Choosing Your Gamma-Butyrolactone Gbl Buy Online: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for gamma-butyrolactone gbl buy online

In today’s rapidly evolving global marketplace, sourcing gamma-butyrolactone (GBL) online presents unique challenges for B2B buyers. The complexity of navigating different suppliers, understanding regulatory compliance, and assessing product quality can be daunting, especially for businesses in regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Germany. This guide aims to demystify the process of purchasing GBL online by providing comprehensive insights into various types of GBL products, their applications across industries, and the critical factors for vetting suppliers effectively.

Throughout this guide, we will explore essential topics such as the diverse applications of GBL, from solvent use to its role in chemical synthesis, along with an analysis of pricing structures and shipping logistics. Understanding these elements is crucial for making informed purchasing decisions that align with your business needs and compliance requirements. Additionally, we will highlight best practices for ensuring supplier reliability and product integrity, empowering you to mitigate risks associated with online sourcing.

By equipping B2B buyers with actionable insights and practical strategies, this guide serves as a valuable resource to streamline your procurement process and enhance your competitive edge in the global market for gamma-butyrolactone. Whether you are a seasoned buyer or new to the industry, the information presented here will help you navigate the complexities of online sourcing with confidence and precision.

Understanding gamma-butyrolactone gbl buy online Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Industrial Grade GBL | High purity (>99%), suitable for chemical synthesis | Solvent in chemical manufacturing, polymer production | Pros: Versatile, high quality; Cons: Regulatory scrutiny |

| Food Grade GBL | Compliance with food safety standards, often labeled as Kosher/Halal | Food flavoring, aroma enhancement | Pros: Safe for consumption; Cons: Limited applications |

| Research Grade GBL | Specifically formulated for laboratory use, high assay purity | Analytical chemistry, reference material | Pros: Reliable for experiments; Cons: Higher cost |

| Pharmaceutical Grade GBL | Meets strict pharmaceutical standards, often requires certification | Drug formulation, therapeutic applications | Pros: High quality, regulatory compliance; Cons: Expensive |

| Custom GBL Solutions | Tailored formulations for specific client needs | Specialty chemical applications, proprietary products | Pros: Customized to needs; Cons: Longer lead times |

What Are the Characteristics of Industrial Grade GBL?

Industrial Grade GBL is characterized by its high purity, typically exceeding 99%. This type is primarily used in chemical synthesis and manufacturing processes, making it essential for companies involved in polymer production and other industrial applications. When purchasing, B2B buyers should consider the regulatory implications, as this grade often faces scrutiny regarding its use and handling. However, its versatility and reliability in various chemical processes make it a staple in the industry.

How Does Food Grade GBL Differ from Other Variants?

Food Grade GBL is specifically formulated to meet food safety standards, often bearing certifications such as Kosher and Halal. It is primarily used as a food flavoring agent and for aroma enhancement in culinary applications. Buyers in the food and beverage sector should prioritize suppliers that can provide documentation of compliance with safety regulations. While it is safe for consumption, its applications are limited compared to industrial grades, which may restrict its use in broader manufacturing contexts.

What Makes Research Grade GBL Suitable for Laboratories?

Research Grade GBL is tailored for laboratory environments, offering high assay purity and stability. It is commonly utilized as a reference material in analytical chemistry and various research applications. B2B buyers in academic and industrial research should evaluate the supplier’s ability to provide comprehensive technical documentation and certificates of analysis. Although it comes at a higher price point, the reliability and precision it offers in experimental setups often justify the investment.

Why Is Pharmaceutical Grade GBL Important for Drug Formulation?

Pharmaceutical Grade GBL adheres to stringent regulatory standards, making it crucial for drug formulation and therapeutic applications. This grade requires certification and is often subject to rigorous quality control processes. B2B buyers in the pharmaceutical industry must ensure that their suppliers comply with all necessary regulations and can provide documentation to support quality claims. While it is more expensive than other grades, the assurance of safety and efficacy in drug development is invaluable.

What Are the Benefits of Custom GBL Solutions?

Custom GBL Solutions are tailored formulations designed to meet specific client requirements, offering flexibility in applications ranging from specialty chemicals to proprietary product development. This option is particularly beneficial for businesses that need unique properties or concentrations not available in standard offerings. However, B2B buyers should be prepared for longer lead times and potentially higher costs associated with customization. The advantage lies in obtaining a product that perfectly aligns with specific application needs.

Key Industrial Applications of gamma-butyrolactone gbl buy online

| Industry/Sector | Specific Application of gamma-butyrolactone gbl buy online | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Manufacturing | Solvent in chemical synthesis and formulation | Enhances product purity and consistency | Ensure compliance with local regulations and safety standards |

| Pharmaceutical Industry | Intermediate in drug production | Facilitates the development of new medications | Verify quality certifications and sourcing from reputable suppliers |

| Cosmetics and Personal Care | Ingredient in formulations for skin care products | Improves product stability and efficacy | Look for suppliers with extensive experience in cosmetic-grade GBL |

| Food and Beverage | Flavoring agent and solvent for extraction | Provides a unique taste profile and enhances quality | Ensure compliance with food safety standards and certifications |

| Textile Industry | Used in dyeing and finishing processes | Improves color fastness and textile durability | Consider bulk purchasing options for cost efficiency |

How Is gamma-Butyrolactone Used in Chemical Manufacturing?

In the chemical manufacturing sector, gamma-butyrolactone (GBL) serves as a versatile solvent in various synthesis and formulation processes. Its excellent solvency properties make it ideal for dissolving a wide range of substances, thereby enhancing product purity and consistency. For international buyers, especially from regions like Africa and South America, it is crucial to ensure that the GBL sourced meets local regulations and safety standards to avoid compliance issues during production.

What Role Does gamma-Butyrolactone Play in the Pharmaceutical Industry?

In the pharmaceutical industry, GBL is utilized as an intermediate in the production of several drugs. Its ability to facilitate chemical reactions and improve the solubility of active pharmaceutical ingredients (APIs) makes it invaluable. Buyers, particularly from Europe and the Middle East, should verify that their suppliers provide quality certifications and adhere to stringent regulatory standards, ensuring that the GBL meets the necessary purity and safety requirements for drug manufacturing.

How Is gamma-Butyrolactone Applied in Cosmetics and Personal Care?

GBL is an important ingredient in the cosmetics and personal care industry, where it is used to enhance the stability and efficacy of skin care formulations. Its hygroscopic nature helps in moisture retention, making products more effective. For B2B buyers in this sector, sourcing GBL from suppliers with proven expertise in cosmetic-grade materials is essential to ensure compliance with health and safety regulations and to maintain product quality.

In What Ways Does gamma-Butyrolactone Benefit the Food and Beverage Sector?

In the food and beverage industry, gamma-butyrolactone is used as a flavoring agent and solvent for extracting flavors from natural sources. Its unique properties can enhance the quality and taste profile of various products. International buyers must ensure that the GBL they procure complies with food safety standards and possesses the necessary certifications, particularly when dealing with markets in Europe and North America, where regulations are stringent.

How Is gamma-Butyrolactone Utilized in the Textile Industry?

Within the textile industry, GBL is employed in dyeing and finishing processes to improve color fastness and enhance the durability of fabrics. Its effectiveness in dissolving dyes and other chemicals makes it a preferred choice for manufacturers looking to achieve high-quality results. Buyers should consider bulk purchasing options to optimize costs and ensure a consistent supply chain, particularly when sourcing from global suppliers.

3 Common User Pain Points for ‘gamma-butyrolactone gbl buy online’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance for GBL Purchases

The Problem: B2B buyers often encounter significant challenges when it comes to ensuring compliance with local and international regulations surrounding the purchase and use of gamma-butyrolactone (GBL). Many countries have stringent laws regarding chemical substances, particularly those that may be used in pharmaceuticals or industrial applications. Buyers may find themselves unclear about the necessary documentation, such as Certificates of Analysis (CoA) and Safety Data Sheets (SDS), or may struggle to identify suppliers who can provide compliant products. This uncertainty can lead to delays, increased costs, or even legal repercussions if the regulations are not adhered to properly.

The Solution: To mitigate these issues, buyers should conduct thorough research on the specific regulations pertaining to GBL in their respective countries or regions. This includes understanding the classification of GBL under local laws and the requirements for safe handling and storage. Partnering with reputable suppliers who provide comprehensive documentation is crucial. Buyers should insist on obtaining CoAs and SDS before making a purchase. Additionally, utilizing resources such as trade associations or legal consultants that specialize in chemical regulations can provide further clarity and guidance. Establishing relationships with suppliers who have a proven track record in compliance can streamline the procurement process and ensure that all legal requirements are met.

Scenario 2: Ensuring Product Quality and Purity When Buying GBL Online

The Problem: Another common concern for B2B buyers is the variability in product quality and purity when sourcing gamma-butyrolactone online. Given that GBL is used in critical applications such as solvent extraction and chemical synthesis, any inconsistency in quality can lead to subpar results in production processes or even product failures. Buyers may find it challenging to assess the reliability of online suppliers and often fear receiving products that do not meet their specifications or industry standards.

The Solution: To ensure the procurement of high-quality GBL, buyers should prioritize sourcing from established suppliers with a transparent reputation. This can be achieved by seeking suppliers who provide detailed product specifications, including purity levels (ideally ≥99%) and molecular structure information. Requesting third-party testing results and quality certifications can provide additional assurance of the product’s integrity. Additionally, buyers should consider requesting samples before placing bulk orders to evaluate the product firsthand. Maintaining a list of trusted suppliers and regularly reviewing their performance can help in consistently obtaining high-quality materials.

Scenario 3: Overcoming Shipping and Delivery Challenges for International Orders

The Problem: International B2B buyers often face logistical hurdles when purchasing gamma-butyrolactone online, including shipping delays, restrictions on hazardous materials, and high freight costs. These challenges can disrupt supply chains, leading to production delays and increased operational costs. Buyers may also be concerned about the safe and compliant transport of GBL, as improper handling can pose risks during transit.

The Solution: To navigate these shipping challenges effectively, buyers should engage with suppliers who have experience in international logistics and can provide insights into the best shipping methods for hazardous materials. It is advisable to discuss shipping options upfront, including estimated delivery times and costs, and to inquire about the supplier’s experience with customs clearance procedures. Utilizing freight forwarders who specialize in chemical transportation can further streamline the process, ensuring that all regulatory requirements are met and that the product is transported safely. Additionally, buyers should consider establishing long-term relationships with suppliers who have proven reliability in shipping to their specific regions, thereby minimizing future shipping uncertainties.

Strategic Material Selection Guide for gamma-butyrolactone gbl buy online

What Are the Key Properties of gamma-Butyrolactone (GBL) for B2B Buyers?

gamma-Butyrolactone (GBL) is a versatile solvent and chemical intermediate with a variety of applications across different industries, including pharmaceuticals, agriculture, and chemical manufacturing. Understanding its properties is essential for B2B buyers to ensure compatibility with their intended applications.

-

Purity and Composition: GBL is typically available in high purity grades (≥99%) and is often supplied in solutions with solvents like acetonitrile. High purity is crucial for applications requiring stringent quality standards, such as pharmaceuticals.

-

Physical Properties: GBL has a boiling point of approximately 204°C and a flash point above 93°C, indicating its stability under normal conditions. Its low melting point (-45°C) allows for easy handling and storage. Additionally, GBL is miscible with water and many organic solvents, enhancing its versatility.

-

Chemical Stability: GBL is stable under a wide range of conditions, making it suitable for various chemical reactions. However, it should be stored in a cool, well-ventilated area to prevent degradation.

What Are the Advantages and Disadvantages of Using GBL?

When considering GBL for specific applications, it’s important to weigh its advantages against potential disadvantages.

Pros:

– Versatility: GBL can be used in multiple applications, including as a solvent, a precursor for other chemicals, and in formulations for cleaning agents.

– High Solubility: Its ability to dissolve a wide range of substances makes it ideal for various industrial processes.

– Regulatory Compliance: GBL is often compliant with international standards, which is crucial for B2B transactions, especially across regions like Europe and the Middle East.

Cons:

– Safety Concerns: GBL is classified as a hazardous material, requiring careful handling and adherence to safety regulations. This can increase operational costs for companies that need to implement additional safety measures.

– Cost Variability: The price of GBL can fluctuate based on market demand and supply chain factors, potentially impacting budgeting for B2B buyers.

How Does GBL Impact Specific Applications?

GBL’s properties make it suitable for various applications, but specific considerations must be taken into account based on the intended use.

- Pharmaceuticals: GBL is used as a solvent and in drug formulation. Its high purity and stability make it an excellent choice for these applications, but buyers must ensure compliance with stringent pharmaceutical regulations.

- Agriculture: In agrochemical formulations, GBL serves as a solvent for active ingredients. Buyers should consider local regulations regarding agricultural chemicals, particularly in regions like Africa and South America.

- Chemical Manufacturing: GBL is often used as an intermediate in synthesizing other chemicals. It is essential for buyers to assess compatibility with other materials and processes to avoid adverse reactions.

What Should International B2B Buyers Consider When Purchasing GBL?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, several factors should be considered:

- Regulatory Compliance: Different regions have varying regulations regarding the handling and use of GBL. Buyers must ensure that their suppliers comply with local laws, such as REACH in Europe or similar regulations in other regions.

- Quality Standards: Familiarity with common standards such as ASTM, DIN, or JIS is essential. Buyers should verify that the GBL they purchase meets these standards to ensure product quality and safety.

- Logistics and Shipping: Given that GBL may have specific shipping requirements due to its classification as a hazardous material, buyers should work with suppliers who can navigate these complexities efficiently.

Summary Table of gamma-Butyrolactone (GBL) Material Selection

| Material | Typical Use Case for gamma-butyrolactone gbl buy online | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| gamma-Butyrolactone (GBL) | Solvent in pharmaceuticals and chemical manufacturing | High purity and versatility | Classified as hazardous, requiring safety measures | Medium |

| GBL in Acetonitrile Solution | Reference standard in analytical chemistry | Stable under various conditions | Limited shelf life if not stored properly | Medium |

| GBL for Agrochemical Formulations | Solvent for active ingredients | Excellent solubility with various compounds | Regulatory compliance may vary by region | Medium |

| GBL as a Chemical Intermediate | Precursor for synthesizing other chemicals | High chemical stability | Price volatility based on market conditions | Medium |

This strategic guide aims to equip international B2B buyers with the necessary insights to make informed decisions when sourcing gamma-butyrolactone, ensuring compatibility with their specific applications and compliance with local regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for gamma-butyrolactone gbl buy online

What Are the Key Stages in the Manufacturing Process of Gamma-Butyrolactone (GBL)?

Manufacturing gamma-butyrolactone (GBL) involves several critical stages that ensure the final product meets the high standards expected by international B2B buyers. The process can be broadly categorized into four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The initial stage involves sourcing high-purity raw materials, typically including butyrolactone derivatives and solvents. Quality assurance begins here, as the purity and consistency of the raw materials directly impact the final product. Suppliers often conduct rigorous testing, including Gas Chromatography (GC) and High-Performance Liquid Chromatography (HPLC), to verify the quality of the incoming materials.

-

Forming: This stage encompasses the chemical synthesis of GBL. The most common method is the gamma-butyrolactone synthesis from 1,4-butanediol (BDO) through dehydration. This reaction requires precise temperature and pressure control to optimize yield and minimize impurities. Advanced techniques such as continuous flow reactors may be employed for scalability and consistency in production.

-

Assembly: In the context of GBL manufacturing, assembly refers to the integration of various components in the production line, including mixing and reaction vessels. This stage is crucial as it ensures that the synthesized GBL is thoroughly mixed with any necessary solvents or additives under controlled conditions. Automation technology plays a significant role here, enhancing precision and reducing human error.

-

Finishing: The final stage involves purification processes such as distillation or crystallization to achieve the desired purity levels (typically ≥99%). This step is vital for ensuring that the GBL meets both regulatory standards and customer specifications. The finished product is then packaged in suitable containers that ensure stability and prevent contamination during shipping.

What Quality Control Measures Are Essential for GBL Manufacturing?

Quality control (QC) is a cornerstone of the manufacturing process, particularly for chemicals like gamma-butyrolactone, where purity and consistency are paramount. Various international standards and industry-specific guidelines govern QC procedures.

-

International Standards: Many manufacturers adhere to ISO 9001 standards, which outline a framework for quality management systems. This certification signifies a commitment to continuous improvement and customer satisfaction. Additionally, compliance with Good Manufacturing Practices (GMP) is critical, especially for suppliers targeting pharmaceutical applications.

-

Industry-Specific Certifications: Depending on the end-use of GBL, additional certifications may be required. For example, if the GBL is intended for pharmaceutical use, adherence to the guidelines set forth by the FDA or the European Medicines Agency (EMA) is crucial. Similarly, compliance with CE marking regulations may be necessary for products sold within the European Union.

-

Quality Control Checkpoints: The QC process typically includes several checkpoints:

– Incoming Quality Control (IQC): This initial phase verifies the quality of raw materials before they enter production. Suppliers should provide Certificates of Analysis (CoA) to validate the quality.

– In-Process Quality Control (IPQC): During manufacturing, regular sampling and testing are conducted to ensure the process remains within specified parameters. Techniques such as NMR (Nuclear Magnetic Resonance) spectroscopy can be utilized for real-time monitoring.

– Final Quality Control (FQC): Once production is complete, the final product undergoes extensive testing to confirm it meets all specifications. This may include purity testing, stability assessments, and packaging inspections.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must implement robust verification processes to ensure that their suppliers maintain high-quality standards. Here are some actionable strategies:

-

Supplier Audits: Conducting regular audits of suppliers is one of the most effective ways to evaluate their quality control practices. This can include on-site visits to assess their manufacturing processes, QC protocols, and compliance with industry standards. Audits provide insights into the supplier’s operational efficiency and adherence to regulatory requirements.

-

Requesting Documentation: Buyers should request comprehensive documentation from suppliers, including CoAs, safety data sheets (SDS), and quality management system certifications. These documents serve as evidence of the supplier’s commitment to quality and regulatory compliance.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased evaluation of the supplier’s QC processes. These agencies can conduct inspections and testing to verify that the products meet the required specifications before shipment.

-

Understanding Certification Nuances: International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of the specific certification requirements for their markets. For instance, products sold in the EU may need CE marking, while those entering the U.S. market may require FDA approval. Understanding these nuances can help buyers ensure compliance and avoid potential legal issues.

What Testing Methods Are Commonly Used in GBL Quality Assurance?

To maintain high-quality standards, various testing methods are employed during the QC process of gamma-butyrolactone. These methods ensure that the product is safe, effective, and compliant with industry regulations.

-

Chromatographic Techniques: GC and HPLC are widely used for purity analysis. These methods can separate and quantify the components of GBL, ensuring that impurities are within acceptable limits.

-

Spectroscopic Methods: Techniques such as NMR and Infrared (IR) spectroscopy are employed to confirm the chemical structure and purity of GBL. These methods provide detailed insights into the molecular composition, helping to identify any deviations from expected standards.

-

Stability Testing: To ensure that GBL maintains its quality over time, stability testing is conducted under various environmental conditions. This testing helps predict the shelf life and storage requirements of the product.

-

Physical Testing: Parameters such as boiling point, melting point, and viscosity are assessed to ensure they meet specified criteria. These physical characteristics can significantly impact the usability of GBL in various applications.

Conclusion

In the competitive landscape of B2B chemical procurement, understanding the manufacturing processes and quality assurance measures for gamma-butyrolactone is essential. Buyers must be proactive in verifying supplier quality control practices through audits, documentation requests, and third-party inspections. By emphasizing the importance of quality and compliance, B2B buyers can secure reliable sources of GBL that meet their specific needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gamma-butyrolactone gbl buy online’

To successfully procure gamma-butyrolactone (GBL) online, it is essential to follow a systematic approach. This guide provides a step-by-step checklist to help B2B buyers navigate the sourcing process efficiently, ensuring compliance with regulations, quality assurance, and supplier reliability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Consider factors such as purity levels, packaging requirements, and the intended application of GBL. For instance, if you require GBL for laboratory use, ensure it meets the necessary purity standards, typically ≥99%, as specified by suppliers.

Step 2: Research Regulatory Compliance

Understanding the regulatory landscape for GBL is crucial, especially given its controlled status in many regions. Verify that the suppliers comply with local and international regulations, including safety data sheets (SDS) and certificates of analysis (CoA). This step will help you avoid legal complications and ensure safe handling practices.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Request documentation such as company profiles, case studies, and references from buyers in similar industries. Look for suppliers with a solid track record of reliability and quality, and consider their reputation in the market as a crucial factor in your decision-making process.

Step 4: Request Samples for Quality Assessment

To ensure that the GBL meets your quality standards, request samples from shortlisted suppliers. Conduct thorough testing to verify the product’s purity and performance as per your specifications. This step helps mitigate risks associated with product quality and enables you to make informed decisions based on empirical data.

Step 5: Compare Pricing and Terms

Once you have assessed the quality of the samples, compare pricing and terms from different suppliers. Look beyond just the price; consider factors such as minimum order quantities, payment terms, and delivery timelines. A comprehensive comparison will help you identify the best overall value, not just the lowest price.

Step 6: Confirm Shipping and Handling Procedures

Before finalizing the order, confirm the shipping and handling procedures with your chosen supplier. Ensure they have protocols in place for safe transportation, especially if GBL requires specific conditions, such as refrigeration. Understanding these logistics will help you avoid delays and ensure that the product arrives in optimal condition.

Step 7: Establish a Communication Plan

Lastly, establish a clear communication plan with your supplier. This includes agreeing on points of contact for order updates, issue resolution, and feedback mechanisms. Effective communication is vital for maintaining a smooth procurement process and fostering a strong supplier relationship for future orders.

By following these steps, B2B buyers can confidently navigate the complexities of sourcing gamma-butyrolactone online, ensuring they receive high-quality products that meet their specific needs while adhering to regulatory standards.

Comprehensive Cost and Pricing Analysis for gamma-butyrolactone gbl buy online Sourcing

What Are the Key Cost Components for Sourcing Gamma-Butyrolactone (GBL) Online?

When analyzing the costs associated with sourcing gamma-butyrolactone (GBL) online, several key components come into play. Materials represent the primary expense, with prices influenced by the purity level and sourcing location. For example, high-purity GBL often commands a premium due to its stringent production standards. Labor costs are another significant factor, particularly in regions where manufacturing is labor-intensive. Additionally, manufacturing overhead—which includes utilities, depreciation, and indirect labor—contributes to the final pricing.

Tooling costs may arise depending on the production method, especially if specialized equipment is necessary for custom formulations. Quality Control (QC) is essential for ensuring compliance with safety and regulatory standards, which adds another layer to the cost structure. Logistics, encompassing shipping and handling, can significantly impact overall pricing, especially for international buyers who must navigate customs and potential tariffs. Finally, the margin set by suppliers can vary widely based on their operational efficiencies and market positioning.

How Do Price Influencers Affect GBL Sourcing Costs?

Several factors influence the price of gamma-butyrolactone, notably volume and Minimum Order Quantity (MOQ). Suppliers often provide tiered pricing, where larger orders yield lower per-unit costs. Customization requests, such as specific formulations or packaging, can also affect pricing. The quality and certifications of GBL, including compliance with international safety standards, directly influence its cost, as higher-quality products typically involve more rigorous testing and validation processes.

Supplier factors play a pivotal role in determining pricing. Established suppliers with a strong reputation may charge more due to perceived reliability and quality assurance. Furthermore, understanding Incoterms is crucial for international transactions, as they dictate who is responsible for shipping costs, insurance, and risk, which can significantly affect the total landed cost.

What Buyer Tips Can Help Optimize GBL Sourcing Costs?

For B2B buyers, effective negotiation can lead to more favorable pricing and terms. Establishing long-term relationships with suppliers may provide leverage for better pricing and service levels. Understanding the Total Cost of Ownership (TCO) is vital; beyond the initial purchase price, consider factors such as shipping, storage, and potential regulatory compliance costs.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of pricing nuances that may arise due to exchange rates, regional tariffs, and varying shipping costs. Conducting thorough market research to compare suppliers can uncover competitive pricing and unique offerings.

Additionally, leveraging bulk purchasing agreements can lead to significant savings over time. Finally, always request detailed quotes that break down costs to identify any hidden fees or unnecessary expenditures.

What Are the Important Considerations Regarding Indicative Prices?

It’s important to note that the prices for gamma-butyrolactone can fluctuate based on market demand, raw material costs, and global economic conditions. Therefore, indicative prices should be treated as a guide rather than fixed rates. Always verify current pricing directly with suppliers and consider requesting a custom quote to ensure accurate budgeting for your specific needs.

Alternatives Analysis: Comparing gamma-butyrolactone gbl buy online With Other Solutions

Introduction: Understanding Alternatives in Chemical Solutions

In the realm of chemical procurement, particularly for industrial applications, it’s essential to explore alternatives to products like gamma-butyrolactone (GBL). By evaluating different solutions, businesses can make informed decisions that optimize performance, cost-efficiency, and suitability for specific applications. This analysis will compare GBL with two viable alternatives: ethyl lactate and dimethyl sulfoxide (DMSO), both of which serve as solvents and have various industrial uses.

Comparison Table

| Comparison Aspect | Gamma-Butyrolactone GBL Buy Online | Ethyl Lactate | Dimethyl Sulfoxide (DMSO) |

|---|---|---|---|

| Performance | High solvency, versatile applications | Moderate solvency, biodegradable | Excellent solvent properties, polar aprotic |

| Cost | Moderate ($40-$60 per liter) | Low ($20-$30 per liter) | Moderate ($30-$50 per liter) |

| Ease of Implementation | Readily available online | Widely available, easy to use | Requires careful handling |

| Maintenance | Low maintenance required | Low maintenance required | Moderate maintenance required due to handling precautions |

| Best Use Case | Industrial solvents, chemical synthesis | Food industry, biodegradable solvents | Pharmaceuticals, polymer chemistry |

Detailed Breakdown of Alternatives

Ethyl Lactate

Ethyl lactate is a biodegradable solvent derived from renewable resources. Its moderate solvency makes it suitable for applications in the food industry, particularly as a flavoring agent and cleaning solvent. The main advantage of ethyl lactate is its low cost and environmental friendliness, aligning with sustainability goals. However, it may not perform as effectively in high-solvency applications compared to GBL, limiting its use in more demanding industrial processes.

Dimethyl Sulfoxide (DMSO)

DMSO is renowned for its exceptional solvent properties, particularly for polar compounds. It is widely used in pharmaceutical applications and chemical research due to its ability to penetrate biological membranes. While its performance is superior in specific applications, DMSO requires careful handling due to its potential to absorb harmful substances from its environment, which can complicate its use. Moreover, its moderate cost and maintenance requirements make it a less attractive option for businesses seeking straightforward solutions.

Conclusion: How to Choose the Right Chemical Solution

When selecting the appropriate chemical solution, B2B buyers should assess their specific needs based on performance, cost, and ease of implementation. For applications requiring high solvency and versatility, gamma-butyrolactone remains a strong contender. However, for those prioritizing sustainability and cost-effectiveness, ethyl lactate may be more appropriate. Conversely, if the application demands exceptional solvent properties and the buyer is prepared for careful handling, DMSO could be the ideal choice. Ultimately, understanding the unique properties and applications of each alternative will empower businesses to make informed purchasing decisions that best align with their operational goals.

Essential Technical Properties and Trade Terminology for gamma-butyrolactone gbl buy online

What Are the Key Technical Properties of Gamma-Butyrolactone (GBL) That B2B Buyers Should Know?

Understanding the technical properties of gamma-butyrolactone (GBL) is crucial for B2B buyers in various industries, including pharmaceuticals, cosmetics, and chemical manufacturing. Here are the essential specifications to consider:

-

Molecular Formula and Weight

GBL has a molecular formula of C4H6O2 and a molecular weight of 86.09 g/mol. This information is essential for chemical formulation and product compatibility assessments. Knowing the molecular weight helps in calculating dosages and concentrations required for specific applications. -

Purity Level

GBL is typically available with a purity range of 98-100%. High purity levels are critical in applications such as pharmaceuticals, where impurities can affect efficacy and safety. Buyers should always verify purity levels to ensure compliance with regulatory standards. -

Boiling and Melting Points

The boiling point of GBL is approximately 204°C, while its melting point is around -45°C. These thermal properties are important for storage and handling, as they indicate the conditions under which GBL remains stable. Understanding these points helps in selecting appropriate storage facilities and equipment. -

Flash Point

GBL has a flash point greater than 93°C, categorizing it as a non-flammable liquid under standard conditions. This property is crucial for safety assessments and regulatory compliance during transportation and storage. Buyers should ensure that their handling procedures align with this safety data. -

Hazard Classification

GBL is classified as dangerous, with hazard statements indicating potential harm if ingested or if it comes into contact with eyes. Familiarity with hazard classifications aids in compliance with occupational safety regulations and informs safety training for employees handling the substance. -

Shelf Life

GBL typically has a shelf life of up to 36 months under proper storage conditions. This information is vital for inventory management, ensuring that buyers rotate stock efficiently and avoid using expired materials in their production processes.

What Common Trade Terms Should B2B Buyers of GBL Be Aware Of?

Familiarity with trade terminology can streamline the purchasing process and enhance communication between buyers and suppliers. Here are some common terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers negotiate better terms and ensure that they receive quality products tailored to their needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their budgets and inventory levels effectively, allowing for cost-effective purchasing strategies. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and other details for specific quantities of goods. This process helps buyers compare prices and terms from multiple suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms can help buyers avoid unexpected costs and ensure that all parties are clear on their obligations. -

SDS (Safety Data Sheet)

An SDS provides detailed information about the handling, storage, and hazards of a chemical substance. Buyers should request an SDS for GBL to ensure compliance with safety regulations and to maintain a safe working environment. -

CAS Number

The Chemical Abstracts Service (CAS) number for GBL is 96-48-0. This unique identifier is crucial for accurately sourcing the chemical and differentiating it from similar substances. It simplifies the procurement process by ensuring that buyers are purchasing the correct product.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when purchasing gamma-butyrolactone, ensuring compliance, safety, and optimal use in their applications.

Navigating Market Dynamics and Sourcing Trends in the gamma-butyrolactone gbl buy online Sector

What Are the Key Market Dynamics and Trends Influencing the Gamma-Butyrolactone (GBL) Sector?

The gamma-butyrolactone (GBL) market is experiencing significant growth, driven by diverse applications in industries such as pharmaceuticals, chemicals, and agrochemicals. As a versatile solvent and chemical intermediate, GBL is essential in producing various compounds, including butyric acid derivatives and gamma-hydroxybutyric acid (GHB). This broad utility is catalyzing demand from international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe, including Germany and Vietnam.

Emerging B2B sourcing trends reflect a shift toward digital procurement platforms, enabling buyers to streamline their purchasing processes. This trend is accompanied by the increasing importance of supplier transparency and reliability. Buyers are leveraging technology to access real-time data on product availability, pricing, and compliance with international standards. Furthermore, the growing emphasis on just-in-time inventory management necessitates efficient logistics and supply chain strategies, particularly for temperature-sensitive products like GBL.

Market dynamics are also influenced by regulatory frameworks and environmental considerations. The evolving legal landscape surrounding chemicals, particularly those with psychoactive properties, requires buyers to stay informed about compliance issues in their respective regions. This is particularly pertinent for buyers in regions with stringent regulations, such as the EU, where chemical safety and environmental impact assessments are mandatory.

How Can B2B Buyers Prioritize Sustainability and Ethical Sourcing for GBL?

Sustainability and ethical sourcing are increasingly crucial for B2B buyers in the gamma-butyrolactone market. As businesses face mounting pressure from stakeholders to adopt eco-friendly practices, the environmental impact of sourcing decisions has come under scrutiny. GBL production involves energy-intensive processes, and buyers are encouraged to seek suppliers that utilize renewable energy sources and sustainable practices.

The importance of ethical supply chains cannot be overstated. Buyers should prioritize suppliers with certifications that demonstrate a commitment to sustainability, such as ISO 14001 for environmental management and other ‘green’ certifications. These credentials not only reflect a supplier’s dedication to minimizing their environmental footprint but also enhance product credibility and marketability.

Moreover, the demand for ‘green’ materials is on the rise. Buyers are advised to inquire about the sustainability of raw materials used in GBL production and the suppliers’ waste management practices. By aligning with suppliers who prioritize sustainable practices, B2B buyers can ensure that their procurement processes contribute positively to their corporate social responsibility goals while mitigating risks associated with environmental regulations.

What Is the Historical Context and Evolution of GBL in the B2B Sector?

The historical evolution of gamma-butyrolactone (GBL) reflects its transformation from a niche chemical to a widely utilized industrial solvent. Initially synthesized in the 19th century, GBL gained prominence in the mid-20th century due to its applications in pharmaceuticals and as a precursor to various chemicals. The rise of the synthetic aroma chemicals market in the late 20th century further expanded GBL’s applications, particularly in the food and fragrance industries.

As awareness of the health effects associated with its derivative, GHB, grew, regulatory scrutiny increased, impacting its availability and use in some markets. Despite these challenges, the ongoing development of GBL’s applications in diverse sectors has solidified its role in the chemical industry. Today, B2B buyers must navigate a complex landscape shaped by regulatory frameworks, evolving market demands, and the imperative for sustainable sourcing practices. Understanding this history equips buyers with insights into the current dynamics and future trends that will influence their purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of gamma-butyrolactone gbl buy online

1. How do I ensure the quality of gamma-butyrolactone (GBL) before purchasing?

To ensure the quality of gamma-butyrolactone, request a Certificate of Analysis (CoA) from your supplier. This document provides detailed information on the product’s purity, batch number, and testing methods used. Additionally, consider suppliers that offer third-party testing and compliance with international quality standards, such as ISO certifications. It’s also beneficial to read reviews and testimonials from other buyers to gauge the supplier’s reliability and product quality.

2. What are the common applications of gamma-butyrolactone (GBL) in industry?

Gamma-butyrolactone is widely used in various industries, including pharmaceuticals, cosmetics, and chemical manufacturing. It serves as a solvent for polymers and resins, an intermediate in the synthesis of other chemicals, and a cleaning agent. Understanding your specific application can help in sourcing the right grade and purity level, ensuring optimal performance in your processes.

3. What are the minimum order quantities (MOQs) for gamma-butyrolactone when buying online?

Minimum order quantities for gamma-butyrolactone can vary significantly among suppliers. Typically, MOQs range from 1 liter to several hundred liters, depending on the supplier’s policies and the intended use of the product. It is advisable to inquire directly with potential suppliers about their MOQs to ensure they align with your purchasing needs and budget constraints.

4. How can I verify the legitimacy of a supplier when buying GBL online?

To verify a supplier’s legitimacy, check for their business registration, industry certifications, and compliance with local regulations. Look for customer reviews and ratings on independent platforms. Additionally, request references from other businesses that have previously purchased from them. Engaging in direct communication and asking for detailed product information can also provide insights into their professionalism and reliability.

5. What payment terms should I expect when purchasing gamma-butyrolactone online?

Payment terms for purchasing gamma-butyrolactone can vary by supplier. Common options include upfront payment, net 30 or 60 days, and payment through letters of credit for larger orders. It’s crucial to discuss these terms during negotiations to ensure they fit your cash flow requirements. Always ensure that payment methods are secure, and consider using escrow services for added protection on large transactions.

6. What are the shipping options and logistics considerations for international orders of GBL?

When ordering gamma-butyrolactone internationally, consider the shipping methods available, such as air freight or sea freight. Ensure that the supplier complies with international shipping regulations and provides necessary documentation, including customs declarations. Additionally, be aware of potential import tariffs and restrictions in your country, as GBL may be regulated in certain regions. Confirm the estimated delivery times to avoid disruptions in your supply chain.

7. Are there any safety regulations I should be aware of when handling gamma-butyrolactone?

Yes, handling gamma-butyrolactone requires adherence to specific safety regulations due to its hazardous nature. Ensure that your team is trained in proper handling procedures, including the use of personal protective equipment (PPE) such as gloves and goggles. Familiarize yourself with the Safety Data Sheet (SDS) provided by the supplier, which outlines potential hazards, safe handling practices, and emergency procedures. Compliance with local health and safety regulations is also essential.

8. Can I customize my order of gamma-butyrolactone to meet specific requirements?

Many suppliers offer customization options for gamma-butyrolactone orders, such as specific purity levels or packaging sizes. When reaching out to suppliers, clearly communicate your requirements and any particular applications you have in mind. This will help them provide tailored solutions that meet your needs. Additionally, inquire about the possibility of bulk discounts or special pricing for customized orders to maximize your purchasing efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Gamma-Butyrolactone Gbl Buy Online Manufacturers & Suppliers List

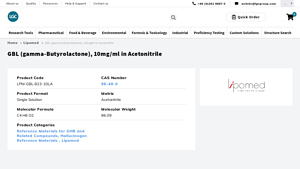

1. Lipomed – GBL (gamma-Butyrolactone)

Domain: lgcstandards.com

Registered: 2007 (18 years)

Introduction: {“Product Name”: “GBL (gamma-Butyrolactone)”, “CAS Number”: “96-48-0”, “Concentration”: “10mg/ml”, “Solvent”: “Acetonitrile”, “Brand”: “Lipomed”}

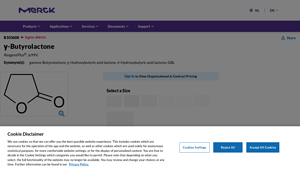

2. Sigma-Aldrich – γ-Butyrolactone

Domain: sigmaaldrich.com

Registered: 1998 (27 years)

Introduction: {“name”: “γ-Butyrolactone”, “synonyms”: [“gamma-Butyrolactone”, “γ-Hydroxybutyric acid lactone”, “4-Hydroxybutyric acid lactone”, “GBL”], “empirical_formula”: “C4H6O2”, “CAS_number”: “96-48-0”, “molecular_weight”: “86.09”, “Beilstein_REAXYS_number”: “105248”, “EC_number”: “202-509-5”, “MDL_number”: “MFCD00005386”, “UNSPSC_code”: “12352100”, “PubChem_substance_ID”: “24891553”, “NACRES”: “NA.22”, “v…

3. Thermo Scientific Acros – 2-Hydroxy-gamma-butyrolactone, 99%

Domain: fishersci.no

Registered: 2007 (18 years)

Introduction: {‘product_name’: ‘2-Hydroxy-gamma-butyrolactone, 99%’, ‘product_code’: ‘10333722’, ‘brand’: ‘Thermo Scientific Acros’, ‘quantity_options’: [‘5 g’, ’25 g’], ‘packaging’: ‘Glass bottle’, ‘CAS_number’: ‘19444-84-9’, ‘molecular_formula’: ‘C4H6O3’, ‘molecular_weight’: ‘102.09 g/mol’, ‘MDL_number’: [‘MFCD00134268’, ‘MFCD00211245’], ‘InChI_key’: ‘FWIBCWKHNZBDLS-UHFFFAOYNA-N’, ‘synonyms’: [‘alpha-hydroxy-…

4. WebMD – Gamma Butyrolactone (GBL)

Domain: webmd.com

Registered: 1998 (27 years)

Introduction: Gamma Butyrolactone (GBL) is a chemical found in cleaning solutions and nail polish. It is converted in the body to gamma-hydroxybutyrate (GHB), which is associated with serious safety concerns, including its use as a date-rape drug. GBL is classified as a Schedule I controlled substance in the US, making it illegal. It is considered unsafe when taken by mouth, with potential side effects includin…

5. GBL – Wheel Cleaner

Domain: console.playblackdesert.com

Registered: 2017 (8 years)

Introduction: GBL Wheel Cleaner is available in various sizes: 2 liter, 5 liter, 10 liter, 20 liter, 25 liter, 5 gallon, and 10 gallon drums. It is biodegradable, dissolves in water, and is non-flammable, making it safe and easy to use with proper precautions. The cleaner effectively removes paints, graffiti, printing ink, rust, oil stains, super-glue, brake dust, and other dirt from wheels, restoring their app…

6. Chemicalsglobal – Gamma Butyrolactone (GBL)

Domain: chemicalsglobal.com

Registered: 2015 (10 years)

Introduction: Gamma Butyrolactone (GBL) – Category: Industrial Raw Materials – Tags: QUOTE, Rubber Industry – Contact: +1 305-317-5577, [email protected] – Supplier and Distributor of Industrial Chemical Products in multiple countries including the USA, Venezuela, Guatemala, Peru, Colombia, Honduras, Dominican Republic, Aruba, Panama, Nicaragua, El Salvador, Belize, Costa Rica, Trinidad & Tobago, Ecuador, Chile…

7. GBL – Rim Cleaner

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, GBL – Rim Cleaner, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Gamma Butyrolactone GBL Cleaner – High Purity Solvent

Domain: plasticportal.eu

Introduction: For Sale: Gamma Butyrolactone GBL Cleaner

– Product Name: Gamma Butyrolactone GBL Cleaner

– Purity: 99% – 99.9%

– Packaging: Iron drum & plastic drum packaging

– Quantity: 1000kg/drum or 850kg/drum

– CAS Number: 96-48-0

– Contact: Seth Baron

– Email: [email protected]

– Phone: 61 2 1234 5678

– Discount: Up to 25% off

– Advertisement ID: 15330

– Date Listed: 04.01.2023

Strategic Sourcing Conclusion and Outlook for gamma-butyrolactone gbl buy online

In the evolving landscape of chemical procurement, strategic sourcing of gamma-butyrolactone (GBL) presents significant opportunities for international B2B buyers. Understanding the diverse applications of GBL—from industrial uses to specialized laboratories—enables organizations to tailor their sourcing strategies effectively. By prioritizing suppliers that offer compliance with international standards and robust documentation, buyers can mitigate risks associated with product quality and regulatory issues.

Moreover, considering logistics and shipping constraints is crucial. Buyers should engage with suppliers who can assure timely delivery and proper handling of GBL, particularly given its specific storage and transportation requirements. This proactive approach not only enhances operational efficiency but also fosters stronger supplier relationships.

As we look ahead, the demand for GBL is expected to rise, driven by its versatility across various sectors. B2B buyers should seize this moment to refine their sourcing strategies, leveraging market insights and supplier capabilities. By doing so, they can position themselves competitively in their respective markets. Embrace the potential of strategic sourcing today, and ensure your business is well-equipped to meet future demands for gamma-butyrolactone.