine options mentioned: 27hp Kohler; Intended use: Residential snow removal; Concerns: Perceived weakness and slow operation; Alternative manufacturers mentioned: Bear Fabrication; Discussion on horsepower requirements: 300-500 hp for serious use; Visibility and effectiveness concerns when mounted on tru…

4. Bobcat – Snow Blower

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Heavy Snow Blower & Snowplow Attachments for sale on eBay. Types include Snow Blower, Snowplow, and Snow Pusher. Brands available: Bobcat, John Deere, Fisher, Toro, Western, and more. Compatible equipment types include Articulated Dump Truck, Backhoe Loader, Sidewalk Plow, Skid Steer Loader, Tiller, Tractor, Utility Vehicle, and Wheel Loader. Condition options: New and Used. Price range: Under $75…

5. Wausau Equipment – Snogo Model TU3 Truck Mounted Snow Blower

Domain: wausauequipment.com

Registered: 2009 (16 years)

Introduction: Truck Mounted Blower – Iowa Department of Transportation: Snogo Model TU3 Truck Mounted Snow Blowers. Features: Two-Stage full mechanical auger type blower head, Ideal for spot casting/loading of snow, Capacity up to 2,500 tons per hour, Engine power range 350HP – 425HP, 3-18″ horizontal augers, Cutting width 102″, Height 60″, Impeller diameter 41″, Separate shear pin protection for both augers an…

6. MacQueen Group – Larue Loader-Mounted Snow Blowers

Domain: macqueengroup.com

Registered: 2016 (9 years)

Introduction: Larue Loader-Mounted Snow Blowers: 1. D30 Loader Mounted Two-Auger Snow Blower – Capacity: 1,800 tons/hour, Engine: Cummins F3.8 Turbo Diesel; 173 hp, Casting distance: 150 ft, Screw Conveyor: Heavy-duty 17-in. augers (2). 2. D40 Loader Mounted Two-Auger Snow Blower – Capacity: 2,400 tons/hour, Engine: Cummins QSB6.7; 235 hp, Casting distance: 150 ft, Screw Conveyor: Heavy-duty 17-in. augers (2). …

7. IronPlanet – Used Snow Blower Trucks & Trailers

Domain: ironplanet.com

Registered: 1999 (26 years)

Introduction: Used Snow Blower Trucks & Trailers for sale. Types available: Snow Equipment (97). Buying formats include Auction (80), Online Auction (6), On-Site Auction (74), Buy Now (17), Make Offer (15). IronClad Assurance available for some items (12 yes, 85 no). Popular makes include AgriMetal (5), Allied (2), Ariens (4), EMC (4), Farm King (3), Normand (9), RPM Tech (5), Toro (3), Trackless (6). Various m…

Strategic Sourcing Conclusion and Outlook for truck mounted snow blower

As the demand for efficient snow removal solutions grows, particularly in regions experiencing harsh winters, the strategic sourcing of truck-mounted snow blowers becomes imperative for B2B buyers. These machines provide unparalleled efficiency, allowing operators to clear substantial amounts of snow swiftly and effectively. The latest models, designed for larger trucks, offer advanced features such as electric controls and powerful engines, making them ideal for both municipal and commercial applications.

Investing in high-quality snow blowers not only ensures operational reliability but also enhances customer satisfaction by maintaining safe and accessible environments during winter storms. For buyers from Africa, South America, the Middle East, and Europe, understanding the unique regional requirements and available models is crucial in making informed purchasing decisions.

Looking ahead, the market for truck-mounted snow blowers is poised for growth, driven by advancements in technology and increasing awareness of the importance of effective snow management. We encourage international buyers to explore partnerships with reputable manufacturers and suppliers to secure the best solutions for their specific needs. By prioritizing strategic sourcing, businesses can enhance their operational capabilities and respond effectively to winter challenges.