Choosing Your Face To Face Glider Swing For Swing Set: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for face to face glider swing for swing set

In today’s global marketplace, sourcing face-to-face glider swings for swing sets presents unique challenges for B2B buyers. With a growing demand for outdoor recreational equipment that prioritizes safety, comfort, and durability, it’s crucial for businesses to navigate this sector effectively. This comprehensive guide delves into the various types of face-to-face glider swings, their applications across residential and commercial spaces, and the factors influencing their cost.

International buyers from regions such as Africa, South America, the Middle East, and Europe, including Nigeria and Germany, will find valuable insights into supplier vetting processes, ensuring they select partners who meet their quality and compliance standards. The guide empowers decision-makers with actionable strategies for evaluating product specifications, assessing supplier reliability, and understanding market trends.

By addressing common pain points such as installation challenges, maintenance requirements, and safety standards, this resource positions buyers to make informed purchasing decisions that enhance their offerings. Whether you are looking to enrich a playground, a resort, or a community park, this guide serves as your roadmap to successfully sourcing the ideal face-to-face glider swings that align with your business objectives and customer expectations.

Understanding face to face glider swing for swing set Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Face-to-Face Glider | Molded plastic seats, powder-coated frame, adjustable rope length | Residential playgrounds, daycares | Pros: Affordable, easy to install. Cons: Limited weight capacity, residential use only. |

| Wooden Face-to-Face Glider | Crafted from decay-resistant timber, customizable design options | Public parks, community centers | Pros: Durable, aesthetic appeal. Cons: Higher cost, requires maintenance. |

| Heavy-Duty Dual Glider | Supports multiple riders, robust construction, ergonomic features | Schools, amusement parks | Pros: High weight capacity, versatile use. Cons: Bulkier, may need specialized installation. |

| Adjustable Glider Swing | Adjustable height chains, suitable for various ages | Backyards, family entertainment spaces | Pros: Flexible installation, safe for kids. Cons: Limited to two riders, installation may require additional hardware. |

| Luxury Custom Face-to-Face Glider | Premium materials, bespoke designs, additional features like armrests | High-end resorts, private estates | Pros: Unique, high-quality build. Cons: Very expensive, longer lead times for production. |

What Are the Characteristics of Traditional Face-to-Face Gliders?

Traditional face-to-face gliders typically feature molded plastic seats and powder-coated frames, designed for easy installation in residential settings. They often come with adjustable ropes, making them suitable for various heights. These swings are ideal for daycares and residential playgrounds, providing a safe and engaging experience for young children. Buyers should consider their weight limits and intended use, as these gliders are generally limited to lighter loads and are not recommended for commercial use.

How Do Wooden Face-to-Face Gliders Stand Out?

Wooden face-to-face gliders are crafted from decay-resistant timber, offering a natural aesthetic that blends well in parks and community centers. Their customizable designs allow businesses to cater to specific branding or thematic needs. While they provide durability and can withstand harsh weather conditions, they come with a higher price tag and may require periodic maintenance to preserve their appearance. Buyers should weigh the long-term investment against immediate costs when considering these options.

What Makes Heavy-Duty Dual Gliders a Good Choice?

Heavy-duty dual gliders are engineered to accommodate multiple riders, making them perfect for schools and amusement parks where high traffic is expected. These swings boast robust construction and ergonomic features that enhance user comfort. While they offer versatility and high weight capacities, their bulkier design may necessitate specialized installation. B2B buyers should assess the space available and ensure that the installation area can support the additional weight and size.

Why Choose Adjustable Glider Swings?

Adjustable glider swings are designed with chains that can be modified for different heights, making them suitable for various age groups. They are excellent for family entertainment spaces and backyards, promoting safe play for children. Although they typically seat only two riders, their safety features and ease of installation make them attractive to buyers. It is essential to confirm that the necessary mounting hardware is included, as some installations may require additional parts.

What Are the Benefits of Luxury Custom Face-to-Face Gliders?

Luxury custom face-to-face gliders are made from premium materials and can be tailored to meet specific aesthetic or functional needs. These swings often include additional features like armrests and are designed for high-end resorts or private estates. While they offer a unique and high-quality experience, they come with a significant cost and longer production times. Buyers should consider their target market and budget constraints when opting for these premium products.

Key Industrial Applications of face to face glider swing for swing set

| Industry/Sector | Specific Application of face to face glider swing for swing set | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Outdoor play areas in schools and kindergartens | Encourages social interaction and physical activity | Durability for high usage, safety standards compliance |

| Hospitality | Recreational facilities in hotels and resorts | Enhances guest experience and family-friendly offerings | Weather-resistant materials, aesthetic appeal |

| Community Parks | Public playgrounds and recreational areas | Promotes community engagement and healthy lifestyles | Compliance with local safety regulations, maintenance support |

| Residential Developments | Family-oriented housing complexes | Increases property value and appeal to families | Space for installation, safety features for children |

| Event Planning | Temporary installations for festivals and outdoor events | Creates memorable experiences and encourages participation | Quick assembly/disassembly, portability |

How is the Face-to-Face Glider Swing Used in Educational Settings?

In educational institutions, face-to-face glider swings are utilized in outdoor play areas, promoting social interaction among children. These swings encourage cooperative play, enhancing communication skills and physical activity. For international buyers from regions like Africa and South America, sourcing durable and safe swings that comply with local safety standards is essential. Additionally, schools may require customization options to match their branding or specific educational themes, ensuring that the swings are both functional and appealing.

What Benefits Do Face-to-Face Glider Swings Offer in the Hospitality Industry?

In the hospitality sector, face-to-face glider swings are installed in outdoor recreational facilities of hotels and resorts, providing families with engaging activities. These swings enhance the guest experience by offering a unique, relaxing environment for parents and children to bond. International buyers from the Middle East and Europe should consider sourcing weather-resistant materials to withstand diverse climates, as well as aesthetic designs that align with the resort’s overall theme. Ensuring that the swings are easy to maintain will also be a key consideration.

How Do Community Parks Benefit from Face-to-Face Glider Swings?

Community parks utilize face-to-face glider swings to foster social interaction and physical activity among residents. These swings serve as a focal point for family gatherings and community events, promoting a healthy lifestyle. For B2B buyers in Europe, compliance with local safety regulations is crucial when sourcing these swings. Additionally, parks may require ongoing maintenance support from suppliers to ensure the equipment remains safe and functional over time, enhancing community satisfaction.

Why Are Face-to-Face Glider Swings Important for Residential Developments?

In residential developments, face-to-face glider swings are a valuable addition to family-oriented housing complexes. They increase property value and attract families looking for safe, engaging outdoor spaces for their children. Buyers from regions like Nigeria should focus on swings that offer safety features, such as non-pinch mechanisms and sturdy construction, to ensure they meet the needs of families. Additionally, sufficient space for installation and compliance with local building codes are critical factors for buyers in this sector.

How Can Event Planners Incorporate Face-to-Face Glider Swings into Their Offerings?

Event planners can utilize face-to-face glider swings for temporary installations at festivals and outdoor events, creating engaging spaces that encourage participation. These swings enhance the overall experience, making events more memorable for attendees. For international buyers, sourcing swings that are easy to assemble and disassemble is vital for efficient logistics. Portability and the ability to withstand various weather conditions will also be key considerations to ensure successful event execution.

3 Common User Pain Points for ‘face to face glider swing for swing set’ & Their Solutions

Scenario 1: Sourcing Durable Materials for Long-lasting Use

The Problem:

B2B buyers often face difficulties in sourcing high-quality materials for face-to-face glider swings that can withstand varying weather conditions and heavy usage. For instance, purchasing swings made from subpar materials can lead to rapid deterioration, resulting in safety hazards and increased replacement costs. This concern is particularly pronounced in regions with extreme weather variations, such as the Middle East or Africa, where swings must resist both intense heat and occasional rainfall. Buyers need assurance that the products they source will maintain their integrity and appearance over time.

The Solution:

To mitigate these concerns, B2B buyers should focus on sourcing swings made from durable, weather-resistant materials such as powder-coated steel and high-grade, UV-resistant plastics. Engaging with manufacturers that specialize in outdoor recreational equipment is crucial. It’s beneficial to request samples and conduct material tests to evaluate their performance under local environmental conditions. Additionally, buyers should consider suppliers who provide warranties or guarantees on their products, as this reflects confidence in their durability. Building long-term relationships with reputable manufacturers can ensure consistent quality and access to innovations in material technology, resulting in swings that not only last longer but also reduce the frequency of replacement.

Scenario 2: Assembly Complexity and Installation Challenges

The Problem:

Many B2B buyers encounter significant challenges during the assembly and installation of face-to-face glider swings. The complexity of assembly instructions, coupled with the need for specific mounting hardware, can lead to delays and increased labor costs. This issue is particularly prominent in playground installations where time is critical, and any setbacks can impact project timelines and budgets. Additionally, inadequate installation can compromise safety, creating liability concerns for businesses.

The Solution:

To address assembly and installation challenges, B2B buyers should prioritize products that come with comprehensive, easy-to-understand assembly instructions and all necessary mounting hardware included in the purchase. Seeking vendors who offer professional installation services or clear instructional videos can also facilitate a smoother setup process. It’s beneficial to train staff on basic assembly techniques or collaborate with local contractors familiar with swing set installations. Investing in tools and training can streamline the installation process, ensuring that swings are securely and properly mounted, thereby enhancing safety and project efficiency.

Scenario 3: Safety Compliance and Child Weight Limitations

The Problem:

Safety is a paramount concern for B2B buyers when selecting face-to-face glider swings for public parks or playgrounds. Many products have specific weight limits that must be adhered to, yet buyers often find themselves questioning the accuracy of these ratings or struggling to find swings that accommodate a diverse range of users. This challenge can be particularly acute in regions where children’s sizes and weights vary widely, leading to potential safety risks if swings are not used within their intended specifications.

The Solution:

To ensure compliance with safety standards, B2B buyers should thoroughly research and select swings that meet or exceed relevant safety regulations, such as those established by local or international playground safety organizations. When sourcing glider swings, buyers should look for detailed specifications regarding weight limits and age appropriateness. Engaging with manufacturers that provide thorough documentation and testing results can offer additional peace of mind. Furthermore, implementing a regular inspection and maintenance schedule for all playground equipment can help identify any wear or potential safety issues early on, ensuring that all swings remain safe and compliant over time.

Strategic Material Selection Guide for face to face glider swing for swing set

What Are the Key Materials for Face-to-Face Glider Swings?

When selecting materials for face-to-face glider swings, several options are commonly used, each with unique properties and implications for performance, durability, and cost. Understanding these materials is crucial for B2B buyers, especially those operating in diverse international markets such as Africa, South America, the Middle East, and Europe.

How Does Steel Perform in Glider Swing Applications?

Steel is a popular choice for the structural framework of glider swings due to its high strength and durability. It typically has excellent temperature resistance and can withstand significant loads, making it suitable for both residential and commercial applications. Steel is also resistant to deformation under pressure, ensuring long-term stability.

Pros: Steel’s high tensile strength allows it to support heavy weights, making it ideal for glider swings designed for multiple users. It can be treated with protective coatings to enhance corrosion resistance, which is vital in humid or coastal environments.

Cons: The primary drawback is its susceptibility to rust if not properly coated or maintained. Additionally, steel can be heavier than other materials, complicating installation and transportation.

Impact on Application: Steel’s strength makes it compatible with various swing designs, but buyers must ensure compliance with local safety standards, such as ASTM in the U.S. or DIN in Germany.

What Role Does Plastic Play in Glider Swing Design?

Plastic, particularly high-density polyethylene (HDPE), is frequently used for seats and footrests in glider swings. This material is lightweight, resistant to UV radiation, and does not rust or corrode, making it suitable for outdoor applications.

Pros: Plastic is easy to mold into various shapes, allowing for ergonomic designs that enhance user comfort. It is also cost-effective, reducing overall manufacturing expenses.

Cons: While durable, plastic can become brittle over time, especially in extreme temperature conditions. It may not support as much weight as metal counterparts, which can limit its application in larger swings.

Impact on Application: Plastic components must meet safety and durability standards relevant to the target market, such as EN 1176 in Europe, ensuring they are safe for children’s use.

How Does Wood Compare as a Material for Glider Swings?

Wood, particularly treated hardwood like redwood or cedar, offers a natural aesthetic and good durability. It has excellent resistance to environmental factors when properly treated, making it suitable for outdoor use.

Pros: Wood provides a warm, inviting look and is often preferred for residential applications. It can be sustainably sourced, appealing to environmentally conscious buyers.

Cons: Wood requires regular maintenance to prevent decay and insect damage. It can also be more expensive than synthetic materials, depending on the type of wood used.

Impact on Application: Buyers must consider local regulations regarding wood sourcing and treatment, especially in regions with strict environmental laws. Compliance with standards like JIS in Japan or EN standards in Europe is also crucial.

What Are the Benefits of Composite Materials in Glider Swings?

Composite materials, which combine plastic and wood fibers, are increasingly used in glider swings. They offer the benefits of both materials, providing durability and a natural appearance.

Pros: Composites are resistant to moisture, UV rays, and insects, making them low-maintenance. They can be manufactured to mimic the appearance of wood while offering greater longevity.

Cons: The initial cost of composites can be higher than traditional materials. Additionally, they may require specific manufacturing processes that can complicate production.

Impact on Application: Composites must meet safety and performance standards relevant to their application, such as ASTM for playground equipment. Buyers should be aware of the certifications required in their respective markets.

Summary of Material Selection for Face-to-Face Glider Swings

| Material | Typical Use Case for face to face glider swing for swing set | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural framework for durability and strength | High tensile strength and load-bearing capacity | Susceptible to rust without proper coating | Medium |

| Plastic | Seats and footrests for lightweight and UV resistance | Cost-effective and easy to mold | Can become brittle in extreme temperatures | Low |

| Wood | Aesthetic components for a natural look | Sustainable and visually appealing | Requires maintenance to prevent decay | High |

| Composite | Durable, low-maintenance seating solutions | Resistant to moisture and insects | Higher initial cost and complex manufacturing | Medium |

This strategic material selection guide provides a comprehensive overview for B2B buyers, helping them make informed decisions that align with their operational needs and market requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for face to face glider swing for swing set

What Are the Main Stages in the Manufacturing Process of Face-to-Face Glider Swings?

The manufacturing of face-to-face glider swings involves several critical stages, each designed to ensure the highest quality and durability of the final product.

Material Preparation

The first stage begins with material preparation, which typically involves sourcing high-quality components. Common materials include weather-resistant wood, such as redwood or cedar, and robust metal parts like powder-coated steel for frames. Buyers should be aware that the choice of materials significantly impacts both the swing’s durability and aesthetic appeal. Suppliers often perform rigorous tests on raw materials to check for strength, moisture content, and resistance to decay.

Forming

In the forming stage, the prepared materials are shaped into the necessary components. This can include cutting wood to specified dimensions, bending metal into the appropriate shapes, and molding plastic for seats and footrests. Advanced machinery, such as CNC routers and hydraulic presses, are commonly used to ensure precision. For glider swings, it’s crucial that each piece fits together seamlessly to maintain safety and performance standards.

Assembly

Once components are formed, they move into the assembly phase. This is where the swing’s structure is put together, often requiring skilled labor to ensure that all parts are correctly aligned and securely fastened. The assembly process may involve using specialized fasteners and techniques to enhance stability, such as employing a four-point attachment system for gliders. Quality control checkpoints are integrated throughout this phase to catch any issues before proceeding.

Finishing

The final stage is finishing, which can include sanding, painting, and applying protective coatings. For face-to-face glider swings, a powder coating is often applied to metal parts to prevent rust and fading from UV exposure. Wood components may receive a sealant or stain to enhance longevity and protect against the elements. This finishing touch not only improves appearance but also significantly contributes to the swing’s overall lifespan.

How is Quality Assurance Implemented in Manufacturing Face-to-Face Glider Swings?

Quality assurance is crucial in ensuring that face-to-face glider swings meet international safety and quality standards. Manufacturers typically adhere to several quality control (QC) processes that are structured around various checkpoints throughout the production stages.

What International Standards Should Buyers Look For?

International standards such as ISO 9001 are essential indicators of a manufacturer’s commitment to quality management systems. This certification demonstrates that the manufacturer has established effective processes to ensure continuous improvement and customer satisfaction. Additionally, compliance with European standards like CE marking or American standards like ASTM can indicate that the swings meet safety and performance criteria for specific markets.

Which Quality Control Checkpoints are Essential?

Quality control checkpoints are essential for maintaining product integrity. These include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): During manufacturing, periodic checks are performed to ensure that each step adheres to quality standards.

- Final Quality Control (FQC): Before products are packaged and shipped, they undergo a thorough inspection to confirm they meet all safety and quality standards.

Common testing methods used in QC include load testing for weight capacity, durability tests for weather resistance, and inspections for any defects in finishing.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is essential for ensuring product reliability.

What Steps Can Buyers Take?

-

Supplier Audits: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. This can involve on-site inspections to observe manufacturing practices and assess compliance with international standards.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality reports, including results from any tests conducted during the manufacturing process. This transparency can help establish trust and ensure that the supplier adheres to their stated quality standards.

-

Third-Party Inspections: Engaging third-party inspection services can further validate the quality of the swings. These services can provide unbiased evaluations and certifications that may be critical for securing contracts, especially in regulated markets.

What Nuances Should International B2B Buyers Consider in Quality Control?

Navigating the complexities of international trade introduces unique challenges for buyers. Understanding the regional regulations and standards is essential, as compliance can vary widely between countries. For instance, glider swings sold in the European market must meet stringent CE standards, while products in the U.S. may need to comply with ASTM guidelines.

Additionally, cultural differences can influence manufacturing practices. For example, suppliers in regions with less stringent regulations may not prioritize the same level of QC as those in more regulated markets. Therefore, buyers should conduct thorough due diligence, including researching local manufacturing norms and practices.

Conclusion: Ensuring Quality in Face-to-Face Glider Swings

In summary, the manufacturing processes and quality assurance practices for face-to-face glider swings are integral to delivering a safe and enjoyable product. By understanding the stages of production, the importance of quality control standards, and how to verify supplier practices, B2B buyers can make informed decisions that enhance their product offerings and ensure customer satisfaction. As the global market continues to evolve, staying informed about manufacturing and quality assurance trends will be essential for maintaining a competitive edge.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘face to face glider swing for swing set’

Introduction

Sourcing a face-to-face glider swing for swing sets requires careful consideration of various factors to ensure quality, safety, and value for your investment. This checklist serves as a practical guide for B2B buyers, helping you navigate the procurement process effectively and make informed decisions that meet your operational needs.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the glider swing, including dimensions, weight capacity, and material requirements. Understanding the intended use—whether for residential or commercial applications—will dictate the durability and safety standards needed. For instance, residential models may not withstand heavy usage in public parks, so it’s crucial to distinguish these needs early on.

Step 2: Research Market Trends and Regulations

Stay informed about industry trends and regulations that could affect your purchase. Different regions may have specific safety standards for playground equipment, which could impact your sourcing decisions. Look for certifications such as ASTM or EN standards that ensure compliance with safety regulations, particularly in the regions you are targeting like Africa, South America, and Europe.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough due diligence. Request company profiles, case studies, and references from buyers in similar markets to assess their credibility. Pay attention to their production capabilities, lead times, and customer service quality, as these can significantly impact your procurement experience.

Step 4: Assess Material Quality and Durability

Ensure that the materials used in the glider swing are high-quality and suitable for outdoor use. Look for features like powder-coated frames, UV-resistant plastics, and decay-resistant woods that enhance longevity. High-quality materials will not only improve the swing’s lifespan but also reduce maintenance costs over time.

Step 5: Request Samples or Demonstrations

Where possible, request samples or demonstrations of the glider swings. This step allows you to assess the product firsthand, ensuring it meets your quality standards and functional requirements. Pay attention to the comfort and safety features during testing, as these will be crucial for user satisfaction.

Step 6: Verify Supplier Certifications

Check that your potential suppliers hold necessary certifications and compliance documentation. Certifications can provide assurance regarding the quality and safety of the products. This is particularly important in international transactions where standards may vary significantly between countries.

Step 7: Negotiate Terms and Conditions

Once you have identified a suitable supplier, enter into negotiations regarding pricing, payment terms, and delivery schedules. Establish clear terms that protect both parties, including warranties and return policies. A well-negotiated contract will help mitigate risks and ensure a smooth transaction process.

By following this checklist, B2B buyers can streamline their sourcing process for face-to-face glider swings, ensuring they select the right products that meet their specific needs and adhere to industry standards.

Comprehensive Cost and Pricing Analysis for face to face glider swing for swing set Sourcing

What Are the Key Cost Components in Sourcing Face to Face Glider Swings?

When sourcing face to face glider swings, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects pricing. High-quality, weather-resistant materials such as powder-coated steel and durable plastic can elevate costs but offer better longevity and safety. For premium offerings like redwood, expect higher prices due to the material’s rarity and durability.

-

Labor: Labor costs will vary based on the region of production. Countries with higher wages may lead to increased manufacturing costs. Conversely, sourcing from regions with lower labor costs might provide savings, but it’s essential to ensure that quality isn’t compromised.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can minimize overhead costs, influencing the final pricing.

-

Tooling: The initial investment in tooling can be substantial, especially for custom designs or unique specifications. Buyers should factor in these costs when assessing the overall pricing structure.

-

Quality Control (QC): Implementing strict quality control measures is crucial for ensuring product safety and compliance with international standards. While this adds to the cost, it can prevent future liabilities and enhance customer satisfaction.

-

Logistics: Shipping and handling costs vary widely based on distance, shipping method, and weight. International buyers, particularly from regions like Africa and South America, should consider logistics as a significant cost influencer.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding industry standards for margins can help buyers negotiate better deals.

How Do Price Influencers Affect the Cost of Glider Swings?

Several factors influence the pricing of face to face glider swings:

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly affect pricing. Bulk orders often come with discounts, making it economically advantageous for buyers to purchase larger quantities.

-

Specifications and Customization: Custom features, such as unique colors, sizes, or additional safety features, can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., safety standards) can lead to higher prices. Buyers should assess whether the added cost aligns with their quality expectations and target market.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their products due to their proven quality and service levels.

-

Incoterms: Understanding Incoterms is essential for international transactions, as they dictate responsibilities for shipping, insurance, and tariffs. This knowledge can help buyers calculate the total cost of ownership accurately.

What Are Essential Buyer Tips for Cost-Efficiency in Glider Swing Sourcing?

To achieve cost-efficiency when sourcing face to face glider swings, consider the following tips:

-

Negotiation Strategies: Engage in negotiations with suppliers to explore volume discounts or favorable payment terms. Building a relationship with suppliers can lead to better deals in the long run.

-

Evaluating Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs, including maintenance, durability, and potential replacements. Investing in higher-quality swings may reduce overall TCO.

-

Understanding Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local market dynamics that can affect pricing. Collaborating with local distributors can provide insights into market trends and pricing strategies.

-

Conducting Supplier Audits: Regularly reviewing supplier performance and product quality can help maintain standards and ensure ongoing value for money.

By carefully analyzing these cost components and price influencers, international B2B buyers can make informed decisions that align with their business goals and customer expectations.

Alternatives Analysis: Comparing face to face glider swing for swing set With Other Solutions

Introduction to Alternatives for Face to Face Glider Swings

When it comes to outdoor recreational equipment, particularly for children, the face-to-face glider swing offers a unique blend of interaction and fun. However, several alternative solutions cater to similar needs, each with its own benefits and drawbacks. Understanding these alternatives can help B2B buyers make informed decisions that align with their specific requirements, whether they are sourcing for playgrounds, schools, or recreational facilities.

Comparison Table of Face to Face Glider Swing and Alternatives

| Comparison Aspect | Face To Face Glider Swing For Swing Set | Tandem Swing Seat Glider | Dual Ride Glider with Handlebar |

|---|---|---|---|

| Performance | Smooth gliding motion, limited height | Good for two, secure with non-skid surface | Comfortable with handlebars, supports weight |

| Cost | Moderate (varies by brand) | Affordable, typically under $130 | Slightly higher, around $154 |

| Ease of Implementation | Requires assembly, specific mounting needs | Easy assembly, includes hardware | Simple installation with hangers |

| Maintenance | Minimal, check for wear on ropes | Low, durable materials resist wear | Regular checks for wear on chains |

| Best Use Case | Ideal for social interaction | Perfect for casual backyard use | Suitable for both kids and adults, adds versatility |

Detailed Breakdown of Alternatives

Tandem Swing Seat Glider

The Tandem Swing Seat Glider is an excellent alternative for those looking for a simple, cost-effective solution. It features a durable plastic seat and half-coated steel chains, designed to withstand outdoor elements. The glider provides a secure, non-skid surface, making it a safe choice for children. However, it is limited to a two-person capacity and may require additional mounting hardware, which could complicate the initial setup for some buyers.

Dual Ride Glider with Handlebar

This glider offers a robust design with ergonomic handlebars and footrests, making it safe and comfortable for users of all ages. With a weight capacity of up to 1,000 lbs, it can accommodate both children and adults, providing versatility for various settings. The installation process is straightforward, as it comes with necessary mounting hangers and chains. However, its higher price point compared to simpler models may be a consideration for budget-conscious buyers.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right swing solution involves evaluating specific needs, such as target audience, budget, and installation capability. The face-to-face glider swing excels in promoting social interaction and engagement among children, making it ideal for playgrounds and community spaces. Alternatively, the Tandem Swing Seat Glider offers a more economical choice for casual settings, while the Dual Ride Glider with Handlebar caters to a wider age range and heavier usage scenarios. By assessing these factors, B2B buyers can determine which option aligns best with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for face to face glider swing for swing set

What Are the Key Technical Properties of Face-to-Face Glider Swings?

1. Material Composition

The primary materials used in face-to-face glider swings are typically high-grade, weather-resistant plastics, stainless steel, and treated wood (like redwood). The choice of materials affects durability, safety, and maintenance. For instance, powder-coated frames offer corrosion resistance, making them ideal for diverse climates, especially in regions with high humidity or intense sunlight. Understanding the material properties is crucial for B2B buyers as it influences the lifespan and reliability of the swings.

2. Weight Capacity

Weight capacity is a critical specification that determines how many users can safely use the swing at one time. Most face-to-face glider swings are designed to accommodate two children or a combined weight limit of around 200-300 lbs. This specification ensures that the product meets safety standards and is suitable for the target market, whether residential or commercial playgrounds. Buyers need to ensure that the swings meet local regulations regarding weight limits.

3. Dimensions and Space Requirements

The dimensions of the swing set, including the seat size and overall swing height, are vital for installation. Common dimensions for face-to-face gliders range from 24 inches in height to 38 inches in width. Additionally, the space required for safe installation must be considered. For B2B buyers, understanding the spatial requirements helps in planning installations and ensures compliance with safety regulations.

4. Safety Features

Safety features like non-skid surfaces, padded edges, and secure attachment points are essential for minimizing risks during use. Many glider swings include adjustable ropes or chains that enhance safety by allowing customization based on installation height. Buyers must prioritize swings with robust safety features to mitigate liability and ensure user safety in playground settings.

5. Warranty and Durability Standards

A warranty period typically indicates the expected durability of the product. Many manufacturers offer warranties ranging from one to five years, reflecting the confidence in their product’s longevity. This aspect is significant for B2B buyers as it affects long-term cost considerations and maintenance planning.

What Are Common Trade Terms Related to Face-to-Face Glider Swings?

1. OEM (Original Equipment Manufacturer)

In the context of glider swings, an OEM refers to a company that manufactures the swings or their components based on the specifications provided by another company. Understanding OEM relationships is crucial for B2B buyers who are sourcing products, as it impacts quality, pricing, and delivery schedules.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For glider swings, this may vary based on the supplier’s capacity. Buyers need to be aware of MOQs to manage inventory costs effectively and to negotiate favorable terms with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing information from suppliers for specific products. B2B buyers should utilize RFQs to compare prices, terms, and delivery timelines for face-to-face glider swings, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade regarding shipping, insurance, and tariffs. Familiarity with these terms is essential for B2B buyers to understand the logistics and financial implications of purchasing glider swings from international suppliers.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. In the context of glider swings, this can vary based on production schedules and shipping distances. Buyers should consider lead times in their project planning to ensure timely delivery and installation of swings in playgrounds or parks.

By understanding these critical technical properties and industry terms, B2B buyers can make informed decisions that align with their operational needs and safety standards, ultimately enhancing their product offerings in the market.

Navigating Market Dynamics and Sourcing Trends in the face to face glider swing for swing set Sector

What are the Current Market Dynamics and Key Trends in the Face to Face Glider Swing Sector?

The face to face glider swing market is experiencing a notable transformation driven by several global factors. One of the primary drivers is the increasing demand for safe, engaging outdoor play equipment, particularly in residential and commercial settings such as parks and schools. As urbanization continues to rise in regions like Africa and South America, there is a growing emphasis on creating recreational spaces that encourage family interaction and physical activity.

Emerging B2B technology trends are also influencing sourcing strategies. The integration of e-commerce platforms is making it easier for international buyers to access a broader range of glider swing options, ensuring competitive pricing and increased transparency in the supply chain. Moreover, manufacturers are leveraging data analytics to better understand consumer preferences and optimize inventory management, which is particularly advantageous for buyers looking to streamline their procurement processes.

Another significant trend is the customization of products to cater to diverse cultural and regional preferences, which is essential for international buyers. For instance, glider swings made from locally sourced materials resonate better in markets like Germany and Nigeria, where sustainability and local craftsmanship are valued. The ongoing development of innovative designs that enhance user experience, such as adjustable seating and safety features, further exemplifies the market’s adaptability to consumer demands.

How Does Sustainability and Ethical Sourcing Impact the Face to Face Glider Swing Market?

Sustainability is increasingly becoming a focal point in the face to face glider swing sector. The environmental impact of sourcing materials, particularly wood, has prompted manufacturers to adopt ethical supply chain practices. International buyers are now more discerning, seeking products that come from certified sustainable sources, such as those with Forest Stewardship Council (FSC) certification. This not only helps in reducing deforestation but also supports responsible forestry practices.

The use of eco-friendly materials, such as recycled plastics and sustainably harvested wood, is gaining traction. Buyers are encouraged to inquire about the environmental certifications of products and the sustainability practices of suppliers. These considerations are essential for businesses aiming to align their purchasing decisions with corporate social responsibility goals and consumer expectations for greener products.

Additionally, the trend towards ethical sourcing encompasses fair labor practices and transparency in production processes. Buyers should prioritize suppliers who can demonstrate ethical practices, as this enhances brand reputation and meets the growing consumer demand for accountability.

How has the Face to Face Glider Swing Evolved Over Time?

The evolution of the face to face glider swing can be traced back to the broader development of swing sets in playgrounds. Initially designed for simple enjoyment, these swings have evolved into complex structures that emphasize safety, durability, and social interaction. Early models were often made from basic materials, but advancements in technology and materials science have led to the creation of gliders that are not only more aesthetically pleasing but also provide enhanced safety features.

Today, modern glider swings are constructed with advanced composite materials that resist weathering and fading, ensuring longevity and reduced maintenance costs. The introduction of ergonomic designs has further improved user comfort, catering to a wider age range. This evolution reflects a growing understanding of the importance of outdoor play in child development, with manufacturers continuously innovating to meet the needs of families and communities worldwide. As the market continues to grow, future developments are likely to focus on integrating smart technology, enhancing user engagement, and further promoting sustainable practices.

Frequently Asked Questions (FAQs) for B2B Buyers of face to face glider swing for swing set

-

How do I ensure the quality of face-to-face glider swings when sourcing from international suppliers?

To ensure quality, start by vetting suppliers through trade platforms and industry directories. Request product samples to assess material durability and craftsmanship. Look for certifications that guarantee compliance with safety standards, such as ASTM or EN standards, which are crucial for children’s playground equipment. Additionally, consider visiting the manufacturing facility if possible or hiring third-party inspection services to evaluate production processes and quality control measures. -

What are the key features to consider when selecting a face-to-face glider swing for commercial use?

When choosing a glider swing for commercial settings, prioritize durability, safety, and capacity. Look for materials resistant to weather conditions, such as powder-coated steel or decay-resistant wood. Ensure the swing can accommodate the weight of multiple users, ideally with a limit above 200 pounds. Safety features, like non-skid surfaces and proper attachment points, are essential. Finally, consider ease of maintenance and assembly, as this will affect long-term usability in a commercial environment. -

What customization options are typically available for face-to-face glider swings?

Many manufacturers offer customization options for face-to-face glider swings, including size, color, materials, and additional features such as armrests or built-in footrests. Some suppliers may also allow custom branding, enabling you to add your logo to the swing. Inquire about lead times and any minimum order quantities (MOQs) associated with custom designs, as these factors can impact your purchasing decisions. -

What are the common payment terms for purchasing face-to-face glider swings from international suppliers?

Payment terms can vary widely by supplier and region. Common arrangements include upfront payments, such as a deposit followed by the balance upon shipment, or net payment terms, typically ranging from 30 to 90 days post-delivery. It’s crucial to negotiate terms that align with your cash flow and risk tolerance. Additionally, consider using secure payment methods, such as letters of credit or escrow services, especially for larger transactions to mitigate risks. -

How do I determine the minimum order quantity (MOQ) for face-to-face glider swings?

MOQs are influenced by factors such as production costs, materials, and supplier policies. Most manufacturers will specify their MOQ in product catalogs or during initial discussions. If the MOQ seems high for your needs, consider negotiating a lower quantity, especially if you’re a new customer or if you can commit to future orders. Alternatively, you may collaborate with other businesses to pool orders and meet MOQ requirements. -

What logistics considerations should I be aware of when importing glider swings?

When importing glider swings, consider shipping costs, customs duties, and delivery timelines. Work with a freight forwarder to navigate international shipping regulations, ensuring that all documentation is in order to avoid delays. Assess the supplier’s shipping capabilities and inquire about their experience with your region’s logistics. It’s also wise to discuss insurance options for your shipment to protect against damage or loss during transit. -

How can I assess the reputation and reliability of a supplier for glider swings?

Research potential suppliers by checking online reviews, testimonials, and case studies to gauge their reliability. Utilize platforms like Alibaba or Global Sources, which provide ratings and feedback from previous buyers. Additionally, ask for references and contact previous clients to inquire about their experiences. Engaging in direct communication with the supplier can also provide insights into their responsiveness and professionalism. -

What safety standards should face-to-face glider swings meet for international markets?

Safety standards can vary by region, but commonly accepted guidelines include ASTM F1148 for swings in the United States and EN 1176 for playground equipment in Europe. Ensure that your supplier’s products comply with these or other relevant standards in your target market. Compliance not only ensures the safety of users but also reduces liability risks for your business and enhances the product’s marketability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Face To Face Glider Swing For Swing Set Manufacturers & Suppliers List

1. Swingset Stuff – Face to Face Glider

Domain: swingsetstuff.com

Registered: 2005 (20 years)

Introduction: {“name”: “Face to Face Glider”, “sku”: “SSS-0379-P”, “upc”: “813084017082”, “price”: “$113.30”, “weight”: “17.63 LBS”, “shipping”: “Calculated at Checkout”, “current_stock”: “Available”, “description”: “Face to Face Glider with powder coated frame, molded plastic seat and footrests, suitable for 2 children sitting face to face up to 105 pounds. Includes approximately 6 foot long rope with loop cli…

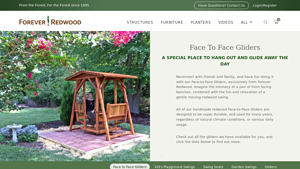

2. Forever Redwood – Face to Face Gliders

Domain: foreverredwood.com

Registered: 2005 (20 years)

Introduction: Face to Face Gliders from Forever Redwood are designed for comfort and durability, allowing users to reconnect with friends and family while enjoying a gentle glide. These handmade redwood gliders are built to withstand various climate conditions and heavy usage. Available styles include Dustin’s Face-to-Face Gliders, Jean’s Ultimate Swing Sets, St. Anthony’s Face-to-Face Gliders, and Santa Rosa F…

3. Pinterest – Face to Face Glider Swing

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Face to Face Glider Swing for Two Kids, Gondola glider swing designed for two children, made from fade resistant molded plastic seats, powder coated green frame.

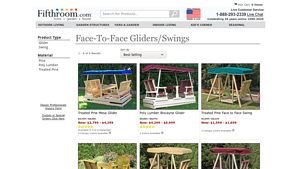

4. Fifth Room – Treated Pine Mesa Glider

Domain: fifthroom.com

Registered: 2005 (20 years)

Introduction: Product Type: Face-To-Face Gliders/Swings

Materials: Pine, Poly Lumber, Treated Pine

Key Products:

1. Treated Pine Mesa Glider – Price: $2,799 – $4,299 (Now: $2,799 – $4,299), Available in 4 or 6 Passenger, 3 Canopy Colors Available

2. Poly Lumber Biscayne Glider – Price: $4,299 – $6,999 (Now: $4,299 – $6,999), 2 Colors Available

3. Treated Pine Face to Face Swing – Price: $1,599 – $1,699 (Now: $1…

5. Foter – Glider Swing Set

Domain: foter.com

Registered: 2006 (19 years)

Introduction: Glider Swing Set – Designer Picks & 91 Real Photos. Glider swings are a safe choice for children, preventing finger pinching and limiting swing height for added safety. The collection includes various models such as:

1. **Otteridge 3 Person Outdoor Patio Swing** – $249.99

– Seats: 3

– Frame: Powder-coated steel

– Weight Capacity: 750 lbs

– Features: Breathable seating, adjustable…

6. Target – Face to Face Swing Sets

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Face to Face Swing Sets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for face to face glider swing for swing set

In evaluating the strategic sourcing for face-to-face glider swings, international buyers must consider the durability, safety, and design of these products to meet diverse consumer preferences across regions like Africa, South America, the Middle East, and Europe. The emphasis on high-quality materials, such as powder-coated frames and decay-resistant woods, ensures longevity even in challenging climates. Additionally, the ergonomic designs that promote safety and comfort make these swings an attractive option for families seeking outdoor recreational activities.

Strategic sourcing not only facilitates cost-effective procurement but also fosters partnerships with reputable manufacturers known for their craftsmanship and innovation. This approach enhances supply chain efficiency, allowing businesses to respond promptly to market demands while maintaining product quality.

Looking ahead, the growing trend of outdoor family activities presents significant opportunities for B2B buyers. Engaging with suppliers who offer customizable options can help businesses differentiate their offerings in the competitive landscape. Now is the time to explore partnerships that align with your market needs, ensuring that your product lineup includes appealing and safe glider swings that resonate with consumers’ desires for shared experiences.