Choosing Your Pool Table Slate Replacement: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for pool table slate replacement

In the competitive landscape of the billiards industry, sourcing high-quality pool table slate replacement can be a daunting challenge for international B2B buyers. As the primary component that ensures a level and durable playing surface, the choice of slate directly impacts the playing experience and longevity of pool tables. This comprehensive guide delves into the intricacies of pool table slate replacement, offering insights into various types of slate, their applications, and the critical factors to consider when selecting suppliers.

From understanding the nuances of one-piece versus three-piece slates to evaluating cost implications and shipping logistics, this guide serves as a vital resource for businesses across Africa, South America, the Middle East, and Europe, including key markets like Brazil and Germany. With a focus on supplier vetting processes, buyers will gain the knowledge needed to make informed decisions that align with their operational needs and budget constraints.

By equipping B2B buyers with essential tools and insights, this guide aims to simplify the procurement process, ensuring that businesses not only meet their slate replacement needs but also enhance their overall service offerings in the billiards market. With the right information at hand, navigating the global market for pool table slate replacement becomes a strategic advantage rather than a logistical hurdle.

Understanding pool table slate replacement Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 1-Piece Slate | Solid slab, typically heavier, offers maximum stability | High-end pool tables, commercial venues | Pros: Exceptional durability, excellent playing surface; Cons: Difficult to transport, higher cost. |

| 3-Piece Slate | Composed of three separate slabs, allows for easier handling | Residential and small commercial tables | Pros: Easier to move and install; Cons: May require more precise leveling. |

| Laminated Slate | Slate with a laminate finish for enhanced durability | High-traffic environments, bars, and clubs | Pros: Resistant to wear and tear; Cons: Slightly less traditional feel, potential for laminate to peel over time. |

| Reclaimed Slate | Reused slate from older tables, cost-effective | Budget-conscious buyers, refurbishing projects | Pros: Eco-friendly, lower cost; Cons: Potential for hidden damage, variable quality. |

| Custom Slate | Tailored dimensions and thickness based on specific needs | Custom-built tables, specialty venues | Pros: Perfect fit for unique designs; Cons: Longer lead time, higher cost. |

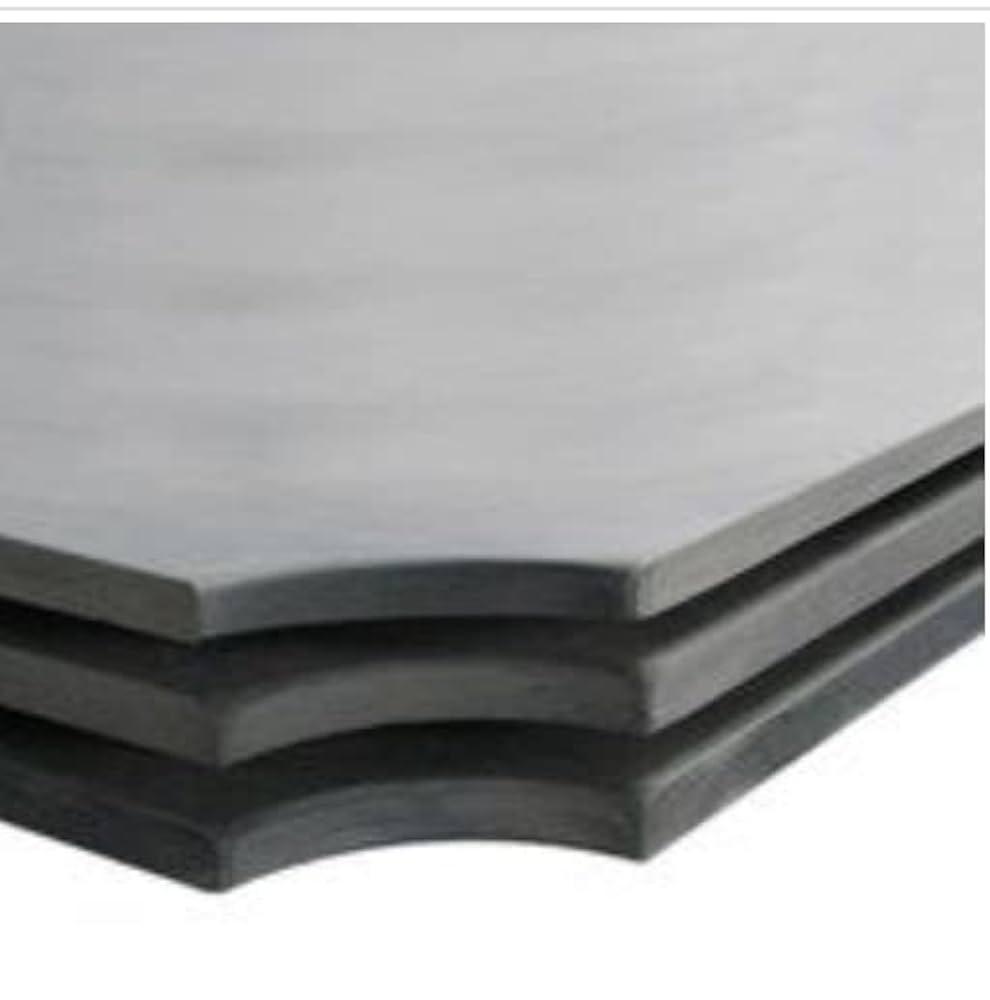

What are the Characteristics of 1-Piece Slate for Pool Tables?

1-piece slate is renowned for its stability and durability, making it the preferred choice for high-end pool tables. Its solid construction ensures a flawless playing surface, which is crucial for professional environments where precision is key. However, the weight of a single slab can complicate transportation and installation, making it less suitable for smaller venues or residential setups. B2B buyers should consider the long-term investment of 1-piece slate, as its durability can reduce maintenance costs over time.

How Does 3-Piece Slate Differ in Handling and Installation?

3-piece slate offers a balance between performance and practicality, consisting of three slabs that can be more easily transported and installed. This design allows for easier adjustments during setup, which is beneficial for residential and small commercial applications. While it provides a great playing surface, buyers must ensure that the installation is done with precision to avoid leveling issues. B2B buyers should weigh the benefits of easier handling against the need for meticulous installation.

What Are the Advantages of Laminated Slate?

Laminated slate features a protective layer that enhances its durability, making it ideal for high-traffic environments like bars and clubs. This type of slate can withstand the rigors of frequent use, which is essential for venues that host regular games. However, buyers should be aware that while laminated slate is resistant to wear, it may not provide the same traditional feel as unlaminated options, and the laminate could peel over time. B2B buyers should evaluate their usage patterns when considering laminated slate.

Why Choose Reclaimed Slate for Cost-Effective Solutions?

Reclaimed slate is an eco-friendly option that appeals to budget-conscious buyers looking to refurbish older tables. This type of slate can offer significant cost savings, but the quality may vary, and there is a risk of hidden damage that could affect performance. B2B buyers should conduct thorough inspections and consider the potential need for repairs when purchasing reclaimed slate to ensure that they are making a wise investment.

What Are the Benefits of Custom Slate for Unique Applications?

Custom slate allows for tailored dimensions and thickness, catering to specific requirements of custom-built tables or specialty venues. This option is particularly advantageous for businesses that require unique designs or configurations. However, the lead time for custom slate can be longer, and the cost is typically higher than standard options. B2B buyers should assess their project timelines and budget constraints when considering custom slate solutions.

Key Industrial Applications of pool table slate replacement

| Industry/Sector | Specific Application of pool table slate replacement | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality & Entertainment | Replacement for pool tables in bars and clubs | Enhances customer experience and retains clientele | Quality of slate, shipping logistics, local suppliers |

| Sports Facilities | Upgrading or replacing slate in competitive venues | Ensures precise gameplay and meets tournament standards | Compliance with international standards, durability |

| Education & Training | Slate replacement in educational institutions | Provides students with a quality playing experience | Bulk purchasing options, warranty and support |

| Home Recreation | Replacement for personal pool tables | Improves home entertainment value | Size specifications, ease of installation |

| Retail & Distribution | Stocking replacement slates for resale | Increases product range and customer satisfaction | Supplier reliability, pricing strategies |

How is Pool Table Slate Replacement Used in the Hospitality & Entertainment Sector?

In bars and clubs, pool tables are central to customer engagement. When slate becomes damaged, it can affect gameplay quality, leading to customer dissatisfaction. By replacing the slate, establishments ensure a smooth playing surface, enhancing the overall experience for patrons. For international buyers, sourcing high-quality slate that can withstand various climates is essential. Additionally, understanding local shipping regulations and ensuring timely delivery can significantly impact operational efficiency.

What Are the Benefits of Pool Table Slate Replacement in Sports Facilities?

Sports facilities that host tournaments require precise and level playing surfaces to meet competitive standards. Replacing worn or damaged slate ensures that players can perform at their best without concerns about uneven surfaces affecting their game. For buyers in regions like Europe and South America, it is crucial to ensure compliance with international sports standards and to source durable slate that can withstand extensive use. This investment enhances the facility’s reputation and attracts more events.

How Does Pool Table Slate Replacement Enhance Educational Institutions?

Educational institutions that offer billiards as part of their curriculum benefit from replacing old slate. A quality playing surface allows students to learn and practice effectively, fostering better skills development. For B2B buyers in Africa and the Middle East, bulk purchasing options may provide cost savings, while warranties and after-sales support are vital for long-term maintenance. Schools should also consider the ease of installation to minimize downtime.

Why is Pool Table Slate Replacement Important for Home Recreation?

In the home recreation sector, pool tables are a popular addition for entertainment. When the slate is damaged, it can diminish the enjoyment of the game. Replacing the slate not only restores functionality but also increases the value of the home entertainment setup. Buyers should pay attention to the size specifications to ensure compatibility with their existing tables. Additionally, ease of installation is a key consideration, as many homeowners may prefer DIY solutions.

How Can Retailers Benefit from Stocking Pool Table Slate Replacement Products?

Retailers and distributors can enhance their offerings by stocking replacement slates for pool tables. This expands their product range and meets the needs of both casual players and serious enthusiasts. Reliability of suppliers is crucial to ensure consistent product availability. Retailers should also consider pricing strategies that appeal to different market segments, particularly in diverse regions like South America and Europe, where consumer preferences may vary.

3 Common User Pain Points for ‘pool table slate replacement’ & Their Solutions

Scenario 1: Difficulty Sourcing Quality Slate for Replacement

The Problem: B2B buyers often encounter challenges when trying to source high-quality slate for pool table replacement. Many suppliers may offer slate at competitive prices, but the quality can vary significantly. In regions such as Africa or South America, where local suppliers might not have a reputation for reliability, buyers may struggle to find slate that meets international standards. Additionally, the logistics of importing slate can add complexity, leading to delays and potential damage during shipping.

The Solution: To overcome sourcing challenges, B2B buyers should prioritize establishing relationships with reputable suppliers who specialize in billiards equipment and materials. Conduct thorough research to evaluate potential suppliers based on their reputation, customer reviews, and certifications. Additionally, consider requesting samples of the slate before making a large order. This allows you to assess the quality firsthand. Establishing a strong supply chain network can also mitigate risks associated with shipping; consider logistics partners who specialize in handling delicate materials. Lastly, ensure that your purchase includes a clear return policy in case the slate does not meet your quality expectations upon arrival.

Scenario 2: Understanding Installation Challenges for Slate Replacement

The Problem: Another common pain point for B2B buyers is the complexity involved in the installation of new slate. Many buyers may underestimate the skill required to properly install slate, which is essential for ensuring a smooth playing surface. Improper installation can lead to unevenness, affecting gameplay and potentially damaging the table. This scenario is particularly problematic for businesses looking to maintain a professional appearance and provide an optimal experience for customers.

The Solution: To address installation challenges, buyers should consider hiring professional pool table technicians with experience in slate replacement. This ensures that the installation is performed correctly and minimizes the risk of future problems. If hiring a technician is not feasible, buyers should invest time in understanding the installation process thoroughly. Resources such as instructional videos and detailed guides can provide valuable insights. When preparing for installation, ensure that the pool table is level and that all necessary tools are on hand. Also, it’s advisable to have a contingency plan in place for unforeseen complications, such as needing to adjust the table or re-level it after installation.

Scenario 3: Managing Costs Associated with Slate Replacement

The Problem: Cost management is a significant concern for B2B buyers involved in pool table slate replacement. The price of slate can vary widely based on quality, size, and shipping costs. For businesses operating on tight margins, unexpected expenses can lead to budget overruns. Moreover, the costs associated with installation, maintenance, and potential repairs can further complicate financial planning.

The Solution: To effectively manage costs, buyers should adopt a comprehensive budgeting approach that includes all aspects of the slate replacement process. Begin by researching different slate options and comparing prices from multiple suppliers, including international and local sources. It’s also prudent to factor in shipping costs and potential tariffs. Consider bulk purchasing or negotiating with suppliers for discounts, particularly for larger orders. Additionally, establish a maintenance schedule for your pool tables to prolong the lifespan of the slate and reduce the frequency of replacements. Regular upkeep can prevent costly repairs and extend the time between necessary replacements, allowing for better financial forecasting.

Strategic Material Selection Guide for pool table slate replacement

When considering materials for pool table slate replacement, it is essential to evaluate the properties, advantages, and limitations of each option. This analysis will help international B2B buyers make informed decisions tailored to their regional preferences and standards.

What Are the Key Properties of Slate for Pool Tables?

Slate is the traditional material used for pool table surfaces due to its unique properties. It is a natural stone that is mined and processed into flat slabs. The key properties of slate include its ability to remain flat over time, resistance to warping due to temperature and humidity changes, and excellent durability under heavy use. Slate typically has a high density, making it resistant to impact and providing a smooth playing surface.

Pros: Slate offers unmatched durability and stability, ensuring a consistent playing experience. Its natural composition allows for precise leveling, which is crucial for professional play.

Cons: The main drawbacks are its weight, which can complicate installation and transportation, and its cost, which tends to be higher than alternative materials. Additionally, slate can be prone to cracking if mishandled.

How Do Alternative Materials Compare to Slate?

1. MDF (Medium Density Fiberboard)

MDF is a manufactured wood product made from wood fibers, wax, and resin. It is often used as a more affordable alternative to slate.

Key Properties: MDF is lightweight and easy to work with, allowing for straightforward installation. However, it lacks the natural durability of slate and can warp in high humidity.

Pros: Cost-effective and readily available, MDF is suitable for recreational tables where high performance is not critical. Its smooth surface can be finished to mimic slate.

Cons: MDF is less durable and can deteriorate over time, especially in humid environments. It is not recommended for professional-grade tables.

2. Composite Slate

Composite slate combines natural slate with synthetic materials, offering a balance between performance and cost.

Key Properties: This material is engineered to provide a flat surface while being lighter than solid slate. It can resist warping better than MDF.

Pros: Composite slate offers improved durability over MDF and is more affordable than pure slate. It can also be easier to install due to its lighter weight.

Cons: While it performs well, it may not provide the same level of playability as natural slate, and its longevity can vary based on the quality of the composite materials used.

3. Glass

Glass is an unconventional choice but is sometimes used in high-end or designer pool tables.

Key Properties: Glass can provide a sleek and modern aesthetic and is easy to clean. However, it is fragile and can break under heavy impact.

Pros: Offers a unique look and can be customized in terms of color and thickness. It is also resistant to moisture and does not warp.

Cons: The fragility of glass makes it unsuitable for standard use, and the costs can be significantly higher due to the need for specialized manufacturing and installation.

What Should International Buyers Consider?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should consider local climate conditions, compliance with regional standards (such as ASTM in the U.S. or DIN in Germany), and the availability of materials. For instance, in humid climates, materials resistant to moisture, like composite slate or treated MDF, may be more suitable. Additionally, understanding local market preferences and the competitive landscape can guide purchasing decisions.

| Material | Typical Use Case for pool table slate replacement | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Slate | Professional and high-end recreational tables | Unmatched durability and stability | High weight and cost | High |

| MDF | Recreational and budget-friendly tables | Cost-effective and easy to install | Prone to warping in humidity | Low |

| Composite Slate | Mid-range tables seeking balance | Improved durability over MDF | Variable longevity based on quality | Medium |

| Glass | Designer or luxury tables | Unique aesthetic and easy to clean | Fragile and high cost | High |

This guide provides a comprehensive look at the materials available for pool table slate replacement, helping B2B buyers select the most suitable option for their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for pool table slate replacement

What Are the Key Stages in the Manufacturing Process of Pool Table Slate Replacement?

The manufacturing process of pool table slate replacement is a meticulous endeavor that involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential to ensure the final product meets the rigorous standards expected by B2B buyers.

Material Preparation: Sourcing and Quality Selection

The first step in the manufacturing process is the selection of high-quality slate. Slate is a natural stone formed through geological processes over centuries, making it an ideal material for pool tables due to its durability and flatness. Manufacturers typically source slate from specific regions known for their high-quality deposits.

Once the slate is mined, it undergoes initial processing where it is cut into large slabs. Each slab is inspected for cracks, chips, or imperfections. This preliminary quality check is crucial, as flaws can affect the performance of the pool table. The best suppliers will have strict criteria for selecting slate, ensuring only the finest materials proceed to the next stage.

How Is Slate Formed and Shaped for Pool Tables?

After the slate has been prepared, it enters the forming stage. This involves cutting the slate into precise dimensions according to various pool table sizes, which typically range from 7 to 9 feet. Advanced cutting techniques such as diamond-tipped saws are employed to achieve clean and accurate cuts.

Following cutting, the slate pieces are shaped and smoothed using grinding techniques. This step is vital to ensure that the slate provides a perfectly flat surface, as any unevenness can significantly impact gameplay. Manufacturers often use CNC (Computer Numerical Control) machines for precision shaping, which allows for intricate designs and customizations if required.

What Assembly Techniques Are Commonly Used in Slate Replacement?

The assembly process for pool table slate replacement involves joining multiple slate pieces, especially for larger tables that require more than one slate slab. This is typically done using specialized adhesives that maintain the integrity and flatness of the assembly.

Additionally, manufacturers will often incorporate support structures or frameworks to ensure the slate remains stable when installed in the table. This assembly stage is crucial as it affects not only the performance of the table but also its longevity.

What Finishing Processes Ensure Quality in Pool Table Slate?

Finishing is the final stage in the manufacturing process and involves several critical steps to enhance the slate’s performance and aesthetic appeal. After assembly, the slate surface is polished to a high sheen, which not only improves the table’s appearance but also reduces friction during gameplay.

Furthermore, some manufacturers apply a sealant to protect the slate from moisture and potential damage over time. This is particularly important for international B2B buyers in regions with high humidity, as it ensures the longevity of the slate.

What Quality Assurance Standards Are Relevant for Pool Table Slate?

Quality assurance (QA) is an integral part of the manufacturing process for pool table slate replacement. International standards such as ISO 9001 play a critical role in ensuring that manufacturers maintain consistent quality throughout their production processes. This standard focuses on meeting customer expectations and regulatory requirements, which is essential for B2B buyers looking for reliability.

Additionally, industry-specific certifications like CE marking in Europe or API standards in certain regions can further validate a manufacturer’s commitment to quality. These certifications indicate compliance with specific safety and quality benchmarks, which are vital for pool table slate products.

How Are Quality Control Checkpoints Implemented?

To ensure that the slate meets quality standards, manufacturers implement several quality control checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw slate upon delivery to ensure it meets specified criteria before processing begins.

-

In-Process Quality Control (IPQC): During manufacturing, random samples of slate are tested for flatness, size accuracy, and surface finish. This ongoing monitoring helps catch issues early in the process.

-

Final Quality Control (FQC): Once the slate has been finished, it undergoes a thorough inspection where it is checked for any defects and tested for durability and performance standards.

What Testing Methods Are Commonly Used for Quality Assurance?

Common testing methods employed in the quality assurance of pool table slate include:

-

Flatness Tests: Using laser levels or precision measuring tools to ensure the slate surface is perfectly flat.

-

Durability Tests: Subjecting the slate to stress tests to evaluate its resistance to cracking or chipping under pressure.

-

Moisture Resistance Tests: Particularly important for B2B buyers in humid climates, these tests evaluate how well the slate withstands exposure to moisture.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is paramount. Buyers should consider:

-

Supplier Audits: Conducting regular audits of suppliers can help ensure compliance with quality standards and manufacturing processes.

-

Requesting Quality Reports: Suppliers should provide documentation detailing their quality control processes, including results from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging third-party inspection services can provide an impartial assessment of the slate quality before shipment.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers should be aware of the nuances in quality control and certification processes that may vary by region. For example, European buyers may prioritize CE compliance, while buyers in the Middle East might look for adherence to local standards. Understanding these regional differences is crucial for ensuring that the slate meets local regulations and expectations.

In conclusion, the manufacturing and quality assurance processes for pool table slate replacement are complex yet essential for ensuring high-quality products. By understanding these processes and the relevant quality standards, B2B buyers can make informed decisions and choose reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pool table slate replacement’

In the competitive world of billiards, ensuring the quality and longevity of your pool tables is paramount. One of the most critical components to maintain is the slate. This guide provides a step-by-step checklist for B2B buyers looking to procure pool table slate replacements, ensuring you make informed decisions that will enhance your offerings.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to clearly define the technical specifications of the slate you require. Consider factors such as size (1-piece vs. 3-piece), thickness, and weight, as these will affect the overall performance of the pool table. Understanding your needs helps in sourcing the right product that meets quality standards.

- Size Variations: Ensure you know the exact dimensions required for your pool tables.

- Weight Considerations: Heavier slates often provide better stability, so factor this into your specifications.

Step 2: Research Quality Material Options

Not all slates are created equal. Investigate the different types of slate available, focusing on their durability and performance characteristics. High-quality slate is essential for providing a smooth playing surface and maintaining the table’s level over time.

- Natural vs. Engineered Slate: Natural slate is typically preferred for its longevity and stability.

- Origin of Slate: Consider sourcing from regions known for high-quality slate, such as Italy or Brazil.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specifications and quality standards. Request detailed company profiles, product catalogs, and references from other businesses that have procured slate from them. This step is vital to avoid issues with quality and delivery timelines.

- Supplier Experience: Look for suppliers with a proven track record in the billiards industry.

- Customer Reviews: Seek feedback from other B2B buyers to gauge reliability and product quality.

Step 4: Verify Supplier Certifications

Confirm that your chosen suppliers have the necessary certifications and quality assurance processes in place. This verification is crucial for ensuring that the slate meets industry standards and regulations.

- ISO Certifications: Check for relevant ISO certifications that indicate quality management.

- Sustainability Practices: Inquire about the supplier’s sustainability practices, which can be an important factor for many businesses today.

Step 5: Request Samples for Assessment

Before finalizing your order, request samples of the slate. This will allow you to evaluate the quality, feel, and performance of the product firsthand. Testing the slate in your environment can help you assess its suitability for your tables.

- Surface Finish: Check for smoothness and consistency, as this impacts gameplay.

- Durability Testing: If possible, conduct basic durability tests to ensure the slate can withstand typical use.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations to secure favorable terms and conditions. This includes pricing, payment terms, delivery schedules, and after-sales support. Clear agreements help prevent misunderstandings and ensure a smooth procurement process.

- Bulk Purchase Discounts: Explore options for bulk pricing if you’re ordering large quantities.

- Warranty and Return Policies: Understand the warranty terms and what the return process entails in case of defects.

Step 7: Plan for Installation and Maintenance

Finally, plan for the installation and future maintenance of the slate. Consider hiring professionals for installation to ensure it is done correctly, as improper installation can lead to performance issues.

- Professional Installers: Look for experienced installers who specialize in pool table setups.

- Maintenance Schedule: Establish a regular maintenance schedule to prolong the life of the slate and enhance the playing experience.

By following this checklist, B2B buyers can navigate the sourcing process for pool table slate replacements effectively, ensuring they make informed choices that will benefit their business and customers alike.

Comprehensive Cost and Pricing Analysis for pool table slate replacement Sourcing

What Are the Key Cost Components in Pool Table Slate Replacement?

The cost structure for pool table slate replacement encompasses several critical components that international B2B buyers should consider. Firstly, materials represent a significant portion of the total cost. High-quality slate, sourced from reputable mines, can vary in price depending on thickness, size, and finish. Generally, one-piece slates are costlier than three-piece options due to their manufacturing complexity and the quality assurance involved.

Labor costs also play a vital role, particularly if skilled technicians are required for installation. The complexity of the replacement process often necessitates specialized labor, which may be priced higher in certain regions. Manufacturing overhead includes expenses related to factory operations, which can differ markedly based on geographical location and local economic conditions.

Additionally, tooling costs should be factored in, especially if custom sizes or finishes are requested. Companies often need to invest in specific equipment for unique slate specifications, which can impact the overall pricing. Quality control (QC) measures are essential to ensure that the slate meets performance standards, adding another layer of cost.

Lastly, logistics must be accounted for, particularly with international shipments. Costs can escalate due to shipping fees, customs duties, and potential delays in transit.

What Influences Pricing for Pool Table Slate Replacement?

Several factors can influence the pricing of pool table slate replacement. One of the most significant is volume or minimum order quantity (MOQ). Bulk purchases often lead to discounts, making it crucial for buyers to assess their needs accurately. The specifications and customization of the slate can also affect pricing. Custom sizes or finishes typically incur additional costs.

The quality of materials and any certifications (such as environmental or safety standards) also play a role. Premium slate sourced from established mines will come at a higher price but may offer better longevity and performance. Supplier factors such as reputation, reliability, and payment terms can also influence pricing structures.

Understanding Incoterms is vital for international buyers, as they dictate the responsibilities of buyers and sellers in shipping arrangements. Knowing whether costs include delivery, insurance, and customs duties can significantly affect the overall budget.

How Can Buyers Negotiate for Better Pricing on Slate Replacement?

Buyers looking to optimize their costs should consider several negotiation strategies. First, gaining a clear understanding of the Total Cost of Ownership (TCO) is essential. This includes not just the purchase price but also installation, maintenance, and potential future replacements. By presenting a comprehensive view of costs, buyers can justify requests for lower pricing or better terms.

Another effective strategy is to leverage multiple supplier quotes. This not only provides a clearer market view but also places pressure on suppliers to offer competitive pricing. Establishing long-term relationships with suppliers can also yield better pricing and terms over time, as trust and reliability build.

Buyers should also be aware of pricing nuances in their specific regions. For instance, slate prices may vary significantly between Africa, South America, the Middle East, and Europe due to local demand, availability, and shipping costs. Understanding these regional dynamics can empower buyers to make more informed decisions.

Conclusion and Pricing Disclaimer

While the pricing for pool table slate replacement can vary widely based on the factors discussed, it’s important for buyers to approach each transaction with a thorough understanding of their specific needs and market conditions. Prices may fluctuate due to material availability, labor costs, and geopolitical factors, so it is prudent to obtain current quotes before proceeding. Always consult with multiple suppliers to ensure the best possible deal tailored to your business requirements.

Alternatives Analysis: Comparing pool table slate replacement With Other Solutions

Exploring Alternatives to Pool Table Slate Replacement

In the world of billiards, maintaining a high-quality playing surface is crucial for optimal performance. While pool table slate replacement is a popular solution for damaged or aging slates, there are several alternatives worth considering. This analysis will compare pool table slate replacement with other viable solutions, helping B2B buyers make informed decisions based on their unique needs.

Comparison Table

| Comparison Aspect | Pool Table Slate Replacement | Alternative 1: Wood Playing Surface | Alternative 2: Composite Materials |

|---|---|---|---|

| Performance | High; provides a smooth, level surface | Moderate; can warp and dent over time | High; can mimic slate performance |

| Cost | Moderate to high; typically $300-$600 | Low; generally $100-$300 depending on quality | Moderate; $200-$400 for decent quality |

| Ease of Implementation | Complex; requires professional installation | Easy; can be DIY installed | Moderate; may require professional help for best results |

| Maintenance | Low; durable and long-lasting | High; requires regular upkeep and replacement | Moderate; can require periodic checks for wear |

| Best Use Case | Professional and commercial settings | Casual home use, low-budget solutions | Versatile; good for both casual and competitive play |

Detailed Breakdown of Alternatives

Alternative 1: Wood Playing Surface

Wood has long been used as a playing surface, particularly in lower-end pool tables. While it can be an economical choice, its performance is often inferior to slate. Wood surfaces can warp due to humidity changes and are more susceptible to dents and scratches. However, they are easy to install, making them a popular option for DIY enthusiasts or those on a tighter budget. For casual players or home use, wood can suffice, but for serious play, it may not deliver the desired experience.

Alternative 2: Composite Materials

Composite materials, which often combine wood and synthetic elements, are designed to provide a balance between cost and performance. These surfaces can offer a similar feel to slate and are less prone to warping than pure wood. While their initial cost is moderate, they may require more maintenance than slate surfaces. Composite options can be ideal for venues that want to maintain performance without the higher expense of slate, making them suitable for both casual and competitive environments.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right playing surface for a pool table involves evaluating performance, cost, installation ease, maintenance requirements, and specific use cases. For businesses looking to invest in long-term quality, pool table slate replacement remains the gold standard. However, alternatives like wood and composite materials can provide viable solutions for budget-conscious buyers or those with less demanding performance needs. Ultimately, understanding the trade-offs of each option will empower B2B buyers to make the best choice for their particular market and clientele.

Essential Technical Properties and Trade Terminology for pool table slate replacement

What are the Key Technical Properties of Pool Table Slate?

When considering pool table slate replacement, several critical specifications must be understood to ensure optimal performance and durability. Here are the essential properties:

1. Material Grade

The grade of slate used for pool tables is paramount. High-quality slate, typically graded as “premium” or “first-grade,” is sourced from specific quarries and is less porous, ensuring better playability and longevity. Lower-grade slates may be cheaper but can lead to warping and cracking, affecting the quality of play. B2B buyers should prioritize premium grades to enhance the product’s overall value.

2. Thickness

Slate thickness usually ranges from 3/4 inch to 1 inch. Thicker slates provide a more stable playing surface and can absorb impacts better, reducing the risk of damage. This specification is critical for B2B buyers looking to ensure a durable product that can withstand frequent use in commercial environments.

3. Tolerance

Tolerance refers to the allowable deviation from the specified dimensions. For pool tables, a tolerance of ±0.1 mm is ideal, ensuring a flat and level surface for optimal gameplay. High tolerance levels are crucial in maintaining the integrity of the slate during installation and over time, which can significantly impact customer satisfaction.

4. Finish Quality

The finish of the slate affects both aesthetics and gameplay. A finely honed surface ensures a smooth and consistent playing experience, while a rough finish can lead to unpredictable ball movement. B2B buyers should assess the finish quality to ensure it meets the expectations of their clientele.

5. Weight

Slate is heavy, with weights varying based on size and thickness. A standard 8-foot slate can weigh between 400 to 600 pounds. Proper handling and installation are essential to avoid damage. B2B buyers should consider logistics and transportation options due to the weight when sourcing slate.

What Are Common Trade Terminology and Concepts in Pool Table Slate Replacement?

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce slate specifically for pool tables or other equipment. Partnering with an OEM ensures that you receive high-quality, standardized products that meet industry specifications, minimizing risks associated with quality control.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory and costs effectively. It can significantly influence purchasing decisions, especially for smaller businesses or those just starting.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. It’s a crucial step in the procurement process, allowing buyers to compare costs and terms from multiple suppliers to make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international contracts that define the responsibilities of buyers and sellers. Understanding these terms is essential for B2B transactions, particularly when dealing with international suppliers, as they dictate shipping responsibilities, risk management, and costs.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. In the context of pool table slate replacement, understanding lead times helps buyers plan installations and manage customer expectations effectively.

6. Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and longevity of the slate. Knowing the warranty terms is essential for B2B buyers to protect their investments and ensure product reliability.

By comprehensively understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing pool table slate, ultimately enhancing their business operations and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the pool table slate replacement Sector

What are the Current Market Dynamics and Key Trends in Pool Table Slate Replacement?

The pool table slate replacement market is experiencing significant growth driven by several global factors. As recreational activities gain popularity, particularly in regions like Africa and South America, the demand for high-quality pool tables and their maintenance has surged. Key trends include the increasing adoption of technology in sourcing processes, such as online marketplaces and virtual consultations, allowing international B2B buyers to easily access suppliers and products from different regions.

Emerging technologies are reshaping procurement practices, with platforms offering real-time inventory updates and logistics tracking, making it easier for buyers in Europe and the Middle East to source slate efficiently. Additionally, there’s a growing trend toward customization, with manufacturers providing tailored slate options to meet specific table dimensions and preferences. This trend is particularly prominent in countries like Brazil and Germany, where local preferences for table styles differ significantly.

Furthermore, the market is becoming increasingly competitive, with new entrants focusing on innovative materials and manufacturing processes. This competition often drives down prices while enhancing product quality, providing international buyers with a broader range of options. However, buyers should remain vigilant about quality, as not all suppliers adhere to stringent manufacturing standards.

How is Sustainability and Ethical Sourcing Influencing the Pool Table Slate Replacement Market?

Sustainability is becoming a central focus in the pool table slate replacement sector. The environmental impact of mining and processing slate is significant, prompting many manufacturers to adopt more sustainable practices. This includes sourcing slate from quarries that adhere to environmental regulations and utilizing eco-friendly transportation methods.

Ethical supply chains are increasingly important for B2B buyers, particularly in regions with heightened awareness of corporate responsibility. Suppliers that offer ‘green’ certifications or use recycled materials are gaining preference among conscientious buyers. For instance, some manufacturers are exploring alternative materials or composite slates that reduce environmental impact while maintaining performance.

Moreover, transparency in sourcing is crucial. Buyers are encouraged to inquire about the provenance of the slate and the practices employed by suppliers to ensure ethical standards are met. By prioritizing sustainability and ethical sourcing, B2B buyers can not only enhance their brand reputation but also contribute to a more responsible marketplace.

What is the Brief Evolution of Pool Table Slate Replacement?

The use of slate in pool tables has a rich history, dating back to the 19th century when it emerged as the preferred material due to its durability and ability to remain flat over time. Initially, pool tables were made from wood or other materials, but the introduction of slate transformed the industry, providing a superior playing surface that could withstand the rigors of play.

As the popularity of billiards grew, so did the demand for high-quality slate. The manufacturing processes evolved, with advancements in quarrying and cutting techniques leading to more precise slate slabs. Over the decades, the focus has shifted from merely replacing damaged slate to providing customized solutions that cater to the varying preferences of players worldwide.

Today, the market continues to evolve, with an emphasis on sustainability, technology, and ethical practices, ensuring that the legacy of slate in billiards remains relevant in a modern context. For international B2B buyers, understanding this evolution is crucial for making informed purchasing decisions that align with current trends and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of pool table slate replacement

-

How do I determine if my pool table slate needs replacement?

To assess whether your pool table slate requires replacement, look for visible cracks, chips, or uneven spots that affect gameplay. You can also check for any warping or significant wear over time. If the surface feels bumpy or causes unpredictable ball movement, it is likely time for a replacement. Consulting a professional can provide a thorough inspection and confirm if repair is feasible or if replacement is necessary. -

What is the best type of slate for pool tables?

The best type of slate for pool tables is quarried slate, known for its durability and flatness. It typically comes in one-piece or three-piece configurations, with three-piece being easier to handle and install. High-quality slate should be at least 1 inch thick to ensure stability during play. When sourcing slate, consider the climate and conditions of your location, as some slates perform better in varying environments. -

What are the minimum order quantities (MOQ) for pool table slate?

Minimum order quantities for pool table slate can vary significantly based on the supplier. Typically, MOQs might range from a few pieces to several hundred, depending on the supplier’s capacity and your specific needs. It’s advisable to discuss your requirements directly with potential suppliers to negotiate terms that suit your business, especially if you are looking to import for resale in regions like Africa or South America. -

How can I vet suppliers for pool table slate replacement?

When vetting suppliers, consider their reputation in the industry, customer reviews, and the quality certifications of their products. Request samples to assess the quality of the slate firsthand. Additionally, inquire about their production processes, sourcing of materials, and compliance with international trade regulations. Establishing direct communication can also help gauge their responsiveness and reliability in meeting your needs. -

What are the typical payment terms for international purchases of pool table slate?

Payment terms for international purchases can vary widely but often include options such as advance payment, letters of credit, or payment upon delivery. It is crucial to clarify these terms with the supplier before finalizing any agreements. Establishing secure payment methods, like escrow services, can also protect your investment when dealing with new suppliers in regions like the Middle East or Europe. -

What logistics considerations should I keep in mind when importing pool table slate?

Logistics for importing pool table slate involve understanding shipping costs, customs duties, and potential delays. Choose a reliable freight forwarder who is experienced in handling heavy materials and understands the regulations for importing goods into your country. It’s also essential to ensure that the slate is packaged securely to prevent damage during transit, especially for international shipments. -

Can I customize the size and shape of the pool table slate?

Yes, many suppliers offer customization options for pool table slate to fit specific table dimensions and designs. When placing an order, provide precise measurements and any special requirements you may have. Keep in mind that custom orders may have longer lead times and could affect pricing, so it’s best to discuss these details upfront with the supplier to avoid any misunderstandings. -

What quality assurance processes should I expect from suppliers?

Reputable suppliers should have quality assurance processes in place, including inspections of raw materials and finished products. Ask about their quality control standards and whether they conduct tests to ensure the slate meets industry specifications. Inquire if they provide warranties or guarantees on their products, as this can be a good indicator of their commitment to quality and customer satisfaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Pool Table Slate Replacement Manufacturers & Suppliers List

1. Games for Fun – Pool Table Slate

Domain: gamesforfun.com

Registered: 1998 (27 years)

Introduction: Pool Table Slate for sale, available in 1-piece and 3-piece options. New and used slate available. Several sizes of slate offered. Slate is mined rock, known for its durability and ability to remain flat over time, making it ideal for pool tables in various climates.

2. Brunswick – Replacement Slate Options

Domain: forums.azbilliards.com

Registered: 1998 (27 years)

Introduction: The user is seeking a replacement slate for a 10′ Brunswick pool table, with a budget of around $300. There are suggestions for repairing the broken slate using epoxy or JB Weld, but opinions vary on the effectiveness of these repairs. New slates can be ordered for approximately $150, but shipping costs are significantly higher. The discussion includes various repair methods and experiences shared…

3. MRCues Billiards – Slate Replacement Services

Domain: mrcuesbilliards.com

Registered: 2002 (23 years)

Introduction: Slate replacement for pool tables, including inspection for damage, removal of rails and felt, installation of new slate, and reinstallation of felt and rails. Services offered for both residential and commercial spaces.

4. StoneContact – Billiard Slate

Domain: stonecontact.com

Registered: 2003 (22 years)

Introduction: Billiard Slate – Natural Stone, Artificial Stone; Available from various suppliers including XIAMEN REFINESTONE INDUSTRIAL CO.,LTD., Lushan Wenlei Stone Co., Ltd., Xiamen Asian Stone Imp.& Exp. Co.,Ltd., Fujian Nanan JADA Stone Co., Ltd., Jiujiang Slateofchina Stone Co., Ltd., Xiamen Shapex Stone Enterprise Ltd, Jiangxi Xinmao Slate Co.,Ltd, Grupo Minar – Extra Quality Slate, Belle Star Stone Co.,…

Strategic Sourcing Conclusion and Outlook for pool table slate replacement

In the realm of pool table slate replacement, strategic sourcing stands as a critical component for international B2B buyers. As the demand for high-quality slate persists across diverse markets in Africa, South America, the Middle East, and Europe, suppliers must focus on offering durable and reliable products. By understanding the unique needs of each region, buyers can ensure they select slate that not only meets performance standards but also withstands varying climatic conditions.

Key takeaways emphasize the importance of sourcing from reputable manufacturers who prioritize quality and customer service. Engaging with suppliers that provide a range of slate options—such as 1-piece and 3-piece configurations—can streamline the procurement process and enhance customer satisfaction. Additionally, considering suppliers that offer repair services or guidance can further establish a long-term partnership.

Looking ahead, as the pool and billiards industry continues to evolve, now is the time for B2B buyers to strengthen their sourcing strategies. Embrace innovation and quality in your slate procurement to stay competitive. Connect with trusted suppliers today and pave the way for successful business growth in the global billiards market.