Choosing Your Polycarbonate Awnings: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for polycarbonate awnings

In today’s global market, sourcing high-quality polycarbonate awnings presents a unique challenge for international B2B buyers. These versatile structures not only enhance the aesthetic appeal of buildings but also provide essential protection against the elements, making them a popular choice across various industries. However, navigating the complexities of product specifications, supplier reliability, and price fluctuations can be daunting, especially for businesses operating in diverse regions such as Africa, South America, the Middle East, and Europe, including key markets like Brazil and Germany.

This comprehensive guide aims to empower B2B buyers by dissecting the myriad options available in the polycarbonate awning market. From understanding different types and applications to effective supplier vetting processes, we will explore crucial factors that influence purchasing decisions. Additionally, we will delve into cost considerations, ensuring that buyers can make informed decisions that align with their budgetary constraints and project requirements.

By equipping buyers with actionable insights and practical knowledge, this guide serves as a vital resource for making confident, strategic investments in polycarbonate awnings. Whether you are looking to enhance the exterior of commercial properties or seeking durable solutions for residential projects, our guide will help you navigate the global landscape and secure the best products for your needs.

Understanding polycarbonate awnings Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solid Polycarbonate Awnings | Single-piece polycarbonate sheets, high impact resistance | Commercial entrances, retail facades | Pros: Durable, UV protection, aesthetic appeal. Cons: Limited customization in design. |

| Twin-Wall Polycarbonate Awnings | Multi-layered panels for enhanced insulation and strength | Warehouses, industrial buildings | Pros: Energy-efficient, lightweight, good thermal insulation. Cons: Higher initial cost compared to single-layer options. |

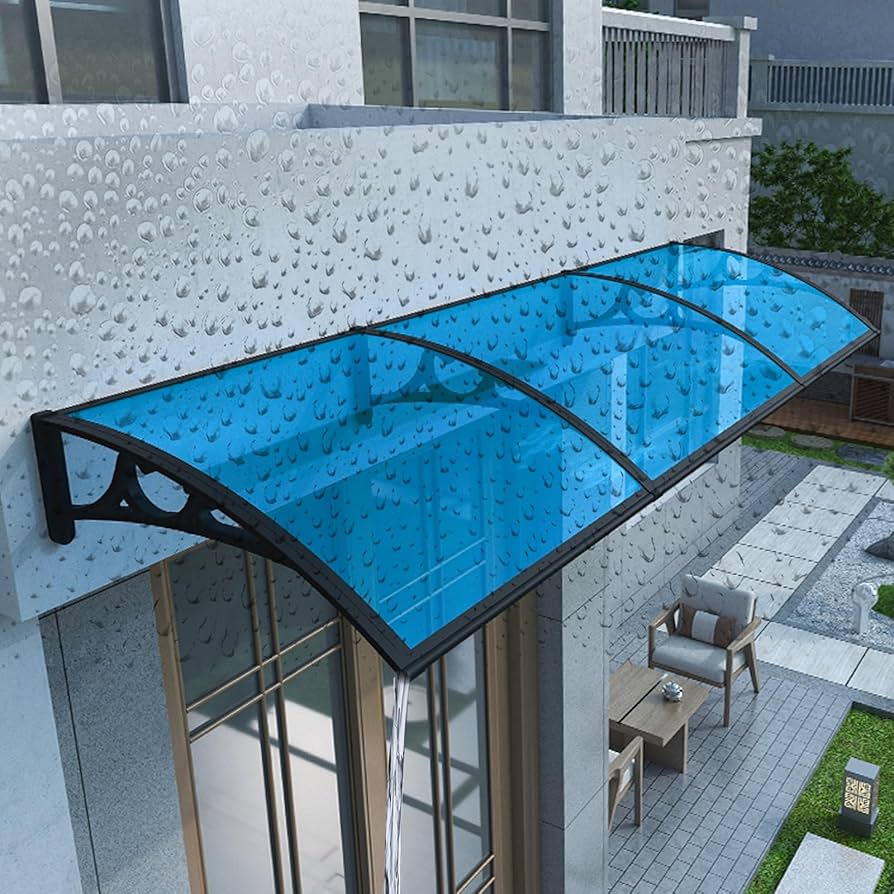

| Curved Polycarbonate Awnings | Aesthetic curved design, often used for modern architecture | Cafés, restaurants, and hotels | Pros: Unique appearance, effective rainwater diversion. Cons: May require more complex installation. |

| Retractable Polycarbonate Awnings | Adjustable coverage, allowing for flexibility in usage | Outdoor event spaces, patios | Pros: Versatile, space-saving when not in use. Cons: Mechanism can be prone to wear and tear. |

| Door Canopies | Specifically designed for doorways, providing overhead protection | Residential and commercial entrances | Pros: Easy installation, enhances curb appeal. Cons: Limited coverage area compared to larger awnings. |

What are the characteristics of Solid Polycarbonate Awnings?

Solid polycarbonate awnings are made from a single piece of high-impact polycarbonate, providing excellent durability and UV protection. These awnings are ideal for businesses looking to enhance their entrances while protecting doors and windows from the elements. They are commonly used in commercial settings such as retail stores and office buildings. When purchasing, buyers should consider factors like size, color options, and installation requirements, as customization may be limited.

How do Twin-Wall Polycarbonate Awnings differ from other types?

Twin-wall polycarbonate awnings feature a multi-layered design that offers superior insulation and strength. This makes them particularly suitable for warehouses and industrial buildings where energy efficiency is a priority. Their lightweight nature simplifies installation, but the initial investment is higher than that of solid options. B2B buyers should evaluate their insulation needs and budget constraints when considering these awnings.

What makes Curved Polycarbonate Awnings a popular choice?

Curved polycarbonate awnings are characterized by their modern aesthetic, making them a favored choice for cafés, restaurants, and hotels. Their design effectively diverts rainwater while adding a stylish element to the building’s exterior. However, the installation process can be more complex due to the curvature. Businesses should assess their design goals and the potential need for professional installation when opting for this type.

Why consider Retractable Polycarbonate Awnings for outdoor spaces?

Retractable polycarbonate awnings provide flexibility, allowing businesses to adjust coverage based on weather conditions. They are particularly useful in outdoor event spaces and patios where space-saving solutions are necessary. While they offer versatility, the mechanical components can wear over time, requiring maintenance. B2B buyers should weigh the benefits of flexibility against potential long-term maintenance costs.

What are the advantages of Door Canopies in commercial settings?

Door canopies are specifically designed to protect entrances from rain and snow, enhancing the appeal of both residential and commercial properties. They are easy to install and can significantly improve curb appeal. However, their coverage area is limited compared to larger awnings, which might not suit all businesses. Buyers should consider their specific protection needs and aesthetic preferences when selecting door canopies.

Key Industrial Applications of polycarbonate awnings

| Industry/Sector | Specific Application of Polycarbonate Awnings | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Storefront Protection and Aesthetic Enhancement | Increases foot traffic by creating a welcoming entrance while protecting customers from weather elements. | Consider durability, UV resistance, and design options to match branding. |

| Hospitality | Outdoor Dining Area Canopies | Extends usable space for dining or events, enhancing customer experience while providing shelter. | Evaluate size, installation requirements, and maintenance needs based on local climate. |

| Transportation | Bus and Train Station Shelters | Protects passengers from rain and sun, improving comfort and safety while waiting for transport. | Focus on structural integrity and weather resistance, particularly in areas with extreme weather conditions. |

| Construction | Temporary Site Protection | Shields workers and materials from adverse weather, reducing downtime and protecting investments. | Assess installation ease and material strength, especially for long-term projects. |

| Residential Development | Home Entrance and Patio Awnings | Adds aesthetic appeal and functional outdoor space, increasing property value. | Look for customizable options to fit various architectural styles and local building codes. |

How Are Polycarbonate Awnings Used in Retail Environments?

In the retail sector, polycarbonate awnings serve as an effective solution for storefront protection while enhancing aesthetic appeal. These awnings can attract more foot traffic by creating a welcoming atmosphere that shields customers from rain and sun. Retailers should prioritize sourcing durable, UV-resistant materials that complement their brand’s design. Additionally, customization options for size and color can further align the awning with the store’s exterior, improving overall customer experience.

What Benefits Do Polycarbonate Awnings Provide to the Hospitality Industry?

In hospitality, polycarbonate awnings are utilized to create outdoor dining areas that allow restaurants and cafes to extend their services year-round. By providing shelter from the elements, these awnings enhance the customer experience and increase seating capacity. When sourcing, hospitality businesses should consider the awning’s size, installation requirements, and maintenance needs, particularly in regions with fluctuating weather patterns. A well-designed awning can significantly contribute to a venue’s ambiance and functionality.

How Do Transportation Hubs Benefit from Polycarbonate Awnings?

Transportation hubs like bus and train stations benefit from polycarbonate awnings by offering passengers protection from inclement weather while they wait. This enhances comfort and safety, contributing to a more positive travel experience. For sourcing, it’s crucial to focus on the structural integrity of the awnings, ensuring they can withstand high winds and heavy rainfall. Additionally, the aesthetic design should align with the station’s overall look to maintain a cohesive environment.

Why Are Polycarbonate Awnings Essential in Construction?

In the construction industry, polycarbonate awnings play a vital role in protecting work sites from adverse weather conditions. They help to shield both workers and materials from rain, snow, and sunlight, thus minimizing downtime and safeguarding investments. When sourcing for construction applications, businesses should evaluate the ease of installation and the material’s strength, especially for long-term projects that require robust solutions to withstand harsh conditions.

How Do Residential Developments Utilize Polycarbonate Awnings?

In residential developments, polycarbonate awnings are commonly used to enhance home entrances and patio areas. They add both aesthetic value and functional outdoor space, appealing to potential buyers and increasing property value. Buyers in this sector should look for customizable options that adhere to local building codes and fit various architectural styles. The ability to choose colors and designs can significantly impact the overall appeal of a property, making it more attractive in a competitive real estate market.

3 Common User Pain Points for ‘polycarbonate awnings’ & Their Solutions

Scenario 1: Managing Weather-Related Damage to Structures

The Problem:

Many B2B buyers, particularly those in construction and property management, face the challenge of protecting entryways and windows from harsh weather conditions. This is especially pertinent in regions prone to heavy rainfall, snow, or intense UV exposure. Without adequate protection, water damage can lead to structural integrity issues, increased maintenance costs, and a negative impact on property aesthetics. Buyers often worry about the durability and effectiveness of the awnings they choose, fearing that they may not withstand extreme weather or might require frequent replacements.

The Solution:

Investing in high-quality polycarbonate awnings can effectively mitigate these concerns. Buyers should prioritize products that feature twin-wall polycarbonate sheets, which are not only shatter-resistant but also provide superior insulation and UV protection. When sourcing these awnings, it is crucial to consider suppliers that offer warranties and performance guarantees, ensuring that the product can withstand local weather conditions. Additionally, installing awnings with proper drainage channels can redirect water away from entryways, minimizing potential water damage. Buyers should also request detailed specifications and testing certifications from manufacturers to ensure the awnings meet industry standards for durability.

Scenario 2: Difficulties with Installation and Maintenance

The Problem:

Another common pain point for B2B buyers is the complexity involved in the installation and maintenance of polycarbonate awnings. Companies that manage multiple properties or projects often lack the time or skilled labor necessary for proper installation, leading to subpar results. Furthermore, buyers are concerned about ongoing maintenance requirements; poorly designed awnings may accumulate dirt and debris, requiring frequent cleaning and risking damage over time.

The Solution:

To address these issues, buyers should select polycarbonate awnings designed for easy installation. Products that come with pre-drilled holes and all necessary mounting hardware can significantly reduce installation time. Buyers should also consider opting for maintenance-free aluminum brackets, which resist corrosion and eliminate the need for regular upkeep. Additionally, choosing awnings with a self-cleaning feature or a smooth surface can minimize dirt accumulation, thereby reducing maintenance efforts. Partnering with suppliers who offer installation support or training can further ensure that the installation process is straightforward and effective.

Scenario 3: Limited Customization Options Affecting Aesthetic Appeal

The Problem:

B2B buyers often seek customized solutions to meet specific architectural styles and branding needs. However, many polycarbonate awning suppliers provide limited color and design options, which can hinder a company’s ability to maintain a cohesive aesthetic across their properties. This is particularly relevant for businesses in hospitality or retail sectors, where visual appeal directly impacts customer perception.

The Solution:

To overcome this challenge, buyers should research manufacturers that offer a wide range of customization options, including various colors, finishes, and sizes. Engaging with suppliers that provide bespoke design services can ensure that the awnings complement existing architecture while also reflecting the brand identity. Furthermore, buyers can explore polycarbonate sheets that allow for printing or branding opportunities, enhancing the visibility of the business while providing functional benefits. It’s advisable to request samples and visual mock-ups during the selection process, allowing for informed decisions that align with aesthetic goals and functional requirements.

Strategic Material Selection Guide for polycarbonate awnings

What Are the Key Materials Used in Polycarbonate Awnings?

When selecting materials for polycarbonate awnings, it is essential to understand the properties, advantages, and limitations of various materials. This knowledge will enable international B2B buyers to make informed decisions that align with their specific needs, particularly in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polycarbonate?

Polycarbonate is a robust thermoplastic material known for its high impact resistance and durability. It can withstand temperature variations from -40°C to 120°C (-40°F to 248°F) without losing structural integrity. Additionally, polycarbonate provides excellent UV protection, making it suitable for outdoor applications. Its lightweight nature also facilitates easier installation and reduces shipping costs.

What Are the Advantages and Disadvantages of Polycarbonate?

Pros:

– Durability: Polycarbonate is shatter-resistant and can endure harsh weather conditions, making it ideal for outdoor use.

– Cost-Effectiveness: Compared to glass, polycarbonate is often less expensive while offering similar transparency and strength.

– Ease of Fabrication: The material can be easily molded and cut to various shapes and sizes, allowing for customization.

Cons:

– Scratching: While it is durable, polycarbonate can be prone to scratching unless treated with a protective coating.

– Thermal Expansion: This material can expand and contract with temperature changes, necessitating careful installation to avoid warping.

How Does Material Selection Impact Application?

The choice of material significantly impacts the application of polycarbonate awnings. For instance, areas with high UV exposure require materials with enhanced UV protection to prevent degradation. Similarly, regions prone to heavy rainfall or snow accumulation may necessitate thicker polycarbonate sheets to ensure structural stability. Buyers should also consider local environmental conditions when selecting materials.

What Should International Buyers Consider When Selecting Materials?

International buyers, particularly in regions like Africa, South America, the Middle East, and Europe, must consider compliance with local standards such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards). Understanding these regulations ensures that the selected materials meet safety and performance criteria. Additionally, buyers should be aware of local preferences regarding aesthetics, color options, and installation methods, which can vary significantly across regions.

Summary Table of Material Selection for Polycarbonate Awnings

| Material | Typical Use Case for Polycarbonate Awnings | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Residential and commercial awnings | High impact resistance and UV protection | Prone to scratching without protective coating | Medium |

| Aluminum | Structural support for awnings | Corrosion-resistant and lightweight | Higher initial cost compared to steel | High |

| Galvalume Steel | Framework for larger awnings | Excellent durability and rust resistance | Heavier, which may increase installation complexity | Medium |

| Acrylic | Decorative awnings and canopies | Clear and lightweight with good UV resistance | Less impact-resistant than polycarbonate | Low |

This strategic material selection guide provides valuable insights for B2B buyers in the polycarbonate awning market. By understanding the properties, advantages, and limitations of various materials, businesses can make informed choices that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for polycarbonate awnings

What Are the Main Stages in the Manufacturing Process of Polycarbonate Awnings?

The manufacturing of polycarbonate awnings involves several critical stages that ensure the final product meets both aesthetic and functional requirements. Understanding these stages can provide B2B buyers with insights into the quality and reliability of their suppliers.

Material Preparation: What Materials Are Used in Polycarbonate Awnings?

The initial stage of manufacturing begins with the selection and preparation of raw materials. Polycarbonate, a thermoplastic polymer known for its high impact resistance and UV protection, is the primary material. Suppliers typically source polycarbonate sheets in various thicknesses, commonly 3mm to 6mm, based on the intended application.

In addition to polycarbonate, aluminum or steel components are often used for brackets and support structures. These metals are chosen for their durability and resistance to corrosion. Before production, materials undergo quality checks to ensure compliance with specifications, such as thickness, clarity, and UV resistance.

How Are Polycarbonate Awnings Formed?

Once the materials are prepared, the next step is the forming process. This involves cutting the polycarbonate sheets into the desired dimensions and shapes, often using CNC machinery for precision. The forming process may also include the creation of features like curves or slopes, which enhance both functionality and aesthetics.

Aluminum brackets are cut and shaped concurrently, often utilizing die-cutting techniques. These brackets are crucial for securing the polycarbonate sheets and are designed to withstand varying weather conditions.

What Techniques Are Used in the Assembly of Polycarbonate Awnings?

The assembly of polycarbonate awnings is a meticulous process that combines the formed polycarbonate sheets with the metal brackets. This step typically involves pre-drilling holes in the sheets to facilitate easy attachment to the brackets.

Screw and bolt fastening techniques are employed to ensure a secure connection, often using corrosion-resistant screws to enhance longevity. During assembly, it is crucial to maintain proper alignment and spacing, which can be achieved using jigs or fixtures to minimize human error.

What Finishing Processes Enhance the Quality of Polycarbonate Awnings?

The final stage of manufacturing involves several finishing processes that enhance the product’s durability and appearance. Common practices include surface treatments to improve scratch resistance and UV protection. Some manufacturers apply a protective film or coating that further enhances the awning’s longevity against environmental factors.

Additionally, the awnings may undergo a quality check for aesthetic defects, ensuring that the final product meets visual standards. This stage may also include packaging for shipment, ensuring that all components are secure and protected from damage during transportation.

What Quality Assurance Standards Are Relevant for Polycarbonate Awnings?

Quality assurance (QA) is a critical aspect of the manufacturing process for polycarbonate awnings, particularly for international B2B buyers. Adherence to recognized standards can significantly influence product quality and supplier reliability.

How Does ISO 9001 Impact the Quality of Polycarbonate Awnings?

ISO 9001 is a globally recognized quality management standard that outlines requirements for a quality management system (QMS). Manufacturers of polycarbonate awnings that comply with ISO 9001 demonstrate a commitment to quality and continuous improvement. This standard encompasses the entire production process, from material sourcing to final delivery.

By ensuring that suppliers adhere to ISO 9001, buyers can mitigate risks associated with product defects and inconsistencies. Buyers should request certificates of compliance and audit reports to verify adherence to these standards.

What Industry-Specific Certifications Should Buyers Look For?

In addition to ISO 9001, several industry-specific certifications may apply to polycarbonate awnings. For example, the CE mark is essential for products sold in the European market, indicating compliance with health, safety, and environmental protection standards.

Similarly, buyers looking to import to regions like Africa or South America should be aware of local certifications that may influence market access. Understanding these certifications can help B2B buyers ensure that their suppliers meet necessary legal and safety requirements.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integral to ensuring that polycarbonate awnings are produced to the highest standards. Key checkpoints throughout the manufacturing process include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery. Suppliers should verify that materials meet specified standards for thickness, clarity, and UV resistance before they enter production.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC is conducted to monitor the assembly process and ensure proper techniques are followed. This can involve regular checks of dimensions and alignment during assembly.

-

Final Quality Control (FQC): Once the awnings are fully assembled, FQC involves a thorough inspection of the finished product. This includes checking for defects, ensuring proper packaging, and verifying compliance with relevant standards.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to quality control practices, B2B buyers should take proactive steps. Here are some actionable strategies:

-

Conduct Supplier Audits: Regular audits of suppliers can help verify adherence to quality standards. Buyers should evaluate the supplier’s QMS, manufacturing processes, and compliance with relevant certifications.

-

Request Quality Reports: Suppliers should provide documentation detailing their quality control processes, including inspection reports and certifications. This information can help buyers assess the reliability of their suppliers.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased evaluation of the manufacturing process. These services can perform quality checks at various stages, providing peace of mind to buyers.

What Are the Unique QC Considerations for International B2B Buyers?

International B2B buyers must navigate various complexities when sourcing polycarbonate awnings. Differences in regulatory standards, certifications, and quality expectations can pose challenges. For example, a product compliant with EU standards may not meet the requirements in South America or Africa.

It is essential for buyers to understand the local regulations in their target markets. Collaborating with suppliers who have experience in international trade can help navigate these complexities. Additionally, establishing clear communication regarding quality expectations can minimize misunderstandings and ensure product quality.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices for polycarbonate awnings is essential for B2B buyers. By focusing on supplier verification, adherence to international standards, and quality control checkpoints, buyers can confidently source high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘polycarbonate awnings’

Introduction

This practical sourcing guide is designed to assist B2B buyers in efficiently procuring polycarbonate awnings. By following this checklist, you will ensure that you consider all essential factors, from technical specifications to supplier evaluations, facilitating a successful purchase that meets your business needs.

1. Define Your Technical Specifications

Start by establishing clear technical specifications for the polycarbonate awnings you require. This includes determining the dimensions, thickness of the polycarbonate panels, UV resistance, and design style. A well-defined specification will help you communicate your needs effectively to potential suppliers and ensure that the products align with your project requirements.

2. Identify Your Budget Constraints

Establish a budget range for your procurement. Understanding your financial limits will guide your decision-making process and help you narrow down options. Be sure to consider not only the initial purchase price but also potential shipping costs, installation fees, and long-term maintenance expenses.

3. Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers of polycarbonate awnings. Look for companies with a strong reputation in the industry, and consider their geographic location, especially if you are sourcing from regions like Africa, South America, or Europe. Shortlist suppliers based on their product offerings, pricing, and customer reviews.

4. Evaluate Supplier Certifications

Before proceeding with a supplier, verify their certifications and compliance with international quality standards. Certifications such as ISO 9001 or specific industry-related standards indicate a commitment to quality and safety. Additionally, check if the materials used are sourced sustainably, which can be crucial for businesses focused on environmental responsibility.

5. Request Samples and Product Specifications

Request product samples and detailed specifications from shortlisted suppliers. Assess the quality of the polycarbonate material, its clarity, and structural integrity. This step is vital for ensuring that the awnings meet your durability and aesthetic requirements before making a large purchase.

6. Understand Shipping and Delivery Terms

Clarify shipping options and delivery timelines with your chosen supplier. Understanding the logistics involved, especially for international shipping, can help you avoid delays and unexpected costs. Inquire about shipping insurance and return policies to protect your investment.

7. Negotiate Terms and Finalize the Purchase

Once you have selected a supplier, engage in negotiations to finalize the terms of your purchase. Discuss payment options, warranty terms, and after-sales support. A clear agreement will help prevent misunderstandings and ensure that both parties are aligned on expectations.

By following this comprehensive checklist, B2B buyers can streamline the sourcing process for polycarbonate awnings, ensuring they make informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for polycarbonate awnings Sourcing

What Are the Key Cost Components for Sourcing Polycarbonate Awnings?

When sourcing polycarbonate awnings, it is crucial to understand the various cost components that contribute to the overall price. These include:

-

Materials: The primary material, polycarbonate, is available in different grades and thicknesses, affecting both durability and cost. The choice between solid sheets and twin-wall options also influences pricing.

-

Labor: Labor costs encompass both the manufacturing process and assembly. Skilled labor may be required for custom installations or complex designs, which can increase costs.

-

Manufacturing Overhead: This includes operational expenses such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: The design and production of custom molds or tools for specialized awning shapes can be a significant upfront investment.

-

Quality Control (QC): Ensuring that products meet required standards incurs additional costs. This may involve inspections and testing to verify durability and UV resistance.

-

Logistics: Shipping and handling fees can vary widely based on the supplier’s location, destination, and chosen shipping method. For international buyers, understanding customs duties and tariffs is also critical.

-

Margin: Suppliers typically add a margin to cover their costs and generate profit. This can vary based on competition and market demand.

How Do Price Influencers Affect the Cost of Polycarbonate Awnings?

Several factors can influence the pricing of polycarbonate awnings, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to lower unit prices. Understanding a supplier’s MOQ can help negotiate better terms.

-

Specifications and Customization: Custom designs or specific dimensions may incur additional costs. Buyers should clarify their requirements upfront to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials or those with specific certifications (e.g., UV resistance, fire ratings) typically cost more. Buyers should weigh the benefits against the price.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their perceived quality and service.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can impact total costs. Understanding whether costs include freight, insurance, and duties is essential for accurate budgeting.

What Are Effective Buyer Tips for Negotiating Prices on Polycarbonate Awnings?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to enhance cost efficiency:

-

Negotiation: Always negotiate pricing, especially when placing large orders. Suppliers may be willing to offer discounts for long-term contracts or repeat business.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes purchase price, installation, maintenance, and potential replacement costs. Sometimes, a higher initial investment can lead to lower long-term costs.

-

Pricing Nuances for International Buyers: Be aware of regional market trends and competition. Prices can vary significantly based on local demand, currency fluctuations, and economic conditions.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and priority service. Regular communication and feedback can foster mutual benefits.

-

Research and Benchmarking: Conduct market research to compare prices and specifications among different suppliers. This knowledge equips buyers with leverage during negotiations.

Disclaimer on Indicative Prices

Prices for polycarbonate awnings can fluctuate based on various factors, including market conditions, material costs, and supplier pricing strategies. The figures presented in this analysis are indicative and should be used as a starting point for discussions with suppliers. Buyers are encouraged to obtain formal quotes and consider all associated costs for accurate budgeting.

Alternatives Analysis: Comparing polycarbonate awnings With Other Solutions

Exploring Alternative Solutions to Polycarbonate Awnings

When considering protective structures for doors and windows, polycarbonate awnings present a popular choice due to their durability and aesthetic appeal. However, there are several alternative solutions worth evaluating. This analysis focuses on comparing polycarbonate awnings with two viable alternatives: fabric awnings and metal canopies. Each option has its unique advantages and drawbacks, making it crucial for B2B buyers to understand these differences.

| Comparison Aspect | Polycarbonate Awnings | Fabric Awnings | Metal Canopies |

|---|---|---|---|

| Performance | High impact resistance, UV protection | Provides shade but less durable | Extremely durable, weather-resistant |

| Cost | Moderate to high investment | Lower initial cost | Higher initial investment |

| Ease of Implementation | Generally easy to install with brackets | Requires more skill to install | Can be complex, often needs professional installation |

| Maintenance | Low maintenance, resistant to fading | Requires regular cleaning and care | Minimal maintenance, occasional rust treatment |

| Best Use Case | Ideal for residential and commercial use | Suitable for temporary setups | Best for permanent structures needing high durability |

In-Depth Analysis of Alternatives

What are the Benefits and Drawbacks of Fabric Awnings?

Fabric awnings, often made from canvas or acrylic, are a cost-effective option for shade and protection. They are lightweight and can be easily retracted, making them suitable for variable weather conditions. However, fabric awnings are less durable compared to polycarbonate options and can be susceptible to fading and tearing over time. They require regular maintenance to keep them clean and to ensure they remain in good condition, which may increase long-term costs.

How Do Metal Canopies Compare to Polycarbonate Awnings?

Metal canopies are known for their robustness and longevity. They provide excellent protection against harsh weather conditions, making them ideal for environments with heavy rain or snow. However, the initial investment is generally higher, and their installation can be more complex, often requiring professional assistance. While they are low-maintenance and resistant to the elements, they can lack the aesthetic flexibility that polycarbonate awnings provide, which might be a consideration for businesses focused on exterior design.

How to Choose the Right Solution for Your Needs

When selecting the appropriate awning or canopy solution, B2B buyers should consider factors such as budget, intended use, and maintenance capabilities. Polycarbonate awnings are an excellent option for those seeking a balance between durability and aesthetics. In contrast, fabric awnings may serve well for temporary or seasonal needs, while metal canopies are ideal for permanent installations requiring maximum protection. Understanding these alternatives ensures that businesses can make informed decisions that align with their specific requirements and operational goals.

Essential Technical Properties and Trade Terminology for polycarbonate awnings

What Are the Key Technical Properties of Polycarbonate Awnings?

When considering polycarbonate awnings for commercial applications, understanding the essential technical properties is crucial for making informed decisions. Here are some of the critical specifications:

-

Material Grade: Polycarbonate is available in various grades, with the most common being solid polycarbonate sheets. High-grade polycarbonate offers superior impact resistance and UV protection. B2B buyers should prioritize high-grade options for durability and longevity, especially in regions with extreme weather conditions.

-

Thickness: The thickness of the polycarbonate sheet is a vital specification, often ranging from 3 mm to 10 mm. Thicker sheets provide enhanced strength and insulation, making them ideal for commercial settings that require greater durability against hail, snow, or heavy rain. Specifying the appropriate thickness can significantly affect the awning’s performance and lifespan.

-

UV Resistance: Awnings made from polycarbonate typically feature UV-resistant coatings. This property is crucial for maintaining the aesthetic appeal of the awning and preventing material degradation over time. Buyers in regions with high sun exposure should prioritize UV protection to ensure the longevity of their investment.

-

Load Capacity: Understanding the load capacity is essential, especially for large installations. Polycarbonate awnings should be able to support not just their weight but also the weight of accumulated snow or rainwater. This specification is particularly important for B2B buyers involved in construction or outdoor applications, as it impacts safety and compliance with local building codes.

-

Installation Type: Polycarbonate awnings can be fixed or retractable. Fixed awnings are generally more durable but less flexible, while retractable options offer versatility for changing weather conditions. Buyers should consider their specific application needs when selecting the installation type.

What Are Common Trade Terms Related to Polycarbonate Awnings?

Navigating the procurement of polycarbonate awnings also involves familiarizing oneself with industry-specific jargon. Here are several key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of polycarbonate awnings, understanding OEM relationships can help buyers source quality materials and components effectively.

-

MOQ (Minimum Order Quantity): This term indicates the smallest quantity of a product that a supplier is willing to sell. For polycarbonate awnings, knowing the MOQ is essential for budget planning and inventory management, especially for businesses looking to purchase in bulk.

-

RFQ (Request for Quotation): An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products. B2B buyers should use RFQs to obtain competitive pricing for polycarbonate awnings, ensuring they receive the best possible deal.

-

Incoterms (International Commercial Terms): These are a series of predefined commercial terms used in international transactions. Understanding Incoterms is crucial for B2B buyers engaged in global sourcing of polycarbonate awnings, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

-

Lead Time: This term refers to the time taken from placing an order to receiving the goods. For polycarbonate awnings, understanding lead times is vital for project planning and ensuring timely installation, particularly in regions with seasonal weather constraints.

-

Customization Options: Many suppliers offer customization in terms of size, color, and design of polycarbonate awnings. Understanding the available customization options can help buyers tailor products to their specific needs, enhancing customer satisfaction and project outcomes.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that their investments in polycarbonate awnings meet their operational and aesthetic requirements.

Navigating Market Dynamics and Sourcing Trends in the polycarbonate awnings Sector

What Are the Key Market Dynamics and Trends Affecting the Polycarbonate Awnings Sector?

The polycarbonate awnings market is witnessing robust growth driven by several global factors. Increasing demand for durable, weather-resistant outdoor structures is propelling the market, particularly in regions like Africa, South America, the Middle East, and Europe. In urban areas where space is limited, polycarbonate awnings provide a practical solution for extending living spaces while offering protection from harsh weather conditions. Additionally, the rise in DIY home improvement projects has led to a growing interest in readily available, easy-to-install awning solutions.

Emerging B2B technologies are also shaping sourcing trends within this sector. E-commerce platforms are making it easier for international buyers to access a wide range of products, allowing for price comparisons and supplier evaluations from the comfort of their offices. Furthermore, advancements in manufacturing techniques, such as automated cutting and precision molding, are enhancing product quality and reducing lead times. Buyers are increasingly looking for customizable options that cater to specific architectural styles and climatic conditions, thereby influencing product offerings.

The sustainability movement is gaining momentum, prompting buyers to seek eco-friendly solutions. This shift not only reflects changing consumer preferences but also aligns with regulatory pressures in many regions that mandate sustainable construction practices. As a result, manufacturers are investing in research and development to create innovative, environmentally responsible polycarbonate materials.

How Is Sustainability and Ethical Sourcing Influencing the Polycarbonate Awnings Market?

The environmental impact of polycarbonate awnings is an important consideration for B2B buyers. Traditional materials can contribute to significant waste and pollution, whereas polycarbonate offers a more sustainable alternative. Modern polycarbonate products are designed to be durable, reducing the need for frequent replacements and minimizing waste over time. Additionally, many manufacturers are adopting recycling practices for polycarbonate materials, further contributing to sustainability.

Ethical sourcing is becoming a vital factor in procurement decisions. Buyers are increasingly scrutinizing supply chains to ensure that materials are sourced responsibly, with a focus on fair labor practices and environmental stewardship. Certifications such as ISO 14001 (Environmental Management) and the Forest Stewardship Council (FSC) label for sustainable sourcing are gaining traction. These certifications not only assure buyers of a product’s environmental integrity but also enhance brand reputation in a competitive market.

Moreover, the trend towards “green” building materials is pushing manufacturers to innovate. Products that incorporate recycled materials or that can be recycled at the end of their lifecycle are becoming more sought after. This trend is especially relevant in regions with stringent environmental regulations, making it essential for international buyers to prioritize suppliers who align with these values.

What Is the Historical Context of the Polycarbonate Awnings Market?

The evolution of polycarbonate awnings can be traced back to the late 20th century when polycarbonate materials were first introduced as a lightweight and durable alternative to traditional glass. Initially, these products were primarily used in commercial applications due to their strength and UV resistance. Over time, as residential construction trends shifted towards modern aesthetics and functionality, polycarbonate awnings began to gain popularity in the residential sector.

The introduction of various design options, including customizable sizes and finishes, has further propelled their adoption. Today, polycarbonate awnings are recognized not only for their practicality but also for their ability to enhance the visual appeal of buildings. This historical context highlights a significant transformation in consumer preferences, driven by a desire for both durability and aesthetic value, which continues to shape the market today.

Conclusion

In summary, the polycarbonate awnings sector is poised for significant growth, influenced by market dynamics that favor durability, sustainability, and technological advancements. B2B buyers should stay attuned to emerging trends, focusing on ethical sourcing and sustainability to align with consumer demands and regulatory standards. As the market continues to evolve, those who adapt to these changes will be well-positioned to capitalize on new opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of polycarbonate awnings

-

How do I ensure the quality of polycarbonate awnings before purchasing?

To ensure the quality of polycarbonate awnings, request samples from suppliers to evaluate the material’s clarity, thickness, and UV resistance. It’s crucial to verify certifications related to strength and safety standards. Additionally, consider conducting a factory audit or reviewing third-party inspection reports. Engaging with suppliers who have a solid reputation and extensive experience in the industry can also enhance your confidence in the quality of their products. -

What are the best features to look for in polycarbonate awnings?

When sourcing polycarbonate awnings, prioritize features such as UV protection, impact resistance, and weather durability. Awnings with multi-wall construction provide better insulation and strength. Look for aluminum or corrosion-resistant brackets for long-lasting support. Customizable sizes and finishes can also enhance the aesthetic appeal and functionality of the awnings, making them suitable for various architectural styles. -

How can I customize polycarbonate awnings for my business needs?

Customization options for polycarbonate awnings typically include size, color, and design. Many manufacturers allow you to specify dimensions that fit your architectural requirements. You may also choose different finishes, such as clear or tinted panels, to achieve desired aesthetics and functionality. Discussing your specific needs with suppliers will help you explore available options and ensure the final product aligns with your brand identity. -

What is the minimum order quantity (MOQ) for polycarbonate awnings?

Minimum order quantities for polycarbonate awnings can vary significantly between suppliers. Typically, MOQs range from 50 to 200 units, depending on the product specifications and supplier capabilities. For smaller businesses, it may be beneficial to negotiate with suppliers or consider joining a buying group to meet MOQ requirements. Always clarify MOQ details during initial discussions to avoid potential misunderstandings later. -

What payment terms should I expect when ordering polycarbonate awnings?

Payment terms for polycarbonate awnings can vary by supplier and may include options such as upfront payment, a deposit with the balance upon delivery, or payment against documents. Many suppliers offer flexible terms for bulk orders, especially for repeat customers. It’s essential to negotiate terms that suit your cash flow while ensuring you have adequate protection against supply chain risks. -

What logistics considerations should I keep in mind when importing polycarbonate awnings?

When importing polycarbonate awnings, consider factors like shipping methods, costs, and customs regulations specific to your country. Engage with logistics partners who have experience in handling such products to ensure safe and timely delivery. Additionally, verify that the supplier can provide necessary documentation, including bills of lading and certificates of origin, to facilitate smooth customs clearance. -

How do I vet suppliers of polycarbonate awnings?

To vet suppliers, start by researching their reputation through online reviews and industry references. Request case studies or testimonials from previous clients to gauge their reliability and quality. It’s also advisable to check for certifications such as ISO or similar standards that reflect their commitment to quality. Additionally, engaging in direct communication to assess their responsiveness and willingness to address your concerns can provide further insights. -

What are the best practices for the installation of polycarbonate awnings?

Best practices for installing polycarbonate awnings include ensuring the structural integrity of the installation site, using appropriate mounting hardware, and following the manufacturer’s installation guidelines closely. It’s important to allow for proper drainage to prevent water pooling and damage. If possible, hiring a professional installer familiar with polycarbonate materials can help achieve a secure and aesthetically pleasing result.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Polycarbonate Awnings Manufacturers & Suppliers List

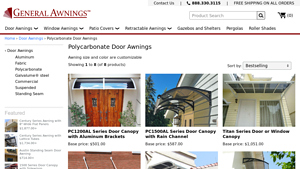

1. General Awnings – PC1200AL Series Door Canopy

Domain: generalawnings.com

Introduction: Polycarbonate Door Awnings available in customizable sizes and colors. Key products include: PC1200AL Series Door Canopy with Aluminum Brackets – $501.00, PC1500AL Series Door Canopy with Rain Channel – $587.00, Titan Series Door or Window Canopy – $1,051.00, Titan Series Door or Window Canopy with Overhead Braces – $1,108.00, Titan Series Curved Top Door or Window Canopy – $1,116.00, PC1200 Serie…

2. Advaning – PA Series Solid Polycarbonate Awning

Domain: advaning.com

Registered: 2014 (11 years)

Introduction: Product Name: PA Series Solid Polycarbonate Awning

SKU: N/A

Categories: Door Polycarbonate Awnings, Polycarbonate Awnings

Customer Rating: 4.39 out of 5 based on 132 ratings (120 reviews)

Purpose: Protects doors and windows from water damage by diverting rain, snow, and hail.

Design: Modern design enhances exterior aesthetics without distracting from existing architecture.

Size Options: 47″x35″, 5…

3. Lida Garden – Polycarbonate Awnings

Domain: lidagarden.com

Registered: 2016 (9 years)

Introduction: Polycarbonate awnings are lightweight, durable coverings made from polycarbonate panels known for their optical clarity and exceptional impact resistance. They come in two types: multiwall and solid. Multiwall panels are lighter, flexible, and suitable for complex installations, while solid panels are heavier, offer high strength, and achieve glass-like clarity. Key advantages include unmatched im…

4. Rightway – Polycarbonate Awnings

Domain: rightway.company

Introduction: Polycarbonate Awnings offer many benefits for residential and commercial use. They are available for installation in Brooklyn, Queens, Bronx, Staten Island, Long Island, and Manhattan. Key features include:

– Trimming Colors: White, Black, Gold, Silver, Brown

– Rust Resistant Aluminum Frame

– Affordable for all customers

– Multiple Post Styles

– Quick and Easy Installation

– 99% UV Resistance with…

5. Awning Works Inc. – LEXAN® THERMOCLEAR® Polycarbonate Canopies

Domain: awningworksinc.com

Registered: 2001 (24 years)

Introduction: Polycarbonate Canopies – LEXAN® THERMOCLEAR®: the Exclusive Polycarbonate Panel of Awning Works Inc. Key Features: Pre-Engineered or custom designed, Structural welded aluminum frame and posts, Integrated gutter and downspouts, 10 year panel warranty from Structured Products, Lexan® Thermoclear® available in clear, green, opal, white, bronze tint, All aluminum and stainless steel components, Alumi…

6. G&J Awnings – Polycarbonate Awnings

Domain: gjawning.com

Registered: 1998 (27 years)

Introduction: Polycarbonate Awnings from G&J Awnings are designed for windows, doors, and store fronts, offering a translucent and impact-resistant option compared to traditional canopies. They provide protection from harmful UV rays while allowing sunlight to filter through clear or opaque panels. Key benefits include being virtually indestructible, UV resistant, and resistant to extreme temperatures. G&J Awni…

7. Pinterest – Customized Polycarbonate Awnings

Domain: pinterest.com

Introduction: Polycarbonate Awning, Fully customized awning, Clear Polycarbonate Panel, Aluminum frame, Polycarbonate roof canopy, Enhanced Protection against rain, snow, and sunlight, Sturdy aluminum brackets, Stylish entrance design, Lightweight and durable polycarbonate sheets, 250% lighter than glass, 30x enhanced impact resistance, Modular installation systems, Typhoon resistant, Outdoor patio covering, Re…

8. Lawrence Fabric – Polycarbonate Awnings & Canopies

Domain: lawrencefabric.com

Registered: 1998 (27 years)

Introduction: Polycarbonate Awnings & Canopies: Impact-resistant, lightweight panels, easy installation, requires less structural support, lower installation costs, can be cold formed for unique designs, ideal for commercial and industrial use, provides diffused daylighting, energy cost savings, prevents glare, and offers optimum visibility. Glass Awnings & Canopies: Custom fabricated, modern architectural elem…

Strategic Sourcing Conclusion and Outlook for polycarbonate awnings

The strategic sourcing of polycarbonate awnings presents a significant opportunity for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. As demand for durable, aesthetically pleasing, and weather-resistant outdoor solutions continues to rise, polycarbonate awnings stand out due to their versatility and low maintenance requirements. Key takeaways include the importance of selecting suppliers that offer customizable options, ensuring compliance with local building regulations, and prioritizing products with robust warranties to safeguard investments.

Investing in polycarbonate awnings not only enhances the architectural appeal of buildings but also provides essential protection against environmental elements, thereby extending the lifespan of doors and windows. As the market evolves, staying informed about emerging trends, such as sustainable materials and innovative designs, will be crucial for making informed purchasing decisions.

As you consider your sourcing strategies, we encourage you to explore partnerships with reliable suppliers that align with your business goals. By prioritizing quality and sustainability in your procurement processes, you can position your business for success in the competitive global market.