Choosing Your Reverse Mc Connector: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for reverse mc connector

In the dynamic landscape of global commerce, sourcing reliable reverse MC connectors poses a significant challenge for B2B buyers across various regions. With the increasing demand for efficient electrical connectivity solutions, understanding the diverse types of reverse MC connectors and their specific applications is crucial for businesses looking to enhance their operational efficiency. This guide offers a comprehensive exploration of the reverse MC connector market, covering essential aspects such as product specifications, application scenarios, supplier vetting processes, and cost considerations.

Designed specifically for international B2B buyers from Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Brazil—this guide serves as a vital resource for making informed purchasing decisions. It not only highlights the technical features and advantages of different connector types but also provides insights into supplier reliability and market trends. By equipping buyers with actionable information, this guide empowers businesses to navigate the complexities of sourcing high-quality reverse MC connectors, ensuring they secure the best products at competitive prices.

As you delve into this guide, you will discover how to effectively evaluate suppliers, understand pricing dynamics, and select the right connectors for your specific needs, ultimately driving success in your procurement strategies.

Understanding reverse mc connector Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Retrofit SNAP²IT® Connector | One-piece design, tool-free installation, insulated throat | Electrical retrofits, circuit additions | Pros: Easy installation, versatile cable compatibility. Cons: Limited to specific cable sizes. |

| E-Z Lock® Duplex Connector | Insulated, die-cast zinc construction | New and old work installations | Pros: Durable, secure connections. Cons: Slightly higher cost than plastic alternatives. |

| Insulated Snap-In Connector | Insulation for safety, available in various sizes | Residential and commercial wiring | Pros: Enhanced safety, easy to use. Cons: May require more space for installation. |

| AC/MC Continuous Connector | Designed for continuous corrugated aluminum cable | Heavy-duty applications, industrial settings | Pros: Robust design for high-load scenarios. Cons: May be over-engineered for lighter applications. |

| MCI-A Cable Connector | Compatibility with steel and aluminum cables | Specialized electrical setups | Pros: Versatile for different cable types. Cons: Installation might require specific tools. |

What are the Key Characteristics of Retrofit SNAP²IT® Connectors?

The Retrofit SNAP²IT® Connector is designed with a one-piece structure that simplifies installation, making it an ideal choice for retrofitting existing electrical systems. It accommodates a wide range of cable sizes from 14/2 to 10/3, ensuring compatibility with various applications. This connector is particularly advantageous for B2B buyers looking to enhance electrical circuits without extensive labor costs or complicated installation processes.

How Do E-Z Lock® Duplex Connectors Stand Out?

E-Z Lock® Duplex Connectors feature a robust die-cast zinc construction, providing durability and secure connections. Their insulated design makes them suitable for both new and existing installations, catering to a wide array of electrical applications. B2B purchasers in construction and renovation sectors will find these connectors beneficial for ensuring long-lasting and reliable electrical connections, though they may come at a slightly higher price point.

Why Choose Insulated Snap-In Connectors for Electrical Wiring?

Insulated Snap-In Connectors are engineered for safety and ease of use, making them suitable for both residential and commercial wiring projects. These connectors come in various sizes, allowing for flexibility in installation. For B2B buyers, the enhanced safety features can reduce liability and ensure compliance with electrical standards. However, the requirement for additional space during installation may be a consideration for tighter setups.

What Makes AC/MC Continuous Connectors Ideal for Heavy-Duty Applications?

Designed specifically for continuous corrugated aluminum cables, AC/MC Continuous Connectors are perfect for heavy-duty applications, especially in industrial environments. Their robust construction ensures they can handle high loads, making them a reliable choice for B2B buyers focused on durability. However, their strength may be unnecessary for lighter applications, leading to potential over-specification.

How Do MCI-A Cable Connectors Cater to Specialized Needs?

MCI-A Cable Connectors are versatile and compatible with both steel and aluminum cables, making them suitable for specialized electrical setups. They are particularly useful in environments that require adaptability in cabling materials. For B2B buyers, the ability to accommodate various cable types can streamline purchasing decisions, though installation might necessitate specific tools, which could be a consideration for procurement.

Key Industrial Applications of reverse mc connector

| Industry/Sector | Specific Application of reverse mc connector | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Electrical wiring in commercial buildings | Ensures secure and efficient electrical connections | Compliance with local electrical standards and regulations |

| Renewable Energy | Connecting solar panel systems | Enhances reliability and safety in installations | Availability of connectors compatible with various cable types |

| Manufacturing | Machinery and equipment wiring | Facilitates seamless integration of electrical systems | Durability to withstand industrial conditions |

| Telecommunications | Data center wiring and connectivity | Optimizes data transmission reliability | Sourcing for high-temperature and moisture-resistant options |

| Oil & Gas | Power distribution in remote locations | Reduces downtime and maintenance costs | Consideration for connectors designed for harsh environments |

How is the Reverse MC Connector Used in Construction?

In the construction industry, reverse MC connectors are essential for ensuring secure electrical wiring in commercial buildings. They allow for the integration of various electrical systems, providing a reliable connection for power distribution. These connectors are particularly advantageous for retrofit applications, where existing infrastructure needs to be adapted for new electrical loads. Buyers must ensure compliance with local electrical codes and standards, which can vary significantly across regions, especially in areas like Africa and the Middle East.

What Role Does the Reverse MC Connector Play in Renewable Energy?

Within the renewable energy sector, particularly in solar installations, reverse MC connectors are utilized to connect solar panels to inverters and other electrical components. Their robust design ensures that connections remain secure under varying weather conditions, enhancing the overall reliability of solar systems. B2B buyers in this sector should prioritize sourcing connectors that accommodate diverse cable types and sizes to ensure compatibility with different solar technologies.

How is the Reverse MC Connector Beneficial in Manufacturing?

In manufacturing, reverse MC connectors are crucial for wiring machinery and equipment. They facilitate the seamless integration of electrical systems, which is vital for maintaining operational efficiency. The ability to withstand industrial conditions, such as exposure to dust and moisture, makes these connectors a preferred choice. Buyers should consider sourcing connectors that are durable and compliant with industry-specific safety standards to minimize the risk of electrical failures.

Why Are Reverse MC Connectors Important for Telecommunications?

In the telecommunications industry, reverse MC connectors play a pivotal role in ensuring reliable data center wiring and connectivity. They contribute to optimized data transmission and minimize signal loss, which is critical for maintaining high-speed internet services. When sourcing these connectors, businesses must focus on options that offer high-temperature resistance and moisture protection, particularly in regions with extreme climates, such as parts of South America and the Middle East.

How Do Reverse MC Connectors Benefit the Oil & Gas Sector?

In the oil and gas sector, reverse MC connectors are vital for power distribution in remote locations where traditional wiring may be impractical. Their robust construction helps reduce downtime and maintenance costs by ensuring stable electrical connections even in harsh environments. Buyers in this industry should seek connectors specifically designed to withstand extreme temperatures and corrosive conditions, which are common in oil and gas operations.

3 Common User Pain Points for ‘reverse mc connector’ & Their Solutions

Scenario 1: Installation Complications with Reverse MC Connectors

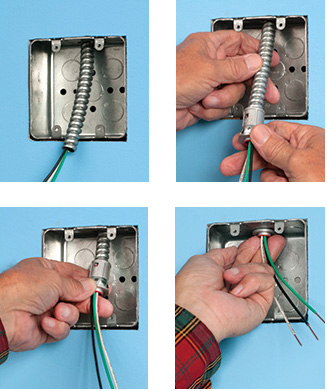

The Problem: B2B buyers often encounter challenges during the installation of reverse MC connectors, particularly in existing structures where space is limited. For instance, electrical contractors may struggle to fit these connectors into tight knockout areas without damaging surrounding components. This issue can lead to delays in project timelines and increased labor costs, as workers spend additional time on complex installations or troubleshooting.

The Solution: To mitigate these installation complications, it’s essential to prioritize connectors designed for retrofitting. Select reverse MC connectors with a snap-in feature, which allows for tool-free installation. This design not only simplifies the process but also enhances the connection’s security. When sourcing these connectors, ensure they have a wide cable range compatibility, accommodating various cable sizes from 14/2 to 10/3, which is crucial for flexibility in different projects. Additionally, investing in connectors with an insulated throat can enhance safety and performance, minimizing the risk of electrical shorts during installation.

Scenario 2: Compatibility Issues with Different Cable Types

The Problem: Another significant pain point for B2B buyers is the compatibility of reverse MC connectors with various cable types. In regions such as Africa and South America, where infrastructure varies widely, the existing cabling systems may not align with standard connectors. This can lead to frustration when trying to integrate new systems or expand existing ones, often resulting in the need for costly rework or sourcing specialized connectors.

The Solution: To address compatibility issues, it is crucial to perform a thorough assessment of the cable types in use before purchasing connectors. Buyers should seek reverse MC connectors that are versatile and compatible with multiple cable types, including AC, MC, and HCF cables. Look for connectors that explicitly state their compatibility with both aluminum and steel cables, as this will provide greater flexibility for varying project requirements. Additionally, maintaining close communication with suppliers about the specific types of cables used in the region can lead to better recommendations and prevent costly compatibility mismatches.

Scenario 3: Safety Concerns with Electrical Connections

The Problem: Safety is a paramount concern for B2B buyers, especially in industries where electrical reliability is critical. Poorly made or improperly installed reverse MC connectors can lead to electrical failures, posing significant risks for both equipment and personnel. Buyers may worry about the long-term reliability of the connections, especially in harsh environmental conditions often found in the Middle East or during heavy rainfall in South America.

The Solution: To enhance safety, prioritize sourcing reverse MC connectors that meet rigorous industry standards, such as CSA and UL certifications. These certifications ensure that the connectors have been tested for durability and safety in various conditions. Additionally, consider selecting connectors with features like anti-short bushings, which provide an added layer of protection against electrical shorts. Implementing regular training for installation teams on proper installation techniques and safety protocols can also significantly reduce the risk of accidents. By emphasizing quality and safety in sourcing, B2B buyers can enhance the reliability of their electrical systems and ensure compliance with local regulations.

Strategic Material Selection Guide for reverse mc connector

What Are the Key Materials Used in Reverse MC Connectors?

When selecting materials for reverse MC connectors, it is essential to consider their properties, advantages, limitations, and suitability for specific applications. The following analysis focuses on four common materials: zinc die-cast, aluminum, plastic, and stainless steel. Each material offers unique characteristics that can influence performance and cost-effectiveness.

How Does Zinc Die-Cast Perform in Reverse MC Connectors?

Zinc die-cast is a prevalent choice for reverse MC connectors due to its excellent mechanical properties. It offers high strength and durability, with a temperature rating typically around 150°C (302°F). Zinc die-cast connectors are also resistant to corrosion, making them suitable for various environments, including those with moisture and humidity.

Pros: Zinc die-cast connectors are robust and can withstand significant mechanical stress. They are relatively easy to manufacture, leading to lower production costs. Additionally, their corrosion resistance makes them ideal for applications in coastal or humid regions.

Cons: While zinc die-cast is durable, it can be more expensive than plastic alternatives. The manufacturing process can be complex, requiring specialized equipment. Furthermore, they may not be suitable for extremely high-temperature applications.

Impact on Application: Zinc die-cast connectors are compatible with a wide range of cable types, making them versatile for electrical installations. They are particularly effective in environments where mechanical protection is crucial.

What Advantages Does Aluminum Offer for Reverse MC Connectors?

Aluminum is another common material used in reverse MC connectors, known for its lightweight nature and good conductivity. It typically has a temperature rating similar to zinc die-cast, around 150°C (302°F), and exhibits excellent resistance to corrosion when anodized.

Pros: The lightweight nature of aluminum makes it easier to handle and install, reducing labor costs. Its good electrical conductivity enhances the performance of the connectors in electrical applications.

Cons: While aluminum is corrosion-resistant, it may not be as durable as zinc die-cast under heavy mechanical stress. Additionally, aluminum connectors can be more susceptible to galvanic corrosion when in contact with dissimilar metals.

Impact on Application: Aluminum connectors are ideal for applications requiring lightweight solutions, such as in overhead installations. They are widely accepted in various international markets, including Europe and South America, where standards for electrical safety are stringent.

How Do Plastic Connectors Compare in Terms of Performance?

Plastic connectors, often made from high-density polyethylene (HDPE) or polyvinyl chloride (PVC), are lightweight and resistant to moisture. They typically have lower temperature ratings, around 80°C (176°F), which may limit their use in high-heat environments.

Pros: The primary advantage of plastic connectors is their cost-effectiveness and ease of installation. They are also resistant to corrosion and do not conduct electricity, providing additional safety in certain applications.

Cons: Plastic connectors may not withstand mechanical stress as well as metal options. Their lower temperature rating limits their application in high-heat environments, making them less versatile.

Impact on Application: Plastic connectors are suitable for residential applications and environments where moisture is a concern but may not be ideal for industrial settings requiring high durability.

Why Choose Stainless Steel for Reverse MC Connectors?

Stainless steel connectors are known for their exceptional strength and corrosion resistance, making them suitable for harsh environments. They typically have a temperature rating of up to 200°C (392°F), offering versatility in various applications.

Pros: The durability of stainless steel ensures a long service life, reducing the need for frequent replacements. Its resistance to corrosion makes it ideal for applications in marine or chemical environments.

Cons: Stainless steel connectors are generally more expensive than other materials. The manufacturing process can be complex and may require specialized techniques.

Impact on Application: Stainless steel connectors are often preferred in industries such as oil and gas or chemical processing, where exposure to harsh conditions is common. Compliance with international standards like ASTM and DIN is crucial for buyers in these sectors.

Summary Table of Material Selection for Reverse MC Connectors

| Material | Typical Use Case for reverse mc connector | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Zinc Die-Cast | General electrical installations | High strength and durability | Higher cost than plastic | Medium |

| Aluminum | Overhead installations | Lightweight and good conductivity | Susceptible to galvanic corrosion | Medium |

| Plastic | Residential applications | Cost-effective and easy to install | Lower temperature rating | Low |

| Stainless Steel | Harsh industrial environments | Exceptional strength and corrosion resistance | Higher cost and complex manufacturing | High |

This comprehensive analysis of materials for reverse MC connectors provides B2B buyers with actionable insights, helping them make informed decisions based on performance, cost, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for reverse mc connector

What Are the Key Stages in the Manufacturing Process of Reverse MC Connectors?

The manufacturing process of reverse MC (Metal Clad) connectors is a multi-step procedure that ensures the production of high-quality and reliable components essential for electrical installations. Understanding these stages can help B2B buyers evaluate potential suppliers and make informed purchasing decisions.

Material Preparation: What Materials Are Used in Reverse MC Connectors?

The first stage of manufacturing involves selecting and preparing the materials. Reverse MC connectors typically utilize high-grade materials such as:

- Zinc Die-Cast: Known for its durability and corrosion resistance, zinc die-cast is commonly used for the body of connectors.

- Insulating Throat Materials: These are often made from thermoplastic or rubber compounds to ensure electrical safety.

- Metallic Components: For connectors, aluminum or steel is often used to ensure structural integrity.

Once the materials are selected, they undergo rigorous quality checks to ensure they meet industry standards. This step is crucial for ensuring that the final product can withstand environmental stresses and electrical loads.

How Are Reverse MC Connectors Formed and Assembled?

The forming and assembly stages involve several techniques that ensure precision and reliability:

-

Die-Casting: The zinc die-casting process allows for the production of complex shapes with high dimensional accuracy. The molten zinc is injected into molds under high pressure, creating the main body of the connector.

-

Injection Molding: This technique is used for producing the insulating throat components. The selected thermoplastic material is heated and injected into molds, where it cools and solidifies.

-

Assembly: In this stage, the various components are assembled. This typically includes fitting the insulating throat onto the die-cast body. Advanced automated assembly lines may be employed to enhance efficiency and reduce human error.

-

Finishing: The final stage involves surface treatment processes such as plating or coating to improve resistance to corrosion and enhance aesthetic appeal. This can also include marking or labeling for identification.

What Quality Assurance Measures Are In Place for Reverse MC Connectors?

Quality assurance (QA) is a critical aspect of the manufacturing process for reverse MC connectors. It ensures that the products meet international safety and performance standards, which is particularly important for B2B buyers in diverse markets.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with several international and industry-specific quality standards, including:

- ISO 9001: This is the standard for quality management systems and is crucial for ensuring that manufacturers maintain a consistent level of quality throughout their processes.

- CE Marking: For products sold in the European market, CE marking indicates compliance with safety, health, and environmental protection standards.

- UL Certification: In North America, UL certification is essential for electrical products, ensuring they meet rigorous safety standards.

These certifications not only enhance product credibility but also provide assurance to buyers regarding product safety and performance.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential in monitoring the manufacturing process. Common QC stages include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials before they enter the production process. Materials are tested for compliance with specifications to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections and tests are conducted to monitor ongoing processes. This ensures that any deviations from quality standards are identified and corrected immediately.

-

Final Quality Control (FQC): After assembly, each connector undergoes thorough testing to verify its performance and compliance with specifications. This may include electrical testing, mechanical stress tests, and visual inspections.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are several strategies:

-

Supplier Audits: Conducting onsite audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational practices of potential suppliers.

-

Requesting Quality Reports: Suppliers should provide documentation detailing their quality control processes, including test results, certifications, and compliance records.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturer’s quality control practices. This can be particularly useful for buyers unfamiliar with local suppliers.

What Common Testing Methods Are Used in Quality Assurance?

Quality assurance for reverse MC connectors involves various testing methods to ensure reliability and performance. Some common methods include:

-

Electrical Testing: This tests the connectors’ ability to handle specified voltages and currents without failure. It includes insulation resistance testing and continuity testing.

-

Mechanical Testing: This evaluates the physical strength and durability of the connectors, including pull-out tests to ensure secure cable retention.

-

Environmental Testing: Connectors may undergo exposure to extreme temperatures, humidity, and corrosive environments to assess their performance under various conditions.

How Do Quality Control Nuances Affect International B2B Transactions?

B2B buyers from diverse regions may encounter unique challenges related to quality control. For instance:

-

Cultural Differences: Different countries may have varying standards for quality and safety. Buyers should be aware of these differences and ensure their suppliers comply with the relevant standards.

-

Regulatory Compliance: Understanding local regulations regarding electrical components is crucial for avoiding legal issues. Buyers should ensure that suppliers can provide the necessary certifications for their target markets.

-

Shipping and Logistics: Quality can be compromised during shipping. Buyers should work with suppliers who have established procedures for packing and transporting products to minimize damage.

In conclusion, understanding the manufacturing processes and quality assurance measures for reverse MC connectors is vital for B2B buyers. By focusing on material quality, manufacturing techniques, and rigorous testing protocols, buyers can ensure they procure reliable and compliant products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘reverse mc connector’

In this guide, we aim to provide international B2B buyers with a structured approach to sourcing reverse MC connectors. This checklist outlines essential steps to ensure that you procure quality products that meet your specific requirements while navigating the complexities of international supply chains.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in sourcing reverse MC connectors. Determine the types of cables and environments the connectors will be used in, including specifications such as size, material, and insulation type. This information will help you communicate effectively with suppliers and ensure that you receive the right product.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of reverse MC connectors. Look for companies that specialize in electrical components and have a strong presence in your target regions, such as Africa, South America, the Middle East, and Europe. Pay attention to their product range, industry experience, and customer reviews to assess their reliability.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, it’s crucial to verify their certifications and compliance with international standards. Look for certifications such as UL, CSA, or IEC that indicate the products meet safety and performance criteria. This step is essential to mitigate risks associated with product quality and ensure that you are sourcing connectors that adhere to regulatory requirements.

Step 4: Request Samples for Testing

To ensure the connectors meet your specifications and quality standards, request samples from shortlisted suppliers. Testing the samples in your operational environment can help identify any potential issues before making a bulk purchase. Evaluate aspects such as durability, ease of installation, and compatibility with existing systems.

Step 5: Negotiate Terms and Pricing

Once you have selected a preferred supplier, engage in negotiations to establish favorable terms and pricing. Consider factors such as minimum order quantities, lead times, payment terms, and shipping costs. Establishing clear agreements will help prevent misunderstandings and protect your interests throughout the procurement process.

Step 6: Verify Logistics and Delivery Capabilities

Assess the supplier’s logistics and delivery capabilities to ensure timely receipt of your order. Inquire about their shipping methods, customs handling, and tracking options. Understanding their logistics will help you plan your inventory and avoid delays in project execution.

Step 7: Establish Ongoing Communication

After placing your order, maintain open lines of communication with your supplier. Regular updates on order status, shipping schedules, and any potential issues will foster a strong relationship and ensure that any concerns are addressed promptly. Establishing this rapport can also lead to better service and support for future orders.

By following this checklist, you can streamline your sourcing process for reverse MC connectors, minimizing risks and enhancing the efficiency of your procurement strategy.

Comprehensive Cost and Pricing Analysis for reverse mc connector Sourcing

What Are the Key Cost Components for Sourcing Reverse MC Connectors?

When evaluating the cost structure of reverse MC connectors, several components come into play. The primary cost factors include materials, labor, manufacturing overhead, tooling, quality control, logistics, and supplier margins.

-

Materials: Reverse MC connectors are typically made from durable materials such as die-cast zinc, which provides long-lasting performance and corrosion resistance. The quality and sourcing of these materials can significantly impact the overall cost.

-

Labor: Labor costs vary by region and production scale. For instance, labor costs in countries with lower wage standards can lead to reduced overall pricing for connectors, making sourcing from these regions attractive for international buyers.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize overhead, thus reducing the final product cost.

-

Tooling: The initial investment in molds and tools for producing reverse MC connectors can be substantial. However, the costs can be amortized over large production runs, making it essential to consider volume when assessing pricing.

-

Quality Control (QC): Ensuring the connectors meet industry standards incurs additional costs. Certifications such as UL and CSA can enhance product reliability but may also lead to higher prices.

-

Logistics: Transportation and shipping costs play a critical role, especially for international buyers. Factors such as distance, shipping method, and import duties must be considered.

-

Margin: Supplier margins vary based on market competition, brand reputation, and the perceived value of the product. Understanding these margins can help buyers negotiate better prices.

How Do Price Influencers Affect Sourcing Decisions for Reverse MC Connectors?

Numerous factors influence pricing for reverse MC connectors, which can significantly affect the sourcing strategy for international buyers.

-

Volume/MOQ: Purchasing in bulk can lead to lower per-unit prices. Manufacturers often provide discounts for larger orders, making it beneficial for buyers to consolidate their purchases.

-

Specifications and Customization: Custom connectors tailored to specific applications may come at a premium. Buyers should evaluate whether standard options meet their needs to avoid unnecessary expenses.

-

Materials and Quality Certifications: Higher-quality materials and certified products generally command higher prices. Buyers should balance the need for quality with their budget constraints, considering the Total Cost of Ownership (TCO).

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge more due to their track record, while new entrants might offer competitive pricing to gain market share.

-

Incoterms: The choice of Incoterms can significantly impact final pricing. Terms like CIF (Cost, Insurance, and Freight) versus FOB (Free on Board) determine who bears the shipping costs, affecting the overall expense for the buyer.

What Are the Best Negotiation Tips for B2B Buyers in International Markets?

For international buyers, especially those in Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant savings.

-

Research and Benchmarking: Understanding market rates and having data on competitors can empower buyers during negotiations. This knowledge helps in setting realistic pricing expectations.

-

Leverage Volume Discounts: Communicate potential future orders to suppliers. This can often lead to better pricing agreements, especially if a supplier sees an opportunity for long-term business.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, durability, and potential failures. This holistic view can justify higher upfront costs for better quality connectors.

-

Clarify Specifications Early: Clear communication regarding product specifications can prevent misunderstandings that lead to costly changes or delays.

-

Utilize Local Representatives: Engaging local representatives can provide insights into regional market dynamics and cultural nuances, enhancing negotiation effectiveness.

Conclusion

In summary, understanding the cost components and price influencers for reverse MC connectors is essential for B2B buyers. By leveraging effective negotiation strategies, buyers can achieve better pricing and ensure they are making informed purchasing decisions. Keep in mind that prices can vary widely based on the factors outlined above, and it is crucial to approach each sourcing opportunity with comprehensive research and strategic planning.

Alternatives Analysis: Comparing reverse mc connector With Other Solutions

Understanding Alternative Solutions for Reverse MC Connectors

When it comes to electrical installations, choosing the right connector is crucial for performance, safety, and efficiency. The reverse MC connector is a popular choice, but there are several alternatives available that can meet various application needs. This section explores these alternatives, allowing B2B buyers to make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison of Reverse MC Connector with Alternative Solutions

| Comparison Aspect | Reverse MC Connector | SNAP²IT Connectors | E-Z Lock Connectors |

|---|---|---|---|

| Performance | Excellent for a wide range of cables | High performance with easy installation | Reliable with secure connections |

| Cost | Moderate, varies by supplier | Generally low-cost per unit | Competitive pricing |

| Ease of Implementation | Requires specific tools for installation | Tool-free installation | Quick snap-in design |

| Maintenance | Low maintenance required | Minimal maintenance required | Low maintenance |

| Best Use Case | Ideal for continuous corrugated aluminum | Retrofit applications in existing setups | New work or existing installations |

What Are the Benefits and Drawbacks of SNAP²IT Connectors?

SNAP²IT connectors offer a simple, tool-free installation process, making them particularly appealing for retrofit applications. They accommodate a variety of cable types, including AC, MC, and HCF cables, providing versatility in electrical systems. Their low cost per unit makes them an economical choice for bulk purchases. However, while they are designed for easy installation, the requirement for specific cable types may limit their applicability in some scenarios.

How Do E-Z Lock Connectors Compare?

E-Z Lock connectors are known for their reliable performance and secure connections, which are essential in high-stakes electrical environments. They are designed for both new work and existing installations, making them versatile for a range of projects. The quick snap-in design allows for efficient installation, which can save time on the job site. However, their pricing can be slightly higher than other alternatives, which might be a consideration for budget-conscious buyers.

Conclusion: How to Choose the Right Connector for Your Needs?

When evaluating the right connector for your application, consider factors such as the specific electrical requirements, installation environment, and budget constraints. The reverse MC connector excels in performance and is suitable for various cable types, while SNAP²IT connectors shine in ease of installation and cost-effectiveness for retrofitting. E-Z Lock connectors provide reliability for both new and existing installations but may come at a higher price point. Ultimately, the best choice will align with your operational needs, ensuring safety and efficiency in your electrical systems.

Essential Technical Properties and Trade Terminology for reverse mc connector

What Are the Key Technical Properties of Reverse MC Connectors?

Understanding the technical specifications of reverse MC connectors is essential for B2B buyers looking for reliable electrical connections. Here are some critical properties to consider:

-

Material Composition

– Reverse MC connectors are primarily made from zinc die-cast or aluminum. These materials offer durability and resistance to corrosion, making them suitable for various environments. The choice of material impacts the connector’s lifespan and performance, which is vital for businesses seeking long-term solutions. -

Cable Compatibility

– These connectors accommodate a range of cable types, including AC, MC, HCF, and continuous corrugated aluminum cables. The ability to handle various cable sizes (typically from 14/2 to 10/3) is crucial for flexibility in installations. Businesses must ensure that the connectors they choose can fit the specific cables used in their projects to avoid compatibility issues. -

Insulated Throat Design

– Many reverse MC connectors feature an insulated throat, which enhances safety by reducing the risk of electrical shorts. This design is essential for compliance with safety standards and regulations. For B2B buyers, investing in connectors with insulated throats can mitigate risks associated with electrical installations. -

Installation Methodology

– The one-piece design of reverse MC connectors allows for tool-free installation. This feature significantly reduces labor costs and installation time, providing a competitive advantage for contractors and electrical professionals. Understanding the ease of installation can influence purchasing decisions, especially for projects with tight deadlines. -

Performance Standards

– Compliance with industry standards, such as UL and CSA listings, ensures that the connectors meet safety and performance benchmarks. B2B buyers should prioritize products that are certified, as this indicates reliability and adherence to quality protocols. -

Pullout Resistance

– A key performance metric is the pullout resistance of the connector, which prevents accidental disconnections. This property is particularly important in applications where vibrations or movement may occur. Ensuring strong pullout resistance can enhance the overall safety and reliability of electrical installations.

Which Trade Terms Should B2B Buyers Understand When Sourcing Reverse MC Connectors?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for buyers looking to ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchasing strategy and manage inventory effectively, especially in regions with varying demand. -

RFQ (Request for Quotation)

– An RFQ is a document issued by a buyer to solicit price quotes from suppliers. This process is vital for ensuring that buyers receive competitive pricing and can make informed purchasing decisions based on market offerings. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms used in international trade. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is essential for smooth international transactions and logistics. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order until the product is delivered. Knowing the lead time helps businesses plan their projects and manage expectations with clients. -

Warranty

– A warranty is a guarantee provided by the manufacturer regarding the quality and lifespan of the product. Understanding warranty terms is crucial for B2B buyers to ensure they are protected against defects and performance issues.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing reverse MC connectors, ensuring they choose products that meet their specific needs and standards.

Navigating Market Dynamics and Sourcing Trends in the reverse mc connector Sector

What Are the Key Market Dynamics and Trends in the Reverse MC Connector Sector?

The reverse MC connector market is witnessing significant growth driven by advancements in electrical infrastructure and increased demand for reliable connectivity solutions across various industries. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are focusing on sourcing high-quality reverse MC connectors due to their critical role in electrical installations. Key trends include the adoption of retrofit solutions, which allow for easy integration into existing systems without extensive modifications. This is particularly beneficial for buyers in rapidly developing regions where infrastructure upgrades are essential.

Emerging technologies like smart wiring and IoT (Internet of Things) are influencing the design and functionality of reverse MC connectors. The growing emphasis on energy efficiency and reduced installation times is pushing manufacturers to innovate, leading to products that are easier to install and more versatile in accommodating various cable types. B2B buyers should also be aware of the rising importance of digital platforms for sourcing, which enhance transparency and streamline procurement processes. Moreover, the demand for connectors that comply with international standards is increasing, as buyers seek to ensure reliability and safety in their installations.

How Is Sustainability Influencing the Sourcing of Reverse MC Connectors?

Sustainability and ethical sourcing are becoming integral to the procurement strategies of international B2B buyers in the reverse MC connector sector. The environmental impact of manufacturing processes and the lifecycle of products is under scrutiny, prompting companies to seek suppliers that prioritize eco-friendly practices. Buyers are increasingly looking for connectors made from recyclable materials and those that meet ‘green’ certifications, which demonstrate compliance with environmental standards.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are keen on partnering with manufacturers that uphold fair labor practices and ensure responsible sourcing of raw materials. This is especially relevant in regions where regulatory frameworks may be less stringent. By prioritizing sustainability and ethical sourcing, companies not only enhance their brand reputation but also contribute to a more sustainable future, which resonates well with increasingly conscious consumers and stakeholders.

How Have Reverse MC Connectors Evolved Over Time?

The evolution of reverse MC connectors can be traced back to the growing need for efficient electrical solutions in various sectors. Initially, connectors were primarily designed for simplicity and functionality, but as technology advanced, so did their complexity and capabilities. Early versions were often cumbersome and required significant manual labor for installation. However, recent innovations have led to the development of snap-in connectors that allow for tool-free installation, drastically reducing labor costs and installation times.

Additionally, the introduction of materials like die-cast zinc has enhanced durability and performance, making modern reverse MC connectors more reliable than their predecessors. The focus has shifted towards creating products that not only meet technical specifications but also align with sustainability goals. As the market continues to evolve, it is expected that reverse MC connectors will further integrate advanced technologies and materials, catering to the diverse needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of reverse mc connector

-

How do I ensure the quality of reverse MC connectors when sourcing internationally?

To guarantee the quality of reverse MC connectors, it’s essential to vet suppliers rigorously. Request certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, ask for product samples to assess the material and construction quality firsthand. Utilizing third-party inspection services can also be beneficial, ensuring that the connectors meet the required specifications before shipment. Lastly, establish clear quality assurance protocols in your contract to hold suppliers accountable for product quality. -

What are the key features to look for in reverse MC connectors?

When sourcing reverse MC connectors, prioritize features such as durable materials (preferably die-cast zinc), compatibility with various cable types (like AC and MC cables), and a secure installation design that minimizes pullout risks. An insulated throat is also crucial for safety, preventing electrical shorts. Additionally, consider ease of installation; connectors that require no tools can significantly reduce labor costs and installation time. -

What are the typical minimum order quantities (MOQs) for reverse MC connectors?

MOQs for reverse MC connectors can vary significantly based on the supplier and order specifications. Generally, expect MOQs to range from 100 to 1,000 units. It’s advisable to discuss your project needs with potential suppliers to negotiate MOQs that align with your requirements, especially if you’re looking for customization. Some suppliers might offer flexibility for first-time buyers or bulk orders, which can be beneficial for establishing long-term relationships. -

How can I find reliable suppliers for reverse MC connectors in my region?

To locate dependable suppliers for reverse MC connectors, leverage online B2B marketplaces like Alibaba or Global Sources, where you can filter suppliers based on ratings and reviews. Additionally, industry trade shows and exhibitions are excellent venues for meeting manufacturers and distributors face-to-face. Networking through industry associations can also provide referrals to reputable suppliers. Always conduct due diligence by checking references and requesting product samples before placing large orders. -

What payment terms should I expect when sourcing reverse MC connectors internationally?

Payment terms for international orders of reverse MC connectors typically vary by supplier and can range from upfront payments to 30-60 days after delivery. Common methods include wire transfers, letters of credit, and online payment platforms. It’s crucial to negotiate terms that protect your interests, especially for larger orders. Consider using escrow services for added security, ensuring that funds are released only upon satisfactory delivery of goods. -

Are there customs duties or import taxes I should be aware of when importing reverse MC connectors?

Yes, importing reverse MC connectors can incur customs duties and import taxes, which vary by country and depend on the product classification and value. It’s essential to consult your country’s customs regulations to determine applicable rates. Engaging a customs broker can facilitate the process, ensuring compliance with local laws and helping to avoid unexpected fees. Understanding these costs upfront will aid in accurate budgeting for your imports. -

Can I customize reverse MC connectors to fit specific project needs?

Many suppliers offer customization options for reverse MC connectors, allowing you to specify dimensions, materials, or packaging that suit your project requirements. Discuss your needs directly with potential suppliers to explore available options. Customization may involve additional costs and longer lead times, so ensure you clearly communicate your specifications and timelines. It’s beneficial to get written confirmation of any custom agreements to avoid misunderstandings later. -

What logistics considerations should I keep in mind when importing reverse MC connectors?

When importing reverse MC connectors, consider shipping methods, lead times, and logistics partners. Air freight is faster but more expensive, while sea freight is cost-effective for larger volumes. Ensure your logistics partner has experience with electrical components to navigate any specific handling requirements. Additionally, factor in storage solutions for your inventory upon arrival and ensure compliance with local regulations regarding electrical products. Proper planning can mitigate delays and additional costs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Reverse Mc Connector Manufacturers & Suppliers List

1. AIFittings – Retrofit SNAP²IT® MC Cable Connectors

Domain: aifittings.com

Registered: 1998 (27 years)

Introduction: Retrofit SNAP²IT® MC Cable Connectors

– Material: Zinc die-cast

– Compatibility: AC, MC, HCF, MC Continuous corrugated aluminum cable, MCI-A cables (steel and aluminum), AC90 ACG90 and FLEX

– Design: Fully assembled one-piece design with insulated throat

– Cable Range: Accommodates cables from 14/2 to 10/3

– Part Numbers: 38RAST (UPC-A: 018997135865, Trade Size: 1/2″, Unit Pkg: 25, Standard Pkg: 2…

2. Rexel – Arlington 38RAST MC/AC Cable Connector

Domain: rexelusa.com

Registered: 1997 (28 years)

Introduction: {“Product Name”: “Arlington 38RAST MC/AC Cable Connector”, “Type”: “Snap-In”, “Diameter”: “3/8 inch”, “Insulation”: “Insulated”, “Material”: “Zinc Die Cast”, “Item Number”: “785740”, “Catalog Number”: “38RAST”, “UPC”: “018997135865”, “Cable Range”: “0.405 – 0.605 Inch”, “Features”: “Easy to use in old work installations, ideal for adding circuits to load centers, no tools required for installation…

3. NSI Industries – E-Z Lock® AC/MC Snap-In Connectors

Domain: nsiindustries.com

Registered: 2004 (21 years)

Introduction: AC/MC Snap-In Connectors include various models such as E-Z Lock® Duplex AC/MC Connector and E-Z Lock® Insulated Duplex AC/MC Connector, all made of die-cast zinc. Key specifications include: 3/8″ and 1/2″ sizes, with model numbers like #3838-DC2, #3838-DCI2, #3838ASP, #3838SP, #38ACDS, #38ADS, #38ASP, #3939ASP, and #3939SP. Dimensions vary, for example, #3838-DC2 measures 1.843″ x 1.979″ and #38A…

4. Primus – Snap2It® MC Flex Cable Connectors

Domain: primuscable.com

Registered: 2007 (18 years)

Introduction: Snap2It® MC Flex Cable Connectors w/ Ground

Strategic Sourcing Conclusion and Outlook for reverse mc connector

As the demand for reliable and efficient electrical solutions continues to rise, the strategic sourcing of reverse MC connectors presents a significant opportunity for international B2B buyers. By prioritizing quality and innovation, businesses can leverage products like the Retrofit SNAP²IT® MC Cable Connectors, which offer a versatile and secure installation process. The ease of integration with various cable types, coupled with a robust one-piece design, minimizes labor costs and enhances safety, making these connectors a valuable asset for any electrical project.

Investing in high-quality connectors not only ensures compliance with safety standards but also fosters long-term relationships with manufacturers who prioritize sustainable practices. For buyers in Africa, South America, the Middle East, and Europe, understanding the regional availability and pricing dynamics of these products is crucial for making informed purchasing decisions.

Looking ahead, the landscape of electrical connectivity is set to evolve further, driven by technological advancements and increased demand for energy-efficient solutions. Now is the time to engage with trusted suppliers to secure the best products for your projects. Embrace the future of electrical connectivity by exploring strategic sourcing options that align with your business goals and operational needs.