Choosing Your Motorized Telescoping Pole: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for motorized telescoping pole

As global industries seek innovative solutions to enhance operational efficiency, the demand for motorized telescoping poles has surged across diverse sectors. These versatile tools, designed for a myriad of applications—from surveillance and inspection to communication and broadcasting—offer significant advantages in terms of reach and accessibility. However, sourcing the right motorized telescoping pole can pose challenges, particularly for B2B buyers navigating the complexities of international procurement.

This comprehensive guide aims to empower buyers by dissecting the motorized telescoping pole market. We delve into various types available, including lightweight carbon fiber models and heavy-duty aluminum options, highlighting their unique features and applications. Additionally, we cover essential aspects such as supplier vetting processes, cost considerations, and regional market insights specifically tailored for international buyers from Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Germany.

By providing actionable insights and data-driven recommendations, this guide equips B2B buyers with the knowledge to make informed purchasing decisions. Whether you are looking to enhance your operational capabilities or expand your product offerings, understanding the motorized telescoping pole landscape is crucial for ensuring your investment aligns with your business objectives and market demands.

Understanding motorized telescoping pole Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| HD Carbon Fiber Poles | Lightweight, rugged carbon fiber construction; integrated motorized hinge; various lengths. | Surveillance, inspection, and remote monitoring. | Pros: Durable, easy to transport; Cons: Higher cost compared to aluminum. |

| Tactical Masts | Heavy-duty composite or aluminum; can be motorized for quick deployment; various sizes. | Military, emergency services, and telecommunications. | Pros: Robust and stable; Cons: May require additional setup time. |

| Adjustable Light Poles | Telescoping action allows for height adjustment; often includes mounting brackets. | Event lighting, construction sites, and outdoor events. | Pros: Versatile for different lighting needs; Cons: Limited height range. |

| Electric Telescoping Poles | Motorized operation for easy extension and retraction; often used with cameras or sensors. | Inspection, maintenance, and utility work. | Pros: Reduces manual labor; Cons: Requires power source and maintenance. |

| Universal Telescoping Poles | Compatible with various accessories; can be customized for specific applications. | CCTV installations, broadcasting, and photography. | Pros: Flexible and adaptable; Cons: May require additional accessories for full functionality. |

What are the characteristics and suitability of HD Carbon Fiber Poles?

HD carbon fiber poles are designed for high-performance applications, particularly in surveillance and inspection sectors. Their lightweight yet robust construction makes them ideal for scenarios where portability is essential, such as remote monitoring. Buyers should consider the cost-to-benefit ratio, as these poles are generally more expensive but offer enhanced durability and ease of use. Their ability to withstand harsh conditions while maintaining structural integrity is a key selling point for B2B purchasers.

How do Tactical Masts serve various industries?

Tactical masts are engineered for demanding environments, often utilized by military and emergency service organizations. Made from heavy-duty materials, these poles are capable of supporting significant loads and can be quickly deployed, making them suitable for telecommunications and field operations. When purchasing, businesses should evaluate the mast’s height and load capacity in relation to their specific operational needs. Though they are robust, these masts may require additional setup time, which is a crucial consideration for time-sensitive operations.

Why are Adjustable Light Poles beneficial for outdoor events?

Adjustable light poles provide versatile lighting solutions for various applications, from construction sites to outdoor events. Their telescoping design allows for easy height adjustments, accommodating different lighting requirements. Buyers should assess the pole’s stability and maximum height to ensure it meets their specific needs. While they are generally adaptable, their height range may be limited, which could affect suitability for larger venues.

What advantages do Electric Telescoping Poles offer for inspections?

Electric telescoping poles are particularly advantageous for inspection and maintenance tasks, as they allow for effortless extension and retraction. This motorized operation minimizes manual labor, making them ideal for utility work where safety and efficiency are paramount. Buyers should consider the need for a power source, as this can affect the pole’s usability in remote locations. While they significantly enhance operational efficiency, ongoing maintenance is essential to ensure reliability.

How do Universal Telescoping Poles adapt to different applications?

Universal telescoping poles are designed to be compatible with a wide range of accessories, making them highly customizable for various applications, including CCTV installations and broadcasting. Their flexibility allows businesses to tailor the poles to their specific requirements, enhancing their utility. When purchasing, organizations should evaluate the types of accessories needed and the pole’s adaptability to different setups. Although these poles offer great versatility, the need for additional components can increase overall costs.

Key Industrial Applications of motorized telescoping pole

| Industry/Sector | Specific Application of motorized telescoping pole | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Installation and maintenance of antennas and communication devices | Enhanced safety and efficiency in reaching high locations | Durability, weight capacity, and compatibility with existing equipment |

| Security and Surveillance | Mounting surveillance cameras in hard-to-reach areas | Improved security coverage and operational efficiency | Weather resistance, ease of operation, and range of motion |

| Event Management | Setting up lighting and audio equipment for outdoor events | Quick setup and breakdown, enhancing event execution | Portability, height range, and motor control precision |

| Utilities and Infrastructure | Inspecting and maintaining power lines and communication cables | Reduced downtime and enhanced safety during inspections | Robust construction, ease of transport, and operational reliability |

| Construction and Engineering | Supporting tools and equipment at elevated heights during projects | Increased safety and efficiency in work processes | Load capacity, stability, and ease of use in various environments |

How Are Motorized Telescoping Poles Used in Telecommunications?

In the telecommunications sector, motorized telescoping poles are essential for the installation and maintenance of antennas and communication devices. They allow technicians to safely reach heights that would otherwise require scaffolding or ladders, thereby reducing the risk of accidents. International buyers should consider the durability and weight capacity of these poles, as they need to withstand various environmental conditions while supporting heavy equipment.

What Role Do Motorized Telescoping Poles Play in Security and Surveillance?

Motorized telescoping poles are increasingly used in security and surveillance applications, particularly for mounting cameras in hard-to-reach locations. Their ability to extend quickly and securely allows for optimal camera placement, enhancing overall security coverage. Buyers in this sector must prioritize features like weather resistance and ease of operation to ensure reliable performance in diverse environments, especially in regions with extreme weather conditions.

How Do Event Management Professionals Utilize Motorized Telescoping Poles?

In event management, motorized telescoping poles facilitate the swift setup of lighting and audio equipment for outdoor events. Their portability and ease of use streamline the process of creating a professional ambiance, allowing for quick adjustments as needed. B2B buyers should focus on the pole’s height range and motor control precision to accommodate varying event requirements and ensure efficient operations.

What Benefits Do Utilities and Infrastructure Gain from Motorized Telescoping Poles?

Utilities and infrastructure sectors utilize motorized telescoping poles for inspecting and maintaining power lines and communication cables. These poles reduce downtime by allowing for quick and safe inspections, thus enhancing operational efficiency. Buyers should consider the poles’ robustness and operational reliability to ensure they can withstand the rigors of utility work, particularly in remote areas.

How Are Motorized Telescoping Poles Applied in Construction and Engineering?

In construction and engineering, motorized telescoping poles support tools and equipment at elevated heights, significantly improving safety and efficiency during projects. By providing a stable platform for various tasks, these poles help minimize the risk of accidents. Buyers should evaluate load capacity and stability, ensuring that the poles can safely support the required equipment in diverse construction settings.

3 Common User Pain Points for ‘motorized telescoping pole’ & Their Solutions

Scenario 1: Navigating Height Limitations in Remote Locations

The Problem: B2B buyers often encounter challenges when needing to operate equipment at significant heights, especially in remote areas where traditional lifting methods may not be feasible. This is particularly true for industries such as telecommunications and construction, where access to towers or elevated structures is crucial. Without an effective solution, employees may face safety risks, operational delays, and increased costs due to the necessity of hiring cranes or scaffolding.

The Solution: When sourcing a motorized telescoping pole, it’s essential to prioritize models that offer a robust height extension while maintaining a lightweight design for easy transport. Buyers should consider poles made from durable materials like carbon fiber or heavy-duty aluminum that can withstand harsh environmental conditions. Additionally, integrating a motorized hinge feature allows for easy adjustments without the need for manual labor, enhancing safety and efficiency. Implementing these poles not only reduces operational costs but also streamlines workflows by enabling quick setup and takedown in challenging locations.

Scenario 2: Ensuring Compatibility with Existing Equipment

The Problem: A common pain point for international B2B buyers is ensuring that new motorized telescoping poles are compatible with existing systems and accessories. Many buyers invest in specialized equipment, such as cameras or lighting fixtures, but find that new poles do not integrate seamlessly, leading to wasted resources and operational inefficiencies.

The Solution: To avoid compatibility issues, buyers should conduct thorough research and ask suppliers for detailed specifications regarding attachment systems and compatibility with existing accessories. Look for poles that feature standardized threading or adjustable mounts that can accommodate a variety of equipment. Additionally, consider poles that come with versatile accessory options, allowing for customization based on specific operational needs. By investing in adaptable solutions, businesses can maximize their existing equipment’s utility and avoid unnecessary expenses in the long term.

Scenario 3: Addressing Maintenance and Durability Concerns

The Problem: Many buyers express concerns about the longevity and maintenance of motorized telescoping poles, particularly in demanding environments like construction sites or outdoor events. The potential for wear and tear, especially in the mechanical components, can lead to unexpected downtime and costly repairs.

The Solution: To mitigate these concerns, it is crucial to select poles designed with durability in mind. Look for models that feature weather-resistant materials and robust mechanical designs, such as built-in slip clutches to prevent damage during operation. Buyers should also inquire about warranty options and maintenance support from suppliers, which can provide peace of mind and reduce long-term costs. Implementing a regular inspection and maintenance schedule can further enhance the lifespan of the equipment. By proactively addressing maintenance needs, businesses can ensure consistent performance and minimize operational disruptions.

Strategic Material Selection Guide for motorized telescoping pole

When selecting materials for motorized telescoping poles, it is essential to consider the unique properties and performance characteristics that each material brings to the table. This analysis will focus on four common materials: aluminum, carbon fiber, fiberglass, and stainless steel. Each material has distinct advantages and disadvantages that can significantly impact the functionality and suitability of motorized telescoping poles in various applications.

What Are the Key Properties of Aluminum for Motorized Telescoping Poles?

Aluminum is a widely used material in the manufacturing of motorized telescoping poles due to its favorable properties. It is lightweight, which enhances portability and ease of use. Aluminum also offers good corrosion resistance, making it suitable for outdoor applications. However, its temperature and pressure ratings are moderate, which may limit its use in extreme conditions.

Pros:

– Lightweight and easy to handle.

– Corrosion-resistant, prolonging product life.

– Cost-effective compared to other materials.

Cons:

– Less durable than carbon fiber or stainless steel.

– Can deform under high stress or pressure.

For international buyers, particularly in regions with varying climates like Africa and the Middle East, aluminum poles may require additional coatings or treatments to enhance corrosion resistance, especially in coastal areas.

How Does Carbon Fiber Compare in Performance for Motorized Telescoping Poles?

Carbon fiber is renowned for its high strength-to-weight ratio, making it an excellent choice for applications requiring both rigidity and lightness. It can withstand higher stress levels without deformation, and its thermal properties allow it to perform well in extreme temperatures. However, carbon fiber is more expensive and can be more complex to manufacture due to the specialized processes involved.

Pros:

– Exceptional strength and rigidity.

– Lightweight, facilitating ease of use.

– Excellent thermal stability.

Cons:

– Higher cost compared to aluminum and fiberglass.

– Vulnerable to impact damage if not properly designed.

For B2B buyers in Europe, such as those in Germany, carbon fiber poles may align with high-performance standards and expectations for advanced technology applications, making them a preferred choice despite the higher cost.

What Role Does Fiberglass Play in the Selection of Motorized Telescoping Poles?

Fiberglass is another viable option for motorized telescoping poles, especially in environments where electrical insulation is necessary. It offers good strength and is resistant to corrosion, making it suitable for various outdoor applications. However, fiberglass is heavier than aluminum and carbon fiber, which can affect portability.

Pros:

– Good electrical insulation properties.

– Corrosion-resistant, suitable for harsh environments.

– Moderate cost.

Cons:

– Heavier than aluminum and carbon fiber.

– Less durable under extreme mechanical stress.

In regions like South America, where electrical safety is a concern, fiberglass poles can be particularly advantageous due to their insulating properties, aligning with local safety regulations.

Why Is Stainless Steel Considered for Motorized Telescoping Poles?

Stainless steel is known for its exceptional durability and corrosion resistance, making it ideal for applications in harsh environments. It can withstand high loads and is less likely to deform under stress. However, stainless steel is significantly heavier than other materials, which can impact the usability of the pole.

Pros:

– Highly durable and long-lasting.

– Excellent corrosion resistance.

– Suitable for heavy-duty applications.

Cons:

– Heavier, making it less portable.

– Higher cost due to material and manufacturing processes.

For buyers in the Middle East, where durability is paramount due to extreme environmental conditions, stainless steel poles can be an excellent investment despite their weight and cost.

Summary Table of Material Selection for Motorized Telescoping Poles

| Material | Typical Use Case for motorized telescoping pole | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General outdoor use, lightweight applications | Lightweight and corrosion-resistant | Less durable under high stress | Low |

| Carbon Fiber | High-performance applications, extreme conditions | Exceptional strength and rigidity | Higher cost and impact vulnerability | High |

| Fiberglass | Electrical insulation needs, outdoor environments | Good insulation and corrosion resistance | Heavier than aluminum and carbon fiber | Medium |

| Stainless Steel | Heavy-duty applications in harsh environments | Highly durable and corrosion-resistant | Heavier and more expensive | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of different materials for motorized telescoping poles. By understanding these factors, buyers can make informed decisions that align with their specific application needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for motorized telescoping pole

The manufacturing process of motorized telescoping poles involves several critical stages, each designed to ensure the final product meets the high standards required by international B2B buyers. Understanding these stages, along with the quality assurance (QA) measures in place, is essential for buyers from diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Main Stages of Manufacturing Motorized Telescoping Poles?

Material Preparation: Selecting the Right Components

The manufacturing process begins with the selection of appropriate materials. Common materials include lightweight yet durable carbon fiber and aluminum, which provide strength without adding excessive weight. During this stage, raw materials are tested for structural integrity and resistance to environmental factors, which is crucial for outdoor applications.

Forming: Precision Engineering Techniques

Once the materials are prepared, they undergo forming processes. Techniques such as extrusion and molding are often used to create the tubular sections of the poles. CNC (Computer Numerical Control) machining may be employed to ensure precise dimensions and tolerances. This step is vital for ensuring that each component fits seamlessly during assembly.

Assembly: Integrating Components for Functionality

The assembly stage involves integrating various components, including the motorized hinge, internal wiring, and controls. Attention to detail is critical, as any misalignment can affect the pole’s performance. Automated assembly lines may be used to enhance efficiency, but manual inspections remain crucial at this stage to ensure quality.

Finishing: Enhancing Durability and Aesthetics

Finishing processes such as anodizing or powder coating are applied to protect the poles from corrosion and wear while enhancing their visual appeal. This stage may also include the installation of additional features, such as ergonomic handles or slip clutches, that improve usability and safety.

How Is Quality Assurance Implemented During Manufacturing?

What International Standards Are Relevant for Motorized Telescoping Poles?

Quality assurance for motorized telescoping poles typically adheres to international standards, such as ISO 9001, which outlines quality management systems. Compliance with CE marking is essential for products sold in Europe, indicating they meet EU safety, health, and environmental protection standards. For specific industries, adherence to API (American Petroleum Institute) standards may also be required, particularly if the poles are used in industrial or oilfield applications.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint ensures that all raw materials meet specified standards before production begins. Suppliers should provide certification for materials used.

-

In-Process Quality Control (IPQC): During the manufacturing stages, periodic inspections are conducted to monitor the adherence to specifications. This may involve testing dimensions, strength, and functionality of components.

-

Final Quality Control (FQC): Once assembly is complete, a final inspection assesses the overall quality of the motorized telescoping pole. This includes functional testing of the motorized mechanisms and visual inspections for any cosmetic defects.

What Common Testing Methods Are Used?

Common testing methods for motorized telescoping poles include:

-

Load Testing: To verify the pole can support the maximum load specified by the manufacturer without failure.

-

Functional Testing: This involves operating the motorized components to ensure they function smoothly and reliably under varying conditions.

-

Environmental Testing: Assessing the pole’s performance in extreme temperatures, humidity, and exposure to UV light to ensure durability.

How Can B2B Buyers Verify Supplier Quality Control?

What Steps Can Buyers Take to Ensure Supplier Compliance?

B2B buyers can take several proactive steps to verify the quality control processes of potential suppliers:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities, processes, and QC measures in place. This also provides insight into the supplier’s commitment to quality.

-

Requesting QC Reports: Buyers should request detailed quality control reports that outline inspection results, testing methodologies, and compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and final products, ensuring they meet the specified quality standards.

What Are the Nuances of QC and Certification for International Buyers?

International buyers, particularly from regions like Africa, South America, and the Middle East, should be aware of the nuances in quality certification. Products may require different certifications depending on the target market’s regulations. For instance, products intended for the European market must comply with CE standards, while those aimed at the Middle Eastern market may need to meet specific local regulations.

Moreover, understanding the logistics of importing certified products can be complex. Buyers should ensure that all documentation, including certificates of conformity and test reports, accompany shipments to facilitate smooth customs clearance.

Conclusion: Ensuring Quality in Motorized Telescoping Poles

In summary, the manufacturing process of motorized telescoping poles is intricate, involving careful material selection, precise forming techniques, meticulous assembly, and robust finishing processes. Quality assurance is embedded throughout, adhering to international standards and incorporating multiple QC checkpoints. By understanding these processes and actively verifying supplier compliance, B2B buyers can make informed decisions that enhance their procurement strategies and ensure the reliability of their purchases.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘motorized telescoping pole’

Introduction

Sourcing a motorized telescoping pole requires careful consideration of various factors to ensure you select the right product for your specific needs. This guide provides a comprehensive checklist designed for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. By following these steps, you will be equipped to make an informed purchasing decision.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is critical before starting your procurement process. This includes determining the necessary height range, weight capacity, and material specifications. For instance, poles made from carbon fiber offer a lightweight yet sturdy option, while aluminum poles may provide different durability levels.

- Height Requirements: Assess the maximum and minimum heights needed for your applications.

- Weight Capacity: Ensure the pole can support the intended equipment, such as cameras or lighting fixtures.

Step 2: Research Market Trends and Applications

Stay informed about the latest trends and applications in your industry that utilize motorized telescoping poles. This knowledge will help you understand which features are essential and which innovations could benefit your operations.

- Industry Use Cases: Review how other companies are using these poles—whether for surveillance, lighting, or communication.

- Emerging Technologies: Look for advancements such as remote controls or enhanced mobility features that could improve usability.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct a thorough evaluation. Request detailed company profiles, product catalogs, and customer testimonials to assess their reliability and product quality.

- References: Ask for references from other B2B clients in similar industries to gauge satisfaction and performance.

- Certifications: Verify any industry certifications or compliance with international standards to ensure product quality.

Step 4: Request Samples and Product Demonstrations

Once you have shortlisted potential suppliers, request samples or product demonstrations. This step allows you to assess the quality, functionality, and ease of use of the motorized telescoping poles firsthand.

- Hands-On Testing: Evaluate how easily the pole extends and retracts, and check the robustness of its construction.

- Compatibility Testing: Ensure that the pole works seamlessly with any equipment you plan to attach.

Step 5: Negotiate Pricing and Terms

Negotiating pricing and terms is a vital step in the procurement process. Ensure that you are getting the best value for your investment, taking into account not just the initial cost but also long-term service and support.

- Bulk Purchase Discounts: Inquire about volume pricing if you plan to order multiple units.

- Warranty and Support: Review warranty terms and after-sales support to ensure you are covered in case of defects or issues.

Step 6: Finalize Your Order and Confirm Delivery Timelines

After selecting a supplier and negotiating terms, it’s time to finalize your order. Confirm all details, including product specifications, quantities, and delivery timelines, to avoid any misunderstandings.

- Order Confirmation: Ensure all specifications match your original requirements before placing the order.

- Tracking Delivery: Establish a clear timeline for delivery and tracking methods to monitor your order’s progress.

By following this checklist, B2B buyers can navigate the complexities of sourcing motorized telescoping poles effectively, ensuring they select a product that meets their operational needs while also adhering to budgetary constraints.

Comprehensive Cost and Pricing Analysis for motorized telescoping pole Sourcing

What Are the Key Cost Components Involved in Motorized Telescoping Poles?

When sourcing motorized telescoping poles, understanding the cost structure is crucial for international B2B buyers. The main cost components include:

-

Materials: The choice of materials significantly affects the cost. Lightweight options like carbon fiber and aluminum are popular due to their strength-to-weight ratios but tend to be more expensive. Buyers should balance material choice with intended use and environmental conditions.

-

Labor: Labor costs vary by region and complexity of the manufacturing process. Skilled labor for assembly, particularly for precision components like motorized hinges, can increase costs.

-

Manufacturing Overhead: This includes factory costs, utilities, and administrative expenses. Efficient manufacturing processes can help minimize overhead, impacting the final pricing.

-

Tooling: Custom tooling for unique designs or specifications adds to initial costs. If standard designs can be utilized, savings can be realized.

-

Quality Control (QC): Ensuring high-quality standards through rigorous testing and inspection processes incurs additional costs. Certifications such as ISO can further add to this.

-

Logistics: Shipping costs, influenced by distance, weight, and mode of transportation, are significant, especially for international shipments. Incoterms can dictate who bears these costs and responsibilities.

-

Margin: Manufacturers and suppliers will typically add a profit margin, which can vary based on market competition and demand.

How Do Pricing Influencers Affect the Cost of Motorized Telescoping Poles?

Several factors can influence the pricing of motorized telescoping poles:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom features, such as specific length, weight capacity, or additional accessories, can increase costs. Standardized products may offer better pricing.

-

Quality and Certifications: Higher quality products often come with certifications that ensure reliability and safety, which can justify a higher price. Buyers in regions with stringent safety regulations may need to prioritize certified options.

-

Supplier Factors: The supplier’s reputation, reliability, and location can affect pricing. Established suppliers with proven track records may charge a premium but offer better assurance of quality and service.

-

Incoterms: Understanding Incoterms is crucial for managing logistics costs. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who pays for shipping and insurance, impacting the total cost.

What Are Effective Buyer Tips for Negotiating Costs and Pricing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-effectiveness:

-

Negotiate Terms: Always engage in discussions regarding pricing, MOQ, and payment terms. Suppliers may be willing to adjust their offers based on your purchasing power or long-term potential.

-

Consider Total Cost of Ownership (TCO): Beyond initial purchase price, consider maintenance, potential repairs, and operational costs over the product’s lifespan. This holistic view can lead to better purchasing decisions.

-

Leverage Competitive Bids: Request quotes from multiple suppliers to understand market pricing and leverage this information during negotiations. This can help in securing favorable terms.

-

Stay Informed on Market Trends: Understanding market dynamics, such as material shortages or shifts in labor costs, can provide leverage in negotiations and help buyers anticipate price changes.

-

Plan for Currency Fluctuations: For international purchases, consider the impact of currency exchange rates on costs. Fixed pricing agreements can help mitigate risks associated with currency volatility.

Conclusion

Navigating the cost and pricing landscape for motorized telescoping poles involves a deep understanding of various cost components and pricing influencers. By employing strategic negotiation tactics and considering the total cost of ownership, international B2B buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that pricing can vary widely based on specific requirements, and it is prudent to seek multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing motorized telescoping pole With Other Solutions

In the realm of elevation solutions, motorized telescoping poles stand out for their versatility and efficiency. However, businesses often seek alternatives that may better suit their specific operational needs. This section explores viable alternatives to motorized telescoping poles, comparing their performance, cost, ease of implementation, maintenance requirements, and best use cases.

| Comparison Aspect | Motorized Telescoping Pole | Manual Telescoping Pole | Fixed Height Pole |

|---|---|---|---|

| Performance | High (adjustable height, motorized control) | Moderate (requires manual adjustment) | Low (static height) |

| Cost | High initial investment | Moderate initial investment | Low initial investment |

| Ease of Implementation | Easy (plug-and-play) | Moderate (requires setup) | Very easy (permanent installation) |

| Maintenance | Moderate (occasional checks) | Low (minimal wear) | Low (no moving parts) |

| Best Use Case | Dynamic applications (e.g., surveillance, event staging) | Temporary setups (e.g., events) | Permanent installations (e.g., lighting) |

What Are the Advantages and Disadvantages of Manual Telescoping Poles?

Manual telescoping poles offer a simpler and more cost-effective solution for applications requiring elevation. These poles are typically made of lightweight materials and are easy to transport. However, they require manual effort to adjust the height, which can be cumbersome during rapid deployments or in emergencies. While they are less expensive than motorized options, the need for physical labor can limit their practicality in high-demand environments.

How Do Fixed Height Poles Compare in Terms of Use?

Fixed height poles provide a stable solution for applications where elevation requirements are consistent. They are easy to install and maintain, with no moving parts that could wear out over time. However, their lack of adjustability makes them unsuitable for dynamic environments where height flexibility is necessary. Fixed poles are ideal for permanent installations, such as lighting or signage, where height does not need to change frequently.

Conclusion: How Should B2B Buyers Choose the Right Elevation Solution?

When selecting an elevation solution, B2B buyers must consider their specific operational needs, including the required flexibility, budget constraints, and maintenance capabilities. Motorized telescoping poles excel in dynamic scenarios, while manual poles can serve well in more static or temporary situations. Fixed height poles are best for consistent, long-term applications. By weighing these factors, businesses can make informed decisions that align with their operational goals and budgetary constraints, ensuring they choose the most effective solution for their needs.

Essential Technical Properties and Trade Terminology for motorized telescoping pole

What Are the Key Technical Properties of a Motorized Telescoping Pole?

1. Material Composition

Motorized telescoping poles are typically made from materials like carbon fiber or aluminum. Carbon fiber is favored for its lightweight and high rigidity, making it ideal for applications that require portability without sacrificing strength. Aluminum, while slightly heavier, offers excellent durability and resistance to corrosion. For B2B buyers, understanding the material composition is crucial as it directly affects the pole’s performance, longevity, and suitability for specific environments, especially in challenging climates like those found in Africa or the Middle East.

2. Extended and Collapsed Length

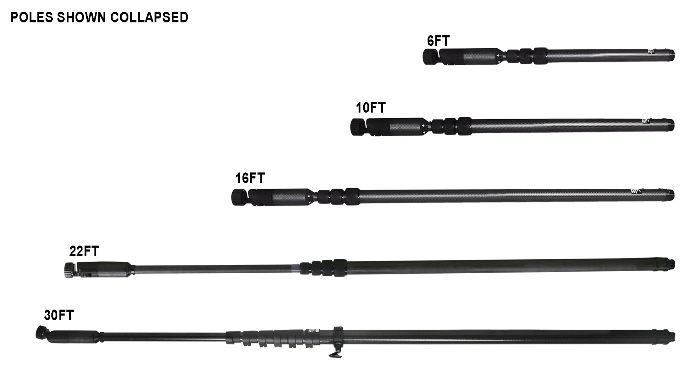

The ability of a motorized telescoping pole to extend and collapse is fundamental to its functionality. Specifications often include both the extended and collapsed lengths. For instance, a pole might extend up to 30 feet while collapsing to just a few feet for easy transport and storage. This feature is particularly important for industries requiring flexible reach, such as surveillance, telecommunications, and emergency response. Buyers should evaluate these dimensions based on the specific operational needs of their projects.

3. Load Capacity

The maximum load capacity, often measured in kilograms or pounds, indicates how much weight the pole can safely support. This is a vital specification for B2B buyers, as it ensures the pole can handle the necessary equipment, such as cameras or lighting fixtures, without risk of failure. Understanding load capacity helps in selecting the right pole for specific applications, ensuring safety and efficiency.

4. Motorized Control Mechanism

The motorized control mechanism allows for easy extension and retraction of the pole at the push of a button. This feature enhances operational efficiency, especially in time-sensitive situations. B2B buyers should consider the reliability and responsiveness of this mechanism, as it can significantly impact productivity during critical operations.

5. Weather Resistance

Many motorized telescoping poles are designed to be fully submersible or resistant to various environmental conditions. This feature is crucial for buyers operating in diverse climates, as it ensures the longevity and reliability of the equipment. Understanding the weather resistance of a pole can prevent costly replacements and maintenance, making it a key consideration for B2B procurement.

Which Trade Terminology Should B2B Buyers Know for Motorized Telescoping Poles?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of motorized telescoping poles, understanding OEM relationships can help buyers identify reliable suppliers and ensure product quality.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. B2B buyers must be aware of MOQ requirements to effectively manage inventory and budget constraints, especially when entering new markets or testing product lines.

3. RFQ (Request for Quotation)

An RFQ is a formal request to suppliers for price quotes on specific products or services. For businesses looking to procure motorized telescoping poles, issuing an RFQ can streamline the purchasing process and facilitate better negotiations with suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with these terms can help B2B buyers understand shipping costs, risks, and logistics associated with the procurement of motorized telescoping poles.

5. Warranty and Service Agreement

A warranty guarantees the quality of the product for a specified period, while a service agreement outlines the maintenance and support provided by the manufacturer. Understanding these terms helps buyers assess the long-term value and support they can expect, which is crucial for operational planning and risk management.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing motorized telescoping poles, ensuring they choose products that meet their specific operational needs and business objectives.

Navigating Market Dynamics and Sourcing Trends in the motorized telescoping pole Sector

What Are the Key Market Dynamics and Trends Influencing the Motorized Telescoping Pole Sector?

The motorized telescoping pole sector is experiencing significant growth driven by advancements in technology, increased demand across various industries, and a focus on operational efficiency. One of the primary global drivers is the integration of advanced materials, such as carbon fiber and lightweight composites, which enhance the durability and functionality of these poles. This shift allows for versatile applications, from surveillance and telecommunications to utility inspections and emergency services.

In regions like Africa, South America, the Middle East, and Europe, there is a noticeable trend towards automation and remote operations. B2B buyers are increasingly seeking motorized solutions that offer ease of use, such as remote-controlled extensions and collapsible designs. For instance, poles that can be operated with a simple button press are gaining traction, particularly in sectors where safety and efficiency are paramount. Additionally, the growing focus on digital transformation is pushing companies to incorporate smart technology into their equipment, allowing for data collection and real-time monitoring.

Emerging markets are also fostering a competitive landscape, with local manufacturers entering the fray, which is influencing pricing and innovation. As companies in regions such as Saudi Arabia and Germany prioritize sustainable practices, sourcing from suppliers that emphasize quality, reliability, and ethical manufacturing processes is becoming essential. This shift is likely to continue as buyers demand more transparency in their supply chains.

How Can Businesses Ensure Sustainability and Ethical Sourcing for Motorized Telescoping Poles?

Sustainability and ethical sourcing have become pivotal in the procurement strategies of B2B buyers in the motorized telescoping pole sector. The environmental impact of production processes and materials is under scrutiny, prompting companies to seek suppliers that demonstrate a commitment to sustainable practices. This includes using recycled or eco-friendly materials in the construction of poles, such as aluminum or biodegradable composites, which minimize the carbon footprint.

Furthermore, the importance of ethical supply chains cannot be overstated. Buyers are increasingly favoring manufacturers that adhere to fair labor practices and provide transparent sourcing information. Certifications like ISO 14001 for environmental management and Fair Trade can enhance a supplier’s reputation and assure buyers of their commitment to sustainability.

Incorporating these practices not only aligns with global sustainability goals but also appeals to environmentally conscious customers. By prioritizing green certifications and materials, businesses can differentiate themselves in a crowded market, potentially gaining access to new customer bases that prioritize sustainability.

What Is the Historical Context of Motorized Telescoping Poles in B2B Markets?

The evolution of motorized telescoping poles can be traced back to the growing need for versatile and efficient solutions in various industries. Initially, telescoping poles were primarily manual, requiring significant physical effort and time for deployment. However, with advancements in technology and materials, the design has shifted towards motorized systems that enhance usability and reduce labor costs.

The introduction of electric motors and lightweight materials in the late 20th century revolutionized the sector, allowing for poles that could extend and retract at the push of a button. This innovation has been particularly beneficial in sectors such as telecommunications and surveillance, where rapid deployment is crucial. Today, motorized telescoping poles are integral to various applications, embodying a blend of efficiency, safety, and technological advancement that continues to evolve with market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of motorized telescoping pole

-

How do I choose the right motorized telescoping pole for my needs?

Selecting the appropriate motorized telescoping pole involves evaluating the specific application requirements, such as height, weight capacity, and material. Consider whether you need a lightweight pole for easy transport or a more robust option for heavy-duty tasks. Assess the features offered, such as motorized controls, stability mechanisms, and compatibility with cameras or other attachments. Additionally, ensure the pole meets the operational environment conditions, such as weather resistance or submersibility if needed. -

What are the key features to look for in a motorized telescoping pole?

When sourcing a motorized telescoping pole, prioritize features like material durability (carbon fiber or aluminum), extension length, weight capacity, and ease of operation. Look for integrated motorized hinges that provide smooth adjustments and feedback mechanisms that display angular positions. Other vital aspects include user-friendly controls, safety features like slip clutches, and compatibility with various accessories. A fully submersible design can also be critical for specific industrial or environmental applications. -

What is the typical lead time for ordering motorized telescoping poles?

Lead times for motorized telescoping poles can vary based on the supplier, the complexity of the order, and customization requests. Generally, standard orders may take 4-6 weeks for delivery, while customized products can extend to 8-12 weeks. It’s advisable to discuss lead times upfront with suppliers and factor in potential delays due to international shipping or customs, especially when sourcing from different continents such as Africa, South America, or Europe. -

How can I ensure quality when sourcing motorized telescoping poles internationally?

To ensure quality, conduct thorough research on potential suppliers, including reviewing their certifications, production processes, and customer testimonials. Request product samples or detailed specifications to evaluate the quality firsthand. Implement a quality assurance (QA) process that includes inspections during production and before shipping. Consider working with suppliers who have established quality control measures and are willing to provide guarantees or warranties for their products. -

What customization options are available for motorized telescoping poles?

Customization options can vary widely among manufacturers but may include modifications in length, weight capacity, material choice, and specific features like motorized controls or attachment compatibility. Some suppliers offer branding options or specialized configurations for unique applications. Engaging in discussions with the supplier about your specific needs can lead to tailored solutions that enhance performance and usability for your particular industry requirements. -

What are the minimum order quantities (MOQs) for motorized telescoping poles?

Minimum order quantities for motorized telescoping poles can differ significantly based on the supplier’s production capabilities and your specific requirements. Typically, MOQs range from a few units for standard products to larger quantities for customized orders. It is crucial to clarify these details during initial discussions with potential suppliers, as some may offer flexibility depending on your long-term purchasing plans or the nature of your business relationship. -

What payment terms are common when sourcing motorized telescoping poles?

Payment terms can vary by supplier and region, but common arrangements include upfront payments, deposits with the balance due upon delivery, or net payment terms (e.g., net 30 days). For international transactions, consider factors such as currency exchange rates and transaction fees. It’s advisable to negotiate terms that align with your cash flow requirements and ensure that both parties agree on a secure payment method, such as letters of credit or escrow services. -

How do logistics and shipping impact the sourcing of motorized telescoping poles?

Logistics play a crucial role in the sourcing process, influencing costs, delivery times, and overall supply chain efficiency. Factors such as shipping routes, customs regulations, and handling of oversized or heavy items should be taken into account. Engage with suppliers who have experience in international shipping to ensure compliance with local regulations and timely delivery. Additionally, consider the option of using freight forwarders to streamline the shipping process and mitigate potential delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Motorized Telescoping Pole Manufacturers & Suppliers List

1. Motorized Telescoping Pole – Various Stroke Lengths & Voltage Options

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Motorized Telescoping Pole available in various stroke lengths: 1000mm (40 in), 600mm (24 in), 500mm (20 in), 400mm (16 in), 300mm (12 in), 200mm (8 in), 100mm (4 in), 50mm (2 in). Voltage options include 12V and 24V. Condition options are New and Used. Price range varies with listings under $75, $75 to $150, and over $150. Buying formats include Auction and Buy It Now. Shipping options include fr…

2. Telescoping Poles – Motorized Patio Lighting Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Telescoping poles for lighting, ideally motorized. Height requirement: 8-10ft for patio lighting. Concerns about durability with 20-30ft strings of lights. Suggestions for automation include car antenna solutions. Mention of Harbor Freight flagpoles as a durable, non-automated option.

3. Larson Electronics – Telescoping Light Pole

Domain: larsonelectronics.com

Registered: 2001 (24 years)

Introduction: {“Product Name”: “Telescoping Light Pole”, “Model”: “TPM-12-V2”, “Price”: “$739.11”, “Height Range”: “3 feet to 8.5 feet”, “Weight”: “3 lbs”, “Weight Capacity”: “100 pounds”, “Material”: “Aluminum”, “Features”: [“Telescoping design”, “CNC machined precision parts”, “Air cushioned chamber”, “Self-locking collar”, “No tools required for adjustment”], “Mounting”: “Bottom mounting bracket included for…

4. Arduino – Telescoping PVC Tubing Solutions

Domain: forum.arduino.cc

Registered: 2005 (20 years)

Introduction: This company, Arduino – Telescoping PVC Tubing Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Jonard – Telescoping Pole CF-200

Domain: jonard.com

Registered: 1998 (27 years)

Introduction: This company, Jonard – Telescoping Pole CF-200, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Clinton Electronics – Telescoping Poles and Mounting Solutions

Domain: clintonelectronics.com

Registered: 1999 (26 years)

Introduction: Telescoping Poles – Clinton Electronics offers a variety of mounting solutions including: CE-CPUPM Universal Pendant Mount Plate, CE-CPPMD Camera Pole Pendant Mount Dome Housing, CE-IDPC ID Series Camera Pendant Cap, CE-CPUJB Universal Junction Box, CE-CMDH2 Dual Head Monitor Mount, CE-CM-LX-9 9′ Telescoping Ceiling Mount, CE-CPLR Camera Pole Swivel Coupler, CE-SFTCBL 15′ Safety Cable, CE-CP3105 P…

Strategic Sourcing Conclusion and Outlook for motorized telescoping pole

In summary, the strategic sourcing of motorized telescoping poles offers significant advantages for businesses seeking to enhance operational efficiency and versatility. These poles, characterized by their lightweight, durable materials and motorized features, cater to diverse applications across industries, including telecommunications, security, and construction. Buyers should prioritize suppliers that provide robust warranties, comprehensive support, and adaptable products that can seamlessly integrate with existing systems.

As international markets continue to evolve, particularly in regions such as Africa, South America, the Middle East, and Europe, the demand for innovative and reliable equipment is set to grow. Strategic sourcing not only mitigates risks associated with supply chain disruptions but also fosters partnerships that enhance technological capabilities and cost efficiencies.

Looking ahead, B2B buyers are encouraged to explore the latest advancements in motorized telescoping pole technology, ensuring they align their procurement strategies with future market trends. By doing so, businesses can secure a competitive edge and drive long-term success in an increasingly globalized economy. Embrace the opportunity to elevate your operations with cutting-edge solutions tailored to your specific needs.