Choosing Your Camo Sheet Metal: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for camo sheet metal

In the dynamic landscape of global construction and design, sourcing high-quality camo sheet metal presents a unique challenge for international B2B buyers. Whether you’re in the burgeoning markets of Africa, the innovative sectors of South America, or the established industries of Europe and the Middle East, understanding the nuances of camo sheet metal is critical. This guide offers a comprehensive exploration of various types, applications, and sourcing strategies for camo sheet metal, including insights into product specifications, supplier vetting, and cost considerations.

Camo sheet metal is not merely a decorative choice; it serves a multitude of functional purposes across industries, from agricultural applications to architectural designs. By providing in-depth information on the latest camouflage patterns, material durability, and innovative manufacturing techniques, this guide equips buyers with the knowledge necessary to make informed purchasing decisions.

Additionally, we delve into the importance of establishing reliable supplier relationships and the factors that can influence pricing and availability in different regions. With this resource at your disposal, B2B buyers can confidently navigate the complexities of sourcing camo sheet metal, ensuring that they select products that not only meet their aesthetic needs but also adhere to stringent quality and performance standards. Embrace the opportunity to enhance your projects with camo sheet metal that stands out in both style and functionality.

Understanding camo sheet metal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Realtree Camo Steel Panels | High-resolution digitally printed designs, durable AZ-50 Galvalume steel | Roofing, siding, hunting blinds | Pros: Aesthetic appeal, long-lasting durability; Cons: Higher cost compared to standard panels. |

| Hardy Rib Camo Panels | Available in various lengths, ribbed design for enhanced strength | Agricultural buildings, residential roofing | Pros: Cost-effective, easy installation; Cons: Limited design variations. |

| Pro-Rib Camouflage Steel Panels | Custom lengths, lightweight, available in multiple colors | Pole barns, storage sheds | Pros: Lightweight, customizable; Cons: May require additional support for larger structures. |

| Digital Camo Coil | Flexible application, high-definition printing, various patterns | Indoor and outdoor decor, animal feeders | Pros: Versatile use, visually appealing; Cons: Requires specialized processing equipment. |

| Textured Camo Panels | Textured finish for added grip, available in various gauges | Industrial applications, aesthetic projects | Pros: Improved slip resistance, diverse applications; Cons: Texture may increase cleaning needs. |

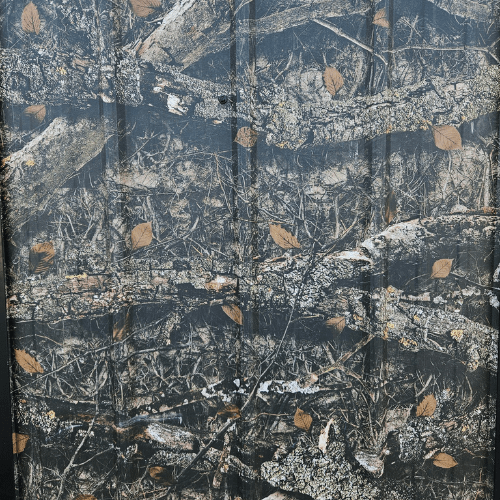

What Are the Characteristics of Realtree Camo Steel Panels?

Realtree camo steel panels feature high-resolution digitally printed designs that provide both aesthetic appeal and functionality. Made from durable AZ-50 Galvalume steel, these panels are ideal for roofing and siding applications, particularly in outdoor settings such as hunting blinds. B2B buyers should consider the long-lasting durability and unique designs, though the cost may be higher than standard options.

How Do Hardy Rib Camo Panels Differ from Other Types?

Hardy rib camo panels are known for their ribbed design, which enhances structural strength while offering an economical solution for agricultural and residential roofing. Available in various lengths, these panels are easy to install, making them a popular choice for contractors. While they are cost-effective, buyers may find fewer design variations compared to other camo options.

Why Are Pro-Rib Camouflage Steel Panels Suitable for Specific Applications?

Pro-Rib camouflage steel panels are lightweight and customizable, making them well-suited for applications like pole barns and storage sheds. Their availability in custom lengths allows for tailored solutions to meet specific project requirements. However, due to their lightweight nature, buyers must consider additional structural support for larger installations.

What Makes Digital Camo Coil a Versatile Option?

Digital camo coil offers flexibility in application, featuring high-definition printing that allows for a range of camouflage patterns. This type is suitable for both indoor and outdoor uses, including decor and animal feeders. While the visual appeal and versatility are significant advantages, B2B buyers should note that specialized processing equipment may be necessary for installation.

What Are the Advantages of Textured Camo Panels?

Textured camo panels provide an added grip, making them ideal for industrial applications and aesthetic projects where slip resistance is essential. Available in various gauges, these panels cater to diverse applications. However, buyers should consider that the texture may require more frequent cleaning and maintenance compared to smooth finishes.

Key Industrial Applications of camo sheet metal

| Industry/Sector | Specific Application of camo sheet metal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Roofing and siding for residential and commercial buildings | Aesthetic appeal and functional camouflage for rural settings | Gauge specifications, durability against weather, and local regulations |

| Agriculture | Animal feeders and shelters | Enhances blending with natural surroundings, reducing stress on livestock | Corrosion resistance, size customization, and ease of installation |

| Outdoor Recreation & Hunting | Hunting blinds and outdoor equipment | Provides concealment and durability in harsh environments | Weight, portability, and weather resistance |

| Manufacturing & Fabrication | Custom metal products for consumer goods | Unique branding opportunities and product differentiation | Availability of custom designs, print quality, and lead times |

| Landscaping & Garden Design | Decorative elements like trellises and fencing | Adds visual interest while maintaining a natural look | Material thickness, finish quality, and compatibility with landscaping materials |

Camo sheet metal serves a significant role in the construction industry, particularly for roofing and siding. Its aesthetic appeal enhances the visual integration of buildings into rural landscapes, while its robust properties ensure longevity and weather resistance. Buyers must consider gauge specifications and local building codes, especially in regions with unique environmental challenges like Africa and South America, where durability is paramount.

In agriculture, camo sheet metal is increasingly used for animal feeders and shelters. Its camouflage properties help reduce livestock stress by blending structures into the natural environment, promoting a more serene atmosphere. Buyers should prioritize corrosion resistance and the ability to customize sizes to fit specific agricultural needs, particularly in humid or arid climates common in the Middle East and Africa.

For outdoor recreation and hunting, camo sheet metal is a preferred choice for hunting blinds and equipment. Its ability to provide concealment while withstanding harsh weather conditions makes it invaluable. Buyers need to focus on weight and portability for ease of transport, especially in regions like Europe where outdoor activities are popular.

In the manufacturing sector, camo sheet metal can be utilized for custom metal products aimed at consumer goods. The unique camouflage designs not only serve functional purposes but also provide branding opportunities. Buyers should assess the availability of custom designs, print quality, and lead times to ensure timely delivery for product launches.

Lastly, in landscaping and garden design, camo sheet metal is used for decorative elements such as trellises and fencing. Its visual appeal enhances outdoor aesthetics while maintaining a natural look. Buyers should consider material thickness and finish quality to ensure compatibility with various landscaping materials, particularly in regions with diverse climates and landscaping styles.

3 Common User Pain Points for ‘camo sheet metal’ & Their Solutions

Scenario 1: Difficulty in Custom Sizing and Availability of Camo Sheet Metal

The Problem: Many B2B buyers in the construction and manufacturing sectors struggle with sourcing camo sheet metal in the precise sizes required for their projects. Often, suppliers have limited stock or only offer standard dimensions, which leads to delays and increased waste when modifications are necessary. This can be particularly challenging for businesses in regions with less access to specialty materials, resulting in costly project overruns and operational inefficiencies.

The Solution: To address this issue, buyers should prioritize partnerships with suppliers who offer customizable options for camo sheet metal. When sourcing, inquire about companies that provide cut-to-length services or allow for custom orders tailored to specific project dimensions. Establishing a clear line of communication about your project’s requirements and timelines can ensure that suppliers understand your needs. Additionally, consider leveraging digital platforms that connect buyers with multiple suppliers for broader options. Utilizing these platforms can help you quickly compare availability and pricing, ultimately streamlining the procurement process.

Scenario 2: Uncertainty Regarding Material Durability and Performance

The Problem: Another common challenge faced by B2B buyers is uncertainty regarding the durability and performance of camo sheet metal, especially in outdoor applications. Buyers may worry about the material’s ability to withstand environmental factors, such as moisture, UV exposure, and temperature fluctuations, which can lead to rusting, fading, or other forms of deterioration. This concern is particularly pronounced in regions with extreme weather conditions, where reliable performance is crucial for long-term investments.

The Solution: To mitigate these concerns, buyers should thoroughly research the specifications of camo sheet metal, particularly focusing on coatings and material composition. Look for products that feature advanced protective coatings, such as Galvalume or polyester finishes, which enhance resistance to corrosion and UV degradation. Request detailed product data sheets from suppliers that outline the expected lifespan and warranty terms. Additionally, consider seeking samples or case studies from the supplier to evaluate their performance in similar conditions. Engaging with suppliers who have a solid reputation for quality assurance can also provide peace of mind.

Scenario 3: Navigating the Complexities of Compliance and Regulations

The Problem: B2B buyers often face the daunting task of ensuring that the camo sheet metal they purchase complies with local building codes and regulations. This is especially critical in international markets, where standards can vary significantly. Failing to meet these compliance requirements can result in project delays, additional costs for retrofitting, or even legal issues. Buyers may find it challenging to stay updated on these regulations, particularly if they are new to the market or working across borders.

The Solution: To successfully navigate compliance challenges, buyers should invest time in understanding the specific regulations that apply to their projects. Collaborating with local building authorities or industry consultants can provide valuable insights into compliance requirements. Additionally, establish relationships with suppliers who are knowledgeable about regional regulations and can provide certification for their products. Inquire whether the supplier can assist with documentation that verifies compliance with local standards. Regularly attending industry seminars or workshops can also keep you informed about any changes in regulations, enabling proactive adjustments in your sourcing strategy.

Strategic Material Selection Guide for camo sheet metal

When selecting materials for camo sheet metal, it’s essential for B2B buyers to understand the properties, advantages, and limitations of the most common materials available in the market. This knowledge not only aids in making informed purchasing decisions but also ensures compliance with regional standards and meets specific application needs.

What are the Key Properties of Galvalume Steel for Camo Sheet Metal?

Galvalume steel, an alloy of zinc and aluminum, is a popular choice for camo sheet metal applications. It boasts excellent corrosion resistance due to its protective coating, making it suitable for outdoor applications. The material is also lightweight yet strong, allowing for easy handling and installation. Galvalume has a temperature rating that can withstand a range of environmental conditions, which is particularly beneficial in regions with extreme weather.

Pros: The main advantages of galvalume steel include its durability, resistance to rust and corrosion, and relatively low maintenance requirements. It is also cost-effective, making it a preferred choice for large-scale projects.

Cons: However, galvalume can be more expensive than traditional galvanized steel, and its manufacturing process can be complex. Additionally, while it offers good thermal performance, it may not be suitable for applications requiring high-temperature resistance.

How Does Aluminum Perform as a Material for Camo Sheet Metal?

Aluminum is another viable option for camo sheet metal, known for its lightweight nature and excellent corrosion resistance. It is non-ferrous, which means it won’t rust, making it ideal for environments with high humidity or exposure to moisture. Aluminum also has a good strength-to-weight ratio and can be easily formed into various shapes.

Pros: The key benefits of aluminum include its lightweight, ease of fabrication, and resistance to corrosion. It is also recyclable, which appeals to environmentally conscious buyers.

Cons: On the downside, aluminum can be more expensive than other metals like steel. It also has a lower tensile strength compared to steel, which may limit its use in heavy-load applications.

What Advantages Does Stainless Steel Offer for Camo Sheet Metal?

Stainless steel is renowned for its exceptional durability and aesthetic appeal. It is highly resistant to corrosion, staining, and rust, making it suitable for a wide range of applications, including those in harsh environments. Its high-temperature resistance also makes it a preferred material for applications that may experience heat exposure.

Pros: The primary advantages of stainless steel include its longevity, low maintenance needs, and ability to withstand extreme conditions. It also has a modern appearance that can enhance the visual appeal of the end product.

Cons: However, stainless steel is typically more expensive than both aluminum and galvalume. Its heavier weight can also complicate handling and installation, especially in large sheets.

What is the Role of Digitally Printed Coated Steel in Camo Sheet Metal Applications?

Digitally printed coated steel, particularly those featuring high-resolution camouflage patterns, is increasingly popular in the camo sheet metal market. This material combines the durability of traditional steel with the aesthetic appeal of custom designs. The printing process allows for intricate patterns that can be tailored to specific customer needs.

Pros: The main advantages include high customization potential, aesthetic flexibility, and the use of durable inks that offer UV protection and weather resistance.

Cons: The downside is that the printing process can add to manufacturing costs and complexity. Additionally, while the base steel may be durable, the printed surface may require special care to maintain its appearance over time.

Summary Table of Camo Sheet Metal Materials

| Material | Typical Use Case for camo sheet metal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvalume Steel | Roofing, siding, and outdoor structures | Excellent corrosion resistance | Higher initial cost than galvanized steel | Medium |

| Aluminum | Lightweight applications, decorative uses | Lightweight and highly corrosion-resistant | Generally more expensive than steel | High |

| Stainless Steel | Heavy-duty applications, aesthetic designs | Exceptional durability and low maintenance | Higher cost and heavier weight | High |

| Digitally Printed Steel | Custom applications like hunting blinds | High customization and aesthetic appeal | Increased manufacturing complexity | Medium to High |

This guide provides a comprehensive overview of the strategic material selection for camo sheet metal, enabling international B2B buyers to make informed decisions based on their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for camo sheet metal

What Are the Key Stages in the Manufacturing Process of Camo Sheet Metal?

The manufacturing process of camo sheet metal involves several critical stages, each designed to ensure the final product meets both aesthetic and functional requirements. These stages include material preparation, forming, assembly, and finishing.

1. Material Preparation

The first step in the manufacturing process is material preparation. Camo sheet metal typically begins with high-quality steel substrates, often made from AZ-50 Galvalume steel for enhanced corrosion resistance. The sheets are cut to size based on specifications provided by the customer. This stage may also include surface cleaning to remove any contaminants that could affect adhesion during the printing process.

2. Forming

Once the materials are prepared, they undergo forming processes to achieve the desired shape and structural integrity. This can involve techniques such as roll forming, where the metal is passed through a series of rollers to create specific profiles. For camo sheet metal, precision is crucial to ensure that the final product fits seamlessly in applications like roofing or siding.

3. Assembly

For certain applications, different components of the camo sheet metal may need to be assembled. This could involve joining multiple sheets or integrating additional features such as insulation or protective coatings. Automated welding and fastening techniques are often employed to ensure strong, durable connections.

4. Finishing

The finishing stage is where the camouflage patterns are applied. This can involve advanced digital printing techniques that allow for high-resolution images to be transferred onto the metal surface. The use of specialty inks ensures that the patterns are not only vibrant but also durable, providing UV protection and resistance to weathering. Following printing, a clear protective coating may be applied to enhance longevity and protect against scratches or fading.

How Is Quality Assurance Implemented in Camo Sheet Metal Production?

Quality assurance is a critical component of the manufacturing process for camo sheet metal, ensuring that products meet international standards and customer specifications. Several key quality control (QC) checkpoints are established throughout the manufacturing process.

1. International and Industry-Specific Standards

Manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems, and industry-specific certifications like CE marking for compliance with European safety standards. Additionally, for specific applications, standards from organizations like the American Petroleum Institute (API) may also be relevant.

2. Quality Control Checkpoints

Quality control is typically structured around three main checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

IQC: This stage involves inspecting the raw materials upon receipt to ensure they meet specified quality standards. This includes checking for material composition, gauge, and surface finish.

-

IPQC: Throughout the manufacturing process, regular inspections are performed to monitor the quality of work in progress. This can involve dimensional checks, adherence to specifications, and visual inspections to identify any defects early.

-

FQC: The final inspection occurs before the products are packaged and shipped. This includes a comprehensive review of the finished product against customer specifications and relevant standards, ensuring that the camouflage patterns are applied correctly and that the product meets durability requirements.

3. Common Testing Methods

Various testing methods are employed to ensure quality, including tensile strength tests, corrosion resistance tests, and adhesion tests for the printed designs. These tests help verify that the product will perform reliably in its intended environment.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential. Here are several actionable steps buyers can take:

1. Conduct Supplier Audits

Performing on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control practices. During an audit, buyers can assess the supplier’s adherence to international standards and their internal quality management systems.

2. Request Quality Control Reports

Buyers should ask for documentation of quality control processes, including IQC, IPQC, and FQC reports. This documentation provides transparency regarding how the supplier manages quality throughout production.

3. Third-Party Inspections

Engaging third-party inspection services can offer an independent assessment of the supplier’s quality control measures. These inspections can verify compliance with international standards and provide an objective evaluation of product quality.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing camo sheet metal internationally, buyers should be aware of specific nuances related to quality control that may vary by region:

1. Regional Standards and Compliance

Different countries may have varying regulations and standards for manufacturing materials. Buyers should familiarize themselves with local compliance requirements, especially when importing products into their respective markets.

2. Language and Communication Barriers

Language differences can complicate the verification of quality control processes. It may be beneficial to work with local partners or hire translators to ensure clear communication regarding specifications and quality expectations.

3. Cultural Considerations

Understanding cultural attitudes towards quality can influence supplier relationships. In some regions, there may be a greater emphasis on personal relationships, which can affect negotiations and adherence to quality standards.

Conclusion

The manufacturing processes and quality assurance measures for camo sheet metal are intricate and essential for delivering high-quality products. By understanding these processes and taking proactive steps to verify supplier capabilities, international B2B buyers can ensure they are making informed decisions that align with their quality expectations and operational requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘camo sheet metal’

In the competitive landscape of B2B procurement, sourcing camo sheet metal requires a structured approach to ensure quality, cost-effectiveness, and supplier reliability. This checklist serves as a comprehensive guide to help you navigate the complexities of sourcing camo sheet metal effectively.

Step 1: Define Your Technical Specifications

Start by establishing the precise requirements for your camo sheet metal. Consider factors such as gauge thickness, material type (e.g., Galvalume steel), and dimensions.

– Key considerations: Identify the specific camouflage patterns needed (e.g., Realtree designs) and any additional features like corrosion resistance or UV protection.

– Why it matters: Clear specifications help prevent misunderstandings with suppliers and ensure that the materials meet your project needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in camo sheet metal. Utilize industry directories, trade shows, and online platforms to compile a list of potential vendors.

– What to look for: Focus on suppliers with a strong reputation and experience in your specific market (e.g., construction, automotive).

– Why it matters: A well-researched supplier list increases the chances of finding a reliable partner who can deliver quality products on time.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify the certifications and quality standards of your potential suppliers. This includes ISO certifications, safety standards, and environmental compliance.

– Specific details: Ask for documentation that demonstrates adherence to relevant standards, particularly if you are sourcing from international suppliers.

– Why it matters: Ensuring your supplier meets industry standards minimizes risks related to product quality and compliance with regulations.

Step 4: Request Samples

Always request samples of the camo sheet metal before placing a large order. This allows you to assess the quality, color fidelity, and overall appearance of the product.

– What to assess: Check for consistency in print quality and material durability. Evaluate how well the camouflage pattern meets your expectations.

– Why it matters: Samples provide a tangible sense of the product, ensuring it aligns with your project requirements.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations regarding pricing, lead times, and payment terms.

– Key considerations: Be clear about volume discounts and shipping costs, especially if you’re ordering large quantities.

– Why it matters: Effective negotiation can lead to better pricing and terms that improve your project’s overall profitability.

Step 6: Verify Delivery and Lead Times

Confirm the supplier’s delivery capabilities and lead times for your specific order. Inquire about their process for handling backorders or delays.

– What to ask: Understand their logistics capabilities and whether they can meet your deadlines, particularly for projects with tight schedules.

– Why it matters: Timely delivery is crucial to maintaining project schedules and avoiding costly delays.

Step 7: Establish a Quality Assurance Process

Implement a quality assurance process to monitor the quality of the camo sheet metal received. Define inspection criteria and protocols for handling defects.

– What to include: Set up a communication channel with your supplier for addressing any quality issues that may arise post-delivery.

– Why it matters: A robust quality assurance process ensures that the materials received align with your specifications, safeguarding your project’s integrity.

By following this step-by-step checklist, you can confidently navigate the sourcing process for camo sheet metal, ensuring that you select the right materials and suppliers for your B2B needs.

Comprehensive Cost and Pricing Analysis for camo sheet metal Sourcing

Understanding the cost structure and pricing dynamics of camo sheet metal is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will provide insights into the cost components, price influencers, and actionable tips for buyers navigating this niche market.

What Are the Key Cost Components in Camo Sheet Metal Sourcing?

-

Materials: The primary material for camo sheet metal is typically AZ-50 Galvalume steel, known for its durability and resistance to corrosion. The gauge of the metal (e.g., 29 gauge) directly impacts pricing, with thinner gauges generally being less expensive. Additionally, specialized coatings or digitally printed designs can increase material costs.

-

Labor: Labor costs encompass the wages for workers involved in manufacturing, processing, and finishing the camo sheet metal. This can vary significantly based on the region, with labor rates in developing countries often being lower than in developed markets.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and facility costs. Overhead rates can fluctuate based on the scale of production and the efficiency of the manufacturing process.

-

Tooling: Custom tooling may be required for specific designs or dimensions, adding to the initial cost. This is particularly relevant for buyers seeking unique camouflage patterns or specific panel sizes.

-

Quality Control (QC): Implementing rigorous quality control measures ensures that the final product meets specified standards. This can involve additional testing and inspection, which contribute to overall costs.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, mode of transportation, and Incoterms (e.g., FOB, CIF) can significantly impact logistics expenses.

-

Margin: Suppliers typically incorporate a profit margin into their pricing. Understanding the standard margins in the camo sheet metal market can help buyers gauge the fairness of quotes received.

What Factors Influence Pricing in Camo Sheet Metal?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often benefit from economies of scale, leading to lower per-unit costs. Buyers should negotiate MOQs to align with their purchasing capacity.

-

Specifications and Customization: Customized products, especially those requiring specific designs or sizes, will generally be priced higher. It’s essential to clearly define specifications to avoid unexpected costs.

-

Material Quality and Certifications: Products that meet specific industry certifications or standards (e.g., ASTM, ISO) may command higher prices. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: Reputation, reliability, and service levels of suppliers can affect pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can impact the total landed cost.

How Can Buyers Optimize Costs When Sourcing Camo Sheet Metal?

-

Effective Negotiation: Engage suppliers in negotiations to secure better pricing, especially for bulk orders. Building strong relationships with suppliers can lead to more favorable terms over time.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also maintenance, durability, and potential resale value of the camo sheet metal. A higher upfront cost may be justified by lower long-term costs.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, tariffs, and import duties, as these can significantly affect the final cost. Understanding local market conditions can provide leverage in negotiations.

-

Request Detailed Quotes: Always ask for itemized quotes that break down costs into materials, labor, shipping, and other charges. This transparency will help identify potential areas for cost reduction.

-

Stay Informed About Market Trends: Keep abreast of changes in material costs, supply chain disruptions, and emerging technologies in metal processing to make informed purchasing decisions.

Disclaimer on Indicative Prices

Prices for camo sheet metal can vary widely based on the aforementioned factors. The examples provided in the reference data illustrate typical pricing but may not reflect current market conditions. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing camo sheet metal With Other Solutions

When evaluating solutions for camouflage applications in the metal industry, businesses often face a range of options beyond traditional camo sheet metal. Understanding these alternatives can enhance decision-making and optimize outcomes for specific projects. Here, we will compare camo sheet metal with two notable alternatives: digitally printed camouflage coatings and vinyl wraps.

| Comparison Aspect | Camo Sheet Metal | Digitally Printed Camouflage Coatings | Vinyl Wraps |

|---|---|---|---|

| Performance | Durable, weather-resistant steel | High-resolution prints, varying durability | Good for temporary applications; not as durable as metal |

| Cost | Moderate ($2.26 – $4.99 per foot) | Typically higher due to printing costs | Variable; generally lower initial investment |

| Ease of Implementation | Requires specialized installation | Can be applied with standard coating techniques | Easy to apply; DIY-friendly |

| Maintenance | Low maintenance; rust-resistant | May require reapplication over time | Prone to wear and tear; may need replacement |

| Best Use Case | Long-term structures (roofs, walls) | Decorative applications (interior/exterior) | Short-term projects, promotional displays |

What Are the Advantages and Disadvantages of Digitally Printed Camouflage Coatings?

Digitally printed camouflage coatings offer a unique alternative, particularly for businesses seeking high-resolution designs and patterns that can be customized. This method allows for intricate designs that can enhance aesthetic appeal. However, the cost tends to be higher due to the technology involved in producing these prints, and while they can be applied to various substrates, they may not offer the same longevity as camo sheet metal. Maintenance can also be a concern, as these coatings may need to be reapplied periodically depending on the environmental conditions.

How Do Vinyl Wraps Compare to Camo Sheet Metal?

Vinyl wraps provide a cost-effective solution for temporary or promotional needs. They are easy to apply and can be customized to feature any design, making them an attractive option for businesses looking for flexibility. However, vinyl wraps are generally less durable than camo sheet metal and may not withstand harsh weather conditions as effectively. They are best suited for short-term applications, such as vehicle advertising or temporary structures, where long-lasting durability is not a primary concern.

How Should B2B Buyers Decide on the Best Solution for Their Needs?

Choosing the right camouflage solution depends on the specific requirements of the project at hand. B2B buyers should consider factors such as the intended lifespan of the installation, environmental exposure, budget constraints, and aesthetic preferences. For long-term projects that require durability and low maintenance, camo sheet metal is likely the best choice. Conversely, if the goal is a visually striking design for a temporary application, digitally printed coatings or vinyl wraps may be more suitable. By weighing these aspects carefully, buyers can make informed decisions that align with their operational needs and strategic objectives.

Essential Technical Properties and Trade Terminology for camo sheet metal

What Are the Key Technical Properties of Camo Sheet Metal?

When evaluating camo sheet metal for B2B applications, understanding specific technical properties is crucial for making informed purchasing decisions. Here are some of the most important specifications:

-

Material Grade

Camo sheet metal is often made from Galvalume steel, which combines aluminum and zinc to provide excellent corrosion resistance. A typical material grade for this product is AZ-50, indicating that the steel has a coating weight of 50 grams per square meter. This property is essential for buyers looking for durability, especially in outdoor applications where exposure to the elements is a concern. -

Gauge Thickness

The gauge of camo sheet metal, often specified as 29 gauge (approximately 0.0142 inches thick), directly affects its strength and weight. A thinner gauge may be more economical but can compromise durability and structural integrity. For B2B buyers, selecting the right gauge is crucial based on the intended application, whether it be roofing, siding, or decorative purposes. -

Coverage Area

Camo sheet metal panels are typically sold in specific coverage sizes, such as 36 inches wide and various lengths (e.g., 10 feet). Understanding the coverage area helps buyers calculate how many panels are needed for their projects, impacting budgeting and material waste. Accurate coverage information is vital for effective planning and cost management. -

Finish Type

The finish applied to camo sheet metal plays a significant role in aesthetics and functionality. Digitally printed finishes, such as those from Realtree, offer high-resolution camo patterns suitable for various applications. The finish not only enhances visual appeal but also provides additional UV protection, which is crucial for outdoor longevity. -

Tolerance Levels

Tolerance refers to the allowable variation in dimensions of the sheet metal. For example, a standard tolerance might be ±0.1 inches in length or width. Understanding tolerance levels is critical for B2B buyers to ensure that the materials fit properly in their specific applications, minimizing the risk of costly errors during installation. -

Lead Time and Availability

Lead time is the time required to manufacture and deliver the product after an order is placed. For instance, specific camo sheet metals may have a lead time of 24-48 hours for in-stock items. Knowing lead times helps businesses manage their supply chain effectively, ensuring that projects remain on schedule.

What Trade Terminology Should B2B Buyers Know in the Camo Sheet Metal Industry?

Familiarity with industry jargon can streamline communication and enhance negotiations. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that may be marketed by another company under its brand name. Understanding OEM partnerships can be beneficial for buyers looking for branded camo sheet metal products. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is crucial for buyers, as it affects purchasing decisions and inventory management. For example, if a supplier has an MOQ of 100 panels, a buyer must plan accordingly to meet this requirement. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. B2B buyers should understand how to create effective RFQs to ensure they receive accurate and competitive pricing for camo sheet metal. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. For instance, terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping costs and risks. Familiarity with Incoterms can help buyers avoid misunderstandings and additional costs. -

Lead Time

As mentioned earlier, lead time is the period between placing an order and receiving the goods. Understanding lead times allows buyers to plan their projects more effectively, avoiding delays in construction or manufacturing. -

Cut-to-Length

This term refers to metal sheets or panels that are customized to specific lengths as per the buyer’s requirements. Knowing about cut-to-length options can help buyers optimize material usage and minimize waste.

By grasping these technical properties and trade terms, B2B buyers can navigate the camo sheet metal market more effectively, ensuring that their purchases meet their operational and project needs.

Navigating Market Dynamics and Sourcing Trends in the camo sheet metal Sector

What Are the Key Market Trends Influencing Camo Sheet Metal Sourcing?

The camo sheet metal sector is currently experiencing a surge in demand driven by several global factors. The popularity of camouflage designs in various applications, from construction to recreational products, is fostering innovation and expansion in this niche market. B2B buyers are increasingly focused on versatile products, such as digitally printed camo patterns that can be adapted for roofing, siding, and specialty items like hunting blinds. This shift toward customization is facilitated by advancements in printing technologies, enabling high-resolution designs on metal surfaces, which adds aesthetic value while maintaining functionality.

Emerging technologies in the sourcing landscape also play a crucial role. E-commerce platforms are streamlining the procurement process, allowing international buyers, particularly from Africa, South America, the Middle East, and Europe, to access a broader range of suppliers and products. Additionally, the rise of data analytics and AI-driven insights is enabling more informed purchasing decisions, enhancing supply chain efficiency. Buyers are advised to leverage these technologies to identify reliable suppliers, compare pricing, and assess product quality before committing to orders.

How Is Sustainability and Ethical Sourcing Shaping the Camo Sheet Metal Market?

Sustainability has become a focal point in the camo sheet metal sector, as environmental concerns gain traction among buyers and regulators alike. The production of metal products can have significant environmental impacts, including energy consumption and greenhouse gas emissions. As a result, many manufacturers are now prioritizing sustainable practices, such as using recycled materials and implementing energy-efficient processes.

Ethical sourcing is equally important, as businesses seek to align with suppliers who adhere to fair labor practices and responsible resource management. Certifications such as LEED (Leadership in Energy and Environmental Design) and other green credentials are increasingly sought after by B2B buyers. These certifications not only enhance a company’s reputation but also meet the growing consumer demand for environmentally responsible products. Buyers should prioritize suppliers who offer transparency in their sourcing practices and can demonstrate their commitment to sustainability.

What Is the Historical Context of Camo Sheet Metal Development?

The evolution of camo sheet metal can be traced back to its origins in military applications, where camouflage was essential for concealment in various environments. Over the decades, the technology behind metal processing and printing has advanced significantly, leading to the introduction of high-quality, durable camouflage patterns suitable for commercial use. Initially limited to military and hunting applications, the versatility of camo sheet metal has expanded into diverse sectors, including architecture, automotive, and consumer products. Today, partnerships between manufacturers and design firms, such as Titan Steel’s collaboration with Realtree, are pushing the boundaries of creativity and functionality in this specialized market. As demand continues to grow, the camo sheet metal sector is poised for further innovation and expansion, driven by both aesthetic appeal and practical applications.

Frequently Asked Questions (FAQs) for B2B Buyers of camo sheet metal

-

How do I select the right camo sheet metal for my project?

Selecting the right camo sheet metal involves considering several factors, including gauge thickness, material type (such as Galvalume or stainless steel), and the specific camouflage pattern that suits your application. Evaluate the intended use, whether for roofing, siding, or decorative elements, and ensure the product meets your durability and aesthetic requirements. Additionally, consult with suppliers about custom options and patterns that can be tailored to your project’s needs. -

What are the common applications for camo sheet metal in construction?

Camo sheet metal is widely used in construction for various applications, including roofing, siding, and decorative features in residential and commercial buildings. It is particularly popular in areas where aesthetics and camouflage are essential, such as hunting lodges, cabins, and outdoor structures. Additionally, it can serve functional purposes in agricultural settings, such as animal feeders and water troughs, combining both utility and design. -

What is the typical lead time for ordering camo sheet metal?

Lead times for camo sheet metal can vary based on factors such as inventory levels, customization needs, and supplier location. Generally, standard orders can be fulfilled within 1 to 4 weeks, while custom orders may require additional time for production. It’s advisable to confirm lead times with your supplier before placing an order, especially if you have specific project timelines to meet. -

What are the payment terms usually offered by suppliers of camo sheet metal?

Payment terms for camo sheet metal suppliers often vary based on the buyer’s creditworthiness, order size, and supplier policies. Common terms include payment upon order, net 30, or net 60 days. International buyers should also consider additional factors such as currency exchange rates and transaction fees. It’s crucial to discuss and negotiate payment terms upfront to ensure clarity and avoid potential issues. -

How can I vet suppliers when sourcing camo sheet metal internationally?

Vetting suppliers involves several steps: check their certifications, read customer reviews, and request references from other businesses that have purchased from them. Additionally, verify their manufacturing capabilities and quality assurance processes. Engaging in direct communication about your needs and expectations can provide insights into their professionalism and reliability. Utilizing platforms such as Alibaba or industry-specific trade shows can also help identify reputable suppliers. -

What is the minimum order quantity (MOQ) for camo sheet metal?

Minimum order quantities (MOQs) for camo sheet metal can vary significantly by supplier and product type. Some suppliers may have MOQs as low as 100 square feet, while others may require larger orders, especially for custom designs. Always clarify the MOQ during the inquiry stage, as this can impact your purchasing strategy and overall project costs. -

What quality assurance measures should I look for in camo sheet metal?

When sourcing camo sheet metal, seek suppliers who implement stringent quality assurance measures, including material certification and testing for durability, corrosion resistance, and adhesion of printed patterns. Inquire about their production processes and whether they adhere to international standards, such as ISO certifications. A supplier’s willingness to provide samples for evaluation can also be a strong indicator of their commitment to quality. -

How do logistics and shipping work for international orders of camo sheet metal?

Logistics for international orders of camo sheet metal typically involve coordination between the supplier and a shipping service. It’s essential to discuss shipping options, including freight costs, delivery timelines, and customs regulations for your destination country. Ensure that the supplier can provide the necessary documentation for customs clearance. Working with a freight forwarder experienced in handling metal products can streamline the shipping process and minimize potential issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Camo Sheet Metal Manufacturers & Suppliers List

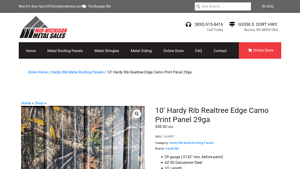

1. Hardy Rib – 10′ Hardy Rib Realtree Edge Camo Print Panel

Domain: midmichiganmetalsales.com

Registered: 2014 (11 years)

Introduction: {“Product Name”: “10′ Hardy Rib Realtree Edge Camo Print Panel 29ga”, “SKU”: “10HRRT”, “Category”: “Hardy Rib Metal Roofing Panels”, “Brand”: “Hardy Rib”, “Gauge”: “29 gauge (.0142\” min. before paint)”, “Material”: “AZ-50 Galvalume Steel”, “Length”: “10′”, “Coverage”: “3′ (36\”)”, “Price”: “$48.50 USD”, “Availability”: “40 in stock (Additional Qty’s made to order)”, “Pickup Options”: “In-Store pi…

2. Allsteel Metal – Realtree® Camouflage Panels

Domain: allsteelmetal.com

Registered: 2009 (16 years)

Introduction: Product Name: Realtree® Camouflage

Gauge: 29 Gauge

Available Panel Profiles: Tuff Rib, Apex

Warranty: 20 Year Warranty

Description: Realtree® Camouflage features a blend of fall leaves, evergreens, lichen dappled bark, exposed wood grain, and overlapping branches, creating a color-rich scene that can hide or highlight a project’s form, function, and design. It is ideal for various applications.

3. Realtree – Camo Panels

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Realtree Camo Panels (Flat Sheets & TEX-RIB), suitable for Blinds, RV Siding Panels, Sheds, or Carports. Available as cut-to-length panels. Contact: 956-714-1111.

4. Graber Post Buildings – Realtree® Edge Metal

Domain: graberpost.com

Registered: 2001 (24 years)

Introduction: {“product_name”: “Realtree® Edge Metal”, “type”: “roofing/siding panels and flat stock sheets”, “distributor”: “Graber Post Buildings”, “applications”: [“hunting blinds”, “trophy rooms”, “man caves”], “gauge”: “29 gauge galvalume”, “available_products”: [“G-Rib Profile (36\” Coverage)”, “Flat Sheets (41\” Wide)”, “Coil(s)”], “warranty”: “20-Year Warranty”, “customization”: “Panels cut to the 1/2\”…

5. ASC Building Products – Camo Metal Roofing

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Camo Metal Roofing for the Outdoor Enthusiast, Woodland Camo Print for Metal Roofing or Walls, ASC Building Products, Metal Roofing and Siding.

Strategic Sourcing Conclusion and Outlook for camo sheet metal

What Are the Key Insights for Strategic Sourcing of Camo Sheet Metal?

In summary, the strategic sourcing of camo sheet metal presents significant opportunities for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. The demand for innovative camouflage patterns in metal applications is on the rise, driven by diverse industries such as construction, agriculture, and recreational equipment. Buyers should prioritize suppliers who offer high-quality materials, such as AZ-50 Galvalume steel, and those who can provide customization options to meet specific project needs.

Furthermore, leveraging partnerships with established brands, like Realtree, can enhance product offerings and ensure access to the latest designs and technologies. Buyers are encouraged to consider the total cost of ownership, including lead times and delivery logistics, when selecting suppliers.

How Can International Buyers Prepare for Future Trends in Camo Sheet Metal?

As the market evolves, staying informed about technological advancements, such as digital printing for high-resolution designs, will be crucial. By proactively engaging with suppliers and exploring innovative applications, businesses can position themselves ahead of the competition.

International buyers are urged to take action now—evaluate potential suppliers, explore customization options, and capitalize on the growing trend of camo sheet metal. Embrace this unique opportunity to enhance your product offerings and meet the demands of a diverse customer base.